International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

2Ass

ociate

Professor,Dept. of Civil Engineering, N. K. Orchid College of Engineering & Technology, Solapur,

1Student, Dept. of Civil Engineering, N. K. Orchid College of Engineering & Technology, Solapur, Maharashtra, India. Maharashtra, India ***

Abstract - Since quite a long time back, polypropylene filaments have been utilized to give support in concrete mortars and cement. The filaments keep breaks from spreading and gainfully affect various other substantial properties. Regular practice to use filaments have been mathematically misshaped or changed to improve the adherence of polypropylene to solidify framework. By applying fibrillated filaments that have a construction like a net produced using polypropylene sorts, one might come by positive results. To make the fibrillated polypropylene filaments, creation started. The filaments were then utilized for the building up of cement and concrete mortars in the wake of being sliced to the suitable lengths. The attributes of both new concrete and supported concrete, as well as the mechanical boundaries of mortar, were not entirely set in stone. It was accounted for that the filaments significantly affect the compressive strength of the mortar or the supported cement. In the wake of going through many patterns of freezing and defrosting, one can see the positive effect that filaments have on the compressive strength of cement. The twisting strength of the mortars is impacted by the presence of the filaments. It has been shown that the twisting strength of mortars that have been supported with fibrillated filaments is fundamentally expanded. Since the organization structure was opened up and the fibrillated filaments were parted, there was an expansion in the mechanical securing, which prompted an expansion in the interfacial attachment, which prompted an expansion in the twistingstrength.

Keywords: polypropylene fibrillated fibres, concrete, mortar, adhesion, compressive, bending strength, etc.

It has been known for a long while that the expansion of filaments may fundamentally work on the mechanical qualities of the materials utilized in building. At the point when individualsinitiallybeganliving in cottagesmade of mud, they blended the earth in with straw to reinforce it. In the years that followed, blocks were made by baking

earth with straw, and in this manner, lime and concrete were joined with horse hair to make mortar. During the nineteenth hundred years, an undeniably well known development material was substantial that included asbestos filaments. At the turn of the 20th hundred years, specialists put forth their most memorable attempts to work on the strength of cement by integrating steel filaments in with the general mish-mash. Years and years after the fact, both regular and substance filaments were utilized for building up concrete, which started to become normal practice. As per the exploration distributed on the subject,various regularfilaments,aswell asglass,carbon, polyaramide, and other normal kinds of manufactured strands, have been effectively utilized in different applications[1-7].

The polypropylene filaments have a place with the classification of manufactured strands, and they are the ones that are utilized the most ordinarily [8, 9]. The elevated degree of interest in polypropylene filaments might be credited to the way that these strands are exceptionallyreasonable,promptlyaccessibleinenormous amounts, and have different advantageous characteristics [10, 11]. The filaments are sans risk, easy to work with, and viable with every one of the synthetic admixtures utilized in concrete. The filaments are not responsive to any synthetic substances and have an elevated degree of compound and organic obstruction [12], remembering an extraordinary degree of opposition for the soluble climate of cement. Since they have such an extraordinary obstruction, the filaments don't rust or consume when theyareutilizedinconcreteasaresultoftheirsturdiness. The filaments have a hydrophobic nature, practically minimal wet retention, and take up no water during the blending system of concrete glue. The support is lightweight and contributes no additional weight to the designssincethefilamentshavealowthickness,whichisa lotoflowerthanthethicknessofsteel.

[13-15] Utilizing short polypropylene filaments that are scattered similarly across the entire limit of the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

substantial, the lips of breaks might be sewn together, which restricts the cracks' capacity to proliferate. The counteraction of breaking is of basic significance, especially in the initial not many hours after the substantial has been poured. During this time, the substantial has low industriousness and a low Youthful's modulus,andtheburdensthatcreatebecauseofshrinkage are more noteworthy than the strength of the substantial [16]. Because of the filaments' capacity to scatter the interioranxieties,theproliferationofconstrictioncracksis successfully confined. A few filaments snap at the exact momentthatthe break beginstocreate,othersarepartof thewayhauledoutofthesubstantialaftertheassociations that tight spot them to the substantial are broken, and others can overcome any barrier made by the split as it broadens [17]. As a result of these cycles, the strains that were developing at the break's finishes in the long run started to disseminate. Regardless of whether the limit of individualfilamentstoalleviatestressesisn'texceptionally high, an aggregation of the impact might be seen when there are more strands present, which brings about a successfulrestrictionofthecracks'capacitytoproliferate.

The utilization of filaments goodly affects different other substantial properties as well as bringing down the probability of break advancement. When contrasted with conventionalconcrete,substantialthathasbeensupported with polypropylene filaments has expanded strength, further developed exhaustion obstruction, higher protectionfromdynamicloads,andlowergrindability[1822]. Furthermore, concrete with polypropylene fiber supporthasahigherprotectionfrombreakingattwisting. Theimperviousnesstofire ofthesubstantial aswell asits warm protection from unexpected temperature vacillations are both superior by the expansion of filaments. When warmed to a sufficiently high temperature, filaments will start to dissolve and will be partofthewayconsumedbytheconcreteframework.The filaments give a permeable organization that empowers the outward development of gas, in this manner bringing down the pore tension in the material and, subsequently, eliminating the probability of dangerous spalling [23, 24]. The substantial's capacity to endure freezing is one more perspective that advantages from the expansion of filaments. Substantial's sturdiness is extraordinarily expanded because of the incorporation of filaments [25, 26].

