International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:10Issue:01|Jan2023 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:10Issue:01|Jan2023 www.irjet.net p-ISSN:2395-0072

Dr. Rahul Pol1 , Suujay Dhhoka2

1Robotics & Intelligent System Design Lab Vishwakarma Institute of Information Technology, Pune, India

2Electronics and Telecommunication Vishwakarma Institute of Information Technology, Pune, India ***

Abstract- Today, a robotic arm may be utilized for a wide range of tasks, such as pick-and-place operations, medical procedures, industrial automation, and many other things. The robotic arm moves and completes the work based on the hand motions of humans.This device imitates the movements of human hands. The arm is incredibly versatile and may be utilized in fields like making fireworks and bomb disposal when the atmosphere is dangerous for peopletobein. Therobotic arm may be controlled in a variety of ways. The Dobot Studio programmeisused in this studytodiscusstheDobot's applicationsasaroboticarm.

Keywords- Dobot (Robotic arm), pick and place, colour sorting, stacking, 3D printing, laser engraving, writing and drawing.

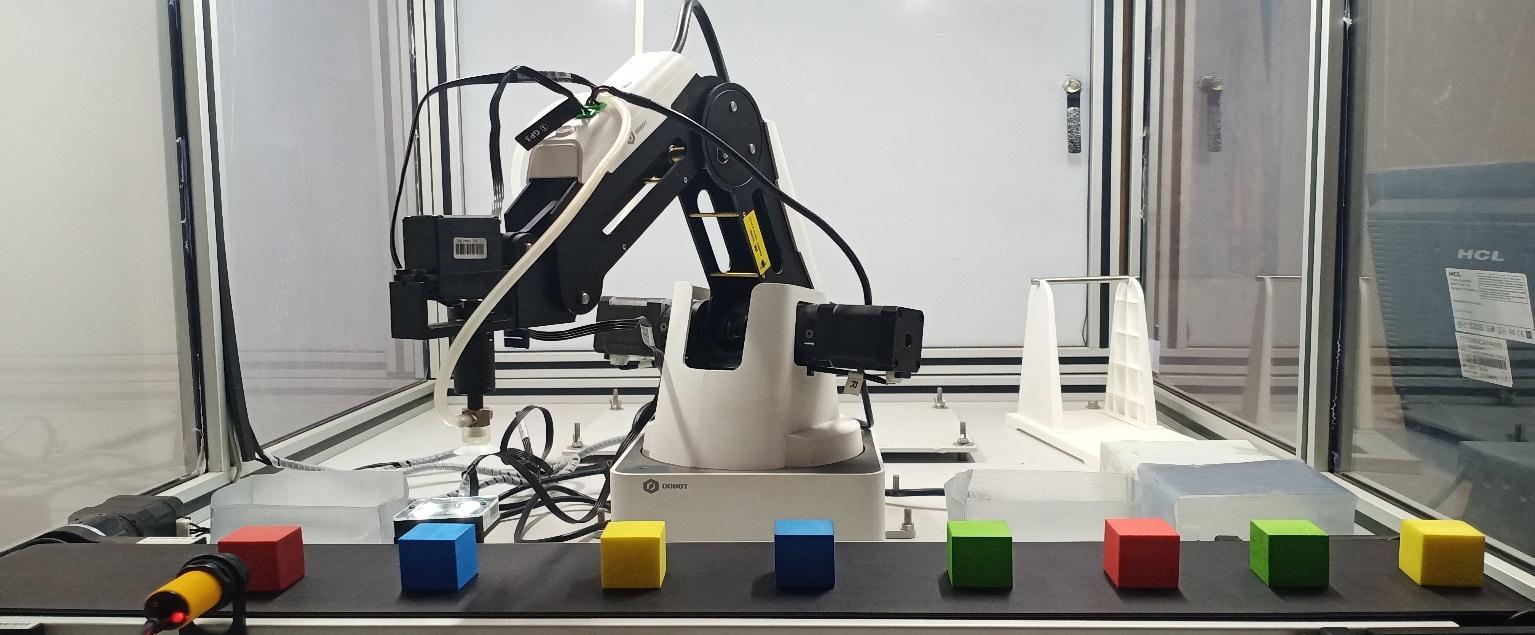

Reserve room for robotics in all disciplines, including engineering, medicine, and space science, among others, because it has had a significant influence on our civilization in the current day. Robots can be utilized in emergencyscenarioslikebombdisposalwherehumanlife isatrisk.Anartificialmechanicalarmknownasa robotic arm may be programmed and has functions that are similar to those of a human arm. The arm could be the whole device or it might be a part of a more complex robot.Aroboticarmcanbeusedtoperformawiderange of activities starting from small scale household use to a largerscaleindustrialpurpose.Inthisarticle,Ihavetried toscaledownafewapplicationsthatIhaveperformedon a dobot magician as shown in figure1. I have used an application namely Dobot Studio linking it with my robot arm.

Pick and place robots give businesses the ability to employ automated methods for moving goods from one spot to another. Lifting or transferring goods from one spottoanotherdoesnotneedmuchconsiderationwhenit comes to simple activities. Lifting or moving goods is a simple action that doesn't take much thought. Consequently, hiring human labour for these jobs might

be inefficient because the workforce could be better utilizedfortasksrequiringhighercognitivecapacities.The pick-and-place robots are in charge of these repetitious chores. These robots frequently have vision and sensing systems that allow them to take items off of a moving conveyorbelt.

[1]Pick and place robots come in a variety of designs depending on the particular task they are utilized for. The majority ofthese designshavea similarfundamental idea. These robots often have a long arm that can reach their wholeworkingareaandaremountedonasturdypedestal. Forthekindofthing the robot wishesto move, the end of the arm attachment is tailored. These robots can move objectsfroma movingsurfacetoa movingsurface,froma moving surface to a stationary surface, and from a stationary surface to a moving surface (such as between twoconveyorbelts).

My robotic arm had 4-axis. However, there are also 5-axis and 6-axis robotic arms in use that can twist the items to rotatetheirorientation.Differentend-effectorscanbeused such as a gripper or a suction cup. Coding can be done in blocklyandpython.

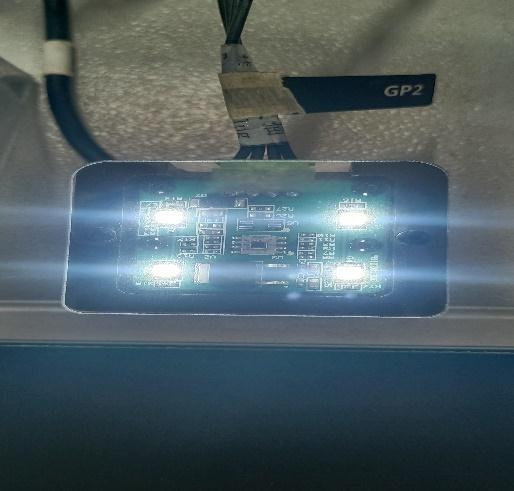

As seen in figure 2, the colour sensor is utilized to determine an object's colour. It determines the RGB color's light intensity and outputs a result in accordance.ItincludesaninbuiltIR blockingfilterthat accurately detects colour. The colour sensor has four analoguetodigitalconverters

detects the object's colour and then grasps it with a gripper. Controlling the gripper motor is necessary for this. The gripper motor is once again commanded to drop the object oncethecontroller hasmoved thearm to the dropping area. Since the o/p voltage of the microcontroller unit is substantially lower than that needed to operate the motors, motor drivers are utilised to connect motors with the microcontroller unit.Threeservomotorsandonesteppermotorpower theentiresystem.

[4]ThecoloursensorpicksuptheRGBprimarycolours and then searches for reflected colour intensities, which are then translated into 8-bit values for each primary colour. As with the GREEN and BLUE colours, theREDcolouritemreflectstheREDcolourwithstrong intensity. The additional colours are made by combining the RGB's three primary colours. Knowing the preset primary colour values makes it simple to identify the colour of the tested object. Since each colour has a specific value and the matching light intensity is reflected on the sensor, the sensor will generatetheoutput.

