Volume:

Study of Performance of Wooden Box Type Solar Cooker

Madhav V. Jadhav, Department of Physics, S. M.B.S. Thorat College Sangamner, Dist. Ahmednagar Maharashtra, India. ***ABSTRACT

This paper presents the design, development and performance evaluation of wooden box type solar cooker. The Stagnationtestandthe water boilingtestofthesolarcooker wereperformed duringApril,2022.The resultingvaluesof firstfigureofmerit(F1),secondfigureofmerit(F2)andefficiency( )was0.135,0.307and32.89%,respectively,which categorized the cooker as class A grade. This wooden box solar cooker was found to have high values of F1 and F2 (F1 >0.12andF2>0.40).ThecostofthecookerisINR3000.00.

Key words:Solarcooker,woodenboxtypesolarcooker,Thermalefficiency

INTRODUCTION

In order to keep pace with the development there is rise in energy use but it has adverse effect on greenhouse gas emissions due to burning of fast depleting fossil fuels. In this context, we need to harness and use more and more renewableformsofenergy,especiallysolarenergythatisplentifulinmostpartsofthecountry[1].Solarcookingoffersan effectivemethodofutilizingsolarenergyformeetingaconsiderabledemandforcookingenergyand,hence,protectingthe environment. Considerable effortshave gone intothe development and performancetestingof a variety ofsolarcookers and their suitability for cooking different foods [2]. Solar cookers are mainly of two types: box types and concentrating types. Box type solar cookers are simple and suitable for limited cooking due to their relatively low heat collection capacity,whileconcentratingtypesolarcookersarecapableofgeneratinghighertemperaturesandcanefficientlybeused for a variety of cooking applications. However, the latter require continued adjustment of the orientation of the concentratortoreflecttheincidentsolarradiationonthefocuswherethecookingpotisplaced.

The solar cooker is very useful even for common people in developing world specifically because of its low drudgery. A major portion of total available energy resource in rural areas of developing world is utilized for cooking and is mainly suppliedbynon-renewableenergysourcese.g.fuelwood,agriculturalwaste,cowdung,keroseneetc.Theenvironmental effectsoffuelwoodburninghavebeenreportedinseveralliteratures[3-6].InIndia,halfamillionbox typesolarcookers havebeenpropagatedinthecountrythroughthepopularschemeslaunchedbytheMinistryofNon-conventionalEnergy Sources,GovernmentofIndia[7].

Intheboxtypesolarcooker,solarenergyistrappedinsideaninsulatedboxandthefooditemsarekeptinsidetheboxfor cookingpurpose.Differenttypesofboxtypesolarcookershavebeendesigned,developedandtestedindifferentpartsof the world [8-11] Different designs of solar cookers reported in the literature have separate provisions for energy collection and the cooking units. The box type solar cooker is the most popular one due to its simple design and easy handling requirements [12]. Conducted extensive experimental studies and developed a test procedure for performance evaluationandstandardizationofboxtypesolarcookers[13].Theperformanceofaboxtypesolarcookerlargelydepends on selection of materials for various components viz. glazing, insulation, casing and absorber tray. For improving the efficiencyofboxtypesolarcookers,awoodenboxtypesolarcookerwasdesignedandevaluatedforitsuseasadomestic solarcookerforsmallfamiliesinthecurrentsocialconditions.

MATERIALS AND METHODS

Development of wooden Box type Solar Cooker

coverswas15mmtoavoidthermallosses.Arubbergasketwasprovidedbetweenthetrayandthewoodenframetomake itleakproof.A5mmthickplainmirrorreflectorofsize443mmx437mmwasfixedoverit.Thereflectorcanbefittedto woodenlidandplacedoverthecookerandactsasalid.Thetiltofthereflectorcanbevariedfrom600 to1200 depending upontheseason.Thetiltisfixedonceinafortnight.Thereflectorcouldbefoldedonthecookerwhilethedeviceisnotin use.Theapertureareaofthesolarcookerwas0.1599m2 .Thefourcookingutensilsof298.42gm,296.25gm,and297.55 gmand296.20gmweight.Stainlesssteelboxeswithlidcanbekeptinsideitforcookingfourdishessimultaneously.

