The future of manufacturing in Australia is now - in Western Sydney

It’s a cliché to say that the future of Australian manufacturing is already here, but jumping out of the car at the brand new Advanced Manufacturing Readiness Facility (AMRF) in southwest Sydney, it’s hard not to believe it.

The facility itself is as futuristic as it gets, but its location is the giveaway.

The AMRF is in Bradfield City, and if that means nothing to you, that’s OK: currently, it’s the only thing there, and indeed, the facility itself is known as The First Building, a reference to its foundational status in a suburb-to-be.

This is all part of the NSW

Government’s huge scale project around the Western Sydney Aerotropolis, the centrepiece of which is the new Western Sydney International Airport (WSI) but which also includes a brand new city, the first to be purpose-built in Australia in over a century.

At the heart of that development is the AMRF, making Bradfield a manufacturing city from birth.

That’s why Industry Update went

Tickets on sale for Australian Manufacturing Awards as nominations close

Excitement is growing ahead of the Australian Manufacturing Awards, with nominations now closed, tickets going fast and a raft of new sponsors throwing their weight behind the event.

Hundreds of nominations were received across 22 categories, with judges now going through the submissions with a fine-toothed comb to select the finalists for the big night.

along to meet the team, see the site and discover the future of industry, being Continues on page 12

Tickets for tables are already selling fast as businesses look to lock in their place for the industry’s night of nights.

Continues on page 10

on Mental Health

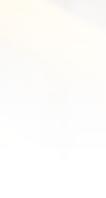

Don’t gamble with an open type laser

Publisher SCOTT FILBY scott@industryupdate.com.au

Advertising & Sales Manager PAUL FERRIS paul@industryupdate.com.au

Editor MIKE WOOD editor@industryupdate.com.au

Sub Editor RENATA GORTAN subeditor@industryupdate.com.au

Writer LUCY JONES writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Publisher’s Assistant and Administration Manager JERIN BURZACOTT jerin@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Advertising & Sales Manager PAUL FERRIS paul@industryupdate.com.au

Marketing Manager DUMINSHA UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMINSHA UDESHIKA copy@industryupdate.com.au

Video Editor & Producer

CHARLIE LOUGHLIN video@industryupdate.com.au

Office Admin JESSICA SUDESH admin@industryupdate.com.au

Finance & Accounts

MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Coordinator GUSTAV RHEEDER info@industryupdate.com.au

Circulation Coordinator RHYS MITCHELL info@industryupdate.com.au

Trump’s manufacturing policy backfires as key index shows slide

US President Donald Trump has made the revitalisation of American manufacturing his major economic policy since returning to office in January - but the latest figures reveal that his flagship tariffs are backfiring badly.

The Institute for Supply Management (ISM) Manufacturing Purchase Managers Index (PMI) marked a six consecutive month of retraction, reflecting the trouble that US manufacturers are having buying inputs.

The PMI is measured out of 100, with a score above 50 representing growth and a score beneath 50 indicating a contraction.

The study featured quotes from diverse manufacturing businesses across the States that reflected the issues faced by the sector.

“Tariffs continue to wreak havoc on planning/scheduling activities/ New product development costs continue to increase as unexpected tariff increases are announced… Our materials/supplies are now rising in price, so our sell pricing is again being reviewed to ensure we keep a sustainable margin. Plans to bring production back into U.S. are impacted by higher material costs, making it more difficult to justify the return,” read one account from the computer and electronics industry.

Another was even more stark.

The August data came in at 48.7, the sixth successive month under the breakeven point, below forecasts.

In the same time period, Australia marked a score of 52.9, the best result since late 2022 and the fastest rise in over three years, while the global version - including the EU and Japan - scored even better at 53.6.

Of particular worry for the President will be the notes that accompanied the PMI, which indicated that the ultimate aim of his tariffs - adding American manufacturing jobs - was actually going backwards.

“Regarding output, the Production Index returned to contraction and the Employment Index edged up slightly, as panelists indicated that managing head counts is still the norm at their companies, as opposed to hiring,” read the statement from ISM.

“We’ve implemented our second price increase,” said an electrical equipment manufacturer.

“‘Made in the USA’ has become even more difficult due to tariffs on many components. Total price increases so far: 24 percent; that will only offset tariffs. No influence on margin percentage, which will actually drop.

“In two rounds of layoffs, we have let go of about 15 percent of our U.S. workforce. These are high-paying and high-skilled roles: engineers, marketing, design teams, finance, IT and operations.

“The administration wants manufacturing jobs in the U.S., but we are losing higher-skilled and higher-paying roles. With no stability in trade and economics, capital expenditures spending and hiring are frozen. It’s survival.”

President Trump’s tariffs are backfiring, says a new report

How FlexGuard is shaping safer industrial environments

As automation reshapes warehouses, factories and distribution centres, the risks of collisions between people, forklifts and automated guided vehicles (AGVs) are only increasing.

According to Safe Work Australia, vehicle incidents remain the single biggest cause of workplace fatalities.

For operators, the challenge is twofold: safeguarding workers and protecting expensive infrastructure without sacrificing operational efficiency.

Traditional steel barriers have long been the default choice. They’re strong, reliable and well-understood.

But as traffic volumes rise and AGVs share more floor space with people, rigidity can create a new problem: repeated impacts translate into bent posts, damaged floors and costly downtime.

That’s where a new class of polymer barriers, like Barrier Group’s FlexGuard range, comes in.

Why Polymer?

Polymer systems are engineered to absorb energy. FlexGuard’s multi-layer blends flex and rebound after collisions, reducing damage to vehicles, floors and the barriers themselves.

The result: less time and money spent on repairs and a safer environment for workers. In high-traffic settings, that difference is measurable in uptime.

Beyond impact resistance, design flexibility is increasingly valuable. Layouts evolve as facilities expand, automation ramps up or workflows change.

FlexGuard addresses this with a modular system that can be quickly reconfigured or extended. Highvisibility colours enhance safety by clearly marking pedestrian zones and vehicle lanes - a detail that reduces the “grey space” where accidents occur.

“FlexGuard broadens our range of safety solutions and gives customers greater flexibility to choose the right system for their specific site requirements,” said Barrier Group Product Manager Ming Wong.

Most facilities already rely on some form of steel protection. FlexGuard is designed to work alongside metal barriers, providing a hybrid approach: steel where immovable strength is needed, polymer where repeated impacts are likely.

For operators, this means incremental adoption without ripping out existing infrastructure.

It is best suited for:

• Logistics and 3PL: AGV routes, forklift aisles and pedestrian segregation

• Manufacturing: Production lines with constant equipment-pedestrian interaction

• Warehousing: Racking ends, scalable layouts and pallet protection

• Cold storage and food facilities: Where temperature variations can test material performance

• Airports and high-traffic hubs: Airside zones, baggage handling and back-of-house operations

“Australian industry is under pressure to do more with less: higher volumes, tighter margins and greater automation. Safety systems must evolve in step,” said Barrier Group CEO Tom Garwood.

“FlexGuard is about protecting people and infrastructure without slowing the operation down.

“It’s a smarter approach to risk and one we believe will become a new standard in industrial design.”

A single forklift-barrier collision can cost thousands in repairs, replacement parts and lost productivity. Multiply that across dozens of incidents in a busy facility and the expense quickly outweighs

the investment in more suited infrastructure.

Polymer systems like FlexGuard reduce both the frequency and severity of these events.

There’s also the cost of downtime to consider. Every hour spent replacing damaged barriers or repairing floor anchors is an hour lost to production.

By flexing and recovering, polymer barriers extend service life and keep operations running.

For safety managers and operations executives, this changes the conversation from “How do we minimise accident costs?” to “How do we build resilience into the site?”

That shift is where the next wave of competitive advantage in industrial safety lies.

A broader safety trend

The launch of FlexGuard reflects a bigger shift in industrial safety: moving from damage control to proactive risk management.

Facilities are increasingly judged not only on compliance but on resilience - how quickly they recover from inevitable bumps and scrapes.

Polymer barriers don’t eliminate accidents, but they help ensure that one mistake doesn’t cascade into costly downtime. Barrier Group -

Barrier Group FlexGuard Impact Tested Polymer Barriers are pushing workplace safety forward

Flexible Protection That Bounces Back

Publisher Scott Filby

he Australian Manufacturing Awards countdown is on, and with just over a month until the big night in Sydney, industry is abuzz with who will win Australia’s most

AUSTRALIA’S BEST KEPT HOIST SECRET NOW REVEALED

For almost 50 years, Hydromech has built and supplied hoists and cranes that exceed expectations - meetin strict Australian standards, backed by local support and trusted worldwide

Why choose us?

The nominations period has now closed, and I’d like to personally thank our sponsors, partners and each person and business that made a nomination.

We were overwhelmed by the number of nominations, and our team put in long hours to categorise them all, ensuring that our independent judges have the best possible information to work with.

The sheer volume of nominations, the incredible effort by partners and industry organisations to get involved says that industry has spoken and they love the Australian Manufacturing Awards!

We have been overwhelmed by the excitement and outstanding support of

Moreover, we are delighted to confirm the attendance of both the Federal Minister for Industry and Innovation Tim Ayres and the NSW Minister for Industry Anoulack Chanthivong on the night, throwing further weight behind the Awards concept.

We are also able to welcome Investment NSW, Roxset Australia, CeMAT and SEMMA on board as sponsors, further proving the backing from business for what we are doing.

Mike Wood

roductivity has been at the very top of the agenda of late, with politicians and industry figures meeting in Canberra for the Economic Reform Roundtable. It was, as far as Australian manufacturing is con-

For all that the summit was decried in the media as a talking shop, it does help to talk through these issues, and any opportunity for leaders from across politics, business and academia to get together and plan outcomes for the country is to be applauded.

Here at Industry Update, we see first hand the issues with productivity on a daily basis, but also the solutions.

Our lead story this month features the Advanced Manufacturing Readiness Facility (AMRF), a key new site in Western Sydney that will be at the forefront of both the new Bradfield development, close to the Badgerys Creek Airport, but also the industrial future of Australia.

It sits between the cutting-edge practices of our universities, which have always been world leaders, and the needs of regular manufacturing businesses, acting as a catalyst that can

Putting on the Awards has involved a lot of work so far, and with only weeks to go, we know the hardest part starts now.

It’s been a strange year for manufacturing, with plenty of uncertainty both at home and abroad, but as you can read in this edition of Industry Update, things are starting to look up.

The vital Purchasing Managers’ Index data showed a three-year high and the fastest growth since 2022 - and it would be remiss not to point out that America, the cause of that uncertainty, is in the middle of a six month slump in the same numbers.

Australian consumer spending in July 2025 broke all previous records which should bring a lot of joy to manufacturers.

There are plenty of reasons to be optimistic about Australian manufacturing in 2025 - and I hope to see you at the Sofitel Sydney Wentworth on October 23 to celebrate them all. There are still select sponsorship opportunities available for the Awards, so if you want to put your business in the spotlight, get in touch now before they’re all gone!

We have also fielded many inquiries about tickets, and Early Bird rates are available for a limited time only for companies to book their place on October 23.

supercharge capabilities. We have done the tour, and it looks like the future.

We can also see through the nominations that have come in for the Australian Manufacturing Awards - and thanks to everyone who got in touch! - that great things are happening across the country.

In attending the iLAB event put on by William Buck, St.George Bank, Coleman Greig Lawyers and Aon, we also witnessed the strength of leadership in manufacturing, with small business owners able to dissect issues and come up with solutions in a collaborative environment.

At CeMAT, we saw just how much robotics and automation are taking hold, and the huge potential for efficiency gains.

Like everyone else, we await the concrete developments from the three days of discussion - and hope that they can help move manufacturing forward.

From where we’re sat at Industry Update, we can see the Australian manufacturing sector taking positive steps - and if everyone can get on board, the pace of that could pick up yet further.

YAWEI. WORLD CLASS PERFORMANCE, WITHOUT THE PRICE TAG. THAT’S APPLIED THINKING.

HLF Series Fiber Lasers.

One of Australia’s leading high-end, high speed fiber lasers. World class componentry and build quality, whilst still offering excellent value for money.

3kW-40kW, wide range of sheet capacities and automation options available.

YLT Series Tube Fiber Laser.

6m to 12m capacity with chuck sizes from 150mm to 600mm. Small profiles through to heavy structural profiles. Bevel cutting and automation options are available to suit your requirements.

PBH Series CNC Pressbrakes.

Simply put, one of Australia’s favourite CNC pressbrakes. Precision manufacturing and high end components with hydraulic crowning compensation. Available from 50 ton through to 3000 ton capacities.

Combine the practicalities of a punch press for your forming needs, with the speed and accuracy of a laser for profile cutting of the same part. Tapping head and automation options available for your volume work.

Robotic Bending Cell.

Automate your repetitive pressbrake jobs with a smart bending cell from Yawei. Robots and accessories from Kuka, Yaskawa and Estun to suit all budgets and applications. Save time and money, whilst improving efficiencies.

For maximum return and efficiencies, utilise the speed and precision of a Yawei CNC panel folder. With sheet capacities up to 3000mm and automation options available, there’s a Yawei panel folder to suit most applications.

With every Yawei machine you get the expert advice and support that only a local supplier like Applied Machinery can provide. With over 30 years’ experience, and thousands of satisfied customers across the country, we’re here for the long term. Real Service. Real Support. Real People. That’s Applied Thinking.

Call:

Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au

CNC Panel Folder.

HPML Series Laser Punch Press.

Tickets on sale for Australian Manufacturing Awards as nominations close

Corporate sponsorships continue to grow, with a raft of well-known brands choosing to back what is sure to be a spectacular evening.

Presented by St.George Bank and owned and operated by Industry Update Manufacturing Magazine, the highest-circulated publication in the manufacturing sector, the black-tie gala will be held at the Sofitel Sydney Wentworth on 23 October 2025. They are the first national awards for the manufacturing sector in Australia, and have been welcomed by influential figures across industry.

Federal Minister for Industry and Innovation Tim Ayres and NSW Minister for Industry Anoulack Chanthivong are both confirmed as attendees on the night, where they will address an audience made up of the best and brightest of

manufacturing.

Sponsors have also backed the Awards, with major names coming onboard to support the event.

Investment NSW, the state’s central economic development agency, have taken a Gold Award, one of the most prestigious on the night, joining St.George Bank and SugarCRM as sponsors for the top prizes.

Roxset Australia, a leading provider of production flooring, will sponsor the newly-minted Food & Beverage Award, recognising their long-term support of manufacturers across Australia’s F&B sector.

A-Safe, one of the biggest names in Australian workplace health & Safety, are also on board, as are SEW-Eurodrive, a global giant in motors and drives.

Several leading industry groups have also agreed to sponsorship deals.

The South East Melbourne Manufacturers Alliance (SEMMA) will lend their name to an Award, as will CeMAT, the leading trade show for the intralogistics, robotics and automation, warehousing, supply chain management and materials handling industries.

Judging is now underway, with a panel of over 50 experts from across industry, politics, peak bodies and academia applying their experienced eyes to the submissions.

Industry Update has worked closely with the University of Technology, Sydney (UTS), who are also a major partner of the Awards, to ensure that impartiality and independence is maintained at all times.

“The excitement only continues to grow for the Australian Manufacturing Awards, whether that is nominations, tickets or

sponsors,” said Scott Filby, publisher of Industry Update

“We were overwhelmed by the number of nominations, as well as the detail and effort that businesses have gone to in putting their submissions together.

“Moreover, the backing from industry in terms of sponsorships has only underlined further how much an event like this has galvanised the manufacturing community.

“The only thing left is for companies to book their tables for the big night. It is sure to be a spectacular evening at the Sofitel Sydney Wentworth, so get in now to secure your Early Bird discount!”

Continued from front cover

Join us to celebrate the people and businesses powering Australia's manufacturing sector. The Australian Manufacturing Awards, presented by Industry Update and proudly supported by St.George Bank as Platinum Sponsor, will recognise outstanding contributions and achievements across the manufacturing industry.

Date: Thursday, 23rd October 2025

Venue: Sofitel Sydney Wentworth

Time: 6:30pm onwards

Recognise and celebrate outstanding manufacturers Network with industry leaders, partners and peers Enjoy a premium gala experience with fine dining & entertainment

Scan the QR code or visit industryupdate.com.au/awards to book.

INDUSTRY NEWS

The future of manufacturing in Australia is now - in Western Sydney

built right now, from the ground up.

The first, most notable thing is that, is obvious before you arrive: while the roads to the AMRF are still largely local, the infrastructure is already there for far more people and far more business. This area is built to scale up quickly.

The building itself is spectacular, so much that it won the NSW Premier’s Prize for Architecture, and the structure itself is designed so that the entire building could be moved if needs be.

Our tour of the site began on the roof, where the footprint of Bradfield city centre can already be seen taking place.

The Metro station that will serve the community is already well under construction, and through the trees, one can see the cranes from the new WSI airport.

Downstairs, a scale model shows just how large the city will be in a few decades’ time, a process that is already underway at the AMRF with The Second Building, four times the size of the First, already pencilled in.

All of this is done with the future of the Australian manufacturing industry - and the prominence of the sector in Western Sydney - in mind.

“The AMRF as a project has been on the go since 2020,” explained Ben Kitcher, Executive Director, when we sat down for an interview.

“It’s been a long time in planning. We’ve been flat out building out the team and capabilities in the building.

“This is all part of the broader Bradfield City project — the Western Sydney Aerotropolis program — and the development of infrastructure around the new airport, creating jobs, creating places to live, more economic activity.

“If we go back a number of years, through the 2010s, there were several reports that were really instructive about what was going to happen in Western Sydney, what was intended to happen economically.

“The purpose here isn’t to replicate somewhere else in Sydney - it’s not another Sydney CBD, it’s not Parramatta. It needs its own economic identity.

the right support.

“The AMRF was identified as one of the actions that government could take that would provide a platform for manufacturers to access and develop their capabilities.

“I’m strongly of the view that some of the things manufacturers have found frustrating for a long time — governance, regulation, oversight — have always been additional burdens in doing business in Australia. I genuinely think those are future opportunities for Australia.

“What we’re seeing is more instability and uncertainty in global supply chains. That’s driving purchasers of big, complex, highvalue systems — aerospace, defence, medtech, semiconductors — to higher-cost supply chains where they can get more certainty about product supply over the long term.

“If we acknowledge that, then Australia — as a politically and economically stable part of the world — has a great opportunity to provide capability. That would be very attractive.”

They provide machinery across additive manufacturing, advanced composites, engineering design, automation, metrology and precision machining, all of which can be booked by manufacturing businesses.

“If you look at things like the New South Wales industry strategy, the economic blueprint and the city deal for Western Sydney, all of those pointed to high-value manufacturing — particularly for industries like defence and aerospace — being the opportunity for this part of the world.”

“The question is, how do you get to that? What do you need to do to be able to get there?”

The AMRF is the answer to those questions, creating a facility where the most state-of-the-art capabilities would be available to manufacturers, a single port of call for solutions with equipment, expertise and, crucially, accessibility.

“Providing access to technical capabilities that can be built out by the private sector is probably the biggest challenge,” said Kitcher.

“There was a recognition that this had been done elsewhere in the world — areas that hadn’t necessarily had high-tech manufacturing industries — and that they could quickly adopt and grow them if given

“We know that if manufacturers adopt technologies and processes that are generally commercially available — these aren’t new inventions — they’re often difficult to access and involve risky investment decisions. If done well, they can unlock productivity gains or profitability,” said Kitcher.

“But there are barriers: capital cost, uncertainty over which technical direction to take, local skills availability, whether you’re buying enough of a resource or machine to satisfy demand. There are a huge number of unknowns that make the investment decision hard.

“So what we do here is “test before you invest”. Prove something out, work out process KPIs, walk the team through the process so they’re comfortable with the tech.

“That way, when they go to make the investment, they know how many parts per year they can do, how many available hours, what return on investment to expect.

“That certainty is key. Say you’re adopting a new five-axis machine tool but think you need 1.2 machines’ worth of hours.

Inside the AMRF, the new manufacturing hub of Western Sydney

“If we can help optimise the process to bring it below one machine, it becomes an investable decision. That’s the kind of pre-procurement support we offer.”

The technical capacity is one thing, but the other resource on offer is expertise.

The AMRF is intended to fit in the value chain between universities, who excel in research, and manufacturers, who excel in delivery.

By filling the gap between the two, the hope is that the new facility can supercharge innovation - which if it comes to pass, will see the huge investment by the NSW Government pay for itself, and the local manufacturing industry, for decades to come.

“It’s not just the machine, it’s also having people who know how to apply it and use lean practices in that industry,” said Kitcher.

“Some improvements are easy to implement but not obvious — those often provide near-free productivity gains before you even buy new equipment.

“New South Wales and Australia have world-class research capability. Once you start working with

the universities, you realise that’s genuinely true. Across many fields, universities are high-quality and high-impact.

“But they don’t necessarily focus on technical services that help manufacturers become more productive.

“Take additive manufacturing: universities are fantastic at materials development, optimisation, even multi-materials. But when it comes to scaling from lab to 100,000 units in continuous production, that’s where the AMRF team comes in.

“We operate between manufacturing readiness levels 3 to 6 — first-off prototypes to factory implementation. That sits downstream from the university’s role and complements it.

“The difference in approach here is key. Some past programs treated productivity as a fixed-term improvement. But that’s not how the world works.

“What we’re doing is saying: invest a little in productivity this year. By next year, it pays for itself, and you reinvest again. Each cycle compounds benefits. It’s a long-term, positively reinforcing approach to building productivity in industry.”

Automation specialists announce new Australia & NZ MD

Turck, one of the biggest names in Australian automation, has announced that Geoff Thorp will take over as Managing Director.

Thorp is an experienced operator in the manufacturing industry, with over 20 years of service behind him across the electrical and automation sectors.

He was previously Chief Product and Marketing Officer at NHP Electrical Engineering, where he rose from the position of product engineer to overseeing all products for the company, as well as marketing, sales operations and commercial strategy.

“I’m genuinely excited to join the Turck family and to work alongside the team here in Australia and New Zealand to shape the next phase of growth,” he said.

“Turck is known for its innovation, customer focus and quality

The Surftest SJ-210 is a user-friendly surface roughness measurement instrument designed as a handheld tool that can be carried with you and used on-site

Easy to use

• 2.4-inch colour graphic LCD with backlight

• Simple key layout

The Surftest SJ-210 can be operated easily using the keys on the front of the unit and under the sliding cover.

Highly functional

• Advanced data storage capabilities

• Optional memory card

• Password protection

• Multilingual support

• Stylus alarm

An alarm warns you when the cumulative measurement distance exceeds a preset limit.

Extensive analysis and

display features

• Complies with many industry standards

The Surftest SJ-210 complies with the following standards: JIS (JISB0601- 2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO-1997, and ANSI.

• Displays assessed profiles and graphical data

In addition to calculation results, the Surftest SJ-210 can display sectional calculation results and assessed profiles, load curves, and amplitude distribution curves.

Turck

New Turck MD Geoff Thorp

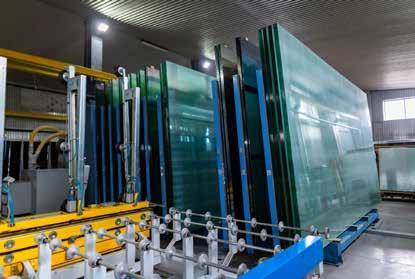

Top class glass in the Top End thanks to multimillion dollar deal

Northern Trade Solutions, a Northern Territory construction company, is set to branch out into manufacturing thanks to a $5.4m deal backed by the NT Government.

Northern Glass Solutions (NGS) will engage in glass manufacturing, including special-purpose and energy-efficient glass products, backed by funding from the Advanced Manufacturing Growth Centre (AMGC) and the Advanced Manufacturing Ecosystem Fund (AMEF), which seeks to build the sector in the Top End.

NGS will manufacture triple-glazed and quadruple-glazed, laminated, tempered, acoustic, fire-resistant, cyclone-resistant, safety and bullet-proof glass - the last of which is currently not manufactured anywhere in Australia at all.

The glass products that NGS will produce are not manufactured anywhere in the NT and therefore have

to be imported, either from abroad or other parts of Australia, with knock-on effects in pricing, logistical issues and lead times.

“Our management team is excited by the opportunities to strengthen and grow the glass processing industry through the support of the Northern Territory Government,” said Jiayun Li, Owner of Northern Glass Solutions.

With over 15 years of experience guiding us, we’re proud to be expanding NTS into glass manufacturing - supporting our loyal customers and helping build a more self-sufficient and resilient Territory.”

NGS will receive over $660,000 from the AMEF, administered by AMGC, which they will then match themselves to fund the total project, as well as a further $4.1m in investment, taking the total to beyond $5m into Northern Territory manufacturing.

Multimillion dollar deal sealed for Western Australian wind manufacturing

Western Australia’s net zero transition has received a boost thanks to a new funding deal that will see $5.3m invested in wind manufacturing in the state.

RCR Advanced Technologies, a division of RCR Mining Technologies, will receive the investment as part of the WA Government’s Wind Energy Manufacturing Co-Investment Program.

They will use the cash to fund the manufacturing of innovative transition flanges, as well as for facilities upgrades at their Bunbury site.

Delivery comes via the Advanced Manufacturing Growth Centre

(AMGC), and after the completion of the 18-month-long project, will see domestic Australian manufacture of transition flanges, a key component in wind turbines, which are currently only made overseas.

“RCR Mining Technologies is harnessing its strong track record in manufacturing by expanding its capabilities and creating new jobs to deliver critical components for the growing wind energy sector,” said Western Australian Industry Minister Amber-Jade Sanderson.

“Through the Wind Energy Manufacturing Co-Investment Program, we’re enabling local companies to scale up, invest in advanced equipment and secure

“This increased capability will address a yawning gap in the local market which Northern Trade Solutions understands better than just about anyone else,” said AMGC’s Northern Territory

Director, Charmaine Phillips.

“This will provide a comprehensive range of specialised glass solutions, designed for our demanding climate and with great value outside of it as well.”

their place in global clean energy supply chains.

“This project demonstrates the WA Government’s commitment to building a competitive, future-focused manufacturing base that drives decarbonisation and creates quality jobs for Western Australians.”

The new investment will see co-operation between RCR and international wind turbine giants Vestas, which could potentially also grow to include renewable energy project developer Green Wind Renewables.

“Through this program, AMGC aims to highlight the real

opportunities in growing manufacturing capability,” said Ellen McGarrity, Program and State Director for the AMGC.

“RCR is leveraging its expertise in heavy, precision-engineered equipment to deliver a locally unmatched solution for a new customer base.

“RCR is extending its heritage, reducing supply-chain complexity and delivery times, and helping address demands from industry and the state for the clean energy this era will be powered by.”

Advanced Manufacturing Growth Centre - amgc.org.au

RCR Advanced Technologies have received the funding

Glass manufacturing is coming to the Top End.

How doubling down on data transformed this Aussie manufacturer

For decades, Street Furniture Australia (SFA) has been a cornerstone of public space design, crafting durable and vibrant furniture for streets, parks, campuses and transport hubs across the globe.

Since its founding in 1986, the company has completed over 30,000 installations worldwide, including high-profile projects for Google Campus in Washington, the Long Island Railroad in New York and Sydney Trains.

SFA’s reputation for design excellence, local manufacturing and dedication to enhancing public spaces is well-established.

The company’s growth revealed weaknesses in its systems, which depended on disconnected, manual spreadsheets and led to missed deadlines, unprofitable products and staff uncertainty.

This fragmented setup caused operational problems that threatened customer satisfaction and team effectiveness.

To fix this, the company pursued a full overhaul, resulting in a successful partnership with AVT and NetSuite ERP.

“We had growth. What we desperately needed was control and process automation,” explained Blair Saddington, CEO of SFA.

“Consolidating everything onto a single platform provided us with that essential control and the agility to move swiftly.

“AVT, with their deep understanding of manufacturing processes, coupled with their expertise in NetSuite, process improvement and integration, were ideal for us to partner with.”

Before NetSuite’s implementation, SFA’s on-time delivery rate

hovered around 50 per cent. Errors in inventory, quoting and production frequently resulted in costly rework and miscommunication.

“Without accurate information, sound decisions are impossible,” said Saddington.

“We were adept at manufacturing furniture, engaging with customers and making sales. But coordinating all these elements and ensuring precise timing was incredibly difficult when reliable information was lacking. Data is paramount.”

To facilitate its operational transformation, SFA evaluated four Enterprise Resource Planning (ERP) platforms before selecting NetSuite. The deciding factors were the promise of a rapid return on investment and the strong, trusted collaborative partnership forged with AVT.

“Transitioning from multiple disparate systems to a single NetSuite environment, where all our information resided, was a game-changer,” said Saddington.

“We finally had genuine, dependable data, allowing us to make decisions with confidence. It made a profound difference.”

For Chris Morgan, Head of Operations at SFA, NetSuite’s impact was both immediate and fundamental.

“All our data, from finance, manufacturing, warehousing, sales and marketing, is now consolidated within one system,” he said.

“Everything is linked. Everyone can see what others are working on. If you need a bit of information, you can trace it from a sales order right through to a purchase order. It has become integral to how we operate.”

Previously plagued by unexpected shortages and time-consuming twoweek stocktakes, SFA now boasts less than one per cent variance in inventory and has eliminated stockouts on high-volume production runs.

“We used to arrive in the morning to discover two parts we never ordered and jobs would be delayed for months while we air-freighted castings at exorbitant costs,” said Morgan.

“Now, we have a clean, accurate and reliable warehousing system. We are even considering moving to just one annual stocktake, thanks to cycle counting and the built-in controls.”

The shift to NetSuite also brought substantial benefits across engineering, sales and customer service.

NetSuite has accelerated and improved many business processes, with quoting speed and accuracy improved thanks to a new product configurator that standardises sales

language and production specs, reducing departmental friction. Order fulfilment is now a point of pride.

SFA recently delivered 800 seats for Sydney Trains without stockouts or delays, customer complaints have dropped and real-time visibility allows the business to proactively update clients about any potential problems.

Their success story is a testament to the digital maturity underway in Australian manufacturing, where ERP systems like NetSuite are now the operational backbone of datadriven enterprises.

Saddington stresses that this shift is crucial for smaller manufacturers facing complex environments and margin pressures.

“You cannot manage this scale in Excel anymore,” he said.

“ERP enables growth and, more importantly, provides clarity. With clear insights into margins, capacity and stock, you can invest wisely in people, equipment and projects.”

Implemented by AVT, NetSuite has helped SFA streamline manufacturing, inventory and customer engagement around shared data, resulting in faster product launches and consistent performance.

Staff trust the system’s accuracy, and as the company looks ahead, its integrated ERP platform provides the confidence to pursue further growth, quality, innovation and precision.

For Australian manufacturers striving for growth without compromising control, SFA stands as a clear example: true clarity stems from interconnectedness and sustainable growth is built upon reliable, trusted data.

