HAZARD ASSESSMENT AND ITS CONTROL IN BULK MATERIAL HANDLING PROCESS OF AN INTEGRATED STEEL PLANT

Abstract – The proliferation of conveyor systems in various industrial sectors has fueled a growing demand for conveyors that surpass the capabilities ofconventionalsystems.Theneed to transport bulk materials over longer distances at higher speeds and with greater efficiency has necessitated the development of a comprehensive and safe working methodology.

However, the widespread use of conveyor systems has sometimes led to overlooking potential hazards and hazardous activities, putting workersatriskoffatalaccidents. To address this, it is imperative to continuously monitor all activities and identify potential hazards through a Hazard Identification and Risk Assessment with Controls (HIRA) approach. This research aims to determine the hazards associated with various activities of conveyor systems using HIRA andensure a safer workingenvironmentforallinvolved. The implementationof increasinglycomplexconveyorsystems without a thorough understanding of the system can result in inefficiencies and decreased productivity. This study seeks to address this issue by identifying hazards through HIRA and creatingstandard operatingproceduresfordifferentmaterial handling activities. The conclusions drawn from this research will provide valuable insights and offer recommendations for future work to further enhance the safety and efficiency of conveyor systems.

Key Words: HIRA,ConveyorSystem,SOP,IntegratedSteel Plant

1. INTRODUCTION

The steel industry is a highly sophisticated and technologically advanced sector, characterized by interdependentmaterialflowsandrevenuestreams.Itisa crucial productinthemodernworld,witha widerangeof applications, from infrastructure building and industrial machinerytoconsumergoods.Theindustryisalsodiversein termsofthetechnologiesused,whicharedependentonthe natureandquantityofrawmaterialsutilized.InIndia,steel hasaprofoundimpactontheeconomy,witha1.4Xmultiplier effectonGDPanda6.8Xemploymentmultiplierfactor.

AtthetimeofIndia'sindependencein1947,thecountry onlyhadthreesteelplants-theTataIron&SteelCompany, theIndianIronandSteelCompany,andVisveswarayaIron&

SteelLtd-andahandfulofelectricarcfurnaceplants.Despite itssmallcapacityof1milliontonnes,thesteelindustrywas robust and entirely in private hands. Today, India is the second largest crude steel producer in the world and the largest producer of sponge iron, with the Iron and Steel Industrycontributing2%totheGrossDomesticProductand employingaround25lakhindividualsdirectlyorindirectly. The Indian steel industry, once with a negligible global presence,isnowrecognizedforitsproductquality,having successfully navigated the challenges of the businesscycle overitslonghistorysinceindependence.

In the year 2021, the global production of crude steel reachedastaggering1911.9milliontonnes,demonstratinga growthof3.6%comparedtothepreviousyear.TheWorld SteelAssociation'srankingsrevealedthatChinaemergedas the leading producer of crude steel, with a production of 1032.8milliontonnes,followedbyIndia,with118.1million tonnes,Japanwith96.3milliontonnesandtheUnitedStates with 86.0 million tonnes. The per capita finished steel consumptionin2020was228kgglobally,withChinaleading thewaywith691kg,whileIndiarecordedaconsumptionof 70kg.

In the domestic scenario, the Indian steel sector has enteredanewphaseofgrowth,followingde-regulation,asa result of the resurgence of the economy and increased demand for steel. This has led to a significant rise in production,andIndiaisnowthesecondlargestproducerof crudesteelintheworld,surpassingitspreviousthirdlargest status.Inaddition,IndiawasthelargestproducerofSponge Iron and the second largest consumer of finished steel globally, as per rankings released by the World Steel Association.

Ina de-regulatedandliberalizedmarketsuchasIndia,the role of the government is to act as a facilitator, providing policy guidelines and creating an institutional mechanism thatpromotesefficiencyandperformanceinthesteelsector. Inthisregard,theNationalSteelPolicy2017,releasedbythe government,outlinesthebroadroadmapforthelong-term growth of the Indian steel industry, both in demand and supply,by2030-31.Thegovernmenthasalsointroduceda policythatprovidespreferencetodomesticallymanufactured ironandsteelproductsingovernmentprocurement.Table2 showstheproductiondataofIndiansteelindustryasshared byjointplantcommittee.Table3showsthedataonimport and export of total finished steel in the past five years respectively.

and injectants. The high speed gas forms the area knownastheracewayinfrontofthetuyeres.

