International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

1Associate Professor, Department of Civil Engineering, Rajeev Gandhi Memorial College of Engineering and Technology (Autonomous), Nandyal, India 2,3,4,5,6,Student, Department of Civil Engineering, Rajeev Gandhi Memorial College of Engineering and Technology (Autonomous), Nandyal, India ***

Abstract – The use of Self Compacting Concrete (SCC) is increasing day by day in India and many infrastructure projectsaregoinginforSCC,theexamplebeing‘TheSignature

Bridge’ on river Yamuna near New Delhi and the Bandra Worli sea link project, Mumbai The effectofPortland Slag Cement (70%) and GGBS (30%) on compressive strength of different grades of SCC Mix is not investigated as per the literature cited. The present investigation finds the effect of above proportion on compressive strength of SCC Mixes

The modified Nan-Su mix design for application to PSC concrete is used The workability properties Slump Flow, JRing, V- Funnel and L Box values satisfy EFNARC Guidelines. For all grades compressive strength obtained is less than the target mean strength. For M35 and M40 grades compressive strength is less than the characteristiccompressivestrengthof concrete

Key Words: Self Compacting Concrete (SCC), GGBS, Portland Slag Cement, Nan-Su Mix Design, EFNARC Guidelines,SlumpFlowTest,J-RingTest,V-FunnelTestand L-BoxTest.

TheuseofSelfCompactingConcrete(SCC)isincreasingday bydayinIndiaandmanyinfrastructureprojectsaregoingin forSCC,theexamplebeing‘TheSignatureBridge’onriver Yamuna near New Delhi and the Bandra-Worli sea link project,Mumbai.

TheworkabilitypropertiesofSCCcanbecharacterizedby thethreeproperties(EFNARC,2002):fillingability,passing abilityandsegregationresistance.

The modified Nan-Su mix design for application to PSC concreteisused MasterGleniumSKY8233superplasticizer is used. Mix grades M20 to M40 are considered in investigation

ThematerialsusedintheSCCare

i. PortlandSlagCement(JSWcompany)(IS:12089)

ii. GGBS

iii. FineAggregate

iv. CoarseAggregate-12.5mm(70%)and20mm(30%)

v. MasterGleniumSky8233(SuperPlasticizer)

Thepropertiesofmaterialsaredeterminedandareshownin Table 1, 2, & 3 . Table 4 shows the super plasticizer propertiesasgivenbythemanufacturer.

The steps used in Nan-Su Mix Design for M40 Grade are givenbelow.

Step 1: Calculation of Coarse and Fine aggregate contents:

=853.507kg/m3 (1)

=737.587 kg/m3 (2) Where,

Wfa:contentoffineaggregatesinSCC(kg/m3),

Wca :contentofcoarseaggregatesinSCC(kg/m3),

fa:unitvolumeweightoflooselypiledsaturatedsurfacedryfineaggregatesinair(kg/m3),=146550kg/m3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

Cementitious Material Specific Gravity Of Cement

Initial Setting Time Final Setting Time Standard Consistency Soundness of Cement Fineness of Cement

2.935 2hrs22min 8hrs10min 38% 2mm 4% GGBS 2.840 > 600min - 34% - 2% PSC(70%)&GGBS (30%) 2.810 1hrs55min 7hrs31min 36% 3%

PortlandSlag Cement (JSWCompany)

Ranges(For Cement) 3.00–3.15 >30min <10hrs - <10%

Table 2: Properties of Coarse Aggregate (IS: 383-2016)

Properties Size Standard range 20 mm 12.5 mm

SpecificgravityofCoarseAggregate 2.785 2.711 2.5-3.0

BulkDensityofCoarseAggregatetightlypacked(Kg/m3) 15503 1518.5 -

BulkDensityofCoarseAggregatelooselypacked(Kg/m3) 1385.2 1371.4Crushingtest 14.84%

ShapeTests

a)FlakinessTest 13.87% 16.80% <35% b)ElongationTest 14.56% 14.56% <40% ImpactTest 14.05% <35%

Table 3: Properties of Fine Aggregate (IS: 383-2016)

Properties

Property Value Standard range

SpecificGravity 2.75 2.5to3 BulkDensity,(kg/m3)LooselyPacked 14655BulkDensity,(kg/m3)TightlyPacked 1561.5FinenessModulus 3.008(Zone–I) 2.2–2.6(FineSand)

Table 4: Master Glenium Sky 8233(Super Plasticizer)

Properties Test Results of Manufacturer Catalogue Appearance ReddishBrownLiquid pHValue >6 Solubility ReadilySolubleInWater RelativeDensity 1.08+0.02at25oC

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page151

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

ChlorideContent 0% Solid 50+1% Appearance ReddishBrownLiquid

ca:unitvolumeweightoflooselypiledsaturatedsurfacedrycoarseaggregatesinair(kg/m3),=137200kg/m3

PF:packingfactor,theratioofmassofaggregatesoftightly packedstateinSCC tothat oflooselypackedstateinair,= 1.12(Assumed)

:volumeratiooffineaggregates(sand)tototalaggregates, whichrangesfrom50%to57% =52%(Assumed)