Asoflate,fiber-supportedconcretehasbecomemorewell knownforuseinthestructureofanexpansiveassortment of designing items, including streets and expressways, air terminal asphalts, watersides, and numerous other

designing designs [27-29]. The communication between the concrete framework and the filaments decides the presentation of the fiber-supported concrete, which not entirely set in stone by the attachment and grinding powers [30-33]. The attachment powers that guarantee the cohesiveness of the interfacial district are guaranteed by feeble anxieties, as talked about in section 190 of Superior Execution Substantial Innovation and Applications. Under these circumstances, the interior anxietiesarecommunicatedbybothofthepartsthatmake upthecomposite,andtherelocationsofthefilamentsand theframeworkatthestagelimitareviablewitheachother. Whenexposedtoexpandingloads,thecementassociations that keep the filaments and the framework intact start to bomb because of the tremendous dissimilarity in the versatile moduli of the strands and the lattice. Following thecuttingoffofsuchaconnection,acourseofhaulingthe filaments out initiates, which is portrayed by the transcendence of powers coming about because of grinding[34-36].

Asaresultoftheirsubstanceconstructionandlowsurface energy, polypropylene filaments have an extraordinarily low wettability and an unfortunate adherence to cementitious framework. This outcomes in unfortunate attachment. In the exploration that has been finished, numerous methodologies for adjusting filaments have been portrayed. These methodologies endeavor to expand the wettability of the filaments and work on their ability forattachment.Onewayincludesthepresentationofpolar gatherings onto the outer layer of the filaments through responses that happen during the plasma therapy or different cycles that are instigated by UV or gamma radiation[37-42].Theouterlayerofthefilamentsmightbe treated with synthetic substances or exposed to actual pressure to make them more grating, which is the second way for improving the cement characteristics [43]. This procedure might incorporate the utilization of microwave radiation,substancescratching,firetherapy,crownrelease, or every one of the four. [44] Creasing or contorting the filaments brings about a significant improvement in the cement capacity [45, 46]. This improvement might be achieved by disfiguring the filaments. Another captivating chanceistheutilizationoffibrillatedfilamentsthathavea construction like that of a net and are gotten from a few sortsofpolypropylene[47-49].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

[52]. To build up concrete, fibrillated filaments that have been sliced to a particular length going from a couple of millimeters toseveral millimetersareused.Insidea scope of 15 to 100 micrometers, filaments that are industrially open have thicknesses that match to the film's general thickness. The width of a singular fibril could go somewhere in the range of 100 to 600 micrometers on account of filaments. The particular surface region of the filaments falls some place in the scope of 80-600 mm2/mm3 relying upon the sort. The Youthful's modulus of filaments falls some place in the district of 3-5 GPa, which is a critical sum lower than the modulus of cementitious materials, which might fluctuate somewhere in the range of 15-40 GPa. Elasticity of used filaments is betweensomewhereintherangeof140and690MPa[8].

Since the mid 1960s, fibrillated polypropylene filaments have been fabricated [50]. The production of such filaments quickly arose as a reasonable option in contrast to conventional dissolve turning as an outcome of the exceptionally direct and minimal expense procedure required, as well as the magnificent mechanical characteristicsithad. Beforevery long, theprocedure was frequently carried out into modern practice, and the filaments found a large number of utilizations, including enormousscopeassemblingofsackfabric,ropes,andfloor covering backing materials, notwithstanding agro-, geo, andnumerousotherspecializedmaterials.

Theproductionofthefibrillatedfilamentsisaninteraction that happens across many stages. The interaction starts withtheexpulsionofthepolypropylenedissolvebymeans of a level kick the bucket. This makes the principal item. After the film has been cooled in water to accomplish a strongstate,itisuniaxiallydrawnandafterwardthermally balanced out. The capacity to stretch to more noteworthy lengths in following handling stages is made conceivable by compelling extinguishing in fluid media. After the film hasbeenbalancedout,itisfirstcutintoslendertapeswith widths going from 1 to 20 mm, and afterward a needle roller fibrillation unit is utilized to partition the material into stringy material. In the last step, the winding mechanicalassemblytakesinthefilamentstobewound.It is feasible to lay out a construction like a customary organization by cutting and partitioning the filaments (Figure 1). The particular tasks and handling conditions fundamentally affect the construction and extreme attributes of the filaments [51]. Through control of the development boundaries, it is feasible to deliver filaments with a large number of mechanical and warm properties

Theessentialgoalistodirectawritingconcentrateon the exploration that zeroed in onthe impactof conveying half and half fiber in unbending asphalt and their response to different stacking conditions to address the essential discoveries. What's more, in light of the discoveries of the earlier review, a differentiation will be drawn between conventional concrete and half and half fiber supported concrete.

Fiber-supported concrete, frequently known as FRC, is a composite material that comprises of concrete mortar or substantial blends and generally dissipated filaments. Improving the mechanical properties of substantial pavement is utilized. The quantity of filaments that are added to the substantial combination is estimated as a negligible portion of the complete volume of the compound. This estimation is alluded to as the Volume Division (Vf) of filaments. Such filaments that are consolidated in the substantial are settled on in the wake of thinking about various attributes, including the Youthful's modulus, thickness, elasticity, and perspective proportion of the strands [6]. Fiber-supported concrete (FRC)isutilizedforawideassortmentofutilizationstoday, including spans, pressure driven structures, burrows, waterway linings, pipes, wellbeing vaults, blast safe designs, cladding, and roller-compacted concrete. In the first place, fiber supported concrete was fundamentally usedforasphaltsandassemblingfloormaterials.

The utilization of FRC in development parts like sections, pillars, and segments has been explored by an extraordinarynumberofspecialists[7].Usageoffilaments incementmightbringaboutanincrementofthematerial's

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

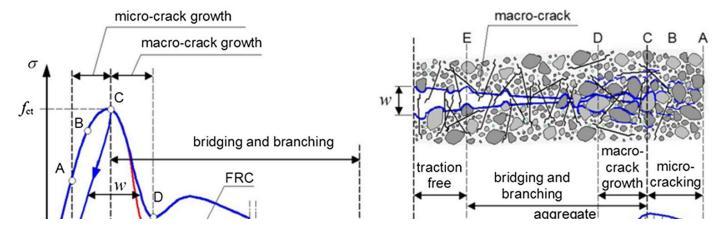

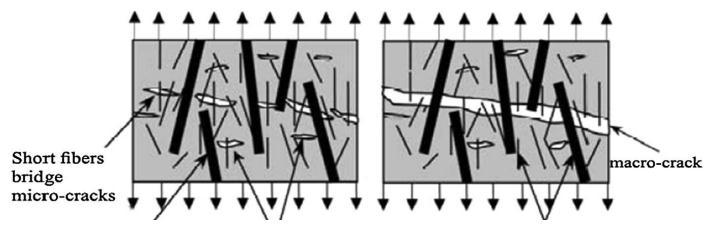

presentation in solid asphalt. The consolidation of these filaments into substantial will bring about enhancements to the material's characteristics, including expanded flexural strength, malleability, sturdiness, exhaustion strength, and effect obstruction. Furthermore, there is a negligible improvement in the material's compressive strength[5]. Theproportion ofthe absolutevolumeofthe composite to the amount of fiber that is added to the substantial combination is the way that how much fiber thatisaddedtothesubstantialblendisexpressed(cement and fiber). This extent is alluded to as the "volume division" (Vf), and its worth will ordinarily fall between somewhere in the range of 0.1 and 3 percent. The perspective proportion, indicated by the documentation "l/d," is acquired by partitioning the length of the fiber by its measurement. In case of shapes that are not roundabout, the cross-segment of the filaments that are usedshouldbepickedsoastoprocurethedistanceacross comparabletoworkouttheperspectiveproportion.Onthe off chance that the filaments have a higher modulus of flexibility than the framework (which may be concrete or mortar),then,atthatpoint,thematerial'selasticitywillbe improved, which will help it to endure the weight [8]. At the point when filaments are remembered for the substantial combination, they help to associate the blend, postponethedevelopmentofmicrocracks,andsuccessfully tie these crevices by giving pressure distribution medium, which defers the reconciliation of the microcracks and lopsideddevelopment[9].Theviabilityoffiberincrossing over the crack is found in Figure 2. The interaction that starts with the development of a break and finishes with the breakdown of the part is frequently separated into three unmistakable zones: the principal zone is contained microcracks, while the second and third zones are made out of macrocracks. The subsequent zone is known as the zoneforcrossingover,whilethethirdzoneisknownasthe zone without foothold [10]. The post-break load is higher than the breaking load in light of the fact that the proportion of filaments that traverses the break and the holdingofstrandsinthecombinationarebothanswerable for this. This peculiarity is known to produce a strain solidifying circumstance with spread breaks. Be that as it may, when the fiber content of the substantial arrives at one percent, strain-mellowing processes start to happen. These demonstrations keep the harm from spreading furtherfollowingtheprincipalbreakshowsup.

Fig- 2 : Comparisonofthestress-crackopeningrelationsfor thenonfibrousconcreteandfibrousconcrete.[10]

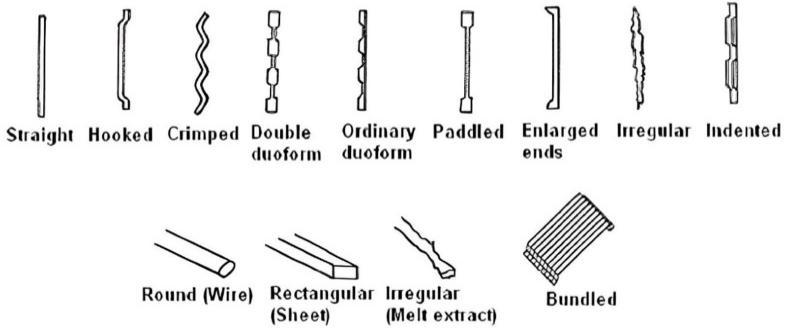

Filaments might be produced using a wide assortment of materials and can take on different shapes and sizes all through the assembling system. These are the most predominant sorts of materials used to make filaments: [11]

Figure 2 [12] portrays the most widely recognized utilization of steel filaments in present day development, which is to expand the tractable or flexural strength of cementtoworkonitssolidness.Thesteelstrandsthatare cutintolittlelengthsandgivenaperspectiveproportionof around20to100tomakestringycementareutilized.The length of the fiber corresponding to its measurement is implied by the expression "perspective proportion." The filaments have different cross-segments, and the more modest size strands are haphazardly scattered in another substantial blend that is being blended in the traditional way. Steel filaments have a sensibly high flexibility modulusandstrength[13]. AsdisplayedinFigure3,there are a few assortments of steel fiber, every one of which fluctuates as far as the structures and sizes it might take. It'sworkableforsuchfilamentstohaveastraightshapeor acontortedone.

Fig- 3 : Typesofsteelfiber

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

These are round and straight filaments with distances acrossgoingfrom0.005to0.015mm;theyareimpervious tosolublebases;theirthicknessislowerthanthatofsteel; theyarelightweightyetvigorous;andtheirmeasurements range from 0.005 to 0.015 mm. This fiber displays a giganticexpansioninsturdiness,fillsinasabreakarrester, andimprovesthetwoitsstaticanddynamicqualities[15].

In the twentieth hundred years, manufactured filaments were utilized fundamentally as a development material determined to upgrade the cementitious parts of different structure items. Nylon, aramid, acrylic, carbon, polyethylene,polyester,andpolypropyleneareaportionof the filaments that are remembered for this classification, as demonstrated in a review [10] on FRC that was delivered by ACI 544. Albeit these filaments have a high rigidity,theirmodulusofflexibilityisveryunobtrusive.By adding them to concrete, one might get an all the more even dissemination of breaking and a more modest generally speaking break size. As should be visible in Figure 4, polypropylene filaments are accessible in a wide assortment of sizes, shapes, and structures, as well as a large number of characteristics, for example, resembling hairorbeingframedofplastic.

ofshortfilaments isa critical supporterof theprogress of endeavors to upgrade the mechanical qualities of cement. It does this by means of expanding the versatile modulus, as well as controlling the beginning and proliferation of cracks. In other words, there would be correspondence betweenthegatherings.

When contrasted with non-stringy supported concrete, super elite execution fiber-built up concrete (UHPFC) displays critical enhancements concerning its solidarity, malleability,sturdiness, and functionality. UHPFC is one of the mechanical progressions that have been made in the field of substantial innovation in hundred years. As indicated by the examination directed by Uchida (2006) [20].AsperUchida(2006),theexpression"UHPFC"canbe characterized as follows: "The UHPFC is a kind of cementitious composites supported by fiber with trademark values over 150 N/mm2 in compressive strength, 5 N/mm2 in elasticity, and 4 N/mm2 in first breaking strength." UHPFCs are described by having high qualities in compressive strength, rigidity, and first breaking strength. Coming up next is what the framework of this composite ought to seem to be: it ought to be comprised of totals, the most extreme molecule sizes of which ought to be under 2.5 millimeters, concrete, and pozzolans, and the proportion of water to concrete ought tobeunder0.24.Ithasbuildingupfilamentsthatmakeup multiplepercentofitsvolumeandhaveanelasticitythatis inexcessof2000N/mm2.Thesefilamentsrangelongfrom 10to20mmandhaveameasurementof0.1to0.25mm.

The expression "hybridization" alludes to the most commonwayofconsolidatingvarioussortsoffilamentsto improve or complement the characteristics of the substantial combination. The hybridization of various kinds of filaments might be fundamental for the decrease of breaks and the arrangement of worked on substantial execution.It isfeasible toconsolidate twodistinct sorts of filaments, or significantly more than two, to make a blend that is productive for every one of the various types of strandsrememberedforthiscomposite.Theconsolidation

Specialists from different establishments have taken a gander at the impacts that utilizing different sorts of filaments might have on the mechanical properties of cement.Comingupnextareaportionoftheinvestigations that were directed. Bentur and Mindess [22] reached the resolution in 2006 that the durability and malleability of the substantial were bothimproved with the expansion of half and half steel filaments that had a blend of short and long strands. The short filaments that were remembered for the combination were the wellspring of this improvement.Theyintegratedtheminiaturebreaks,which prompted an expansion in either the flexural or elasticity of the composite. During this time, the long filaments fundamentally worked on the sturdiness and malleability of the asphalt while at the same time diminishing the probability of macrocracks spreading further. This is displayedinthegoingwithfigure,whichisnumber5.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

substantialwhenthehalfandhalffibercomprisingof1.5% steel and 0.5% palm filaments is remembered for the blend.

Eswari S. et al [23] directed research on the malleability executionofHFRCinthe year2008.Themodulus ofburst administration, extreme stacking, administration, and inevitable disfigurement, energy malleability, and break size were the attributes that the review researched. To investigatethesevariables,27crystalsestimating100mm oneachsideand500 millimetersgenerallyspeakingfilled in as the examples that were broke down. The examples weremodifiedbyaddingaproportionofsteeltopolyolefin fiber that fell some place in the district of 0.0 to 2.0 percent.Bothhalfandhalfstringycementandnon-sinewy substantial examples were assessed for their presentation andcontrastedwitheachother.

