A COMPARATIVE STUDY ON STRENGTH ASPECTS OF HD PET THERMOPLASTIC WITH METAKAOLIN AND GROUND GRANULATED BLAST FURNACE SLAG"

Suryabhan Singh Chundawat 1 , Mr. Mohit Jakhar2

Suryabhan Singh Chundawat, Maharishi Arvind International Institute of Technology, Kota (Rajasthan)

Mr. Mohit Jakhar Assistant Professor , Maharishi Arvind International Institute of Technology, Kota (Rajasthan) ***

Abstract –

When we talking about the most versatile, reliable and durable material in the field of construction first name comes is Concrete, after that cement comes. These materials make the world beautiful but this is one aspect, the other aspect says that it pollutes the environment, as the cement plants that emit a lot of carbon die oxide. The main aim of this study is to concern towards the environment and provide the best alternate amongst GGBFS and Metakaolin.

resent study evaluates strength parameters of the concrete containing the combination of above mentioned materials. The experimental program consists of preparing concrete mixes with Meta kaolin and GGBFS as a partial replacement of cement (5%, 10% and 15%) and similarly Fine aggregate replaced by the HD Pet thermoplastic in proportion of 5%and 10% simultaneously. The performance of the concrete mixes for compressive strength at the age 28 days, flexural strength at 28 days test were investigated. After checking the strength with various replacement levels, we finally concluded the variation in strength parameters.

1. INTRODUCTION

Concrete is quite possibly the most flexible and generally acknowledgedconstructionmaterialaroundtheworld.The explanationforthisisthenormally,efficientlyandeffectively accessibility of fixings as concrete, river sand, coarse aggregateandwater.Afterthewater,concreteisthesecond most construction material on the planet. At present day time of innovation concrete plays, a significant part exceptionallythegreensubstantialwhichutilizesindustrial waste.Thefastconstructionontheplanetneedsimaginative greenconstructionmaterials.Anywayafewissuesrelated with this fast construction exercises is that it is liable for roughly40%normalassetsutilization.Thefastconstruction ontheplanet need quick creation ofcement which makes two major natural issues for which we need to figure out inventive Civil engineering solutions. The extraordinary ecologicalissueisemanationofCO2intheproductioncycle of the cement. It is realizing that CO2 emanation is exceptionally hurtful which makes bunches of natural changesinexact1tonsofcarbondioxideisassessedtobe

deliveredtotheclimatewhen1toneofstandardPortland cement is made, so it is fundamental for control the production of cement. As there is no alternative binding materialwhichtotallyreplacethecementsotheutilization of partial replacement of cement is well accepted for concrete composites. As a Supplementary cementitious materialGround granulatedblast-furnaceslag,flyash,silica fume,Metakaolin,calciumcarbideresiduecanbeused.The Use of Supplementary Cementitious Material in concrete buildingsnownotbestpreventsthesematerialstocheckthe pollution but additionally to decorate the properties of concreteincleanandhardenedstatesandadditionallymake them durable specifically GGBFS. Present look at consciousness on the durability and strength parameters with partial substitute of cement with some above noted substances.Ground-granulatedblast-furnaceslagandMeta kaolinisknowntoproduceahighstrengthconcreteandis usedasacementreplacement,inordertoreducethecement content (usually for techno economic reasons) and as an additive to improveconcretepropertiesin both fresh and hardenedstates.Alotofstudieshavealreadybeendoneon GGBSandMetakaolin,asitprovidessatisfactoryresultsto researcherbutthepresentstudydealswithGGBFSusedasa partialreplacementofCementatdifferentproportionsalong with the CCR and Hd Pet thermo plastic as a partial replacement of fine aggregate, similarly the work is to be repeatedforMetakaolinaspartialreplacementofCementat differentproportionsalongwiththeCCRandHdPetthermo plastic as a partial replacement of fine aggregate, not so much studies have done on this combination and comparisonsofar.

1.1 Materials

High Density Polyethylene Terephthalate Thermoplastics

Thermoplastic isamaterialwhichturnsouttobedelicate whenwarmedandhardwhencooled.Thermoplasticcanbe cooled and warmed a few times, and they can likewise be reused,theyadditionallyfreezetoaglazystatewhencooled enough.

Thermoplasticsarethematerialswhichareproducedbythe reusingofwasteplasticasplasticgranulesofsizegoingfrom 4-5mmlong.

Ground-granulated blast-furnace slag GGBFSisacquired viaquenchingmoltenironslagfromablastfurnaceinwater, tosupplya glassy,granularproductthisisthendried and convert into a fine powder. GGBFS is used to make long lasting concrete structures in combination with normal Portlandcementorotherpozzolanicmaterials.GGBFSreacts likePortlandcementwhilstintouchwithwater.