Thesystemusescolourasitssortingcriterion,hencea photodiode serves as its colour sensor. [2]The RGB colour model, which encompasses a large variety of colours, forms the foundation for the sensor's colour recognition.Themicrocontrollerisacrucialcomponent thatmanagestheotherbuildingblocksintheunit.The microprocessor analyses the intensities and regulates the operations of the other building elements of the system using the photo sensor's output as input.

Threeservosandonesteppermotorareusedtocontrol thepick-and-placecontrolaction.PWMpulsesareused to drive a servo motor and change and maintain position.Thearmisrotatedataparticularangleusinga stepper motor. The mechanical part's arm and gripper are built of compressed 2 mm aluminium sheet, which willassistmakethemodellighter.Theobjectischosen by the sensor using a gripper once it recognises the colour of the thing. Controlling the gripper motor is necessaryforthis.Thegrippermotorisnowdirectedto drop the thing once more as the controller now moves thearmtothatpoint.

Figure3showsarobotarmstackingtheblocksoneabove another and forming a pyramid. Stacking is the process whichdoesnotrequirealotofthinkingandthereforeitis pointless to appoint a human being to perform that job whenmachinescandoittirelessly.Arobotarmisthebest possiblechoiceforit.Itcancarryheavyloadsaswelland at times can be very flexible as well. Different end effectorscanbeusedandthattooofdifferentsizesasper therequirement.Agripperandthesuctioncupareamong them.

Stacking is mainly done at industries for packaging purpose.Itcanalsobeveryuseful atthewarehousesand alsoinarrangingthetransportablecontainers.

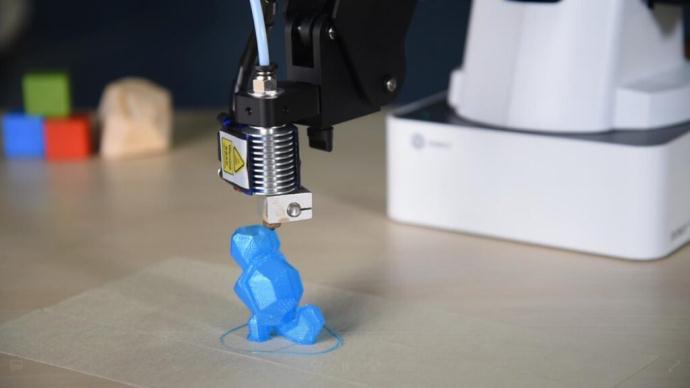

produced 3D items can be designed or constructed using computer-aided design software, scanned using 3D digitising equipment, or created by taking pictures of the object's exterior. The format is translated into extremely thin horizontal slices and consecutively printed one atop theothertogeneratethefinishedproduct.Thedigitalform elements that hold the essential data direct the threedimensional printer, which guides the format. Figure 4 showsadobotbuildinga3-dimentionalmodel.

To create the required shape and the appropriate item, processes including modification, moulding, alignment, and combination are used. [7]The dobot Magician is similar to many other 3D printers on the market and is accurateenoughtoproducethingswithfinedetails.Dobot can also print in multiple colours because to its twin extruders. Furthermore, it works with well-known opensource 3D printing programmes like Repetier Host and Pronterface.

