International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

***

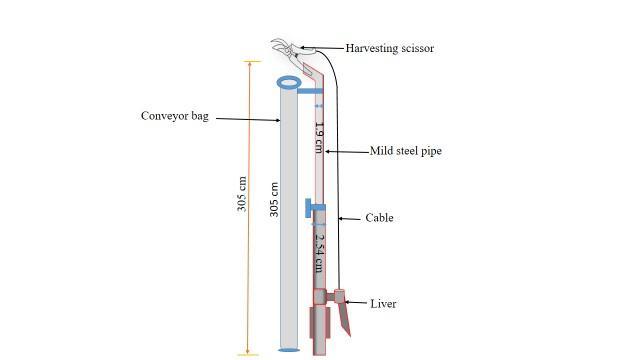

Abstract- The drumstick (moringaoleifera) i.e. 'Shevga' is called the 'tree of life' because of huge variety of uses. India is the largest producer of drumstick. The country produces 1.2 million tons from a 380����2, as per the official release of 2010. In day-today life drumstick damage is the vital problem facing by farmers. It occurs in various ways while picking, by using sharp edge materials like scissors,blade, knife etc., by picking manually the drumstick get damaged whenever falls down which is a permanent damage or the labour can fell down because of its height from ground. Current forms of harvesting include climbing the trees and using ad-hoc harvester made out of scrap materials to ensure the drumstick is not damaged during harvesting, that’s why drumstick harvester is designed in such manner. It mainly consist of mild steel pipe, harvesting scissor, lever, galvanized spring cable, conveyor bag. The improved harvesting system found better than traditional methods and reduce musculoskeletal stress on the operator. The harvesting capacity of developed manual drumstickharvester was found to be 21.99 kg/h (364.33 Nos. /h) and the average damage percent of the developed manual drumstick harvester was found to be 1.59 percent and damage drumstick percent was very low as compared to traditional drumstick harvesting devices.

Keywords: -Scissor,Cable,Lever,Mildsteelpipe,Conveyerbag

Indiaisthelargestproducerofdrumsticktree(Moringaoleifera) intheworld,withanannualproductionof1.1to1.3 million tons of tender fruits[1].Andhra Pradesh leads in both area of 156.65 ����2plantation and production of drumstick, followed by Karnataka102.8 ����2 andTamil Nadu74.08 ����2 inotherstateoccupies anarea of46.13 ����2[1]. In Maharashtra, drumstick is cultivated over around an area 800 ha. In India basically it is called shevga (Marathi); sanjna, suhujna (Hindi); murunga, murangai (Tamil) are mentioned for drumstick tree. The drumstick harvester is mostly found in large amount in Satara,Sangli,Solapur,Yavatmal,NashikandPunedistricts.Solapur isthelargest producer ofdrumstickharvester, 91.5% of total cultivated area is under dry land farming. The varieties of drumstick is Rohit-1,Coimbatore1. The hybrid varieties are PeriyakulamPKM-1, PKM-2 andheightoftheplantis2to4m.Inday-to-daylifedrumstickdamageisthevitalproblemfacing by farmers. It occurs in various ways while picking, by using sharp edge materials like scissors, blade, knife etc., by picking manually the drumstick get damaged whenever it falls down which is a permanent damage or the labour can fell down becauseofthetreesheightfromtheground.

The development of Indian agricultural sector depends on the development of farm mechanization, so that there should be introducing such a machinery and equipment to fulfill the need of the labour which is major problem now a days, andalsoreducesthehumandrudgeryandproductdamages.Currentlydrumstickharvestingisdonemanuallywithknifesickles andstabswithhookattachedtoit.Skilledlabouristobeneededforsuchtraditionallyharvestingmethodofdrumstick.

