14 – 17 April 2026

Karlsruhe,

14 – 17 April 2026

Karlsruhe,

4– 6 March 2026

Hall. 22 - Booth: C50 Bologna, Italy

14 – 17 April 2026 Hall 2 - Booth: 2536 Karlsruhe, Germany

ENGINEERED PAINT STRIPPING BY ALIT

At ALIT, chemical paint stripping is not a standalone operation We design the chemistry

We build the systems

Europe’s tumultuous chemicals industry: how are coatings impacted?

SPHERILEX® DP-0117 - Enabling high durability matte powder coatings

Easy PROG PORTAL: the automatic painting system for windows, doors, and cylindrical objects 22

OF

From industrial paint to design language: the evolution of Adapta collections through technology, innovation, and art

EMU: sustainable and digital powder coating within a smart factory

High-performance amino resins for thermosetting coatings

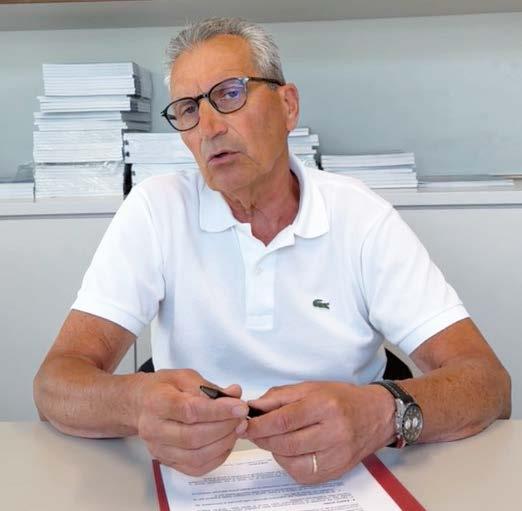

When is it time to replace a coating system: the experience of Verona Impianti 2002

50 FOCUS ON TECHNOLOGY

A new cataphoresis plant: high quality and control in the production of components for heavy-duty vehicles

58 HIGHLIGHT OF THE MONTH

SAITA inaugurates new premises focusing on innovation and training 62

Painter: investing in technology to build quality, reliability, and a clear industrial vision

72 HIGHLIGHT OF THE MONTH

Sustainable industrial tinting: the evolution of colour systems according to Ralston Tinting Systems

78 FOCUS ON TECHNOLOGY

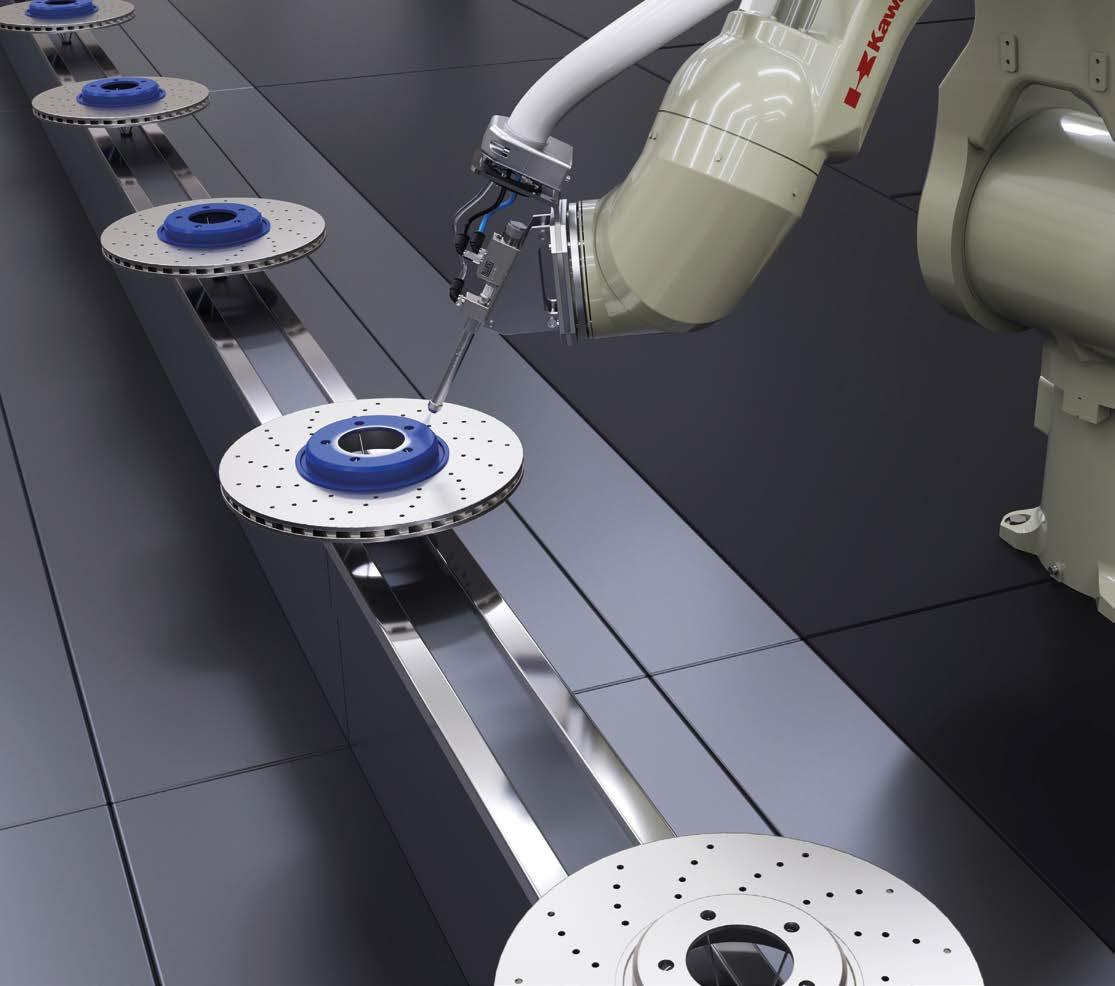

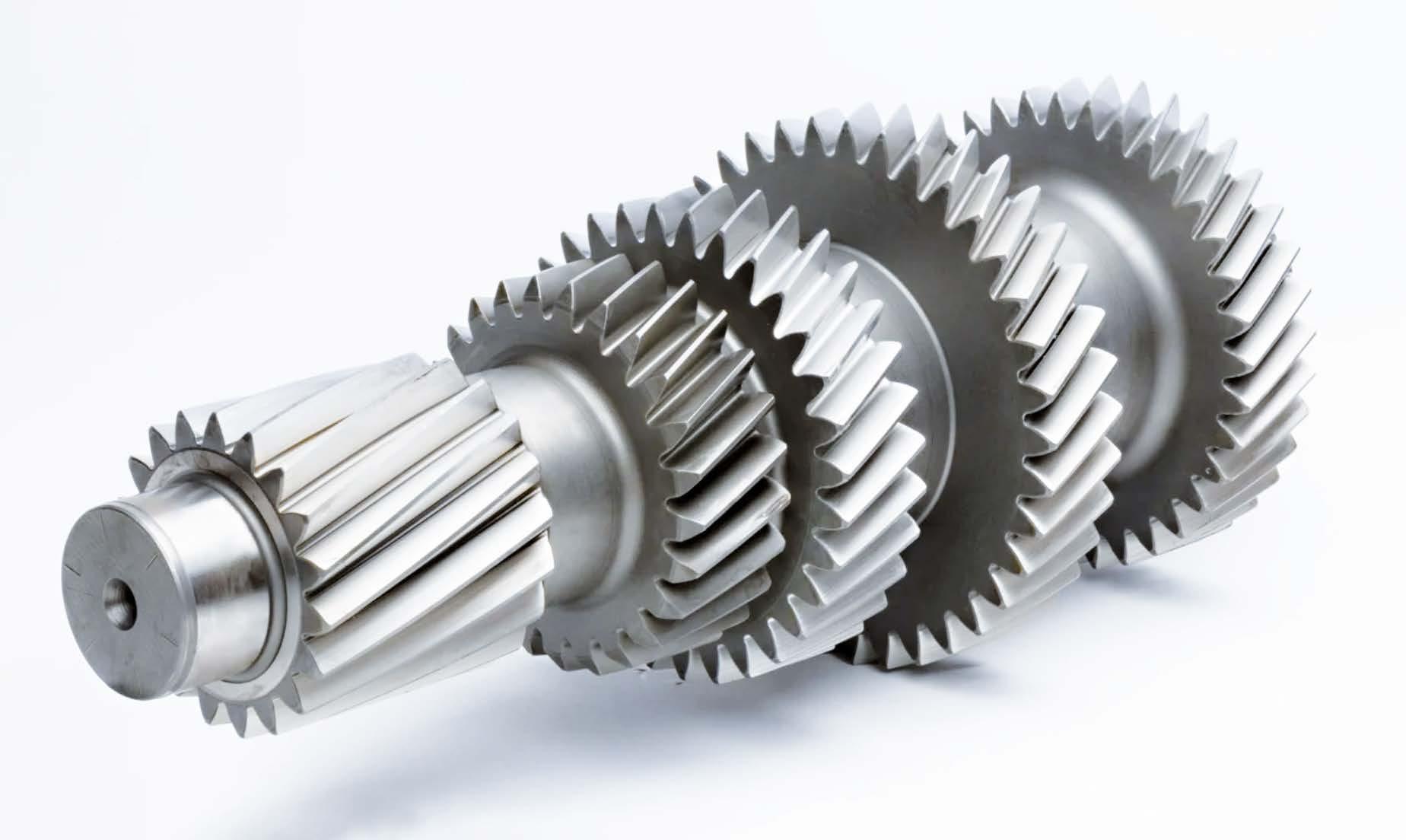

Mechanical finishing as the key to Euroricambi’s excellence

86 HIGHLIGHT OF THE MONTH

Mirodur: boundless excellence

90 SUCCESS STORIES

Elevators that save space – and a coating line that saves resources

94 HIGHLIGHT OF THE MONTH

Finmat focuses on energy efficiency and plant flexibility to meet the challenges of the automotive and general industry sectors

a comprehensive

Berizzi Srl celebrates its first thirty years in business with an eye to the future

Architectural powder coatings: where design meets resilience

Water Energy takes centre stage at the 2025 Future Italy Awards: technological innovation and a circular vision for water treatment

Decorluxe invests in innovation: a new coating line with Jet Metal technology for VMC Mottini

An innovative pigging system that meets the new requirements of automotive coating operations

Arzuffi’s new laboratory: from the testing to the industrialisation of PVD cycles on plastic and glass

Royal Van Wijhe Verf puts water at the heart of its new Concept Paint

Industrial coating: from an operational task to a strategic lever

Anticipating challenges: ddchem’s DMAPA-free curing agents for safer epoxy systems

Paolo Rami and the ipcm® Academy’s specialised training courses for the surface treatment industry

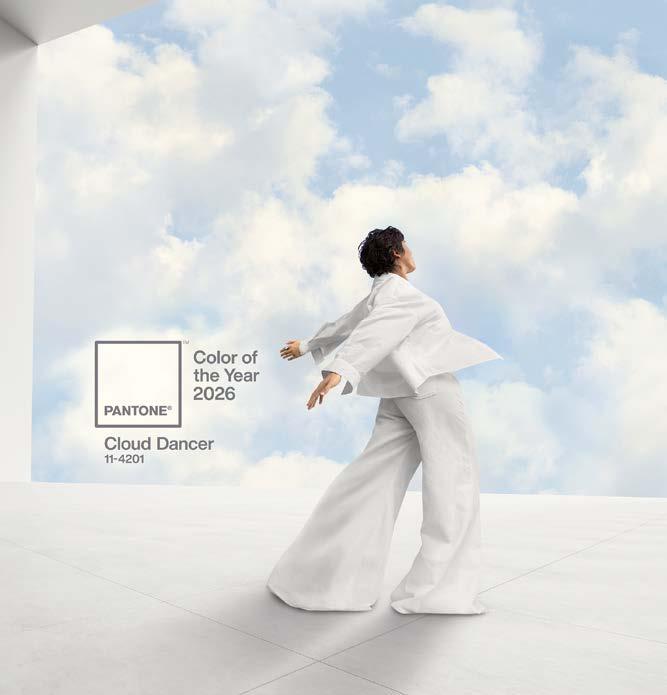

Pantone introduces Pantone Color of the Year 2026: PANTONE 11-4201 Cloud Dancer

UCIF: a year of vision, expertise, and support for the finishing sector

One Group, One Vision:

Engineering Excellence for ZLD & Anodizing Finishing Lines

Anodizing & P

Waste Wa Chemicals

Waste Wa

A new line of nanotechnologic conversion for corrosion classes C3H – C4H – C5M

DOLLCOAT GP 107 based on graphite engineered by

Multimetal no rinse product to be used at room temperature

Compatible with any plant and applied by spraying, deep immersion or by nebulization modules

Excellent pre-cataphoresis pretreatment

Alessia Venturi Editor-in-chief Direttore Responsabile

Finding the right balance in uncertain times.

