International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net

p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net

p-ISSN:2395-0072

Sujeet Kumar Panika*, Prof. GOURAW BEOHAR , Dr. SHAILESH GUPTA**

* SUJEET KUMAR PANIKA, Department of Mechanical Engineering, SHRIRAM INSTITUTE OF TECHNOLOGY , JABALPUR MP . Prof. Gouraw Beohar, H.O.D ( Department of Mechanical engineering), SHRIRAM INSTITUTE OF TECHNOLOGY , JABALPUR MP .

**Dr. Shailesh Gupta, Department of Mechanical Engineering, SHRIRAM INSTITUTE OF TECHNOLOGY , JABALPUR MP .

Abstract: Journal bearings have been used in rotating equipment since the invention of the wheel. The objective of current

researchistoconductFSI(fluidstructureinteraction)studiesonjournalbearingusingCFD.TheCADdesignofjournalbearing is developed in Creo parametric design software and FSI simulation is conducted in ANSYS simulation package. The CFD analysisandstructuralanalysisisconductedonjournalbearingtodeterminethepressureinducedandstressesinducedonit. Different materials are tested for feasibility in journal bearing and MMC’s have shown encouraging results.The total deformation induced on P100/6061 Al MMC journal bearing is found to be 41.4% lower than conventional steel journal bearing.ThetotaldeformationinducedonBoron/AlMMCjournalbearingisfoundtobe13.33%lowerthanconventionalsteel journalbearing.

Key Words: Journal Bearing, FSI

Thepurposeofbearingistoreducefrictionbetweenparts whichareinrelativemotiontoeachother. Thetwomajor categoriesofjournalbearingsarerollingelementbearings andhydrodynamicjournalbearings.Themajorfunctionof journal bearing is to “carry load between a rotor and the casewithaslittlewearaspossible”[1].

Li et al. [1] have conducted numerical investigation on journal bearing using techniques of Computational Fluid Dynamics. Using CFD, the effect of shear cavitation on bearing performance was investigated. The study was conducted by varying viscosity, eccentricity and speed of operations.

Novotny´ et al. [2] have conducted numerical thermohydrodynamicinvestigation onjournal bearingusingCFD. TheCFDanalysiswasconductedatdifferentrotorspeeds. The CFD simulation results have shown that CFD results overpredictedcertainoutputparameterssuchaspressure andstressascomparedtoanalyticalmodel.

Fedorynenko et al. [3] have conducted analytical and experimental testing on hybrid bearing design. The research findings have shown that hybrid bearing design have better performance with 1.5 times reduced total energyloss(inhydrostaticmode).

The bearings are found in various kinds of machineries used on daily basis i.e. wrist watch, computer disk drive and also in various machineries operating at low speeds andathighspeeds.

Fillon et al. [4] have conducted numerical analysis on hybrid bearings to determine temperature field and pressure field. The dimensions of recess depth taken for the analysis is “nominal value – h = 2 mm” and “recess diameter (nominal value – d = 170 mm)”. The research

findings have shown that small reduction on temperature field is obtained and the “performance of hybrid bearings is improved with the recess presence, while the thermal propertiesarepreservedorslightlyenhanced”[4].

Wasilczuk et al. [5] have conducted experimental investigation on hybrid bearing. The research findings have shown that large viscosity of oil results in lower temperatureduetogreaterfrictionallosses.

The objective of current research is to conduct FSI (fluid structure interaction) studies on journal bearing using CFD. The CAD design of journal bearing is developed in Creo parametric design software and FSI simulation is conductedinANSYSsimulationpackage.

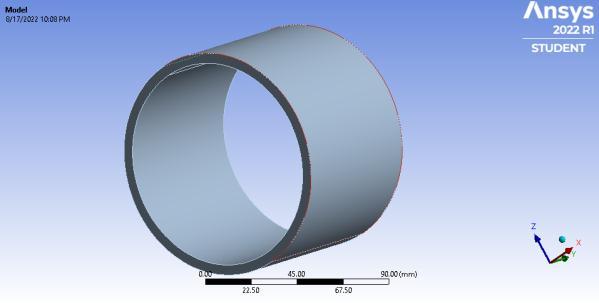

The CAD model of journal bearing is developed using sketchandextrudetool.Thefilmgeometryisalsomodeled indesignmodeler.

The loads and boundary conditions involve defining material type, material property. The energy model is turnedON.Thesolvertypeissettopressure-basedmodel. Thematerialtypeisdefinedfortheanalysis.

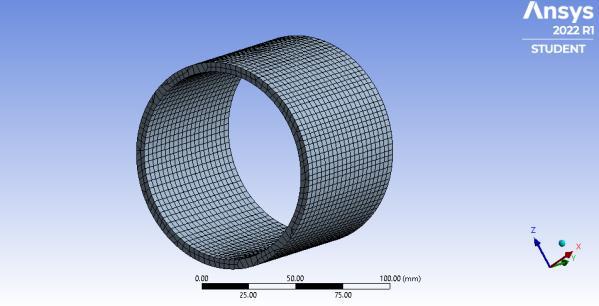

Frommeshing,thenumber ofelementsgeneratedis3980 andnumberofnodesgeneratedis22221.Thegrowthrate issetto1.2andtransitionratiosetto.272.

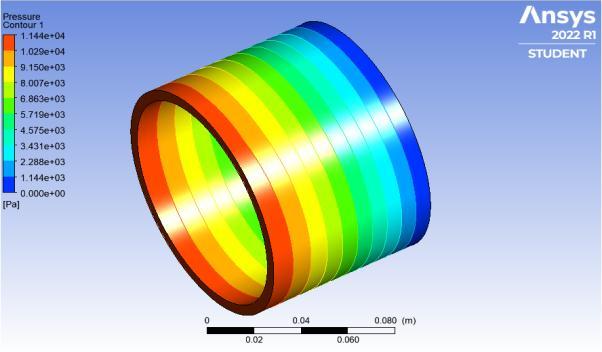

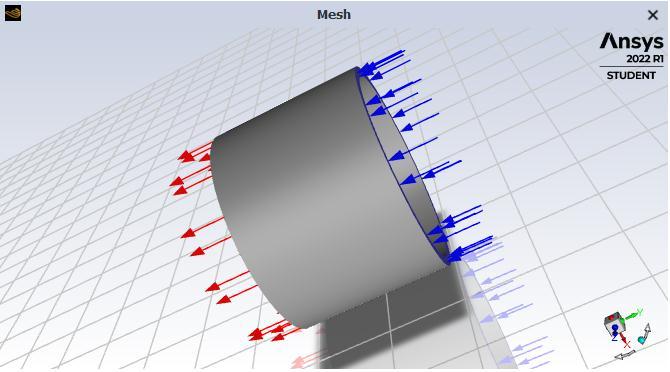

The pressure load is obtained from CFD analysis and is mappedoninnersurfaceofthebearing

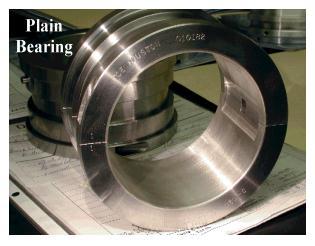

The CFD simulation is conducted to determine pressure inducedonjournalbearing.

Theinducedpressuredistributionincreasesfromonefree end to other free end which is represented in blue color contour for low pressure and red colored region for high pressuremagnitude.

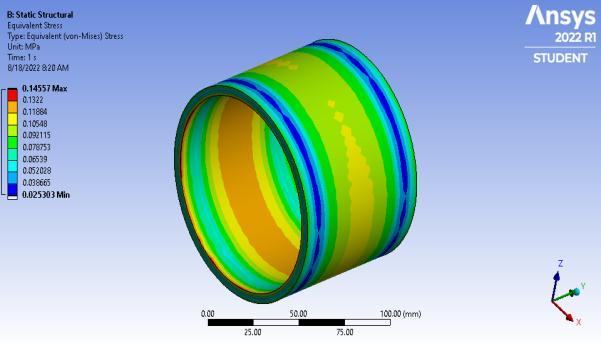

The equivalent stress plot is generated on bearing as showninfigure6above.Themaximumequivalentstressis obtained onthe open free endsof bearing. The equivalent stress distribution pattern is in close agreement with the equivalent stress distribution shown in literature. The maximum equivalentstress obtainedisatthecorneredge ofthebearingwith.14557MPa.

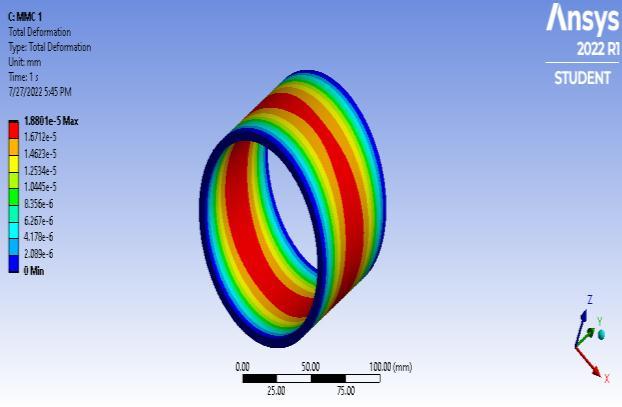

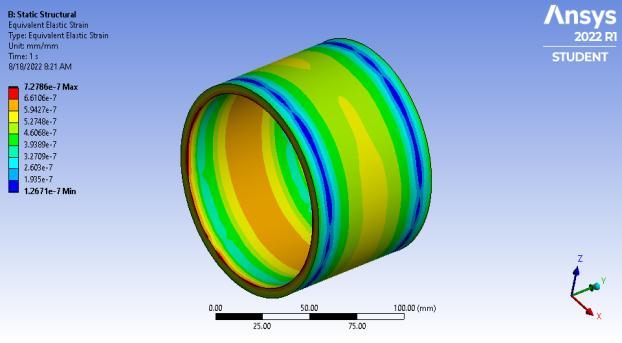

The equivalent elastic strain plot is generated on bearing as shown in figure 7 above. The maximum equivalent elastic strain obtained from the analysis is 7.27mm/mm. The total deformation plot is generated for bearing made of P100/6061 Al as shown in figure 7. The maximum deformationisobtainedatthecenterofthebearing.

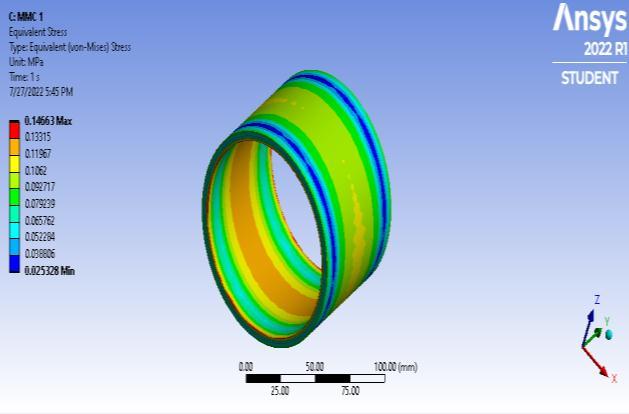

The equivalent stress plot is generated on bearing as shown in figure 9 above. The maximum equivalent stress obtained is at the corner edge of the bearing with .14663MPa.

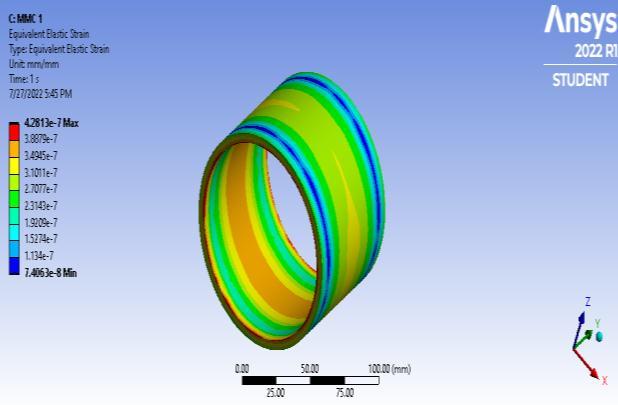

The equivalent elastic strain plot is generated on bearing as shown in figure 10 above. The maximum equivalent elasticstrainobtainedfromtheanalysisis4.28mm/mm.

The total deformation comparison plot is obtained from the analysis as shown in figure 11 above. The maximum deformationisobtainedforcarbonsteelwithmagnitudeof .0000321mm and minimum deformation is obtained for P100/6061Albearingwithmagnitudeof.0000188mm.

The FSI (fluid structure interaction) is a viable tool in analysis of journal bearing. The CFD analysis and structural analysis is conducted on journal bearing to determinethepressureinducedandstressesinducedonit. Different materials are tested for feasibility in journal bearing and MMC’s have shown encouraging results. The detailedfindingsare:

1. The total deformation induced on P100/6061 Al MMC journal bearing is found to be 41.4% lower thanconventionalsteeljournalbearing.

2. The total deformation induced on Boron/Al MMC journal bearing is found to be 13.33% lower than conventionalsteeljournalbearing. MMCjournalbearing.

3. The equivalent stress obtained for carbon steel bearing is found to be lower as compared to P100/6061AlMMCjournalbearing andBoron/Al

[1] Q. Li, S. Zhang, Y. Wang, W.W. Xu, Z. Wang, Z. Wang, Principal normal stress cavitation criterion for CFD analysis of loading capacity in journal bearings, Ind. Lubr. Tribol. 71 (2019) 1047–1054, https://doi.org/10.1108/ILT-01-2019-0013.

[2]P.Novotny´,J.Hrabovsky´,J.Juracˇka,J.Klíma,V.Hort, Effectivethrustbearingmodelforsimulationsoftransient rotordynamics,Int.J.Mech.Sci.157–158(2019)374–383, https://doi.org/10.1016/j.ijmecsci.2019.04.057.

[3] D. Fedorynenko, S. Sapon, S. Boyko, A. Urlina, Increasing of energy efficiency of spindles with fluid bearings, Acta Mech. Autom. 11 (2017) 204–209, https://doi.org/10.1515/ama-2017-0031

[4] M. Fillon, M. Wodtke, M. Wasilczuk, Effect of presence ofliftingpocketontheTHDperformanceofalargetiltingpad thrust bearing, Friction. 3 (2015) 266– 274, https://doi.org/10.1007/s40544-015-0092-4

[5] M. Wasilczuk, M. Wodtke, L. Dabrowski, Field tests on hydrodynamic and hybrid operation of a bidirectional thrust bearing of a pump-turbine, Lubricants. 5 (2017), https://doi.org/10.3390/lubricants5040048

[6]Dimitrios A. Bompos., Pantelis G. Nikolakopoulos.: CFD simulation of magneto rheological fluid journal bearings, Simulation Modelling Practice and Theory, Vol. 19, pp. 1035–1060,2011.

[7]Chasalevris,A.,Sfyris,D.:Evaluationofthefinitejournal bearing characteristics, using the exact analytical solution of the Reynolds equation, Tribology International, Vol. 57, pp.216–234,2013.

[8]Arumugam, S., Sriram, G.: Synthesis and characterization of rapeseed oil bio-lubricant dispersed with nano copper oxide its effect on wear and frictional behavior of piston ring cylinder liner combination, Proc Inst Mech Eng Part J: Journal of Engineering Tribology, Volume228,pp.1308-1318,2014.

[9]Arumugam, S., Sriram, G., Ellappan, R.: Biolubricant –Biodiesel combination of rapeseed oil: An experimental investigation on engine oil tribology, performance and emission of variable compression engine, Energy, Vol. 72, pp.618-627,2014.

[10]Baskar, S., Sriram, G., Arumugam, S.: The Use of Doptimal Design for Modeling and Analysing the Tribological Characteristics of Journal Bearing Materials Lubricated by Nano Based Biolubricants, Tribology Transactions,Vol.59,no.1,pp.44-54,2016.