Thanon and Ramli [24] distributed an article in 2011 in which they investigated the utilization of steel fiber in concrete at different rates of volume, including 0%, 1%, 1.0%, 1.25, 1.5, 1.75, and 2%. In this manner, the effect of utilizingthehalfandhalfsteelandpalmfilamentsas2%of volume was researched on the compressive, flexural, and shear qualities, as well as the thickness of every single blend. The discoveries showed that adding 1.0 percent of steelfilamentsbroughtaboutathirteenpercentincrement in the compressive strength of the material. Notwithstanding, involving a level of palm fiber in a half and half fiber blend that was higher than 0.75 percent prompted a decrease in the substantial's compressive strength.Thisisonthegroundsthatahigherlevelofpalm fiber prompts a decrease in the fiber's solidness, which thuslypromptsadecreaseinthesubstantial'scompressive strength.It wasfoundthatthestrengthoffiber-supported substantial combinations improved with an expansion in thevolumepercentofthefiber,andtheidealextentofsteel fiber,whichconveyshigher properties,is1.5percent.This was found while taking a gander at the strength of fibersupported substantial combinations in pressure. The expansion of 0.25 percent palm filaments brought about a morenoteworthyexpansioninflexuralstrengthcontrasted with the expansion of half and half fiber blends. What's more, the ascent in sturdiness recommends high strength

Patodi SC.et al. [25] directed research in 2012 to investigatethe impactofutilizingfluctuating volume rates of polyester filaments and wavy steel strands to make HFRC and assess pressure, strain, and flexure strength. Examples of M20 grade concrete with and without fly debris,aswellasvarietiesintheamountoffilamentsgoing from0to1percentofthevolumeofcement,weremade.It was found that the blend with a volume level of hybridization that contains 0.7 percent of steel and 0.3 percent of Recron fiber had the ideal mechanical properties. Thesepartsmakeup the hybridizationvolume division.

Empelmann and Oettel [26] directed research in 2012 to explore the impact that utilizing steel filaments with the volume level of (1.5 and 2.5 percent) had on the torsional UHPFRC box support execution. They were exposed to different sorts of testing, and the outcomes showed that the consolidation of steel filaments prompted an improvement in the material's presentation when it came tobreaking.Thisimprovementshoweditselfasdiminished breakwidthsandquantitiesofbreaks,aswellasexpanded extreme and breaking force and upgraded torsional solidness. It is fascinating to take note of that the point of the corner to corner cracks was found to be near 45 degreesforalltestseries,notwithstandingthewaythatthe grade of the steel fiber fluctuated. Generally speaking, filaments are utilized to give protection from concrete. In 2013, Rana [27] directed probes steel stringy cement to research the impact that steel fiber had on the flexural strength of the substantial. The aftereffects of these investigations were contrasted with M25 grade concrete. Followingcomprehensive testingin the researchfacility, it was found that rising the extent of steel fiber in the composite material prompted a recognizable expansion in thematerial'sflexuralstrength.Indeed,evenat1%ofsteel fiber content, the material has a flexural strength of 6.46 N/mm2, whichis a lothigher than the flexural strength of 5.36 N/mm2 it has when there is no fiber present. As an immediate consequence of this, the flexural strength workedonbyaround1.1percent.

In 2013, Sekar and Ramamoorthy [28] distributed the consequences of an examination that checked out at the chance of expanding the malleable capacities of cement partiallybyinvolvingjustasinglesortoffiberasasupport. Theyresearchedtheeffectofhalfandhalffilamentsonthe malleabilityofRCradiatesandmadeacorrelationbetween solo fiber, cross breed fiber supported concrete, and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

controlled built up concrete. Despite the fact that half and half filaments with at least two sorts in a similar blend mightdeliverbetteradvantages,theyresearchedtheeffect of cross breed strands on the malleability of RC radiates. Differentperspectiveproportionsofsnaredendsteelfiber, polyester recron fiber, and coirfiber wereutilized, each at a level of 1% of complete fiber content. The parametric examination took a gander at the compressive, flexural, solidness, and malleability qualities of the material, notwithstanding its definitive burden conveying capacity. Projecting 7 pillars and 42 solid shapes was important to achieve this objective. The consequences of the examinations showed that the expansion of filaments brought about a misfortune in the substantial's solidarity when it was exposed to pressure; in any case, the malleabilityofthe substantial that wassupported bysteel and half and half strands was more noteworthy than that ofthecontrolledcement.

An examination on themechanical attributes of steel fiber concretewascompletedbyVasudevandVishnuram[29]in the year 2013. The consequences of a few exploratory investigations were introduced to break down the way of behaving of tractable and compressive qualities of substantial blends including fluctuating rates of filaments. The substantial blends were M20 and M30, and the fluctuated proportions of filaments went from 0% to 1%, withaugmentationsof0.25percentbetweeneachlevel.As indicated by the investigation of the aftereffects of the tests, the substantial that had been adjusted with steel filaments performed obviously better than the substantial thathadbeenmadewithstandardsteelstrands

Mehul and Patel [4] directed research in 2013 to decide how the characteristics of high-strength concrete were impacted when different rates of polypropylene filaments were utilized. The grade of M40 substantial combination thatcontainspolypropylenefilamentsintheextentsof0.5 percent,1%,and1.5percentseparately.Projectsubstantial exampleswereutilizedintheexaminations,andtheywere put through a progression of tests at different ages to decide how the age of the substantial impacted the tractable, flexural, and compressive qualities. Additionally considered is the impact of the fiber on the plastic shrinkage breaking. The investigation uncovered that every one of the three sorts of solidarity flexural, malleable,andshear hadseencriticaladditions.

Vibhuti and Aravind [30] directed research in 2013 to explore the impacts of adding single and half and half filaments to substantial blends on the subsequent solidified characteristics of the asphalts. The negligible portionofonepercentofsteelfilamentsand0.036percent

of polypropylene strands, individually. Independently, the filamentswereworkedintothesubstantialcombinationat first as single strands, and in this manner they were consolidated to make half and half fiber-supported concrete. Various types of tests, including compressive, flexural, and split elastic qualities, were completed on examples to assess the solidified attributes. The discoveries exhibited that half and half filaments increment strength under pressure to some degree more than mono strands do. This is as opposed to the mono filaments.Whiletheflexuralandsplitelasticqualitieswere fundamentally expanded as an outcome of hybridization, the rigidity generally speaking was not essentially impacted. The improvement in the mechanical properties of HFRC causes a decrease in how much distorting stresses, both present moment and long haul breaking, as well as a general decrease in the thickness of the asphalt. Polypropylene filaments were integrated into concrete by Thirumurugan and Sivakumar [31] in 2013 to direct research on the functionality and mechanical characteristics of the material. They arrived at the resolution that the expansion of polypropylene filaments to concrete diminished its functionality (caused isolation challenges), however that this inconvenience might be alleviated by the utilization of "high reach water decrease Admixtures."Withtheexpansionofpolypropylenestrands, the material's compressive, split malleable, and flexural qualitieswerefundamentallygottentothenextlevel.

Withregardsto enduringmalleablepower,thesubstantial solid asphalt doesn't perform well. Subsequently, cracks show up affected by unobtrusive malleable strains just because. Fundamental supported substantial asphalts utilize a wide assortment of fiber types to essentially increment execution related characteristics. Filaments are open in a large number of structures, lengths, widths, and profundities, and they might be utilized in substantial asphaltseitherseparatelyorsimultaneously(ina halfand half design). Coming up next are the essential discoveries thatcanbegatheredfrombeforeresearch:

The consequences of past examination make obviously half and half filaments are predominantthanmonostrandswith regards toworkingonthecharacteristicsofcement.

The utilization of filaments in a combination works on the properties of both new and solidified concrete, which prompted an expansion in the expense of the construction when contrasted with the utilization of

International Research Journal of Engineering

Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

customarycement.Bethat asitmay,thiscost increment isn't really an issue in light of the fact that the utilization of filaments in a combination likewise worked on the properties of the substantial after it had been solidified.

[1]. Gill S, Maharaj DK. 2015 The behavior of rigid pavement by nonlinear finite element method. Int JLatestResSciTechnol.

Albeit polymeric filaments, for example, polyester and polypropylene have been demonstrated to be financially savvy and impervious to consumption, the mechanical way of behaving of these strands in concrete has been demonstrated to be substandard comparedtothatofsteelfilaments.

[2]. Belekar Yuvaraj, Mullani Irshad. 2015 Effect of Dynamic Load on Rigid Pavement. Int J Eng Res. 4(03)287–90

[3]. AchilleosC,HadjimitsisD,NeocleousK,Pilakoutas K, Neophytou PO, Kallis S. 2011 Proportioning of steelfibrereinforcedconcretemixesforpavement construction and their impact environment and cost.Sustainability3(7)965-983.

It is feasible to reach the determination that the utilization of hybridization in supported substantial asphalt empowers a decrease in thickness of up to 30%, because of an improvement in both the compressive and elasticqualities.

[4]. Mehul J. Patel SMK.2013 Effect of Polypropylene Fibre on The High Strength Concrete. J Information,KnowlResCivEng.2(2):127.

Themostcommon wayofaddingfilamentsto the substantial combination has brought about an expansion in the air voids and air content of the caught air. This has caused a disintegration in the combination's functionality, which thusly has brought on some issues in compacting the blend. The expansion of superplasticizers is an expected answerforthisimperfection.

[5]. Daniel JI, Ahmad SH, Arockiasamy M, Ball HP, Batson GB, Criswell ME, et al. 2002 Report on Fiber Reinforced Concrete Reported by ACI Committee544.V96(Reapproved).

[6]. PrincessRosalineSJ, JayanthiR.2019Influenceof hybrid fibre on the mechanical properties of concrete.IntJEngAdvTechnol.9(1)2637–41.

The consolidation of filaments into the substantial blends promptedanimprovement in the substantial's mechanical attributes, to be specific its compressive strength, split elasticity, and flexural strength. When contrasted with the elasticity, the presence of filaments lessly affects the compressive strength of ordinary strength stringy cement thanitdoesontherigidity.

[7]. Balasubramanian M, Senthilselvan S, Sabarish K V.2016Experimentalinvestigationonstrengthand durability properties of sisal fiber reinforced concrete.IntJChemSci14241–6.

[8]. Ravikumar CS, Ramasamy V, Thandavamoorthy TS.2015Effectoffibersinconcretecomposites.Int JApplEngRes.10(1)419–30

[9]. Rathore H. 2013 Steel Fiber Reinforced Concrete: AnAnalysis.TheInquisitiveMeridian.1(2)1–16.

The utilization of super elite execution fiber supported concrete (UHPFRC) in the retouching and fortifying of built up concrete (RC)individualscameabouttoenhancements inadefinitiveburdenandsolidness,aswellas a decrease in the break width of the underlyingpart.

[10]. Lofgren I. 2005 Fibre-reinforced Concrete for Industrial Construction-a fracture mechanics approach to material testing and structural analysis.ChalmersUniversityofTechnology;

[11]. Naaman AE.1985 Fiber reinforcement for concrete.ConcInt.7(3)21–5.

[12]. Bhalchandra SA, Bajirao PA.2012Performance of steelfiberreinforcedselfcompactingconcrete.Int JComputEngRes)21042–6.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

[13]. Design consideration of steel fiber reinforced concrete (ACI 544.4 R. 88). 1998 ACI Farmington Hills,MI.

[14]. Nipurte O, Patil L, Patil P, Potinda V.2018 Study of Behaviour of Steel Fiber Reinforced Concrete in Deep Beam for Flexure. Int J Scient Res Sci Eng Technol(IJSRSET)4(1):1018-1025

[15]. Qureshi LA, Ahmed A. 2013 An Investigation On Strength Properties Of Glass Fiber Reinforced Concrete.IntJEngResTechnol.2(4).

[16]. Patel PA, Desai AK, Desai JA.2012 Evaluation of Engineering Properties for polypropylene fibre reinforced concrete. Int J Adv Eng Technol. 3(1) 42–5.

[17]. Banthia N, Gupta R. 2004 Hybrid fiber reinforced concrete (HyFRC): Fiber synergy in high strength matrices.MaterStructConstr.37(274)707–16.

[18]. Huang L, Xu L, Chi Y, Xu H. 2015 Experimental investigationon the seismic performance of steelpolypropylene hybrid fiber reinforced concrete columns.ConstrBuildMater.8716–27.

[19]. Pakravan HR, Latifi M, Jamshidi M. 2017 Hybrid short fiber reinforcement system in concrete: A review.ConstrBuildMater142280–94.

[20]. UchidaY,NiwaJ,TanakaY,KatagiriM,FischerG,Li V 2006 Recommendations for Design and Construction of Ultra High Strength Fibre ReinforcedConcreteStructuresJSCE.343-351

[21]. VooYL,FosterSJ.2010Characteristicsofultra-high performance ductile concrete and its impact on sustainable construction. IES J Part A: Civ Struct Eng.3(3)168–87.

[22]. Bentur A, Mindess S. 2006 Fibre reinforced cementitiouscomposites.CrcPress.

[23]. Eswari S Raghunath P.N, and Suguna K. 2008 Ductility performance of Hybrid Fibre Reinforced Concrete..AJAS5(9):1257–62.

[24]. Thanon E, Ramli M .2011 Contribution of Hybrid Fibers on The Hybrid Fibers on the Properties of High Strength Concrete Having High Workability. ProcediaEng14(8)14–20.

[25]. Patodi SC,Kulkarni CV. 2012 Performance evaluation of hybrid fiber reinforced concrete matrix.IntJEngResAppl.2(5)1856–63.

[26]. EmpelmannM,Oettel V.2012UHPFRCboxgirders under torsion. Proceedings of the third international symposium on UHPC and nanotechnology for high performance constructionmaterial.p.517–24.

[27]. Rana A. 2013 Some studies on steel fiber reinforced concrete. Int J Emerg Technol Adv Eng. V3(1):120–7.

[28]. Sekar CC, Ramamoorthy N V.2013 Flexural Behaviour Of Solo And Hybrid Fibre Concrete-A Comparative Study. Int J Eng Res Technol 2(7) 2148–57.

[29]. Vasudev R, Vishnuram BG. 2013 Studies on Steel Fibre Reinforced Concrete - A Sustainable Approach.IntJSciEngRes4(5)1941–4.

[30]. VibhutiRB.2013MechanicalPropertiesofHybrid FiberReinforcedConcreteforPavements.IntJRes EngTechnol.2244-247.

[31]. Thirumurugan S, Sivakumar A.2013 Compressive strength index of crimped polypropylene fibres in highstrengthcementitious matrix. WorldApplSci J.24(6)698–702.

[32]. Sinha D,Mishra CB, Solanki R V.2014 Comparison of normal concrete pavement with steel fiber reinforced concrete pavement. Indian J Appl Res. 4(8)

[33]. Anand S, Pammar L.2016 Experimental Investigation on Hybrid Fiber Reinforced Concrete.IntJInnovaResSciEngTechnol5(9)59–65.

[34]. Kumar Jdc,Abhilash G,Khan Pk, Sai Gm, Ram Vt, Professor -Assistant, et al. 2016 Experimental Studies on Glass Fiber Concrete. Am J Eng Res 5 100–4.A

[35]. Mohammed TJ, Bakar BHA, Bunnori NM. 2016 Torsional improvement of reinforced concrete beams using ultra high-performance fiber reinforced concrete (UHPFC) jackets experimental study. Constr Build Mater. 106 533–42

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page264

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

[36]. Al-OstaMA,IsaMN,BaluchMH,RahmanMK.2017 Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr Build Mater 134 279–96.

[37]. J N, K RB, Patil S, Gutteder VA. 2017 A Study on Hybrid Fiber Reinforced Concrete. Int Res J Eng Technol.4(06)1647–56.

[38]. Jamwal V, Singh P. 2018 Use of glass fiber in pavementqualityconcreteslab.IntJAdvResIdeas InnovTechnol.4(2)1949–54.

[39]. AticsCD,KarahanO.2009Propertiesofsteelfiber reinforced fly ash concrete. Constr Build Mater. 23(1)392–9.

[40]. ErenO,CelikT.1997Effectofsilicafumeandsteel fibers on some properties of high-strength concrete. Construction and Building Materials 11(8)373–82.

[41]. BencardinoF,RizzutiL,SpadeaG,SwamyRN.2008 Stress-strain behavior of steel fiberreinforced concrete in compression. J Mater Civ Eng. 20(3) 255–63.

[42]. Khitab A, Arshad MT, Hussain N, Tariq K, Ali SA, Kazmi SMS, et al. 2013 Concrete reinforced with 0.1 vol% of different synthetic fibers. Life Sci J. 10(12)934–9

[43]. Hossain KMA, Lachemi M, Sammour M, Sonebi M. 2013 Strength and fracture energy characteristics of self-consolidating concrete incorporating polyvinyl alcohol, steel and hybrid fibres. Constr BuildMater.4520–9.

[44]. MirabediniSM,RahimiH,HamedifarS,MohseniM. Microwave irradiation of polypropylene surface: a study on wettability and adhesion. International Journal of Adhesion and Adhesives. 2004;24:163–170.

[45]. Merhej T, Cheng LL, Feng DC. Polypropylene fiber reinforced concrete for rigid airfield pavement. Advanced Materials Research. 2011;228–229:627–633.

[46]. Sounthararajan VM, Thirumrugan S, Sivakumar A. Reinforcing efficiency of crimped profile of

polypropylene fibres on the cementitious matrix. ResearchJournalofAppliedSciences,Engineering andTechnology2013;6:2662–2667.

[47]. GoelP,KumarR,MathurR.Anexperimentalstudy on concrete reinforced with fibrillated fiber. Journal of Scientific and Industrial Research 2012;71:722–726.

[48]. Goel P, Kumar R, Mathur R. Performance of concrete containing polypropylene multifilament fibre vis-a vis fibrillated fibres. Indian Concrete Journal2014;88:16–24.

[49]. He X, Cao Y. Mechanical properties o selfcompacting concrete reinforced with fibrillated polypropylenefiberandtheirrelationship.Journal of Basic Science and Engineering. 2014;22:501–511.

[50]. Krassig HA. Fiber Technology: From Film to Fiber. MarcelDeckerInc.,1984.ISBN:0-8247-7097-8.

[51]. Baczek M, Slusarczyk C, Broda J. Crystalline and lamellar structure of polypropylene fibrillated fibres. Solid State Phenomena. 2013;203–204:439–442.

[52]. Broda J, Przybylo S, Lewandowski S. Selection of optimal formation parameters of polypropylene fibrillated fibres designed for concrete reinforcement.Fibres&TextilesinEasternEurope 2012;20:69–74.

[53]. Mazaheripour H, Ghanbarpour S, Mirmoradi SH, HosseinpourI.Theeffectofpoly‐propylenefibres on the properties of fresh and hardened lightweight self-compacting concrete. Construction and Building Materials 2011;25:351–358.

[54]. Naaman AE, Moavenzadeh F, MaGarry FJ. Probabilistic analysis of fiber reinforced concrete. Journal of Engineering Mechanics 1974;100:397–413

[55]. Richardson AE. Compressive strength of concrete with polypropylene fibre additions. Structural Survey2006;24:138–153.

[56]. Mindess S. Properties of concrete reinforced with fibrillated fibres under impact loading. Cement andConcreteResearch1988;18:109–115.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

[57]. Parveen,SharmaA.Structuralbehaviouroffibrous concrete using polypropylenefibres.International Journal of Modern Engineering Research. 2013;3:1279–1282.

[58]. Aulia TB. Effects of polypropylene fibres on the properties of high-strength concretes. Lacer. 2002;7:43–59.

[59]. Pentalla V. Surface and internal deterioration of concreteduetosalineandnon-salinefreeze–thaw loads. Cement and Concrete Research 2006;36:921–928.

[60]. RichardsonAE.Freeze/thawdurabilityinconcrete with fibre additions. Structural Survey 2003;21:225–233.

[61]. Cavdar A. Investigation of freeze–thaw effects on mechanical properties of fiber reinforced cement mortars.Composites:PartB2014;58:463–472.

[62]. Broda J, Brachaczek W. Influence of the polypropylene fibres geometry on mechanical propertiesofcementmortars.Fibres&Textilesin EasternEurope2015;23:123–129.