International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

1Post Graduate Student, Sri Venkateswara College of Engineering & Technology, Etcherla 2Assistant Professor, Sri Venkateswara College of Engineering & Technology, Etcherla

Abstract –

Energy conservation, conversion, and recovery are vital thinking among people due to environmental issues. The effectively way to save energy of materials and facilities in which heat exchanger plays a significant role. Mostly in industries uses heat exchangers for enchantment of heat transfer. The common used heat transfer fluids are water, ethylene glycol and propylene glycol as base fluids in heat exchanger.DispersionofNanoparticlesinabasefluidshows solution in problems such as high pressure loss, erosion of material.Thethermalconductivityofthebasefluidincreases by adding Nano particle which in turn increases the heat transfer rate. In this paper heat exchanger performance is analyzed by adding Magnesium oxide with base fluid (a mixtureofDistilledwaterandpropyleneglycol).Thethermal propertyi.e.overallheattransfercoefficientofheatexchanger iscalculatedandcomparedwithbasefluid.Experimentswere conductedforvariousvolumeconcentration0.1%,0.3%and 0.5% and observed that the addition of manganese oxide nanoparticles enhances the thermal performance. The maximum enhancement in the convective heat transfer is observedat0.5%volumeconcentration.Experimentswillbe conducted by varying the inlet temperature, nanoparticle volume concentration and fluid flow rate. Heat transfer coefficient,thermalconductivityandnusseltnumberofMgO nano particles are selected as performance assessment parameters.

Key Words: Heattransferrate,heatexchanger,Manganese NanoparticleNussletnumber.

Mostindustrialprocessesinvolveheattransferandmore often, it is required that these heat transfer processes be controlled.Heattransferisthetermusedforthermalenergy fromahottoacolderbody.Heattransferalwaysoccursfrom a hot body to a cold one, as a result of thesecond law of thermodynamics. Where there is a temperature difference betweenobjectsinproximity,heattransferbetweenthemcan neverbestoppedbutcanonlyoccurthroughthreewayswhich areconduction,convectionandradiation.Thoughstudyhas alsoshownthat phasechangeisaccompaniedwiththermal energytransfer.

Mohammad Hossein Aghabozorg et al. [1], experimentallystudiedtheoverallheattransfercoefficientof anautomobileradiatorusinggraphenenanoplateletsbased

coolant with the volume fractions of 0.1-0.5% and the nanofluidflowratesof12.5g/s-62.5g/s.Theyalsovariedthe ambientairvelocityandthenanofluidinlettemperaturesfrom 1-5m/sand35to45respectively.Theirresultsstatedthatthe overallheattransfercoefficientenhancedupto104%at0.5% volume fraction, 62.5g/s flow rate and 5 m/s ambient air velocitycomparedtothebasefluidand39%enhancementin pressuredropwasrecordedatthehighestmassflowrateof 62.5g.

T Aseer Brabin1 et al. [2], conductedtheexperiments on an automobile radiator with ethylene glycol based Cu nanofluids. They varied the volume fraction of the nanoparticlesintherangeof0-2%andobservedthat3.8%of heat transfer enhancement with the dispersion 2% MgO nanopowderattheReynoldsnumberof6000and5000forair and coolant respectively. K.Karimullah Khan et al. [3], experimentallystudiedtheoverallheattransfercoefficientof CuO/waternanofluidinacarradiator.Theirresultsshowthat theoverallheattransfercoefficientincreaseswiththevolume fractionofthenanoparticlesandthemaximumenhancement inoverallheattransfercoefficientupto8%obtainedat0.4% concentrationincomparisonwiththebasefluid.

M. Raja.R.M. Arunachalam. et al. [4], investigated thermal conductivity and dynamic viscosity of TiO2-SiO2 nanofluids in PG+water mixture. The experiments were performedwith the volume fractions of 0.5-3.0% and the temperatures from 30°C-80°C. The resultsstated that the maximumthermalconductivityofnanofluidswasenhanced upto22.8%for3.0Vol%andtemperatureof80°C.Meanwhile, thehighestaveragerelativevelocitywasobtainedfor3.0Vol% with62.5%increment.

