Study of Plastic Waste Mix Bitumen

1Assistant Professor, Civil Engineering Department, Kali Charan Nigam Institute of Technology,Banda,(U.P.)(India)

2Assistant Professor, Civil Engineering Department, Kali Charan Nigam Institute of Technology,Banda,(U.P.)(India)

3Assistant Professor, Civil Engineering Department, Kali Charan Nigam Institute of Technology,Banda,(U.P.)(India)

4Assistant Professor, Civil Engineering Department, Kali Charan Nigam Institute of Technology,Banda,(U.P.)(India)

5Director, Kali Charan Nigam Institute of Technology,Banda,(U.P.)(India)

Abstract - Plastic garbage and the method used to dispose of it are major environmental problems that contribute to pollution and global warming Alternative methods have typically been required to properly dispose of these desperate objects because all plastic materials are unacceptably bad for the environment. The characteristics and strength of bituminous mixtures are improved by adding plastic garbage. Therefore, it is imperative that everyone adopts efficient techniques for using these plastic wastes from the social context. Additionally, it will be a fix for numerous pavement flaws like potholes, corrugation, ruts, etc., as well as a way to dispose of plastic. Plastic waste is used to make polyethylene, polystyrene, and polypropylene. Therefore, it is imperative that everyone adopts efficient techniques for using these plastic wastes from the social context. Population growth in the area, urbanization, and significant lifestyle changes all contribute to the massive use of polythene. The proper disposal of waste plastic has historically presented a significant problem, especially in a collaboratively developing developed country like India. The environmental impact of polythene is intolerable. Environmentally unacceptably harmful and not biodegradable is polythene. India produces 3.3 million metric tons of plastic waste annually on average, according to a Central Pollution Control Board (CPCB) report (2018–19). Only 9% of the total amount of plastic garbage produced in the global world which includes the 9.46 million tons of waste that India naturally produces each year is adequately recycled. The purpose of the current study, which is published under the creative commons license, is to adequately analyze the specific behavior of modified bituminous concrete (BC) mixes containing plastic garbage. In this social study, various sizable quantities of modern plastic are typically used to create the required special mixes with a selected aggregate grading as determined by the IRC Code. The waste plastic is shredded & coated over aggregate & mixed with hot bitumen and resulted mix is used for pavement construction. This will not only strengthen the

***

pavement and also increases its durability. The titanium-dioxide is employed as a smoke absorbent material, which can absorb the smoke from the vehicles. This cutting-edge technology will soon be available in India's hot and humid climate. It is cost-effective and green.

Keywords: Bituminous Concrete (BC), MarshallStability, Voids filledBitumen, Wasteplastic.

I. INTRODUCTION

The disposal of waste plastic presents the biggest environmental concern. The main issue with the national highway nowadays is the corrugation and potholes. Plastic pavement will be a superior solution to the concerns mentioned above, according to my research work and other papers that have been published too far. The term "plastic" refers to a bituminous substance that comprises one or more largemolecularweightorganicpolymersandissolidinitsfinal state.Plasticissaidtobehighlydurableandtodeterioratevery gradually. Plastic is also very resistant to the deterioration of natural life. As of 31 November 2020, the total network of modern highways in India will have a navigable length of 5.89 millionkilometers,makingitthesecond-largestnetworkinthe world. The moral foundation of any developed nation's established economy and sustained development is its road network. The finished development of the well-known boulevard obviously requires a huge quantity of necessary money. If good engineering design is always applied, the local road in a creative common will certainly have the requisite durability and considerable savings will be made during the modern construction of used roads. The many quantities of private features that must be carefully taken into account during the original design of the bituminous mix in the commons are enough good stability, excellent durability, flexibility, workability, air voids, and economy. This massive volume of produced plastic had really created a significant challenge for our financial environment. The effective removal of Plastic wastes frequently causes serious problems. The Indian government has already begun a new procedure to

effectively apply the four R's: Reuse, Reduce, Recycle, and Recover. This effort takes the unusual form of the "SwachhBharatAbhiyan"seriously.

II. IMPORTANCE OF STUDY

Temperature increases of up to 50°C are common in India, which has a good impact on the social life of flexible pavement. The greater flexibility of the pavement is demonstrated by the modified plastic mix bitumen. The modification procedure involves coating aggregate with plastic trash, which naturally increases the specific surface area of social contact and merely ensuresthatbitumenandeconomicaggregatearemore tightly bonded. In the conclusion, the bituminous mix accurately represents sufficient economic stability, great durability, flexibility, workability, air voids, and extremely economy when all factors were properly taken into account during current design. It will accuratelycalculatethestaggeringamountofplasticin use today and create environmentally friendly technology.

III. SCOPE OF THE RESEARCH

Togetridofpotholes.

Determiningthephysicalcharacteristicsoffiller, bitumen,andaggregates.

Findingtheenhancedstabilityandflowparameters usingtheOBC.

Measuringthemechanicalcharacteristicsof bituminousmixturesmadewithvariousamountsof wastePET

Comparisonofthestabilityofmodifiedand traditionalbituminousmixes.

Toreducepollution,greenhousegasemissions,and globalwarming.

Itispossibletolengthenthelifespanofthe roadways.

Ecologicalinnature.

IV. METHODOLOGY

The process of combining plastic waste with finer filler that is not less than 0.075 mm and aggregates that are not less than or greater than 25 mm in size. In order to consistently generate a workable, intoxicating, durable, and cost-effective compound, waste plastic mix

bituminous design attempts to determine the significant proportion of bitumen, filler, fine aggregates, and coarse aggregates. In addition to avidly consuming societal aggregate, waste plastic, bituminous binders, and different used grades of polythenearecrucialmaterialsemployedinbituminousconcrete mixtonaturallyfindtheBitumenStudyofPlasticWasteMix.The bitumen eagerly consumed for the current investigation appropriately comes from the PWD, Gorakhpur, and is of penetration grade 60/70. The local plastic waste recycling facility in Gorakhpur city shreds the plastic garbage that was previously separated from the massive amount of municipal rubbish. This published study uses polythene as a stabilizing component in the FORTUNE OIL, AMUL MILK, and LAYS CHIPS packaging, because AMUL MILK is extensively accessible for commercialpurposesincontemporaryGorakhpur,thepolythene usedtopackagemilkisalsowidelyaccessiblethere.AMULMILK and priceless FORTUNE OIL Polythene bags are carefully gatheredfromvariouslocations,rinsed,andcleanedbycarefully submerging them in hot water for around 4-5 hours. They were then naturally absorbed after that. The priceless packets were immediately divided into slightly more consistent parts after drying. When routinely adding the polythene to bitumen and socialaggregates,carefulmixingisrequired.Polythenehasbeen foundtohaveaspecificgravityof0.92.

V. TESTING MATERIALS USING

Inthisstudy,thegivenmaterialsusedare:

A) Bitumen

B) Aggregates(FineandCoarse)

C) PET/Plasticwaste

D) FillerMaterial

A. Bitumen

Bitumen is a binding substance that is a byproduct of the refining of petroleum. When the temperature rises above 100 degrees Celsius, it becomes solid and is correctly exceedingly viscous. The bitumen employed in this research study is typically 60/70 grade. Bitumen has been tested in labs for fundamentalmaterialproperties.

Table 3. Physical properties of ( PET )

Sieve Analysis

A. Filler

mmsieveand retainedon2.36 mm sieve

Theyobtainmanyvarioustypesoffillersareavailabletouse likeflyash,cement,stonedust.Butinthiscasepebblesdust isusedasthefilleraspecificGravityofthestonedust. Itgoeswithoutsayingthatcaremustbetakeninselectingan economic aggregate that has good and adequate strength, hardness, toughness, and fundamental soundness. This mental process uses a complex blend ofaggregates with a maximum and minimum size of 25 mm. Higher stability is produced by crushed aggregates. Using a variety of tests, such as those listed in the table, criticalmaterial properties ofsocialaggregatesarediscovered.

C. Polyethylene Terephthalate Waste (PET)

The organic food industry uses polyethylene terephthalate (PET), a tough plastic from the well-known polyester family, primarily for packaging soft drinks, food, mineral water, tainted milk, essential oils of all kinds, baked goods, frozen foods, salad dressings, cleaners, and various other products. In this unusual example, the PET was used to investigate and collect data from several locations in Gorakhpur (Gida and Bargadwa Industrial area, City Mall, RestaurantPublicplace,NaukaVihar,etc.).

Marshall testing Machine

The test was conducted as the prescribed format perASTM D-06procedure.

International Research Journal of Engineering and Technology (IRJET)

10 Issue: 01 | Jan 2023 www.irjet.net

Marshall Stability value-

It is specifically described as the highest load at which Marshall stability determines the highest load that the bituminous material has been able to withstand at a loadingrateof50.8mm/minute.Thetestloadisgradually increased until it normally exceeds the maximum that couldbeachieved.Afterthat,thenegativeloadingishalted amicably,andthemaximumload(i.e.,MarshallStability)is meticulously recorded when the dynamic load just barely beginstonormallydecrease.