The method of creating three-dimensional items by the printingoradditionofincrediblythinlayersofmaterialis known as additive manufacturing, or 3D printing. It is extensively utilised in quick manufacturing, rapid prototyping, healthcare, dentistry, orthopaedics, jewellery, and architecture, and its application in additional fields is constantly expanding. [8]Digitally

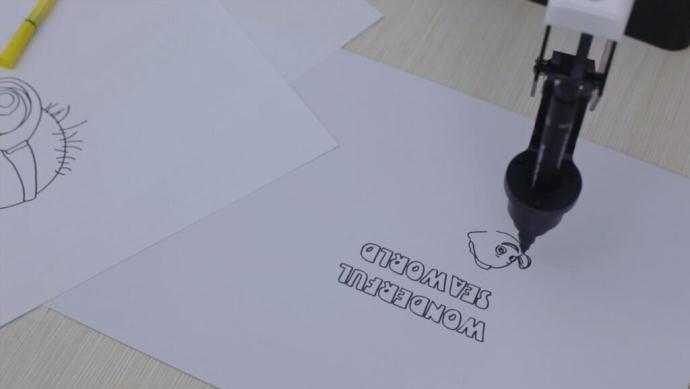

Becauseofits exceptional precisionandstability,theDobot Magician can draw smooth lines. Customized artwork may be sent into Dobot's software to be translated to code and thendrawnonpaperbythearm.Similarsettingscanalsobe used for custom text. It may be a great ally for creatives. A robot arm can also be used for calligraphy, portraits, and muchmore.

IusedDobotStudioapplicationforwritinganddrawing.Itis very easy to use. Just select the text or the drawing and place it properly between the coordinates. Then, adjust all the three axis properly as per the sheet placed beneath the pen and it’s all set. PCB designs can also be created on a copperplateforprojectpurpose.

