Evaluation of Machine Tool Thermal Stability against Dimensional Accuracy

Joel Arumun1 , Shadrack Abiola2

Joel Arumun1 , Shadrack Abiola2

1Alumni, University of Huddersfield, Huddersfield, United Kingdom

2Alumni, University of Huddersfield, Huddersfield, United Kingdom ***

Abstract - Monitoring of energy consumption patterns on machine tools over variable workloads for a machine in operation is important in improving production. This paper seeks to relate machine thermal stability with dimensional accuracy. Machine tool signal acquisition and processing techniques are applied over three set of experiments in idle, runtime and production modes using a CNC machine tool; Fanuc RoboDril Model α-T14iDe. The same work piece and same workshop floor temperatures are maintained with critical discussion on outcomes. The study uses analytical methods to monitor and evaluate thermal stability in the machine tool and how it affects dimensional or measurement accuracy. It established the fact that it is important to bring up a machine toolto its thermal stability before anyoperation if high dimensional accuracy is deserved.

Key Words: MachineTool,ThermalStability,Dimensional Accuracy.

1. INTRODUCTION

Manufacturingtakesabouthalfofthetotalworld’sprimary energy consumption and a large part of this energy is consumedbymachinetools[1].Thecourseofactiontoward energyefficiencyinthemanufacturingsphereisconstantly beingdrivenbymachinetool userslookingfor regimes of low operational costs. Deliberate monitoring of machine operation to ensure efficient production processes will minimizewastages.Havingadequateknowledgeaboutthe amountofenergyconsumptionbymachinetoolsformsthe basis for optimizations of machine tools’ measurement accuracyandmonitoring.

The global manufacturing industry is driven by machine tools which aid in the production of other industrial equipment and machinery. Bawa, (2004) defines machine tools as power-driven machines capable of holding and supportingtheworktoolandatthesametimedirectingand guiding the cutting tool or job or both to perform various metalcuttingoperationsforprovidingdifferentshapesand sizes [2].Themachiningprocessischaracterizedbythree basic elements namely, the workpiece, tool, and Chip or swarf[3]

Machinetoolsmaybedividedintoconventionaltypesand computer numerical controlled (CNC). This project is

concerned with the CNC machine type [4]. A machining centre is a sophisticated CNC machine that can perform multiple machining operations in the same setup with a variety of tools. Vertical Machining centres (VMC) and Horizontal Machining Centres (HMC) are the two types of CNC machine centres we have and are based on the orientationofthespindle.VMCsarethemostwidelyused machinecentresdesignedforoperationsintheX-Ymotions toadesireddepth[5].Athirdtypeofmachiningcentreisthe universal machining centre which incorporates both a verticalandhorizontalspindleinonemachine,makingthem abletomachineallsurfacesofanyworkpiece[6]

Shaohuaetal[2012],usesamulti-componentapproachthat takes into account the energy monitoring of nearly all components of a machine tool [7]. However, Kordonowy, (2003)arguedthatthismethodologyposesgreatdifficulties in the accurate measurement and monitoring of energy efficiencyandutilization[8]. Heemphasizedthatconstant energyconsumptionisindependentofmachining,whereas, thevariableenergyconsumptionwhichisthecuttingpower consumed during the machine operation, is dependent on machining.

Thecomponentsthatdrawthemostpoweraretherotating spindle,servomotor,andcoolingdevices[9].Othersarethe hydraulic unit, cutting oil pumps, and other peripheral devices. Most energy monitoring methodologies are very superficial,onlytakingintoaccountthemeasurementofthe machine cutting power with torque sensors or dynamometerswhichisnotefficientoradequate. Another majorissueofcontentionisthatofthedifferentdefinitions ofthemachinetoolsgivenbydifferentbodieslookingatit fromdifferentperspectives,asisthecasewiththeCECIMO andNACE.

2. SIGNAL AQUISITION

Theconsequenceofthemanysourcesandmechanismsof energy demand in machine tools and the robust auxiliary metrologytools,nodoubtrequiretheuseofamulti-sensor systems approach in the acquisition and monitoring of process flow signals [10]. These multi-sensor systems encounterseveraltechnicalissuessuchasthederivationof effective down-sampling methods required to extract the most vital signals representative of desired measured parameters(Diazetal,2009).Theseeminglycomplexnature

of machine tools makes signal acquisition and analysis a challengingtask.