2. Stock house. The burden materials and coke are deliveredtoastockhouse.Thematerialsarestored, screenedandthenweighedbeforefinaldeliveryinto the furnace. The stock house is operated automatically. Corrections for coke moisture are generallymadeautomatically.Theburdenmaterials andcokearebroughttothetopofthefurnaceviaskip carsorviaaconveyorbelt,wheretheyarecharged intothefurnaceinseparatelayersoforeandcoke.

3. Gas cleaning. The top gas leaves the furnace via uptakesandadowncomer.Thehottopgascontainsa substantialquantityoffineparticles,soitisrequired to remove these particles and cool the gas in a gas cleaning system consisting of a dust catcher or cyclone, a scrubber for wet cleaning of the gas and finallyademisterforremovingthewater.

4. Casthouse. The liquid iron and slag collect in the hearthofthefurnace,fromwhichtheyaretappedvia thetapholeintothecasthouseandtotransportladles. Depending on the size of the furnace, there may be onetofivetapholesandoneortwocasthouses.

5. Slaggranulation.Themoltenslagmaybequenched withwatertoformgranulatedslag,whichisusedfor cementmanufacturing.

1.2 Conveyor System

The functioning of the Belt Conveyor is facilitated by electrical energy, a mechanism designed to enhance operationalefficacyandserveasasolutiontothedrawbacks ofthetraditionalFlatBeltConveyor.Ourteamofexpertshas chosentoemploytheFlatBeltConveyormechanism.

1.1 Equipment overview

Anoverviewofthemajorequipmentisprovidedbelow. Theseinclude:

1. Hot Blast Stoves. Air preheated to temperatures between 1000 and 1300 °C is produced in the hot blaststovesandisdeliveredtothefurnaceviaahot blast main, bustle pipe, tuyere stocks and finally throughthe tuyeres. The hotblastreactswithcoke

TheBeltConveyorconsistsofaminimumoftwopulleys, aroundwhichacontinuousloopofmaterial-theconveyor belt-rotates.Oneorbothpulleysarepowered,drivingthe movement of the belt and its load. The powered pulley is known as the drive pulley, while the unpowered pulley is referred to as the idler. The Belt Conveyor system can be classified into two industrial categories, namely general material handling, which involves the transfer of boxes within a factory environment, and bulk material handling, which encompasses the transportation of industrial and agriculturalmaterialssuchascoal,grain,andmustardsacks, generally in outdoor settings. It is important to note that companies specializing in general material handling Belt Conveyors typically do not provide conveyors for bulk materialhandling.

Furthermore,theBeltConveyorhasseveralcommercial applications, including in grocery stores. The belt is

composed ofone or morelayers of material, whichcanbe made of rubber. The majority of belts used in general materialhandlinghavetwolayers,includingacarcasslayer, whichprovideslinearstrengthandshape,andacoverlayer. DifferenttypesofBeltConveyorsexist,includingtheFlatBelt Conveyor, the Troughed Belt Conveyor, and the Blanket Conveyor,amongothers.

2. LITERATURE REVIEW

Conveyors,being durableand reliablecomponents,are widely utilized in various industries such as automated distribution and warehousing, manufacturing, and productionfacilities.Whenpairedwithcomputer-controlled pallet handling equipment, these conveyors enable more efficient retail, wholesale, and manufacturing distribution, actingasalabor-savingsystemthatallowsforlargevolumes tobeswiftlyprocessedwithreducedstoragespaceandlabor expenses(3).

Rubber conveyor belts, commonly used for conveying itemswithirregularbottomsurfaces,smallitemsthatmay fallbetweenrollers,orsaggybags,consistofametalframe with rollers at either end, looped around the belt. Upon powering one of the rollers with an electrical motor, the beltingglidesoverthemetalframebed,movingtheproduct. Inheavyusecases,themetalbedsarereplacedbyrollersthat reducefrictionfromtheheavierloadonthebelting(3).

Curvedbeltconveyors,withtaperedrollersandcurved belting,arewidelyusedinpostalsortingofficesandairport baggage handling systems. Sandwich belt conveyors, with twoface-to-faceconveyorbelts,allowforsteepinclineand vertical-liftrunsbyfirmlycontainingtheitemsbeingcarried.