woodenboxtypesolarcooker

Evaluation of Cooker

Theon-siteexperimentsonwoodenboxtypesolarcookerwereperformedduring April,2022atthephysicsdepartment, S. M. B. S. Thorat College of Arts, Science & Commerce, Sangamner, Dist. Ahmednager (M.S.) India. In these experiments, the solar radiation intensity (Gs ) on a horizontal surface was measured using a Sun meter. A thermometer with point contactthermocoupleswasusedtomeasurethetemperaturesatthebaseplate,watertemperatureandcookingfluid.The ambientairtemperaturewasmeasuredusingamercurythermometer,placedinanambientchamber.Themeasurements oftemperaturesofdifferentregionswerecarriedoutonclearsunnydaysatevery5minintervalforthedurationof10:00 to1:15IndianStandardTime(IST).Reflectorwasusedwheneverrequiredaspertestconditions.

Thermal performance and testing:

The solar cooker was evaluated based on Bureau of Indian Standards Testing Method (BIS 2000). Based on the existing testing standards three tests were performed on the wooden box type solar cooker; these were: first figure of merit F1, second figure of merit F2 and standardized cooking power (Ps). The first figure of merit (F1) was determined by conductingtheno-loadtest;secondfigureofmerit(F2)wasdeterminedbyloadtestinwhichknownamountofwaterwas heatedinsolarcookerandcookingpowerwasestimated.Theefficiencyofthewoodenboxtypesolarcookerwasobtained by measuring the rise in temperature of a known quantity of water in a specified time as proposed by the method of calculationof efficiency(ɳ) ofthesolarcooker byNahar(2001 and 2009). Thesolarradiation, ambientairtemperature, baseplatetemperatureandwatertemperatureweretakenata5minutesintervalinordertodeterminethefirstfigureof merit F1 and second figure of merit F2 of the box type solar cooker. The reflector of wooden box type solar cooker was surroundedwithblackclothduringthestagnationtemperaturetest.

First Figure of Merit (F1) without water load (Stagnation test):

The hot junction of the thermocouple should be fixed at the midpoint of tray with proper thermal contact and without protrudingout.Thenoloadtestshallbecarriedoutonacleardayinfollowingsteps.

a) Placethesolarcookerwithoutpotinopensuncondition.

b) Coverthereflectorofthesolarcookerwithblackcloth.

c) Monitor the cooker tray temperature at an interval of 5 min. continuously. Also measure intensity of total solar radiation,ambienttemperatureandwindspeedatthelevelofglazing’sofsolarcooker;and

d) When the cooker tray temperature has reached a quasi-steady state note down the final steady cooker tray temperature (Tpx) and the corresponding outside ambient air temperature (Taz) along with the solar radiation (Gs)atthattime.

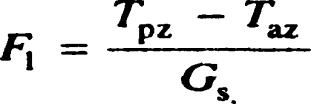

Thefirstfigureofmerit(F1)isdefinedastheratioofopticalefficiency,(ɳ0 ),and theoverallheatlosscoefficient,(UL).A quasi-steady state (stagnation test condition) is achieved when the stagnation temperature is attained. High optical efficiencyandlowheatlossaredesirableforefficientcookerperformance.Thus,theratioɳ0 /UL whichisauniquecooker parametercanserveasaperformancecriterion.Instagnationtestinitiallytemperatureof bare plate increases and after some time it gets stagnant. Higher values of F1 would indicate better cooker performance (Mullicketal.,1987):

WhereF1isfirstfigureofmerit,Tpzismaximumplatesurfacetemperature(0C),Tazisambienttemperature(0C),andGs isglobalsolarradiationonahorizontalsurface(W/m2).

Second Figure of Merit (��2) with water load (Sensible heat test):

Weight the empty cooking pots and then fill with 8 litters of water per square meter of aperture area. Water at ambient temperature is equally distributed in all the cooking pots if they are of the same size. If sizes are different, then water quantityineachcookingpotshallbeinproportiontotheirbottomarea.Reweight andcalculatetheexactmassofwater. Place the pots in the cooker from which the mirror has either been removed or covered with cloth. Place temperature probeofthermocoupleinthelargestofthecookingpotswiththemeasuringtipsubmergedinthewater.Thetemperature probe leadshall besealed where itleavesthe cooking potsand thecooker. Theambient temperatureand windspeedat thelevelofglazing’sofsolarcookeraremeasuredthroughoutthetest.Thetestshallstartinthemorningbetween10:00h to10:30hoflocalsolartime.Iftheradiationandtemperaturearemeasuredbyspotchecks,theseshallbenomorethan5 min apart. Constant monitoring at 30 s intervals or or less is desirable with averages of radiation recorded over 2 min intervals.

