FIBER REINFORCED CONCRETE USIING SISAL FIBER

Dhaval Pateliya1 , Mauni Modi2

1PG Student, M.E (civil) Infrastructure Engineering, L.D.R.P. Institute of Technology & Research, Gandhinagar

2 Assistant professor, Dept. of Civil Engineering, L.D.R.P. Institute of Technology & Research, Gandhinagar

Abstract - This research work involves the topic of adding natural fibers to the concrete to study the strength properties and observe whether thepropagationofshrinkageproblemsis reduced. Basically, there are two types of natural fibre. Natural inorganic fibres like asbestos, basalt, etc. as well as natural organic fibres like banana, bamboo, coconut, palm, pine, kenaf, jute, sisal, sugar cane, and soon. Naturalfibres are studied as construction materials by differentresearchersand can be used in cement, mortar or concrete in building materials. This research work may include the characteristics of sisal fibre, its properties and also compatibility of fibre(sisal) and compares its nature of fibre- freeconcreteand concrete with natural fibre(sisal). But it also to compare and draw the conclusion of the proportion of different fibres cement. This study summarizes the comparisonanddifference between fiber-free concrete and concrete with natural fiber(sisal).

Key Words: Sisalfiber,Fiberreinforcedconcrete,Natural fiber,Artificialfiber,Testing.

1. INTRODUCTION TO SISAL FIBER

Sisalfiberisthemostcommonlyusedplantfibersandisvery easytogrow.Sisalisastrongfiberobtainedfromthesisal plantsleaves.Theplantofsisalfiberisofficiallycalledagavesisalana.Theplantshavingleaveslikeasword-shapedrose thatbeginstohaveteethandgraduallywearsmatureteeth overtime.Allleaveshavemanystraightandlongfibersthat canbe eliminated by means ofa method calledpeeling or decortication. During the peeling process, the leaves are brokentoremovethepulp andplantmaterial,left behind the strong fibers. For the production of twine and textile, fiberswillbewarpedintothread,orpulpedtomakepaper makepaperproducts.

1.1 PROPERTIES OF SISAL FIBER

Theactualcontentofthefiberelementsisabout4%ofthe weight of the plant and can be extracted by a method as “decortication”.Intheirnaturallife,typicalplantsgenerate 200to250fruitfullyavailableleaves.Alsoeachleafofsisal plantswillproduceapproximately1000fibers.

Inordertoobtainasuperiorqualitystructureandgood sustainability,itispreferabletousesisal fiberstodevelop several strength characteristics of the structure. Different plantfibersofsisalfibersofsisalweretestedforitsadequacy

***

fortheadditionincementconcrete.Thephysicalproperties of the fibers do not show deterioration of the concrete structure. The leaves are dried out, brushed and bailed to producefibersfromsisalplant.

1.2 CHARACTERISTICS OF SISAL FIBER

Sisalfiberisthehardestcellulosefiberslikecoconutfiber.It containscelluloseabout70%inthefiber.Withcellulose,this fiberalsoconsists ofhemicellulose,lignin, pectinand wax etc. the properties of this fiber are greatly affected by its chemical composition. In cellulosic fibers like sisal and coconutfibers,celluloseisthestrongestorganicconstituent that imparts fiber stability, stiffness and strength, where sisalfiberscontain70%ofcelluloseonly.Hence,wecansay thatsisalfiberisaoneofthestrongestfibres.Hemicellulose isapolysaccharidethatbindstogetherinarelativelyshort branch. Lignin is an aromatic hydrocarbon polymercompositethatgivesstiffnesstothesisalplant.

1.3 NEED OF STUDY

Theapplicationofconcrete asa strengthening material in structuralissomewhatlimitedbythedisadvantagesuchas poor ductility and durability, fatigue, lower impact resistance, low tensile strength, brittleness. It is also very muchrestrictedtoabsorbdynamicstressescauseddueto shock loading. The brittleness is compensated in the structuralmemberbyaddingareinforcingbarorpre-stress inthetensilearea.Thedevelopmentofsteelbarssolvesthe problemoflowertensilepropertyofconcrete.Lowertensile strengthandhigherstrengthrequirementsoftheconcreteis the main problems of steel and these problems are still existed, and will be improved through different types of reinforcement material. Further concrete also has lower ductility. In concrete, increasing the fiber- content will increasewillincreasethestrengthanddecreasedryingand plasticshrinkagebylimitingthecrack-expansion.

1.4 SCOPE

The scope pf this study work is to find out the gap in researchoftheFRCusingsisalfiberbandimprovementin thephysicalandmechanicalpropertiesofSFRC(sisalfiber reinforced concrete). A limited number of additional tests are also performed to determine the tensile and flexure properties,compressive-anddurabilitypropertiesandalso tocheckitssuitabilitybycomparingtheconcretewithsisal fiberandwithoutsisalfiber.

2. RESULTS AND DISCUSSION

2.1 Compression Strength Test

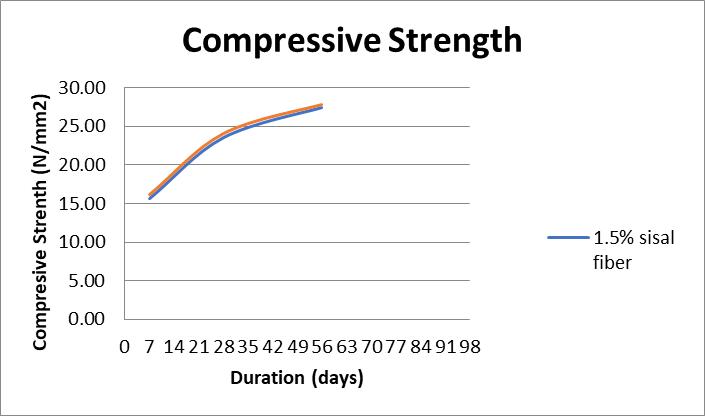

Thecompressionstrength(cubestrength)ofconcreteisthat the strength of hardened concrete measured by the compressiontest.For testingata singletime3specimens were tested under ACTM (Accelerated Corrosion Testing Method) and average value of 3 specimen was taken as a final result. Concrete compression test was performed according IS 516-1959. Testing for compression strength wasexecutedat7,28,56,and90daysageofcuring.

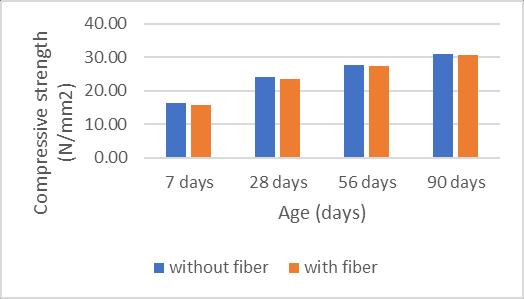

Thecompressionstrengthofeachsampletestedafter7,28, 56 and 90 days of curing period. The average of three samplesistakenasthecompressivestrength.Theresultsof average compressive strength and also the percentage change in compressive strength with fiber reinforced concreteandnormalconcrete.

From table-2, we can say that the sisal fiber shows no improvement in compression strength when compares to normalconcrete.

Chart -2 shows a slight decrease in compressive strength whenaddingsisalfiberstotheconcrete.Attheageof7days thecompressivestrengthwasdecreasedby3.29%andthis reduction decrease with the time of curing. After that the differenceofcompressivestrengthbetweenconcretewith sisalfiberandwithoutsisalfiberdecreasewiththeincrease of curing period. As show in chart-2 the compressive strength of SFRC after 56 days decrease the compressive strengthwasonly1.33%andafter90daysdecreaseinthe compressivestrengthwasonly0.98%.

Therefore, based on the results, Sisal fiber reinforcedconcreteisnotsuitableforcompressivestrength.

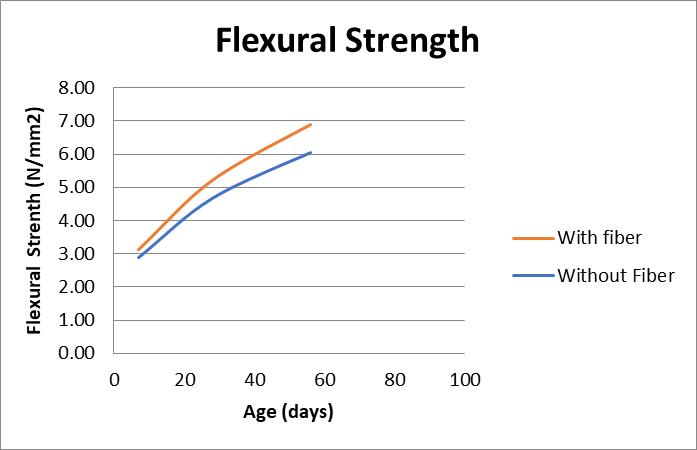

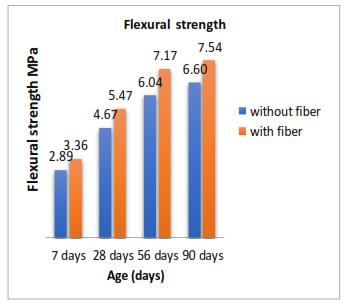

2.2 Flexural Strength Test

The flexural strength test was performed according to IS516:1959.Flexuralstrengthtestwasperformedat7,28,56 and90daysageofcuring.

Theresulttestperformedisgiveninthetabularformbelow. Theflexuralstrengthofeachspecimenfsampletestedafter thecuringperiodof7,28,56and90days.Theaverageof threespecimensistakenastheFlexuralstrengthormodulus

of rupture. The average Flexural strength and also the percentagechangeinflexuralstrengthwithfiberreinforced concreteandnormalconcrete.

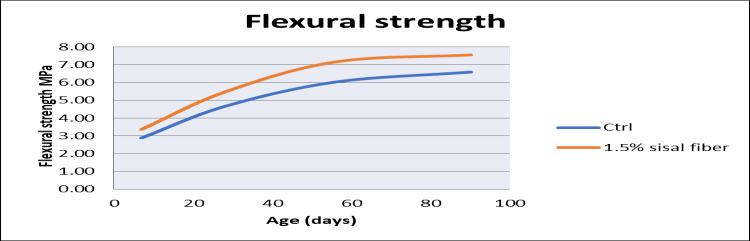

Flexural strength

The result given in table 4 is point out that the flexural strength is improved with sisal fiber. The percentage incrementsinflexuralwithsisalfiberare16.20%,17.09%, 18.61% and 14.47% at the age 7, 28, 56 and 90 days respectively.Itcanalsobeconcludedthatwithincreasingage the%changeflexuralstrengthisalsoincreasing

Chart -4 shows that the flexural strength of SFRC is significantlyenhancedascomparetonormalconcrete.The obtainedFlexuralstrengthat90dayswas7.54MPa.

Splittensilestrengthtestwere performed according toIS5816:1999.Splittensilestrengthtestwasperformedat7,28, 56and90daysageofcuring.Splittensilestrengthsamples were tested at UTM (universal testing machine) with an averageof3asthefinalresults.

The result of test performed is given in the tabular form below.Thesplittensilestrengthofeachspecimenofsample testedafterthecuringperiodof7.28,56and90days.The averageofthethreespecimensistakenasthesplittensile strength of concrete sample. The average split tensile strength and also the percentage change in split tensile strengthwithfiberreinforcedconcreteandnormalconcrete.

Theresultsintable6isspecificthattheSplittensilestrength is improved significantly with sisal fiber. The percentage increments in Split tensile strength with sisal fiber are 11.67%,13.97%,15.26%and16.12%attheageof7,28,56, and 90 days respectively. It can be concluded that with increasing age the % change flexural strength is also decreasing.

Chart-6 shows that the split tensile strength of sisal fiber reinforcedconcreteissignificantlyimprovedascompareto normalconcrete.TheobtainedmaximumFlexuralstrength improvementwas15.26%attheageof56days.

3. CONCLUSIONS

Thecompressionstrengthwasslightlydecreasedwiththe additionofsisalfiber.Thecompressionstrengthlossatthe age7days was3.29%andlossdecreaseswiththetime of curingandat90daysthelossincompressivestrengthwas 0.98%only.Therefore,basedontheobtainedresults.Sisal fiber reinforced concrete is not suitable for compressive strength purpose as it shows slight loss in compressive strength.

The percentage increments in flexural strength with sisal fiberare16.20%,17.09%,18.61%and14.47%attheageof 7, 28, 56, days 90 days respectively. Its concrete is significantlyimprovedascomparetonormalconcrete.

TheSplittensilestrengthisimprovedsignificantlywithsisal fiber. The percentage increments in Split tensile strength withsisalfiberare11.67%,13.97%,15.26%and16.12%at theageof7,28,56,and90daysrespectively.