The signal acquisition follows the procedure itemised below. Probing for accuracy under three thermal energy measurementscenarios:

(A) Keeping the machine tools in the idle state for 24 hours and subsequently running in production mode to probeastablegraniteblockatintervalsof6minutesfor4 hours. This is to determine (measurement) accuracy with eachprobe

cycle,inthethreeaxestoidentifythedeviationresulting from the effect of heat on the ball screw as a result of the prolongedproductionmodeofthemachine.

(B) ProbinggraniteblockinproductionmodeforZ-axis accuracy, at intervals of 6 minutes for 4 hours, with the incorporationoftemperaturesensors.Thisisdoneafterthe machineiscompletelyshutdownfor16hours.Theprobing cyclesarerequiredtodeterminetheeffectsofthermalenergy onthemachinetoolfromitscoldstatetoaperiodwhenthe temperatureofkeycomponentshasreachedthermalstability whileinproductionmode.

(C) The Z-axis motor is moved in ten quick motions upwardsanddownwardstorapidlyheatthemotor,toseeif thiscouldbringthemachineandespeciallythemotorfaster tothermalstabilitythantheprocedurein(b).Thisisfollowed byaprobeofthegraniteblockandrapidmotionoftheZ-axis motor again. This sequence is carried out for 4 hours and incorporates temperature sensors to monitor the temperatureofthevariouscomponentsinrealtime.

3. EXPERIMENTS

3.1 Experiment One

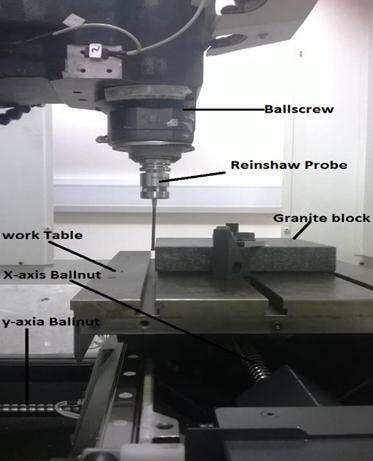

A granite block is probed for machine dimensional accuracytodeterminetheresponsetoheatingofthemachine tooloveralongoperatingperiod.FanucRoboDrilModelαT14iDewhichincorporatesaRenishawprobingtoolisused. SeeFig-1. Themachinetoolwaskeptinanidlestatefor24 hours and subsequently operated in production mode to probethegraniteblockatintervalsof6minutesfor4hours ataworkshoptemperatureof25Co

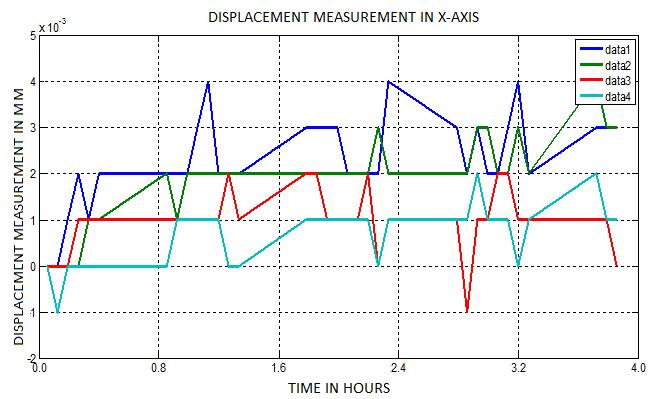

ThedimensionalvaluesintheX,Y,andZaxispositionsof eachcornerofthegraniteblockwereextractedandMATLAB was applied to graphically show the deviation from the originaldatumpointsforeachaxisandatthevariouscorners. BlockdatumisgiveninTable1.

Result and Analysis of Experiment One

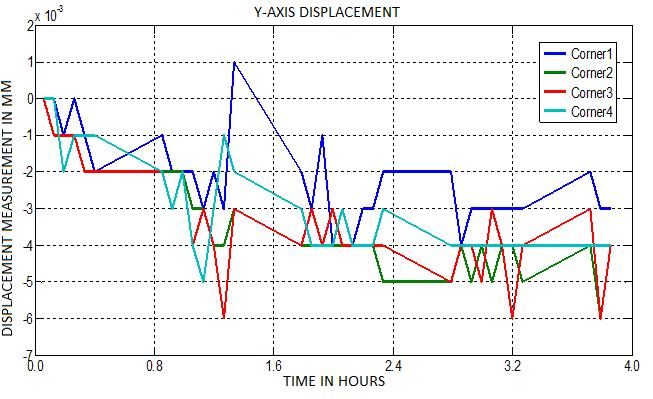

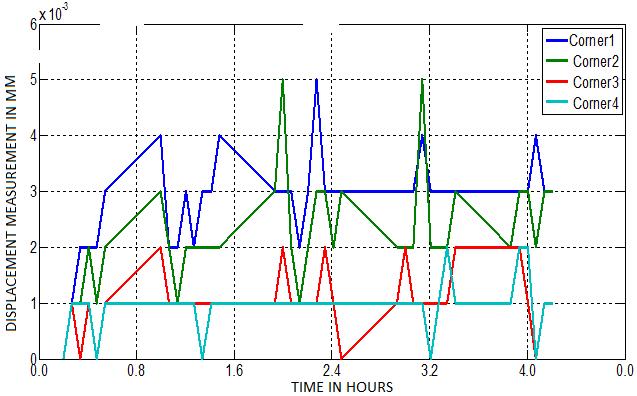

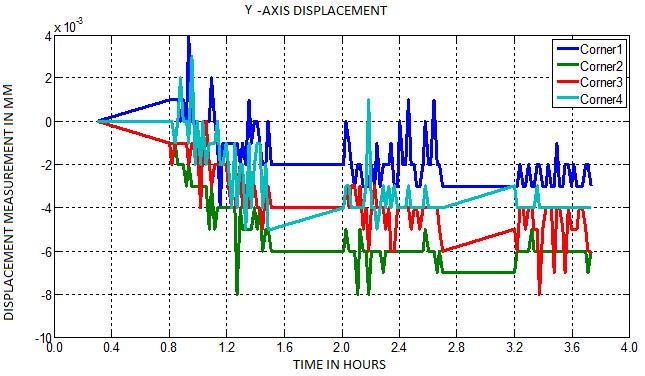

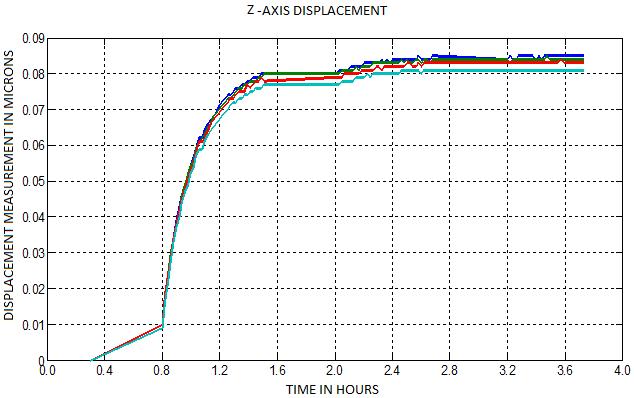

Theplotofprobedatashowedsomesignificantdeviationin measurementfromtheinitialdatumpoints. Seechart1,2, and3

ofpartsrequiringtighttolerancesasthesedeviationscould

manifestassignificantcumulativeerrors.Fromtheresults,it isseenthatthemaximumdeviationisonthez-axis.

Thisisprobablybecausetheheatistransferredtotheball screwandthentothetool,whichcouldleadtomachining errorsasaresultoftheexpansion.TheMachinetoolreaches thermalstabilityeventually.

Thoughthevariousaxesarrivedthermalstabilityatdifferent times,ittooktheZ-axesthelongesttimeofabouttwoanda halfhours.

3.2 Experiment Two

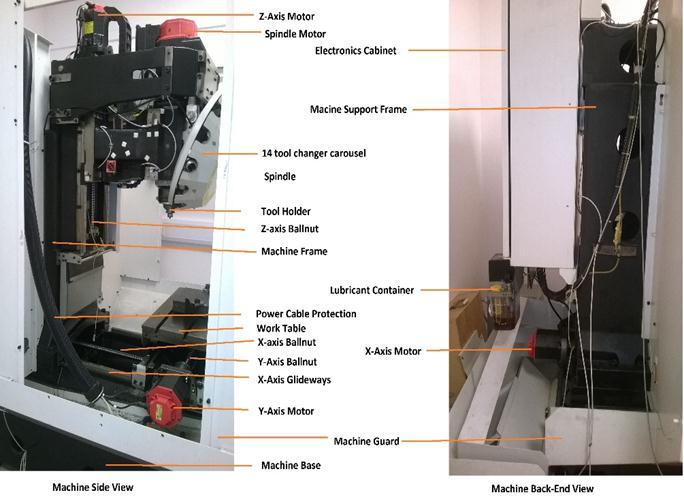

Probingthegraniteblockfordimensionalaccuracyusingthe same machine tool and workshop temperature with the incorporationof24temperaturesensors(seeFig-2)andit runsfor6hours

This second experiment sought to go further in not just determiningthedeviationofdimensionfromthedatumover prolongedmachineusage,butalsotodeterminethethermal energyemittedbykeyoperatingcomponentswithtime,such asthemachinecolumn,columnBolt,Spindle,spindleMotor, Z-axis Motor, etc. A total of 24 sensors are used for temperature measurement. A temperature software, ‘TempSpy’samplesthesignalsevery30seconds.

This procedure was performed in three stages after the machinewasleftcompletelyshutdownfor16hours:

(a) Probing granite block in production mode every 6 minutesfor4hoursand20minutes.

Whilethesedeviationsmaynotbevisibletothehumaneyes, theirpresencemayconstituteachallengeinthemanufacture

(b)Themachinewasthenplacedontheemergencystopand completelyshutdownforabout1hourtoobservetherateof coolingandheatdissipationfromthemachinecomponents, and

(c)Themachinewastakenofftheemergencystopandthen poweredtoproductionmodetoprobethegraniteblockfor 45minutes,asinstageone.

Result and Analysis of Experiment Two

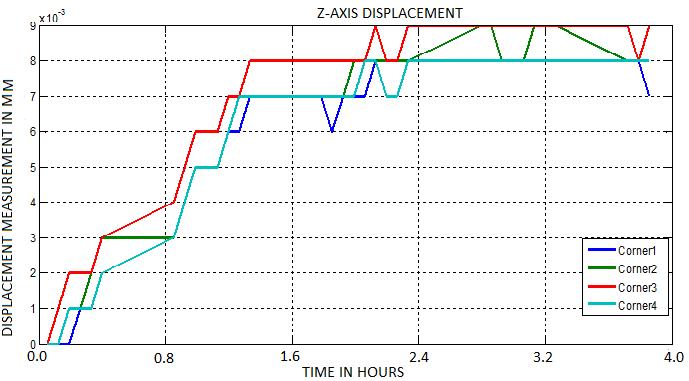

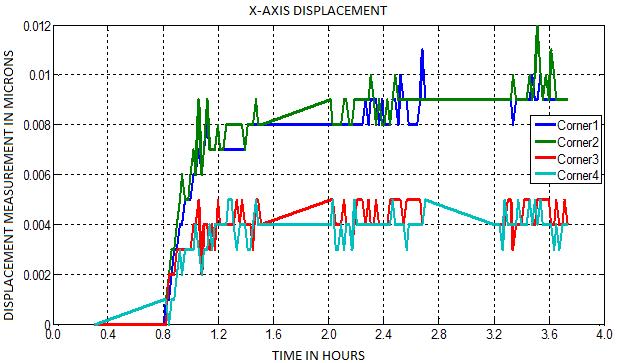

A two-dimensional graphical plot of displacement measurement in microns against time is obtained for the threeaxes(X,Y,andZ)atthefourcornersoftheblockusing MATLAB.

