Multi objective optimization of triple concentric tube heat exchanger

Rajesh Kushwah1, Purushottam Sahu2, Ghanshyam Dhanera 31First Author Research Scholar, BM College of Technology, Indore

2Professor and HEAD, BM College of Technology, Indore

3Example: 2 Assistant Professor, BM College of Technology, Indore, MP ***

Abstract:

Inthisstudy,theheattransferandpressuredroppropertiesofatripleconcentrictubesexchangerwereoptimisedusing onlyCFDeffects.Theresponsesurfacetechnique(RSM)andGRAmethodswereusedtogenerateanidealresponseaswell as a functional relationship primarily based on the examined variety of design/control parameters. The Nusselt number and friction factor were the response variables, while the Reynolds number and length to hydraulic diameter ratio were thedesignvariables.AmathematicalmodelisbuiltusingtheinputvariablewithRSMinthisstudy.

Keywords: CFD, numerical modelling, optimization, thermal hydraulic performance, Response surface methodology, tripleconcentric-tube.

1. Introduction

TRIPLE CONCENTRIC TUBE HEAT EXCHANGERS

Adoubletube heat exchanger isthemostcommon heat exchangerkind usedina variety ofapplications.Its operationis basedonthetransmissionofheatbetweentwopipescontainingcoldandhotfluids.

Ithasitssignificanceinfreezing,boilingdrying,dairy,andpharmaceutical,food,pasteurizationandchemicalindustries. In ordertomanagehigh-temperaturedifferences,theheatexchangeareashouldbeincreased,whichcouldbepossibleonly byincreasingtheheatexchanger’slength.TTHE

It has three concentric tubes, or three compartments, referred to as the inner tube, inner annulus, and outer annulus, respectively. The target fluid, whose temperature changes are of primary relevance for application fulfilment, must flow withintheinnerannulusinordertomaximisetheheatexchanger'sefficiency.

When compared to a twin tube device (which only has one heat exchange surface), the inner annulus contains two heat exchangesurfaces(innertubeouter surfaceandoutertubeinnersurface),whichincreasestheheatexchangeareaofthe heat exchanger slightly and thus increases the heat exchange speed. It will also improve the efficiency of the heat exchanger. As a result, when compared to double tube systems, the length of the heat changer required for consistent temperature differentiation is reduced. Parallel flow and counter flow are two flow arrangements for a twin tube heat exchanger. Three fluids pass via the triple tube heat exchanger (TTHE), resulting in four distinct combinations. Eight alternativeflowconfigurationsoccurwhentheabovesetupiscompared.

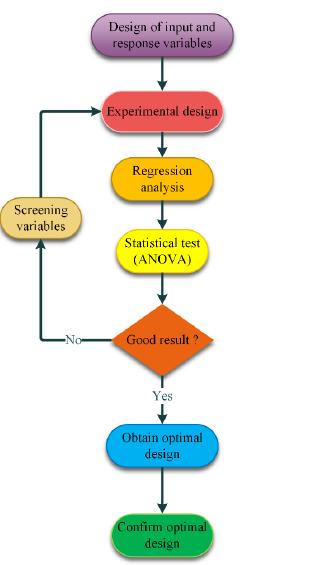

RESPONSE SURFACE METHODOLOGY OF EXPERIMENT

It's commonly used in the industry because it's the most effective technique for meeting welding requirements. This research looked at how to prepare low-cost goods and how to improve welding defects so that they work properly. This type of technique is commonly used to minimise costs and increase product quality, and it logs as functions of desired performance. Via rigorous design of experiments, the approach and variance in a process are minimised to aid in data interpretation and prediction of optimal outcomes. RSM is an effective modeling tool to establish a relationship between controllable input and their dependent output response. The studies concentrated on the modeling and optimization of combustion and thermal performance of the biodiesel in the dual-fuel engine through RSM are even rarer The following arethekeyRSMobjectivesandmeasuresfortheparameterdesignphase:

Choosing an experiment design and optimizing Based on literature survey, it has observed that Taguchi method is most easy and robust method. Also it is cost effective as it identifies the minimum number of experimental trials needed by suggestingcorrectcombinationofdifferentdesignparameterneededforanalysisoftestresultsavoidingunnecessarydata

collection and their analysis. So Taguchi DoE has been used to identify the correct combination of selected design factor and their levels in present study. For the present study, factors and levels were selected based on literature review are mentionedinTable4.