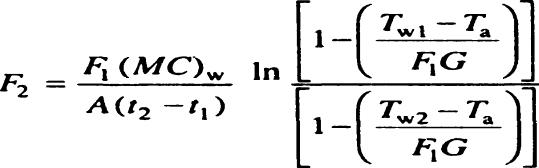

The second figure of merit, F2, of box type solar cooker is evaluated under full-load condition (water load), without reflectorandcanbedefinedastheproductoftheheatexchangeefficiencyfactor(F),opticalefficiency(ɳ0 =αt)andheat capacityratio(CR).Itcanbeexpressedas(Mullicketal.,1996)

whereF2issecondfigureofmerit( 0Cm2 /W),(MC)wisproductofthemassofwateranditsspecificheatcapacity(J/ 0C), �� isaperture area of the solar cooker (m2 ), t1 is initial time (s), t2 is final time (s),Tw1 is initial water temperature(0C), Tw2 isfinalwatertemperature(0C),Gsisaverageglobalsolarradiation(W/m2 ),andTaisaverageambienttemperature (0C).

Efficiency of the box type solar cooker ():

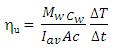

The overall thermal efficiency of the solar box cooker is expressed mathematically by [15, 16] and reported by [14] as follows:

Where ηu represents overall thermal efficiency of the solar cooker; Mw, mass of water (kg); Cw, Specific heat of water (J/kg/oC); ΔT,, temperature difference between the maximum temperature of the cooking fluid and the ambient air temperature; Ac, the aperture area (m2) of the cooker; Δt, time required to achieve the maximum temperature of the cookingfluid;Iav,theaveragesolarintensity(W/m2)duringtimeinterval Δt.

RESULTS AND DISCUSSION

First Figure of Merit (F1) without water load (stagnation test):

The thermal evaluation experiment to determine the stagnation temperature of the wooden box type solar cooker was carriedoutduringclearskyconditionin May2022.The stagnationtemperature experimenttestthatis,noloadtestwas started at 10:00 h. The plate temperature increased up to 95 °C within half an hour and stagnated at about 137 0C at around3:00h.TheincreaseinstagnationtemperaturecorrespondingtothesolarradiationsisshowninFig.2.Thehighest temperatureattainedbyplatewas137 0C(Taz=365 0C,Tpz=137 0C,Gs=741.84W/m2 ).Thisshowsthatalthoughthis cookerissmallinsize,itsthermalperformanceiscomparablewiththesolarcookersdevelopedbytheotherresearchers. The plate temperature indicated that the present cooker provided enough insulation material (black foam) to reduce thermal losses while maintaining the same absorber area. The enough insulation material indicates good thermal performance ofthecooker. Fig.2illustratesthevariationof platetemperature with time.Fig.3 illustratesthevariation of solar intensity with time. The stagnation temperature varied between 70 0C and 120 0C with the variation in insolation from 400 to 960 W/m2 . This figure also shows that the plate temperature remained around more than 120 0C for more than5hourswhichislongdurationforsatisfactorycooking.ThefirstfigureofmeritF1wascalculatedusingEq(1) asper thestagnationthermalperformancetest.Thefirstfigureofmerit(F1)wasfoundtobe0.135andthisvalueisacceptable asperBIS(2000)andMullicketal.(1996).TheconstructedboxtypesolarcookerismarkedasA-Gradesolarcooker.The highervaluesoffirstfigureofmeritindicatedgoodthermalperformanceofboxtypesolarcooker(Mahavaretal.,2012).

Solar intensity

Second Figure of Merit (��2) with water load (Sensible heat test):

To determine F2 , water heat up test was carried out with water load and without reflector in May, 2022 in a clear sky conditions as per BIS (2000) test code. The base plate temperature reached 80° C within 45 min and it remained higher thanthistemperatureforaround6hours.Thewatertemperaturereached90 0Cwithin3hoursandremainedhigherthan this for almost 4 hours, which is sufficient to cook two meals. Fig.4 illustrates the variation of water temperature with time. Fig.5 illustrates the variation of solar intensity with time. The trend of the water temperature curve shows that as timeofdayprogressedwatertemperatureincreasedwithincreasingsolarinsolation.Thevalueofsecondfigureofmerit (F2)usingEq(2)wasfoundtobe0.307(usingF1=0.135,M=1.2kg,C=4186J/kg/°C,A=0.1599m2 ,Tw1=61 0C,Tw2 =90 0C, Gs=657.87W/m2 ,Ta=36.5°C,t1=10.30,t2=13.00)whichwaswithintherecommendedstandardvalueinthe rangeof0.254-0.490.