Beltconveyors,beingthemostversatileandcost-effective powered conveyors, are widely used for conveying a wide rangeofobjects,bothregularandirregularinshape,largeor small,lightorheavy,directlyonthebelt.Toensuresmooth operationandreducemaintenance,theseconveyorsshould utilize only premium belting products that reduce belt stretch. Belt conveyors can be utilized for straight line conveying,changesinelevationordirection,andevenstatic accumulationorcartons(5).

Materialhandlingencompassesthemovement,packing, andstoringofmaterials,andisconsideredacrucialactivityin production, with 80% of the total time spent by materials inside a plant area dedicated to moving and waiting for processing. This function involves vertical, horizontal, or combination movements of fluid, semi-fluid, and discrete materials.Withmaterialhandlingaccountingfor20%oftotal productioncost,itisimportanttooptimizethisprocess.In thispublication,severalresearchpapersarecited,including "Fabrication of a Conveyor Belt with Object Sorting and CountingFacility"byMr.NasifHassanKhan,whichdiscusses theuseoffactorsandbasiccomponentsinaconveyorsystem to avoid accidents and defective parts through control

systems (1). Another study, "A Review of 'Improved Automated Conveyor with Auto Separated System for Oil Packaging Industry'” by Mr. Akshay K. Naphade and Prof. Manish J. Deshmukh, highlights the importance of sensors andmonitoringsystemstodetectdefectiveproductsusing electronicsystemsforhighreliabilityandfastoperation(3). Thepaper"DesignandDevelopmentofAutomatedConveyor SystemandMaterialHandling"byMr.AbhijitGaikwadand Prof. Shreekant Pawar focuses on the design of a belt conveyor system for transporting materials and products fromonemanufacturingstagetoanother(4).Additionally, thepaper"ImplementinganAutomatedSortingSystem"by Mr.JoshuaToddFlukediscussesthecreationofasimulated and theoretical automated process for sorting products comingoutofadistributioncenter(5).Thevarioustransport materialhandlingsystems,rangingfrommanualsystemsto conveyors,cranes,trucks,andautomaticguidedvehicles,are used to move materials over short or long distances, as discussedin"AReviewonMaterialHandlingEquipmentand Their Selection for Potential Applications" by Vikas Gupta, RajeshBansal,andVineetKumarGoel

3. PROBLEM IDENTIFICATION

Toidentifythehazardsandtoassesstheircorresponding risk,frequentsitesafetysurveywascarriedoutforaperiod of30days.Theobjectiveofconductingthesitesurveyswere to note down the details of unsafe acts carried out by the workers/operators/driversandunsafeworkingconditions thatmayleadtoanunwantedfatalaccidentatBlastFurnace andstockhouse.

Table4givesoutthedetailoftheprojectundertakenfor safetysurvey.Theprojectmainlycoverseightmajorpartof the plant covering the blast furnace and stock house in particular.

TheStockhousewilldispensebatchesofmaterialsofthe requiredcompositionandweightforchargingtothefurnace and will include two separate system, one for dispensing batches of coke and one for dispensing batches of ferrous materials. The stockhouse designed for Blast furnace is characterizedby:

A high operating flexibility in handling batch compositionandchargingsequenceoptions,

Sufficientsparechargingcapacity,

Ahighscreeningefficiencyand

Minimumburdensizedegradationthroughalimited numberoftransferpoints.

Stockhouseconsistof:–

FeedingConveyor

ShuttleConveyor

ChargingHutch

Bunkers(Hopper)

RodGate

R/PGate

VibroFeeder

VibroScreen

WeighHopper

Hyd.Gate

Conveyors

MagneticSeparator

Inlightoftheextensiveresearchconducted,ithasbecome evident that numerous scholars have embraced the implementationofconjointriskidentificationandassessment techniques. However, the sole identification of hazards duringvariousconveyoroperations,maintenance,andrepair activitieshasyettoreceiveadequateattention.Theliterature surveyconductedhasshedlightonthehazardidentification andriskassessmentpractices,however,theseassessments havebeenfoundtobesuperficialandnotoperation-specific. Therefore, it is imperative to conduct operation-specific hazard identification and risk assessment in conveyor systems to gain a deeper understanding of the risks associatedwithindividualtasks.