Traditionalharvestingisjustthatthecurrentformofharvestingincludeshakingthetreesbyhand,climbingthetrees, using hook and bamboo made out of scrap material. Drumstick tree is very delicate for climbing hence, there should be accidental chances for labour.Improved harvestingmethod is done by using the manually operated drumstick harvester. In operation, the operator would hold the cable in one hand and another hand hold free end of extension pipe. As soon as drumstick comes in cutting zone of the cutting mechanism, cutting mechanism operated by pulling cable in downward. The drumstick cut by cutting mechanism fallen into conveyor bag. Target the mature drumstick from the ground. To overcome such a problem, there is a need for design and development of manually operated drumstick harvester, which makes easy cuttingofthestalkandeasilyconveysthedrumstickpod.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

Thischapterdealswithmaterialsthosewereusedfordevelopmentofmanuallyoperateddrumstickharvesterandthe methodology thatwasadopted during testing andevaluationofmanually operated drumstick harvester. Theprojectentitled “Development and performance evaluation of manually operated drumstick harvester” was fabricated by considering the followingpointinmind.

1. Thedevelopedharvestingdeviceisaffordableforusingbysmallandmarginalfarmers.

2. Theharvestingdevicedevelopedisportablewithminimumoperatordiscomfort.

3. Theharvestertobedevelopedshouldhavelowinitialcost,lowmaintenanceandoperatingcost.

Scissor are used in gardening, arboriculture, plant nursery works, farming, flower arrangingfor cutting. Harvesting scissorismadeofcarbonsteel.Carbonsteelmakingsaremoremalleablebutarebrittle.Itbecomesbrittlebecauseoftoomuch carbonwhichalsomakesitharder.

Brake lever was used for pressing the movable blade towards fixed blade for cutting operation. The brake lever material used is aluminum alloy. The brake lever is provided to operatethecuttingmechanism.Itconsistsofsteelcablewith oneendisconnectedtothecuttingmechanismandanotherendconnectedtothefreeendofexpansionpipe.Whenthepodsare inthecuttingzone,thecuttingmechanismoperatesbypullingthecabledownwards.TheCabletakesitsoriginal positiondue totheactionofaspringfittedonthecuttingmechanism.

Thegalvanizationistheprocessofapplyingaprotectivezinccoatingtosteeloriron.This typeofmetalisstrongand verydurable.Thegalvanizespringcablewasusedforcuttingmechanismofdrumstickharvester.Thelengthofgalvanizespring cableis3.4m.

ThebodyframeofunitconsistsoftwoM.S.Pipeofdifferentdiameter,differentlengthfor thepurposetoreachupto theheightofdrumsticktree.Theupperpipewasinsertedinlowerpipefortheadjustmentaccordingtotheheightoftree.The material of the pipe is selected from stainlesssteel with high strength, high hardness Corrosion resistance and high wear resistance. This long hollow stainless steel pipe is easily reachable to the drumstick. A locking mechanism is provided for extendingorshortening.

Drumstick conveyor bag is used for collecting the drumstick after cutting from trees. The Conveyorbagfittedatthe end oftheextension pipe in suchway thatthe drumstickcutted bycuttingmechanism will fall inthe bag. The conveyor bag lengthis3m.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

Thetestingofmanuallyoperateddrumstick harvester wasconductedatthesite ofNirgudi,Phaltan, and Dist. Satara. TestingwascarriedoutasperRNAMtestcodefordrumstickharvester. Theexperimentwasreplicatedthrice.Thisharvester was compared for number of field test, comparative performance of the harvester and cost of operation etc. The results obtainedaftertrialsarediscussedinthischapter.

Performanceofdrumstickharvestervariesaccordingtothekindofcrop,conditionofcrop.Therefore,conditionofthe testwereclearlystated.Therangeoftestconditionisdefinedasfollows:

Mr. Rajendra Ghorpade has drumstick farm of area 40R at Nirgudi (Phaltan) was selected for conducting trial of manuallyoperateddrumstickharvester.Detailsoftestplotarepresentedin TableA.Thetableincludedplot,location,shape, areaofthefield,kindoffieldandtypeofsoil.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

The crop conditions were considered during testing are physical properties of drumstick plant, maturity indices, harvesting index etc. The details of crop condition are given in Table B. Thetable included the details about name of crop, plantingpattern,rowspacing,andstageofgrowthdayaftersowingandheightofcrop.

Table No.B:- Crop Condition for Manually Operated Drumstick Harvester

Sr. No Particulates Test 1. Varietyofplant Coimbatore

Heightofplant 4-4.5m

Distancebetweentwoplant 2.4m

Lengthofpod 350mm

The condition of implement and operator was important for Harvesting capacity and net operation. Harvesting capacity was directly depending upon skill of operator. If skill of operator results very good then Harvesting capacity will resultbest. The detailsofconditionofimplement and operatorareinTableC.The tableincludedthedetailsaboutsource of power,skillofoperator,weightofimplement,maximumheightofimplement,adjustmentofworkingpart,clearancebetween scissorandlever.

Table No.C:- Condition of Implement and Operator forManually Operated Drumstick Harvester

Sr. No. Particulars Performance Test 1. Sourceofpower Human

Thetesting of manually operateddrumstickharvester wasconducted atthesite ofNirgudi,Phaltan, and Dist. Satara. TestingwascarriedoutasperRNAMtestcodefordrumstickharvester. Theexperimentwasreplicatedthrice.Thisharvester was compared for number of field test, comparative performance of the harvester and cost of operation etc. The results obtainedaftertrialsarediscussedinthischapter

TheHarvestingcapacitycalculatedinthreetestonfield,thendividedtheareawisetest.Thetotalareaisoneacreand dividedintothreetestplot. Theaverageharvestingcapacityof developedmanualdrumstickharvestingsystemwasfoundto

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page10

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

be 21.99kg/h (364.33Nos./h). In developed manual drumstick harvesting system, the drumsticks could be harvested from a plant upto the height of 4.5 m from ground with comfort and safely without any injury. The harvesting capacity is higher as increased reach of human labour by device and hence more drumsticks are harvested within less time. The productivity increasedduetosavingoftimeandmoretimeutilizedforharvestingofdrumstickduetohigherreach.

Theaverageharvestingcapacitiesfoundtobeforhookmethodswere16.37kg/h(266.33 Nos./h),respectively(Table D).Thecapacitiesarelowerasmoretimeislostinlocatingdrumstickanddrumstickcollection.

Harvestingcapacitywasestimatedbynumberorweightofharvesteddrumstickper unittimebyusingfollowing formula.

Harvestingcapacity(kg/hr)= weightofharvesteddrumstick

Totalharvestingtime

Or Harvesting capacity (Nos./hr) = Total no. of drumstick harvested

Totalharvestingtime

(1)

…(2)

Table D:-Harvesting Capacity of Developed Harvesting System and Traditional Methods

Sr. No. Harvesting Capacity Developed harvesting system Hook method Kg/hr. Nos./hr. Kg/hr. Nos./hr. Test1 20.91 334 18.11 273 Test2 22.64 378 16.27 265 Test3 22.42 381 14.75 262 Average 21.99 364.33 16.37 266.66

The result of the damage drumstick percent during developed harvesting system arepresented in Table E. The average damage drumstick percent while harvesting pods by the developed manual pod harvesting system was found to be 1.59%.Thisdamagepercentincludedthemechanicaldamageandpodfallsduringharvestingwithandwithoutplatformfrom groundsurface.Thedamagetodrumstickwasleastasdrumstickareconveyingindownanddevicereachhigherelevationand thechancesofdamagebyharvestingandfallwasminimum.Theaverage damagedrumstickpercentofthehookmethodwere calculatedas4.06%.Damagetodrumstickmaybeduetoharvestingbystickandfallingofdrumstickfromheight.

Thenumberofdrumstick podsthatgotdamagedduetoscratchingorfallingdown from tree duringharvesting.The followingformulacalculatethedamagepercentofpods.

DamageDrumstickpercent= No.ofdrumstickdamagedduringharvesting ×100

Totalno.of drumstickharvested …(3)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

Table E:-Damage Pod Percent of Developed Harvesting System and Traditional Drumstick Harvesting System

Sr. No. Damage drumstick %

Developed harvesting system

Hook method

Test1 1.97 3.79 Test2 1.39 4.28 Test3 1.43 4.12 Average 1.59 4.06

The following conclusions were drown from the observations recorded during thelaboratoryandfieldtestingof thedevelopedmanuallyoperateddrumstickharvester.

1) The harvesting capacity of developed manual drumstick harvesting system was found to be21.99kg/h(364.33 Nos./h).

2) Theaveragedamagepercentofthedevelopedmanualdrumstickharvestingsystemwasfoundtobe1.59%.

3) Itislightweightandtherefore,caneasilybecarriedfromoneplacetoanother.

4) Theharvesterwasmostefficientandcomfortableaccordingtoergonomicobservations.

[1]AmrutaS.P.,R.D.Raut,R.B.ShelkeandS.D.Ghorpade.2015.Performanceevaluationofmanually operateddrumstick harvester. International Journal of Agricultural Engineering. 8(2):239-243.

[2]Yamagar S. J. and K. G. Dhande. 2019. Performance evaluation of developed manual drumstick harvesting system.International Journal of Agricultural Engineering.36-42.

[3]Dhanashri S. and G. R. Gaur. 2019. Ergonomic design of a drumstick plucker. International Ergonomics Association. Pp.1241-1248.

[4]Chandru M., R.Gowthamvishal, M. Korlmax and S.HarharanSuderson. 2018. Design and fabrication of multiple type fruit picking stick using Renewable energy source. International Journal of Advance Research in Science and Engineering.JESN:2319-8354.

[5]DeogirikarA.A.,P.U.Shahare,K.G.DhandeandR.V.Powar.2020.Developmentofmanuallyoperatedsapotaharvester. International Journal of Agricultural Engineering |Volume13|Issue2|220-226ISSN–0974–2662.

[6]Nahate H. D., V. G. Kothalkar and N. D. Patil. 2021. Development of manually operated citrus fruit Harvester, International Journal of Current Microbiology and Applied Sciences. 10(01):3320-3326T.

[7]PaulD.R.andB.Yadav.2021.Fabricateandergonomicevaluationofmanuallyoperateddrumstickcutter, The Pharma Innovative Journal.10(10).34-40.

[8]SakdeoB.M.,Y.L.JagdaleandS.S.Ali.2018.PerformanceofFrontLineDemonstrationof DrumsticksVariety,PKM-1 inBaramatiTahasilofPuneDistrict(M.S.) International Journal ofScience and Research (IJSR). ISSN:2319-7064.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 01 | Jan 2023 www.irjet.net p-ISSN:2395-0072

[9]TilekarJ.S.andR.S.Adsul.2017.Versatilefruitandvegetablecutter. ISOR Journal of Mechanical and Civil Engineering (IOSR-JMCE). 2278-1684.

[10]TrishnaR., R. Amin, K. U. Sarker, F. A. Tapu and N.Huda. 2021. Design, fabrication and performance evaluation of a simplemangoharvester, International Journal of Natural and Social Sciences.8(2):37-43

FirstAuthor:Er.SunnyV.Tikute(BTechAgril.Engg.&M.TechFMPE,AUS)

SecondAuthor:ShubhamB.Wahurwagh(BTechAgril.Engg.)

ThirdAuthor:SaurabhS.Jadhav(B.TechAgril.Engg.))

ForthAuthor:TusharP.Dubhashe(B.TechAgril.Engg.)

FifthAuthor:TusharD.Bangar(B.TechAgril.Engg.)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |