Review Paper on Performance Analysis of LPG Refrigerator

A. Gawade5, Ankur S. Sovani6Abstract – Ozone depletion due to Chlorofluorocarbon (CFC) and Hydrofluorocarbon (HFC) refrigerants is one the major problem to our natural habitat. Also, availability of electricity is still not available in several areas of the world where one needed electricity and refrigeration of water, food, and medicine The use of LPG for refrigeration purpose can be ecofriendly since it has no ozone depletion potential (ODP). LPG as a refrigerant for refrigeration can be a better alternative. (28) LPG is offered in high-pressure cylinders. When this highpressure LPG gas passes through a capillary tube with a tiny internal diameter, the pressure drops due to expansion, and the LPG phase shifts in an isoenthalpic process. The liquid refrigerant gains latent heat when its phase changes from liquid to gas, and the temperature drops. LPG can generate a cooling effect in this manner. (21))

Key Words: LPG Refrigeration system, COP, VCR, Evaporator temp, refrigerating effect.

1. INTRODUCTION

AccordingtotheIndianGovernment,therefrigeratoris the 3rd heaviest consumer of power among household appliances.Itisoneofthefewappliancesthatisrunning365 daysayear.Accordingtothesecondlawofthermodynamics, thisprocesscanonlybeperformedwiththesupplyofsome externalwork.Itisthusobvious,thatsupplyofpower(say electricalmotor)isregularlyrequiredtodrivearefrigerator. Thesubstancewhichworksinaheatpumptoextractheat from a cold body to deliver it to a hot body is called refrigerant. When we think about refrigerators only rememberrefrigerationinthekitchen,butdividedintothree typesinwhicheachtypehasitsowntypeoffunctioning.One whichisusedforIndustrialpurposesiscalledasIndustrial refrigerator, which is used for food processing, chemical processing & cold storage. Industrial refrigeration, which frequently uses ammonia refrigeration to maintain temperature,isnecessaryforcomputers,foodstuffs,blood, vaccines,andquiteafewothergoodsthatmustmaintaina constantandsteadytemperatureatalltimes.(28)

The climatic change and global warming demand accessible and affordable cooling systems in the form of refrigeratorsandairconditioners.

LPGisstoredinliquefiedstatein acylinderbeforeits utilization as fuel. (1) LPG is more affordable and environmentally beneficial, as it has no Ozone Depletion Potential (ODP) and no Global Warming Potential (GWP) (GDP).Itisusedforcookinginvariousplacesoftheworld. ThispracticemakesuseofarefrigeratorthatrunsonLPG refrigerant.WhenLPGrefrigerantwasusedinsteadofR134a refrigerant,therefrigeratorperformedwell.Wecanforecast themaximumvalueofcoolingimpactwiththeappropriate operatingconditionsofregulatingthecapillarytubeofthe setup based on the demonstration that is done in atmosphericconditions.

2. OBJECTIVES

1) Comparetheimportantcharacteristicsbetweenthe LPG refrigeration system and the traditional refrigerationsystem.

2) To distinguish between the current existing refrigerator. Cost and estimated cost of LPG refrigerator.

3) The performance of existing refrigerator and LPG refrigeratoristobecompared.

3. SCOPE OF WORK

To study and analyze the vapour Compression Refrigeration system is our basic objective. We are substituting the compressor and condenser by a LPG cylinder.ThepressureenergyofLPGisveryhighasitcanbe compressedupto12.5barsandhencethispressureenergy of LPG can be used for refrigeration by usage of this LPG systemisalsoverylow.(16)

Itcanbeusefulinremotepartswhereelectricityisnot available.Itcanplayanimportantroleinrestaurantswhere continuouslycoolingandheatingisrequired.Itcanbeused inautomobilesrunningonLPGorotherGaseousfuelsforair conditioning.(1)

4. EXPERIMENTAL FEATURE

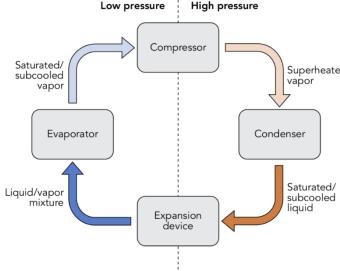

4.1 Vapour Compression Refrigeration System

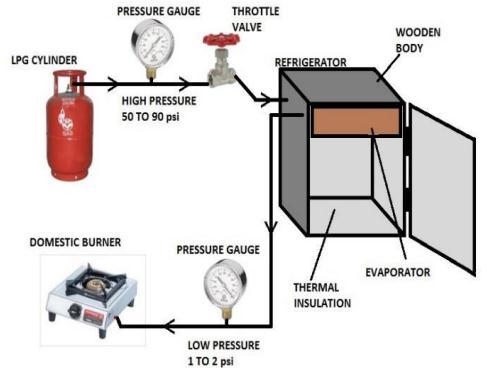

The LPG Refrigerator is work on the simple Vapour Compression Refrigeration system. The construction and workingofsimpleVCRSisasshowninfig.1.

Process 2-3: When the compressor is started, it draws the low-pressure vapour from the evaporator at state 2 and compresses it is entropically to a sufficiently to a high pressureuptostate3.Sincethecompressionworkisdoneon thevapour,itstempalsoincreases.

regulators isopened thenhigh pressureLPG passes ingas pipe.ThisLPGpassedtocapillarytubeathighpressure.High pressureLPGisconvertedinlowpressureatcapillarytube withenthalpyremainsconstant.LowpressureLPGispassed throughevaporator.LPGisconvertedintolowpressureand temperature vapour from passing through the evaporator which absorbs heat from the refrigeration box .Thus the refrigerationboxbecomescoolsdown.Thuswecanachieve cooling effect in refrigerator. LPG from evaporator is then passedthroughpipetotheburner.(1)

Process3-4:Hotvapourfromcompressorunderpressureis discharged into the condenser where condenser cooling medium usually water orsurroundingair isabsorbing the heat from hot vapour. This converts the hot vapour into liquidandtheliquidiscollectedinliquidreceiveratstate4.

Process 4-1: The liquid from the liquid receiver at high pressureisthenpipedtoarefrigerantcontrolvalvewhich regulatestheflowofliquidintotheevaporator.Thiscontrol valve,whilerestrictingtheflow,alsoreducesthepressureof theliquidwiththeresulttheliquidchangeintovapouroflow drynessfractionrepresentedbystate1.Duringthisprocess thetemperatureoftherefrigerantreducescorrespondingto itspressure.

Process 1-2: Finally, the low pressure, low temperature refrigerant passes through the evaporator coil where it absorbsitslatentheatfromthecoldchamberorfrombrine solution at constant pressure and converts into vapour at state2.Itisagainsuppliedtocompressor.Thus,thecycleis completed.(6)

4.2 LPG Refrigeration Cycle Explanation

TheLPGRefrigeratorusesevaporationofLPGtoabsorb heat.LPGisstoredincylindersatpressureatabout80psi. We lowering this pressure to pressure of 1 psi so that the heat absorbed adiabatically from refrigeration box and coolingisobtainedonsurrounding.LPGisstoredintheLPG cylinder under high pressure. When the gas tank of

5. COMPONENT FEATURES

5.1 Gas Cylinder

From gas cylinder LPG in the start at a pressure of approximately 5.156 flows through the pipe to reach the capillarytube.

5.2 Capillary Tube

Acapillarytubeisofcopperhavingasmall-borediameter. ItreducesthepressureofliquidRefrigerantfromcondenser pressuretoevaporatorpressurewhenconnectedtoaliquid line. The length of capillary tube is greater when the evaporatorpressureislower.Thecapillarytubeisasimple devicewithnomovingpart.However,itssmallboremakesit

necessarythatafilteranddrierisfittedbeforethecapillary tubetopreventchoking.Whilepassingthroughcapillarytube theLPGexpandsanditspressuredropslessthan1.2bar.

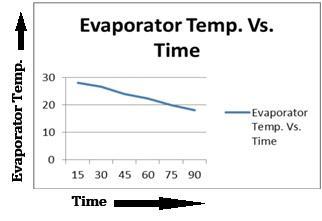

InevaporatorLPGisconvertedintothevaporformwith lowpressure.Theevaporatorisalsoanimportantcomponent oftherefrigerationsystem.Thecoolingeffectisproducedby passingtherefrigerantthroughEvaporatorcoil.

Afterperformingthecoolingeffect,lowpressureLPG gas goes into the burner where it burns and through generatortogenerateelectricity.

The most used mechanical gauge is Bourdon type pressuregauge.Itisastiff,flattenedmetaltubeBentintoa circularshape.Thefluidwhosepressureistobemeasuredis insidethetube.Oneendofthetubeisfixed,andanotherend isfreetomoveinwardoroutward.Theinwardandoutward movementoffreeendmovesapointer,throughalinkageand geararrangement,adialgraduatedinpressureuniti.e.bar. Pressure gauge records the gauge Records the gauge pressurewhichisthedifferencebetweenfluidpressureand outsideatmosphericpressure.TheseGaugesareavailablein thedifferentrangesofpressure.

ThepropertiesofLPGat5.525barsareEnthalpyh1=430.3 kJ/kg

ThepropertiesofLPGat1.22barsareEnthalpyhf=107.3 kJ/Kg

h2=294.8kJ/kg

hg=482.3kJ/kg.

h3=562.46kJ/kg

Sotherefrigeratingeffectis,

RE=h3-h2=562.46-294.8=267.66kJ/kg

ForcalculatingtheCOPofthesystem,werequired the work input. For work input we have a 14.5 Kg. LPG cylinder.Hence,inputworkistheamountofpowerrequired for filling 1 cylinder. From the PCRA energy audit report powerrequiredtorefill1cylinderis3.1354kWh.

Therefore, for filling 1 kg of LPG power required is, = 3.1354/14.5=0.2162kWh

For 1.5 hr. for that power is = 0.2162*1000/ (9.45/10000)*5400=42.39W

COPoftheLPGRefrigerationSystem:

COP=RE/W=267.66/42.39=6.3(1)

7. ADVANTAGES

1) Thereisnoanynoiseorvibrationasthesystemdoes notcontainanymovingpart.

2) Oneenergysourceisutilizedforrefrigerationand burningprocesses,Henceenergysavingsystem.

3) Noelectricityisrequired,sopowersavingsystem.

4) In comparison to other refrigerants, LPG has no ozone depletion potential and no global warming potential.

5) LPG is a low-cost, environmentally beneficial alternativetootherhouseholdrefrigerants.

6) This refrigeration device operates even when the poweristurnedoff.

8. COMPARE WITHDOMESTICREFRIGERATOR

Cop of a domestic refrigerator is normally up to 2.95 which is lesser than the LPG refrigerator. Domestic refrigeratorrequiredhighinputpowerthanLPGrefrigerator. Alsotherearemoremovingpartsindomestic refrigerator

and not eco-friendly. Domestic refrigerator requires more maintenanceandoperationisnoisy.(1)(16)

9. CONCLUSIONS

FromthisabovepapersweconcludedthatLPGisbetter alternative refrigerant and eco-friendly than other refrigerant.(28)

In a LPG refrigeration system capillary tube is more adjustableandbetterdevice.Theinitialandrunningcostof thisLPGrefrigerationsystemisreallyless.Nooutsideenergy sourceisrequiredtorunthesystem.Aswellasnomoving componentsarepresentinthesystemwhichfurtherreduces themaintenancecostaswell.ThisLPGrefrigerationsystem has wide scale application in hotel industries, chemical industrieswheretheLPGconsumptionisatahigherlevel.(1) (16)

Inthispapertherefrigerationisamplifiedremarkably, and a cheaper and eco-friendly method is developed. This system is most suitable for hotel, industries, refinery, chemicalindustrieswhereconsumptionofLPGisveryhigh. (6)

REFERENCES

[1]M.Manohar,P.Sahu,P.Sahu,DeepakSingh,A.Chandra “DesignAnalysisandPerformanceofLowCostRefrigeration SystemusingLPG”ISSN:23213361,May2020,Volume10 IssueNo.5

[2].ZainalZakariaandZulaikhaShahrun Thepossibilityof Using liquefied petroleum gas in domestic refrigeration System International Journal of Research and Reviews in AppliedScience(IJRRAS),December2011,Volume9.

[3].Vishwadip singh J. Ghariya and Swastik R. Gajjar International Journal for Scientific Research and DevelopmentISSN(online):2321-0613,March2014,Vol.2

[4].IbrahimHussainShahandKundanGuptaInternational Journal of Engineering Sciences and Research TechnologyISSN:2277-9655,July2014,Vol.3(206-213).

[5].KhandareR.S.andBhaneA.BInternationalJournalof Emerging Technology and Advanced Engineering ISSN: 2250-2459,March2015,Volume5.

[6] Henry Joseph A., Lenin Divakar J., Lijin Thinishkar S., Nallamuthu K.,Neethi Manickam, S. Shiek Sulaiman “Performance Analysis of LPG Refrigeration System” ISSN(Online): 2319-8753,ISSN (Print): 2347-6710,Vol. 9, Issue2,February2020.

[7] Dipak C. Gosai Thermodynamically Evolution of LPG RefrigeratorInternationalJournalofEngineeringResearch& Technology (IJERT). Volume 2, Issue 12, December 2013, PageNo 2869to2875.

[8]R.HanumaNaik,K.RamachandraManoharIOSRJournal of Mechanical and Civil Engineering (IOSR-JMCE). E-ISSN: 2278-1684,p-ISSN:2320-334X,Pages07-16.

[9]PrabalRoy,SurjeetSinghRajpootInternationalJournalof Engineering Trends and Technology (IJETT). Volume 55, Number1,January2018.

[10]ATextbookofRefrigerationandAirConditioningbyR.S. Khurmi,S.ChandPublication.

[11]Mr.B.KiranKumarEngineeringJournals&Magazineof Engineering,Technology,Management&Research.Volume 3,IssueNo 5,May2016,PageNo 226to235.

[12] Sarthak. M Thakar, R.P. Prajapati, D.C. Solanki, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE). Volume14,Issue3Ver.I,May–June2017,Pages92-103.

[13] Mubashir Hayat Design and Fabrication of Liquefied PetroleumGasRefrigerationSystemandComparisonwith Domestic Refrigerator International Journal of Innovation andScientificResearch.Volume 25,July2016,PageNo 637 to645.

[14]P.Murugan,S.MohanaMurugan,N.Nallusamy,S.Sekar Journal of Applied Fluid Mechanics. Selected papers from International Conference On Newer Techniques and InnovationsinMechanicalEngineering(ICONTIME2K18). Volume11,July2018,Pages53-61.

[15] Jeetendra Kumar Patel, Yogesh Parkhi, Rajesh Soni International Journal for Research in Applied Science & Engineering Technology (IJRASET). Volume 6, Issue I, January2018,Pages 1840to1845

[16]MhaskeM.S.,DeshmukhT.S.,AnkushD.D.,PalkarS.M., Gaikwad V. S. ”Performance Evolution of Domestic RefrigeratorUsingLPGCylinder”,ISSN(Online):2395-0056, ISSN:2395-0072,Volume:03Issue:04|April-2016.

[17]ZainalZakariaandZulaikhaShahrun Thepossibilityof Using liquefied petroleum gas in domestic refrigeration System International Journal of Research and Reviews In AppliedScience(IJRRAS),December2011,Volume9

[18] Vishwadipsingh J. Ghariya and Swastik R. Gajjar International Journal for Scientific Research and DevelopmentISSN(online):2321-0613,March2014,Vol.2

[19]IbrahimHussainShahandKundanGuptaInternational Journal of Engineering Sciences and Research Technology ISSN:2277-9655,July2014,Vol.3(206-213).

[20]KhandareR.S.andBhaneA.BInternationalJournalof Emerging Technology and Advanced Engineering ISSN: 2250-2459,March2015,Volume5.

[21] Utsav Shahare, Krishna Yadav, Viraj Dongre, Aryan Umre,KalpeshGajbhiye,YugalBhaisare”FabricationofLow Cost Refrigeration System by Using LPG”, ISSN (Online) 2581-9429,Volume8,Issue1,August2021.

[22].Mhaske.M.S.etal,(2016),PerformanceEvolutionof Domestic Refrigerator Using LPG Cylinder, International ResearchJournalofEngineeringandTechnology,volume-03.

[23]. Shyam H. Prajapati. Et al, (2020), LPG Refrigeration system,InternationalResearchJournalofEngineeringAnd Technology,volume-07.

[24].DeokateS.M.etal,(2016),AStudyPaperonLPGasan Alternative Refrigerant for Refrigeration, International JournalofCurrentEngineeringandTechnology,issue-0

[25]. Shailesh Dubey. Et al, (2018), Evolution of Domestic Refrigerator by Using LPG as Refrigerant, International JournalofScientific&EngineeringResearch,volume-09.

[26]. Murli Manohar, et al, (2020), Design Analysis and PerformanceofLowCostRefrigerationSystemUsingLPG, ijesc,volume-10.

[27]. Shashil M Sankannavar, et al, (2020), Design and Fabrication of LPG Refrigeration System, International JournalofScientific&EngineeringResearch,volume-11.

[28]Praveenkumargoud.E,NiteshSharma,Mohanraj,MD Abdulkhaleed,Y.Pavankumar,Dr.V.Chokkalingam“LPGAs AnAlternativeRefrigerantForRefrigeration”,ISSN:23219637,SpecialIssue,March2019.

[29]N.Austin.etal(2012),ThermodynamicOptimizationof Household Refrigerator Using Propane Butane as Mixed Refrigerant,InternationalJournalofEngineeringResearch andApplications,2(6),268-271.

[30]NikamS.D.et.Al.,(2015)ElectricityFreeRefrigeration System using Domestic LPG Design of Energy Saving Refrigerator,InternationalJournalofEmergingTechnology andAdvancedEngineering.5(3),45646

[31] Mhaske.M.S.etal, (2016), Performance Evolution of Domestic Refrigerator Using LPG Cylinder, International ResearchJournalofEngineeringandTechnolog,3(4),25862592.

[32] Ibrahim Hussain Shah. Et.al., (2014), Design of LPGRefrigerationSystemandComparativeEnergyAnalysis with Domestic Refrigerator, International Journal of engineeringsciences&researchTechnology,3(7),206-213