4. METHODOLOGY

The methodology adopted in the research focuses on providingthetaskspecificcontrolmeasurestominimizeor tomitigatetheidentifiedhazardduringmetroconstruction project.ThemethodologyusesHazardidentificationandrisk assessmentwithcontrols(HIRA)method.

HazardIdentification,RiskAssessmentandControlisa processthataidsinmanagementofoccupationalandhealth hazardsintheworkplace.HIRACisimplementedtomaintain safe working environment with modern safety and health legislation.

4.1 Hazard Identification

The identification of hazards is a critical component of ensuringasafeworkingenvironment.Thisprocessinvolves recognizing potential dangers in the workplace and comprehendingtheirnature.Hazardscanbecategorizedinto physical,biological,chemical,andpsychosocialtypes,which arecommonlypresentinworksettings.

Undertaking a comprehensive hazard identification process can be labor-intensive and time-consuming, therefore,itiscrucial tocarryouttheprocessregularlyto maintain its effectiveness. A best practice for hazard identificationistodividetheworkplaceintodistinctareas and prioritize high-risk zones based on hazardous substances,processes,plant,orenvironment.

The individuals best equipped to identify hazards are domainexpertswhopossessin-depthknowledgeofthework procedures and processes. This includes workers and supervisors who can provide their valuable insights and experiences.

4.2 Risk Assessment

Riskassessmentistheprocessofevaluatingthelevelof risk and determining its acceptability for a given task. It involvesestimatingthe“likelihood”and“consequence”ofa potentialhazardousevent.Forhigh-risktasks,appropriate measuresmustbetakentoreducetherisklevelandensurea safeworkplace.

Thenextstepinvolveslistingandrankingtheidentified hazards based on the severity of their consequences and likelihood of occurrence. Consequence refers to the harm causedbytherisk,whilelikelihoodistheprobabilitythata riskwilloccur.Theriskleveliscalculatedbymultiplyingthe likelihood(L)andseverity(S).

RiskLevel=LxS

Thescoresoflikelihoodandseverityratingcanbeusedto formtheriskmatrixwhereitispositionedincellsequivalent totheappropriatelikelihoodandseverity.Respectivelyofthe

risks positioned in the table will tumble under one of the categories,forwhichunlikecolourscanbeusedtosignifythe prioritylevel

Table 8:Actiondescriptionforrisklevels

1-4 Low Acceptableandfurtherreductionmay notbenecessary.

5-12 Medium Planned approach to controlling the hazardandappliestemporarymeasure ifrequired.

15-25 High Immediateactiontocontrolthehazard asdetailedinthehierarchyofcontrol.

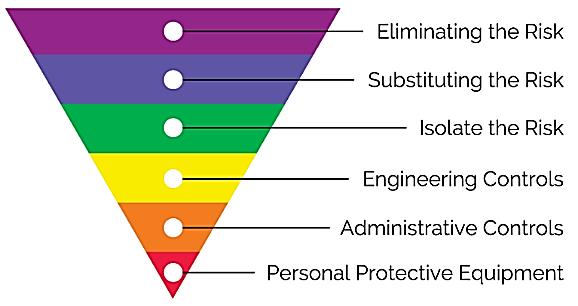

4.3 Risk control

Therisk controlactionsweredeterminedbasedonthe hazard and the application of engineering controls, administrativecontrols,andPPEs.Properhierarchyofrisk controlmeasureshouldbefollowedasshown.

1 Hierarchyofcontrols

5. RESULT

Hazard Identification, Risk Assessment and Control method of assessing hazards in a worksite is a comprehensiveandextensiveapproachaimingtomakethe workplace safe and healthy. However, due to the comprehensive, cumbersome and laborious nature of the approach, it is not possible to assess each activity or task duringthedifferentstagesofconveyorsystemTherefore,in thisresearchtheHazardIdentification,RiskAssessmentand Control method is applied to three major operations that involvesextensiveman-machineinteraction.Theoperations underassessmentare:

Conveyorreplacementwork

Beltpressbeltreplacementwork

Idlerreplacementwork

The outcome from comparative risk will be rank renderingtotheriskmatrixscoreinTable7.Thehigherthe riskrelativescore,thefurthersubstantialactionisneeded. High score calls for instant action, intermediate score requiredpreparationofcontrollingthehazardandlowriskis deliberatedacceptableandtolerable.

