Design and Simulation of Multipurpose Automator

D Karibasavaraja1, Prathiksha CS2, Preethi S3, Priyanka R4, Vidisha HV5Abstract - The world entering the new age equipped with the modern culture and Technological improvements from the atomic level to the space exploring the instruments has never stopped improving. People who push manual wheelchair/cart face difficulties traveling long distances, up slopes or over uneven terrains. A device which aids in moving the wheelchair/cart could reduce the strain. The primary goal of the project is to fabricate an attachable frame that can be used by physically handicapped to move their wheelchairs on their own, also used to push small loaded carts by labors. The easy attachable and detachable mechanism would be used with simple mechanical linkage that gives the user the freedom to detach and attach the frame with ease. The frame would be run by a single high torque electric motor-powered wheel which enables the Automator to move wheelchairs and carts that in turn is fed by a rechargeable battery, which enables considerably a long-range run. The maneuvering freedom is given to the user and is also equipped with w throttle and brake. This multipurpose Automator is mainly for disabled people who use wheelchair on daily basis. They are prone to shoulder and limb injuries while propelling wheelchairs over long time. The area of usage is extended to the hand carts pushed around by workers in construction sites or farms. In these two cases they can attach Automator to their wheelchair/carts.

Key Words: Automator, Holder, Wheelchair, Handcarts.

1. INTRODUCTION

The world entering the new age equipped with the modern cultures and technology improvements from the atomic level tothespace exploringinstrumentshasnever stoppedimproving.Also,mainIdea behindtheinnovation of machines is to reduce the human effort and solve the problems in everyday life, most of which cross parts with thepoorandphysicallydisabled.Peoplewhopushmanual wheelchair/cartfacedifficultiestravelling longdistances upslopesoroverandeventerrains.Adevicewhichaidsin moving the wheelchair/cart could reduce the strain. Among the many issues solutions have been found and implemented to make their lives easier while reducing their dependency on others. While the solutions are availableatacostwhichisnotaccessiblebyeveryone.

Wheelchair:

Thefirstuserprofilewheelchairwasdesignedandbuiltby Stephen farfler in 1665. Made of wood consisted of three wheels similar to today's tricycle was very heavy but played on important part in shaping today's wheelchairs. Usedinhospitalstotransportpatientsandbythephysical disabled to make their movement easier. From selfpropelledtomotorized,fromwheelchairhavecomealong way and are light weighted, comfortable and available at differentmarketends.

Handcarts:

These are manually moved career type frames with wheels. Mainly used by street vendors at construction sites warehouse. These come in different forms 2-wheels, 3-wheels 4-wheels and depending on the need of the job thestructureandsizevaries.

There are 7 billion people leaving on the planet out of which7%orphysicallydisable6%ofthetotaldailywage workers work with handcarts in their daily life 12% of world'spopulationorpronetobebonedamages,ligament displacements, shoulder injuries each year out of which 4% account of wheelchair users or those who push and cards this reports result in caring a mental barrier for those who are weak to propel wheelchairs and handcarts ontheirownyethavetonooption.

Automator:

Automatorisanydevicewho'sworkingelementisamotor powered by a battery used to eliminate human efforts in the process the term was coined by L. Ferdinand in 1952 When she develops a custom-made trolley attached to a scooter which should further be used to carry vegetables for his farm to house. The idea was further used by farmers in England who altered the design has per their needs for the popularised into daily use by meat and vegetablesellermostlywithicecreamvendors.

A device which aids in moving the wheel cart would reduce the strain the primary goal of the project is to fabricate and attachable frame that can be used by physicallyhandicappedtomovetheirwheelchairsontheir ownalsousedtopushsmallloadedcartsbylabourersthe easy attachable and the detachable mechanism would be

used with simple mechanical linkage that gives the uses thefreedomtoorattachandattachtheframewithease.

1.1 Literature Survey:

These papers help detailed information related to calculationlikeTotal tractiveeffort,wheel torque, battery runtimeanddistancetravelledbythevehicle.Itgivesidea relatedtomotorswhicharesuitableforelectricvehicle.It also gives main difference between lithium-ion and leadacid,whichoneismoreefficient,highdurability.

1. Pappuri Hazarathaiah 1 Assistant Professor Y. Ashok Kumar Reddy Associate Professor “Design and Fabrication of Hybrid Electric Bike”. The paper consists of detailed calculation for the tractiveforceandwheeltorquerequired.

2. “Analysis of different types of motors for the use in electric vehicles” Sasha the induction motor is the best choice for high power electric vehicle applications. The brushless DC motor is a viable choice to be used in low power electric vehicles such as electric auto-rickshaws and two –wheelers.

3. Comparison of Burnetel this study types for electric Vehicles Ichodean1, B Vargal, N Burnetel, this study presents the autonomy of an Electric Vehicle that utilizes four different types of batteries: Lithium Ion(Li-Ion), molten salt(NaNiCl2), Nickel Metal Hybride (Ni-MH) and LithiumSulpur(Li-S).

4. “Automotive Chassis1 Design Material selection for Road and Race Vehicles “Shiva Prasad U, Athota Rathan Babu. This work is oriented towards the material usage in the road and race vehiclechassisintheautomotiveindustry.

5. Yu Munkata et al made an external motorised system for driving a manual wheelchair with an active caster. In spite of a single drive wheel, 2DOFofthewheelchairisachievedwithanactive caster drive system that is controlled independentlywithoutanyconstraint.

6. California polytechnic State University, A Luis ObispoandHochsduleMunchen,schoolofapplied sciences jointly designed and built a working portable and detachable hand powered rear will drive wheelchair. They took local resident points over previous generation wheelchairs and designedanewelectricallypoweredwheelchair.

7. Dafne Zulema Morgado Ramirez and Catherine Holloway studied both physical and nonphysical

barriers that a wheelchair user faces while operating it. On interviewing many wheelchair users, they found that those who propelled wheelchairs by themselves are prone to upper limb injuries resulting in upper limb joint pain andreducingmuscularstrength.

8. Girish Khope, Rajesh Pandlik Mali, Onkar Pramod worked on the electrical attached of wheelchair forhandicappedperson.

9. Agarwal N, Ricket, Sarthak Uniyal made semiautomaticwheelchairautomator.

10. Winai chanpeng, Prasert Hachanont worked on design on efficient in wheel motor electric vehicles.

11. Ursina Arnet, Stefan Van Drangelon worked on theshoulderloadduringhandcyclingatdifferent inclineandspeedconditions

12. Richard Simpson, Edmund lopresti Steve hayashi worked on prototype power assist wheelchair than provides for obstacle detection and avoidanceforthosewithvisualimplements.

1.2 Problem Statement:

Most of the physicallydisabledmake use of wheelchair in their daily lives which helps them to move around. These have to be propelled with their own strength using their hands or sometimes with the assist of people around them. Majority of the times they require a helper. Exposure to continuous stresses and movements as time passes by the bones grow weaker making them prone to limb injuries and other problems. Also, the wheelchairs restricttheuser’smovementtoashortdistanceusuallyas itrequiresmanualworktobeperformed.

Every time we go around there is always a sight of a handcart usage whichever the reason maybe. These help in transporting goods at a platform or bricks at a construction site or any kind of luggage on the streets or materials in warehouse. It requires a certain amount of energytomovethecartwhichmaybedifficulttohandleat situations when the work load is heavy and needs to be performedcontinuously.

The efficiency of the worker drops gradually resulting in thedelayofworkthatistobecarriedout.Also,mostofthe workersinvolvedintheseactionsfacejointpain andlimb injuries caused in the process of working with the cart. While both wheelchairs and hand carts move on human musclestrengthoftheuser,whatiftherewasadevicethat could eliminate the human work done on them which could be used in case of both wheelchair and hand cart user.!Thisiswhereourprojectcomesintoaction.

2. Motivation for the proposed work:

We see a lot of people struggling to move around in their wheelchairs as some lack the strength to propel themselves around on their own. Also, those workers inducing lot of work to move handcarts either on streets orfarmsoranother placetheyrequired a compact device thatcouldreducethework ontheirshouldersmakingthe jobeasier.

Overall Aim:

To eliminate the work done by the user in moving the wheelchairandhandcartthusmakingthejobeasier

Specific Objectives:

1. To design an Automator and fixture that can be attached to wheelchairs, 3-wheel carts used in construction sites, 4-wheel carts used in warehousesorfarms.

2. Tosimulatetheautomatorattachedtowheelchair andhandcartthroughafixture.

3. Present Work:

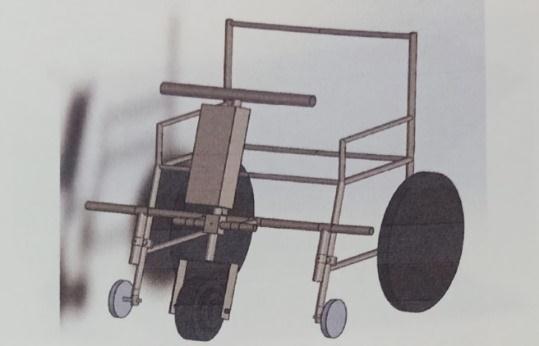

The designed Automator is model and attached to a wheelchairmodelintheFigure1 Theassemblyshowsthe positionofattachmentoftheautomatedtothewheelchair whichcan be adjusted manuallydependingupon theuser requirements.

ConceptualDesign:

We obtained the real-world measurements from the wheelchair and manual carts so as to get required dimensions for the Automator sizing. The drawing from the specification development is inserted with design dimensions. The combination of both yields the model, which on further improvements upon certain areas (linkages, manufacturing process, and analysis) is ready for modelling. They would undergo FEA tests to locate weakpointsandwouldbefurtheroptimizedbasedonthe resultsfromthetests.

A low-end wheelchair used commonly in hospitals was referred for the dimensions which can be seen in the figure 1. The figure depicts a wheelchair where a person cansit onitcomfortablywithbothhandsandlegsineasy position. The measurements were taken keeping in mind theeasinessoftheusertoholdthehandleandisshownin figure1.

4. METHODOLOGY

PrimaryCalculations:

Thispartdealswiththebasiccalculationsassociatedwith the primary operations and components that would be detail in the model thus making it one of the important stepsthatdecidesthemaximumoftheproject.Itincludes topics related to motor and battery performance, loads and moments acting on frame, The factor of safety and externalfactorsthatinfluenceOperation.

Motorcalculation:

1. Diameter=8inches=0.2m

2. Voltage=24v

3. Power=350w

4. Radiusofwheel=0.1m

Assumedvalues:

1. Acceleration=0.5m/s2

2. Desiredtopspeed=5.5m/s

3. Totalmassofvehicle(M)=130kg

Step1:TofindGrossVehicleWeight

GVW=M*9.81 =130*9.81

GVW=1275.3N

Step 2: To find total tractive effort requirement for the vehicle

TTE=RR+GR+FA

Where,

TTE=TotalTractiveEffort(N)

RR=RollingResistance(N)

GR=Forcerequiredtoclimbagrade(N)

FA=Force required to final acceleration to finalvelocity(N)

Thecomponentsofthisequationwillbedeterminedinthe steps.

RollingResistance(RR)

Where, GVW=GrossVehicleWeight

CRR=Co-efficientofRollingResistance

TW=77.75*0.1*1.1

TW=8.55N/m

TherequiredWheelTorqueis8.55N/m.

BatteryCalculation:

1. Voltage=24v

2. Current=20Amp

3. WheelTorque=8.55N-m

Assumedvalue:

1. Displacement=1000

GradeResistance(GR):GVW*Sin(ϴ)

Forplainsurfaceϴ=0

GR=0

AccelerationForce(AF)

FA=M*a

FA=130*0.5

FA=65N.

TotalTractiveEffort(TTE)=RR+GR+FA

TTE=12.75+0+65

TTE=77.75N.

Step3:Tofindthewheeltorque

WheelTorque(TW)

TW=TTE*RW*RF

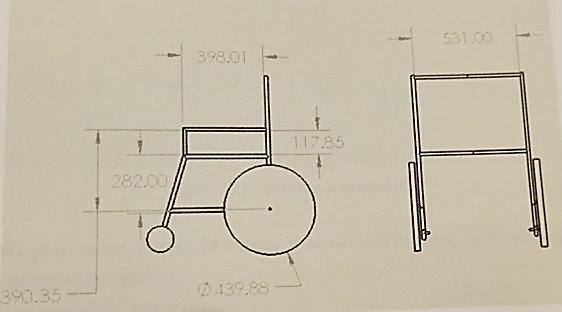

Fig2:DimensionofWheelchair

MeasurementsofWheelchair

1. Distancebetween–(Distancesareinmm)

2. ArmRestandground=610.29

3. HipRestandArmRest=117

4. HipRestandGround=501.94

5. ShoulderRestandArmRestFront=398.01

6. HipRestandlowestFixturePoint=288

7. TheHolders=531.00

Parts:

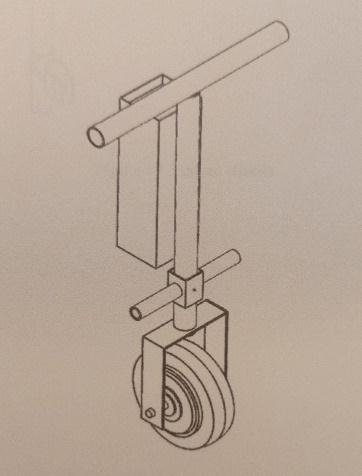

1.Automatorchassis

1. Handle: used by user to manoeuvre, accelerator, breakisattachedtoit

2. Perpendicularextrusionconnecthandletowheel. Carriesthebatteryboxandattachmentfixture.

3. Fixturebody:twocylindricalextrusionsemerging from a hollow cuboid that holds a ball bearing throughwhichtheperpendicularpasses.

4. Wheelplate:holdsthewheelintheposition

5. Wheel:holdsthehubmotor.

6. Battery box: holds the battery and is attached to theperpendicularextrusion

selection is also based on the calculations performed in theaboveprocess.Thematerialswithdesirableproperties based on calculations are shortlisted and are check up on theirusesandperformanceinindustrialpractices.

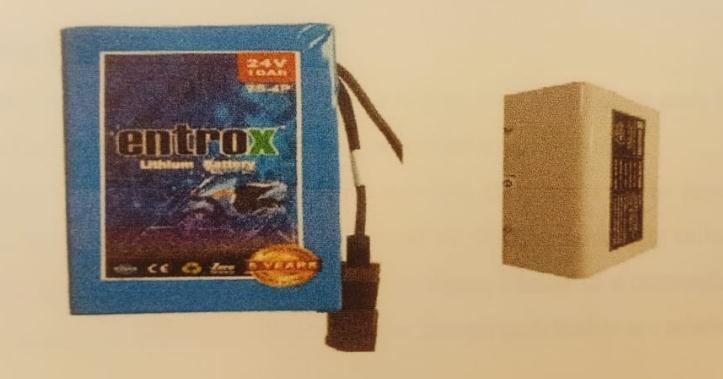

Battery:24volts,20Ahlithium-ionbatteryisrequired.

Materials:Steel4130frame.

(Tensile strength: 560 MPa, Yield Strength:460 MPa, Modulusofelasticity:205GPa)

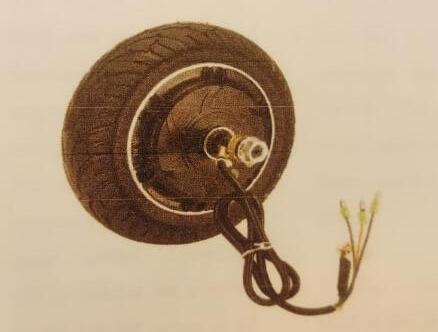

2. Wheels:8inches24V,350W1ElectricWheel.

3. Handles:Steel41302handles.

Electricwheel

Wheelhubmotorwhichisalsocalledwheelmotoritisan electric motor coupled to the wheels of a vehicle. Nowadays wheel hub motor is best suitable for electric vehicle.

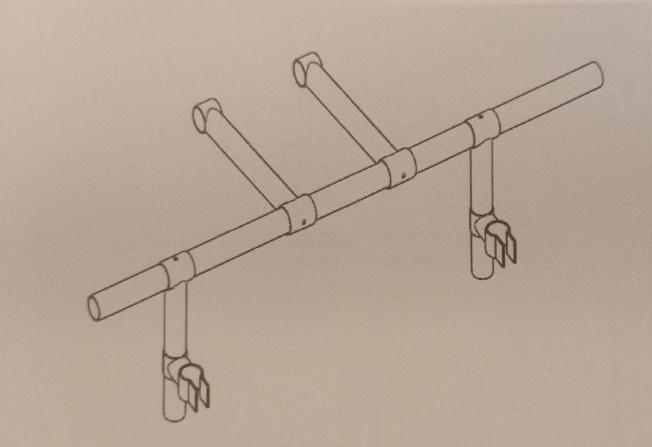

Fixtureframe:

1. Holder 1: connects the automated to the with adjustmentbar

2. Holder 2: connects the holder 3 to the width adjustmentbar

3. Holder3:holdsthewheelchair/cart

4. Width adjustment bar : horizontal bar about whichholderoneandholdertocanbemovedand rotatetoadjusttheuserneeds

Battery:

A lithium-ion battery is a type of rechargeable battery. Medium ion batteries are lighter and smaller than lead acidbatteries.Nowadaysmediumionbatteriesareusedin electricvehicle

Working:

While the battery is discharging and providing an electric current the ion oat releases lithium ion to the cathode generating a flow of electrons from one side to the other. When plugging in the device the opposite happens. Lithium ions released by the cathode and received by the anode.

Advantages:

5 COMPONENTS AND MATERIAL SELECTION

TheCalculationdoneintheabovestepareusedtocreatea shortlist of component that would be Finalized further depending upon the cost and reliability parameters to confirmtheysumupasper the budgetplan. The material

1. Highlydenseinvolume

2. Highdischargerates

3. Highchargerates

4. Compactinsize

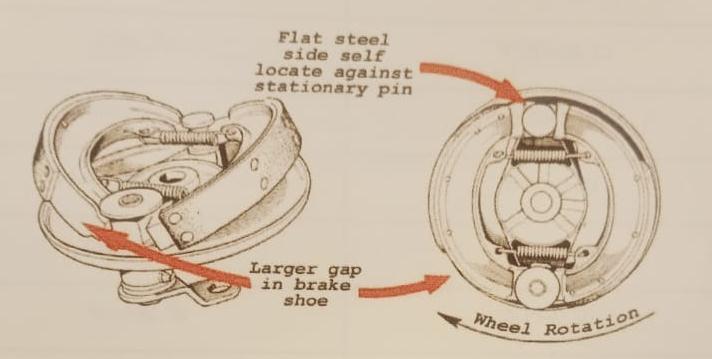

BrakingSystem:

Adrum break isa break thatusesfrictioncaused bya set of shoes or pads that press outward against a rotating cylindrical shaped part called a drum break The term drum break usually means a break in which shoes press ontheinnersurfaceofthedrum.whenshoespressonthe outside of the drum it is usually called a clasp break. Wherethedrumispinchedbetweentwoshoessimilartoa conventional disc brake it is sometimes called A pinch drum break though such breaks are relatively rare. A related type called a band-break uses of flexible belt or bandwrappingaroundtheoutsideofadrum

5. CONCLUSION

1. The developed model can be used for loads of 100kg and under. It runs with the help of an electricbrushlessmotoroftorque20Nmwhichin turn is powered by a lithium-ion battery of 24V and20Ahcharge.

2. The design weight of the model is estimated to 11kgapproximatelywherethechassismadeupof 4130 steels with the fixture weighs around 4kg, thewheelassemblytakesup4kgandlithium–ion batteryis3kg.

3. The detached custom designed fixture is the important part of our project, as it allows the Automatortobeattachedtowheelchair,3-and4wheelcarts.

4. Calculations are performed for a load of 130kg considering flat ground the Automator is able to travel 9.26km at a velocity of 1m/s or with a run timeof2.57hours.

5. This is also cheaper than the commercial wheelchair attached model but with less budget andmorerange.

6. The device is attached to the wheelchair /cart withthehelpoffixture.Aclampstructureisused at the attachment side of the fixture whose ends aretightenedwiththehelpofscrews.

7. Toarresttherotationoftheholdersinthefixture assemblyscrewsareusedtolocktheholdersata particularangleoncetheattachmentisdone.The deviceismaneuveredwiththehelpofahandleto whichanacceleratorandbrakeisattached.

8. Offersanoperational velocityof0-20kmphtothe user. The design is modelled, analyzed for deformationsandsimulated.

References:

1. Pappuri Hazarathaiah Y, Ashok Kumar Reddy, Vijaya Bhaskara Reddy, Sreenivaulu “Design and FabricationofHybridElectricBike”,International Journal of Applied Engineering Research ISSN 0973-4562 Volume 14, Number 4(2019) pp. 930935.

2. Sesha Gopal S “analysis of Different Types of Motors for the Use in electric Vehicles”. InternationalResearchJournalofEngineeringand TechnologyVolume:07Issue:06|June2020.

3. Clclodeanl, B Vargal, N burnetel, D Cimerdeanl and B Jurchig “Comparsion of Different Battery Types for Electric Vehicles “, IOP Conference Series: Material Science and engineering. Volume 252, CAR2017 International Congress of AutomotiveandTransportEngineering–Mobility Engineering and Environment 8-10 November 2017.

4. Shiva Prasad U, Athota Rathan Babu, Bandu Sairaju, Sai Krishna Amiri Shetty, Deepak D “AutomotiveChassisDesignMaterialSelectionfor Road and Race Vehicles”, Journal of Mechanical Engineering Research and developments Vol. 43, No.3,pp.274-282PublishedYear2020.

5. Sruthi ramachandran, N, Vijay Singh, “Motorized Hand Bike for Manual Wheelchair”. International JournalofInnovativeResearchinScience.

BIOGRAPHIES

KaribasavarajaD AssistantProfessor

PrathikshaCS

UnderGraduate

PreethiS UnderGraduate

PriyankaR

UnderGraduate

VidishaHV

UnderGraduate