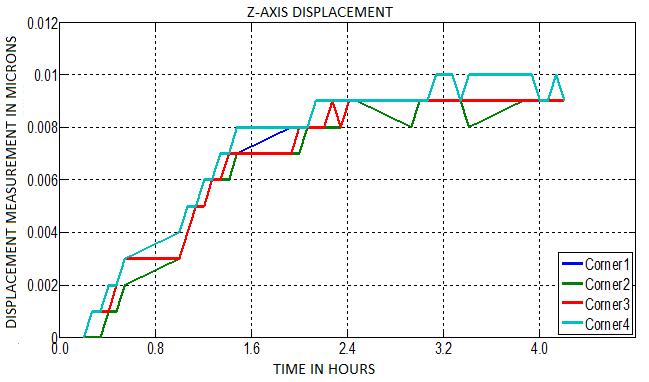

(a) Analysis of Stage One

TheXandYaxeshadalittleriseinmeasurementdeviation withtimebutquicklystabilizedwhiletheZ-axis,ontheother hand,showedasteadyriseinmeasurementdeviationwith probetime.Thisaxisismajorlyaffectedbytheheatingofthe Z-motorandexplainstheveryvisibleriseinmeasurement deviation. It shows the effect of temperature on measurementaccuracy,seeChart4,5,and6.

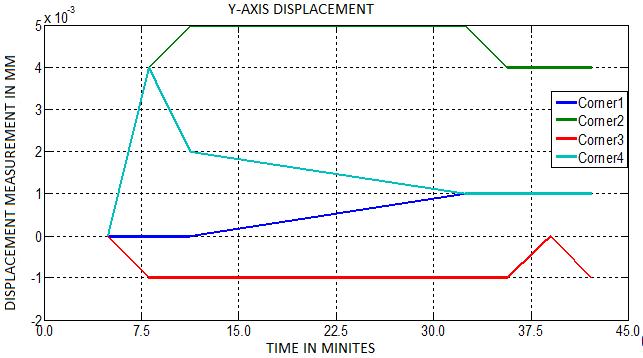

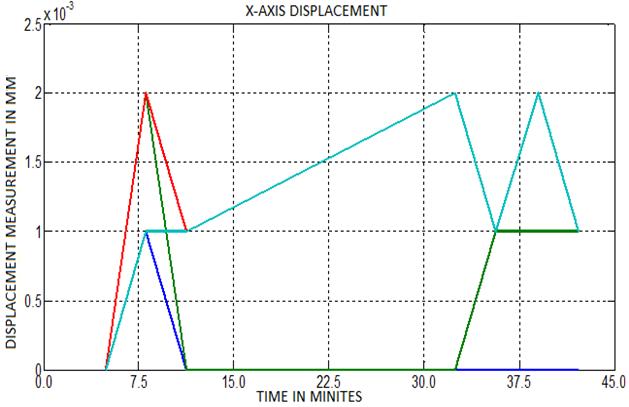

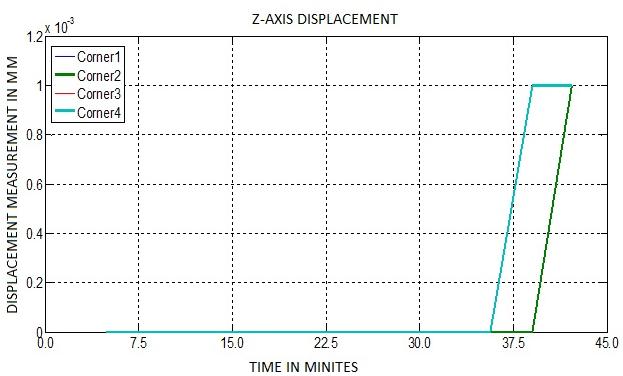

(b) Analysis of Stages Two and Three

TheresultsofmeasurementdeviationareshowninChart7, 8,and9.Thex-axisexperiencesamaximumdeviationof2 micronsthroughouttheperiod.Inthey-axis,themaximum deviation is 5 microns. The Z-axis showed consistency in probingcyclesatthefourcorners.

At this point, there is more expansion of the Z-axis components which are fully soaked with the high temperature,asobjectstendtocoolforamuchlongertime than they get heated up. The Z-axis motor experiences a greaterthermaleffectandheatretentionforalongertimeas comparedwithothercomponentsofthemachine.

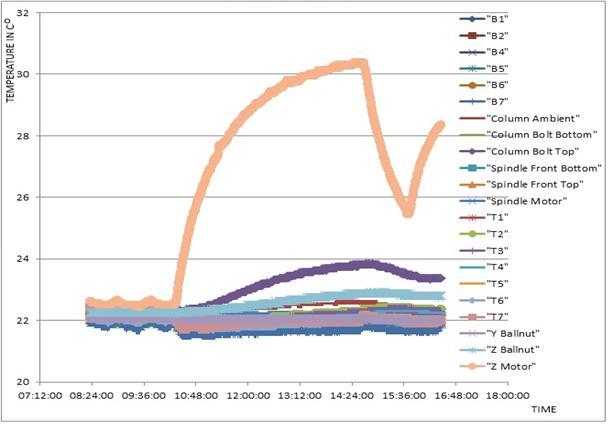

(c) Temperature Analysis of Experiment two

The temperature analysis of the machine tool in this experiment is captured by 24 different sensors affixed to different parts of the machine tool. They capture the temperature data in real-time at a sampling time of 30 secondsandthenanalyseditbytheTempSpysoftware.The graph of Chart 10 indicates the sensor locations and the temperaturemeasurementthroughoutprobing.Itgivesan insight as to how the machine warms up, the component generatingthegreaterheatandthosemostaffectedbyheat, the rate of cooling, and the thermal stability region. The sensorsmonitoredthemachinefromacoldstatewhichis the initial temperature before start-up. This temperature rosegraduallywithveryunstablerippleswhichtook2hours to attain thermal stability. The most substantial rise is noticedinthez-axismotor,whichroseexponentiallyabove theaveragemachinestabletemperatureof22.5Cotoapeak of30.37Coasthemostthermallyaffectedcomponentwithin the experiment period. Other components worthy of mention are the column bolt and Z-ball nut whose temperatures were 23.8oC and 22.9oC respectively at a machinethermalstabilityof22.5oC.

3.3 Experiment Three

Probingthesamegraniteblock,usingthesamemachinetool at the same workshop floor temperature for dimensional accuracy,whilstrapidlyheatingthemachinez-axismotorto attainthermalstability.Rapidheatingisachievedbymoving the Z-axis motor in ten quick upward and downward motions through the use of machine codes. Earlier proceduresshowedagradualheatingupoftheZ-axismotor buthereitisrapidheatingtoascertainwhichthetwowould makeforaquickarrivalatthermalstability.

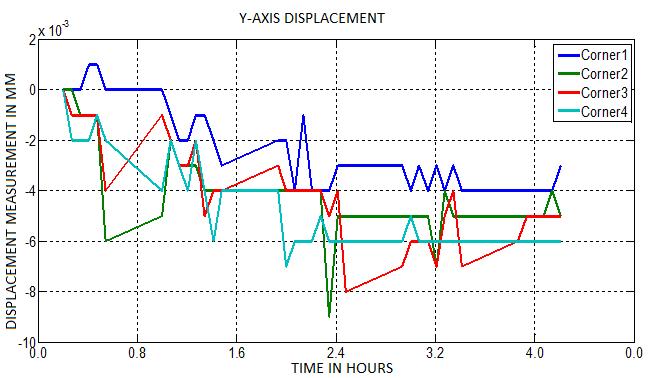

Result and Analysis of Experiment Three

MATLABplotfortheX,Y,andZaxisforallfourcornersof thegraniteblockisexamined. IntheY-axis,themaximum deviation was minus 8 microns. The negative value of the deviationmeasurementintheYaxisisanindicativemotion oftheprobetoolinnegativeCartesiancoordinatesonly.The Z-axisexperiencesasteadyriseindeviationfromthestartof theexperiment.Atremendouslysignificantdeviationatall fourcorners.

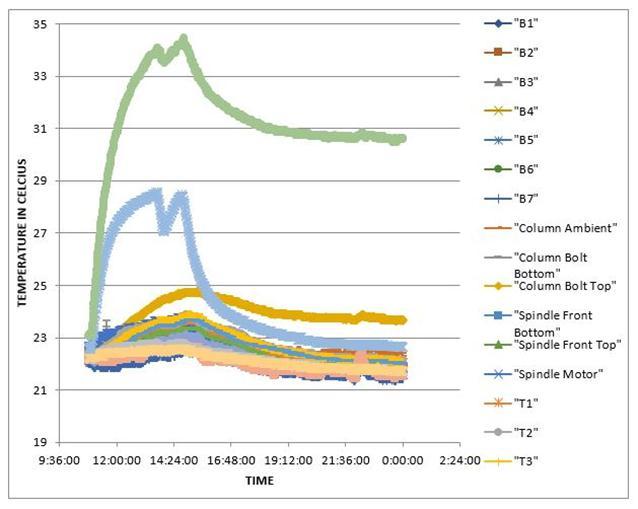

Attheinitiationoftheprobing/Z-axisheatingsequence,the temperature of all the components increased steadily as showninChart14