REFERENCES

1. Baluch H., Zibra Y.N., Azad A.K.: “fracture characteristics of sisal fibre reinforced concrete”, theinternationaljournalofcementcompositesand light weight concrete, volume 9, number 3, 1987:157-168

2. Barros J. A.O., silva F.A., Toledo Filho R.D.: “Experimental and numerical research on the potentialities of layered reinforcement configuration of continuous sisal fibers for thin mortarpanels”,Constructionandbuildingmaterials 102(2016):792-801

3. BergstromSwenG.&GramtH.:“Durabilityofalkalisensitive fibres in concrete”, The international journal of cement composites and lightweight concrete,volume6,number2,1984:75-80

4. Ferreira S.R., Silva F.A., Lopes Lima P.R., Toledo Filho R.D.: “Effect of fiber treatment on the sisal fibrepropertiesandfibre-matrixbondincementbasedsystem.”,Constructionandbuildingmaterials 101(2015):730-740

5. Mwamila B.L.M.:” Natural twines as main reinforcementinconcretebeam”,Theinternational journal of cement composites and lightweight concrete,volume7,number1,1985:11-20

6. Rahumana.,YeshikaS.:“Studyonpropertiesofsisal fibre reinforced concrete with different mix proportions and different percentages of fibre addition”, international journal of research in engineeringandtechnology,vol-4,2015:474-477

7. RaijiwalaD.B.,PatelJ.A.,:“Useofsugarcanebagasse ashaspartialreplacementofcementinconcrete–Anexperimentalstudy”,Globaljournalofresearch inengineering,vol-15(2015)

8. Ramakrishna G., Sundararajan T.: “Studies on the durability of natural fibres and the effect of corrodedfibresonthestrengthofmortars”,cement andconcretecomposites200522):575-585

9. Sanjuan M.A., Toledo Filho R.D.: “Effectiveness of crackcontrolatearlyageonthecorrosionofsteel bars in low modulus sisal and coconut fibrereinforcedmortars”,cementandconcreteresearch, Pergamon,vol-28,1998:555-565

10. Santos S.F., Schmidt R., Almeida A.E.S.F., Tonoli G.H.D.,SAVASTANOJr.H.:“supercriticalcarbonation treatmentonextrudedfibre-cementreinforcedwith vegetablefibres”,cementandconcretecomposites 56(2015)84-94

11. SantoshF.M.R.,deSouzaT.F.,BarqueteD.M.,Amado F.D.R.: “Comparative analysis of the sisal and piassava fibres as reinforcement in lightweight cementitious composites with EVA waste’, construction and building materials 128(2016):315-323

12. Sathish P., Murugesh V.: “Experimental Study on Sisal Fibre Reinforced Concrete with Partial ReplacementofCementbyGroundGranulatedBlast FurnaceSlag”,Internationaljournalofscienceand research,2015:79-82

13. Shetty M.S. “Textbook of Concrete Technology”, 2012:312-327

14. SilvaF.A.,MobasherB.,ToledoFilhoR.D.:“Cracking mechanismindurablesisalfibrereinforcedcement composites”, cement and concrete composites, 31(2009):721-730

15. SilvaF.A.,MobasherB.,ToledoFilhoR.D.:“Fatigue behavior of sisal fibre reinforced cement composites”, Material science and engineering, A527(2010):5507-5513

16. SilvaF.A.,MobasherB.,SoranakomC.,ToledoFilho R.D.: “Effect of fibre shape and Morphology on interfacialbondandcrackingbehaviorsofsisalfibre

cement based composites”, Cement and concrete composites33(2010):814-823

17. Silva F.A., Toledo Filho R.D., Melo Filho J.D.A., De MoraesR.F.:“Physicalandmechanicalpropertiesof durable sisal fibre-cement composites”, ConstructionandBuildingmaterials24(2010):777785

18. SenT., Paul A.:“Confiningconcrete withsisal and jute FRP as alternatives for CFRP and GFRP”, International journal of sustainable built environment(2005)4:248-264

19. SenT.,ReddyH.N.J.:“FlexuralstrengtheningofRC beamsusingnaturalsisalandartificialcarbonand glass fabric reinforced composite system” SustainableCitiesandSociety10(2014):195–206

20. Weij.,Meyerc.: “Improvingdegradationresistance of sisal fiber in concrete through fiber surface treatment", Applied Surface Science 289 (2014) 511–523