International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

1

Abstract - Conventional fluids such as water, engine oil, kerosene, ethanol, and ethylene glycol have lower thermal conductivity compared to solids. Lower thermalconductivityof fluid became an obstacle to use in different applications. To overcome this obstacle, a new method such as dispersing nano sized solid particles in fluids which enhance the thermal conductivity of base fluids significantly and it is named asnano fluids. These nano fluids are succeeded in many applications whereas coming to natural convection it faces debacle. Nano fluids used to enhance the convection heat transfer but conversely by using the nano fluids deterioration occurred. Some of the researchers got enhancement but they got enhancement in lower volume fractions. The reason behindthe deterioration is aggregation of nano particlesleadstoclogging and then to sedimentation and to find out the heat transfer enhancement using ultra sonication, magnetic stirring and surfactant addition is used to modify. But thesemodifiersaffect the properties such as thermal conductivity, viscosity, specific heat etc.

Particle size, shape, structurestronglyinfluencestheproperties of nano fluids. The parameters thermal conductivity, viscosity, specific heat, thermal expansion coefficient, density all are related to volume fraction. It is extremely sensitive to deal everything related to volume fraction. To minimize the complexities Cuo of 30nm with spherical shape are procured. Volume fractions are 0.05%, 0.1%, 0.15%, 0.2% are preferred to conduct experiment ultra-sonication, magnetic stirring is preferred. Enhancement is obtained up to 0.15% volume fraction and further deterioration occurs. In the natural convection heat transfer enhancement through nano fluids is explained Correlations between Nusselt number and Rayleigh are drawn and presented.

Key Words: Nanofluid,Volumefraction,Cuo

Fluids are frequently used as heat carries in heat transfer equipment.Examplesofimportantuseofheattransferfluids include vehicular and avionics cooling systems in the transportation industry, hydraulic heating and cooling systems in buildings, industrial process heating as well as cooling systems in petrochemical, textile, pulp and paper, chemical, food and other processing plants. In all these

applications,thethermalconductivityofheattransferfluids playsavitalroleinthedevelopmentofenergy-efficientheat transferequipment.

1.1 Obstacles encountered to enhancement of heat transfer:

It has to be admitted that despite considerable previous research and development efforts put on heat transfer enhancement, few important improvements in cooling capabilitieshavebeenconstrainedbecauseofthelowthermal conductivityofconventionalheattransferfluids.However,it is well known that metals in solid form have orders of magnitude larger thermal conductivity of copper at room temperatureis700times greaterthan thatofwater and is 3000timesgreaterthanthatofengineoil.And,thethermal conductivityofmetallicliquidsismuchgreaterthanthatof non-metallic liquids. Therefore, thermal conductivities of fluids that contain suspended solid metallic particles are expectedtobesignificantlymoreenhancedwhencompared withconventionalheattransferfluids.

1.2 Role of Nano fluids: decadeago,anewkindofheat transfer fluid called nano fluid was introduced which was derived from stably suspending nano particles in conventional heat transfer fluids, usually liquids resulted fromthepioneeringworkofchoiandEastman(1).Commonly used2oxidenanoparticlesareAluminum(Al),Silicon(Si), Titanium(Ti),Copper(Cu),Zinc(Zn),Iron(Fe),Magnesium (Mg) and Silver (Ag) and base fluids are water, engine oil, kerosene, ethanol, methanol, ethylene glycol and mono ethyleneglycol.Nanofluidsconsistingofsuchnanoparticles suspended in liquids have been shown to enhance the thermal conductivity as well as convective heat transfer Performanceofthebasefluids.Ithasbeenreportedthatthe enhancementofnanofluidsdependsnotonlyonnanoparticle parametersbutalsoontheirsuspensionstabilityinbasefluid

In1883maxwellet.al[1]predictedthatdispersionofsolid particlesmayalterthepropertiesofthefluids.However,he didnotmentionthesizeofsolidparticles.In1993,Masuda et.al[2]usedtodispersethesubmicronparticlesofAl2O3, Sio2,Tio2andheobservedenhancementinthepropertiesof

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

thefluid.FromtheinspirationchoiandEastman[3]developa newkind offluidsandnamedthemasnanofluids.Intheir pioneeringworktheyobservedenhancementupto40%in the thermal conductivity. The work of choi and Eastman attracted most of the researchers to concentrate on nano fluids.Intheearlierstagesofdevelopmentofnanofluidsall theresearchersconcentratedonthethermalconductivity

Putraet.al[4]experimentallyinvestigatednaturalconvection heat transfer by dispersing Al 2O3 and CuO and observed systematic heat transfer deterioration and he stated that nature of this deterioration and its dependence on parameters such as particle concentration, material of the particlesandgeometryofthecontainingcavity.Kouloliaset.al [5] found the deterioration of convective heat transfer coefficient and Nu by increasing of Rayleigh number with nanoparticleconcentration.mohmmadaliet.al[6],Hoet.al [7], sudhakar subhudi et.al [8] observed increase in heat transfer coefficient. This is increment is restricted to low concentrations such as < 1%. Mohammed ali et.al [9] observedheattransfercoefficientincrementupto0.5%and for0.75%observesthedeterioration.Hoet.al[10]observed heat transfer increment of 18% at 0.1% but for cv > 2% observesdeterioration.Subhudiet.al[11]gotenhancementin heattransferforc vin0.01-0.1%.Necessityarisestofindout the reasons for the decrement at these higher volume fractions.Athighervolumefractionsnanoparticlestendto aggregate faster that directly effects the performance. Aggregations made to form fouling at the heating section whichdirectlystatingthatlackofstabilitywoulddegradethe performance.Sothestudyisbasedonthestabilityandheat transferenhancementwasstudiedandpossibleagreements were concluded. Ravi Babu and Sambasiva Rao [12] conductedtheexperimentstofindthenaturalconvectiveheat transferperformancealongaverticalcylinderimmersedin wateraswellaswater+EGblend.RaviBabuandSambasiva Rao [13] All things considered, whatever the heat input is given to the metallic cylinder will be carried away by the coolingwatercirculationandtherebysteady-statecondition is achieved. When steady -state condition is occurred, the readings of vertical brass cylinder surface temperatures at differentpositionsandbulkfluidtemperatureswerenoted down

3.1 Overview: Inordertogetenhancementinconvection heat transfer through nano fluids, nano fluids because all properties of nano fluids are assumed to be constant throughout experiment. Experimentation should be performedonflawlesssetupwhichgivesproperreadingin evaluation of heat transfer enhancement. Construction of experimentalsetupisdescribedinthesection

Selectionofnanomaterialonbasisofpropertiesand itssize.

Measure the size of nano particles XRD analysis, SEM,TEMimages.

To prepare the nano fluids with base fluid for different volume concentrations such as 0.05, 0.1, 0.15,0.2%.

Utilization of Stabilization modifiers such as magnetic stirring and ultra- sonication in terms of timeperiod.

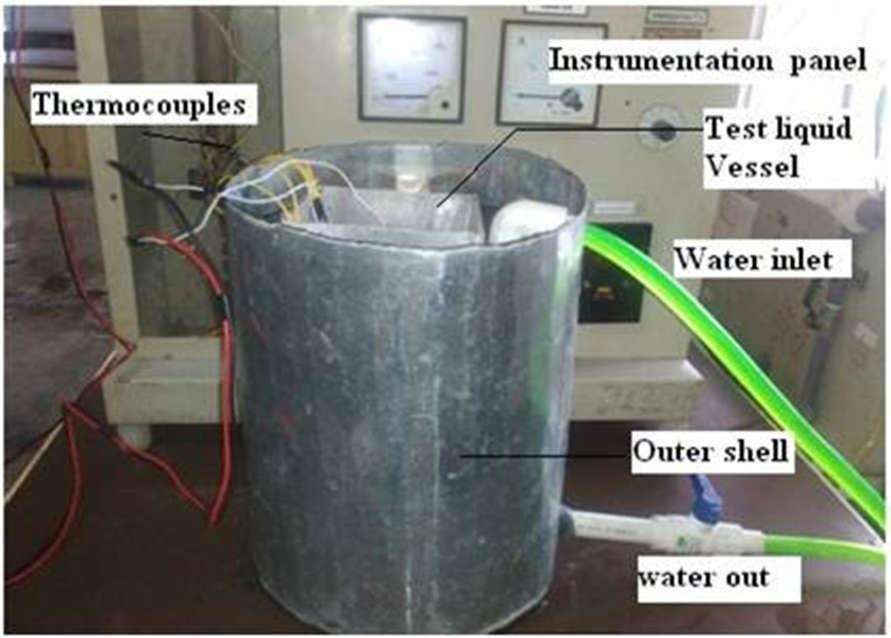

Construction of flawless setup which consist of ammeter, voltmeter, temperature indicator, regulator,heatingcoil,nanofluidcontainer,constant coolingwatersupplyinadequateplace.

Toconducttheexperimentswithtransformeroiland Nanofluidsatdifferentheatinputs30,40,45,50W anddeterminationofheattransferperformanceof transformeroilbased-titaniumoxidenanofluidfor differentvolumeconcentrations.

To calculate and compare the heat transfer coefficientsforbothtransformeroilandNanofluids.

Basedonpropertiesandavailability,Copperoxideisselected as nano material. Aluminum oxide generally has higher thermalconductivitythanCopperOxidebutitsettlesfaster. Duetohigherdensity,coppermoleculestendtoagglomerate earlywhichleadstosedimentationatfasterrate.Copperhas outstanding properties and show less tendency to agglomeratecomparedtoAluminumoxide.Nanoparticlesare availableatrangeof0-100nm,buthighersizednanoparticles will tend to form clusters at every stage. 30 nm size, 6.31g/cm3 ofbulkdensity.

Fromtheliteraturereview,itcanbestatedthatenhancement innaturalconvectionheattransferwouldbepossibleforlow volume fractions. Sudhakar subudhi et.al observed enhancement up to 0.1% and deterioration at 0.12%. It is alreadyknownthatenhancementwouldbepossibleatlow volumefractions,soselectedvolumefractionsshouldbelow and one volume fraction should be high to make a comparativestudy.0.05,0.1,0.15,0.2%volumefractionsare preferred. Transformer oil is selected as base fluid due its naturetosolublewithbothpolarandnon-polarsolvents.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Atypicalexperimentalsetupconsistsofvariouselementslike power supply, ammeter, voltmeter, dimmer stat, heating element, nano fluid container, cooling water supply, temperature indicator, thermocouples and digital thermo meter.Heatinputisselectedat30,40,45,50W

nanoparticle concentration, Nu becomes reduced. For the nanofluidwithmaximumnanoparticleconcentration. 0 100 200 300 400 500 600 700 800 25 35 45 55

Heat transfer coefficient(w/m 2 k) Heat input(w)

Fig1:Variationofheattransfercoefficientwith different heatinputsforvariousvolumefractions

In this section, transformer oil and nano fluid data are comparedforthenanoparticlevolumetricconcentrations,∅= 0.05%,0.1%,0.15%,0.2%forallpowerinputs,Qof30,40,45 and 50 W. The purpose is to identify any changes in the absolutevalueoftheheattransfercoefficienttrendlineasthe imposedheatfluxincreasesforpuretransformeroilandnano fluid. In fig5.2, the heat transfer coefficient of pure transformeroil andnanofluidintermsof the powerinput level is presented. It can be seen that as the power input increases, the heat transfer coefficient increases for all the cases.However,forthemaximumnanoparticleconcentration therateofenhancementisnotablyless.Inmostofthecases, as Ra increases, Nu increases. However, for the maximum

Nusselt number is the function of Rayleigh number so the nusselt number behavior is depends on Rayleigh number behaviorifRayleighnumberincreasenusseltnumberincrease wherethenusseltnumberisincreaseheattransfercoefficient is increase. The heat transfer coefficient is increasing upto 0.15% volume fraction of Nanoparticles for all heat inputs. Beyond0.15vol%ofnanoparticlestheheattransfercoefficient isdecreasingduetoagglomerationofnanoparticles. 0 200 400 600 800 0 0 1 0 2 0 3 Heat transfer coefficient(w/m2k) volume fraction%

30w 40w 45w 50w

Fig2:VariationofheattransfercoefficientwithCuo nanoparticleconcentrationfordifferentheatinput

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page31

• The freeconvectionsteady-stateheattransferofa verticalcylinderheateduniformlyhasbeenexploredinthis study and presented for various heat fluxes. Surface temperatures of the cylinder along the axial directions in case of transformer oil– Cuo nanofluid as mediums are examinedandpresented

• It is identified that in case of transformer oil –Cuo nanofluid the surface temperatures were recorded 9 to 12% lower than the temperatures when basefluidtransformeroilasmedium

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

• Natural convective heat transfer performance is augmented up to 0.15 vol % concentration of Tio2 nanoparticlesandthenitisdecreasedafter0.15vol % even it worse than the carrier fluid at higher concentrations.

• Thenaturalconvectiveheattransferisenhancedby 17.8% at 0.15 vol % concentration compared to transformeroilat50Wheatinputasheattransfer coefficient is increased from 356.172w/m2k to 670.465w/m2k

• 0.05,0.1,0.15,0.2%volumefractionsrequire1hour ofmagneticstirringtogetstablesuspensionduring theexperiment.

• 0.05,0.1,0.15,0.2%volumefractionsrequire30min ofultra-sonicationtogetstable suspensionduring theexperiment

1) Maxwell, J. C, 1881, A Treatise on Electricity and Magnetism,2nded.,1,435,ClarendonPress.

2) Masuda, H., Ebata, A., Teramae K., and Hishinuma, N., 1993,"AlterationofThermalConductivityandViscosity ofLiquidbyDispersingUltra-fineParticles(Dispersion ofyA1203, Si02 and Ti02 Ultra-fine Particles)," Netsu Bussei(Japan),Vol.4,No.4,pp.227-233.

3) S. U. S. Choi and J. A. Eastman, “Enhancing thermal conductivity of fluids with nanoparticles” ASME Int. Mech. Eng. Congr. Expo., vol. 66, no. March, pp. 99 –105,1995.

4) .Hadi, Ghodsinezhad., Mohsen, Sharifpur., and Josua, P.Meyer.,“Experimentalanalysisoncavityflownatural convectionofAlumina–waternanofluids”,International Communications in Heat and Mass Transfer, vol.76, (2016),pp.316-324.

5) JianQu,Hui-yingWu,PingCheng,Thermalperformance of an oscillating heat pipewith Al2O3water nanofluids, Int.Comm.HeatMassTransfer37(2010)111-115.

6) K.B. Anoop, T. Sundararajan, Sarit K. Das, Effect of particlesizeontheconvectiveheattransferinnanofluid in the developing region, Int. J. Heat Mass Transfer 52 (2009)2189-2195.

7) N.Putra,W.Roetzel,andS.K.Das,“Naturalconvectionof nano-fluids,” Heat MassTransf. und Stoffuebertragung, vol.39,no.8–9,pp.775–784,2003.

8) K. Kouloulias, A. Sergis, and Y. Hardalupas, “Sedimentationinnanofluidsduringanaturalconvection experiment,”Int.J.HeatMassTransf.,vol.101,pp.1193–1203,2016. [32]M. Ali, O. Zeitoun, and S. Almotairi,

“Naturalconvectionheattransferinsideverticalcircular enclosurefilledwithwater-basedAl2O3nanofluids,”Int.J. Therm.Sci.,vol.63,pp.115–124,2013.

9) R.ChoudharyandS.Subudhi,“Aspectratiodependence of turbulent naturalconvection in Al2O3/water nanofluids,” Appl. Therm. Eng., vol. 108, pp. 1095–1104,2016.

10) Ravi Babu, S., and Sambasivarao, G., 2016, “Buoyancy Induced Natural Con-vective Heat Transfer Along a Vertical Cylinder Under a Constant Heat Flux,” Int. J. Chem.Sci.,14(4),pp.2763–2774

11) Ravi Babu.S, and Sambasiva Rao.G, 2018, “Buoyancy InducedNaturalconvectiveheattransferusingWater/ Al2O3nanofluids,”ASMEJ.Therm,Sci.Eng.Appl.,10(3), pp.1-7.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page32