Kishan H. Maheshwari. et al. [5], experimentallystudied rheological behaviour of water-EG coolant dispersed with MgO-MWCNTs hybrid nanomaterials with the volume fractionsof0.025-0.8%.Theexperimentswereperformedat various shear rates within the temperatures from 25-60°C. The results showed that nanofluid samples had Newtonian behaviour and nanofluid viscosity decreased with the increasingtemperatureandaugmentedwithincreasing the volumefraction.Thegraterchangesintherelativeviscosity occurred by increasing the ratio of particles with volume fractionof0.8%toalmost80%.

Kallalu Harika., Tummala.Likhitha et al. [6], experimentally studied heat transfer characteristics of Al2O3/waterbasednanofluidsinanautomobileradiatorwith

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

the volume fractions of 0.1%,0.5%,1.5%,2%. The experiments done at different heat load (16,12,8 kw)and coolant and air flow rate conditions. The Maximum percentage increase of the coolant heat transfer rate, coolant heat transfer coefficient, and coolant Nusselt number is 14.79,14.72,and9.51,respectively,whichoccurs atmaximumloadandat0.1Vol%.Themaximumvaluesofair sideheattransfercoefficientandNusseltnumberalsooccurat the same load and concentration and have 14.45% and 13.94%increaseoverthatofthebasefluid,respectively.

I.M. Shahrul., I. M. Mahbubul et al. [7], experimentally studied pressure drop and heat transfer performance of CuO/EthyleneGlycol(60%)-Water(40%)nanofluidinacar radiator. They conducted the experiments with the volume fractionsof0.05%-0.8%andflowratesof4-8l/min,andat different inlet fluid temperatures (34°C,44°C,54°C). The resultsdemonstratedthatthatthepresenceofnanoparticles caused an increase in nanofluid pressure drop, which was intensifiedbyincreasingnanoparticleconcentrationaswellas decreasingtemperatureofinletfluid.

K.Y. Leong., R. Saidur et al. [8],experimentally studied laminar convective heat transfer coefficient of a TiO2-CNT hybridnanofluidthroughtheshellandtubeheatexchanger. They conducted the experiments with 0.1-0.2 wt% of nanopowderandatvarioustemperatures(25°C,32°C,38°C). Theheattransfercoefficientstronglydependsonnanoparticle concentrationandtemperature,which revealedanincrease from 1,861.46 to 2,516.86 by increasing temperature from 25°C to 32°C andan increase from 2,246.46 to 2,516.86by increasing NPs concentration from 0.1 to 0.2 wt%. Furthermore,comparisonoftheresultsbyCNTdemonstrated that the same load of hybrid NFs has 3% lower thermal conductivitycomparedtotheCNT,whichinturn,resultsina 5%lowerheattransfercoefficient.ButtheamountCNTused for preparing hybrid nanopowder was less which in turn reducethecostandstabilityofthenanofluids.

M. Sarafraz., F. Hormozi et al. [9], Numericallystudied heattransfercharacteristicsofacarradiatorusingCu/water basednanofluidwithdifferentnanoparticlesizes(10,50,100 nm) and various volume concentrations of 1-10 Vol%. The resultsstatedthatCu/Waternanofluidthermalconductivityis increasedsignificantlywithnanoparticlevolumefractionof1 %to10

%butdecreasingwiththeincrementofparticlesize.The convective heat transfer coefficientof nanofluid enhanced significantlyupto92%comparedtobasefluid

Hassan Hajabdollahi.et al. [10], experimentallystudied pressuredropandheattransferperformanceofCuO/Ethylene Glycol(60%)-Water(40%)nanofluidinacarradiator.They conducted the experiments with the volume fractions of 0.05%-0.8% and flow rates of 4-8 l/min, and at different inlet fluid temperatures (34°C,44°C,54°C). The results demonstratedthatthatthepresenceofnanoparticlescaused

anincreaseinnanofluidpressuredrop,whichwasintensified byincreasingnanoparticleconcentrationaswellasdecreasing temperatureofinletfluid

A. Coolingwateratroomtemperatureisallowedto flowthroughshellinlet

B. Temperaturereadingisnotedattheshellinlet

C. A total volume of 17 litres(water+nano fluid) is usedinthisexperiment.

D. For every 1000ml of water, 20ml of Mgo oxide nanofliudismixedthrough.

E. The above prcoos is repeated for the whole 17 litres.

F. This mixture is pumped to the geyser using recirculatingpump

G. Thefluidisheatedinthegeyserandthenthehot fluidisallowedtopassthroughthetubeinlet.

H. Astheheatexchangerusedinthisexperimentis 1-Shell 2-tubepassheatexchanger,thehotfluid passesthroughthetubesinboththedirections.

