A Sustainability Approach towards use of Plastic Waste in Bituminous Road

Abstract - Nowadays, disposal of plastic waste has become an issue of great concern for environmental engineers due its non-biodegradable characteristics and health Hazard.

Plastic waste, if not recycled, is either land filled or incinerated, where both of them prove to be a disaster to the environment. Incineration and dumping of waste in open areas leads to environmental pollution as well as contamination of water bodies and soil. Thus, an alternative for treatment of plastic waste is required as soon as possible. In construction of flexible pavement plastic was found to be a potential binder for bitumen mixes used. In this paper, we are going to find out the result of LOW-DENSITY

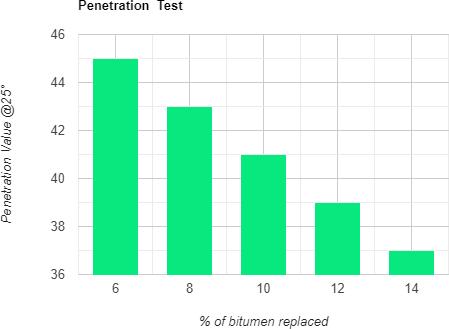

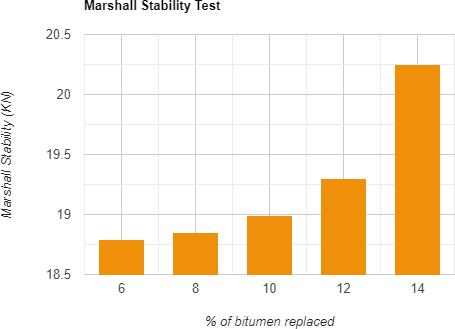

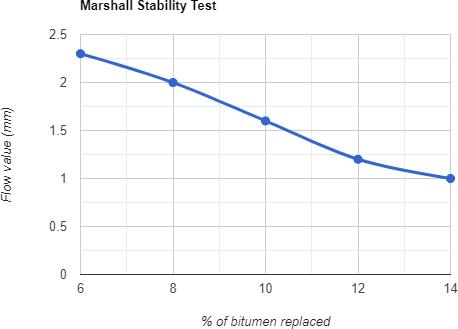

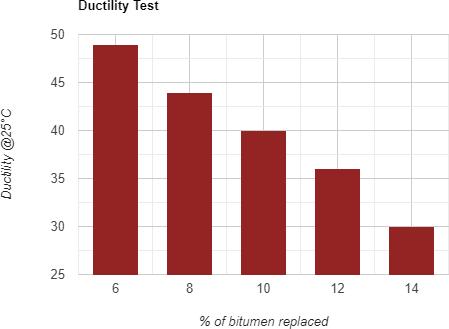

POLYETHYLENE which we will be use as a replacement of bituminous by an amount of 6%, 8%, 10%, 12% & 14% by weight of bitumen in making bituminous mix design for pavement application. To know various properties of bitumen we are going to conduct Penetration test, ductility test, flash and fire point test, softening point test. Marshall Stability Test will be performed on all of the samples. The basic objective of the test is to find out the optimum percentage of plastic waste which can replace the bitumen content in the mix design of flexible pavements. Researches proved that the plastic wastes used after proper processing can enhance the life of the road and also a solution to environmental problems.

Key Words: Non bio-degradable, Polyethylene, Bitumen

1.INTRODUCTION

Large amount of plastic waste is generated on daily basis. Thedisposalofthisplasticwasteisthechallengingproblem facedworldwide.Wasteplasticgetsmixedwithmunicipal solid waste or get disposed on land. Various research attemptshavebeenmadetorecycleandreuseplasticwaste such as polyethylene covers, plastic bags, plastic bottles, etc. Best quality of road functionality is required with the rapidincreaseintrafficintensity,inadditionto significant

fluctuationsindailyandseasonaltemperature.Betterroad infrastructureisneededthatrequireslessmaintenance in developing countries where proper maintenance of road networks is difficult due to lack of funds and efficient machinery.

Extensiveresearcheshasshownthatthestrengthofpaving mixescanbeimprovedbyusingdifferenttypesofmodifiers with bitumen such as tyre rubber, polypropylene and organic polymers. By use of these modifiers temperature susceptibilityandviscositypropertiesareimproved.Italso solved problems such as binder bleeding at peak summer temperatures and aggregate stripping in moisture prone areas.

Manystudiesarebeingconductedtoimprovethebitumen quality used in bituminous road construction. One of the outcome of this study is the application of polymermodified bitumen. Utilizing discarded plastic waste (especially plastic bags) is the need of today's society. Research into the conductive and thermal bonding properties of molten plastic encouraged study into the formationofthewasteplastic-bitumencombinationandits sustainablyinroadconstruction.

Energizing solid municipal plastic waste can take routes such as incineration of the waste in flow-driven incinerators, incinerationof thewasteinheat exchangers, pyrolysis, hydrogenation, and anaerobic digestion. It causes health and environmental problems when it is disposed in form of landfill and incineration. That's why youshoulddisposeofplasticwasteasbitumenmodifierin road construction. Proper addition of plastic in bitumen improvestheroadslifeofandminimizestheconstruction costofroads.Theexceptionalgrowthofvehiclecountson our roads, including the commercial vehicles along with overloading of transport vehicles and changes in seasonal temperature in various parts of our country needs improved performance of roads and better binding propertiesofbitumen.

1.1 Plastic

Plasticishugethreattotheenvironment.Thebestwayfor the disposal of plastic is recycling. Various categories of plastic are LDPE, HDPE, Polypropylene, Polystyrene, PVC and Polyethylene Teryphthalate etc. Here we are using LOW DENSITY POLYETHYLENE which is originating from milkpouchesbecauseofitseasyavailabilityandflexibility.

1.2 Bitumen

Bitumen is viscous material having adhesive properties derived from crude oil either by natural or refinery processes possessing black or brown colour. There are different grades of bitumen available in market according to its viscosity and penetration values. It acts as a binder materialforaggregateinbituminousmixes.

2. LITERATURE REVIEW

2.1 Prof.C.E.G. Justo (2014)

He concludes that addition of 8.0 % by weight of processed plasticforthepreparationofmodifiedbitumen results in a saving of 0.4 % bitumen by weight of the mix or about 9.6 kg bitumen per cubic meter of BC mix. Modified Bitumen enhance the stability & strength, life and other desirable properties of bituminous concrete mix.

2.2 YashMenaria, RupalSankhla (2015)

He stated that polyethylene, polypropylene, and polystyrene are the main constituents or source of waste plastics.Wherethesofteningpointofthistypeofmaterial rangesfrom120˚C-160˚C.Theseheatedmaterialswilldo notgenerateanypoisonousgasesonheatingbutithasgood laminating property when spewed over the hot aggregate at 160˚C. the importance of this study shows reduction in thecostofconstructionaswasteplasticusedandincrease in durability and strength is observed, the combination of plasticbindingwithaggregatesprovidegoodstability.

2.5 U Sathish, A.V.Sandeep (2020)

Recycled plastic along with aggregates can be used for the better performance of the roads. The properties displayed by plastic coated bitumen are beneficial without pursuing much cost leading for effective, economicandefficientlayingofroads.Inthiswayplastic wastecanberecycled

3. OBJECTIVE AND SCOPE

● Tocheck thepropertiesof bituminous mixspecimen due to replacement of bitumen by waste plastic materials.

● To find a better bitumen-plastic mix option for improvementofqualityofroadpavement.

● ToimproveroadStabilityandlife.

● To reduce the quantity of bitumen required for projecttherebyreducingcostofmaterials.

● Select an optimum waste plastic content for the mixtureaftertheanalysingthetestresults

4. METHODOLOGY

4.1 Materials used for bituminous mix

4.1.1Coarse Aggregate

“Plastic wastes opportunities for eco-friendly material of bituminous road constructions”. In this article cost of constructionofplasticroadandbitumenroadiscompared, whilebitumenrequiresforperkmgivingcostof5,00,000/andwhilebitumenmixedwithplasticsthatgivingcostper km of 4,55,000/-, hence plastic road is economical. It enhances resistance to surface initiated cracking due to higher binder content, improved oxidation resistance due tohigherbindercontent.

2.4 Kurmadasu Chandramouli (2016)

“Plastic waste is use in the construction of roads” stated that asphalt concrete using polyethylene modified binders were more resistant to permanent deformation at high temperature and found better performance in strippingcharacteristics of the crumb rubber modified mixascomparedtounmodifiedasphaltmix.

The coarse aggregates should annex good impact value abrasion value, and also crushing strength. The function of coarse aggregates is to carry the stresses due to wheels.FunctionofCoarseaggregatesisalsotowithstand wear dueto abrasion. According to the Asphalt Institute the portion of the mixture which retained on 2.36 mm (No. 08) sieve is termed as Coarse aggregates. Coarse aggregateusedwasBasaltrock.

4.1.2 Fine Aggregate

Voidswhichremainunfilled inthecoarseaggregatesare filled by the fine aggregates. So, the purpose of fine aggregates is to fill the voids of coarse aggregates. Fineaggregates include crushed sand. Aggregates that passedthrough 2.36mm sieve and retained on 0.075 mm sieve were selected as fine aggregate. Crushing sand is used asfineaggregate.

4.1.3 Waste Polythene

ThepolytheneAmulmilkpacketsareusedasrawmaterial forpreparationofthesamples.Thispolythenewaswashed after collecting and cleaned by putting them in hot water for3-4hours.Theywerethendried.

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

4.1.4 Bitumen

Gradesofbitumenusedinthepavementsmustbeselected onthebasisofclimaticconditionsandtheirperformancein thepast.AsphaltbinderVG40isusedinthisresearch.

4.2 Preparation of Sample

4.2.1Collection of aggregates

ItshouldconfirmtoIS383–1983.IRCsuggesttwosizesof aggregates size 12mm, 10mm in our research we used 10mmsizeofaggregate.

4.2.2 Collection of plastic

There are many sources available for the collection of plasticlikedomestic,commercial&publicsources.

Segregation: Plastic waste collected from varioussources mustbeseparatedfromotherwaste.

Cleaningprocess:Plasticwastemustgetcleanedanddried aftercleaning.

Shredding Process: It is the process of cutting the plastic intosmall sizesbetween2.36mm– 4.75mm withthehelp oftheplasticshreddingmachine.

Collection Process: Plastic must be collected of the size of 2.36mm – 4.75mm for the blending process in plastic coatedaggregateandmixingwiththehotmixbitumen.

4.2.3 Coating of aggregate with plastic

The aggregates are heated up to 160°C. Shredded plastic wasteisaddedoverthe hot aggregateinmixing chamber. Then plastic waste coated aggregate is mixed with hot bitumen.

5.EXPERIMENTAL INVESTIGATION

5.1 Marshall Stability Test

TodeterminetheMarshallStabilityofbituminousmixture asperASTMD1559thistestisperformed.Theresistance to plastic flow of cylindrical specimens of a bituminous mixture loaded on the lateral surface is the principle of marshallstability.Theloadcarryingcapacityofthemixat 600 Cwasmeasuredinkg.

Totalweightofthemouldis1200g.

5.1.1 Test Procedure

Heat the weighted aggregates and bitumen-plastic mix separatelyupto170°C.

Mix them proper and transfer mix to compaction mould arrangedoncompactionpedestal.

Give 75 blows on the top side of the specimen mix with a standard hammer (45cm, 4.86kg) and repeat the same procedurebyreversingspecimen.

allowthemouldwiththespecimentocoolforfewminutes then remove the specimen from the mould by gentle pushing.Markthespecimenandallowittocureforaday.

Aseriesofspecimenswithincreasingamountsofbitumen content are created using a similar process, with an incrementof2percent.

Placethemouldina waterbathforminimum45minsata temperatureof60°C.

CheckthemouldsstabilityusingtheMARSHALLSTABILITY apparatus.

In road construction bitumen has good hardness or softness. To determine this softness, we carried out this test.ThistestisconductedasperIS1208–1978.Bitumen sampleistakeninmouldandthenneedlehavingweightof 100gms is penetrated in sample then the penetration is taken.

6.2 Ductility test

In the road construction the bitumen is the important material used as binder. It is important that the binder shouldhaveenoughductilethinfilmaroundtheaggregate. This serves to improve a physical interlocking of an aggregate.ThistestisconductedasperIS1208–1978.This testiscarriedouttodeterminethequalityofbitumen.The bitumen is placed in mould, that mould is placed in water bathandstretchedtillthesamplebreaksintwoparts,then lengthismeasured.

1

2

3

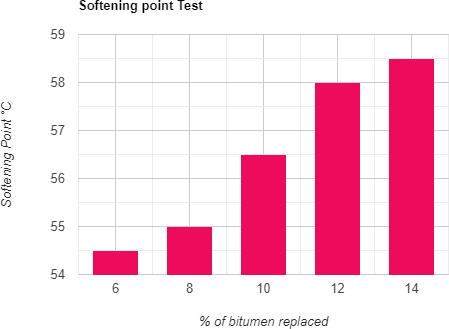

Softening Point °C

Range as per IS73:2013

1 6 54.5 Min50

2 8 55 Min50

3 10 565 Min50

4 12 58 Min50

5 14 585 Min50

Min25

4 12 36 Min25

5 14 30 Min25

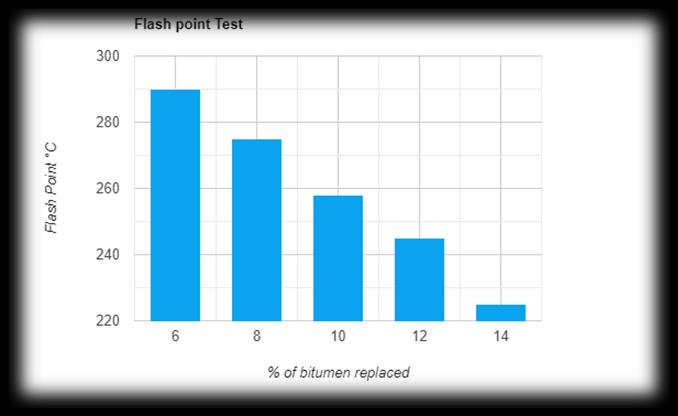

6.4 Flash Point test

Flashpointthetemperatureatwhich,bitumenvapourwill ignite for an instance when a small flame is brought into contactwiththevapourduringheating.

SR NO.

6.3 Softening Point test

Range as per IS73:2013

Softening point test is the temperature at

the substance attains a particular degree of softening under specifiedconditionoftest.Highersofteningindicateslower temperatureand it ispreferred in warmclimate. Bitumen istestedinsofteningpointapparatus.Asbitumensampleis touchedthebottomflangethattemperatureisobtainedas aresult52°-53°C.Thesofteningpointofvariousbitumen gradesusedinpavingjobsvarybetween35°-70°c.Thistest isconductedasperIS:1205–1978.

Table 6 Flash point test

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page924

3. CONCLUSIONS

1) From table 1 and 2 it is observed that the marshall stabilityvalueandflowvaluearewithintheprescribe range according to MORTH (Ministry Of Road TransportAndHighwaysfor6%and8%replacement ofwasteplasticwithbitumenthan10%,12%,14%.

2) From table 3 it has concluded that penetration value decreases with the increase in plastic content which showsthatadditionofpolymerincreasesthehardness ofbitumen.

3) From table 4 it has concluded that ductility value decreases with the increase in plastic content which shows interlocking of the polymer molecules with bitumen.

4) From table 5 it has concluded that softening point increases with the increase in plastic content which showslessbleedingduringsummer.

5) From table 6 it has concluded that flash point of bitumenmixdecreaseswithincreaseinplasticcontent whichmakesuseableincolderclimate.

REFERENCES

1. AmitGawande,G.Zamare,V.C.Rengea,SaurabhTayde, G. Bharsakale, “An Overview On Waste Plastic Utilization In Asphalting Of Roads” - journal of engineering research and studieseissn0976-7916vol. Iii/issueii/april-june,2012/01-05

2. Miss Apurva J Chavan, “Use Of Plastic Waste In Flexible Pavements”, international journal of application or innovation in engineering & management (IJAIEM), volume 2, issue 4, april 2013 pp540-551.

3. U Sathish, A.V.Sandeep “Partial replacement of bitumen with waste plastic in flexible pavements.” International Research Journal of Engineering andTechnologyVolume:7Issue:7.

4. IRC,“TentativeSpecificationsForBituminousSurface DressingUsingPre-CoatedAggregates”.

5. IRC: 48-1972, Indian Roads Congress ISI, “Indian Standards Specifications For Roads Tar”, is: 215, indianstandardinstitution.

6. Vikas R Agrawal, SauravAnand Agrawal, Nikhil Kale “PerformanceEvaluationOfPlasticModifiedBitumen InFlexiblePavement”departmentofcivilengineering, priyadarshin

7. Ge OfEnzahraNiloofarKalantar, Mohamed Rehan Karim, AbdelazizMahrez “A Review Of Using Waste AndVirginPolymerInPavement”-constructionand buildingmaterials33(2012)55–62.

8. AthiraRPrasad“BituminousModificationWithWaste Plastic And Crumb Rubber” - iosr journal of mechanical and civil engineering (iosr-jmce) volume 12,issue3ver.Ii(may-jun.2015).

BIOGRAPHIES

Name : Prof. Shubhra Dhamande

Qualification : M.E.(Construction Management)

Assistant Professor at NHITM, Thane

Name:Mr OmkarPhatak

Qualification:B.E.(Civil)

U.G Student atNHITM,Thane

Name:Mr RoshanPatil

Qualification:B.E (Civil)

U.G Student atNHITM,Thane

Name:Mr PratikTalekar

Qualification:B.E.(Civil)

U.G Student atNHITM,Thane

Qualification:B.E.(Civil)

U.G.