TO INVESTIGATE THE STRENGTH PROPERTIES OF CONCRETE MIX HAVING REPLACEMENT OF CEMENT WITH RED MUD WITH ADDITION OF BAMBOO FIBERS

Akhil Sharma1, Sucharu Sharma2

1M.Tech. Student, SSCET, Badhani, Pathankot, Punjab, India

2Assistant Professor, SSCET, Badhani, Patankot, Punjab, India ***

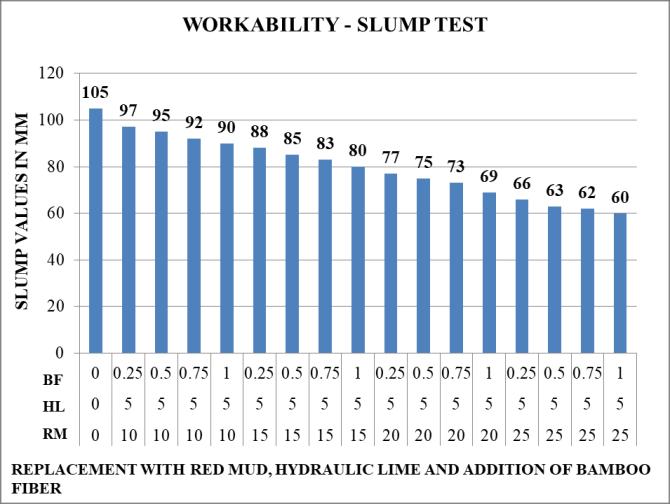

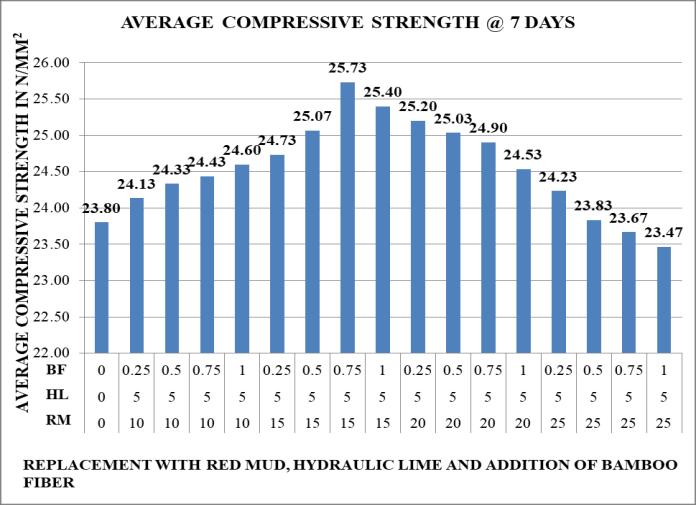

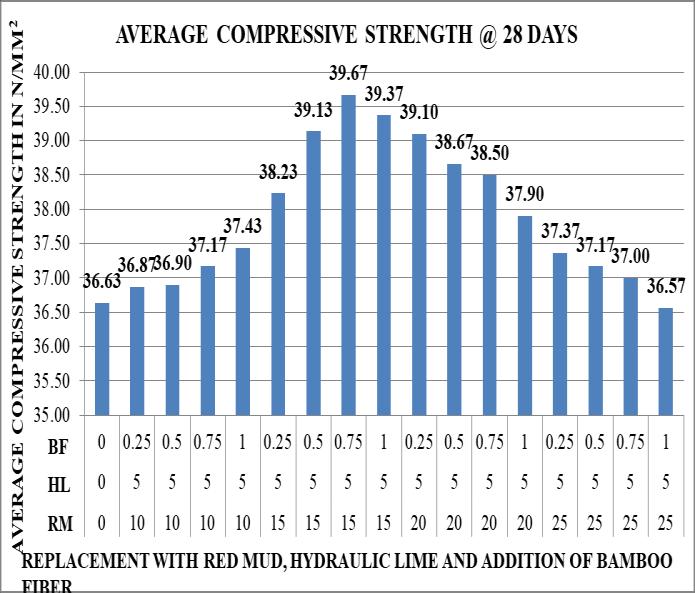

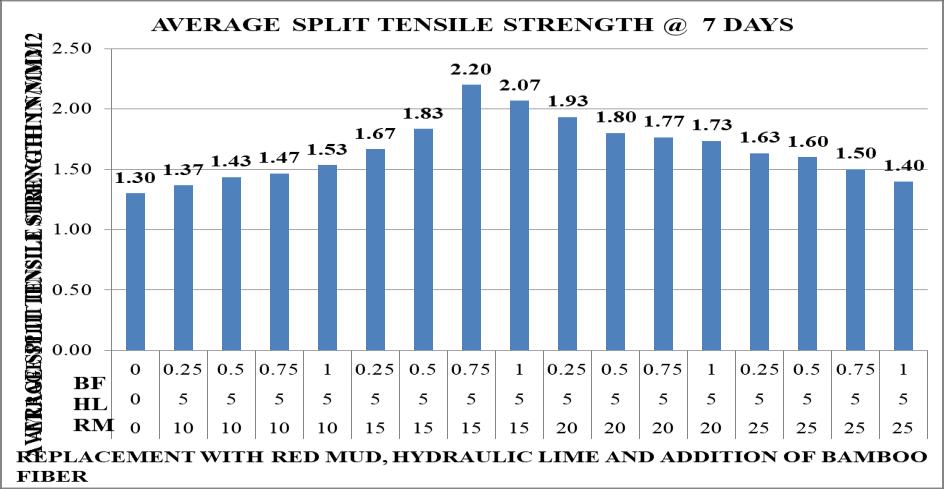

Abstract - Modern concrete can be made using coarse aggregates, fine aggregates, cement, water and admixtures. Because of its capacity to be shaped into various shapes and its fresh plastic condition, concrete is the primary material usedbythebuildingindustry worldwide. Naturallimestone is burned to make cement wit evolution of carbon dioxide gas, considered as a greenhouse gas with adversely affects our environment. Wastematerialscanbeusedinthemanufacture of mortar and concrete to minimize negative consequences and natural resource utilization. In order to increase its tensilestrengthparameter,wegenerallyusesomefibersinthe mix. InPresentStudy,Various strength propertiesofconcrete mix are determined with the effects of replacing the Cement with Red Mud (RM) along with addition of Bamboo Fibers (BF). Red mud is a solid waste that is produced worldwide in aluminum facilities. It is a very difficult task for the designers to determine the economic exploitation and properly disposing of red mud due to its complicated physic-chemical features. The blending of fibers increases the ductility of concrete. In order to provide concrete some desirable characteristics, bamboofibersare alsoemployedasanatural fiber inconcretetocreateBambooFibersReinforcedConcrete (BFRC).Various Mechanical properties such as Slump values, Compressive Strength of Cubes, Split Tensile Strength of Cylinders and Flexural Strength of Beams are thus evaluated inthisstudy withthepercentagevariationsofwastematerials i.e. Red Mud replaced the cement content by 0%, 5%, 10%, 15% and 20% with Bamboo Fibers addition as 0%, 0.25%, 0.5%, 0.75% and 1.0%. All specimens were cured for 7days and 28 days before testing. The Test results of this study are within acceptable limits.

Key Words: Hydraulic lime, Red Mud (RM), Bamboo Fibers (BF), Concrete, Workability, Hardened Properties, Cube Strength, Tensile Strength, Flexural Strength.