I. Bafflesplatesareusedtochangethedirectionof thefluid.

J.Bothshellandtubeoutlettemperaturereadingsare noted.

K. Flow rates is calculated manually b using a measuringflaskandstopwatch.

L. Now, the overall heat transfer coefficient is calculatedusingtheobtainedtemperaturereading andotherparameters

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

Fig1:Variationofheattransfercoefficientwith different heatinputsforvariousvolumefractions

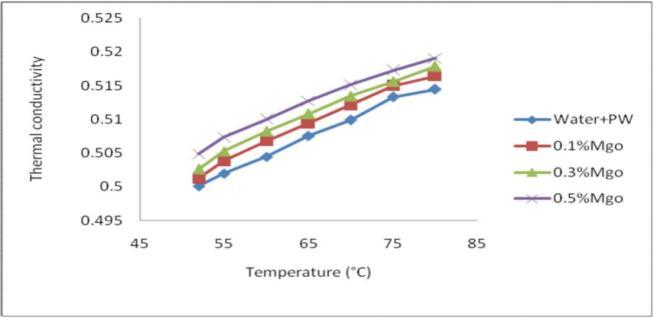

The thermal conductivity of MgO/water nanofluid was significantlyhigherthanthatofwaterandstronglydependent ontemperatureofthefluid.Itexhibitthattheexperimental values of thermal conductivity of nanofluid increased significantly with the fluid temperature. The reason is that, fluid temperature strengthens the Brownian motion of nanoparticlesandalso dropstheviscosityofthebasefluid. WithastrengthenedBrownianmotion,theinfluenceofmicro convection in heat transport rises and in consequence increased enhancement of the thermal conductivity of nanofluids.Resultsobtainedatdifferentconcentrations0.1%, 0.3%and0.5%comparedtobasefluid.

Figuer1:VariationofThermalConductivityofMgO/water nanofluidswithtemperature

thermal conductivity of base fluid and, MgO nanofluids at differentconcentrations(0.1%,0.3%,0.5%)andtemperatures (40°C- 80°C). From Fig 3.4, it is observed that thermal conductivity increases with increase of volumetric concentrationandtemperature.At0.5Vol%,0.6%and0.75% enhancementinthermalconductivity

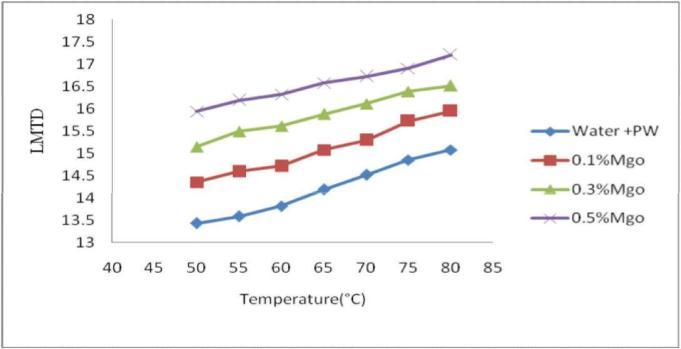

Fig2:InfluenceofLTMDwithTemperatureandparticle volumeconcentrations

LMTD of base fluid and, MgO nanofluids at different concentrations(0.1%,0.3%,0.5%)andtemperatures(40°C80°C). From Fig 3.4, it is observed LMTD increases with increaseofvolumetricconcentrationandtemperature.

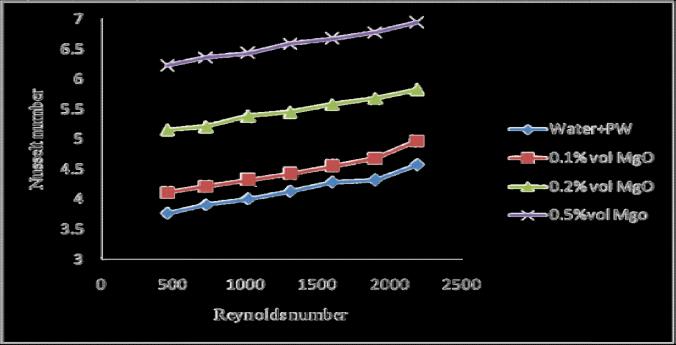

Fig3:InfluenceofLTMDwithTemperatureandparticle volumeconcentrations

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN: 2395-0072

ThevariationofthenusseltnumberwithReynoldsnumber the of the nano fluid. At 0.5 Vol% MgO nanofluid, 24.1% enhancementinnusseltnumberwascomparedtobasefliud.

A. Theperformanceoftheshellandtubeexchanger using MgO/Water + PG, based nanofluids was experimentallyinvestigated.

B. Experiments work performed using distilled water 0.1%vol 0.3%vol and 0.5%vol ConcentrationMgO/waternanofluidashotfluid flowingthetubes.

C. Nusselt number of hot fluid was increased with Reynoldsnumberofhotfluidand nanoparticles volumeconcentration

D. The maximum enhancement in Overall heat transfer coefficient is recorded as 33.51% with 0.5 Vol% and 6lit/min and 12lit/min flow rate and compared to base fluid while using nanofliuds.

E. The maximum enhancement in Overall heat transfer coefficient is recorded as 37.71% with 0.5Vol%and10lit/minand20lit/minflowrate and compared to base fluid while using nanofliuds.

F. Dynamic viscosity and Thermal conductivity of nanofluids were increased with increase of the volumetric concentration of nanoparticles and dynamicviscositydecreaseswithincreasingthe workingfluidtemperatures.

1) Mohammad Hossein Aghabozorg., Alimorad Rashidi., SaberMohammadi.,“ExperimentalInvestigationOfHeat TransferEnhancement OfFe2O3-CNT/WaterMagnetic Nano Fluids Under Laminar, TransientAnd Turbulent FlowInsideAHorizontalShellAndTubeHeatExchanger”, ExperimentalThermalandFluidScience72(2016);182–189.

2) T Aseer Brabin., S Ananth., “Analysis Of Overall Heat TransferCoefficientAndEffectivenessInSplitFlowHeat Exchanger Using Nano Fluids”, Journal of Advances in MechanicalEngineeringandScience,2015;28-40.

3) K.KarimullahKhan.,G.PraveenKumarYa.,“Experimental Investigation Of HelicalBaffles Shell And Tube Heat ExchangerUsing Aluminum OXIDE (II) Nanoparticle” ImperialJournalofInterdisciplinaryResearch,2016;Vol2,Issue-11,527-531.

4) M. Raja., R.M. Arunachalam., S. Suresh., “Experimental StudiesOnHeatTransferOfAlumina/WaterNanoFluid In A Shell And Tube Heat Exchanger With Wire Coil Insert”InternationalJournalofMechanicalandMaterials Engineering(IJMME),Vol.7(2012),No.1,16–23.

5) Kishan H. Maheshwari., Kartik Trivedi., “Experimental Investigation Of Shell And Tube HeatExchanger Using Nano-Fluids” Journal of Emerging Technologies and InnovativeResearch,2016,Volume3,Issue5,210-218.

6) KallaluHarika.,Tummala.Likhitha.,Pulla Varsha Rani., R.Ramakanth., “Experimental Determination And Comparison Of Heat TransferCoefficient And Pressure Drop ForWater And Copper Oxide Nano FluidIn Shell And Tube Heat Exchangers Using Helical Baffles” International Journal of Current Engineering and Technology,(2017);Vol.7,No.3,851-856.

7) I. M. Shahrul., I. M. Mahbubul., R. Saidur., S. S. Khaleduzzaman., M. F. M. Sabri & M.M. Rahman., “Numerical Heat Transfer, Part A:Applications: An InternationalJournalofComputationandMethodology”, NumericalHeatTransfer,PartA,65:699–713,2014.

8) K.Y. Leong., R. Saidur., M. Khairulmaini., Z. Michael., A. Kamyar.,“HeatTransferand Entropy Analysis ofThree Different Types of Heat ExchangersOperated With NanoFluids”,InternationalCommunicationsinHeatand MassTransfer39(2012);838-843.

9) M.M.Sarafraz.,F.Hormozi.,“HeatTransfer,PressureDrop And Fouling Studies Of Multi-Walled CarbonNanotube Nano-FluidsInsideAPlateHeatExchanger”,Experimental ThermalandFluidScience72(2016);1–11.

10) HassanHajabdollahi.,ZahraHajabdollahi.,“Assessment of Nanoparticles in Thermoeconomic Improvementof Shell and Tube Heat Exchanger”, Applied Thermal Engineering106(2016);827–837.