Step 2: Calculation of Cement Content: =524.864kg/m3 (3)

Where, C=Cementcontent(kg/m3); f’c =designedcompressivestrength(psi).=6998psi(48.25 MPaTargetMeanStrengthObtainedfromIS:10262-2019)

Step 3: Calculation of mixing water content required by cement: C C W W wc =188.951kg/m3 (4)

Where, Wwc =contentofmixingwatercontentrequiredbycement (kg/m3), = the water/cement ratio by weight = 0.36 (After Trial mixes)

Step 4: Calculation of SP dosage

DosageofSPusedWsp =n%×WC (5) Where, n%=DosageofSP=0.48%(Assumedandfixedaftertrials) Wc=Cementcontentinkg/m3

AmountofwaterinSPWwsp=(1-m%)Wsp=1.260kg/m3 (6) Where, m%=AmountofbindersanditssolidcontentofSPtakenas 50%.

Step 5: Calculation FA and GGBS contents:

=0.034m3 (7)

Where, w =densityofwater, Gca=specificgravityofcoarseaggregates, Gfa=specificgravityoffineaggregates, Gc =specificgravityofCement, Gw =specificgravityofwater, (W/F)=WatertoFlyashratio(Assumed) (W/G)=WatertoGGBSratio(Assumed) Va =aircontentinSCC(%). AsperNansuMixDesigntheformulaforcalculatingWPM is (8)

WhereA%=percentageofFlyAsh(Weightbasis)=0% B%=percentageofGGBS(Weightbasis)=100% But, the modified formula1 (8.a) for calculating WPM is used (8.a)

Where,GG,GF, areobtainedfromtestsand =0.42and =0.42areassumed, A% =0%andB%=100%are assumedandVPF +VPG obtainedfromEq.(7)

WPM = 48.34kg/m3

WF=0%×WPM =0.0kg/m3 (9)

WG=100%×WPM =48.34kg/m3 (10)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

MixingwatercontentrequiredforGGBSpasteisobtained fromEq(12)

WWG= ×WG =17.403kg/m3 (11)

Step 6: Calculation of mixing water content in SCC: The mixing water content required by SCC is the total amountofwaterneededforcement,FAandGGBSinthemix. Therefore,itcanbecalculatedfromEq.(14)

Ww =Wwc +WWG -Wwsp =205.094kg/m3 (12)

Step 7: Calculation of total GGBS used SCC:

WTG=30%xWC+WG =157.46+48.34=205.80kg/m3 (13)

ConcretegradesM20toM40isconsidered,andmixesare designedasperNan-Sumixdesign.Targetmeanstrengthas perIS10262:2019isusedforthemixesinEq.3inplaceof f’c. BasedontrialmixesW/CratioandSPdosageisfixedto satisfy EFNARC guidelines. The SCC mix proportions for differentgradesofconcreteareshowninTable5.

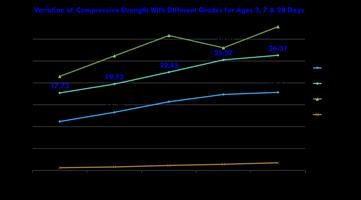

SlumpflowtestandthenJ-Ringtestisconductedinorderby using6litresofconcrete.Vfunneltestisconductedbyusing 14 litres of concrete. L Box test is conducted by using 17 litresofconcrete.Freshpropertiesaredeterminedforthe mixes.TheresultsareasshowinTable6andalsoinFig.1 AllthetestresultsareconformingtoEFNARCguidelinesfor SCC.

