International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

1Dept.of Mechanical Engineering, Govt. Polytechnic Hubli, Karnataka, India 2 Dept.of Mechanical Engineering, Govt. Polytechnic Gadag, Karnataka, India ***

Abstract - In today’s Indian manufacturing industries, practicing of Total Productive Maintenance (TPM) has been widelyacceptedandimplemented, yetit is stillpossibletofind industries facing maintenancechallenges. The mainobjective of this review paper is to identify the hurdles of TPM implementation and its benefits after the effective implementation of TPM in the Indian manufacturing industries. Total productive maintenance is practical approach that targets maximizing theeffectiveuseoffacilities that are available within an organization. Total productive maintenance builds a well-defined system of productive maintenance, encompassingtheentirelifecycleofequipment, coveringall department in industry, involvingparticipationof all associates from high level to bottom level and promotes small group autonomous activities. During the progressive growthperiodthe companies are exhibitingthecoretechnical progress in plant automation and centralization, which necessitates remarkable amount of human work to maintain the automation systems. The strategy of maintaining the equipments at their highest performing level is most important for the profound results in manufacturing. As the competitive edge in the world market continues to increase thepaceofits progress, ourreviewpaperworkintendstohelp companies tolookforTPMimplementationstrategiesandlook for the possible barriers which other organizations faced during TPM implementation phase, to save on costs, develop employees to face future challenges and bring about a new working culture at their work place.

Key Words: World Class Manufacturing, Total Productive Maintenance, Overall Equipment Effectiveness, 5’s, KAIZEN, KANBAN, JIT.

TPMstandsforTotalProductiveMaintenance,whichisfirst developed in Japan, it is team driven preventive and productive maintenance and involves all levels, from high executive to the floor associates. TPM has exhibited to be successfulinhelpingboosttheproductivityandoverallplant equipment effectiveness [1]. TPM is all about total plant maintenance.TPMisasystematicapproachofmaintenance of equipments which focuses on perfect production by lowering the rejection, proper maintenance and making availabilityofequipmentandleadingtowardzerodefects

Factor value:

Alongwiththisitemphasizesonsaferworkingenvironment withzeroaccidentstoo.Itcanbeconsideredassuitableway toincreasetheperformance of equipments.Itemphasizes inclusive and preventive maintenance in improving the operational efficiency of equipment [2]. TPM initiatives in productionhelpusinstrengtheningthemanufacturingand otherbusinessfunctions,andgettingsustainedprofits The strategic results of TPM implementations in any industry are, noticeable reduction in occurrence of unexpected equipment’sbreakdownsthathindersproductionleadingto losses,whichcancrossbillionofamountannually.Overall plant equipment effectiveness (OEE) methodology incorporatesinputsfromallequipmentmanufacturingstate guidelines into a measurement system that helps manufacturing and operations teams improve equipment performance and, therefore, reduce equipment cost of ownership[4].

TPM implementation has achieved the following objectives.Themostimportantonesarelistedhere.Avoid waste in a rapidly changing economic era Producing the goodswithoutcompromisingtheproductquality.Reduced cost.Producingminimumquantitybatchgoodsattheleast possibletime.Goodsdeliveredinhandscustomersshouldbe free from defective. Involve equipment operators in the simple, day-to-day basics of equipment cleanliness and checkstoimproveemployeeownershipinmaintainingand identifyingequipmentrelatedproblemsquickly[3].

TPMgoalsare,ZeroDefectsProduct-ZerosuddenFailures ofequipmentsandZeroAccidents.

ThebelowmentionedeightPillars&theirdetailsas showninfigure1

1. Focusedimprovement(KobetsuKaizen)-Continuously evensmallstepsofimprovement.

2. Planned Maintenance - It focuses on Increasing Availability of Equipments & reducing Breakdown of Machines.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

3. Initial Control - To establish the system to start the production of newer product & new equipment in a short runuptime.

4. Education & Training - Formation of Autonomous associates who have skill & technique for autonomous maintenance.

5. Autonomous Maintenance (Jishu-Hozen) - It means "Maintainingone'sequipmentbyoneself".

6. Quality in Maintenance (Hinshitsu-Hozen) - Quality Maintenanceisestablishingthemachineconditionthatwill not allow the occurrence of defects & control of such conditionsisrequiredtosustainZeroDefectinproducts.

7. Office TPM - To make an efficient working office that removesthelosses.

8. Safety, Hygiene&Environment - The main role of SHE (Safety,Hygiene&Environment)isto establishtheSafe& healthyworkplacewhereaccidentsdonotoccur[1]

shitsuke sustain Trainandmotivatepeople to follow good housekeeping disciplines autonomously

It is a well-defined process of housekeeping to create a convenient environment at the work place involving the associateswithacommitmenttosincerelyimplementand practice housekeeping regularly. If this 5S is practiced honestly,thenitmay leadto5D.TheyareDelays,Defects, Demoralized associates, Declined profits and Dissatisfied customers[1].

Itisatoolofleanmanufacturingthatstandsonthepillars of successful planning and the proper implementation of activities necessary to produce an end product. The main objectiveistoprovideeachandeveryprocesswithonepart atatime,exactlywhenneedarisesforthatpart,whichisthe principleofJIT.Reducedlotsizes,reducedbuffersizes,and reducedorderleadtimesarehighlightedastheimportant componentsofJIT.Thetraditionallyadopted‘push’(based on forecast demand) system was substituted with a ‘pull’ (basedonactualdemand)systemforgettingasmoothand synchronizedsystem,sothatproductsweretobeproduced atthedesiredtimeandwiththedesiredquantity[25].

TPMstartswith5S. Table -1: Nomenclature Japanese nomenclature English 5s Features seiri sort Segregate unnecessary itemsfromtheworkplace anddiscardthem seiton Set in order Arrange all necessary things in good order and in sequence so that, can beeasilypickedupforuse seisio Shine Clean the work place to makeitfreefromdust seiketsu standardize Maintainhighstandardof housekeeping practice andworkplace

A word Kaizen in Japanese is used for continuous improvement.Identifying,focusingandremovingthewastes in machinery, operator or production methods refer to kaizeninmanufacturingcompanies.TheJITapproachcanbe further moulded in an approach that is called continuous improvement or kaizen approach. Where kai stands for change and zen stands for better. So, kaizen means ‘to changecontinuouslyforthebettermentofeachindividual andeverysystemwithintheorganization.Thekaizensystem approachhasbeenutilizedtoremoveproblemsstepbystep by the collection of data, the analysis of root causes, the discovery and selection of one best solution from various available solutions, implementation and proper documentation.Thevariousbenefitsexperiencedbythem after adopting kaizen were the complete elimination of wastessuchaslackofquality,rejection,reworkofproducts andaremarkableamountofexpensesweresaved[25].

Kanban refers to parts-movement system in which materialmovesbetweenworkstationsinaplantproduction linebasedoncards.Asuppliershouldonlydeliverpartsto theproductionlineasandwhentheyarerequired,sothat there is no storage of parts in the plant production area, whichisthebasicneedforKanbansystem.Astatemapwas preparedandanalysedinordertonotedownthecycletime

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page139

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

ofvariousactivitiesinvolvedintheplantproductionofthe component. It is clearly noticed that a push system was usually adopted in manufacturing lines, which was a big issue for the assembly line process. A kanban system was generated to replace the push system with a pull system. Remarkableamountofworkwhichisinprocessinventories, lowervalue-addedtimeweremajordrawbackswhichhad been noticed during initial analysis stage. The kanban systemplayedapivotroleinmakingabetterproductflow [25]

Direct benefits of TPM encompasses, productivity and increasedoverallplantefficiency -Reducedmanufacturing cost -Reduced accidents-Rectifies customer complaintsSatisfies customer’s needs to a great extent-Follows pollution control measures-Improves product qualityIncreasesconsistency[5].IndirectbenefitsofTPMincludes, increases the confidence level among the associatesWorkersfeelownershiptowardsthemachine-Workplaceis alwaysneat,cleanandattractive-Attitudeoftheassociates is changed towards company-Knowledge and experiences aresharedamongalltheassociates-Alltheassociateswork together to achieve organizational goals and horizontal deployment of a new concept in all departments of the organization[5].