Solar Intensity

Fig.5variationofsolarintensitywithtime.

Efficiency of the box type solar cooker ():

Cookerwasloadedwith1.2kgofcoldwater.Theinitialtemperatureofwaterwas37°Candsolarintensity410W/m2 and thefinaltemperatureofhotwaterwas99 0Candsolarintensity962W/m2.Theefficiencyoftheboxtypesolarcookerwas calculatedusingtheEq(3)anditwasfoundthat32.89%(WhereAc =0.1599m2;Cw =4186J/kg/0C;Iav = 657.87W/m2 ; Mw = 1.2 kg; ∆Tw = 62 0C, ▽t = 9000s). The present box type solar cooker has shown the best performance and highest efficiency for the maximum load (1.2 kg) is an indication of better heat retention ability of the cooker as compared with othersfoundintheliterature.

CONCLUSION

Theexperimentalresultsshowedthatfirstfigureofmerit(F1),secondfigureofmerit(F2)satisfiedtheBureauofIndian Standards (BIS) and International standards for thermal performance testing of the wooden box type solar cooker. The thermalefficiencyboxtypesolarcookerwas32.89%forthewaterloadof12kg.

REFERENCES

1. Development and Performance Evaluation of High Insulation Box Type Solar Cooker Surendra Poonia* (LM 11526), A.K. Singh (LM 7438), P. Santra and Dilip Jain (LM 10247), Agricultural Engineering Today, Vol. 43(1), 2019

2. MorrisonGL,MillsDR.In:ProceedingsofConferenceofInternationalSolarEnergySociety,1987.p.13-18.

3. ElliottD.2004.Energyefficiencyandrenewables.EnergyandEnvironment,15:1099–1105.

4. Tingem M; Rivington M. 2009. Adaptation for crop agriculture to climate change in Cameroon: Turning on the heat.MitigationandAdaptationStrategiesforGlobalChange,14:153–168

5. Panwar N L; Kaushik S C; Kothari S C. 2011. Role of renewable energy sources in environmental protection: A review.RenewableandSustainableEnergyReview,15:1513–1524.

6. Huttunen S. 2009. Ecological modernization and discourses on rural non-wood bioenergy production in Finland from1980to2005.JournalofRuralStudies,25:239–247.

7. AnnualReport,MinistryofNon-conventionalEnergySources,GovernmentofIndia,NewDelhi11003,2002-2003.

8. Negi B S; Purohit I. 2005. Experimental investigation of a box type solar cooker employing a nontracking concentrator.EnergyConversionandManagement,46:577-604.

9. Kumar S. 2008. Estimation of design parameters for thermal performance evaluation of box-type solar cooker. RenewableEnergy,30:1117-26.

10. Harmim A; Belhamel M; Boukar M; Amar M. 2010. Experimental investigation of a box type solar cooker with a finnedabsorberplate.Energy,35:3799-802.

11. Mahavar S; Sengar N; Rajawat P; Verma M; Dashora P. 2012. Design development and performance studies of a novelsinglefamilysolarcooker.RenewableEnergy,47:67-76.

12. MullickSC,KandpalTC,KumarS.SolarEnergy1991;46:139.

13. IS13429(Parts1,2&3),IndianStandard:SolarCooker,BureauofIndianStandards,NewDelhi,1992.

14. El-Sebaii, A. A. and I brahim, A., Experimental tesing of a box-type solar cooker using the standard procedure of cookingpower.RenewableEnergy,30,2005,pp.1861-1871.

15. Khalifa,A.M.A,Taha,M.M.A,Akyurt,M.,Solarcookersforoutdoorsandindoors.Energy,10(7),2005,pp819

29.

16. Olwi, I, Khakifa, A. M. A., Numerical modeling and experimental testing of a solar grill. Journal Solar Energy Engineering,115,1993,pp.5–10.