Analysis of M25 Grade of Self-Healing Concrete by Partial Replacement of Coarse Aggregate with E-waste

Vedprakash Gautam1 , Dr. Pramod Sharma2Abstract - Treating electronic waste is urgently needed; India generates 2 million tonnes of E-Waste, 5 percent of which is PCB (Printed Circuit Boards).Onlyasmallpercentage of this waste gets handled, and the vast rest ends up in waterways and landfills. Electronic waste disposal is an international problem, and we propose to employ the e-waste in stiff concrete pavement tocopewithit.With43,20,000miles of highways, India offers severalopportunitiesforrepurposing e-waste in the transportationsector.Thisstudyismostlybased on use of ABS plastic in mix with concrete. Sieve analysis is performed to filter the grain sizesofABSandconcretewiththe grain size of 2.36 to 10 mm. strength of block is analyzed by 3 type of tests which are compression strength test, tensile strength test and 3-point bending test. The compressive strength of the sample shows an increasing trend with the increasing composition of ABS plastic till 15% after which its starts decreasing again. It is also greater for 1% composition of calcium lactate than 0.5% of the same. The compressive strength has been found to be maximum for 15:1 composition of the ABS Plastic and the Calcium Lactate, respectively, i.e., 21.74MPa after 7 days and 33.62 MPa after 28 days

Key Words: ABS plastic, calcium lactate, sieve analysis, concrete.

1. INTRODUCTION

Aworldinperpetualfluxnecessitatesbuildingmethodsthat are always changing. Concrete is one of the most often utilisedbuildingmaterialsnowadays.Inadditiontothewide rangeofusesthatitprovides,itsbehaviour,strength,costeffectiveness, durability, as well as flexibility all play a significant part in its popularity. As a result, construction workersrelyonconcretesincetheyknowitisasafe,solid, andstraightforwardmaterial.Buildingsrangingfromsinglestoryresidencestothemulti-storyofficetowersmaybenefit from this technology (bridges, roads, etc). Various loadbearingcomponents,includingasfoundations,slabs,beams, andcolumns,areconstructedusingconcrete.

Cement(orlime)isthebindingingredientusedtocombine aggregate (brick chips, sand, stone, gravel, etc.) together withwaterandotheradmixturesinparticularquantitiesin ordertomakeconcrete,anartificialstone-likemass.Whenit comestomixing,theratioshaveabigrole

1.1 COMPOSITION OF BASIC CONCRETE MIX

Inaconcretemix,therearefourprimaryconstituents:

• Bindingmaterialssuchascementorlime

• AggregatesorInertMaterials

Fineaggregate(sand)

Coarseaggregate(stonechips,brickchips)

• Water

• Admixture(e.g.Pozzolana)

The following is a basic breakdown of the constituent partsofconcrete.

1 BindingMaterials

Aconcretemix'sprimaryconstituentisbindingsubstance. Most typically, cement is utilised as a binding agent. Lime juiceisanotheroption.Toformapaste,waterisaddedtoan already-mixedcementmixture.Pastesolidifiesintoastonelike material when it combines with the particles and hardens.

2 Aggregates

Sand is made up of a variety of different kinds of little particles.Inmostmixtures,thecoarsestingredientisgravel orcrushedstone.

3 Water

Chemicalreactionswithcementneedwater(hydration), as does providing the concrete with the workability. The water/cement quantitative ratio refers to the amount of water in the mix relative to the amount of cement. The stronger the concrete, the lower the w/c quantitative connection. Increased tensile strength and reduced permeability.

1.2 TYPES OF CONCRETE MIX

Concrete is utilised for anything from simple home improvements to massive buildings in the research community. You may find it in pillars, basements, floors, sidewalks, and walls, among many other places. A broad rangeofconcretetypesareputtouseinthebuildingtrades.