1. INTRODUCTION

Portland cement, fine and coarse aggregates, admixtures, and water are the main ingredients of modern concrete. Becauseofitscapacitytobeshapedintovariousshapesand itsfreshplasticcondition,concreteistheprimarymaterial usedbythebuildingindustryworldwide.Concreteisused twice as frequently as wood, steel, plastic, and aluminium

combinedonaglobalscale,anditisonlysurpassedinthe modernerabytheuseofnaturallyoccurringwater.Large industries and commercial operations are built on the foundational elements used in the manufacturing of concrete. Concrete is renowned for having a high tensile strengthbutalowcompressivestrength(about10%ofthe compressive strength). Since of this, regular concrete components are very likely to crack because they cannot withstand tensile pressures. Concrete technology has advanced throughout time with the use of chemical admixtures and mineral admixtures like fly ash, slag, etc., increasingcompressive strength while maintaining a very low tensile strength. Low tensile stresses cause cracks to startformingunderlightloads,spreadquickly,andenlarge as a result. Furthermore, because to the shrinking phenomenon,fissuresarevisibleevenbeforeloadingbegins. Duetothehighcostofsteel,labour,andcontrol/monitoring procedures, reinforcing bars are typically used to create reinforcedconcrete(RC)constructions,whichraisesoverall prices. The need for this research emanates from the numerous durability problems effecting the Indian constructionindustry[4],suchasfrequentbuildingcollapse [5]confusiononthedesignstrengthofreinforcementsteel fornormalconcretestructuresduetodecliningstrengthof steel bars used in India [6]. The use of fiber-reinforced concrete could, to some extent, compensate for tensile strength deficiencies, reducing the number of building collapses in the nation and enhancing the stability of concrete structures. Therefore, this research carries out variousformsoftestsandanalysistodeterminetheeffectof using red mud and bamboo fibers on the compressive, tensile and flexural strengths of concrete for different percentage volumes. The major aim of this research is to examinethecompositeeffectofredmudandbamboofibers onthestrengthofconcrete.Torealizethisaim,laboratory testswerecarriedonconcretesamplesto obtainstrength propertiesofconcreteusingPortlandcement,amixratioof 1:1.56:3.04,and0%,5%,10%,15%and20%percentagesof red mud and 0%, 0.25%, 0.50%, 0.75% and 1% bamboo fibers.Acorrelationbetweentheconcretestrengthandthe percentageofredmudandbamboofiberswasestablished.

1.1 Red Mud

CompoundsthatwerecreatedduringtheBayerprocessand thosethatwereinitiallypresentintheparentmineralmay combinetoformredmud.Redmuddisposalisnotsimple. Wherevertheworldremovalofredmudisbeingdoneeither towardlandorinsidetheclosebyocean/sea.Disposingof red mud presents a challenge due to the time and effort requiredtocleanuplandthathasnotyetbeendevelopedor farmed.Thesurroundingwater,land,andairareharmedby itshighpHlevel.Asaresult,mineraldisposalraisesgrave andappallingenvironmentalconcerns.Theproductionofa largequantityofredmud(bauxiteresidue)fortheassembly ofaluminaisthemostsignificanteffectoftheenvironmental problemonthealumina industry. Thesuper-fineparticles characteristicofredmudmakesthisapromisingadmixture for mortar and concrete. Clay minerals intopozzolanic admixturesthatareabletoconsumethecalciumhydroxide createdbycementhydration.

1.3 Bamboo Fiber

Bamboo is one of the oldest building materials used by mankind.Thebambooculmsorstemhasbeenmadeintoan extendeddiversityofproductsrangingfromdomestichouse hold products to industrial applications. For building the houses our forefathers used Bamboo as basic material. Becauseofitshighstrengthtoweightratio,traditionallyit hasbeenusedinvariedlivingfacilityandtools. Thefiber' longitudinalparallelismisresponsibleforthischaracteristic. Theelasticitymodulusofbamboofibersisstrongerthanthat ofanyothernaturalmaterial.Thetensilestrengthofafiber increases with length. Bamboo fibers applied to material increasesitstensileandmechanicalstrengths.

2. LITERATURE REVIEW

Kavitha S And T Felix Kala (2016) werecarriedoutontest specimens using one basic mix proportion with three variations of aspect ratio of bamboo fibers and different weight fraction of Bamboo fiber. The workability of fresh concretewasfoundtodecreasewithanincreaseinthefiber content and also a decrease in the workability with the increase in the aspect ratio and the addition of bamboo fibersat1.0%byvolumecausesasignificantenhancement inearlyaswellaslongtermcompressivestrengthandsplit tensilestrengthofconcrete.

Tan Manh Do and Young sung Kim(2016) conductedan experimental study on the properties of red mud-infused controlled low strength materials (CLSM). Red mud may substitute cement in combinations to the extent of up to 30%,whichwouldstillmeetthespecificationsbutresultina modest increase in corrosivity as indicated by pH and a decreaseinflowability.Inparticular,itwasdiscoveredthat adding more red mud to the mix could enhance the suggestedCLSM'sstability(bleedingrate)andspeedupthe settingprocess.Lastbutnotleast,anidealreplacement of

15% red mud to cement might generate CLSM with the higheststrengthat28days.Inoverall,itisworthnotingthat redmudcouldbefeasibleandpotentialinuseasapartial replacementtoPortlandcementinCLSMproduction.

Archila, Hector Kaminski, Sebastian Jonathan Trujillo. Escamilla, Edwin Zea Harries, Kent A. (2018) Thisstudy examines such "bamboo-reinforced concrete" as a steelreinforcedconcretesubstitute,evaluatingitsstructuraland environmental performance. The authors come to the conclusion that while bamboo is a material with extraordinary mechanical properties, using it in bambooreinforced concrete is a poorly thought-out idea that has seriousdurability,strength,andstiffnessissuesanddoesnot live up to the environmental benefits that are frequently associatedwithit.

Chava Venkatesh, Ruben Nerella, and Madhuru Sri Rama Chand (2020) used red mud to replace up to 15% of the cementintheconcreteinincrementsof2.5%.Metakaolin wasalsousedasaternarymineraltoboostthepozzolanic reaction; It substitutes for 10% of the cement. When compared to standard concrete, the RM replacement of cement in concrete showed compressive strength enhancementsof0.57percent,1.25percent,2.70percent, 3.89percent,4.46percent,and0.96percent,respectively. Whencomparedtostandardconcrete,splittensileshowed increases of 5.99%, 12.6%, 15.80%, 28.61%, 37.6%, and 33.24%.

2.1 OBJECTIVES OF THE STUDY

1. Toshowtheadvantageofstrengthgainedbyredmud usagealongwithBamboo.

2. Tochecktheworkabilityoftheconcretehavingpartial replacementofcementwithRedMudwithadditionof Bamboofibers.

3. To extend and toknow the strength propertiesof red mud concrete in terms of compression, tensile and flexuralparameters.

4. The development of alternate low-cost andeconomically suitable building materials fromagricultural and industrial wastes is an economicnecessity.

3. MATERIALS USED

3.1 Water

Potable water can be used in this study to a minimum to ensurebothconstructabilityandservicelife.W/cshouldbe between0.4and0.5forthemajorityofapplications lower forlowerpermeabilityandhigherstrength.

3.2 Cement

Cementisthebindingmaterialinconcrete.Ambujamark43 grade OPC cement is used in this research. The cement shouldhaveaminimumstartsettingtimeof30minutesand amaximumfinalsettingtimeof10hours.

3.3 Fine Aggregates

Fine aggregate (Sand) Fills voids between aggregates. It formsthebulkandmakesmortarorconcreteeconomical.It iscollectedfromlocalsources.

3.4 Coarse Aggregates

Locallyavailablecoarseaggregatehavingaveragesizeof20 mmwasusedinthisstudyconfirmingtoIS:383-1970.

3.5 Red Mud

TheRedmudusedforthereplacementofcementisbrought fromlocalindustryJammu,Obtainedfrommanufacturingof aluminafrombauxiteorebyBayer’sprocess.

3.5: Chemical Characteristics of Red Mud

Source: ChavaVenkatesh et.al. Journal of the KoreanCeramicSocietyhttps://doi.org/10.1007/s43207020-00030-3

ratioofl/dis40.Thevariousadvantagesofbamboofiersin concreteas:

1. BambooisaconsumerofNitrogen,whichcouldsoonbe partofahugeefforttopreventairpollution.

2. Bamboo reinforced concrete is a potential alternative lightconstructionmethodatalowcost.

3. Modulusofelasticityofconcreteincreasesbyadditionof bamboofibres.

4. Bamboofibreisincorporatedtoconcretetoenhancethe tensileproperties.

Lime has ability to set under water thus increases the hydraulicityoftheconcrete.Itispurchasedfromlocalarea ofjammu.Itisusedinthisworkinreplacementofcement with combination of red mud in concrete mix. It replaced cementaconstantrateof5%inconcretemixdesigntocarry outourwork.

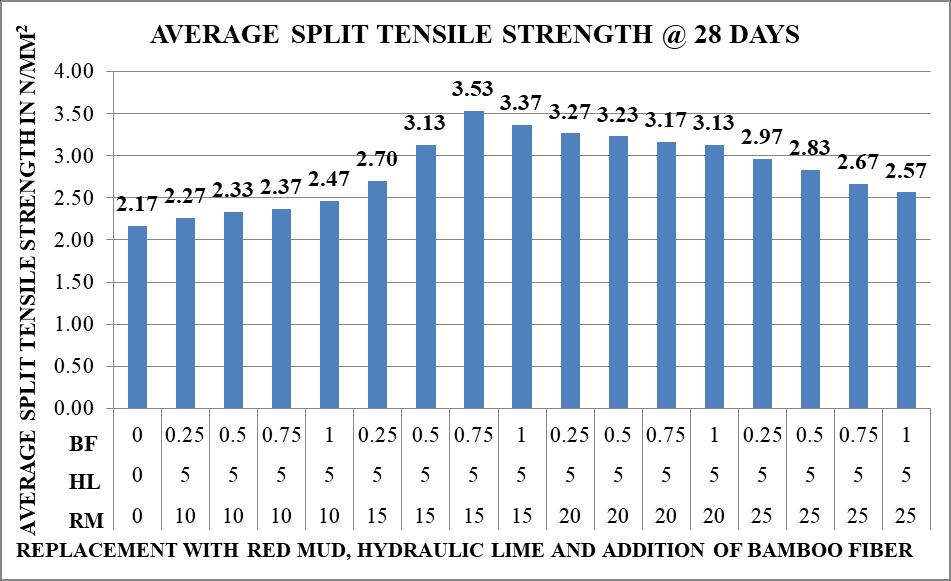

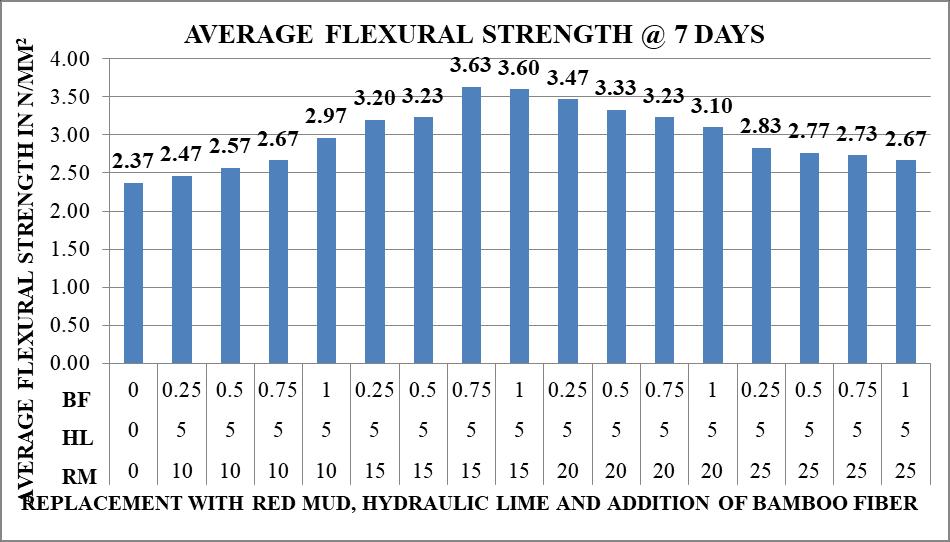

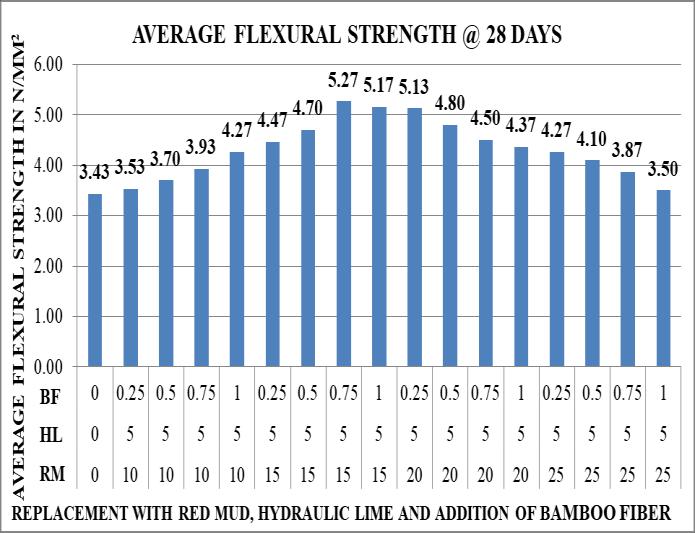

TheresultscorrespondstoconcretedesignmixofgradeM30 usingRedmudpartiallyreplacethecementwithhydraulic lime and addition of bamboo fibers are represented in graphsbelow.

Bambooislowcost,fastgrowingandbroaddistributionof growthisexpectedtocontributesignificantlyinearthquakeresistantconstructionandseismicretrofittechnology.The Bamboousedinthisworkareoflength1.5mmandofaspect

5. CONCLUSIONS

1. Thebestsubstitution%ageofRedmud,hydrauliclime andbamboofibersintermsofstrengthandeconomyis RM15%HL5%BF0.75%. The value of compressive strengthobtainedatoptimumpercentagesubstitutionis 39.67N/mm2 after28daysofcuring.

2. The split tensile strength and flexural strength or modulus of rupture shown same nature as that of compressivestrengthortoughnessstrength.

3. ThepartialreplacementoftheRedMudandHydraulic LimewiththeCementandadditionofbamboofibershas shown positive impact on split tensile strength up to RM15%HL5%BF0.75%substitution.

4. The highest value of tensile strength was obtained at RM15%HL5%BF0.75%replacementwhichis3.53MPa.

5. The maximum flexural strength at optimum mix of RM15%HL5%BF0.75%is5.27MPaat28thday.Bothhelp inincreasingstrengthatlowvolumereplacement.

6. REFERENCES

1. S. Kavitha and T. Felix Kala (2016) “Effect of Bamboo Fibers in Fresh and Hardened Properties of Self Compacting Concrete” Indian Journal of Science and Technology, Vol 9(31), DOI: 10.17485/ijst/2016/v9i31/95347,August2016.

2. TanManhDoandYoung-SangKim(2016)“Engineering PropertiesofControlledlowstrengthmaterial(CLSM) incorporating red mud” International Journal of GeoEngineering,DOI10.1186/s40703-016-0022-y.

3. Hector Archila. Sebastian Kaminski. David Trujillo EdwinZeaEscamilla.KentA.Harries(2018)“Bamboo Reinforced Concrete: a critical Review”, Materials and Strucures, 16 July 2018, https://doi.org/10.1617/s11527-018-1228-6.

4. Chava Venkatesh, Ruben Nerella, Madduru SriRamaChand (2020) “Red mud asanadditive inconcrete:comprehensivecharacterization” Jourrnal of Korean Ceramic Society https://doi.org/10.1007/s43207-020-00030-3