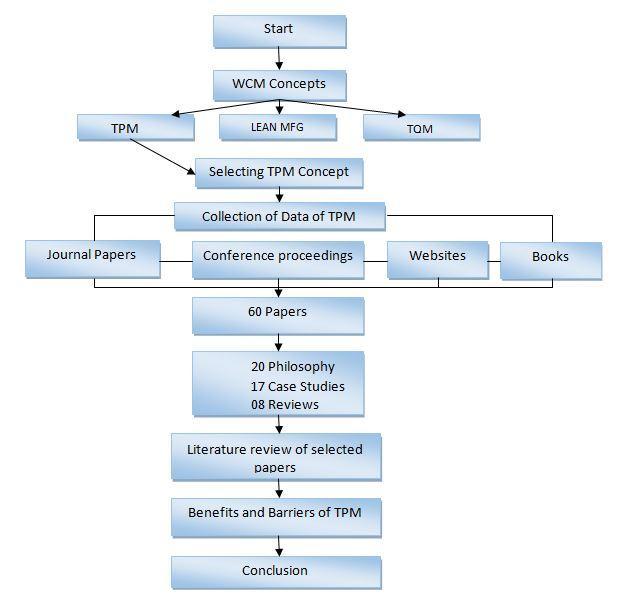

This review paper systematic literature review has been followed Fig -2:Methodology

Thesourceforliteratureisfromleadingjournalpapersfrom various publications and conference proceedings. At the startsomebooksandwebsitesandclassroomlecturingwere helpful in understanding total productive maintenance approach. This review paper would help in inclusive understandingofthetotalproductivemaintenancepractices in manufacturing organizations and the challenges which organizations will encounter during introducing and implementationofthetotalproductivemaintenancewithin theorganization.

Atthebeginning60papershavebeencollectedandlateron a systematic segregation of the paper is done. Different categories of papers as Case study related papers, review papers, TPM philosophy papers is done.17 papers listed undercasestudyand08paperslistedunderreviewpapers 20papersunderphilosophy.Papersselectedforthereview have been studied and author’s findings and issues are summarized.Methodologyisdepictedinfigure2

Selected papers have been put into three sections as TPM philosophy,reviewsandcasestudies.

Totalproductivemaintenancestoodasoneofthebesttools for makingourindustries competitiveand effective, inthe fieldofmaintenence.TPMmaybetheonemajorthingthat clearlydistinguishsuccessandfailureforcompaniesasfaras maintenanceisconcerned.

M Ranjeet, Jadhav M, Mr.Morosin Alessandro, Prof.S.H. Sawant,[1]concludedthatthemainbeneficialobjectiveisto understandTPMprincipleandtobringtheawarenessamong the younger technocrats and enterprises about TPM philosophy adoption. S. Vigneshwaram, M. Maran, G.Manikandan [2] stated about tangible and intangible benefits attained after TPM implementation. It is clearly observed that the direct benefits such as availability, performance,efficiencyandrateofqualityincreaselargely upon TPM implementation which benifitted in the improvementofOEE.NotablyTPMimplementationenhances themoraleofemployeesandtheirlevel ofself-confidence. Cleanandimpressiveworkenvironmentismaintainedafter theTPMimplementation.

SuchisnataPradhani,Prof.AjitSenapati[6]intheirstudy foundthatTPMisnotaquick-fixsolution.Itrequireschange inboththecompany’sandworkersattitude,andtheirvalues, whichtakestimetobringabout.Hence,itnecessitateslongtermplanning.Organizationwidequickbenefitsshouldnot bestressedduringtheinitialstageofimplementation.TPMis notaradicallynewconcept,itissimplythenextstepinthe development of good maintenance practices. TPM is one conceptneedtofocustosustainjust-in-timeoperations.TPM facilitates positively the organizations in improving the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

coordination between maintenance department and other production activities, resulting in removing defects, improving manufacturing process reliability, improving overallequipmenteffectiveness,andreducingcosts,thereby improvingsustainability effortsofanorganisationtomeet globalcompetitionforbusinessexcellence.

I.P.SAhujaandJ.SKhamba [4]clearly revealedthatthe successfulimplementationofTPMpracticecanfacilitatethe manufacturing firms thirst for achieving enhanced manufacturing performance leading to competitive advantage.

Amit Kumar Gupta, Dr. R. K. Garg [24] in their study concludedthatTPMrevealsitsimportancebetweengrowth andfailureforfewcompanies,ithasbeenproventobeatool thatreallyworks.Abhishekjain,RajbhirBhatti,Harwinder singh[5]concludedthatpracticeofTPMisnecessitatedthirst inIndianmanufacturingindustries,notablyinSMEs.Mostof thelarge-scaleindustrieshaveimplementedTPMbuttheir existlimitationin SMEs. Hence, it’sthe need to implement TPMtogetbenefittedinquality,productionrate,equipment availabilityandtolowerthecostofequipmentmaintenance andbreakdown.

Panchali singh[3] in his study concluded that efficient TPM implementation initiative highlights maintenance related issues The pillars of TPM helps in effective TPM implementation and helps to improve overall OEE. TPM succeeds only when all employees at all levels remain committed towards bringing the much-needed cultural change within an organization. TPM also focuses on, to providethemuch-neededtrainingandregularanalysisofthe success or failure of the consequent initiatives of improvementsunderconsideration

Melesse W.Wakjira and et al [26] have studied and analyzedissuesintheimplementingTPM,andthebenefits gained from OEE as an outcome of TPM practice. As an outcome of this overall productivity of industry also increased.OEEvalueisencouragingandwiththepassageof timeresultswillbequitegoodandmayreachaworldclass OEE value of higher percentage Focused TPM practice improved quality issues, reduced the cost and equipment deteriorationandfailures.Assuredautonomousmaintenance activities were followed by all associates with honest participation.Theinvestmentmadeintrainingandeducation helped to boost workers morale and the commitment towardsorganization’slong-termgoals.

SarangG.Katkamwarandetal[27]havecarriedoutstudy in medium scale industry producing cotton spinning. The TPMimplementationpracticehasbeensuggestedtoimprove equipmentavailability,efficientperformanceandtherateof quality, which brought tremendous improvement in OEE TheirstudyutilizedmethodofSeethrough,JH-Checksheet, PM-Checksheet,singlePointLessons,empiricalmethodand inclusivewhichresultedinproperimplementationofTPM.

Post implementation of TPM showed both tangible and intangiblebenefitsforequipmentaswellasforemployees. TPMensuresequipmentavailability,increasedperformance, rateofquality,henceOEEisachieved

Abhijit Gosav [28] and others have developed mathematicallysoundmodels,basedonrenewaltheoryfor TPM. There is a need to point out that models were developed for optimizing mean and variance combination, whichcouldbeadoptedeasilyforcombiningmeanandthe standarddeviation,whichhavethesameunits.Therenewal theory model was motivated by an industrial need for a model that quantifies risk in tractable units. The recorded results showed reduction in unexpected machine breakdowns that improved production rate and hence reducedannualcostofmaintenance.

Thissectionemphasizesonthefactssuchasprinciples, factorsforsuccess,implementationmethods,andapproaches oftotalproductivemaintenance.

C.C.Shen [13] pointed successful key factors of TPM in enterprises. He points out TPM is getting implemented gradually over the years stage wise as preparatory; commencement;implementationandrealizationstage.The successfulkeyfactorsascommitmentofmanagers,overall employee involvement, technical related training to operators, management plans, motivation of employees, launchof5’sarenecessaryforimplementationofTPM.Asa resultheintendsmostofthefactorsfocusedoncommitment and involvement of management and overall employee involvement.