Therearethreemaincategoriesofconcretethatmaybe identifiedbythematerialsandfunctionsforwhichtheyare intended-

1. “LimeConcrete

2. CementConcrete

3. ReinforcedCementConcretes”

Accordingonhowmuchworkhasbeencompleted,there arefourtypesofdefinitedecisionstobemadelikeas

1. “DryReadyMix

2. ReadyMix

3. BulkDryMaterials

4. TransitMix”

Byvaryingtheamountsoftheprimaryconstituents,new varieties of concrete may be produced for a variety of purposeslike:

• “RegularConcrete

• High-strengthConcrete

• StampedConcrete

• High-PerformanceConcrete

• Self-consolidatingConcretes

• VacuumConcrete

• Shotcrete

• Roller-Compactedconcrete

• GlassConcrete

• AsphaltConcrete

• RapidStrengthConcrete

• PolymerConcrete

• Limecrete

• Light-weightConcrete

• Self-healingconcrete”

2. METHODOLOGY

Thepurposeofthisstudyistoexaminetheimpactsofusing varying percentages of E-Waste in lieu of Natural Coarse Aggregate in the concrete and to quantify the latter's capacityforself-healing.Thismightbeusefulforfiguringout howmuchof NaturalCoarseAggregatecouldbesubstituted withthe bacteria-containing E-wastewithoutsignificantly altering the mechanical characteristics of a concrete and givingitthecapacitytocureitself

Collection of Materials

1 Material Selection

Cement

Regularcementisutilisedinthisinvestigation.Ithaspassed allofthetestsrequiredbytheIndianstandards.

Sand

The research sand was purchased. The grains range from very fine to medium. After doing a sieve examination of a sand per ASTM C136, we again checked that the sand's gradationfellwithintherangessetoutinASTMC33.

CoarseAggregate

Coarseaggregateconsists of crushedstone witha specific gravityof2.84andthemaximumsizeof20mm.

2 Sample Preparation

Apparatus: Vicat’sapparatuswithmould,Plunger,Balance, Measuringcylinder,Non-porousplate.

TheequipmentincludesaVicatmould, abalance,aplunger, acylinderformeasuring,andanonporousplate.

ABSPlastic

ABSmaybeeasilyalteredbychangingtheproportionsofits threemonomers, butadiene,acrylonitrile,andstyrene.Nonreinforced and reinforced grades alike are using heat stabilisers,hydrolysisstabilisers,lubricants,UVstabilisers, etc.toimproveuponavarietyofalreadypresentmaterial qualities.

Calciumlactate

The white powder that contains calcium lactate (C6H10CaO6),alsoknownascalciumsaltpentahydrate,has an efflorescent odour. Lactic acid reacts with the calcium hydroxideorthecalciumcarbonatetoproducethispowder

Makeapasteusingthesameamountofwaterascement,as measured by weight (during not less than 3 minutes and evennolongerthan5minutes).Inordertodeterminehow muchtimewillpassuntilthemouldisfilled,rememberto start timing as soon as water is added to dry cement. Put somepasteintheVicat'smouldandworkyourwayallthe waydownto thevery endofthejargently.Setthemould and test block on the nonporous plate and position the plungerinthecentreoftheplate.Carefullybringtheplunger downuntilitjusttouchesthetestblock,thenrapidlyletgo toletitfallintothepaste.

To find out how much water is required to get the Vicat's plungertopenetrate5mmto7mmfromabottom,maketrial pastes with varying% of water and conduct testing as describedabove

Concrete Mix Design

“CharacteristicCompressiveStrength–M25

Nominalmaximumsizeofcoarseaggregates–20mm

ShapeofCoarseaggregates–angular

Degreeofworkabilityrequiredatthesite–100120mmslump

Degreeofqualitycontrol–AsperIS:456

Exposuresite–Moderate(IS:456)

Minimumcementcontent:300kg/m3 (IS 456:2000)

Maximumwater-cementratio:0.50(IS456:2000)

Specificgravityofcement–3.15

Specificgravityofcoarseaggregates–2.84

Specificgravityofmildaggregate(sand)–2.64”

Waterabsorption:

1)“Coarseaggregate:0.5%

2)Fineaggregate(M.sand):2.5%”

Free(surface)moisture:

1)“Coarseaggregate:Nil(AbsorbedMoisturealsoNil)

2)Fineaggregate:Nil”

Material Testing Process

Differenttypeoftesthasbeenperformedtocheckthe strengthofsample

1. CompressionStrengthand

2. TensileStrength

3. 3-PonitBendingtest

Compression Strength Test

TheSCCswerecompressedduringacuringtimeofatleast 28daysthatwasinaccordancewithASTMC39.Afterbeing subjectedtobothroomtemperature&hightemperatures, the "200 x 100 mm SCC specimens"were compressed at speeds of 1 mm/min and 0.5 mm/min, respectively Two linearvariabledifferentialtransducers(LVDTs)wereplaced onthespecimensinasymmetricalfashiononopposingsides tomeasure axialdeformationoftheconcretesinatesting instrument.Thestatedvalueofshorteningwascalculatedby takingthemeanofthetwoLVDTreadings.Theaxialstressstrain plots of the SCCs were calculated using the deformation as well as load data collected during the compression test. The compressive characteristics of the SCCs were derived using these graphs. In addition, each specimen had thin wooden sheets affixed to both ends in ordertogettheuniformdistributionofacompressiveforce throughout the whole end surfaces and prevent stress concentrationcausedbythesurfaceroughness.

Fig. 3 Compression Testing

Thecompressivestrengthiscalculatedby

whereP=LoadinN A=Areainmm2

Tensile Strength Test

TheASTMC496compliantcylindrical200x100mmSCCs were subjected to thecompression test using thetesting instrument. Compression loading was applied along the cylinder,andarateofloadingof0:3mm/minwasusedfor thetensiontest.Tofurtherdispersethecompressiveforce, twothinhardwoodfiberboardswereinstalledattheloading site.

Fig.4 Tensile Strength Testing

3-Point bending test

There was thethree-point bending test conducted on concretewithtextilereinforcement(Figure48).Theflexural tests were performed in theclear span of 150 mm using theInstron 5965 testing machine. At a steady pace of 1mm/min,thespecimenswereloaded.

Thebendingstrengthwascalculatedfromthetestdata as the greatest bending moment divided by anaxial section modulusinthebending.

where

M-maximumbendingmoment,kN-m; W–momentofinertia,m3

3. Result and DIscussion

After 7 days curing duration

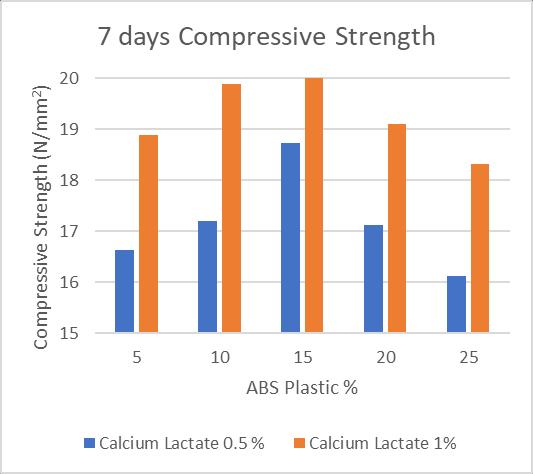

Thecompressivestrengthofthesamplespreparedhave beentestedafter7daysofcuringdurationwhichhave beenmentionedinthetable5.1below.

Table 1 Result of 7 days Compressive Strength

Thecompressivestrengthofthesampleshowsanincreasing trendwiththeincreasingcompositionofABSplastictill15% afterwhichitsstartsdecreasingagain.Italsoincreaseswith higher percentage of Calcium Lactate composition, as the compressivestrengthsoftherespectivesampleswithsame percentageofABSplastichasbeenobservedtobehigherfor 1%Calciumlactatecompositionthan0.5%ofit.However, thecompressivestrengthhasbeenfoundtobemaximumfor 15:1compositionoftheABSPlasticandtheCalciumLactate, respectively,i.e.21.74MPa.

The graph below in the figure 5-1 demonstrates the same comparisonofthecompressivestrengthswhichismaximum forthe15:1ratioofthecompositions.

Strengths of the samples after 7 days After 28 days curing duration

The compressive strength of the samples prepared have beentestedafter7daysofcuringdurationwhichhavebeen mentionedinthetable5.2below.

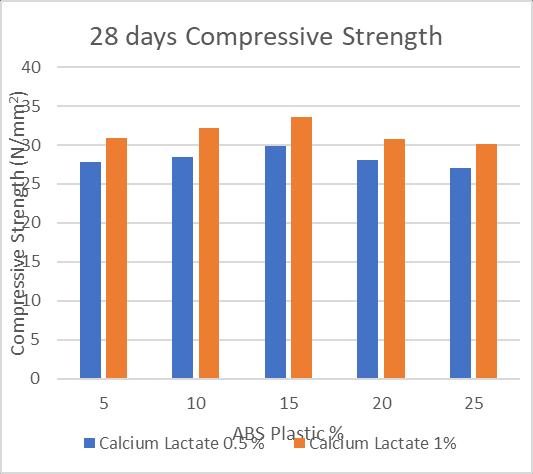

Table 2 Result of 28 days Compressive Strength

Fig.7 Compressive Strengths of the samples after 28 days

Thecompressivestrengthofthesamplesshowagainshowa similartrendafter28daysofcuringduration,i.e.itincreases withtheincreasingcompositionofABSplastictill15%after whichitsstartsdecreasingagainascanbeseeninthetable and the graph above. It also increases with higher percentage of Calcium Lactate composition, as the compressivestrengthsoftherespectivesampleswithsame percentageofABSplastichasbeenobservedtobehigherfor 1%Calciumlactatecompositionthan0.5%ofit.However, thecompressivestrengthhasbeenfoundtobemaximumfor 15:1compositionoftheABSPlasticandtheCalciumLactate, respectively,i.e.33.62MPa.

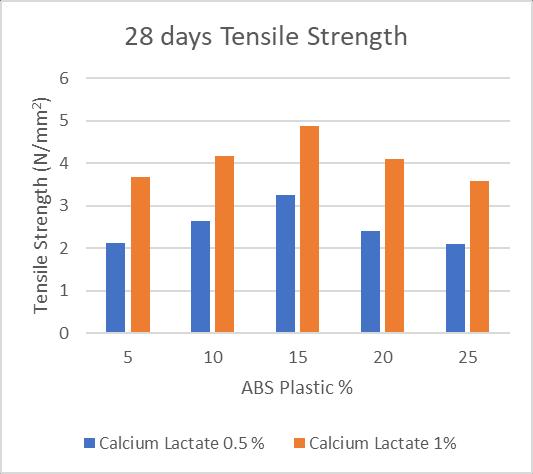

Tensile Strength Test

The compressive strength of the samples prepared have beentestedafter7daysofcuringdurationwhichhavebeen mentionedinthetable5.3below.

Table 3 Result of 28 days Tensile Strength

The tensile strength of the samples show again show a similar trend as that of the compressive strength, i.e. it increaseswiththeincreasingcompositionofABSplastictill 15%afterwhichitsstartsdecreasingagainascanbeseenin thetableandthegraphabove.Italsoincreaseswithhigher percentage of Calcium Lactate composition, as the tensile strengthsoftherespectivesampleswithsamepercentageof ABSplastichasbeenobservedtobehigherfor1%Calcium lactate composition than 0.5% of it. However, the tensile strength has been found to be maximum for 15:1 composition of the ABS Plastic and the Calcium Lactate, respectively,i.e.4.88MPa.Thishasalsobeendemonstrated inthegraphgiveninthefigure5-3below.

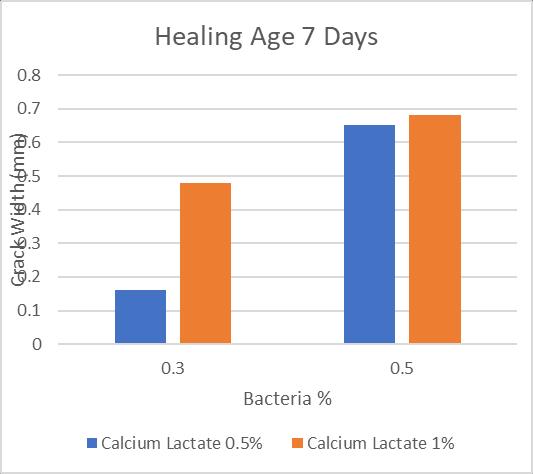

lactate and bacteria, the greater is the width of the crack healed.Thecrackwidthhealedhasbeenfoundmaximumfor 1%ofcalciumlactateand0.5%ofbacteria,i.e.0.68mm.

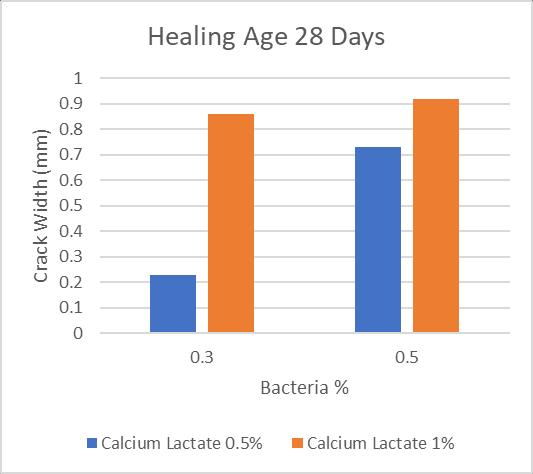

Fig.9 Healing Age 28 Days

28 days healing age

Thetable5.5belowshowsthewidthsofthecrackthathas been healed effectively after 7 days for the 15:0.5 as well 15:1 compositions of ABS plastic and Calcium Lactate, respectively,with0.3%and0.5%ofbacteria.

Table 5 Healing Age 28 Days

Tensile Strengths of the samples after 28 days Crack Healing

7 days healing age

Thetable5.4belowshowsthewidthsofthecrackthathas been healed effectively after 7 days for the 15:0.5 as well 15:1 compositions of ABS plastic and Calcium Lactate, respectively,with0.3%and0.5%ofbacteria.

Healing Age 7 Days

Similarobservationshasbeenillustratedinthegraphgiven in the figure 5.4 below, more the composition of calcium

Similarobservationshasbeenillustratedinthegraphgiven in the figure 5.5 below, more the composition of calcium lactate and bacteria, the greater is the width of the crack healed.Thecrackwidthhealedhasbeenfoundmaximumfor 1%ofcalciumlactateand0.5%ofbacteria,i.e.0.92mm.

3. CONCLUSIONS

Compressive and tensile strengths of M25 grade concrete mixeswithdifferentamountsoftheABSplasticE-wasteand thecalcium lactate were measured after 7 & 28 days of thecuring.Thehealingeffectsofvariousfracturewidthsare next investigated by combining these samples with either 0.3% or 0.5% of bacteria. These findings have been describedbelow:

Compressivestrengthsarehigherafter28daysof curingthanafter7days,indicatingthatcuringtime hasapositiveeffectonthetensileandcompressive strength.

Thesample'scompressivestrengthincreasesuntil theABSplasticcontentreaches15%,afterwhichit begins to decrease again. Calcium lactate at 1% concentrationisalsosuperiortocalciumlactateat 0.5%concentration.Resultsshowthata15:1ratio of ABS plastic to calcium lactate provides the highestcompressivestrength,peakingat21.74MPa after7daysand33.62MPaafter28days.

Thetensilestrengthofthesamplesfollowsthesame patternasthecompressivestrength:itrisesasthe ABS plastic content rises up to 15%, and then it

begins to fall. After 28 days of curing, the ABS plastic/Calcium Lactate 15:1 mixture reaches its maximumstrengthof4.88MPa.

Morecalciumlactateandbacteriaarepresent,the widerthefracturethatcanbemended.Maximum crackhealingwasseenwith1%calciumlactateand 0.5%bacteria,withawidthof0.68mmafter7days and0.92mmafter28days,respectively.

Additionofcalciumlactateandbacteriatogetherby 1%and0.5%giveincreaseincompressivestrength upto2.34%.

In case of coarse aggregate replacement with Ewaste, the strength increases up to 15% replacement,Furtheronincreasingthereplacement percentagestrengthstartsdecreasing.

Optimumstrengthseenat15% replacementofthe coarseaggregatewithE-plasticwasteandaddition of1%calciumlactateand 0.5%bacteria.

By replacement of the coarse aggregate with Ewasteplasticthecostofconstructiondecreseupto 3%to3.5%.

REFERENCES

Abhinav,S.(2020). A Study on Partial ReplacementofCement with Metakaolin and Total Replacement of Fine Aggregate with Stone Dust 7(1),256–263.

Arivalagan,S.(2020).Experimentalstudyontheproperties ofgreenconcretebyreplacementofe-plasticwasteas aggregate. ProcediaComputerScience, 172(2019),985–990.https://doi.org/10.1016/j.procs.2020.05.145

BalaRama Krishna,C.H.,&Jagadeesh,P.(2019).Strength and durability assessment of binary blended selfcompacting concrete replacing partial sand with electronic plastic waste. International Journal of Innovative Technology and ExploringEngineering, 8(5), 107–111.

Bawab, J., Khatib, J., Jahami, A., Elkordi, A., & Ghorbel, E. (2021).Structuralperformanceofreinforcedconcrete beams incorporating cathode-ray tube (Crt) glass waste. Buildings, 11(2), 1–16. https://doi.org/10.3390/buildings11020067

Chunchu,B.R.K.,&Putta,J.(2019).Rheologicalandstrength behaviorofbinaryblendedSCCreplacingpartialfine aggregate with plastic E-waste as high impact polystyrene. Buildings, 9(2). https://doi.org/10.3390/buildings9020050

Dawande, B., Jain, D., Singh, G., & Tech Scholar, M. (2016). Utilization of E-waste as a Partial Replacement of Coarse Aggregate in Concrete. IJSRD-International Journal for ScientificResearch&Development|, 3,2321–0613.www.ijsrd.com

Ganesh, S., Danish, P., & Bhat, K. A. (2020). Utilization of wasteprintedcircuitboardpowderinconcreteover conventional concrete. Materials Today: Proceedings, 42, 745–749. https://doi.org/10.1016/j.matpr.2020.11.161

Garg, A., & Biswas, S. (2020). Determination of strength characteristics of concrete by partial replacement of aggregateswithewasteandhdpegranules. Journal of Xi’an University of Architecture & Technology, XII(Vi), 90

108.

Kakria, K., & Priya, S. (2021). Use of Non-Metallic Powder ReclaimedfromWastePrintedCircuitBoardsinRigid Concrete Pavement. IOP Conference Series: Materials Science and Engineering, 1075(1), 012032. https://doi.org/10.1088/1757-899x/1075/1/012032

Kalpana,M.,Vijayan,D.S.,&Benin,S.R.(2020).Performance study about ductility behaviour in electronic waste concrete. Materials Today: Proceedings, 33(xxxx), 1015

1020.

https://doi.org/10.1016/j.matpr.2020.07.049

Manjunath,B.T.A.(2016).PartialReplacementofE-plastic Waste as Coarse-Aggregate in Concrete. Procedia Environmental Sciences, 35, 731–739. https://doi.org/10.1016/j.proenv.2016.07.079

Mary Treasa Shinu, N. M., & Needhidasan, S. (2020). An experimental study of replacingconventional coarse aggregatewithE-wasteplasticforM40gradeconcrete using river sand. Materials Today: Proceedings, 22(xxxx), 633–638. https://doi.org/10.1016/j.matpr.2019.09.033

Mishra,S.M.,&Trivedi,M.K.(2018).UtilizationofPCBand cost-reduction of Concrete. International Journal of Applied Engineering Research, 13(14),11461–11465.

Murali.K, & Sambath.K. (2020). Transformation of waste Bakeliteintoconcreteandsolidblocks. IOSR Journal of Mechanical and Civil Engineering, 17(2), 31–34.

https://doi.org/10.9790/1684-1702053134

Needhidasan, S., & Sai, P. (2020). Demonstration on the limited substitution of coarse aggregate with the Ewaste plastics in high strength concrete. Materials Today: Proceedings, 22(xxxx), 1004–1009. https://doi.org/10.1016/j.matpr.2019.11.255

Needhidasan, S., Vigneshwar, C. R., & Ramesh, B. (2020). Amalgamation of E-waste plastics in concrete with superplasticizerforbetterstrength. Materials Today: Proceedings, 22(xxxx), 998–1003. https://doi.org/10.1016/j.matpr.2019.11.253

Raja, L. A., Hameed, D. M. S., Kumar, P., & Ragunath, S. K. (2016). Study on Flexural Behaviour of Concrete by Partially Replacing Fine Aggregate with E-Plastic Waste. International Journal of Engineering Research And, V5(11). https://doi.org/10.17577/ijertv5is110341

Santhanam,N.,&Anbuarasu,G.(2020).Experimentalstudy onhighstrengthconcrete(M60)withreusedE-waste plastics. Materials Today: Proceedings, 22(xxxx),919–925.https://doi.org/10.1016/j.matpr.2019.11.107

Vijay, K., & Murmu, M. (2018). Effect of calcium lactate on compressive strength and self-healing of cracks in microbial concrete

Yao,Z.,Ling,T.C.,Sarker,P.K.,Su,W.,Liu,J.,Wu,W.,&Tang, J.(2018).Recyclingdifficult-to-treate-wastecathoderay-tubeglassasconstructionandbuildingmaterials: A critical review. Renewable and Sustainable Energy Reviews, 81(August 2017), 595–604. https://doi.org/10.1016/j.rser.2017.08.027