Table5:MixDesignofDifferentBrandsofOPC53GradeCement

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

Fig.1:WorkabilityPropertiesofDifferentBrandsofCements

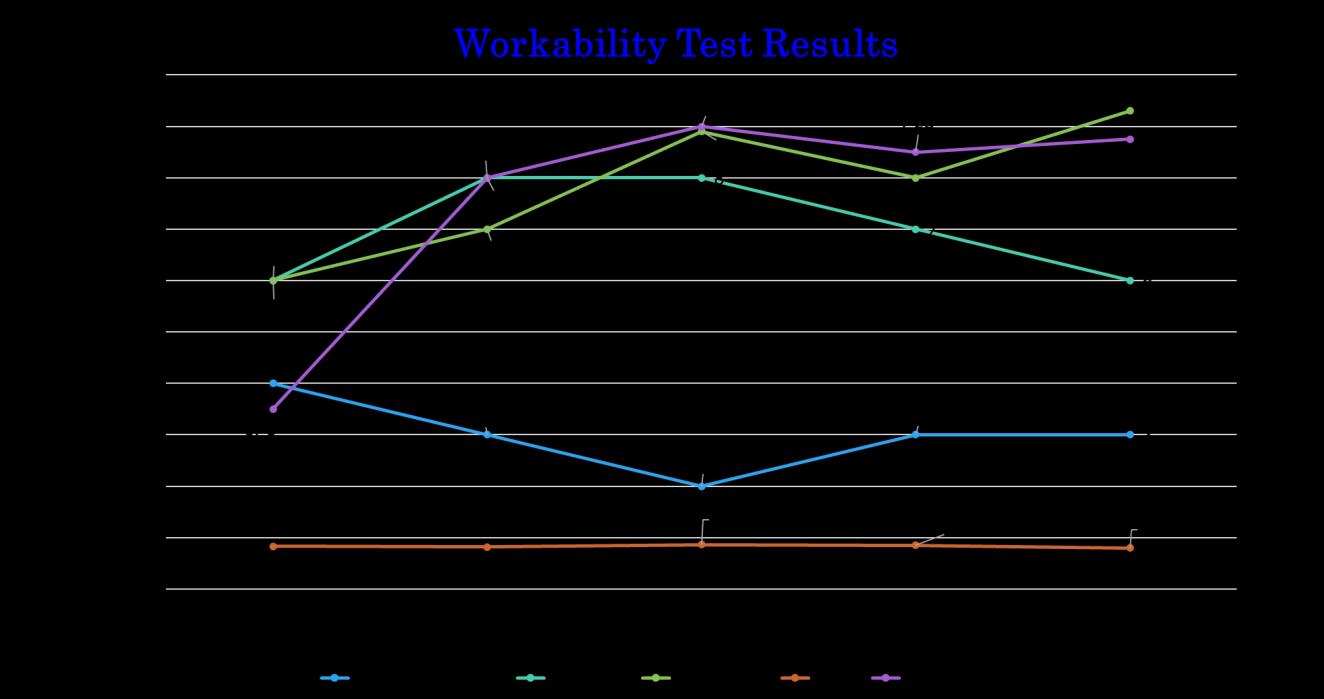

Cubesarecastedforeachmixtodeterminethe3,7and28 days compressive strength. The compressive strength of differentgradesofconcretefor3,7and28dayswithnormal curingisshowninTable7andthevariationofcompressive strength is shown in Fig 2. For all the grades target mean strength is not achieved. For grades M20, M25, M30 characteristiccompressivestrengthisachieved.

Table7:3,7and28DaysCompressiveStrengthof DifferentGradesofSCC

S.N o DifferentGrades of Concrete

CompressiveStrength(N/mm2)

3Days 7Days 28Days

1 M20 11.19 17.73 21.48

2 M25 13.29 19.75 26.20

3 M30 15.73 22.45 30.84

4 M35 17.38 25.27 28.02

5 M40 17.84 26.31 32.87

Fig2.VariationofCompressiveStrengthwithDifferent GradesofSCCforAges3,7&28days

1. ForgradesM20,M25,M30characteristiccompressive strengthisachieved.

2. Forallthegradestargetmeanstrengthisnotachieved (IS:10262-2019).

3. All the workability test results are conforming to EFNARCguidelinesforSCC.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

1. C. Krishnama Raju et. al. (2022) investigated on “Compressive Strength of Different Grades ofSCCMix using Portland Slag Cement (75% ), GGBS(25%) and Replacing 20% Fine Aggregate with Copper Slag” , InternationalResearchJournalofEngineeringand Technology(IRJET),Vol.9,Issue04,April2022pp: 3535-3539,p-ISSN:2397-0072.

2. G. Asif Hussain et.al (2020), “Properties of M60 High Performance Self Compacting Concrete by usingBlendsofDifferentSizesofCoarseAggregate”, National Virtutal Conference on Recent Trends in CivilEngineering-2020(RTCE’20),September2020 pp31-36,ISBN:978-81-942685-2-9.

3. J.VengadeshMarshallRamanet.al.(2017),“Partial Replacement of Cement With GGBS in Self Compacting Concrete for Sustainable Construction” , SSRG International Journal of Civil Engineering,(SSRG-IJCE), Vol. 04, Issue.03, March 2017,ISSN:2348-8352.

4. B. Chandraiah, et. al. (2017) “Variation Of Compressive Strength And Split Tensile Strength Of M40 Self CompactingConcreteWithDifferentSizesOf Coarse Aggregate”, International Journal of Engineering Technology Science and Research (IJETSR), Vol. 4, Issue 8, August 2017, pp.279-285

5. Bhavani, et. al. (2016), ” Effect on Mechanical Properties of M25 SCC with Variation of Class - F Fly Ash & GGBS”. International Journal of ChemTech Research, Vol. 11, No. 07, 2018, pp. 70-77, DOI= http://dx.doi.org/10.20902/IJCTR.2018.110709

6. S. Venkateswara Rao, M.V. Seshagiri Rao, P. Rathish (2010), ”Effect of Size of Aggregate and Fines on Standard and High Strength Self CompactingConcrete”, JournalofAppliedSciences Research,pp.433-442.

7. NanSu,Kung-ChungHsuandHis-WenChai(2001) proposed a ” Simple Mix Design Method for Self Compacting Concrete”JournalofCementConcrete Research , Vol. 31, No. 12, pp. 1799-1807., Dec. 2001.

8. IS:2386(Part-i,Part-iii,Part-iv)-1963, ”Methodsof TestforAggregateforConcrete”.

9. IS:383-2016, ”SpecificationsforFineaggregateand Coarseaggregate”.

10. IS: 10262-2019, ”Concrete Mix ProportioningGuidelines”.

IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal