“EXPERIMENTAL STUDY ON PARTIAL REPLACEMENT OF CEMENT BY SEWAGE SLUDGE ASH AND GGBS IN CONCRETE”

Roshani C. Jopale1 & Dr.R.M.Sawant2Abstract - Concrete is the most widely used construction material in the civil engineering industry because of its high structural strength and stability. The concrete industry is looking for supplementary cementitiousmaterialor industrial by-products to reduce carbon dioxide emission which is harmful to the environment. Sewage sludge is an organic residue generated by municipalities following secondary and tertiary treatment of wastewater streams is used as a soil amendment and fertilizer to improve the yield of selected crops, as well as a fuel in co-combustion with other fuels or types of waste and is used as a replacement material for cement. Ground granulated blast furnace slag (GGBS) is the solid waste generated by the industry that is used as an alternative replacement material for cement.Thispaperdeals with the effective utilization of waste material in concrete production as a partial replacement for Cement. The cement has been replaced by SSA in the range of 7.5%, 9%, 10.5%, 12%, 13.5%, and 15% by weight of cement, GGBS In the range of 10%, 20%, 30%, 40%, 50%, 60% percent by weight of cement. A workability test was carried out on fresh properties of concrete while compressive strength, split tensile strength, and flexural strength were carried out on hardened concrete. It is found that the partial replacement of cement with SSA and GGBS helped in improving the strength of the concrete substantially. Compressive strength test, flexural and split tensile strength test were carried out at 7 and 28 days curing period.

Key Words: SewageSludgeAsh(SSA),GroundGranulated Blast Furnace Slag (GGBS), Compressive Strength, Split TensileStrength,FlexuralStrength,andWorkability.

1. INTRODUCTION

Concretehasbeenthemajorinstrumentforprovidingstable And reliable infrastructure since the days of Greek and romancivilizations.Concreteisthemostworldwidelyused construction material. With the increase in demand for concrete, more new methods and materials are being developed for the production of concrete. Concrete is a mixture ofcement,water,andaggregates with or without chemicaladmixtures.

The most important part of concrete is cement. Use of cement alone as a binder material produces large heat of hydration. Since the production of this raw material producesalotofCO2emission.Thecarbondioxideemission from the cement raw material is very harmful to

environmentalchanges.Nowadaysmanyresearchershave been carried out to reduce CO2. The effective way of reducingCO2emissionsfromthecementindustryistouse industrialby-productsoruseofsupplementarycementing materials such as Sewage Sludge Ash (SSA), Ground Granulated Blast Furnace Slag (GGBS), Fly Ash(FA), Silica Fume(SF)andMetakaolin(MK).Inthispresentexperimental work,anattemptismadetoreplacecementwithSSAGGBS toovercometheseproblems.

2. EXPERIMENTAL PROCEDURE

2.1

Materials and mixture proportions:

2.1.1 Ordinary Portland Cement [OPC]:

The cement used in the experiments was Ordinary PortlandCementofgrade53,whichconfirmsIS12269:1987. ThespecificgravityofOPCcementis3.15;theinitialsetting timeis30minutes.Thenormalconsistencyofcementis30% andtheparticlesizerangeliesbetween31umand7.5um.

2.1.2 Fine Aggregate:

Inconcretetechnology,thespecificgravityofaggregateis used in the design calculation of concrete mixes. The standard specifications in IS:2386 part 3 of 1963 give various procedures to find out the specific gravity of different sizes of aggregates. In this study, tapi river sand wasused.Thespecificgravityis2.68.

2.1.3 Coarse Aggregate:

Theidealcoarseaggregateshouldbecleancubical,angular, and 100% crushed aggregate with a minimum of flat and elongatedparticles,ACI363R,1992.Thespecificgravityof aggregateusedinthedesigncalculationofconcretemixesin the concrete technology. The standard specifications in IS:2386part3of1963givevariousprocedurestofindout the specific gravity of different sizes of aggregates. In this study as a coarse aggregate, the medium well-graded aggregatewasused.Thespecificgravityofthisaggregateis 2.60.

2.1.4 Water:

TherequirementofwaterconfirmedtoIS:10262:2019is found to be suitable for making concrete. The minimum waterrequirementforamediumwell-gradedaggregateof

size20mm-60%and10mm-40%is200Kg/m3asconfirmed byIS:10262:2019Tableno7(clause6.2.4).