Pulleyreplacementwork

Patching/Repairingwork

Hazardshavebeenidentifiedineachtaskinvolvedinthe above work and their risk has been assessed in terms of severity (S) and probability (P) before and after the

application of control measure to minimize the risk level. Refer to Annexure 1 for complete HIRA for all the above conveyoroperations.

6. CONCLUSIONS

The ever-increasingdemandfor bulk material handling systemshasseenbeltconveyorschangemoreinthepast20 years, than they have since their inception. In order to maximise efficiencies and productivity, more complex conveyor systems are being installed without adequate knowledgeofthesystem.Inordertorectifythis,thisThesis is aimed at identifying the underlying hazards in the conveyorsystemusingHIRAandonthebasisofidentified hazards,standardoperating procedureto bepreparedfor different material handling activity. Following this, conclusionsaredrawnabouttheworkcontainedherein,and recommendationsforfutureworkpresented.

Inidlerreplacement,pulleyreplacementandrepairand patchingworkthehazardsidentifiedwerelesscomparedto the earlier activities like conveyor replacement work and press belt replacement work where maximum underlying hazardswereidentified.Duringtheinitialinvestigation,the riskratingofidentifiedhazardsinfewtaskswereabovethe accepted level. With proper implementation of control measuresaccordingtothehazardmitigationhierarchy,the risklevelwasboughtdowntoanacceptablelevelofwork.

Based on the identified hazards, standard operating procedure for different work activity was prepared. Upon implementation of work as per the standard operating procedure the risk involved in job was completely taken downtoanacceptablelevelandinfewcasesmitigatingthe riskcompletely.

Furtherworkcanbeperformedintheconveyorsystem with FMEA approach, where effect of failure of different partsofaconveyorsystemcanbeassessedandonthebasis of which proper action plan can be prepared to make the systemsafer.

REFERENCES

[1] K. P. Shah: “Construction and Maintenance of Belt ConveyorsforCoalandBulkMaterialHandlingPlants, visitwww.practicalmaintenance.net

[2] G.Velmurugan,Dr.E.Palaniswamy,M.Sambathkumar, R.Vijayakumar,T.M.Sakthimuruga (2014).Conveyor Belt Troubles International Journal of Emerging EngineeringResearchandTechnologyVolume2,Issue 3,June2014,pp.21-30

[3] S. Rajeshkumar (2017) ‘Design and Analysis of Belt ConveyorforFinishingHousePulper’,pp.4540–4546. doi:10.15680/IJIRSET.2017.0603212.

[4] Gaikwad, A. et al. (2017) ‘Design and Development of Automated Conveyor System for Material Handling’, IOSRJournalofMechanicalandCivilEngineering(IOSRJMCE),pp.31–34.

[5] Salave,V.IV.,I.S.,Dalvi,A.B.B.B.H.andArulkar,A.C.P. (2017)‘ToDesignandAnalysisof360DegreeRotating ConveyorBeltwithUp-DownMechanism :AReview’ , 5(08),pp.263–265.

[6] S,MemaneVijay,P.N.S.B.andPG(2015)‘Designand AnalysisofBeltConveyorSystemofSugarIndustryfor Weight Reduction’, Journal of Emerging Technologies andInnovativeResearch(JETIR),2(5),pp.1473–1477.

[7] Gupta, D. (2015) ‘Study and Performance of Belt ConveyorSystemwithDifferentTypeParameter’,2(06), pp.29–31.

[8] B.Kharag,A.(2015)‘[Kharage,4(4):April,2015]’,4(4), pp.296–301.

[9] Sangolkar,R.N.andKshirsagar,V.P.(2015)‘Modeling andAnalysisofIndustrialBeltConveyorSystemUsing CreoParametricandAnsysSoftware’,3(4),pp.178–181.

[10] S.Ojha B.K. Pal B.B. Biswal (2015) “Minimising the breakdown in belt conveyor system of Coal Handling Plant” SSRG International Journal of Mechanical Engineering(SSRG-IJME)–volume2Issue9

[11] Vaidya,S.D.,Jagtap,A.A.andSamrutwar,A.R.(2015) ‘Design of Material Handling Conveying System for LucentEnergyPvt.’,3(1),pp.19–24.

[12] Taher, G. A. et al. (2014) ‘Automation of Material Handling with Bucket Elevator and Belt Conveyor’, International Journal of Scientific and Research Publications,4(3),pp.1–13.

[13] Harrison, A., 1983. Criteria for minimising transient stress in conveyor belts. Mechanical Engineering Transactions8(3),pp.129–134.

[14] He, D., Pang, Y., Lodewijks, G., 2016a. Belt conveyor dynamics in transient operation for speed control. InternationalJournalofCivil,Environmental,Structural, ConstructionandArchitecturalEngineering10(7),pp. 828–833.

[15] He,D.,Pang,Y.,Lodewijks,G.,2016b.Determinationof accelerationforbeltconveyorspeedcontrolintransient operation. International Journal of Engineering and Technology8(3),pp.206–211.

[16] He,D.,Pang,Y.,Lodewijks,G.,2016c.Speedcontrol of belt conveyors during transient operation. Powder Technology301,pp.622–631

[17] Limberg, H., 1988. Untersuchung der raumbezogenen bewegungswiderstände von gurtförderern. Thesis, HannoverUniversity.Lodewijks,G.,1995.

[18] The rolling resistance of conveyor belts. Bulk Solids Handling15(1),pp.15–24.

[19] Nave,M.,1996.Acomparisonofsoftstartmechanisms for mining belt conveyors. Tech. rep., Intertec Presentations,Inc.,Englewood,CO(UnitedStates).

[20] Nel,P.,Shortt,G.,1999.Controllingbeltslip.BulkSolids Handling19(4),pp.481–486.

Annexure 01

HIRAforConveyorreplacementwork

*Designatedworkerneedtobeengagedinliftingand shiftingactivity.

*Propertrainingonmaterialhandlingneedtobe ensuretoengagedworkman.

*Testedandrighttoolsandtacklestobeusedfor liftingwork..

objects, Crush/cut injury, Failureof lifting device/ mechanism.

Damagedto theproperties, hitbyobject, crush,cut, caughtin between,

R L

*Whileshiftingofmaterialensurethatitshouldnot beoverloadbeyondthesafeworkingloadofshifting deviceormechanism.

*Guideropewithredflagtobeusedbytheworkmen tohandlethebeltdrumduringshifting.

* RequiredPPEs(Safetyhelmet,Safetyshoe,Safety goggles,handgloves,NoseMasketc.)tobeworn duringworkactivity.

*Strictsupervisiontobeensuredalltime.

*IfpersongetinjuredtheymustbetakentotheOHC centre.

*Fallof material

*Struckby /withother objects

*Crush/cut injury

*Run over/Roll overof conveyor beltdueto applied tensionon belt.

* Accidentally /Suddenly startingof energised equipment.

*Dust exposure.

Damagedto theproperties, hitbyobject, crush, cut, caughtin between, Health hazards

R L

* Workpermitmustbeensurebeforeexecutionof job.

*LOTOmustbecheckedphysicallybythePTW requester/holderafterisolation.

*Trainedandskilledworkmentobedeployedforthe job.

*Liftingandpullingpathofmaterialandequipment mustbefreefromobstructiontoavoidexcessiveload ondevices.

*RequiredPPEs(Safetyhelmet,Safetyshoe,hand gloves,nosemasketc.)tobewornduringwork activity.

*Beawareofcrush/hitinjurywhilelifting/ shifting/pullingaconveyorbelt.

*Strictsupervisiontobeensuredalltime.

*Propercommunicationneedtobeensuredatboth endwhilepositioningofconveyorbelt.

4

*Takeup lifting/holding (Liftingof take-uppulley bychain block,Locking ofliftedtakeup)

*Clampingof beltforjoint

*De-coupling (Decoupling ofgeared coupling (inorderto avoid holdback bearing opening)

*Scrapper Release

*Fallof material

*Struck by/with other objects

* Crush/cut injury

*Run over/Roll overof conveyor beltdue toapplied tension onbelt.

*Slip/trip hazard.

Damaged tothe proprties, hitby object, crush, cut, coughtin between,

L

*Liftingdevicemustbeinspected forhealthinessbeforetoeachuse andensureavailabilityof competentpersoninspection reportofalllifting devices/mechanism.

*Liftingandpullingpathof materialandequipmentmustbe freefromobstructiontoavoid excessiveloadondevice.

*Beltlockingarrangementmust beensuredbyprovidingmultiple lockingatbothcarrying&return sideofthebelt.

*Operateportabletoolswithcare.

*Unauthorisepersonshouldnot allowtooperateelectricalpower tools.

2 2 4 2 2 4 Whenneeded A

*Positioning andlayingof newbelt conveyor.

*Positioning ofwinch machineand ropefor layingof conveyorbelt.

*Pullingnew conveyorby winch machine operation.

*Positioning ofbelt.

*Fallof material

*Struck by/with other objects

* Crush/cut injury

*Run over/Roll overof conveyor beltdue toapplied tension onbelt.

*Slip/trip hazard.

Damaged tothe proprties, hitby object, crush, cut, coughtin between,

R L

* Evacuatetheareaandbarricade torestricttheentrybelow suspendedload(Takeup)and affectedarea.Removeloose materialfromheight.

*Allopeningsandedgesshouldbe hardbarricaded.Useand anchoringofsafetyharnessis mandatoryatheight.

*Whileliftingofmaterialensure thatitshouldnotbeoverload beyondthesafeworkingloadof liftingdeviceormechanism.

* Liftingdevicemustbeinspected forhealthinessbeforetoeachuse andensureavailabilityof competentpersoninspection reportofalllifting devices/mechanism.

* Liftingandpullingpathof materialandequipmentmustbe freefromobstructiontoavoid excessiveloadondevice.

2 3 6 2 2 4 Whenneeded A

cleanedby proper cleaner& lubricated, Tightening ofcoupling Bolts)

*Fallof material

*Struck by/with other objects

*Run over/Roll overof conveyor beltdue toapplied tension onbelt.

*Slip/trip hazard.

Crush/cut injury, Damagedto the proprties, hitby object, crush, cut, coughtin between,

R L

*Skilledbeltjointermustbe deployedforsplicingprocess.

*Usechemicalglovesforbeltjoint chemical.

*Usesoffaceshield/safetygoggle, nosemask,handglovesmustbe ensuretobeltjointerwhilebuffing ofbeltwillbecarriedout.

*Donotkeptopentoavoidcontact withsourceofignition/naked flame.Beltjointchemicalsolution mustbeStoreincool,dryandsafe places.Keepawayfrom combustiblematerial.

*Fireextinguishermustbekept whileperformingthebeltjoint.

*Trainedandskilledworkmento bedeployedforthejob.

*Whileliftingandremovalof supportensurethatitshouldbe donesafely.

*Itistobeensurethatduring releasingoftakeupandbelttension noworkmanwillworknearby conveyorvicinity.

*Liftingandpullingpathof materialandequipmentmustbe freefromobstructiontoavoid excessiveloadondevice.

*Ensurescrapperisproperly tightenedatsuitablepoint.

*RequiredPPEs(Safetyhelmet, Safetyshoe,Safetygoggles,Cotton handgloves,nosemasketc.)tobe wornduringworkactivity.

*Beawareofcrush/hitinjurywhile lifting/shifting/pullingaconveyor belt.

*Itistobeensurethatduring loseningofbeltclampbeltclamp mustbeholdwithpperope.

*Trainedandskilled workmentobedeployed forthejob.

*Testedandrighttools andtacklestobeusedfor liftingwork.

*Testedliftingequipments tobeusedatsite.

*Whileshiftingofmaterial ensurethatitshouldnotbe overloadbeyondthesafe workingloadofshifting deviceormechanism.

*Guideropetobeusedby theworkmentohandlethe beltdrum.

*RequiredPPEs(Safety helmet,Safetyshoe,Safety goggles,Cottonhand gloves,nosemasketc.)to bewornduringwork activity.

*Stictsupervisiontobe ensuredalltime.

*Allunusedmaterials shouldbeproperlycleaned fromtheworkarea.

*RequiredPPEs(Safety helmet,Safetyshoe,Safety goggles,Cottonhand gloves,nosemasketc.)to bewornduringwork activity

*FieldEngineeristotake theinitiativetogoforthe trialruninco-ordination withControlroomand OperationShift-InCharge.

*Trainedworkmanmust beengagedinallpointof conveyorbeltforclose look.

*Priortostartthe conveyorclosemonitoring throughouttheconveyor mustbecarriedouttofind theproblem.

*Hootermustbeblow beforestartofconveyorto alertthenearbyworkman.

1 Shiftingof beltdrumto worksite

HIRA for belt press belt replacement work

2 Positioning&

Fallofmaterial, struckby/with otherobjects, Crush/cut injury,Failureof liftingdevice/ mechanism.

Damagedto the proprties, hitby object, crush,cut, coughtin between,

R L

*Designatedworkerneedtobeengaged inliftingandshiftingactivity.

*Propertrainingonmaterialhandling needtobeensuretoengagedworkman.

*Testedandrighttoolsandtacklestobe usedforliftingwork..

* RequiredPPEs(Safetyhelmet,Safety shoe,Safetygoggles,handgloves,Nose Masketc.)tobewornduringwork activity.

*Strictsupervisiontobeensuredall time.

*Ifpersongetinjuredtheymustbetaken totheOHCcentre.

*Fallofmaterial

*Struckby/with otherobjects

*Crush/cut injury

*Runover/Roll overofbeltdue toapplied tensiononbelt.

*Accidentally/ Suddenlystarting ofenergised equipment.

*Slurrey exposure.

3 Jointprocess. *cameincontact withbeltjointing pin

Damagedto the proprties, hitby object, crush,cut, coughtin between, Helath hazards

R L

* Workpermitmustbeensurebefore executionofjob.

*LOTOmustbecheckedphysicallyby thePTWrequester/holderafterisolation.

*Trainedandskilledworkmentobe deployedforthejob.

*Liftingandpullingpathofmaterialand equipmentmustbefreefromobstruction toavoidexcessiveloadondevices.

*RequiredPPEs(Safetyhelmet,Safety shoe,handgloves,nosemasketc.)tobe wornduringworkactivity.

*Beawareofcrush/hitinjurywhile lifting/shifting/pullingabelt.

*Strictsupervisiontobeensuredall time.

4 Provide tensionto belt

*Struckby/with otherobjects

*Runover/Roll overofbeltdue toapplied tensiononbelt.

*Slip/trip hazard.

Cut/Minor injury, hitbyobject R L

Crush/cut injury, Damagedto the proprties, hitby object, coughtin between,

N L

*Skilledbeltjointermustbedeployed forstitchingprocess.

*Useglovesforbeltjointprocess.

*Trainedandskilledworkmentobe deployedforthejob.

*Whileliftingandremovalofsupport ensurethatitshouldbedonesafely.

*Itistobeensurethatduringproviding tensiontobeltnoworkmanwillwork nearbybeltvicinity.

*Ensurescrapperisproperlytightened atsuitablepoint.

*RequiredPPEs(Safetyhelmet,Safety shoe,Safetygoggles,Cottonhandgloves, nosemasketc.)tobewornduringwork activity.

*Beawareofcrush/hitinjurywhile

*Crush/cut injury

lifting/shifting/pullingabelt. 5

*Trainedandskilledworkmentobe deployedforthejob.

*Testedandrighttoolsandtacklestobe usedforliftingwork.

*Testedliftingequipmentstobeusedat site.

*RequiredPPEs(Safetyhelmet,Safety shoe,Safetygoggles,Cottonhandgloves, nosemasketc.)tobewornduringwork activity.

*Stictsupervisiontobeensuredalltime.

*Allunusedmaterialsshouldbe properlycleanedfromtheworkarea.

*RequiredPPEs(Safetyhelmet,Safety shoe,Safetygoggles,Cottonhandgloves, nosemasketc.)tobewornduringwork activity

HIRA for Idler replacement work

*Tractor/campermust providetocarrytheidler

*Trainedandphysicallyfit workerneedtobeengagedin liftingandshiftingactivity.

*Propertrainingneedtobe ensuretoengagedworkman..

* RequiredPPEs(Safety helmet,Safetyshoe,hand glovesetc.)tobewornduring workactivity.

*Stictsupervisiontobe ensuredwhileliftingshiftingof idler.

*Ifpersongetinjuredthey mustbetakentotheOHC centre.

*ValidPTWfromshift incharge/controlroommust beensurebeforeexecutionof job.

*ProperLockOut&TagOutof permitwithisolation verificationisrequiredbefore commencementofjob.

*Fullbodyharnessmustbe ensurewhileworkingatheight.

*Itistobeensurethattools& tackleusingatheightmust securewithtagline.

*Idlermustbetiedandlocked properlywithliftingbeltbefore liftingatheight.

*Barricationbelowthearea mustbeensurebefore changing/liftingtheidler.

*Closesupervisionneedtobe done.