F.De.FeliceandA.Petrillo[11]intheirstudyrevealedthat practicesofTPM,TQM,Lean,fetchesorganizationworldclass recognitionandhighlightstheissueofcompetitiveadvantage in the global market to provide the product or services at lowest possible cost with an acceptable lead time. This practice encompasses all plant process from safety to environmentandfrommaintenancetologistics,quality.The objective lies at achieving zero waste. World class best manufacturing practices brings employees a culture to identify emerging problems and get involved and brings culturalchangealso.

KamranS,SeyedAhmadY[10]foundthattosustainin trulycompetitiveworldofbusiness,itisnecessarytodeliver the product ofhighest quality in least possible time foran acceptable cost, so to achieve this machine maintenance strategyhastobeimplementedpositively.Theydeveloped modelthroughsystemthinkingapproachwhichshowedTPM isareliablestrategy.Thisreducesissuesrelatedtomachine breakdownmaintenanceandenhancesmachinereliability, productandprocessqualityaswell.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

H.Yamashina[8]pointsoutthatfirststep-inworld-class manufacturingfocusesonTPMimplementationsuccessfully andcreateactiveorganizationbybringingthetotalemployee involvementcultureandtrainingtheemployeeswhichhelps to identify the potential problems and find the solution themselves. It needs continuous improvement culture. AuthoralsofindsproblemsduringTPMimplementation,as resistancefromemployees,lackofcommitmentoftop-level management, risk of losing the trained persons. So, organizations have to tackle the issues to start journey to WCM.

RajeshPrasadM.andetal[9]developedanewframework of world class maintenance where they considered the strategiesrelatedtototalqualitycontrol,justintime,total productivemaintenance;concurrentengineeringmakingit clearthatmaintenancebringsworld-classstatus.

Rajesh P. Mishra and et al [12] discuss that implementationofmaintenancesystemisnecessarytohavea competitiveadvantageoveritscompetitors.TPMapproachis best way to get better results. They established the corelationamongtheelementsofmaintenanceasaframework throughinterpretivestructuremodellingwhichhasstagesof planning, organizing, controlling through identifying the relationship among the specific item so that organizations basedontheiruniquenesscanadoptitintheirownwayto defineandfindthesolutiontotheproblems.

Kathleen E and et al [7] in their work investigate relationship existing between TPM and performance in manufacturingthroughstructuralequationmodelling,where TPMhaspositiveandsignificantrelationshipwithlowcost, highquality,strongdeliveryperformance,whereithelpsto control manufacturing cost. World class manufacturing approach,justintime,totalqualitycontrol,TPMshouldnot be evaluated in isolation, as all have correlation and have positiveeffectonmanufacturingperformance.

Hugo Pinto and et al [14] stated that gaining the competitive edge among its competitors is one of the strategiestosurvive.Thisway,TotalProductiveMaintenance Model provides the development such as autonomous maintenance. The method exhibits the different tools, in order to seek operator’s commitment to maintain optimal conditionsforproductionandequipmentperformance.The TPMpracticepromotedtheinteractionofoperatorswiththe equipment,providingcontinualattentioninidentifyingand anticipatingproblemsresultinginthereductionoffailures, breakdowns and quality defects. The practice of a culture promotingasenseofpsychological ownershipensuresthe involvement of workers and brings increased levels of productivity.

Taufik Djatna, Imam Muharram Alitu [15] pointed that slowmanagerialdecisionmakingisthebigchallengeinTPM

implementation in the manufacturing industry. In their focusedstudyonwoodendoormanufacturingindustryTPM implementation resulted in increased Overall Equipment Effectiveness Dataminingtechniqueswereutilisedtosolve real time problem especially in machine maintenance in a targetedmoldingmachine.TheOEEcalculationofmolding machine shows a machine availability loss due to low effectivenesscausedbyhighsetupandadjustmentloss.

Amit Kumar Gupta, Dr. R K. Garg [16] studied effect of TPMimplementationinanautomobileindustry.Theirstudy revealstheconceptstoincreasetheproductivityintermsof OEE. Before TPM implementation availability was 80%, Efficiency 76.9%, Quality 95.5% and after TPM implementation availability raised to 85.1%, Efficiency to 83.1%,Qualityto99%.

Soraphon Kigsirisin, Sirawit Pussawiroa, Onurai Noohawm[17]intheircasestudy ofwatertreatingplants foundfrequentbreakdownofequipmentandlossofwater during production.By adopting 8 pillar techniques & TPM concepts both aforesaid problems were reduced which enhanced OEE .The operators skills also enhanced in all departmentsincludingmaintenance

DineshSeth&DeepakTripathi[18]havepointed,Total QualityManagementandTotalProductiveMaintenancehave attained considerable acceptance in Indian manufacturing industrytotakeonthechallengeoftransitionfromdomestic economy to global competition. The implenting results provide evidences of effectiveness of TQM and TPM in improvingperformanceofbusinessinIndianmanufacturing industry, both in terms of profitability and operational parameters.Thisisindicatedbothinthecasewhentheseare used individuallyas well assimultaneouslyasa combined approach.

Bupe.G.Mwanza,CharlesMbohwa[19]haveestablished TPMmodeltobringchangeinthemaintenancepracticeata chemicalproducingcompany.Theresearcherssetobjectives tostudythecurrentmaintenancesystem,tofindtheoverall equipment effectiveness, key performance indicators and successfactorsofTPM.Requiredrelevantdatawasgathered usingsetquestionnaires,interviews,directobservationsand availablerecordsofcompany.Theresultscamemultifolded by reviewing overall equipment effectiveness Equipment downtime was a principle issue of plant under utilization with52%ofitduetoshortageofspares,32%duetoshortage of raw materials, 8% because of power failures and 8% others.Amongemployeesofcompany70.5%wereawareoff TPMconceptsand14.7%notsure.29.5%oftheemployees were unaware of TPM with 64.3% not sure that the TPM conceptcanhelpimprovethecurrentmaintenancesystem. Based on these results, they found that knowledge and informationsharing,operatorinvolvementandtrainingare the added advantages. Later they designed a TPM model which could bring effective implementation of TPM in growing dynamic business environment. Adoption of TPM

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

can reduce losses and reduce rework to or below the acceptable marks. The research therefore concluded that TPMcanbeusedasatooltoimproveOEEoftheorganization.

Rajeshchoudharyandetal[20]intheirstudyrevealsthe advantages of TPM implementation An organizational behaviourin the Indian process industry is inthe thirstto gainworld-classcompetitivenessandsustainability.TPMis morefocusedinbridgingthegap between productionand maintenancefunctionsthroughbestworkingpractices,team work,and continuous improvement. As whole TPM brings motivation, self-commitment and competency among the employeesofthecompany.

RanteshwarS,AshishMG,D BShah,SanjayDesai[21]in their investigation for a company producing automotive componentfocusedonTPMconceptimplementation.OEEis usedas measure for outcome of TPM implementation in machine shop having CNC turning centers of different capacity.Authorpointedoutthatqualityandmaintenanceof manufacturing systems areclosely related functions. Total ProductiveMaintenanceandTotalQualityManagementalong withotherconceptstoachieveWorldClassManufacturing system.OEEhasimprovedfrom63%to79%indicatingthe positivechangeinproductivityandimprovementinquality ofproduct.

F.T.S.Chan,andetal[22]suggestedthat,Totalproductive maintenance is a methodology that focus to increase the availabilityofexistingequipmenthencereducingtheneedof additional capital investment. Investment in training the employeescanfurtherresultinhighequipmentutilization, higherproductqualityandreducedlabourcosts. After the implementation of TPM model machine, both direct and indirect benefits were obtained for equipment as well as employees.Theproductivityofequipmentincreasedto83%. These indirect benefits resulted from cultural change in company, coordination between maintenance, production andqualitydepartments.

PanagiotisTsarouhas[23]suggestedadoptingthetotal productivemaintenanceinthefoodindustryoverthespanof five years increases the profitability TPM implementation enhanced the rate of production via reduced downtime of equipment, product quality and provides healthy and safe workplaceviaincreaseinattendanceofoperators.

TPMisteam-basedapproachneedsactiveparticipationfrom allateachlevelwithinanorganizationwhichleadstowards safeworkingenvironmentleadingtozerodefectinproducts andzeroaccidentsandunexpectedequipmentbreakdowns and failures hence enhanced OEE. TPM implementation makestheindustriescompetitiveinthefieldofmaintenance andplayscrucialroleindecidingthesuccessandfailureof theorganization.TPMimplementationincreasesmoraleand confidenceofemployeeatalllevelsasclean-safe-attractive

workplaceismaintained.TPMrequireslongtermplanning and at initial phase of implementation no one should be stressed.Itfocusesonregulartrainingandcommitmentand analysisofbothsuccessandfailureoftheinitiativesforthe improvement under consideration. Organisations have to tackletheresistanceofemployeesinimplementingTPMand lackofcommitmentoftoplevelmanagement.TPMhelpsthe Indian organizations to compete globally by enriching its qualityofproducts-workculture-satisfiedandwell-trained humanresource-reliableequipmentswhichwouldrenderin producingdefectfreeproductsandmaintenancefreeplant

[1] M Ranjeet, M. Jadhav, Mr. Morosin Alessandro, Prof.S.H.Sawant,(2012)“TotalProductive Maintenance TheoreticalAspect:AJourneyTowardsManufacturing Excellence”, IOSR journal of mechanical and civil engineeringISSN:2278-1684,PP:51-59.

[2] S. Vigneshwaram, M.Maran, G.Manikandan(2015) “ImpactofTPMImplementation:LiteratureReviewand direction IJISET - International Journal of Innovative Science, Engineering & Technology, Vol. 2 Issue 12, December2015.ISSN2348-7968.

[3] Panchalisingh(2017)“TotalProductiveMaintenance-a Tool for World Class Manufacturing” International Journal of Advanced Production and Industrial EngineeringIJAPIE-SI-OSCMPP70620–23.

[4] I.P.S Ahuja and J.S Khamba (2008) “Total productive maintenance- literature review and directions” International Journal of Quality & Reliability Management,Vol.25Iss7PP.709–756.

[5] Abhishekjain,Rajbhirbhatti,Harwindersingh(2014) “Totalproductivemaintenance(TPM)implementation practice-Aliteraturereviewanddirections”IJLSS

[6] Suchisnata Pradhani, Prof. Ajit Senapati (2014) “A review on implementation of TPM in manufacturing industry”Internationaljournalofmodernengineering research(IJMER)ISSN:2249-6645Vol4,nov2014.

[7] Kathleen E Mckone, Roger G. schroeder,Kristy Cua(1999)“Theimpactoftotalproductivemaintenance practices on manufacturing performance” Journal of operationsmanagementVol19,2001PP39-58.

[8] H Yamashina (2000) “Challenges to world class manufacturing” Internationl journal of quality and reliabilitymanagementVol17,2000PP132-143.

[9] Rajesh Prasad G. Anand, Rambabu Kodali(2006) “Development of a framework for world class maintenance system” Journal of advanced manufacturingsystemsVol5,2006PP141-165.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

[10] Kamran Shahanagli, Seyed Ahmed Yazdian(2009) “Analyzing the effects of implementation of total productive maintenance in the manufacturing companies:asystemdynamicapproach”Worldjournal ofmodellingandsimulationVol5,2009PP120-129.

[11] FDe.Felice A. Petrillo (2015) “optimization of manufacturing system through world class manufacturing”IFAConlinepappers48-3,2015PP741746.

[12] RajeshMishra, Rambabu Kodali,Gajanand Gupta,Nidhi Mundra(2015) “Development of framework for implementationofWMSusingISMapproach”Procedia CIRP26,2015PP424-429

[13] C.CShen(2015)“Discussiononkeysuccessfulfactorsof TPM enterprise” Journal of applied research and technologyVol.13,2015PP425-427.

