A comparatively analysis of plate type H.E. and helical type H.E. using ANOVA method

Sumit Mishra1, Prof. Swati D. Chaugaonkar2

1 M.Tech. Scholar, Department of Mechanical Engineering SGSITS Indore (M.P.) India

2 Professor, Department of Mechanical Engineering SGSITS Indore (M.P.) India ***

Abstract - The bulk of the chemical industry places a high priority on heat transfer from one fluid to another. The most typical use of heat transfer is in the design of machinery that involves transferring heat from one fluid to another. They are effective heat transporters, these heat exchangers. A heat exchanger's efficiency is frequently categorized based on the transfer process that takes place in it. Using the ANOVA approach, this study analyses two different heat exchangers. programming for design

Key Words: HEanddesign,ANOVA,CATIAV5.

1. INTRODUCTION

Using heat exchangers, heat is transported from one mediumtoanother.Thesemediacanbecomposedofliquids, gases,oracombinationofthetwo.Themediummaybein closeproximitytooneanotherorseparatedbyathickwall topreventmixing.Bymovingheatfromsystemswhereitis unnecessary to systems where it may be used, heat exchangerscanincreasetheenergyefficiencyofasystem.

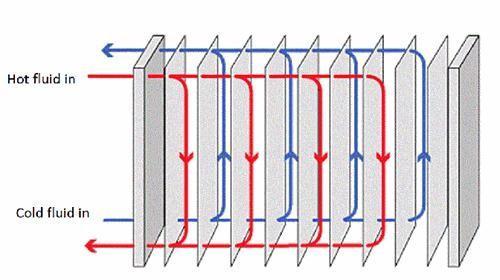

1.1 Plate-type heat exchanger

PlateandFrame-Bystackingthinparallelplates,it isfeasibletoproducebroad,parallelchannels.Heatandcold fluidscanexchangepositionsthroughavarietyofchannels. Theplatescanbebuilttopromoteturbulentflowandare separatedbyweldingorbyemployingagasket[2].

Toincreaseheatingcapacity,moreplatesmightbe addedtothestackofplatesusinggasketdesigns.Theflow canbearrangedbothparallelandanticlockwise.

1.2 HELICAL COIL HEAT EXCHANGER

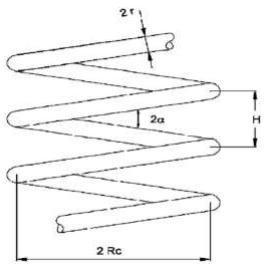

Figure1.2depictstheschematicofahelicalcoil.Inthe pipe,thereisa2rdiameter.Thecoilhasadiameterof2RC and a pitch of H, where RC is the distance between the centersofthepipes.Thecoildiameterisanothernamefor the pitch circle diameter (PCD). The curvature ratio is calculatedusingthepipediametertocoildiameterratio (r/Rc).Bydividingthedevelopedlengthofoneturnbythe pitch,orH/2rRc,thenon-dimensionalpitchisdetermined. Take into account that the coil is being reflected onto a plane that is perpendicular to the coil's axis. The helix angle may be created by extending one coil around in a planeperpendiculartotheaxis.AswithReynoldsNumber, DeanNumbermaybeusedtodescribetheflowinhelical pipes.

Yanhui Han et, al. (2009) have shown The microchannelheatexchanger(MCHX)hasbecomemorepopularin theHVAC&R(Heating,Ventilation,andAirConditioning& Refrigeration) field because of its higher heat transfer efficiency,morecompactdesign,andlowercost.Thisstudy providesanoverviewofthepropertiesoffluiddynamicsand micro-channelheattransfer.Thetechnique’sprosandcons of the MCHX are examined together with information on optimizations (i.e., geometry and thermodynamic performance).

Rongshui Rao et. al. (2015) have Shown are four different types of microchannel heat exchangers used in

domesticairconditioners..Nearlyallautomobileshaveair conditioning, but domestic air conditioners have not yet utilizedmicrochannelheatexchangers.Additionally,inorder to address the issue of frost and de-frost in heat pump outdoorunits,wecreatedanewmicro-channelcondenserin 2012thatswitchedthecorrugatefinforaflatfin.Intheend, we developed four different types of microchannel heat exchangersthatmaybeusedinalldomesticairconditioner devices.

Oana Giurgiu et al. (2015) Comparativeresearchwas doneonhowthegeometricalpropertiesofthetwoexamined plates had an impact on how intense the heat transfer processbecame.Thisinvolvedinvestigatingthedistribution of velocity, temperature fields, and convection coefficient alongtheactivetinychannel.Theinclinationanglesofthe examinedmicrochannelswere30°and60°,respectively,and theReynoldsflownumberwas3500.

3. Methodology

3.1 COEFFICIENT OF HEAT TRANSFER

Achangeindensityoveralayerofsurroundingfluidover thehotsurfacecausesconvectiveheattransfer,whichisthe processofheatbeingmovedfromonelocationtoanotherby moving fluids.Thelargestresistanceisfoundinthislayer since most fluids have low thermal conductivity, which is how heat is transmitted through it. Heat transmission throughthefilmcanbeenhancedbyincreasingthefluidflow rateacrossthesurfacewhileloweringthefilmthickness.The equation for the rate of heat transfer by convection in a steadyconditionisdisplayedbelow:

Q=ha(Tw-Tatm)

wherehisthefilmsurfacecoefficient.aStandsforthewall's area, TW for the wall's temperature, and Tatm for the surroundingair'stemperature.

3.2 ANOVA

Finding a good treatment plan frequently involves looking at how long it takes patients to recover. To determinehowdifferentthesethreetreatmentsamplesare from one another, statistical methods may be used to compare them. An ANOVA is a statistical technique for comparingsamplesbasedontheirmeans.

Iftwoormoregroups'meansdiffersignificantlyfromone another,itmaybedeterminedusingthestatisticalmethod knownasanalysisofvariance(ANOVA).AnANOVAanalyses the means of several distinct samples to investigate the influenceofoneormorefactors.Bydistinguishingbetween systematicandrandomcomponents,thestatisticalanalysis methodknownasANOVAaccountfortheobservedoverall variabilitywithinadataset.Thepresenteddatasetexhibits

systematicimpactsthatarestatisticallymoreimportantthan random influences. The ANOVA test is used in regression analysistoevaluatetheimpactofindependentfactorsonthe dependentvariable.

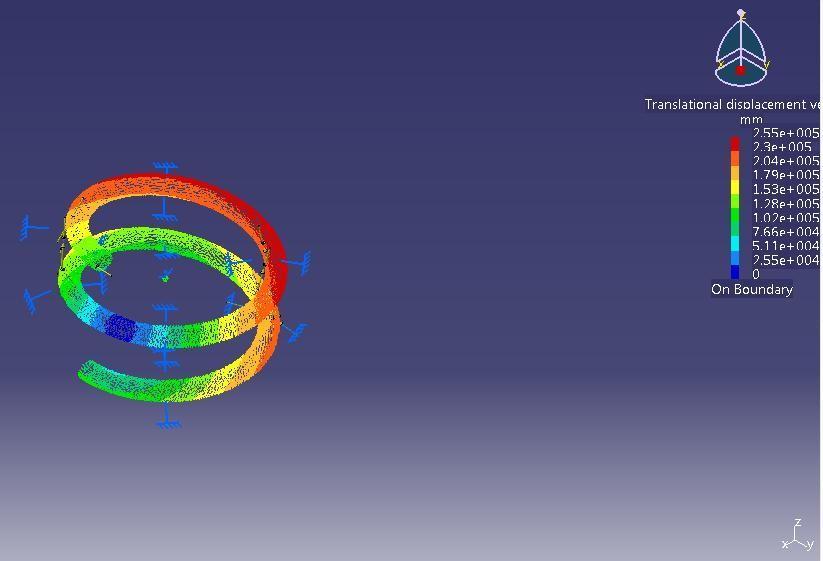

4. RESULT AND ANALYSIS

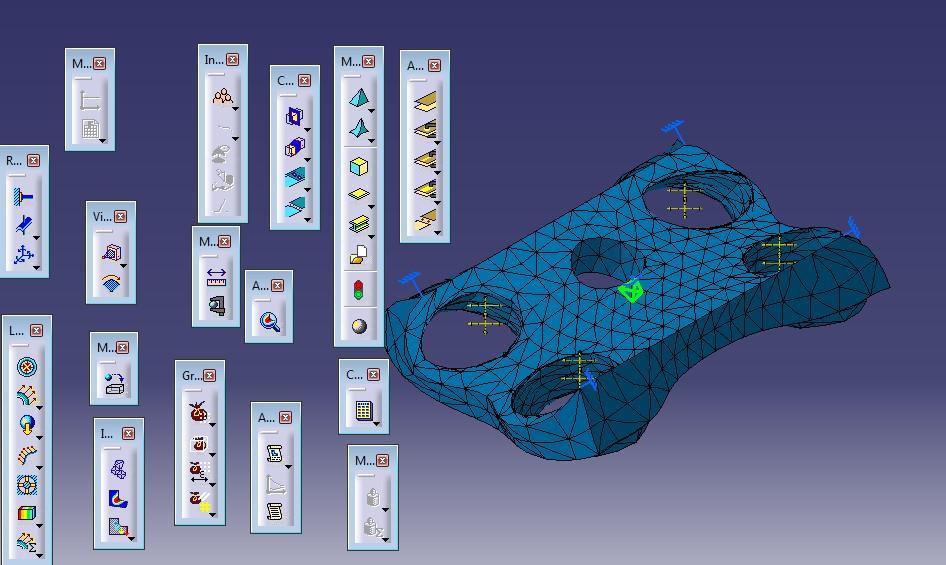

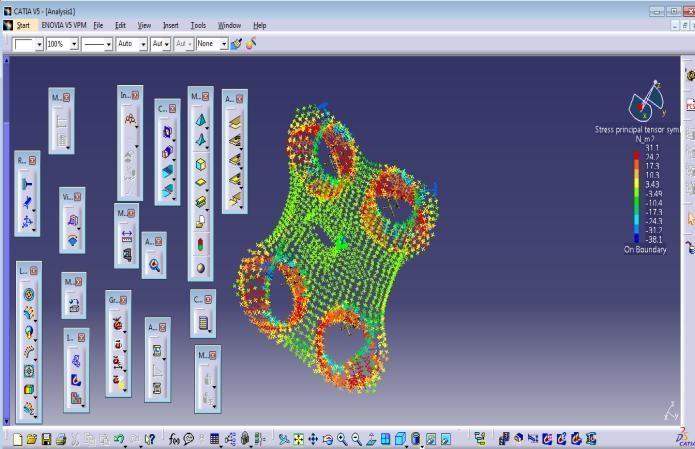

CATIA is the name of a piece of software used for mechanicaldesign.ItisaWindows-basedparametricdesign toolforsolidmodelingwitha user-friendlygraphicaluser interface. It is possible to represent design intent through automaticallyproducedoruser-definedrelationsbycreating completely associative 3D solid models with or without restrictions.Considertheuserinterface.

Solid 3Dgeometry may be madeusing the Part Design workbench. From the Part Design workbench,gototheSketcherworkspacetobuild 2D profiles that will eventually become 3D models.

You can put the components together on the AssemblyDesignworkbenchtomakethefinished product. Use strategies for creating assemblies thatwillhelpwithconcurrentengineerings,such as skeleton models and publishing elements, whiledesigningpiecesinsidetheframeworkofan assembly.

To create surface and wireframe geometry, utilize the GenerativeShapeDesignworkbench.Surfaceandwireframe geometrygivesyoumorecontrolovertheformoftheobject andallowyoutodesignmoreintricatesolidmodels.

5. CONCLUSIONS

When examining heat exchangers in this booklet, it is possibletoignoretemperaturelossesfromradiation.There arevariousprimaryformsofindirectheatexchangers(plate, shell-and-tube, spiral, etc.). The most effective heat exchanger is often the plate kind. It provides the largest pressureandtemperaturelimitswithinthelimitationsofthe presenttechnology,oftenprovidingthegreatestsolutionto thermalconcerns.Aplateheatexchanger'smostsignificant benefitsare:

• Uses substantially less room than a conventional shell andtube-typeheatexchanger.

• A surface for the heat transmission using a thin substance sincetheheatonlyneedstopassthroughthin material,thisresultsinthebestheattransmission.

• Significant medium-level turbulence − More convectionisthusproduced,enablingmoreefficientheat transferacrossthemediums.Alesseramountofsurface area is required and operation is more efficient as a resultoftheimprovedper-unit-areacoefficientofheat transmission. High turbulence also has a self-cleaning characteristic.Asaresult,theheattransfersurfacesare substantially less likely to become fouled than they wouldbeinatraditionalshell-and-tubeheatexchanger. Thistranslatesintoamuchlongerplateheatexchanger lifespanbetweencleanings.

• Flexibility-Thebuildingthatcontainsnumerousheat transferplatesisknownastheplateheatexchanger.To increase capacity, it may be easily expanded. For cleaningpurposes,itisalsosimpletoopen.(Brazedor fusion-bonded elements are unaffected; the only problematiccomponentsaregasketedheatexchangers.

• Adjustable thermal length − The majority of Alfa Laval plate heat exchangers come with one of two pressing patterns. Heat exchanger efficiency is higher when the plate has a thin pattern because it causes a biggerpressuredrop.Thiskindofheatexchangerhasa verylengthythermalchannel.Wideplatedesignshavea somewhatlowerheattransfercoefficientbecausethey have a smaller pressure drop. This kind of heat exchangerhasathermalchannelthatisonlyalittlebit longer. Long and short channels, as well as pressure dropandefficacy,areallcompromisedbythepairingof twoplateswithvariouspressingpatterns.

REFERENCES

1) H.Y.Zhang, M.J.Li, B.X.Wang, Application of microchannelheatexchangerinthehouseholdairconditioning, Heating Ventilating And Air Conditioning(HV&AC),39(2009).

2) Xiaoguang Xu, Experimental and Theoritial InvestigationonPressureDropandHeatTransfer FlowBoilinginMicroehannelNanjingUniversityof Science&Teehnology6(2009).

3) Rongshui Rao, J. Cheng, Applied Research of Microchannelheatexchangerontheairconditioner, RefrigerationAndAir-Conditioning,09(2009).

4) SatishG.Kandlikar,WilliamJ.Grande,Evolutionof microchannel flow passages thermohydraulic performance,Proceedings of IMECE2002 ASME InternationalMechanicalEngineering Congress & ExpositionNovember17-22,NewOrleans,Louisiana (2002)

5) S.K. Yener, M. Avelino, T. Okutucu, Single-phase ForcedConvectioninMicro-channels–aState-of-

the-art Review, Kluwer Academic Publishers, (2005)1-24.

6) Md. Jane, Alam Khan, Md. Rakibul Hasan, M.A.H. Mamun, Flow behavior and temperature distribution in micro-channels for constant wall heat flux, 5th BSMEInternational Conference on ThermalEngineering,,56(2013)350-356.

7) Y. Hana, Y. Liua, M. Lia, J. Huang, A review of development of micro-channel heat exchanger applied in air-conditioning system,, 2nd International Conference on Advances in Energy Engineering (ICAEE2011), Energy Procedia, 14 (2012)148-153.

8) Giurgiu O., Opruta D., Bode F., P. A., Influence of geometricalparametersontheperformanceofplate heat exchangers with gaskets, 3'd International ConferenceLowTemperatureandWasteHeatUsein Communal and lndustrial Energy Supply Systems TheoryandPractice,Bremen,Germania,(2012)9298,.

9) Giurgiu Irimieş O., F. Bode, D. Opruța, Study regardingtheinfluenceofthecrimpingangleonthe performancesoftheheatexchangers,International ConferenceExperimental Fluid Mechanics, Hradec Kralove,Cehia,(2012)297-303.

10)Meslem,F.Bode,C.Croitoru,I.Nastase,Comparison ofturbulencemodelsinsimulatingjetflowfroma cross-shapedorifice,EuropeanJournalofMechanics B/Fluids,(2014).

11) Z.N.Zhao,Effectsofthecorrugatedinclinationangle on heat transfer and resistance performances of plateheatexchangers,Petro-ChemicalEquipment,5 (2001)2-3.

12)Ghosh,S.K.Sarangi,P.K.Das,Analternatealgorithm for the analysis of multistream plate fin heat exchangers,InternationalJournalofHeatandMass Transfer,49(2006)2889-2902.

13) www.fluent.com-FluentUsersGuide.

14) Meslem,F.Bode,I.Nastase,O.Martin,Optimization oflobedperforatedpaneldiffuser:Numericalstudy of orifice geometry, Modern Applied Science, 6 (2012)15.

15) F. Bode, I. Nastase, C. Croitoru, Mesh Dependence StudyUsingLargeEddySimulationofaVeryLow Reynoldscross-shapedjet,MathematicalModelling inCivilEngineering–scientificJournal,7(2011).