SUMMARY

VOLUME 4 2025

‘SEAWEED CEMENT COULD SHRINK CONCRETE’S CO₂ FOOTPRINT’

LOW-SETTLEMENT EQUILIBRIUM FOUNDATIONS

LIVING BUILDING MATERIAL THAT STORES CARBON

RAINPROOF FACADE PANELS MADE FROM WALNUT SHELLS

STUDYING POROUS MATERIALS WITH AI

‘SEAWEED CEMENT COULD SHRINK CONCRETE’S CO₂ FOOTPRINT’

LOW-SETTLEMENT EQUILIBRIUM FOUNDATIONS

LIVING BUILDING MATERIAL THAT STORES CARBON

RAINPROOF FACADE PANELS MADE FROM WALNUT SHELLS

STUDYING POROUS MATERIALS WITH AI

This is a summary of the most recent edition of Innovative Materials. Would you like to read the entire articles? You will find more information about subscriptions HERE.

Innovative Materials is an interactive, digital magazine about new and/or innovative applied materials in civil engineering sector, construction, architecture and design.

Scientists at the University of Surrey claim to have made a breakthrough in the development of eco-friendly batteries that not only store more energy but also help reduce greenhouse gas emissions. These ‘breathable’ batteries release energy while capturing carbon dioxide, offering a greener alternative to conventional lithium-ion batteries.

Until recently, 3D printing of engine components for aerospace applications was limited by the lack of affordable alloys that could withstand extreme temperatures. Only highly expensive metals were suitable, until researchers at NASA’s Glenn Research Center in Cleveland developed GRX-810.

Electronic devices are often discarded once they fail or become outdated, as recycling is complex and usually yields little value. Two research teams at Virginia Tech have now developed an approach that could help ease this problem.

Researchers at Oak Ridge National Laboratory (ORNL) have made progress in developing a cheaper and more efficient dry process for manufacturing lithium-ion batteries. These batteries are widely used in vehicles and electronic devices. The new method produces electrodes that deliver more electrical current while reducing the risk of overheating.

Researchers at Oak Ridge National Laboratory (ORNL) have made progress in developing a cheaper and more efficient dry process for manufacturing lithium-ion batteries. These batteries are widely used in vehicles and electronic devices. The new method produces electrodes that deliver more electrical current while reducing the risk of overheating.

Researchers from the EPFL Laboratory of Soil Mechanics, the University of Applied Sciences and Arts of Southern Switzerland (SUPSI), and the EPFL start-up Medusoil SA have demonstrated that Bacillus megaterium - a versatile microorganism found in soil, freshwater, seawater, and even on plant surfaces - can convert CO₂ into calcium carbonate (CaCO₃), the mineral that makes up limestone and marble, among other things.

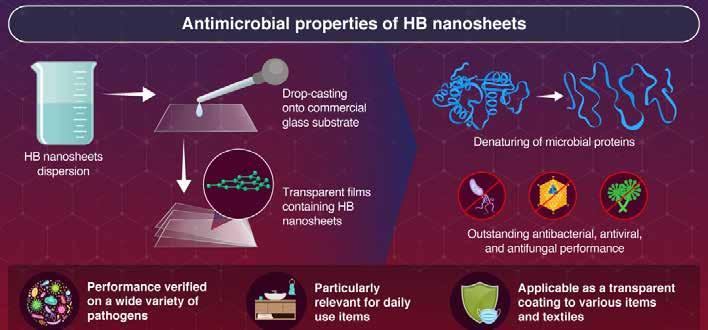

In a recent study, a Japanese research team led by the Material Science and Engineering Department of the Tokyo Institute of Science discovered that HB nanosheets possess excellent antibacterial, antiviral, and antifungal properties.

Researchers at Rice University have developed a new glass coating that can significantly reduce heat loss through windows. The material is a transparent, ultra-thin film created by weaving carbon into the atomic lattice of boron nitride. The result is a strong layer that reflects heat while resisting scratches, moisture, UV light, and temperature fluctuations.

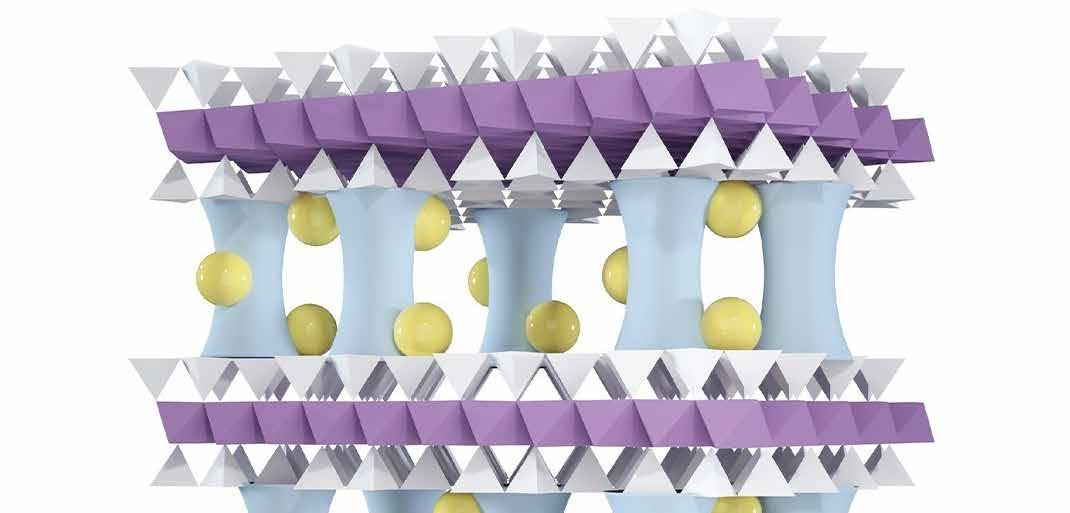

Scientists at Argonne National Laboratory and the University of Chicago have developed a new membrane technology that can efficiently extract lithium from water.

An international research team has developed a new nanomaterial capable of efficiently harvesting drinking water from the atmosphere. The material can hold more than three times its own weight in water and does so much faster than existing commercial technologies. This makes it directly applicable for producing fresh water from airborne moisture.

Engineers at the Oak Ridge National Laboratory (ORNL) of the U.S. Department of Energy have developed a method using 3D-printed metal molds to produce faster, cheaper, and more flexible composite components for mass vehicle production.

Researchers at the University of Houston have developed a method to transform bacterial cellulose into a versatile material that may one day replace (single-use) plastics. Potential applications include packaging materials and even wound dressings.

Researchers at the University of Pennsylvania have now developed a new type of concrete that is not only lighter but also absorbs significantly more CO₂ than conventional mixtures. By combining 3D printing with the fossilized architecture of microscopic algae, they created a material that captures up to 142 percent more carbon dioxide, while requiring less cement and still meeting standard compressive strength requirements.

The German Institute for Textile and Fiber Research Denkendorf (DITF) is developing a comprehensive system for measuring and predicting the acoustic properties of a wide range of textiles, which should ultimately lead to the development of a wide range of sound-absorbing materials.

‘Seaweed cement could shrink concrete’s CO₂ footprint’

Researchers from the University of Washington (UW) and Microsoft have developed a new type of low-carbon concrete by mixing dried seaweed powder with cement. The seaweed-enhanced cement has a 21 percent lower global warming potential, yet maintains the same strength as conventional concrete. Thanks to machine learning models, the team arrived at this new formula in a fraction of the time traditional research would require.

Scientists are constantly seeking new materials derived from polymers. Rather than starting polymer research from scratch each time, they can save time and money by blending existing polymers to achieve desired properties.

A research team at Cornell University, led by designer Jenny Sabin, is developing a flexible solar material called HelioSkin. The material has sun-tracking properties that resemble the biomechanics of sunflowers.

Schiedam-Noord has been used as a sludge depot for several decades since the 1960s. In the 1990s, the site was prepared for the planned housing development by preloading it with 2.70 m of sand. However, this proved unstable, resulting in significant settlement. Within ten years, the neighborhood was subsequently raised several times without any insight into the final settlement. Due to the severe settlement, raising the site was necessary to achieve a a load-neutral or load-reducing effect. Three suitable options exist: EPS, glass foam, and foam concrete.

At ETH Zurich, researchers from various disciplines are working on new materials that combine conventional raw materials with bacteria, algae, and fungi. Their goal is to develop living materials that, thanks to the metabolism of microorganisms, possess beneficial properties, such as capturing CO₂ from the air through photosynthesis. The result is a (building) material that lives, grows, and actively absorbs carbon from the atmosphere.

Rainproof facade panels made from walnut shells

Can food waste streams be used as building materials? This question was central to Lara Neuhaus’s graduation project, ‘Bio-composites from food waste.’ She developed a biobased composite made from walnut shells. Initial material tests show promising results. With her research, she also aims to contribute to a change in the way we view materials: appreciating imperfections in color and texture can pave the way for more sustainable innovations.

Studying porous materials with AI

Advances in artificial intelligence for designing porous materials could impact a wide range of fields, from orthopedic implants to the next generation of batteries.

Jelly ice as a sustainable alternative to melting ice

Ice, whether crushed or cubed, inevitably melts into a puddle. Researchers Jiahan Zou and Gang Sun of the University of California, Davis, have developed an alternative: jelly ice. This material is reusable, compostable, and made from gelatin. Because frozen jelly ice doesn’t leak during thawing, it’s particularly suitable for the food chain and for transporting medicines.

Interested in the limitless possibilities of ceramics? Become a member of the Dutch Ceramic Society (NKV) today!

What does the NKV do?

• Facilitates knowledge sharing, collaboration, meetings, and information exchange with other (ceramic) organizations, institutes, and associations, both domestically and internationally

• Promotes education and research in the field of ceramic materials

• Provides a network of contacts for its members

• Actively spreads knowledge about ceramics and ceramic materials

• Engages in collective promotion of the use of ceramics

Want to know more about membership? Visit www.ceramics.nl. Click here>

Want to know more about membership, incl. free KGK subscription and free ECerS membership? Visit https://nkv.kncv.nl/ or send an email to: info@ceramics.nl>

Renewable Materials Conference

22 - 24 September 2025, Siegburg/Keulen

PARTEC

23 - 25 September 2025, Nuremberg

Solids Rotterdam

1 - 2 October 2025, Rotterdam

Metavak 2025

7, 8 en 9 October 2025

Gorinchem

Barcelona Design Week 2025

7 - 17 October 2025, Barcelona

Staalbouwdag 2025

9 October 2025, Leusden

K Messe 2025

8 - 15 October 2025, Düsseldorf

Holz

14 - 18 October 2025, Basel

Vakbeurs Recycling 2025

11 - 13 November 2025, Gorinchem

A@W Stuttgart

12 - 13 November 2025, Stuttgart

Precisiebeurs 2025

12 - 13 November 2025, ‘s Hertogenbosch

Formnext 2025

18 - 21 November 2025, Frankfurt

Future surfaces 2025 19 - 20 November 2025, Edegem

Advanced Recycling Conference 19 - 20 November 2025, Cologne

Beton Event 2025

20 November 2025, Den Bosch

A@W Düsseldorf

3 - 4 December 2025, Düsseldorf

EUROGUSS 13 - 15 January 2026, Nuremberg

BetonTage

10 - 12 March, 2026, Ulm

BLE.CH 2026

11 - 13 March 2026, Bern

Fensterbau Frontale

24 - 26 March 2026, Nuremberg

Sintering 2026

31 August - 3 September 2026, Aken

Steinexpo 2023

2 - 5 September 2026, Homberg

Batimat 2026

28 september - 1 October 2026

Paris

HärtereiKongress

8 - 10 October 2024, Cologne

Wij leveren complete installaties voor ontstoffing, luchtreiniging en pneumatisch transport

Technieken voor o.a.:

- Ontstoffing van productieruimtes (MAC)

- Reduceren van geuremissies (NER)

- Reduceren van stofemissies (NER)

Componenten die wij o.a. kunnen leveren:

- Natfilters & Droogfilters

- Cyclonen

- Gaswassers

- Topsteen- / Frogreinigers

- Naverbranders

Projecten kunnen turn-key worden uitgevoerd

Wij garanderen de emissie & grenswaarden

Engineering, bouw en onderhoud in eigen beheer

Mesys Industrial Air Systems BV

Molenstraat 27, 6914AC Herwen

+31 (0) 316 248744

www.mesys.nl

Info@mesys.nl

Conference 2025

The key event on advanced recycling technologies and renewable chemicals, building blocks, monomers and polymers based on recycling.

Topics of the Conference New Focus Areas

• Markets, Investments & Policy

• Circular Economy & Ecology of Plastics

• Physical Recycling

• Chemical Recycling

Sponsor

Sponsors

• Thermochemical Recycling

• Other Advanced Recycling Technologies

• Carbon Capture and Utilisation (CCU)

• Upgrading, Pre- and Post-treatment Technologies

19 – 20 November Cologne (Germany) Hybrid Event advanced-recycling.eu Organiser

Recycling

Independent, dedicated, objective research and consultancy. ISO 17025 accredited. Center of expertise for materials characterization.

We are pleased to support you with research and analysis of your innovative materials. Call us on +31 26 3845600 or email info@tcki.nl www.tcki.nl