determinethemosteffectiveandsufficientwaytocarryout these warm cycles required to bring each machine to thermal stability. This has several advantages such as the abilitytodetectanyprobableerrorsthatmayariseduring machineoperationandtomitigateagainstsuch,tobringthe machine to its stable temperature wherein it can operate effectivelyandefficientlywithoutanyadverseeffectstothe tool itself, workpiece, operators and the immediate environment. This is also important for machining over a given period. Graphical results of deviation with time buttressed the fact that the deviational measurement showedsmalldeviationsattheonsetofexperimentationbut throughout machining, there is a steady rise in deviation measurementtopoint(thermalstability)whereitbecomes relativelyconstantonallfourcorners.Thisisindicativethat warm-up cycles are important as machining a workpiece beforethermalstabilitycouldleadtodimensionalerrors.

REFERENCES

[1] Holkup T., Vyroubal J., Smolik J. (2013). Improving energyefficiencyofmachinetools.ResearchCenterfor Manufacturing Technology (RCMT), Czech Technical UniversityinPrague,CzechRepublicintheProceedings of the11th Global conference on Sustainable Manufacturing(GCSM).Berlin:CIRP

[2] Bawa H.S. (2004). Manufacturing processes – 1. (2nd reprint)NewDelhi:TataMcGraw-Hill.

[3] KesavanR.,RamnathV.B.(2010)MachineTools.New Delhi:UniversitySciencePress.

[4] MattsonM.(2002).CNCProgramming:Principlesand applications.NewYork:Delmar-ThomsonLearning

[5] Smid P. (2010). CNC Control Setup for Milling and Turning: Mastering CNC Control System. New York: Industrialpress.

Themachinecomponentsattainedthermalstabilityatabout 3hoursofprobing. Therewashoweverasignificantrisein threecomponentsoftheZ-axis.Thesecomponentsarethezaxis motor, the Z ball nut, and the column bolt top. The temperatureofthemotorroseandadropintemperatureto 33.5Coisseenat3hoursofmachiningtime.Thisisduetoa failure in the machine part programme, resulting in a temporarycrash.Thiswasresolvedandtheprobingprocess continuedforthenext1hour.Afterthez-axismotorreached its stabilized temperature in 4 hours, the Robodrill CNC machine was placed on emergency stop and shut down completely

4. CONCLUSIONS

Itisestablishedthatitisimportanttofirstcarryoutwarmupcyclesforamachinetoolbeforeitgoesintofulloperation mode.Forbetterefficiency,studieswouldbecarriedoutto

[6] Rajput R. K. (2007). A Textbook of Manufacturing Technology: Manufacturing Processes. (1st Ed.). New Delhi:LaxmiPublications.

[7] ShaohuaHu,FeiLiu,YanHe,TongHu(2012).Anon-line approach for energy efficiency monitoring (OEEM) of machinetoolsbyJournalofcleanerproduction.Elsevier

[8] Kordonowy,D.,2003.Apowerassessmentofmachining tools.BScthesis,MassachusettsInstituteofTechnology, Massachusetts,USA.

[9] Mori,M., Fujishima,M., Inamasu,Y., Oda, Y.,(2011).A study on energy efficiency improvement for machine tools.CIRPAnnalseManufacturingTechnology60(1)

[10] Diaz N., Helu M., Jarvis, A., Tönissen S., Dornfeld D., Schlosser, R. (2009). Strategies for Minimum Energy

OperationforPrecisionMachining.GreenManufacturing andSustainableManufacturingPartnership.Laboratory for Manufacturing and Sustainability. California: UC Berkeley.2009TheProceedingsofMTTRF2009Annual Meeting.