Review of Inventory Management System to Ensure the Optimization of Resources

Miss. Sneha Ramesh Menkar1 , Asst. Prof. S.S.Chavan2 ,

Miss. Sneha Ramesh Menkar1 , Asst. Prof. S.S.Chavan2 ,

1PG Scholar, Department of Civil Engineering, Tatyasaheb Kore Institute of Engineering and Technology, Warananagar, India

2Asst. Prof. Department of Civil Engineering, Tatyasaheb Kore Institute of Engineering and Technology, Warananagar, India ***

Abstract - The inventory management system includes procedures for construction, transportation, identification, storage, and retrieval. Each has an unbreakableconnectionto productivity, schedule performance, and safety. Our study's primary objective is to examine the inventory management practices used and the efficient use of inventory at the construction site. One of the most utilized methods for classifying inventories and gathering data for a case study on a company is ABC analysis. The model is able to deal withboth uncertain demand and supply. These results may primarily reflect the key elements that will have an impact on the inventory management system that can result in improved project management effectiveness&decreasedmaterialwaste in the relevant construction industry region.

Key Words: ABC analysis, efficiency, Inventory management

1. INTRODUCTION

An effective and efficient organization depends on excellent inventory management. Additionally, it plays a crucialroleinthemanagementofmaterialsanditemsthat must be stored for later use, whether that is during manufacturingorlaterexchangeactivities,dependingonthe circumstance,forgoodsandservices.Themainobjectiveof inventory management is to strike a balance between competing economic interests and not hold too much inventory. In order to prevent costs like storage, spoilage, theft, and obsolescence from occurring as a result, capital must be secured. Additionally, there is a need to make products and services available when and where they are neededinordertoavoidtheassociatedcosts.Thepresenceof excessive or inadequate volumes of inventory can lead to businessfailure.Acompany'sprofitandreturnontotalassets can both be significantly boosted by excellent inventory management, one might conclude. Thus, inventory management is the term used suitably to describe the management ofthiseconomics ofinvestment.As the main componentontheassetsideofthebalancesheetformany businesses,inventorymanagementisthesubjectofincreased focus.

2. RESEARCH METHODOLOGY

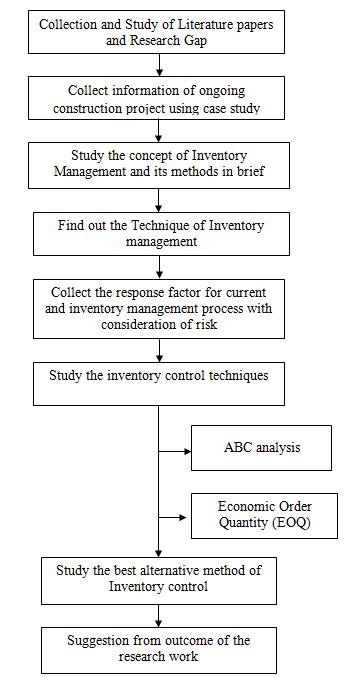

Thefollowingmethodologywillbeadopted-

Examine historical writings to determine where project management practices currently stand in comparisontooneanother.

Gathering data on the ongoing construction site development, including cost data, processing, maintenance, and storage procedures used in construction.

Identify the different inventory management techniquesinconstructionindustry.

Study the inventory control techniques in ABC analysisandEOQmodelininventorymanagement.

Developbestalternativemethod.

3. LITERATURE REVIEW

Khyomesh V. Patel, Prof. Chetna M. Vyas, [1]

Thisresearchaimstofillthevacuumleftbypoormaterials management on construction sites. Running a productive and economical construction site depends on excellent material management. According to studies, the price of buildingequipmentandmaterialsmaymakeupmorethan 70%ofthetotalcostofatypicalconstructionproject. The productivity,costeffectiveness,andon-timethecompletion ofaprojectcanallbeimprovedbypropermanagementof this one key component. One of the major problems that contributes to the delay of construction projects is poor management of the equipment and supplies. The main findingsofastudythatexaminedthematerialmanagement methods used by three well-known Ahmedabadi constructorsarecoveredinthisessay

Lukasz Rzepecki, [3]Thestudyprovidesasystemthatwould allowabusinessitwasoperatingsimultaneouslyonseveral constructionsitesfigureoutandassessthecostsrelatedto inventorymanagement.Itisnowpossibletodeterminethe lowestlogisticalexpenseswiththefuturesupplyschedule arrangementsthankstothe developmentof mathematical models that mimic the functioning of supply logistics systems (delivery volumes in subsequent periods of the projectexecution).Basedonthis,theoptimumsupplychain managementoptionwillbe selected.Todemonstratehow theofferedcontrolcanbeappliedinpractice,anexampleis provided.

Lansford C. Bell and George Stukhart, Members, ASCE, [4] Expertsintheconstructionsectorarebeginningtorecognise how crucial it is to focus on the materials management process as a proactive, observable entity that greatly influences construction costs. Recent years have seen the development of integrated raw material management solutions(MMS),alsoreferredtoas"totalconcept"systems, by the construction industry. These systems combine and integrate the operations for takeoff, vendor evaluation, purchasing, expediting, warehousing, and dissemination. Measurable increases in employment levels, a decrease in the surplus of bulk materials, a disappearance of the requirement for materials top managers, and cash flow savings are all outcomes of these materials management software.Althoughthecostsofdesigningandimplementing these systems can be high, the benefits far outweigh the disadvantages,especiallywhenartisansusethesystemsto scheduletheirworkaroundtheavailabilityofbulksupplies.

Monika Ramdas Nanaware, Prof. U. R. Saharkar, [2] The basic elements of construction material management, the role of inventory management in material management, inventory processes, inventory control systems, key performanceindicatorsofinventorymanagementsystems, inventory models, and inventory optimization are all covered in the paper, with a focus on the necessity of

material resource planning to maintain just-in-time inventories. Financial analysis of the effective use of inventory models in material management is offered in detailintheproject'sclosingsection,whichdealswiththe ABCandEOQAnalysisoftheConstructionCompany.

Olowolaju Monisola,[5]Inventoryisavitalasset,necessary for effective operation of any business organization. The absence of good inventory management practices in the Small and Medium Scale Industrial Enterprises (SMEs) necessitatesastudytodeterminetheactualreasonsfornon applicationofscientificinventorymanagementtechniquesin theSMEs.ThreehundredandtwentySMEsinFood,Textiles, and Wood and Metal Products sectors in South Western Nigeriawereselectedforthestudy.Twohundredandtwelve organizationsreturnedthe questionnaire.Itisestablished thatnonusageofscientificinventorytechniquesforbetter inventorydecisionwasduetolackofskilledpersonneland inadequatedatatouseinventorymodels;andlowlevel of ICT in the SMEs. It is recommended that the SMEs should institute structure to improve the knowledge of their personnel about using quantitative inventory decision models and the SMEs should make the application of Information Communication Technology (ICT) for data managementapriority

Prof. A. N. Eze, Uchenu, Chimezie Adamma, [6]Thepurpose of the author's study was to determine how much the managersandaccountantsofSMSEsinAnambraStateused inventorymanagementstrategies.Thestudywasledbytwo researchquestions,andtwonullhypotheseswereevaluated atthe0.05level ofsignificance.Thesurveyalsoshoweda substantialvariationintheaverageevaluationsofmanagers and accountants of SMSEs in Anambra for the use of inventorymanagementtechniques.Theinvestigationcame totheconclusionthatSMSEmanagersandaccountantsdid not use inventory management procedures to their full potential, which stunted their growth and slowed their development.

Pamela C. Nolz, [7]Inthisarticle,welookatthechallengeof creating a logistics system that will guarantee effective urban construction operations for a cutting-edge urban building region in Vienna. In order to maximize resource efficiencyandminimizetrafficassociatedwithconstruction operations, we address the difficulties of organising personnelandthetimelydeliveryandstorageofmaterial. Tactic and operational construction logistics planning are both included in the formulation of the problem, which is presented as a hierarchical optimization problem. On a weekly basis, a timetable of activities for various construction phases and the accompanying material transportsandstoragedecisionsareoptimised,whileonthe operational level, the daily optimization of material transports modeledasaninventoryroutingproblem is addressed.Amixed-integerprogrammingformulationofthe problemoneachplanninglevelisprovidedandsolvedusing CPLEX. The suggested approach is tested on realistic data

from the city of Vienna. The results linked with different scenariosareanalyzedtoillustratethevalueoftheproposed approachforthedesignofconstructionlogisticsprocesses.

4. DATA COLLECTION AND ANALYSIS

Atotalof30respondentswereaskedtoratethevariableon a5-pointscale,withstrongagreementbeingthehighestand strongly disagreeing being the lowest. Additionally, by speaking with professionals, the questionnaires construct validity and items gathered from various sources were reviewed,andthequestionnairewasmodifiedtomeetthe needs of the study. The months of March and April 2022 wereusedtocarryoutthisinvestigation.Togatherdata,the researcherusedarandomsampletechnique.Basedonthe answer from the construction industries, the data were examinedandtheworkflowwasputintoatypicaltechnique toachievetheintendedgoal.

An overview of the various methods utilised for the inventory management system in the case study of construction enterprises is provided by the questionnaire survey. It is much easier to define the goal of the current studyandtodirectlycontributetotheproject'ssuccessful completionasaresultoftheexhaustiveliteraturereview.A limitedamountofresearchhasbeendone,inparticular,to examinestockcontrolinbuildingprojects.Theeffectiveness of the inventory management is impacted by this. Making sure the project runs efficiently is vital to produce the intended performance. To find out how construction industry professionals felt about their organization's inventory management system, a quiz questionnaire was undertaken.

5.

OF

Throughtheuseofvariousinventorystrategiesexecutedon amicro-ormini-computer,smallfirms,bothmanufacturers andmerchants,nowhavethechancetodramaticallylower costs associated to inventory. The two types of inventory techniques are those for finished goods with independent demand and those for goods with dependent demand (manufacturing-in-processitemsandrawmaterial).Material

requirementsplanning(MRP)systemsarecurrentlyusable on micro- and minicomputers, and their application is expandingquickly.TheseMRPsystemsassistasmallfactory plan, manage, and schedule work centres, as well as the inventory levels of dependent demand products. Savings opportunitieswithindependentdemanditemscanbefound in a number of approaches. There are three categories of independent demand item techniques: continuous review models, periodic review models, and mixed models. The continuous review model (reorder point/economic order quantity model) is the one that is presented the most frequently.Toissuea replenishmentorderonthedaythe reorder point is achieved, national evaluation models, meanwhile,maketheimplicitassumptionthataperpetual inventory be maintained. Therefore, continuous review models presumptively presume that point-of-sale data is being gathered. While the continuous review method is particularly useful for automated tracking inventory that capturepoint-of-saledata,itisnotusefulformanualsystems thathandleawidevarietyofcommodities.

6. CONCLUSION

Inventory management has advanced greatly to solve the escalating problems faced by the majority of corporate organizationsasaresultofthedistinctqualitiesofinventory asanasset.Aquestionnairewasusedtogetopinionsfrom owners,consultants,andcontractorsregardingthefactors affectingthesuccessofconstructionprojects.Theyshouldbe moreconcernedwithconformancetoprojectspecifications in order to avoid conflicts, concerns with timing and expenses,andotherperformanceissues.Qualitymaterials oughttobegivengreaterweightinorderforcontractorsto perform better in terms of cost, time, and quality. Implementinganinventorymanagementsystemcanbefixed by including contractors in material procurement. Contractorsmustmaintainarecordoftheirinventoryand shoppinglists,computematerialutilization,andstoretheir suppliessecurely.Acompany'sprojectcompletionwithina given budget and time period is stated to be greatly dependentontheinventory managementsysteminplace. Theinventorymanagementcrewinanybuildingprojectwill undoubtedlyworkunderintensestress.

REFERENCES

[1] Khyomesh V. Patel, Prof. Chetna M. Vyas, (2011), “ConstructionMaterialsManagementOnProjectSites”, National Conference on Recent Trends in Engineering & Technology

[2] Lukasz Rzepecki, (2019) “Optimization of Inventory Costs Management In The Construction Enterprise”, Materials Science And Engineering, Vol.603.

[3] LansfordC.Bell1andGeorgeStukhart,Members,ASCE, (1987) “Costs And Benefits Of Materials Management Systems”, J. Constr. Eng. Manage. Vol.113,Pp.222-234.

[4] Monika RamdasNanaware,Prof.U.R.Saharkar,(JulyAugust 2017) “Application Of Inventory Control Technique In Construction”, International Journal of Engineering Research and GeneralScience, Vol.5,Issue4.

[5] Olowolaju Monisola, (2013) “An Assessment of Inventory Management in Small and Medium Scale IndustrialEnterprisesinNigeria”, European Journal of Business and Management, Vol.5,No.28.

[6] Prof. A. N. Eze, Uchenu, Chimezie Adamma, (2021) “Inventory Management Techniques Of Small And Medium Scale Enterprises In Anambra State”, Unizik Journal Of Educational ResearchAndPolicyStudies, Vol.3.

[7] PamelaC.Nolz, “Optimizing Construction Schedules andMaterial Deliveries inCity Logistics: ACase Study fromtheBuilding Industry”, Flexible Services And Manufacturing Journal, 2020.

[8] S. L. Adeyemi and A. O. Salami, (2010) “Inventory Management: A Tool of Optimizing Resources in a Manufacturing Industry A Case Study of Coca-Cola BottlingCompany,IlorinPlant”, J Soc Sci, Vol.23(2):Pp. 135-142.

[9] T.Subramani,V.BhaskaranNair,A.David,B.Mohamed Ghouse, N. Siva Kumar, (May 2017) “A Study Of Inventory Management System In Construction Industry”, International Journal of Application or Innovation in Engineering & Management, Vol.6,Issue5.

[10] V.RathinaKumar,K.LalithaPriya,Prasannakumar.I,C. Ravekumar,(2018)“ConstructionMaterialManagement through Inventory Control Techniques”, International Journal of Engineering & Technology, Vol.7Pp.899-903, 2018.