[14] Hugointo,CarinaPimentelandMadalenacunha(2016) “Imlication of total productive maintenance in psychological sense of ownership” Procedia-social behaviouralsciences,2016PP1076-1082

[15] Taufik Djatna, Imam Muharram Alitu (2015)” An applicationofassociationruleminingintotalproductive maintenance strategy: an analysis and modeling in wooden door manufacturing industry”, Procedia Manufacturing4(2015)336–343

[16] Amit Kumar Gupta, Dr. R. K. Garg (oct 2012) “OEE ImprovementbyTPMImplementation:ACaseStudy” , International Journal of IT, Engineering and Applied SciencesResearch(IJIEASR)ISSN:2319-4413Volume1, No. 1, October 2012 Soraphon Kigsirisin, Sirawit Pussawiroa,OnuraiNoohawm(2016)

[17] Soraphon Kigsirisin, Sirawit Pussawiroa, Onurai Noohawm (2016) “Approach for Total Productive MaintenanceEvaluationinWaterProductivity:ACase StudyatMahasawatWaterTreatmentPlant”,Procedia Engineering154(2016)260–267

[18] DINESHSETH_&DEEPAKTRIPATHI(2006)”ACritical Study of TQM and TPM Approaches on Business PerformanceofIndianManufacturingIndustry”,Vol.17, No.7,811–824,September2006

[19] Bupe.G.Mwanza,CharlesMbohwa(2015),“Designofa total productive maintenance model for effective implementation:Casestudyofachemicalmanufacturing company ”,ProcediaManufacturing4(2015)461–470

[20] Inderpreet singh Ahuja, dr. J. S. khamba, Rajesh Choudhary(2006)“Improvedorganizationalbehavior through strategic total productive maintenance implementation”,proceedingsofimece20062006asme

International Mechanical Engineering Congress and ExpositionNovember5-10,2006,Chicago,Illinois,USA

[21] Ranteshwar Singh, Ashish M Gohil, Dhaval B Shah, SanjayDesai(2013),“TotalProductive Maintenance (TPM) Implementation in a Machine Shop: A Case Study”,ProcediaEngineering51(2013)592–599

[22] F.T.S.Chan,H.C.W.Laub,R.W.L.Ipc,H.K.Chana,S.Konga and et al (2005),” Implementation of total productive maintenance:Acasestudy”,Int.J.ProductionEconomics 95(2005)71–94

[23] PanagiotisTsarouhas(2007)“Implementationoftotal productive maintenance in food industry: a case study”, Journal of Quality in Maintenance Engineering Vol.13No.1,2007pp.5-18

[24] Amit Kumar Gupta, Dr. R. K. Garg (2012) “OEE ImprovementbyTPMImplementation:ACaseStudy”, International Journal of IT, Engineering and Applied SciencesResearch(IJIEASR),ISSN:2319-4413,Volume1, No.1,October2012.

[25] ShamanGupta&SanjivKumarJain(2013)“Aliterature reviewofleanmanufacturing”InternationalJournalof ManagementScienceandEngineeringManagement,Vol. 8,No.4,241–249.

[26] MelesseWorknehWakjira,AjitPalSingh(2012)“Total ProductiveMaintenance:ACaseStudyinManufacturing Industry” Global Journal of researches in engineering Industrialengineering0975-5861.

[27] SarangG.Katkamwar,SadashivK.Wadatkar,RavikantV. Paropate (2013) “Study of Total Productive Maintenance&ItsImplementingApproachinSpinning Industries”InternationalJournalofEngineeringTrends andTechnology(IJETT)Volume4Issue5.

[28] AbhijitGosav(2006)“Arisksensitivetototalproductive maintenance”Automatica42(2006)1321-1330.

[29] Fangjuan,zenghongli,Maojunjie,Chendu(2011)“An improved load balancing algorithm of multi TPM” Procediaengineeringvol3356-3360.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page144