Marshall Stability value as calculated-

Fix the flow meter correctly by starting it off at zero. A steady rate of continuous deformation of 51 mm (2 potential inches) each minute evenly distributes the cognitive load. Its Marshall Stability Value accurately capturestheoverallloadatapparentfailure.TheMarshall Flow value of the magnificent specimen is normally transmitted by an accurate flow meter reading in local unitsof0.25mm.

RESULTS

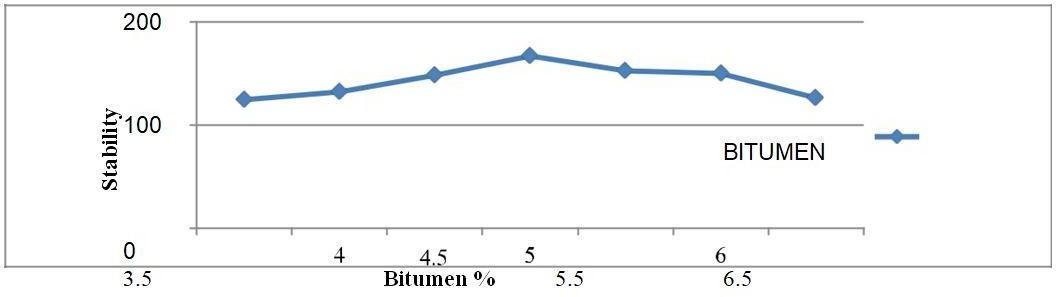

When no PET is mix in bitumen the result afterMarshallStabilityvaluetestis:

RESULT AND CONCLUSION

The correct introduction of waste plastic significantly improved the beneficial characteristics of bitumen binders. By unquestionably raising the softening point and hardness, this innovative approach of significant modification of bitumen has positively improved local resistance to cracking, potholes, and rutting. The general performance of flexible pavement was enhancedbytheuseful inclusionofwasteplastictothe aggregate. The realistic level of waste plastic content where the independent sample typically exhibits maximum Marshall Stability and little Marshall Flow. is knownasthe"optimumpolythene/plasticcontent,"and it often represents 4% accurately. According to the published study, adding useful waste plastic usually reduces the number of voids in the mixture. I carefully notethattheMarshallFlowvaluefallsafterthevaluable addition of polythene, demonstrating an increase in resistance to deformations caused by strong wheel loads.

1) Because the waste material was totally recycled without having a negative effect on the social environment, this creative process is incredibly effectiveinpreciselyminimizingtheenvironmental pollution. This published study supports the widespreaduseofPETandwasteplasticmaterials.

2) The sociological study's potential outcomes clearly showed that the modified combination produced superior results at different stages than the nonmodified mixture. It was always possible to improvethebondingbetweenthebinderandsocial aggregates in the cognitive process by adding PolyethyleneTerephthalate(PET)tothebitumen.

3) I correctly noted that the penetration ratings of ordinary bitumen occasionally drop when the PET content rises. Finally, the direct outcomes accurately reflect a constant improvement in the rutting resistance of the mix ingredients. The valuable addition of PET naturally makes the modified bitumen tougher and more consistent thanplainbitumen.

REFERENCES

1. Flynn, E., (1993) “Recycled plastic finds home in asphalt binder”,Journal,ofRoadsandBridgesVol.58,No.2,pp.32-4.

2. Neeraj Kumar Chaubey (2016) “A STUDY ON EFFECTIVE UTILIZATION OF WASTE PLASTIC IN BITUMINOUS CONCRETE MIX”, International Research Journal of EngineeringandTechnology(IRJET)Vol.03,IssueNo07.

3. Neeraj Kumar Chaubey (2016) “BEHAVIOUR OF BITUMINOUSCONCRETEPAVEMENTWITHOFPOLYTHENE WASTE”, International Research Journal of Engineering and Technology(IRJET)Vol.03,IssueNo07.

4. S.Madan Mohan (2016) “EXPERIMENTAL STUDY ON CHARACTERIZATION OF BITUMEN MIXED WITH PLASTIC WASTE”, International Journal of Engineering Science and ComputingVol.06,IssueNo08.

5. GawandeA.,ZamareG.,RengeV.C.,TaydeS.andBharsakale G. (2012) “An overview on waste plastic utilization in asphaltingofroads”.

6. A. Das and P. Chakroborty (2010), “Principles of TransportationEngineering”,PrenticeHallofIndia, pp. 29429