This is the subtitle of the OECD’s interim economic outlook report released last September. In the first half of 2025, global growth showed greater resilience than expected, particularly in many emerging economies. According to projections, global GDP growth will decline from 3.3% in 2024 to 3.2% in 2025 and 2.9% in 2026, as tariffs and still-high policy uncertainties continue to dampen investment and trade1 In 2025, GDP growth in the Eurozone was modest and structurally low, at around +0.8%; forecasts for 2026 are slightly more optimistic, at +1%. China and the United States are also showing signals of a slowdown compared to the 2024-2025 period.

The manufacturing sector accounts for a large portion of GDP in both Europe and China, 15% and 25%, respectively2. At the same time, European companies are strongly export-oriented and diversified, which increases their resilience. In the US, manufacturing contributes a lower share, around 9-10% of total GDP3

The surface treatment sector is a specialised niche within the manufacturing industry: in 2024, its global market was estimated to be worth over $105 billion4, highlighting growing demand for applications in the automotive (especially the high-end and electric mobility segments), aerospace, electronics, medical, energy, and defence industries. North America holds a significant share of the market (with the US leading the way). Asia-Pacific is the fastest-growing region. Europe maintains critical but relatively declining shares in the global chemical/manufacturing sector – you will find this topic explored in depth in the opening article of this issue. Now, in light of this analysis, does it still make sense to be dynamic entrepreneurs who are willing to invest, take business risks, and pursue development and commercial expansion?

Yes, it does. But not in the same way as it did ten or fifteen years ago.

Slow economic growth does not necessarily equate to a lack of opportunities. On the contrary, in this context, the greatest risk is immobility, the tendency to take a romantic view of entrepreneurship based on ‘feelings’ and optimistic forecasts rather than on know-how, analyses, and skills.

Today, dynamic (and successful) entrepreneurs are well-prepared, selective, clear-headed, and adaptable. They are able to identify the technical needs of the market, presenting themselves as partners rather than suppliers and assisting clients in critical workflow stages with reliable solutions, repeatable processes, and certified quality. They also know it makes sense to invest in digitalisation to reduce errors, in applied R&D, and in flexible automation – in short, in technological risk, to avoid being left without options for survival in five years.

The surface treatment sector offers extraordinary opportunities for growth because its processes are critical to the functionality of products, affecting their quality, durability, and reliability. By investing in surface treatments, companies can enter new value chains, becoming partners that are more difficult to replace. The event to discuss all these issues is PaintExpo 2026, to be held in Karlsruhe (Germany) in April. The pages of this ipcm® issue, which will be distributed at our stand at the trade fair, already include many examples of what it means to be an entrepreneur today.

Because now is the time for above-average thinkers to rise up.

Richiedi la versione in italiano a info@ipcm.it

1 https://www.oecd.org/en/publications/oecd-economic-outlook-interim-report-september-2025_67b10c01-en/full-report.html

2 https://www.china-briefing.com/news/china-manufacturing-industry-tracker-2024-25/

3 https://fred.stlouisfed.org/series/VAPGDPMA

4 https://www.gminsights.com/industry-analysis/surface-treatments-market?utm

Philip Marsh and Wayne Daniell, Ph.D., Directors, The ChemQuest Group, Inc. pmarsh@chemquest.com

The ChemQuest Group, a global business strategy and external technology development firm with expertise in the specialty chemicals markets, continues its in-depth analysis of the coatings sector in particular and the chemical industry in general. This article presents the current perspectives of the latter, which is experiencing one of its most challenging phases in Europe.

It is hard to imagine Europe without a chemicals industry.

Inconceivable, in fact, that a shared history spanning two centuries of discovery, invention, and industrialisation could actually come to an end. Whereas the romantic historian might at this stage reference Alfred Nobel or Marie Curie, two of chemistry’s great pioneers, the industrial historian is more likely to point to Fritz Haber and Carl Bosch, chemists who epitomised an era when the science of chemistry evolved into a true chemicals industry.

The modern historian, however, may simply point to the numbers: the estimated 1.2 million people who are currently employed in the European Union (EU) within the chemicals industry, as well as a further 3 million in related (and partly dependent) sectors. In 2025, this industry generated approximately Euro 635 billion of turnover within Europe, supported on the shoulders of over 30.000 European companies. Inconceivable, indeed, to imagine its demise.

However, that is exactly the stark picture painted by a recent Cefic report. The market downturn is broad and persistent, with little sign of near-term improvement. It has led Europe’s share of the global chemical market to drop to 13%, with market leader China dominating with 46% of global sales. And now Europe faces a pronounced capacity contraction, with about 11 million tonnes of chemical production set to close across 21 major sites.

The planned closures are concentrated in aromatics, accounting for 41% of capacity taken offline in 2023–24, including isopropylbenzene, styrene, ethylbenzene, and toluene diisocyanate. Olefins and polymers represent a further 26% and 23%, respectively.

The envisaged cracker shutdowns are especially damaging, nearly 3 million tonnes of naphtha-cracker capacity—around 5% of Europe’s base— will close, severing a key link between refining and petrochemicals.

Cefic warns that the oversupply is global and structural. New capacity elsewhere, weak European demand, and utilisation falling to about 75% in 2023 (projected to stay at 74–76% through 2028) all undermine European industry development and complicate efforts at decarbonisation.

Even core building blocks are affected—ethylene, propylene, ammonia, chlor-alkali—all continue to be hit hard by high energy costs whilst suffering sluggish demand in Europe.

Downstream, closures are already tightening supply of the resins, solvents, and intermediates used in coatings, forcing formulators to re-qualify materials, secure alternatives, and accelerate substitution and recycling.

The brutal reality is that the competitiveness gap—high energy and carbon costs, weak demand, and overcapacity—makes closures systemic rather than cyclical. Stricter emissions rules, slow permitting, and feedstock growth outside Europe further raise costs and shift production to lower-cost regions, leaving European legacy assets exposed. This creates a self-reinforcing cycle: margin compression leads firms to defer maintenance and capex, reducing reliability and making closures more likely. Each upstream shutdown raises supply risk for downstream resin, solvent, and additive makers, resulting in sustained volatility and rationalisation across coatings and related sectors.

This precarious situation prompted Sir Jim Ratcliffe, CEO of INEOS, to recently describe the European chemical industry as being at a “tipping point” and to call upon Europe’s politicians to make an “eleventh-hour intervention” to save it.

The recent upstream closures in Europe (Table 1) have impacted greatly on several coatings value chains, driving companies within that space to both react to the changes and rethink their strategies.

Formulators and R&D teams must accelerate parallel trials, ageing studies, and pilot runs to validate substitutions, while production and operations contend with tighter feedstock windows, partial shipments, and the need for short and validated recipes, as well as rapid changeovers. Procurement and supply chain groups face longer lead times, freight risk, and single-source exposure, requiring risk-mapping of inputs, supplier

pre-qualification, and tighter contractual clauses. Distributors and traders are forced into allocation management and higher inventory costs, while QA and regulatory teams manage greater material variance and heavier documentation through stricter impurity profiling and expanded pilot capacity. Sales and specification teams must navigate pricing complexity and performance trade-offs with dual-spec options and proactive customer management, while sustainability groups re-baseline recycled-content targets and qualify multiple recyclers. SMEs remain the most exposed, with limited purchasing power and R&D budgets, making pooled procurement, SKU prioritisation, and short-term financing critical mitigations.

Against this backdrop, immediate near-term priorities are clear. Companies should risk-map their top 20 inputs by spend and technical criticality, run parallel requalification streams for two to three substitutes per critical input with supplier co-validation, and secure flexible supply arrangements such as conditional offtake, tolling, or regional blending. Selective safety stock of 30–90 days should be funded only for the highest-risk SKUs, while reclaim and conversion projects—such as

In the wake of widespread upstream closures across Europe’s chemical sector, coatings manufacturers face a structurally tighter supply of resins, solvents, and intermediates. Long-term priorities must therefore be framed not as abstract ambitions, but as direct responses to the contraction of feedstock and monomer capacity.

Strategic feedstock diversification becomes unavoidable when local crackers and aromatic units shut down, cutting off reliable streams of styrene, propylene oxide, and epoxy precursors. By building multi-region sourcing networks for resins and solvents, and qualifying recyclers for polyolefin modifiers or bio-based solvents, coatings producers reduce their dependence on European assets that are disappearing. Diversification is the most immediate hedge against closures.

Technology and R&D investment is the next line of defence. As upstream closures force formulators to source variable resin grades from different regions, coatings must be reformulated to tolerate inconsistency. Accelerated weathering platforms and digital twins allow manufacturers to predict how coatings will perform when inputs shift,

COMPANY SITE UNITS CLOSED / CURTAILED

Solvay Salindres (France) TFA & fluorinated derivatives

Westlake Pernis (Rotterdam, NL)

BASF Ludwigshafen (Germany)

LyondellBasell/ Covestro Maasvlakte (PO11, NL)

INEOS Rheinberg (Germany)

Dow Böhlen, Schkopau, Barry (EU)

Borealis Schwechat (Austria) & others

BPA, liquid epoxy resin; ECH/allyl chloride mothballed

Adipic acid; cyclododecanone; cyclopentanone

PO11 POSM unit (propylene-oxide / styrene monomer)

Epichlorohydrin; chlorine / caustic units

Ethylene cracker; chlor‑alkali/vinyl; siloxanes

Mechanical recycling projects suspended

Evonik Hanau (Germany) & others Keto-acid production discontinued

Shell Various EU assets

Strategic review; selective closures possible

DOWNSTREAM COATING SEGMENTS AFFECTED

Fluoropolymer & specialty additive coatings

Epoxy coatings; marine & industrial primers

Polyester polyols for PU topcoats; UV‑stabilisers

PU binders; polyol feedstocks; styrenic binders

Epoxy precursors; chlorinated intermediates

Alkyd modifiers; styrenic binders; chlorinated intermediates

Announced Sep 2024; stop Oct 2025

Announced Jun 2025; closure 2025

Announced Aug 2024; shutdowns 2025

Announced Mar 2025; phased to 2026

Announced 2025; phased timing

Announced Jul 2025; shutdowns 2026–27

Recycled polyolefin modifiers; circular feedstock Paused Jul 2025

Niche additives; crosslinker intermediates

Base monomers & solvents for PU, epoxy, styrenics

Table 1 Recent upstream closures in Europe

or chlor-alkali unit, modular paint lines and tolling partnerships provide flexibility. Distributed production capacity ensures that coatings can still be manufactured even if one feedstock stream dries up, preventing bottlenecks from cascading downstream.

Policy and advocacy engagement may seem less connected, but closures are often triggered by Europe’s high energy costs and strict permitting. By pushing for competitive energy pricing and pragmatic VOC and emissions rules, coatings manufacturers indirectly address the root causes of upstream contraction. If policy shifts reduce the pace of closures, downstream supply becomes more stable.

Financial risk management is a direct response to the price volatility that follows closures. When epoxy resin or PU polyol supply tightens, freight and solvent costs spike. Hedging, diversified contract structures, and pooled procurement for SMEs help coatings companies absorb the shocks created by upstream rationalisation.

Announced Oct 2024; end-2025

Announced Mar 2025; under review

Customer and market adaptation is another downstream necessity. Closures force substitutions—epoxy primers may need to be replaced with PU alternatives, for example, or solvent-based topcoats with waterborne systems. Dual-spec options and proactive communication allow coatings producers to manage performance trade-offs transparently, maintaining trust even when upstream supply changes force reformulation.

Finally, digitalisation and supply‑chain visibility become critical as closures fragment supply chains. With resins and solvents sourced from multiple regions, impurity profiles and lead times vary. Advanced ERP systems and blockchain traceability help coatings manufacturers manage allocation decisions and quality assurance, ensuring that variability caused by upstream contraction does not undermine compliance or customer confidence.

The fear of the Domino effect

Europe’s chemical sector is entering a period of accelerating decline, with ageing infrastructure, high energy costs, and aggressive global expansion elsewhere eroding competitiveness. Whereas the news headlines have focussed so far on the plant closures, the greater underlying fear is of a detrimental knock-on or domino effect, not only within the entire chemicals supply chain, but extending into downstream European industries such as automotive, industrial manufacturing, electronics, or construction.

Reacting to Dow’s announcement of plans to shut down its steamcracker facilities in Saxony-Anhalt, the state’s Minister of Economic Affairs emphasised “the critical role the steamcracker plays in downstream industries” and warned that its closure could “disrupt both domestic and European supply chains”.

Some companies further downstream have already been driven to explore different countermeasures. Wacker implemented a costsavings program in October, aimed at saving EUR 300 million annually by focussing on reducing manufacturing expenses. Half the targeted savings will be generated through workforce reductions, with more than 1,500 positions expected to be eliminated worldwide (the majority at sites in Germany).

For coatings and paint manufacturers, the impact of these closures means structural exposure to volatility in resins, solvents, and intermediates. With many of the global leaders within the coatings industry (like Akzo, BASF, Jotun, Hempel) active in Europe, they represent a real threat to a EUR 40 billion market. But Europe’s chemical contraction is not just a supply-chain challenge—it is a structural redefinition of how resins, solvents, and additives are sourced, qualified, and integrated into product portfolios. Long-term resilience will depend on embedding sustainability, digitalisation, and diversified supply into operating models, ensuring continuity of performance and credibility with customers and regulators in a structurally tighter market.

• > 90% WATER RECYCLING

• REDUCTION OF DISPOSAL COSTS

• ZERO LIQUID DISCHARGE

• ZERO EMISSIONS

• EASY MAINTENANCE

• FULLY AUTOMATIC

2026 will be a pivotal year for ALIT in terms of trade fairs and strategic positioning, with a structured presence at the main international events dedicated to metal finishing, industrial coating and surface treatment processes. A journey that strengthens the company’s role as a technological partner for industrial paint stripping and process chemistry, both in Europe and overseas.

Following the official debut of ALIT USA at FABTECH Chicago 2025, which marked the operational entry of the Group into the North American market, 2026 represents the natural next step. Not just trade fair participation, but a targeted presence in those contexts where performance, process reliability, real sustainability and concrete alternatives to pyrolysis are discussed.

The first event of the year will be MECSPE 2026, taking place in Bologna from March 4 to 6. After the positive experience of the previous edition, ALIT will return to the leading European exhibition for industrial manufacturing, within the hall dedicated to metal finishing and surface treatment. For ALIT, MECSPE remains a key opportunity for direct dialogue with the Italian and European industrial landscape, where process developments, new chemical formulations and integrated plant solutions can be presented, all designed to improve efficiency, safety and operational sustainability.

PaintExpo 2026: the global meeting point for industrial coating

From April 14 to 17, 2026, ALIT will exhibit at PaintExpo Karlsruhe, the world’s leading trade fair for industrial coating technologies. With more than 400 exhibitors and visitors from all over the world, PaintExpo represents the ideal environment to engage with both contract coaters and companies with in-house coating departments.

ALIT’s presence in Karlsruhe will focus on industrial paint stripping technologies and high-performance chemical solutions, developed to meet the needs of increasingly controlled, repeatable processes aligned with the environmental objectives of the industry.

The European trade fair season will conclude with ALUMINIUM 2026, from October 6 to 8 in Düsseldorf, the leading international event for the aluminum industry. Following the success of the 2024 edition, ALIT will return with an even more structured presence, addressing the specific requirements of aluminum processing: from stripping hooks and masking systems to residue management and the integration of chemistry and equipment.

2026 will also mark a fundamental strategic step in the American market. ALIT USA will participate for the first time in FABTECH Las Vegas, from October 21 to 23, 2026, North America’s largest event for metal forming, fabricating, welding and finishing. This participation strengthens the operational model already in place: technology engineered in Italy, chemistry produced in the United States, and direct support from the local team in Michigan. An approach designed to provide fast response times, process reliability and concrete sustainable solutions to North American manufacturers.

Completing the international picture, ALIT USA will also make its debut at FABTECH Mexico, scheduled from May 12 to 14, 2026, in Mexico City. A strategic move toward a rapidly growing manufacturing market, where demand for metal finishing and industrial paint stripping technologies continues to increase.

The objective is clear: to bring reliable, high-performance and sustainable industrial solutions to a dynamic production environment that is increasingly focused on process efficiency and environmental responsibility.

High-performance dispersants play a vital role in coatings, improving pigment dispersion, colour performance and system stability. CFRP technology meets the demands of high-end markets for a broader colour gamut and superior product performance.

BASF has officially commissioned a high-performance dispersant production line at its Jiangbei New Material Technology Park in Nanjing (China). The new facility enables local production of advanced dispersants using Controlled Free Radical Polymerisation (CFRP) technology, enhancing global supply reliability and flexibility alongside output from the company’s Heerenveen site in the Netherlands.

“This new plant will establish a stable local supply to support fast-growing market demand in the industrial coatings and automotive sectors. With our advanced CFRP technology for dispersants and state-of-the-art production processes, the plant will enable the green transformation of our customers in Asia with lower PCF products,” has stated Stephan Kothrade, member of the Board of Executive Directors of BASF SE and Chief Technology Officer.

“Strong partnerships define our business. By expanding CFRP production in Nanjing, together with supply from the Heerenveen site in the Netherlands, we can respond faster and provide the flexibility that our customers need to thrive in a dynamic market,” has added Gops Pillay, President, Global Operating Division, BASF.

“Introducing CFRP technology at the Nanjing plant reinforces our competitive edge. By delivering advanced dispersant solutions, we empower customers to lead in performance,” has concluded Sylvain Huguenard, Vice-President of Global Additives Business Management.

For further information: www.basf.com/cn/zh

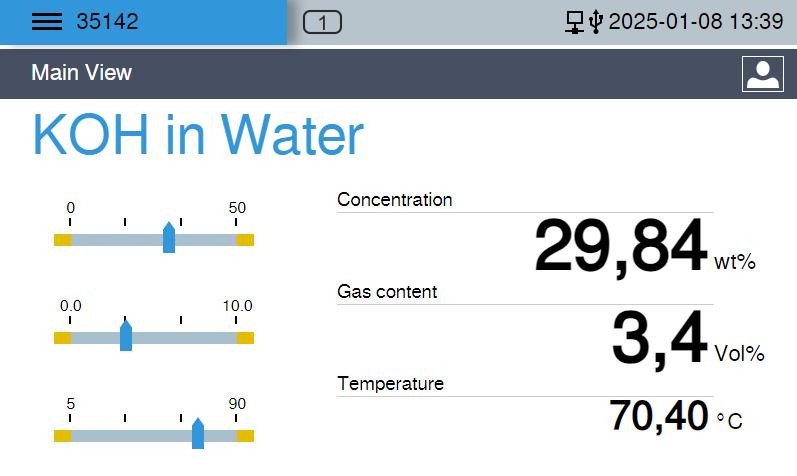

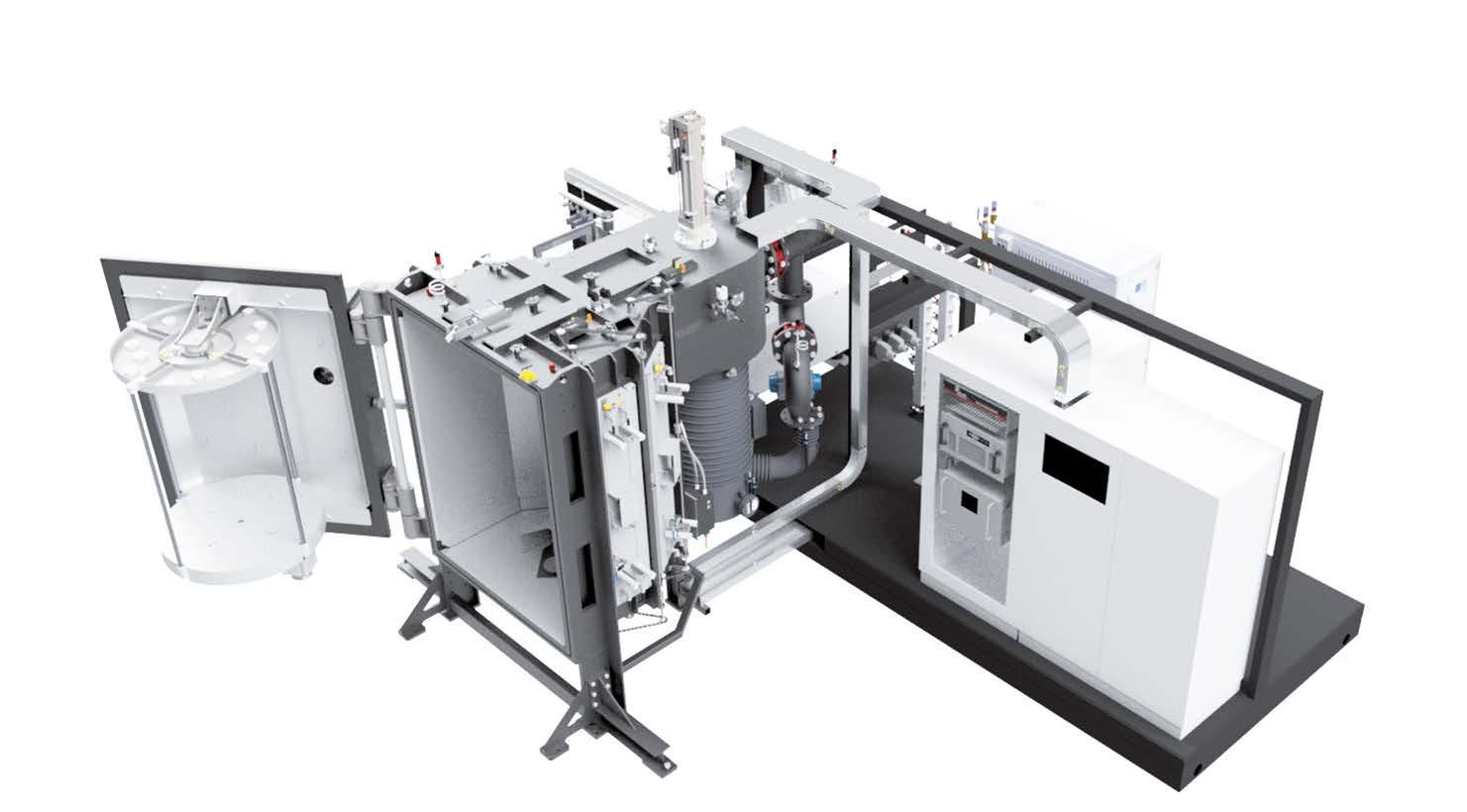

SensoTech offers the LiquiSonic® system, an ultrasonic technology designed to detect gas bubbles in real time and simultaneously monitor concentration in industrial processes, including alkaline electrolysis.

In many industrial processes, including alkaline electrolysis, the early and reliable detection of gas bubbles plays a crucial role in maintaining process stability, product quality, and equipment protection. Even small amounts of gas can indicate disturbances such as leaks, backflow, or phase transitions that compromise measurement accuracy and overall system performance.

Using ultrasonic technology, SensoTech’s LiquiSonic® system provides real-time detection of gas bubbles directly in the process line. The sensor continuously analyses acoustic signals, while an intelligent algorithm identifies characteristic patterns caused by gas-related disturbances. This enables operators to recognize anomalies at an early stage and supports both predictive maintenance and consistent process safety.

LiquiSonic® sensors are designed for continuous inline operation and can simultaneously measure concentration and detect gas bubbles, eliminating the need for manual sampling. Their robust, maintenancefree design and high measurement accuracy make them suitable for a wide range of applications – from chemical and energy processes to carbon capture, green fuel synthesis, and other fluid-based systems where reliability and transparency are essential.

LiquiSonic® combines two critical measurement functions –concentration monitoring and gas bubble detection – into a single, reliable inline solution. By increasing efficiency, operational safety, and scalability, the technology sets a new benchmark for modern process analytics. For further information: www.sensotech.com

From top to bottom:

Principle of ultrasonic gas bubble detection: LiquiSonic® immersion sensor analyses acoustic signals and identifies gas-related disturbances in real time.

LiquiSonic® controller interface showing real time concentration, gas content, and temperature during KOH process monitoring.

LiquiSonic® immersion sensor for inline concentration measurement and gas bubble detection in industrial liquid processes.

The ELETTROSPRAY® manual and automatic painting equipment both for liquid and powder paints application are fully designed and made by RAVARINI CASTOLDI & C. S.r.l. and are on the market since 60 years.

ELETTROSPRAY® electrostatic generators in particular represent a “unicum” in the solvent and water based painting equipment market.

The ELETTROSPRAY® are compliant with CEI/CENELEC standards to guarantee the maximum working safety.

dive@ravarinicastoldi.it

www.ravarinicastoldi.it

Durr Systems Italy S.p.A. will combine expertise in final assembly and painting technologies, operating from Milan and Turin with around 120 employees. The merger aligns with Dürr’s global strategy and aims to deliver a broader, more efficient service offering for customers in the automotive and industrial sectors, while maintaining continuity of existing contracts.

The global mechanical and plant engineering company Dürr has strengthened its footprint in Italy by merging its subsidiaries CPM S.p.A. and Olpidürr S.p.A. The unified company will operate under the new name Durr Systems Italy S.p.A., bringing together the firm’s competencies in final assembly and painting technologies to boost efficiency and enhance value for customers across the automotive and industrial sectors. Effective from 1st December 2025, the merged organisation will operate from Milan and Turin with a workforce of around 120 employees under the leadership of CEO Andreas Hohmann.

Board

© Dürr

The integration combines long-standing expertise in turnkey final assembly solutions with advanced painting, pretreatment and electrocoating technologies primarily used in vehicle production.

“The new company name marks a reinforcement of Dürr’s presence and identity in Italy. The merger strengthens our alignment with Dürr’s global strategy and ensures continuity and added value for all our customers,” has stated Andreas Hohmann.

Existing contracts and services will remain unaffected, while customers are expected to benefit from a broader and more innovative offering. The consolidated portfolio will cover consulting, planning and implementation of assembly processes, alongside painting technology, pretreatment systems and electrocoating. Dürr’s high-performance technologies, including its ProFleet automated guided vehicles (AGVs), are already in use at vehicle manufacturers worldwide, enabling flexible and costefficient production tailored to specific industrial requirements. The new organisational structure is designed to simplify project management, reduce administrative overheads and support stable, long-term customer relationships. Services will include preventive maintenance, technical assistance and plant modernisation.

“We can offer our customers in the automotive and industry sectors a unique combination of expertise, comprehensive manufacturing solutions and reliability throughout the entire production cycle,” has added Andreas Hohmann.

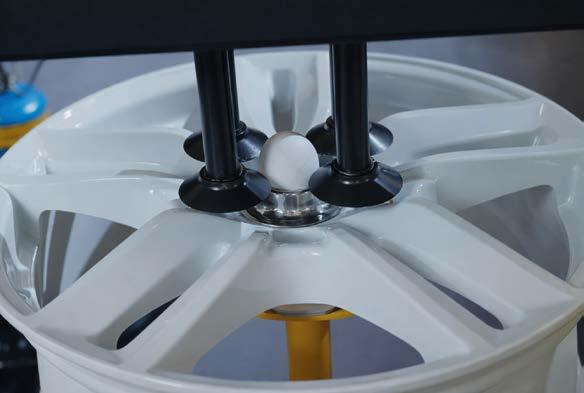

Dürr maintains another subsidiary in Italy, Verind S.p.A., based in Milan. Verind will continue to operate independently within the Dürr Group, specialising in robotic and application technologies. The company designs and manufactures industrial systems for application, ultrafiltration and wastewater treatment serving both automotive and general industry. It also acts as Dürr’s Centre of Excellence for electronic dosing machines. Verind provides engineering, laboratory services and technologies for applying painting and coating products to materials including metal, aluminium wheels, plastic, wood, ceramic, marble, composite and glass.

For further information: www.durr.com/en

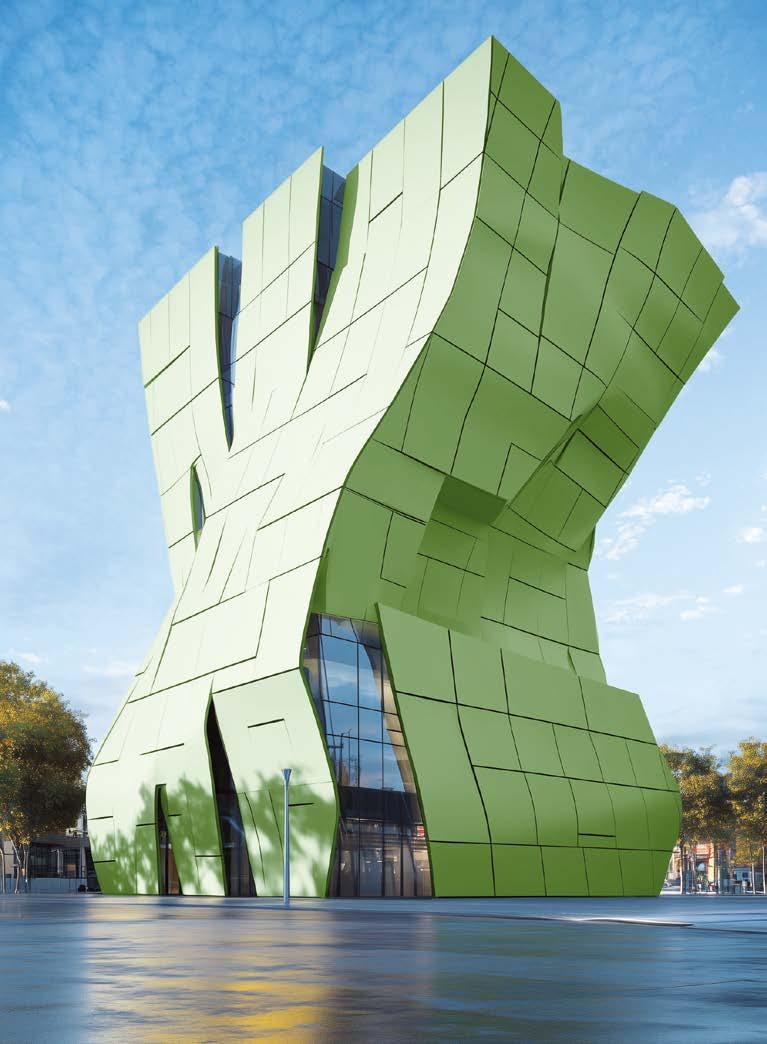

With local production of Interpon D3020 now underway, AkzoNobel is deepening its commitment to India’s fast-evolving architecture and design sector — enabling shorter delivery times and faster colour matching for fabricators and architects across the region.

Interpon D3020 is the ideal choice for bold and creative architectural projects that are exposed to the harshest environments, from searing heat to corrosive coastal climates. Local production means customers in the region can benefit from quicker delivery, and in-country colour development is making it faster for Indian architects to have their designs approved. Overall, the move not only provides faster access to the durability and design flexibility that the Interpon brand is known for but also supports India’s move to more sustainable construction. Based on advanced fluoropolymer technology, Interpon D3020 delivers outstanding resistance to corrosion, UV radiation, and weathering. It meets and exceeds the demanding requirements of Qualicoat Class 3, AAMA 2605, and GSB Premium, and outperforms in the rigorous 10year Florida test. When applied by an Interpon D Approved Applicator, the coating is backed by a warranty of up to 30 years. Crucially, Interpon D3020 is also a high-performance alternative to PVDF liquid coatings, delivering comparable hyper-durability with significant advantages in sustainability and application efficiency. The powder coating is free from Volatile Organic Compounds (VOCs) and generates minimal waste during application. Its exceptional resistance to scratching and marring means less rework on site, while one-coat coverage saves both time and energy, helping to showcase how Interpon powder coatings’ sustainability advantages go hand in hand with competitive benefits. The product is supported by an Environmental Product Declaration (EPD) providing total transparency concerning the sustainability of the raw materials, manufacture and transportation associated with creating Interpon D powder coatings. Simon Timmins, Regional Commercial Director for AkzoNobel Powder Coatings in South Asia, says he is delighted the business is now delivering locally produced D3020 to the Indian market, with shorter delivery times: “Producing Interpon D3020 in India means we can move faster, match colours more efficiently, and better support our customers in creating landmark structures that stand the test of time. The move has given us the agility to react quickly to India’s growing demand for locally-sourced state-of-the-art powder coatings. This collection is known to not only help imagine the future with beautiful colours and finishes, but also to protect it with an unmatched performance to withstand even the most challenging environments while supporting a more sustainable future.”

With 22 distinctive finishes in the colour card and many more colour options available, including sleek matte tones and premium metallic effects, Interpon D3020 gives architects the freedom to design bold, resilient facades that stand the test of time.

For further information: www.interpon.com/nl/en/architectural/warranties

Bernhard Resch

EVONIK INDUSTRIES AG – Essen, Germany bernhard.resch@evonik.com

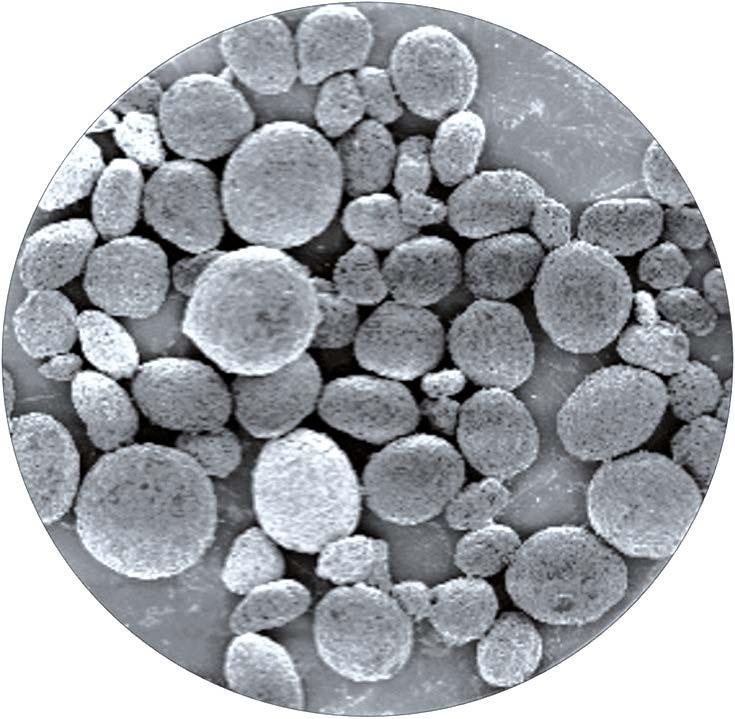

Evonik coating additives spherical silica

SPHERILEX® DP-0117 delivers superior durability and flexibility while achieving stunning matte finishes.

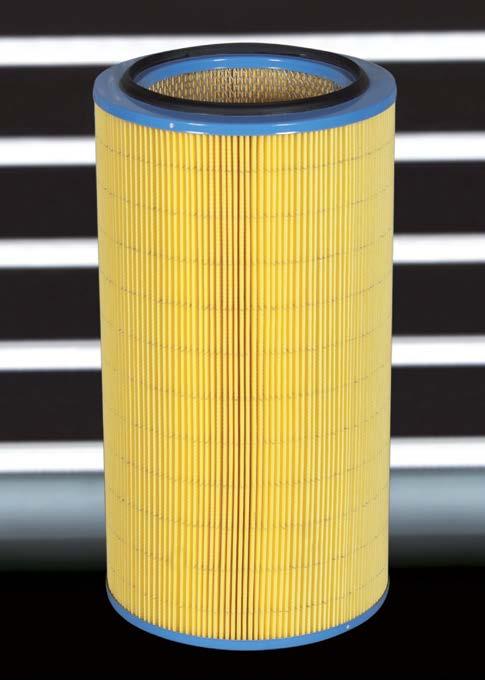

As powder coatings applications continue to diversify, and grow for both indoor and exterior use, the different chemistries that are being developed may find gloss reduction to be more challenging. Adding to the drivers for consistent matte finish are the trend towards lower temperature cure for greater energy efficiency as well as accommodation of heat sensitive substrates.

Matting of powder coatings is facing new challenges

Currently matted powder coatings account for 25-30% of all powders used1. In some of these applications, a greater range of aesthetic appearance is needed while coating performance requirements must be maintained or enhanced. In liquid coatings where film shrinkage occurs during cure, matting effects can be easily accomplished by the addition of matting agents to create the micro-roughness surfaces to readily control gloss levels. However, in powder coatings, since the systems are 100% solids, there is no film shrinkage from the evaporation of solvents, only slight volume shrinkage during cure.

1 Cal EzeAgu, “Gloss Control Powder Coating Resin”, Paint & Coatings Industry, August 7, 2020.

As a result, current methods of creating a matte finish in powder coatings have varying effectiveness and limitations.

Advantages of SPHERILEX® novel synthetic silica

It is well documented that the unique spherical morphology combined with the low oil absorption of SPHERILEX® grades, provide an advantage over conventional fillers when evaluating performance criteria of powder coatings (Fig. 1). At the same use level, compared to standard fillers, a higher matting efficiency is reached, while providing a linear, predictable, and repeatable gloss reduction. The resulting matted surface appearance shows excellent uniformity and consistency. In addition, the unique morphology of these particles provides improved flexibility while also improving hardness. This novel spherical precipitated silica performs equally well in exterior exposure and corrosion tests as current fillers used. Finally, it allows for greater theoretical coverage and transfer efficiency due to its low specific gravity.

Evonik expands its SPHERILEX® family with the largest spherical precipitated silica for coatings

SPHERILEX® offers similar advantages in liquid coating applications and the particle size typically determines the effects and use cases

Surface Cleaning preparation

IBIX systems remove rust, scale, and old coatings to reach SA 2.5 grade (ISO 8501-1).

Anchor Profile

Controlled blasting creates uniform roughness for optimal coating adhesion

Portable powder Coating Technology

For long-term anti-corrosion and waterproofing thermoplastic coatings.

Resistance to extreme weathering, UV and salt spray protection

Fast turnaround: immediate use of coated items

Easy to repair

THE FLAME SPRAY TECHNOLOGY IS THE ONLY SYSTEM WHICH CAN APPLY POWDERS ON SITE AND WITH NO NEED FOR A COATING LINE

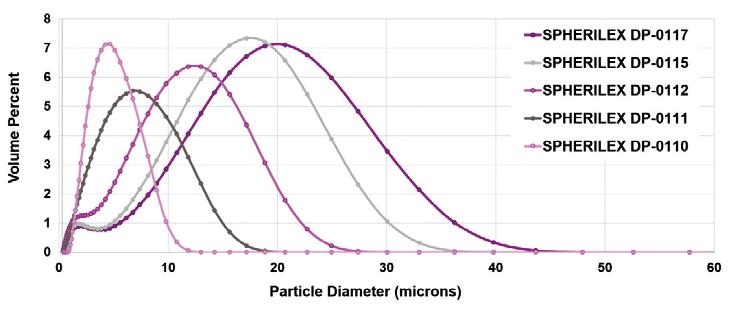

for each coating system. Until now, Evonik’s SPHERILEX® portfolio had ranged from d50 ~4.4 mm to d50 ~15 µm, but new technical advancements allow to introduce a new, larger grade: SPHERILEX® DP-0117 with a d50 ~18 mm (Fig. 2).

How does the new SPHERILEX® DP‑ 0117 perform in powder coatings?

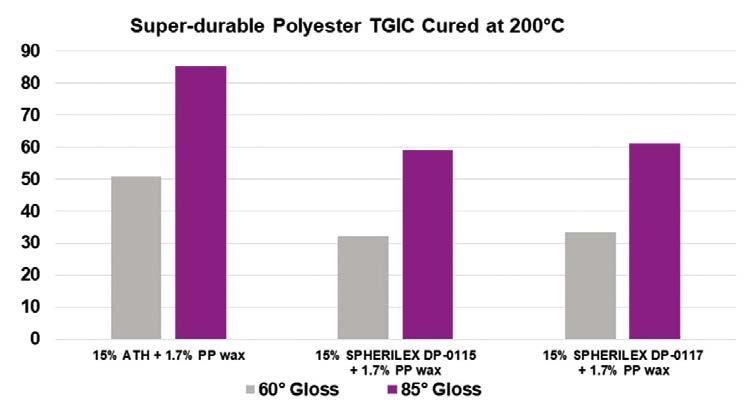

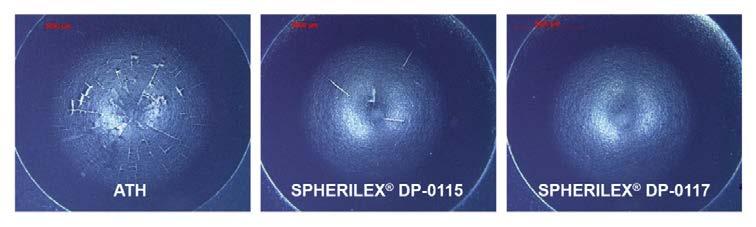

For optimal gloss reduction in powder coatings, combining conventional matting techniques (e.g. waxes, matting agents) with SPHERILEX® grades, results in highly durable low gloss formulations. SPHERILEX® DP0115 grade has been first choice for many applications, but the new SPHERILEX® DP-0117 may open up new opportunities for your powder coatings. Both larger SPHERILEX® grades are comparable in gloss reduction and show improved matting over Aluminium Trihydrate (ATH) of a similar size (Fig. 3). Furthermore durability and scratch resistance is boosted with improved pencil hardness as shown in Table 1

A key performance criteria, especially in super durable resin systems, has always been the positive impact on flexibility the SPHERILEX® grades provide. In Table 2 and Fig. 4 the DP-0117 has shown even further flexibilization properties over DP-0115 and drastically improved compared to ATH.

In summary, SPHERILEX® DP-0117 is a versatile and performance enhancing matting specialty filler, for a wide variety of powder coating applications and chemistries.

From top to bottom:

Figure 2 Particle size.

Figure 3 Improved matting.

Figure 4 Reverse impact (30 in lb) results of reference, DP 0115 and DP 0117.

Table 1 Pencil hardness.

Table 2 - Improved flexibility.

Pinholing/degassing deffects noticeable minor minor

Reverse impact at 30 in-lb* some cracking minor cracking no cracking

Reverse impact at 40 in-lb* severe cracking some cracking minor cracking *Tested at 75µm on Q Panel A 46 (Bare aluminium

Edited by Lesta Srl Dairago (Milan), Italy info@lesta.it

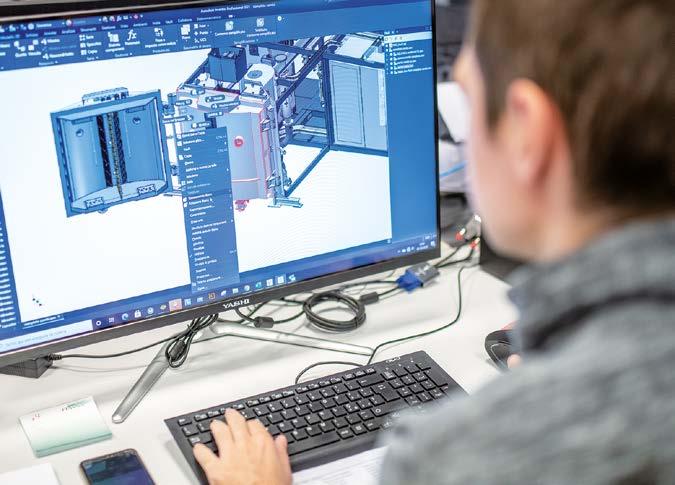

Easy PROG PORTAL by Lesta uses laser scanning to identify the shape and size of each object, then calculates and follows the perfect painting path— ensuring consistent, high-quality results for every unique piece.

Easy PROG PORTAL is Lesta’s robotic system designed for the automatic painting of windows, doors, panels, and cylindrical objects. Thanks to a laser scanning portal, the system recognizes each piece, generates the painting path, and executes it completely automatically, even when the parts have very different geometries.

After hanging, the parts pass through the portal and are scanned in real time, allowing the software to autonomously create the painting program, which the robot can apply immediately afterwards. The operator only needs to load the raw pieces and unload the finished ones, without the need for manual programming.

The system is designed primarily for two categories of objects: on the one hand, windows, frames, panels, doors and cornices, including curved or circular ones; on the other, cylinders and cylindrical objects.

Laser scanning technology ensures precise and uniform coating, automatically adapting the painting path to the actual shape of each piece.

CHEMTEC’s chemicals are revolutionary, cutting-edge, and environmental friendly.

Our revolutionary technologies are designed to have a very limited environmental impact, to reduce consumption of resources and for a greater operational simplicity.

CHEMTEC develops customized solutions that aim to maximize the customer’s satisfaction.

DISCOVER MORE ON WWW.CHEMTEC.IT

Ӳ Innovative chemical process for multi-metal surface treatment

Ӳ Based on the use of organic phosphorus compounds

Ӳ Does not contain heavy metals

Ӳ No consumption of energy and no creation of sludge

Ӳ Single-stage, room temperature multi-metal pre-treatment process

Ӳ No water and low energy consumption

Ӳ No VOC emissions, no rinsing, no pre-degreasing

Ӳ No creation of wastewater or sludge

Ӳ Minimization of energy consumption and environmental impact

Ӳ Denaturation and separation of paints from water, making it reusable

Ӳ Innovative formulations without toxicity symbol

Ӳ Quality technologies and tailored projects to the needs of each specific customer

Ӳ Non-hazardous, non-toxic, not harmful products

Ӳ Free of methylene chloride, NMP and other toxic substances

Ӳ Fast, excellent paint stripping, effective on all coatings

Ӳ Effective solutions at room temperature or low temperatures

The Easy PROG PORTAL uses high-resolution laser light barriers (5x5 mm) to analyze the geometry of each piece. It can handle objects up to 3x3 meters and accurately recognizes internal, external, and frontal surfaces.

This precision reduces waste and ensures consistent painting quality, even on pieces with varying shapes and sizes.

Using the Robot Controller, operators can create and save painting recipes for any type of product.

Each recipe defines parameters such as:

Gun speed and distance

Gun angle and tilts

Number of guns

Gun opening, overlaps, and gradients.

Optional parameters include flow rate, atomization, and fan pattern. Recipes can be easily recalled via barcode or touchscreen, optimizing production times.

Advantages of the easy PROG PORTAL system

No manual programming required

Automatic shape detection

Consistent coating quality

Reduced setup times

Compatible with both liquid and powder coating systems. With Easy PROG PORTAL, industrial painting becomes more efficient, precise, and flexible.

Easy PROG PORTAL is the ideal automatic painting system for windows, doors, panels, and cylindrical objects. It combines the power of laser scanning with Lesta automation, simplifying the operator’s work and improving final quality.

Alessia Venturi ipcm®

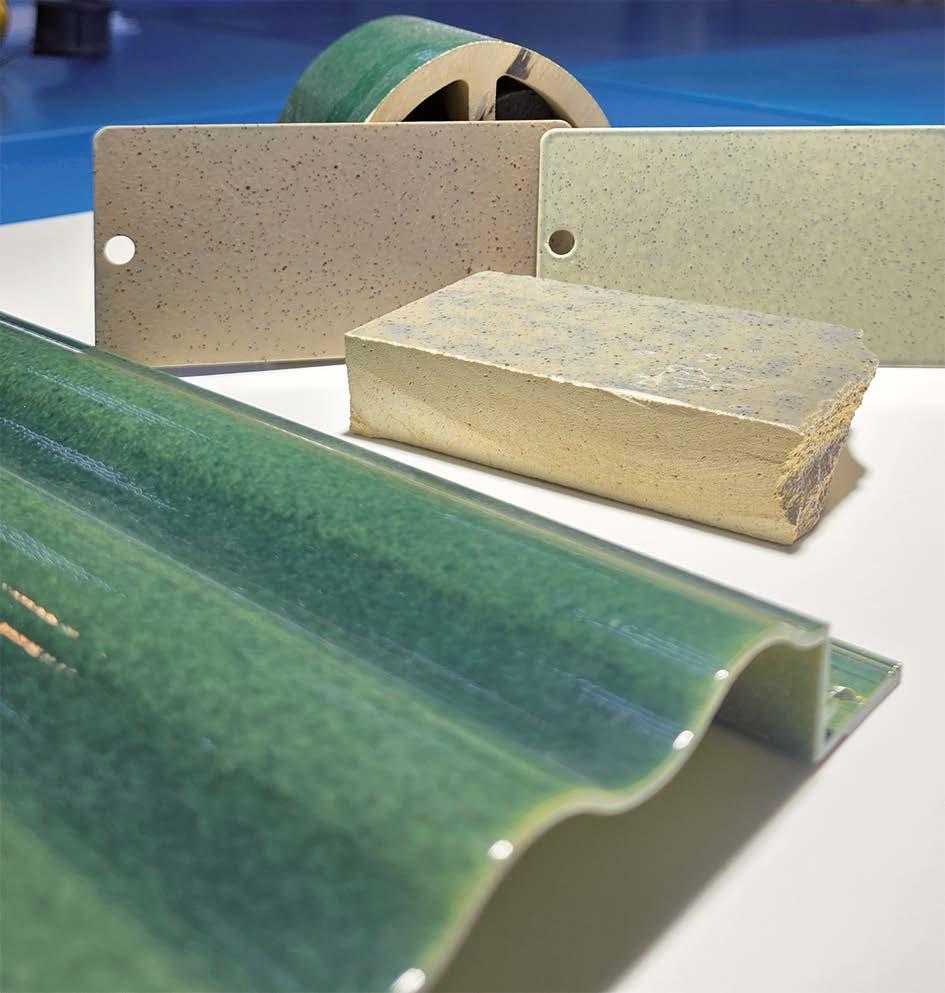

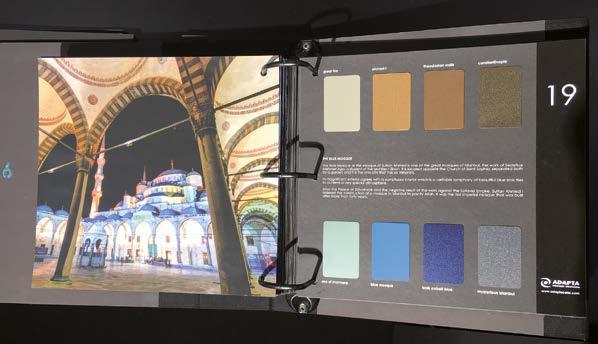

From its founding in 1997 to 2025, Adapta (Peñiscola, Castellón, Spain) has contributed to transforming powder coatings from industrial finishes with little added value into technological and inspirational projects. Below, we retrace the history of this company as told by its most significant colour collections.

Adapta was established as a powder coating manufacturer with exclusively Spanish capital at the end of 1997. From the outset, it proved capable of developing solutions that anticipated market needs by bringing competitive advantages to the products on which they were used, much beyond colour and protection. At the same time, its wide range of hues and special effects emerged as a fundamental part of its identity. Its mission was immediately clear: to elevate powder coatings, which had become established in the industrial market since the late 1970s, to a level of excellence equal to, if not superior to, that of liquid products.

Adapta was thus born with a solid technological and service foundation, but also with a strong focus on colour and finish design. This makes the evolution of its collections a particularly effective key to understanding its history.

When Adapta took its first steps in the late 1990s, its approach was typical of a young company: respond to every market demand, increase volumes, and consolidate relationships. Yet it was precisely during this initial phase that a realisation emerged that would guide its entire subsequent history: coating could be much more than a low-value industrial solution. “We soon realised that our vocation was innovation,” says David Pellicer, the company’s founder and current managing director. “Not just new colours but new effects and new functions, including what we now call smart coatings, ‘intelligent’ paints that can interact with their surroundings.”

In 1998, just one year after its foundation, Adapta invested in its first bonding machine, a strategic technology for the production of high-quality metallic powders, thus embarking on a path of advanced development

specifically in the field of metallic finishes, which at the time were still not widely used and considered complex to manage in terms of both production and application.

In the early 2000s, Adapta began to develop combined product ranges intended for both the architecture and industry sectors, with an increasingly specialised offering. A few years later, in fact, the collections became independent: Vivendi® was launched in 2003 as the company’s first small range for architecture featuring metallic, satin, and textured colours, “released with the ambitious goal of improving people’s modus vivendi, hence the name we gave it,” as Pellicer explains; Polaris was created in 2005 for the industrial sector, offering technical colours with minimalist aesthetics and high resistance, the embryo of the future Smart Coatings collection. The Polaris range also already included some fluorescent finishes that would later become the stars of the Neon collection, released in 2013. For the architecture world, Adapta’s offering was rounded out by the Alchemy and Sfera collections in 2007, which

included functional products providing a high-performance alternative to chemical finishes such as stainless steel, anodised stainless steel, natural aluminium, nickel, and titanium. Serpentia, with craquelé effects, was also launched in 2007.

Those initial lines reflected the company’s desire to offer colour ranges with resistant, high-performance finishes designed for architecture and, ultimately, to specialise in coatings for aluminium profiles and similar applications. Right from the start, Vivendi®, which over the years has incorporated numerous sub-collections as discussed below, has especially stood out for its high-quality colour effects combined with technical and functional characteristics such as durability, compliance, and sustainability.

That marked the beginning of a journey in which colour was no longer just a hue, but became an effect, a texture, a tangible material – a journey that would continue with the creation of a full-fledged architectural collection every four years. Indeed, in 2008, Adapta decided to move away from a volume-oriented approach to focus on niche products and launched A08. A08 was not simply a collection but a statement of intent. Groundbreaking for its time, it brought together the most unique finishes developed for special projects by Adapta during its first ten years of activity, while also introducing a new way of presenting powder coating.

“The aim of these collections has always been to work with specifiers: architects, designers, and clients,” indicates Pellicer. “We want to offer them not only colours but also high-added-value tools capable of making

a structure or object distinctive, unique, exclusive, and unrepeatable.” Each four-year collection includes hundreds of hues and embodies the research and development work carried out by Adapta over that period. In total, between A08, A12, and A16, Adapta currently brings nearly 700 colours to the market, all of which are still in production and in stock. This is a counter-current choice in a market that tends to rationalise, reduce, and optimise. Such production continuity is matched by a commercial strategy that promotes not only the products but also the technological innovation pursued by the company: the most recent collections are reserved for loyal customers, strengthening supplier/customer partnerships and differentiating Adapta’s offering.

Simultaneously, the company’s other focus is on functional coatings. It presented its first Smart Coating collection in 2010, anticipating issues that are central today, such as the antibacterial function, photoluminescence, product traceability, and even air purification through systems such as BioNox, which captures nitrogen oxides in the atmosphere to protect architectural structures from the accumulation of pollution and dirt.

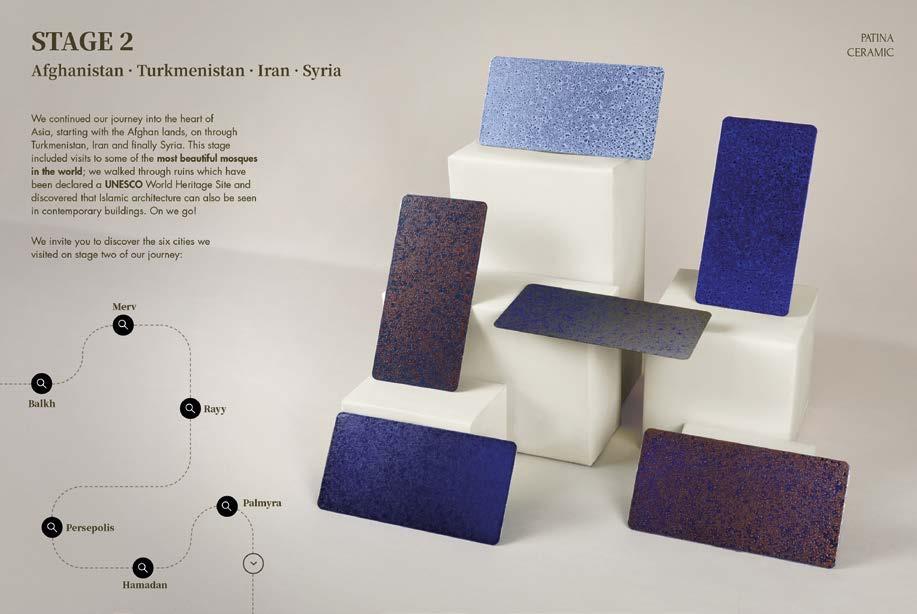

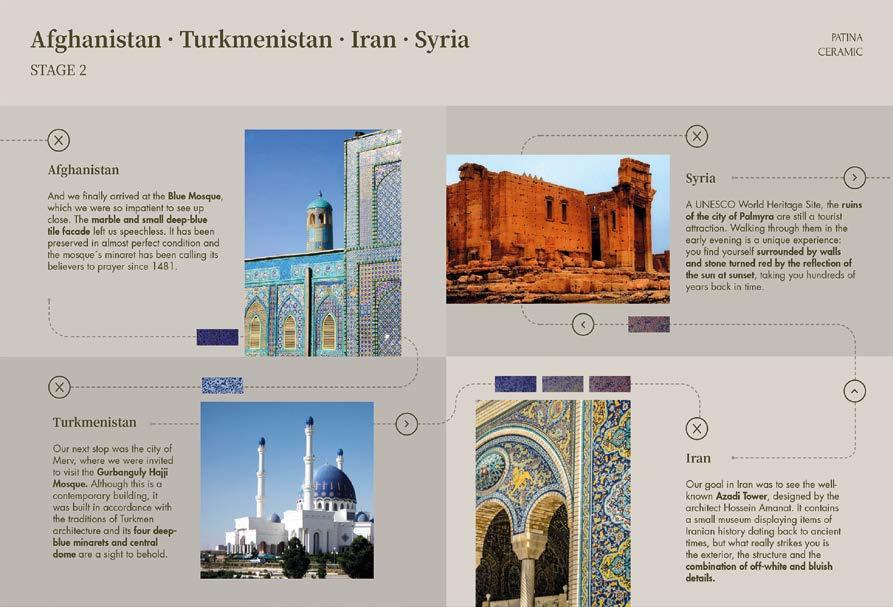

2013, 2014, and 2015 were years of colour innovation: Patina® (2013) was inspired by aged, oxidised, and patinated metals, copper, and bronze; Patina® Wet (2015) included ‘wet’ and ‘spangle’-effect finishes; Neon (2013) offered bright hues and luminous effects; and Dichroic (2015)

featured reflections that change with the light. In 2018, Adapta focused on imitating metallic and anodised finishes with its Metal and Anodic collections, both intended for metal architecture and launched as subsets of the Vivendi® collection.

In recent years, alongside extensive collections for architecture, more compact thematic series have been created, resulting from a strong artistic inspiration that aims to reflect and anticipate trends by enhancing the role of colour in design: Granite (2020,) with surprisingly realistic stone-like effects; Patina® Expression (2021), inspired by the Art Nouveau movement and divided into eight colour ranges reminiscent of natural materials (Metal, Gold & Copper, Neutral, Nature, Earth, Clay, Sand, and Symphony); Polaris III (2022), which integrated technical advances and sustainability; Patina® Ceramic (2021) and Enamel (2022), featuring finishes mimicking ceramics and enamels to create bright, soft surfaces characterised by high colour purity, also representing the fusion of artisanal aesthetics and modern technology; Vintage (2025), including several pastel colours for a reinterpretation of the classic style through the innovation of powder coatings; and Extreme Matt

(2025), the latest frontier, with super-matte finishes that are almost buttery to the touch.

All these collections are designed to offer a curated selection that is easy to navigate and immediately usable in specifications. Regulatory and functional aspects also play a part in this story, such as the systematic integration of the light reflection value (LRV), which is essential for ensuring accessibility and visual contrast in public buildings for the visually impaired.

In addition to their minimalist exterior and vibrant, abundant interior, one of the elements that makes Adapta’s collections recognisable is their narrative quality. Colours are not simple product codes but genuine evocative references: mountain ranges ordered by altitude in Granite, nods to the Silk Road in Patina® Ceramic, and Art Nouveau influences in Patina® Expression. The A08, A12, and A16 collections also have a strong emotional, evocative aspect that can be perceived through both their colours and effects’ names and the photographs that complement them, aimed to inspire specific moods in viewers.

“Powder coating has always been associated with industrial settings,” observes Pellicer. “With these collections, we wanted to change the language, the way people approach and choose powders.”

This change, however, has also entailed specific technical choices. In 2004, driven by strong market demand for special-effect powder coatings, Adapta decided to completely insource the bonding phase of its metallic products, taking on the complexity – and costs – of a process characterised by high material loss but essential for guaranteeing quality and batch-to-batch repeatability. That decision enabled the company to position itself at the highest levels of quality by producing metallic powder coatings that guarantee finishes comparable, and in some cases superior, to those of liquid paints.

“In the liquid coating segment, it is standard practice to apply multiple layers to achieve a robust and aesthetically flawless finish,” explains Pellicer. “Powders, on the other hand, are required to achieve the same level of finish with one coat. This has often led to underestimating the complexity of this technology and relegating it to a secondary role. I am proud to say that Adapta has played a strategic role in positioning powder coatings at a much higher level than when they were first introduced.”

This journey has been underpinned by continuous investment in facilities, processes, and skills. In Peñiscola, Adapta has a highly automated factory with state-of-the-art bonding machines. In addition to colours and effects, the Spanish company’s R&D department works on low-cure systems, biobased resins, and above all, outdoor resistance.

“We listen to our customers’ needs and turn them into market solutions, always adding an emotional and inspirational touch to elevate powder coating to a higher level, far beyond pure industrial functionality. However, technology remains critical: in the architecture sector, powder coatings are subjected to extreme environmental conditions. This is why we continue to conduct research and testing to enhance the outdoor resistance of our products,” emphasises David Pellicer. “In 2019, we created the Eternal system precisely for this purpose: to guarantee extreme durability for emblematic architectural projects1 and meet the requirements of the American specification AAMA2605, which sets criteria comparable to those of the European standard Qualicoat 3.”

Adapta’s factory is also very advanced in terms of resource recovery and self-production of energy, without using sustainability as a marketing message. “We prefer to focus on facts rather than words,” states Pellicer. “We measure the real impact of our production activities, analyse CO2 emissions, and take action wherever we can make real improvements.”

Each collection produced by Adapta in almost thirty years of activity represents a facet of its identity: innovation, adaptation, and design. The result is an offering that combines technology, innovation, and art and has helped redefine the role of powder coating as no longer a mere industrial finish but a language at the service of architecture, design, and industry.

Adapta will be at PaintExpo 2026 in Karlsruhe (Germany) from 14-17 April, Hall 3, Stand 3410.

Establishment of Adapta Color, S.L. (Spain)

Start of powder coating production

Philosophy: colour & protection

Vision: “The only constant is change”

VIVENDI®

Colour complements functionality in architecture

Metallic, satin, and textured finishes

Focus on design and durability

Starting point for the future VIVENDI® line (with an Environmental Product Declaration)

POLARIS

First major collection for the industry. The embryo of the future Smart Coatings collection

Technical and durable colours

Industrial applications

Minimalist aesthetics and high performance

ALCHEMY · SFERA · SERPENTIA

High-performance alternative to chemical finishes

Stainless steel, anodised stainless steel, natural aluminium, nickel, and titanium

Serpentia: craquelé effect finishes

A08 · A12 · A16

Powder coating enters the language of architecture with a range of 688 colours across the three collections

A08: First iconic architectural collection - Colour as a design tool

A12: Expanded colour range - Specifications and applied research

A16: Synthesis of design and technology - High-performance architecture

PATINA® · NEON · DICHROIC

The turning point in special effects

Patina®: oxidised metals and textured surfaces

Neon: bright, high-visibility colours

Dichroic: iridescent reflections

Colours become effects, textures, and experiences

GRANITE · PATINA® CERAMIC · PATINA® EXPRESSION

Thematic collections and artistic inspiration

Granite: natural mineral textures

Patina® Ceramic: ceramic finishes, a journey along the Silk Road

Patina® Expression: Art Nouveau, 8 colour families

Architecture, materials, and sustainability

POLARIS III · ENAMEL

Polaris: Advanced industrial design

Third-generation Polaris, unctional and contemporary colours

Integration of technical innovation and sustainability

Enamel: Reinterpreting the purity of enamel

Glossy, compact surfaces, high colour intensity, aesthetic tradition + modern technology

VINTAGE · EXTREME MATT

Vintage: Inspired by the past

Nostalgic accents and timeless finishes, classic aesthetics with modern performance, continuity between memory and innovation

Extreme Matt: Elegance and tactile appeal

Super-matte finishes, buttery feel, a nod to modernity

Monica Fumagalli ipcm®

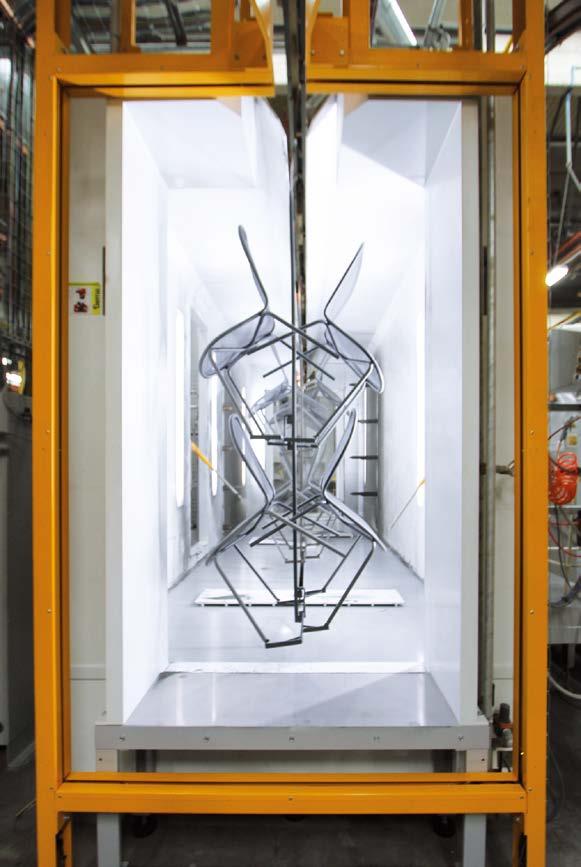

EMU Group, a company specialising in outdoor and indoor furniture solutions, is redefining powder coating in line with Industry 5.0 parameters. With the help of Gema, it has combined sustainability and digitalisation, creating an innovative production model that enhances technology and staff skills.

The Transition 5.0 plan established by the Italian government in 2024, now in its final stages, has been aimed to encourage manufacturing companies to adopt integrated strategies for increasingly sustainable and digitised production. However, some major manufacturing companies, such as EMU Group Spa (Marsciano, Perugia), which specialises in outdoor furniture, had already embarked on this path, through an internal strategic vision focused on continuous product quality enhancement. “We have made significant investments,” explains its production manager, Andrea Ciavola, “with the main objective of improving our overall production cycle and, in particular, the area dedicated to surface treatments.”

EMU, which is celebrating 75 years in business this year, is now a benchmark manufacturer of solutions for outdoor and indoor environments characterised by outstanding aesthetics, functionality, and durability, with coating as a truly distinctive hallmark. “The project to modernise our coating department, which included 2 powder application lines, one of which was integrated with a new booth developed and installed by Gema Europe, was an essential part of a broader plan launched previously. Our pursuit of ever-higher quality, combined with a focus on the environment and employee well-being, has aligned perfectly with the principles of Industry 4.0 and, later, with Italy’s Transition 5.0 plan. For this reason, when the latter was launched, we were among the few companies in Italy that were immediately ready: it was just a matter of refining the project to bring it into line with the required regulatory profile.”

a perfect balance between advanced technology and long‑standing

EMU’s headquarters has 150 employees and covers over 140,000 m², of which almost 50,000 are covered. “Added to this is our 1,000 m²-wide Design & Simulation Centre, where projects developed in collaboration with our customers take shape,” notes general sales manager Luigi Biscarini. “We created it to boost product research and promote the use of our solutions in the indoor and outdoor environments for which they are intended.”

The company’s customer base includes approximately 1,000 retailers worldwide, operating in 85 countries across Europe, North and South America, and the Far East, serving both the professional and residential sectors. “Our products are enjoying constant and growing global popularity thanks to their distinctive comfort, elegance, and style, developed in collaboration with some of the most renowned international designers,” adds Biscarini. “These elements translate into an easily recognisable identity for our collections, which are mainly made of steel and aluminium combined with other technological and innovative materials.”

The ongoing exchange of experiences and ideas with design studios and industry leaders helps EMU understand and often anticipate stylistic trends, contributing to their popularity and market success. The principles on which its activity is based – design, research, knowhow in metalworking and surface protection, sustainability, and multi-materiality – find full expression in the space called ‘Monomarca’, devoted to outdoor furniture and managed in partnership with Interni Design Experience in Milan (Italy): an exhibition area of over 500 m² conceived as a place where the material shapes the environment and the product itself contributes to creating the atmosphere.

Mastery of the most advanced processing technologies, constant attention to detail

and product quality, and the ability to develop solutions that enhance the purity of lines and volumes have strengthened EMU’s key role in its sector. It performs and controls all production stages in-house, both at its factory in Marsciano, in the heart of the Umbria region, and by coordinating its suppliers’ activities within an integrated network, in line with the most modern production models. Every year, it produces over 450,000 workpieces and processes approximately 3,800 tonnes of raw materials. “We work with a very high number of batches, consisting of extremely diverse components, made in solid metal sheets or expanded metal mesh, the latter being used in particular for the contract sector. Expanded metal is one of the most commonly used materials for structures and furnishings that are intended to remain exposed to outdoor conditions for long periods of time, as it promotes heat dispersion when exposed to solar radiation and ensures effective water drainage,” illustrates Biscarini. All production stages are subject to a rigorous monitoring system, from the inspection of incoming raw materials and testing during processing to the verification of the assembled parts before cataphoresis and coating and the final validation of finished products.

EMU’s entire production department has been the focus of ongoing investment to raise the bar on product quality. The operations also covered the machining workshop, where tubes are stamped, cut, and bent using last-generation CNC systems. One of the most significant improvements here was the implementation of a fully automated welding station for expanded metal. This cell, comprising 3 robots and several integrated machines, produces fully welded, clean parts that are ready to be sent to the cataphoresis plant and then to the coating one. The solid sheet metal components, on the other hand, are transferred to the assembly department, where welding operations are carried out on different production lines.

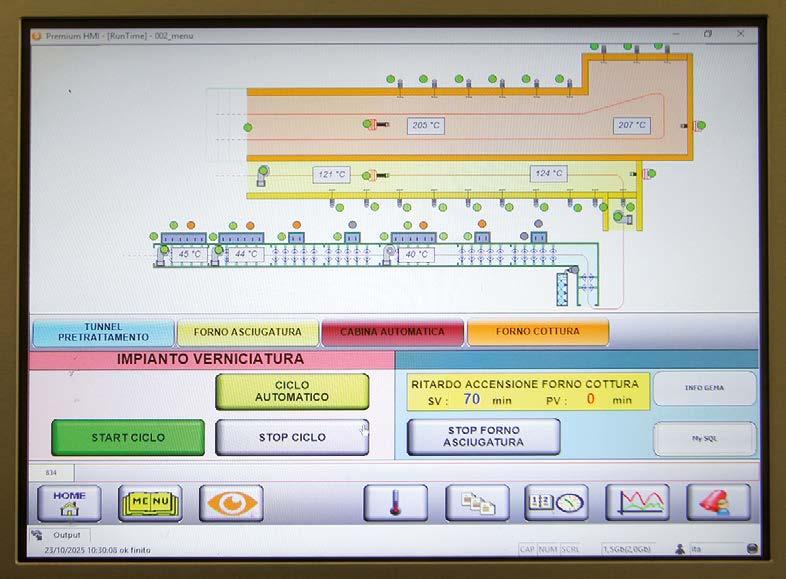

Consisting of 1 cataphoresis plant and 2 powder coating lines, this department meets the main requirements of Industry 5.0 by combining automation, traceability, and sustainability. The cycle is monitored at every stage and organised so operators can verify the characteristics of each required treatment, from loading through the entire coating cycle to packaging.

“Most of the components we produce undergo cataphoresis,” emphasises Andrea Ciavola. “The only parts that are excluded are those that do not require this type of process due to geometric limitations or specific construction characteristics.” After cataphoresis, the products are sent to the pre-treatment tunnel of the 2 powder coating lines installed by Euroimpianti (Valeggio sul Mincio, Verona, Italy), each equipped with 2 booths to ensure high production flexibility. These both apply two-coat polyester powders specially formulated for EMU’s application requirements.

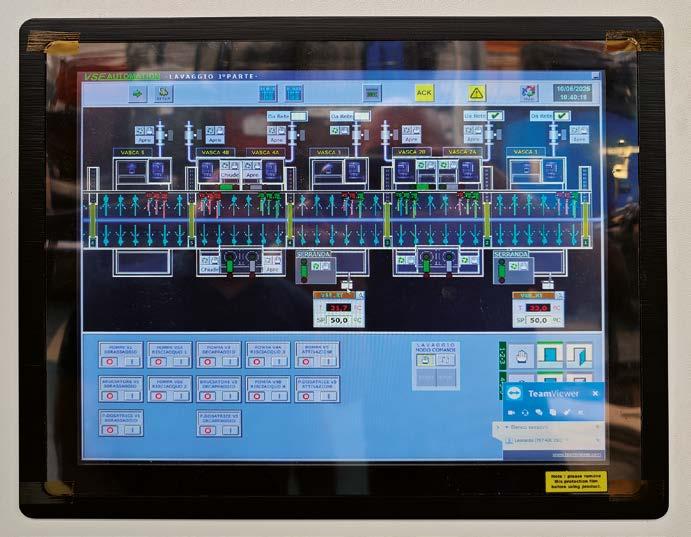

The cataphoresis plant has been progressively digitalised over the last few years. “We have eliminated paper documentation, replacing it with a digital

system that records data relating to the semi-finished product associated with each load bar.”

With a decoder the plant can identify the position of each part at every process stage and monitor the weight of the loaded components in real time. “As the operators load a bar, the machine tracks the total weight, flagging any anomalies that could cause problems during the process. At the same time, it indicates the number of workpieces needed to maintain the correct production rate. This means that the operators only have to report non-compliant products during unloading.”

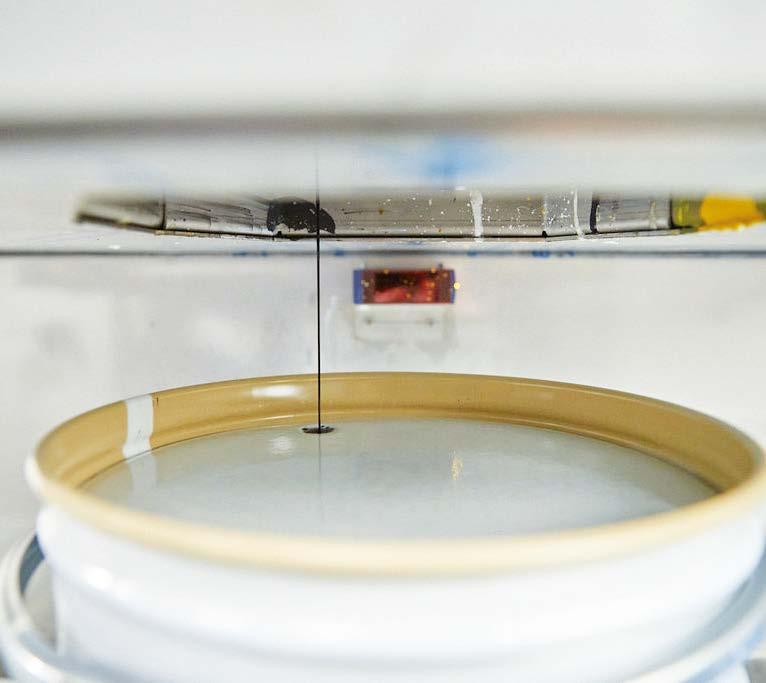

The cataphoresis product is supplied by PPG and is designed to deliver high surface coverage, resulting in a thick havana-coloured coating that requires special application precautions, especially when treating expanded metal.

“Although we distribute our products in over 80 countries worldwide, our production structure remains strongly linked to seasonality,” notes Ciavola. “We work in ‘made to stock’ mode for most of the season: to respond promptly to customer requests, we maintain a warehouse of products already subjected to cataphoresis and ready for coating, which enables us to offer extremely fast response times.”

EMU’s coating department is currently equipped with 2 advanced pretreatment tunnels: the most recent, installed by Euroimpianti in August 2025, is a new-generation 10-stage system; the second underwent a revamp last year, in line with Industry 4.0 requirements. “The 2 tunnels can constantly monitor chemical consumption and dosage thanks to conductivity and pH detectors installed on each tank, thus ensuring uniform parameters throughout the process. Micro-dosing of the pretreatment product, carried out by precision pumps, keeps the baths in optimal condition, with a clear advantage over manual refilling.”

The newest pre-treatment tunnel can also automatically detect whether the part hanging on each hook has previously undergone cataphoresis, adjusting the process cycle by including or excluding specific stages.

This solution ensures significant savings in chemicals and water resources, which are central to the company’s 5.0 transition plan. “Thanks to the collaboration with our long-standing supplier of pre-treatment chemicals, which specialises in the automotive sector, we have perfected this substrate detection solution and integrated it directly with our management system.”

Of the 2 coating plants installed, one is equipped with 2 separate booths connected by a power & free conveyor to enable sequential colour application. The second is configured with 2 in-line booths, one applying primers and the other top coats, and an intermediate pre-curing oven.

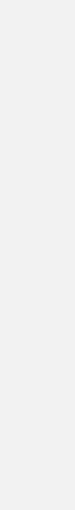

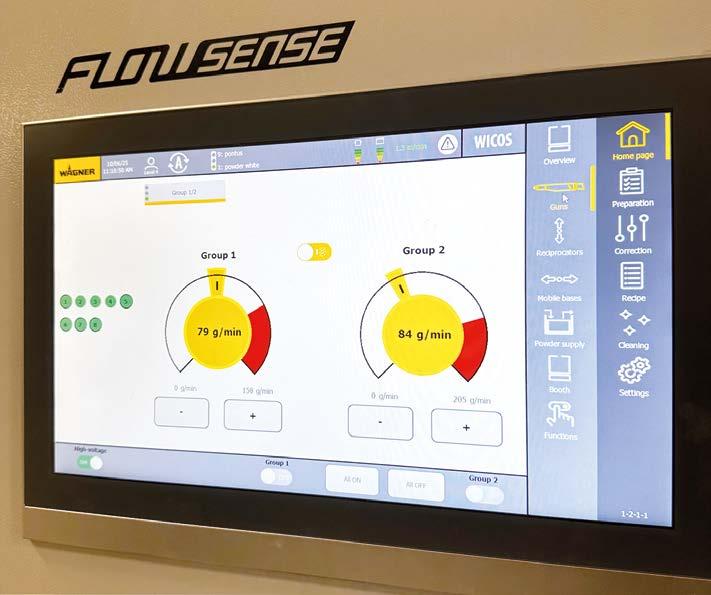

The new Gema powder coating booth

This second line features a state-of-the-art Gema powder coating booth equipped with 8 automatic and 2 manual spray guns, Venturi technology dispensing pumps, an OptiCenter® All-in-One OC06 powder centre, and a filtration system with an inverter that minimises energy consumption when no parts are passing through the booth. “The OptiCenter® All-in-One OC06 controls both electrostatics and powder delivery through a single, compact device,” says Claudio Sergenti, area manager at Gema Europe. “The OptiSpeeder tank is at the heart of this machine, as it ensures optimal powder fluidisation, whereas the large, slanted opening provides quick and easy access to the container. The closed-loop powder circuit is managed fully automatically, ensuring a clean work environment and greater overall efficiency.”

“The new booth is managed by software developed specifically for

EMU and connected directly to our ERP system,” says the company’s production manager. “The application recipes for our approximately 25 standard colours can be selected before the workpieces are positioned in front of the spray guns. Our coating operators, therefore, do not have to manually set the application parameters or adjust the distance of the spray guns depending on the part to be treated: the entire process is managed automatically, which is a decisive factor for high-volume production flows such as ours.” For batches of chairs that do not require assembly after surface treatment, EMU can load, coat, and store about 1,800 units in an 8-hour shift.

The high degree of automation in parameter setting optimises process times and enables operators to focus on post-finishing the most complex workpieces. “A further advantage is the consistency of results: to increase

the resistance of our products, it is essential to comply with the minimum thicknesses established by our quality department, as well as recover overspray.”

Advantages of the new booth

EMU was already familiar with the application characteristics of Gema’s solutions: 90% of the spray guns installed in its coating department have been supplied by the Swiss multinational. “The Gema team provided us with decisive support during both the design and after-sales phases, also with highly reliable spare parts always available. Today, we use the same application technology on both our lines, which is

an important advantage from an operational and management perspective.” Thanks to the digitalisation of its systems in accordance with Industry 5.0 parameters, EMU can also calculate its daily powder consumption and maintain a direct connection to the warehouse for real-time monitoring of available material quantities.

In addition to reducing product and energy consumption, coating quality has now become EMU’s real point of strength. “Determined by process consistency, operational flexibility, and all the technological and management advantages already mentioned, the quality of our coating cycles ensures

Thanks to dedicated software, the recipes for the approximately 25 colours in EMU’s catalogue can be selected before the workpieces are positioned in front of the spray guns.

The Gema OptiCenter® All in One OC06 system.

The ability to recover overspray, especially when coating expanded metal, is a crucial feature of the new booth.

optimal results even with a high degree of production variability, given that we have approximately 400 product codes in our catalogue,” Ciavola points out with satisfaction.

After curing, the parts proceed to the 18 packaging stations, where operators conduct a final quality check before packaging. “When the products reach the packaging department, the 5.0 system flags any items that may be defective based on statistical analyses and notifies an operator to pay particular attention to their most critical areas.”

Once packaged, the finished products are labelled with an RFID tag and

transferred to the dedicated warehouse, located in a 20,000 m² building. “We were among the first companies to adopt this identification and traceability system for metal furniture,” states Ciavola. “Active for 2 years now, this system simplifies loading and unloading operations during peak seasons: operators no longer need to know the contents of each package, as the system guides them directly to the correct bay for storage or retrieval. This has reduced our inventory activities to a few hours and eliminated shipping errors.”

For EMU, every relationship with product and plant suppliers contributes

P25 column standard or customizable system to hang from the smallest parts to heavy 6-metre long bars

to building the technical know-how of its staff, creating a wealth of expertise that also will be transferred to the next generation. “We firmly believe in the importance of investing in employee training first. Further investments can only be considered once the entire team has been properly trained and educated as the skills acquired enable it to identify the most suitable partners. At EMU, the combination of operator training and the advantages brought by Industry 5.0 solutions has streamlined our work, enabling everyone to monitor only the operations within their area of responsibility based on the process phase in progress.”

Through its forward-thinking vision and strong supplier relationships, EMU has stayed ahead of Industry 5.0 transition requirements and structured its coating cycle to the most advanced levels of digitalisation and sustainability. This has laid the foundation for manufacturing products that are not

only more aesthetically appealing but also more durable, advancing one of the company’s core objectives: reducing the environmental impact of its solutions.

EMU’s sustainable approach is rooted in a forwardthinking vision that has long characterised its philosophy and is based on its particular attention to furniture durability. “Creating products that are durable in terms of both aesthetics and resistance is a key element in ensuring sustainability,” says the production manager. “The fundamental concept behind the development of our furniture is the creation of ‘timeless’ products, integrating 100% recyclable and non-combustible materials and design that also takes into account the recovery and recycling phases, thus minimising waste. We have always stood out not

COMPLETE SOLUTIONS FOR HANGING AND MASKING

only for our metalworking capabilities, but also for our metal protection expertise: our know-how is constantly updated by implementing cuttingedge production techniques that focus on the safety of our personnel and the environment, guaranteeing long-lasting products and, as a direct consequence, a lower ecological impact.”

For wooden components, EMU selects special materials such as certified teak or bamboo coated with strictly VOC-free products. It also uses phthalate-free technical fabrics for outdoor use, and the HPL (highpressure laminate) used for some tops is non-toxic and made from 70% renewable sources. The environmental compatibility of EMU’s entire range is also ensured by its commitment to reducing plastic packaging and gradually replacing it with recyclable cardboard. In addition, the company has installed a 1.5-MW photovoltaic system that completely meets the energy needs of its production department. Finally, when designing exhibition stands, EMU is paying increasing attention to developing solutions that enable material reuse and facilitate easy assembly and disassembly of structures.

“The sustainability of our company,” concludes Biscarini, “is also fuelled by ethical and inclusive choices that encourage the expression of

individual potential, also through a significant presence of women and the adoption of an international mindset from design to production. EMU is deeply aware that the high quality of its products is the result of a virtuous balance between technology and human capital, an invaluable asset made up of passion and expertise that has been renewed from generation to generation since 1951. We are convinced that a company’s competitiveness and corporate sustainability depend, first and foremost, on its sustainability.”

Edited by Galstaff Multiresine Spa Mornago (Varese, Italy) sales@galstaffmultiresine.com

Amino resins are typically found in thermosetting coatings. However, they have been under scrutiny by the ECHA for several decades due to their intrinsic nature and the hazardousness of the raw materials that compose them. Despite this, they still have an ‘industrial appeal’ today, with solutions that meet resistance and performance requirements in several practical applications. The innovative and sustainable products developed and manufactured by Galstaff Multiresine are now opening new prospects in a sector that is rapidly evolving due to the increasingly stringent regulations.

Aminoplasts, also known as amino resins, are a class of thermosetting polymers obtained through medium-low temperature polycondensation reactions between compounds containing amino groups (e.g. urea, melamine, or benzoguanamine) and formaldehyde, in the presence of alcohols such as methanol, butanol, and isobutanol. This process leads to the formation of 3D cross-linked structures that give the material excellent reactivity, mechanical strength, thermal stability, and chemical inertness. Thanks to these characteristics, amino resins are used in a diverse range of industrial applications, including wood, food packaging, adhesives, laminates, durable plastics, and protective coatings. In the latter sector in particular, they have been utilised as one of the main cross-linking agents for over sixty years and played a key role in the development of high-performance thermosetting coating systems, which are appreciated for their surface hardness, chemical resistance, and abrasion resistance even in the most specialised and extreme application conditions.

According to data from recent industry studies, the global amino resin market is expected to grow from USD 12,839.6 million in 2025 to USD 22,777.9 million by 2035, with an average growth rate (CAGR) of 5.9%. This growth is driven by the increased use of high-performance thermosetting

polymers in applications such as wood adhesives, laminates, automotive components, building materials, and industrial coatings1. In recent years, rising environmental awareness has been redefining the development of the chemical industry as a whole, inevitably also affecting the amino resin sector, which is the focus of particular attention regarding the presence of formaldehyde and its related emissions.

Regulatory initiatives such as Title VI of the US Environmental Protection Agency (EPA)’s Toxic Substances Control Act (TSCA) and the European Union’s E1 and E0 limits are pushing towards low-emission formulations.

As a result, manufacturers are investing in the development of low-VOC amino resins, which are less hazardous to both users and the environment.

The production process and the nature of the raw materials used are undoubtedly the main levers for action by companies, together with an extension of product ranges, as all market leaders strive to develop solutions reducing formaldehyde content through increasingly advanced technologies. Among them, over half a century in the field of synthetic and auxiliary resins for paints and inks, Italian manufacturer Galstaff

1 https://www.futuremarketinsights.com/reports/amino-resin-market?utm

Global market for amine resins used in paints and coatings: size by application, 2022 2030.

Baking reactivity

High

Cross-linking temperature (°C)

Type of amino resin

80 – 120 °C M170 - M174