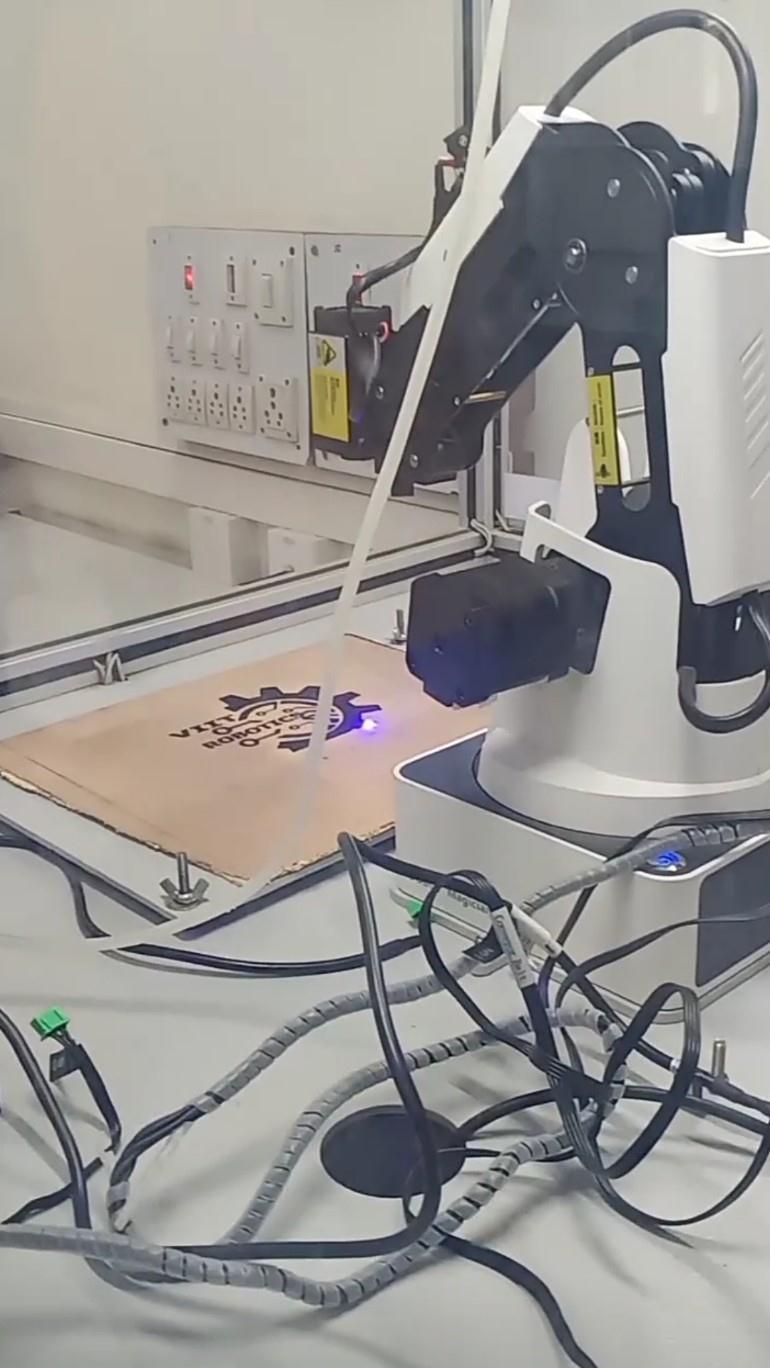

[7] Dobot Magician can engrave not only lines but also shaded sketches of pictures by simply swapping the pen with a laser end-effector. Harder materials like leather and wood may be engraved with its strong laser head. It's a fantastictoolforcreatingartworkanduniquegifts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:10Issue:01|Jan2023 www.irjet.net p-ISSN:2395-0072

Figure6showsadobotengravingmydepartmentlogoona wooden plank. [9] Drawing and laser engraving both use thesamegraphicaluserinterface.Adjustthezeropointand direct the laser beam towards the desired material while laser engraving for the first time. Zero point adjustment refers to aligning the laser nozzle's end effector with the surface of the work item being engraved. In essence, the zeropointdoesnothavezerovaluesinceitmakessurethe lasernozzleonlycontactsthetargetsurface.

oninvestment.Itoffersahighlevelofaccuracyandremoves peoplefromriskyoperations.Inadditiontoeverythingelse, they are now considerably more affordable and frequently marketedwithvariousattachmentsforspecifictasks.

From this article, one can conclude that robotic arm is very useful and isjust likea humanarm. In thiscompetitive and growing world, where robots will be the future, a lot more research and advancements will be made in the similar fields. Working on a dobot magician robotic arm and experiencingitwaslikeagreataccomplishmentforme.

[1] WhatisaPickandPlaceRobotandHowDoesitWork? -PWRPack

[2] S. A. Khan;T. Z. Anika;N. Sultana;F. Hossain;M. N. Uddin Color Sorting Robotic Arm | IEEE Conference Publication | IEEE Xplore, 2019 International Conference on Robotics, Electrical and Signal ProcessingTechniques(ICREST)

[3] I.Vojtko,M.Kocisko,M.JanakandV.Fecova,"TheNew Design of Robot Arm", IEEE 11th International Symposium on Applied Machine Intelligence and Informatics,pp.53-56,2013.

[4] Color Sorting Robotic Arm | IRJET JournalAcademia.edu

[5] stackingblocksusingrobot armresearchpaper -Bing images

[6] Quan Khanh Luu;Hung Manh La;Van Anh Ho, “A 3Dimentional Printing System using an Industrial Robotic Arm”, 2021 IEEE/SICE International SymposiumonSystemIntegration(SII)

[7] DOBOT Magician - Lightweight & Intelligent Robotic Arm-AstirTech

[8] (PDF) Design and 3d Printing of a Robotic Arm (researchgate.net)

[9] (PDF) Technical study of the effect of laser engraving usinguArmswiftprorobot(researchgate.net)

[10] Stackingblockswitharoboticarm–YouTube

For a better understanding of the applicationsof the robotic arm, I have successfully read a number of research articleswrittenbyvariouswriters. Roboticarmsareuseful foravarietyofindustrialandmanufacturingprocessesthat call for quickness, accuracy, and repeatability. [11]Today, roboticarmsareemployedinmanydifferentindustriesand sectors to increase production and yield a quicker return

[11] Working of Robotic Arm: How does a robotic arm work?(universal-robots.com)

[12] Robotic Arms: Features and Applications | Top 3D Shop

[13] Nishigandha Patel, “Pick and Place Robotic Arm”, Volume:08Issue:02|Feb2021