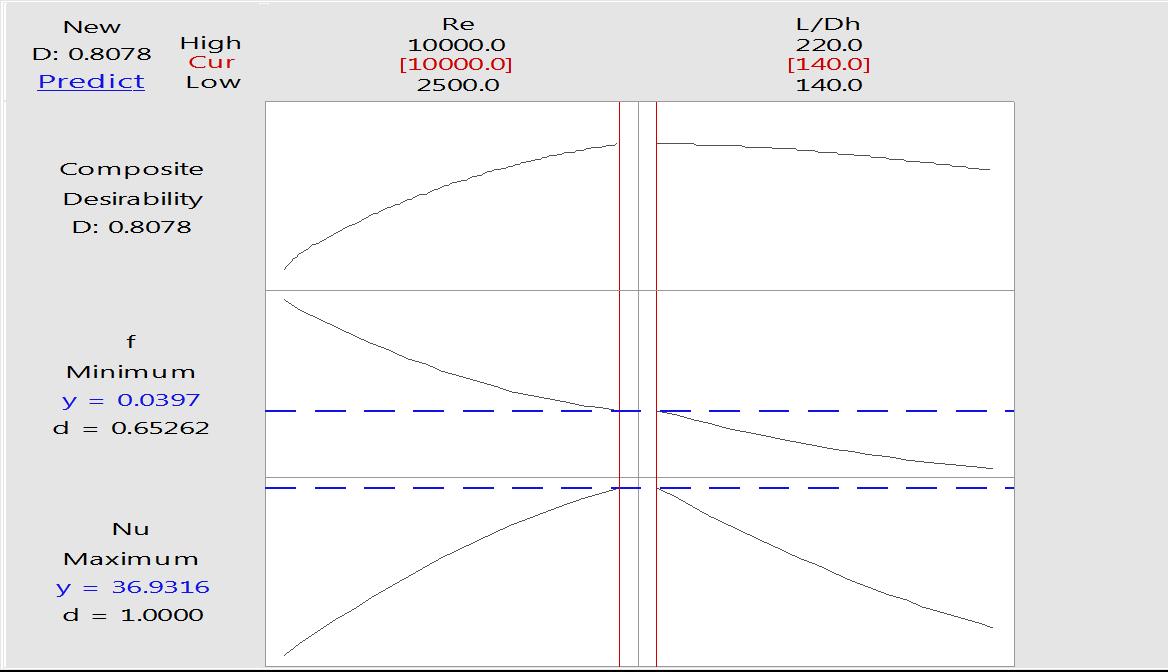

5.1 Multi-objective optimization results

The predicted value of the response variables is precisely closer to the numerical results and hence, it has helped in reducing the size of the required data as the RSM provides useful interaction between the various parameters of the system.Themodelsatisfiesadesired95%confidencelevel.ThevaluesinTable5.1showstheexperimentalandpredicted values,ieerrorisatanacceptablelevel.

CONCLUSION AND FUTURE SCOPE

1. Basedontheresultsofnumericalsimulationandmulti-objectiveoptimization.FromFigure3.3thatthefirstLevel provides maximum value of Nusselt number. (a) Reynolds number A1 2500 (b)Length to hydraulic diameter ratio),B2180

2. From Figure 3.3 that the first Level provides minimum value of pressure drop (friction factor) (a) Reynolds numberA12500(b)Lengthtohydraulicdiameterratio),B2180.

3. Table4.3showstheANOVAresultforfrictionfactor.ItisobservedthattheReynoldsnumber(P=0.000)(54.08%) ismostinfluencesthefrictionfactorfollowedbyhydraulicdiameterratio(P=0.000)(40.33%)

4. The F-test determines whether the parameters are significantly different statistically. The greater the impact on thefrictionfactorperformancecharacteristics,thehighertheFvalue[15].ForReynoldsnumber(P=0.000),larger Fvaluesarefound(58.57%)

5. Table4.3showstheANOVAresultforNusseltno..ItisobservedthattheReynoldsnumber(P=0.000)(54.08%)is mostinfluencesthefrictionfactorfollowedbyhydraulicdiameterratio(P=0.000)(37.53%)

REFERENCES:

[1]J.Y.Long,D.S.Zhu,NumericalandexperimentalstudyonheatpumpwaterheaterwithPCMforthermalstorage,Energy Build.40(2008)666–672,https://doi.org/10.1016/j.enbuild.2007.05.001

[2]CarlosA.Zuritz,Onthedesignoftripleconcentric-tubeheatexchanger,JournalofFoodProcessEngineering21(1990) 113-130.

[3] AhmetǕnal, Theoretical analysis of triple concentric-tube heat exchangers part-1: mathematical modeling, InternationalCommunicationsinHeatandMassTransfer25(1998)949-958.

[4] AhmetǕnal, Theoretical analysis of triple concentric-tube heat exchangers part-2: case studies, International CommunicationsinHeatandMassTransfer28(2001)243-256.

[5]O.García-Valladares,Numericalsimulationoftripleconcentric-tubeheatexchangers,InternationalJournalofThermal Sciences43(2004)979–991.

[6] P.K. Sahoo, I.A. Ansari, A.K. Datta, Milk fouling simulation in helical triple tube heat exchanger, Journal of Food Engineering69(2005)235–244.

[7]EdizBatmaz,K.P.Sandeep,Calculationofoverall heattransfercoefficientsina tripletubeheat exchanger,HeatMass Transfer41(2005)271–279.

[8]P.K.Nema,A.K.Datta,Improvedmilkfoulingsimulationinahelicaltripletubeheatexchanger,InternationalJournalof HeatandMassTransfer49(2006)3360–3370.

[9] Ediz Batmaz, K.P. Sandeep, Overall heat transfer coefficients and axial temperature distribution in a triple tube heat exchanger,JournalofFoodProcessEngineering31(2008)260–279.