2.1.5 Ground Granulated Blast Furnace Slag:

Ground granulated blast-furnace slag, GGBFS, is a byproduct of iron in the blast furnace. It mainly consists of silicate and aluminosilicate of melted calcium that periodicallyneededtoberemovedfromthe blastfurnace. Similar to fly ash, the chemical compositions of GGBFS dependontherawmaterialsusedintheproductionofiron whilethephysicalpropertiesdependonthecoolingprocess used to cool down the molten materials. It can be used in proportions of 5-30% of the cement content in the mix. ConfirmingIS10262:2019,tableno.9(clause6.2.6)Forthis experimentalinvestigation5-30%.

2.1.6 Sewage Sludge Ash:

Sewage sludge is an organic residue generated by municipalitiesfollowingsecondaryandtertiarytreatmentof wastewater streams. It is used as a soil amendment and fertilizertoimprovetheyieldofselectedcrops,aswellasa fuel in co-combustion with other fuels or types of waste. Sewage sludge is disposed of by land spreading, burial in landfills,andincineration.Itcanbeusedinproportionsof530ofthecementcontentinthemix.ConfirmingtoIS10262: 2019. For this experimental investigation, 15% Sewage SludgeAshwasused.

3. TEST METHODS

3.1 Mixing Of Material:

Machinemixingwasusedforthemixingofmaterial.First aggregatewasaddedtothemixer,followedby25%oftotal watertopreventcementfromstickingtothebladesoratthe bottomofthedrum.Initially,thespecimenwascastusinga 0.62water-to-binderratio.Theaggregateofsizes20mmand 10wereusedas60%and40%whiletheSewageSludgeAsh from 7.5 to 15% and GGBS from 5 to 30% by weight of cement at an interval of 2.5% and 10% were used as cementitious materials. In this experimental work, the behavior of mechanical properties of concrete such as compressive, split tensile, flexural, color, and workability was observed. A slump test is conducted for each mix to measure the workability of the concrete. Three cubes of 100X100X100mm,3cylindersof150mmdia.and300mmin height,and3beamsof100X100X500mmwerecastforeach mixes to measure the compressive strength, split tensile strength, and Flexural strength of concrete. A cylinder of 150mmdia.and300mmheightarecastforeachmixesto measure the modulus of elasticity of concrete. Totally 42 cubes, 42 cylinders, and 42 beams are cast. The cast specimenswerekeptatambienttemperaturefor24hours. After 24 hours they were molded and placed in water for curing.

3.2 Testing of Specimen:

Allcubeandcylinderspecimensaretestedforcompression strengthandtensileinCompressionTestingMachine(CTM) andallthebeamsspecimensaretestedforflexuralstrength inauniversaltestingmachine(UTM)showninfigure

4. RESULT AND DISCUSSION: 4.1 Compressive Strength:

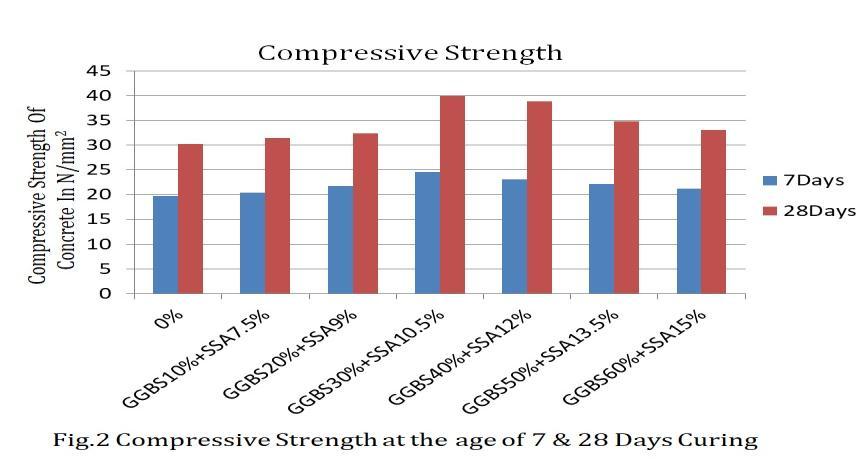

Thecompressivestrengthofconcretewasdeterminedatthe ageof7and28daysaspresentedingraphFig2

levelofstrength,concretefailureoccurred.Whichshownin Table No.2 Concrete compressive strength increased with increasingtheratioofGGBSandsewagesludgeAshcontent.

4.2 Split Tensile Strength:

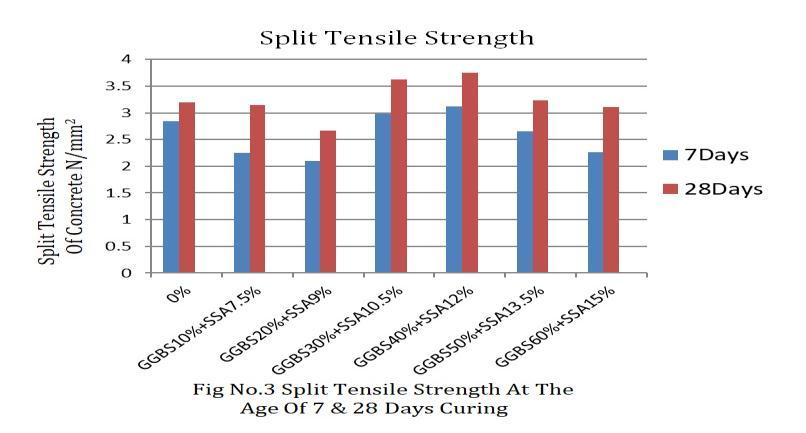

The tensile strength of concrete was determined at the ageof7and28daysaspresentedingraph.FigNo.3

representsthecompressivestrengthofconcretewith partialreplacementofcementbyGGBS0%,10%,20%,30%, 40%,50%,and60%andSSA7.5%,9%,10.5%,12%,13.5%, and15% Duringthecuringperiodof7and28days,three specimens for each curing period were tested for their compressive strength [Fc] and their average compressive strengthwasshownintable2.

Table No:-2 Average Compressive Strength (N/mm2)

represents split tensile strength of concrete with partial replacementofcementbyGGBS0%,10%,20%,30%,40%, 50%,60%&SSA7.5%,9%,10.5%,12%,13.5%,and15%. There is an increase in split tensile strength for the replacement of GGBS and SSA. Maximum strength was obtained for 40% GGBS and 12% percentage of SSA replacementwithcement.Testresultsshowthesplittensile strengthvariedfrom2.84to3.12MPafor7daysand3.2to 3.75in28days for12%ofSSAand40%ofGGBScontent. Whentheloadreachedacertainlevelofstrength,concrete failureoccurred.WhichisshownintableNo3.

Fromthetable,itwasidentifiedthatmixof30%GGBSand 10.5%SewageSludgeAshhasahighercompressivestrength than other GGBS and Sewage Sludge Ash content. Table 2 showsTherelationshipbetweenthecompressivestrength and Sewage Sludge Ash and GGBS volume fraction and aspectratio.Itdemonstratesthatthecompressivestrength increases with increasing Sewage Sludge Ash and GGBS content. However, it shows a relatively lower rate of increase.Testresultsshowthecompressivestrengthvaried from19.70to24.56MPafor7daysand30.21to39.91inthe periodof28daysfor10.5%ofSewageSludgeAshand30% ofGGBScontent.Whenacompressiveloadreachedacertain

4.3 Flexural Strength:

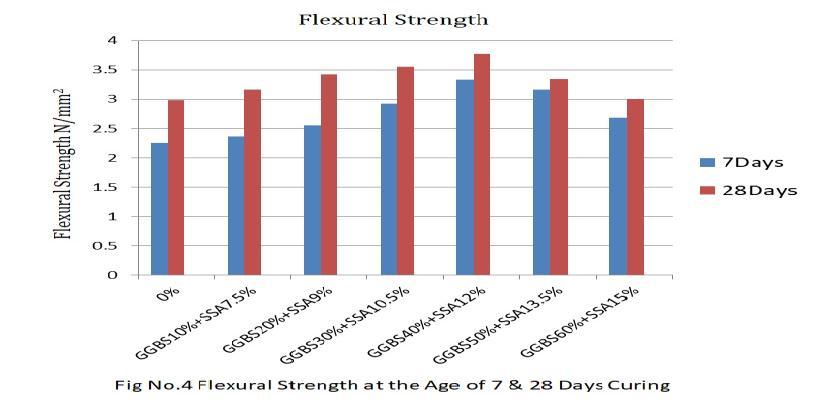

The flexural strength of concrete was determined at the ageof28days.

Fig4representsthe7and28days'flexuralstrengthof concretewithpartialreplacementofcementby10%,20%, 30%, 40%, 50%, 60% GGBS & 7.5%, 9%, 10.5%, 12%, 13.5%and15%percentageofSSA.Theflexuralstrengthof GGBSandSSA-basedconcreteisincreasedwhichishigher than 40% GGBS and 12% SSA. Maximum strength is observedfor40%GGBSand12%SSA.Testresultsshowthe flexuralstrengthofconcretevariedfrom2.26to3.33MPa for7daysand2.98to3.77in28daysfor12% ofSSAand 40%ofGGBScontent.

Table No:-4 Average Compressive Strength (N/mm2)

5. CONCLUSIONS

Based on the experimental investigation the following conclusionisdrawn

[1] SSA has been proven as an efficient pozzolana with propertiessimilartothatofflyash.

[2]NotmuchresearchisbeingcarriedoutinIndiaonSSA. SinceIndiaisapopulouscountrywithahugeproductionof sewagewaste.IfsewagesludgeisconvertedtoSSA,itcan solvetheproblem of disposal ofsewage toa considerable extent.

[3]SincethepropertiesandcompositeofSSAdependupon the source, it is necessary to carry out a detailed characterizationstudyonSSA.

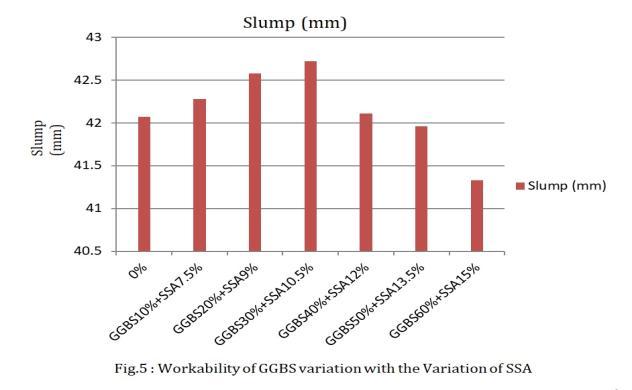

[4]Theworkabilityofconcretewasfoundtoincreasewith theincreaseinSSAandGGBSinconcrete.

[5] Maximum compressive strength was obtained for the replacementofcementby30%GGBSandby10.5%SSA.

[6] Maximum flexural strength achieved for cement replacementby40%GGBSandsandby10.5%SSA.

[7]Maximum splittensilestrengthisachieved forcement replacementby40%SSAandby10.5%GGBS.

REFERENCES

[1] MourtadaRabieG(2016)Usingofwastewaterdryand wetsludgeinconcretemix.JCiv

[2] Piasta W, Lukawska M (2016) The effect of sewage sludgeashonpropertiesofcementcomposite.Inworld multi diciplinary civil engineering architecture urban planningsympo-sium2016,WMCAUS2016(vol161,pp. 1018–1024).

4.4 Slump Test:

Fig 5 represents the workability of the GGBS and SSA concrete mix. From this fig, it can be seen that as the percentageofGGBSincreasestheworkabilityalsoincreases.

[3] Chen Z, Poon CS (2017) Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Constr BuildMater154:791–803.

[4] Fontes CMA, Toledo Filho RD, Barbosa MC (2017) Sewagesludgeash(SSA)inhighperfor-manceconcrete: characterizationandapplication.Revista IBRACONde EstruturaseMater9(6):989–1006.

[5] ChenZ,LiJS,PoonCS(2018)Combineduseofsewage sludgeashandrecycledglassculletfortheproductionof concreteblocks.JCleanerProd171:1447

1459.

[6] Nakic D (2018) Environmental evaluation of concrete withsewagesludgeashbasedonLCA.SustainProduct Consump16:193–201

[7] Dunuweera SP, Rajapakse RMG (2018) Cement types, composition, uses and advantages of nanocement, environmental impact on cement production, and possiblesolutions.AdvMaterSciEng

[8] Liu M, Zhao Y, Xiao Y, Yu Z (2019) Performance of cementpastescontainingsewagesludgeashatelevated temperatures.ConstrBuildMater211:785–795.

[9] Krejcirikova B, Ottosen LM, Kirkelund GM, Rode C (2019)Characterizationofsewagesludgeashanditseff ectonmoisturephysicsofmortar.JBuildEng21:296–403.

[10] Ishwarya G, Singh B, Deshwal S, Bhattacharyya SK (2019) Effect of sodium carbonate/sodium silicate activator on the rheology, geopolymerization and strengthofflyash/slaggeopolymerpastes.CemConcr Compos97:226–238.