Meta kaolin - Metakaolinisnotabyproduct.Itisobtained bycalciminepureorrefinedkaoliniteclayatatemperature of6500to8500°Candthengrindingtoafinenessof700to 900 m 2 / kg. Metakaolin is a pozzolanic supplement / product that has many specific properties. Metakaolin is availableinmanydifferentvarietiesandqualities.Thepurity determinesthebindercapacityorthefreelime.Whenused inconcrete,theemptyspacebetweenthecementparticlesis filled,makingtheconcretemoreimpenetrable.Metakaolin,a relativelynewmaterialintheconcreteindustry,causesan increaseinstrength.

2. Studies Related to Present Research:

Sayed Imran Ali et. Al. (2018) haveexploredtheslumpand strengthparametersessentiallycompressivestrengthofM40Gradeofcementwithpartialsupplantingofcementwith GGBS and fine aggregate with Kota stone powder slurry. Compressivestrengthtestwascompletedfor7,28and56 dayswhileflexuralandsplittensilestrengthtestwasdoneat 28dayscuringperiod.Thecementhasbeensupplantedby GGBSinthescopeof20%,30%,40%byweightofcement, Kota stone powder slurry in the range of 5% to 20% by weight of fine aggregate for M40 grade. The following conclusionsarereported

•Theworkabilityofconcretewasfoundtoincrementwith theincreaseinGGBSinconcrete.Itfurtherdeclinesasthe levelofKSPSincrements.

•Indeed,evenbylesseningcementsubstanceby40%with GGBS, the compressive strength of M 40 Grade concrete doesn'tdiminish(at56yearsolddays)anditisseentobe practicallylikethecontrolmixconcrete(withoutGGBS).

Narmatha and Felixkala (2016) investigatedmetakaolin asa partial replacementwithcement with5%,10%, 15% and20%levels.ThespecimenswerecastedwithM-60Grade ofconcrete.Thefollowingconclusionsweredrawn-

•ThestrengthofallMetakaolinconcretemixesovershoot thestrengthofconcretewithOPC15%cementreplacement byMetakaolinissuperiortoallothermixes.

The utilization of waste PET in concrete gives a few benefits like decrease in the utilization of normal aggregate, removal of waste and counteraction of ecologicalcontamination.

Nadeem and Rohan (2015) presenttheinvestigationofthe halfwaysubstitutionoffinetotalsbyHD-PETthermoplastics andconcretebymattestapleglassfilamentsinM20grade concrete.Inthispioneeringwork,endeavoursweremadeto lookatthecompressive, breakingandflexural strength of M20 grade substantial concrete utilizing HD-PET thermoplasticsandglassstrandsasafragmentaryswapfor finetotals.alsoconcrete.Thecompressivestrengthtestwas completedtozeroinonthestrengthoftheconcreteduring the7and28daysoftherelievingtimeframeandtherigidity and split bowing was coordinated to concentrate on the strengthduringthe28daysoftherestoringtimeframe.

Sachin Patil, Veeresh and Sagar (2019) Present study focused on the increase of the investigation explores and evaluatestheoutcomesofthe ofconcretewithavarietyof replacingof

Sunny and Mohan (2017) investigatedthecharacteristics of M-35 Grade of concrete with w/c ratio 0.42. the meta kaolinusedinstudywere5%to25%with5%replacement levels. The closures made by investigators on Slump, compressiveandtensilestrengthontheconcretefor7and 28daysare–

Based on the experimental investigation the following conclusionarereported–

Meta kaolin concrete upgrade the compressive and flexural strength satisfactorily as compared to conventionalconcrete.Workabilitydecreasesaslevelof metakaolininconcreteincrements.

2.3 Proportion of Meta kaolin and HD-Pet thermoplastic

In present review Meta kaolin and HD-Pet thermoplastic bothutilizedasanincompletesubstitutionofconcreteand finetotalseparately,thetradelevelforMetakaolinutilized in present review differs from 5% and 10% by weight of concrete. Likewise the substitution level for HD-Pet thermoplasticvariesfrom5%to15%,with5%interval.

2.4

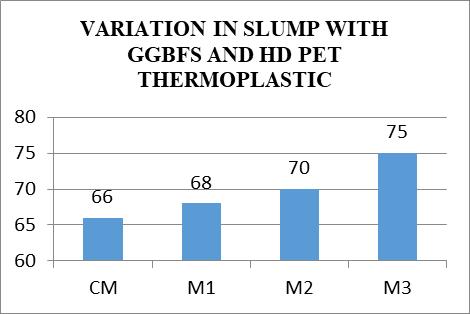

Variation in slump with GGBFS and HD pet thermoplastic

4.2 Comparison in Compressive Strength Test Results

The Comparison in Compressive strength test results of controlmixandconcretepreparedwith5%replacementof cement by Meta kaolin and the replacement levels of fine aggregatebyHdPetthermoplasticsrangingfrom0%to15% with the interval of 5% and the similar replacement with GGBFSarepresentedinTable.

3. Proposed Tests on concrete (Fresh and Hardened State)

Thefollowingtestswereconductedonconcrete.

The Comparison in Compressive strength test results of controlmixandconcretepreparedwith10%replacementof cement by Meta kaolin and the replacement levels of fine aggregatebyHdPetthermoplasticsrangingfrom0%to15% with the interval of 5% and the similar replacement with GGBFSarepresentedinTable.

The Comparison in Compressive strength test results of controlmixandconcretepreparedwith15%replacementof cement by Meta kaolin and the replacement levels of fine aggregatebyHdPetthermoplasticsrangingfrom0%to15%

with the interval of 5% and the similar replacement with GGBFSarepresentedinTable

REFERENCES

1. San Lwin, Swe Nwe, " Investigation on the Use of PET Waste Plastic as Coarse Aggregate for Lightweight Concrete” International Journal of ScientificEngineeringandScienceVolume4,Issue 2,2020

2. Ankit Moond, Nakul, “An Experimental Investigation on concrete containing Meta kaolin and Kota stone powder” International Journal of EngineeringResearch&Technology(IJERT)ISSN: 2395-0056Vol.6Issue7,July-2019.

5. CONCLUSIONS

By evaluating the test results of Slump, Compressive StrengthandFlexuralStrengthtestonConcretemixfollowing conclusionshavebeenmade-

Slump Values - TheValueofslumpincreaseswithincrease ofGGBFSandMetakaolincontentinthemix.

Compressive Strength - Theconcretemixpreparedwith5% CementreplacedbyGGBFSandfineaggregatereplacedbyHD Pet thermoplastics in the range of 5% to 15%, then the compressive strength of mix achieved highest with the combination of 5% GGBFS and 5% HD Pet thermoplastics. Similarpatternfollowsbythemixpreparedwith5%Cement replacedbyMetakaolinandfineaggregatereplacedbyHD Pet thermoplastics in the range of 5% to 15% i.e this combinationalsoshowsthemaximumstrengthat5%Meta kaolinand5%HDPetthermoplasticsattheageof28days.

Theconcretemixpreparedwith10%Cementreplacedby GGBFSandfineaggregatereplacedbyHDPetthermoplastics intherangeof5%to15%,thenthecompressivestrengthof mixachievedhighestwiththecombinationof10%GGBFSand 5%HDPetthermoplastics.Similarpatternfollowsbythemix preparedwith10%CementreplacedbyMetakaolinandfine aggregatereplacedbyHDPetthermoplasticsintherangeof 5% to 15% i.e this combination also shows the maximum strengthat10%Metakaolinand5%HDPetthermoplasticsat theageof28days.

Theconcretemixpreparedwith15%Cementreplacedby GGBFSandfineaggregatereplacedbyHDPetthermoplastics intherangeof5%to15%,thenthecompressivestrengthof mixachievedhighestwiththecombinationof15%GGBFSand 5%HDPetthermoplastics.Similarpatternfollowsbythemix preparedwith15%CementreplacedbyMetakaolinandfine aggregatereplacedbyHDPetthermoplasticsintherangeof 5% to 15% i.e this combination also shows the maximum strengthat15%Metakaolinand5%HDPetthermoplasticsat theageof28days.

3. Sachin Patil, Veeresh H M, Sagar H, Shrinivas and Tippanna, "Compressive Strength of GGBS, Metakaolin and Glass Fibers Based High Performance Concrete", International Journal of Computational Engineering Research (IJCER), Volume-9,Issue-8,August2019.

4. Arzoo and Shubha (2018) ,“An Experimental Analysis on Flexural Strength of concrete beams usingflyashandsilicafume”InternationalJournal for Research in Applied Science & Technology (IJRASET) ISSN: 23291-9653 Vol. 6 Issue 1, Jan2018

5. Panagiotis G. Asteris, Konstantinos G. Kolovos, Adamantia Athanasopoulou, Vagelis Plevris& Gerassimos Konstantakatos, "Investigation of the mechanical behaviour of metakaolin-based sandcrete mixtures", European Journal of Environmental and Civil Engineering, PP-1-25, January2017.