NAPKINS

USING NATURAL FIBRES (BANANA FIBRE, COTTON, LINEN)

1ASSISTANT PROFESSOR, Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamangalam, Erode, Tamil Nadu, India.

2Students,Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamangalam, Erode, TamilNadu, India. ***

ABSTRACT:

The vast amount of menstrual-related non-biodegradable waste produced in a nation like India, where women make up nearly 50% of the population, has serious environmental consequences. The bulk of the population in the country comes from low-middle class origins, therefore maintaining healthy menstrual hygiene practises with eco-friendly products calls for taking into account accessible and highly sustainable options. Furthermore, women are turning to the market for reusable products for inexpensive and durable alternatives because period poverty is now more prevalent than ever due to the COVID-19 pandemic. As a result, we investigated the Feasibility and Acceptability (FA) of a novel menstruation pad made of banana fibre in both rural and urban settings.

Keywords: Cotton, Banana fibre, Linen, Polyethylene film

INTRODUCTION:

Oneofthestrongestnaturalfibresisbananafibre,sometimesreferredtoasMusafibre.Thisstrongnaturalfibreismadefrom thebarkofthebananaplantandisbiodegradable.Thethicker,moredurablefibresemergefromtheoutersheaths,whilethe softestfibresarefoundintheinteriorsheaths(figure1),yetitsItmostlyconsistsoflignin,hemicelluloses,andcellulose.

Thefibrescanbecolouredandareremovedfromthebananastem.Afterbeingwashed,theydonotshrinkandthecolourdoes notchange.Politiciansmightprefertheclothbecauseofitsrigidityevenwithoutstarch.Thefabricmightbemadeentirely of bananafibre(figure1),butforbestdurability,itshouldalsocontain60%cotton.

Itissimpletosortbananafibrebythickness(figure1).Thestrongestandthinneststalkfibresareontheinside,whereasthe softestandmostflexiblestalkfibresareontheoutside.Theprocessofturningwoodybamboo,hemp,orflaxstalksintotextilegradefibresisrelativelylabor-andtime-intensiveandtheoppositeoftheprocessofturningbananastalksintotextiles.

Fabricmadeoflinenhasacoolingsensation,isbreathable,stronger,andmoreglossy thancotton.Itbecomessofterthemore times it is washed. Wet linen is more durable than dry linen. Additionally, it is dirt- and clothing- moth-resistant. As an acquisitionanddistributiontool,itisutilisedinthesecondlayerofnapkins.

Cotton isutilisedin top sheets becauseithasexcellent liquidretentionCapabilities, iskind ontheskin,and hasnoirritating properties.Itprovidescomfortanddrynessandissoftandbreathable.

METHODOLOGY:

MATERIAL EXTRACTION:

Cottonfibreextraction:

We start by processing it through a machine that separates the thick fibre tufts from the ginned cotton bales (figure 2). The fibreisfedintoahopperthatmechanicallyseparatesthefibretufts,andtheseparatedfibreisthenfedintoaseriesof highly sophisticatedcleaningtechnologiesthatwecalledEVC(shorthandforEnhancedVisual,Opening,Cleaningsystem)(figure2). Thesetechnologiesremoveasignificantamountofplantmatter,suchasstalk,stem,andleaves,aswellasextraneousmatter andtrash.

The goal isto eliminateall non-lint material, but in practise,mechanical cleaning methodscan never completelyeradicate it. The remaining steps of the procedure take place in enormous containers known as kiers. To hasten the wet purification procedure,thesekettlescanbeheatedandpressured.Cottoniswetoutandpackedintolargecakeswithaholeinthemiddle (foraperfectvisual,imagineaBundtcake).Thecottoncakesarethenlowereddownintothekieranditisclosed(figure2).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Following that, a sodium hydroxide-containing solution is poured into the cotton scouring process during the processing of cotton (FIGURE 3). The alkali solution is continually pumped through the cakes as the kier is heated and pressured. The residualplantmatterissoftened,thewaxesonthefibrearesaponified(turnedintowatersolublesoaps),andthepectinsand othernon-cellulosiccomponentsaresuspendedsotheymaybewashedaway.

Thesaponifiedwaxesandsuspendeddebrisareremovedwithfreshwaterafterasetamountoftimeatahightemperatureand pressuretoenableathoroughscouring.(SeeFigure4)Thecottonfibreisabsorbentafterscouring,andanytraceamountsof plantmatteraresoftened.

StepThree:Purifying

Acleansingsolutionisinjectedintothekierafterthescouringrinsehasbeendrained.The onlyoxidising(purifying) agentusedbyBarnhardtishydrogenperoxide,makingourprocesscompletelychlorine-free(TCF).

Thehydrogenperoxidewhitens thefibersbyoxidizingthecoloringmatter.Thepurifyingchemicalcanpermeatetheresidual plant matter more efficiently and make it white since the scouring process softens the remaining plant matter.In order to remove all colour bodies, the purifying solution is pushed through the cakes for a specific amount of time at a high temperature.Afterthat,thetankisdrainedandthepurifyingsolutioniswashedawaywithfreshwater.Atthisstageofcotton processing,allimpuritiesandcolouringagentshavebeeneliminated,leavingonlypurecelluloseinthecottonfibres.

StepFour:FiberFinishing

Despitetheremovalofthenaturalfibrefinish(wax),processingthefibremightbechallengingbecauseofthehighamountof fiber-on-fiber friction. Therefore, a fibre finish (lubricant) must be applied to enable efficient processing on high-production webformingmachinery.

Depending on the use required, a variety of fibre coatings can be used. The necessary level of finish can be imparted to the cottonfibresbypumpingthesefinishsolutionsthroughthecakes.Thecompletedsolutionisdrainedoncethetargetlevelhas beenreached.

StepFive:

OpeningandDrying:Thewetcakesaresplitopenoncemoreintotuftsoffibreinthisfinalprocess,andthe fibreisdried toa predeterminedmoisturelevel.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023

BANANA FIBRE EXTRACTION:

Bananafibrescanberemovedfrombananasusingavarietyoftechniques,includingchemical,mechanical,andbiologicalones. Previous research has shown that biological approaches take at least a month before the fibres can be recovered while chemical procedures frequently harm the environment (FIGURE 5). However, the mechanical approach is simple and affordable,anditisverycommoninunderdevelopedcountries.

Layersoffibrethatarefirmlywrappedmakeuptheoutsidesheathofthetrunk.Thefibre canbepulledoffinstripsthatare5 to8cmbroadand2-4mmthickandisprimarilyfoundnexttotheouterlayer.Tuxyingthestrips,sometimesknownastuxies, isthetermforthestripping procedure. The tuxiesarepackedandtransportedto thestrippingknifeforcleaningafterbeing removedfromthesheath.Thetuxedosarepulledundertheknifeduringthisprocedure.Theplanttissuebetweenthefibresis scrapedawaybypressingthebladefirmlyagainstawoodorstoneblock.

The clean fibre bundles are then dried by hanging them. Hand stripping can be substituted with simple machines. They are madeupoftworolls,oneofwhichhasascrapingbladeonit(figure5).Thetrunkissplitintoportionsthatarebetween120 and180cmlongoncethedarkeroutersheathhasbeenremoved.Therotatingdrumsreceivethesepartsasinput.Thetissue thatispulpyisremovedbythescrapingblade.Afterdrying,thepulpcanbeutilisedinthesamewayastuxedos.

Linen extraction: In the scutching process, the woody plant stalk is cut into pieces called shives without damaging the flax fibre,andthenthemachinepullsitthroughhugerollerstofurtherbreakthestalkintoshivesbutkeepthefibreintact.Theflax finallymakesittothedrumsinthelaststage.(Figure6)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023 www.irjet.net

p-ISSN:2395-0072

Fluidacquisitionanddistributionlayer:

Haveexcellenthydrophilicpropertiesandconsequentlycanacceleratetheabsorption

Linenfibre–Knownforfreshnessinhotweather

Durableanddriesquickly

–Allergyfree

–20%waterholdup

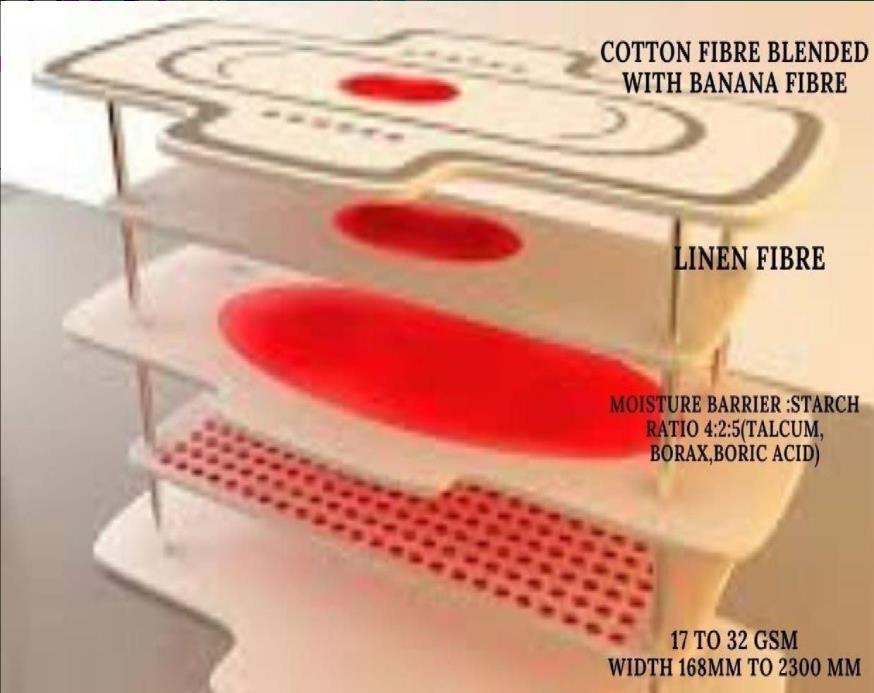

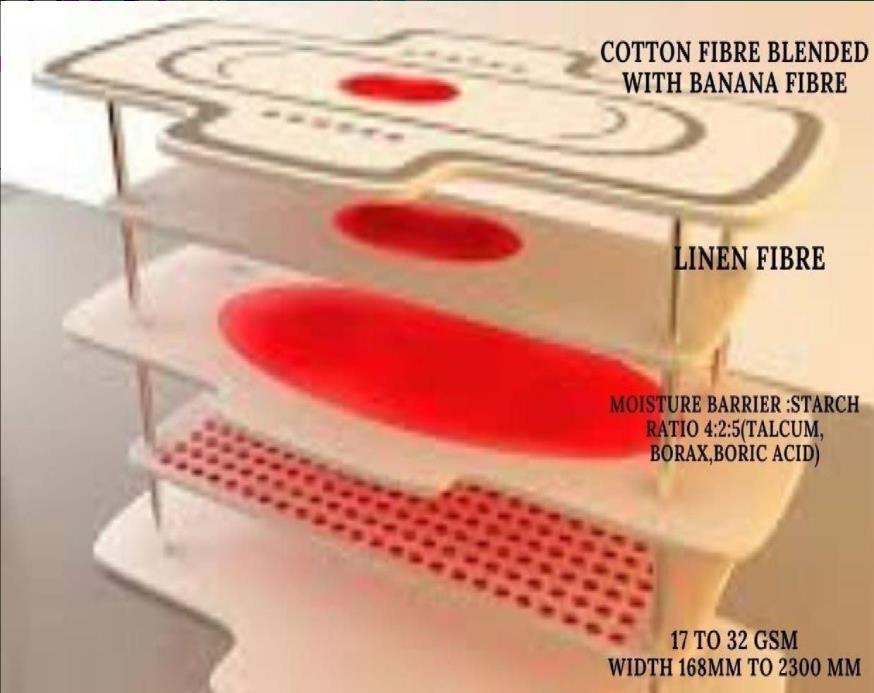

1.Absorbentcore:(figure8)

-Chlorinebleachedwoodpulp(sucksupliquidquickly)

-Moisturebarrier:Starchratio-Inthefirsttaketalcum,borax,boricacid(4:2:5)

-Inthesecondtaketalcum,borax,boricacid(8:11:3)

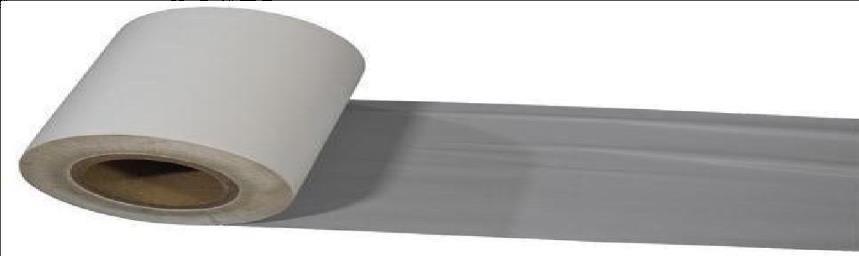

Backsheet:

Breathablefilm:Polyethylenefilm

Basicweight:17-32GSM

Width:168mm-2300mm

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023 www.irjet.net p-ISSN:2395-0072

CONCLUSION

Bananafibreisoneofthemostenvironmentallyfriendlyrawmaterialsforsanitarypadsduetothemonocarpicreplantability ofbanana plantsandtheuseofagricultural wasteastheir pseudo-stem. Theyarebothenergy- efficientandsimpletomassproduce. The superior absorption qualities of banana fibre allowed us to create sanitary pads that are hygienic, simple to wash, and quick to dry. The prolonged life of these sanitary napkins can greatly reduce the environmental risk provided by discardedsanitarypads.

REFERENCES:

1. https://www.the-sustainable-fashion-collective.com/2019/06/03/what-is-banana-fibre-and-how-do- youmaketextilesfrom-it

2. https://www.technicaltextile.net/articles/an-overview-on-sanitary-napkins-7850

3. https://barnhardtcotton.net/technology/cotton-processing/

4. https://www.sciencedirect.com/science/article/pii/S0273230015300386

5. https://sewport.com/fabrics-directory/linen-fabric

6. https://www.sciencedirect.com/topics/engineering/absorbent-core

7. https://www.wptnonwovens.com/acquisition-layer/

8. https://newbusi.en.made-in-china.com/product/HdCmpaRlbUVO/China-Acquisition-and- DistributionLayerfor-SanitaryFemine-Napkin.html

9. https://www.carnegietextile.com/characteristics-of-linen-fabric/

10. https://textilevaluechain.in/news-insights/characteristics-properties-of-banana-fibers/