Street Furniture Australia revolutionised their ERP

SFA have a successful partnership with AVT and NetSuite.

Registration opens for Women in Manufacturing event with prestigious award on the line

Since 2023, the South East Melbourne Manufacturers Alliance (SEMMA) and NorthLINK have held the Women in Manufacturing Network event.

The brainchild of Sue Logan and Mary Jakobenov of NorthLINK and Honi Walker of SEMMA, the centrepiece of the event is featuring a presentation and meet and greet with the winner of the Victorian Woman Manufacturer of the Year Award.

Now, the 2025 event has been announced for Thursday 13 November at The Deck at Box Hill RSL, with registrations now open via the SEMMA events page.

The inaugural presenter (and 2023 winner) was Erika Hughes of Integra Systems - and her story of discovery and determination can act as an inspiration for women within the manufacturing industry.

“I truly believe that women are the superpower in manufacturing,” she told Industry Update.

“We offer unique perspectives and skillsets that create a different dimension within an organisation which would not otherwise be achieved with a male-centred operation.

“Take a look around: for those businesses with either female leadership or high number of women in their STEM operations, you will see and feel the difference.

“We are not just there for gender balance, we are there because of our strong and unique contribution to the industry.”

Hughes added that events such as this were vital to helping women within the industry.

“Building the attraction of women into the manufacturing industry and STEM careers requires a big PR boost to demonstrate how significantly the manufacturing industry has evolved into an inclusive and fascinating environment for women to learn, teach and grow,” she said.

“For many years I have been advocating for women and running multiple development programs for young women within our advanced manufacturing business, and to represent those via being a recipient of the 2023 Woman Manufacturer of the Year Award at the Victorian Hall of Fame was a not just a win for me, but a win for many of those women I have helped to develop and grow.”

In Australia, women make up

just 27% of roles in manufacturing, according to the latest ABS figures, so events like this are necessary to help redress the balance.

“We originally marketed the event to young women who work in manufacturing, but it quickly became so much more than a chance to get out of the safety boots and put on a frock,” said Honi Walker, CEO of SEMMA.

“We soon realised it was a much needed opportunity for women to connect to their local cohort.

“Some told us it can be an isolating workplace if you’re the only woman onsite and we all know what it feels like to be an outsider.”

“As the event has quickly grown, we encourage attendees to come and make contacts – so they can build up their own professional networks.

It’s an essential yet underrated element when you think about industry connections, longevity and the power of strategic events”.

“The 2024 Victorian Woman Manufacturer of the Year was Latinka Cubitt from Catten Industries – who will be the 2025 winner?

“You’ll have to attend our event to hear how the winner intends on progressing and promoting women’s roles in manufacturing for the next generation.”

REDUCE MAINTENANCE COSTS ON OVERHEAD CRANES

LOAD LIMITERS

ROPE AND CHAIN CRANES AND HOISTS

• Helps reduce the risk of accidents

• Protects against overloading of Crane and supporting structures

• Quick and easy installation and available for all capacity cranes

• Available preset or easily calibrated on site

• Helps reduce maintenance costs

• Minimizes down time • Automatic reset by reducing the load

The 2024 Victorian Woman Manufacturer of the Year Erika Hughes

Why the RBA’s rates redemption arc opens path for manufacturing

By Besa Deda, Chief Economist, William Buck

The Reserve Bank of Australia (RBA) redeemed itself in August, delivering the widely anticipated 25-basis-point cut that markets and economists had expected in July.

The move takes the cash rate to 3.60%, the lowest since April 2023 and marks a cumulative reduction of 75 basis points so far this year.

A larger rate cut was not discussed - and the board decision was unanimous, unlike the 6-3 split last time.

The RBA trod cautiously in July’s meeting, opting to wait for the quarterly inflation data before acting.

That data showed underlying inflation easing in line with their forecasts to 2.7% in the June quarter, close to the midpoint of

the 2–3% target band. Together with a labour market performing as expected, this confirmation paved the way for an August rate cut.

The big question now is how much further rates will fall. The Governor signalled that the policy bias remains towards further easing, stating the Bank’s forecasts imply the cash rate ‘may need to be lower than where it is today’.

Much will depend on the data and how economic conditions evolve. The Governor highlighted uncertainty and unpredictability as an ongoing feature of the global economy.

We still expect two more rate cuts - in November 2025 and February 2026 - assuming the RBA sticks to

their cautious, gradual approach.

That pace carries the risk of deeper cuts being needed next year because the recovery may not be strong enough.

The rhetoric from the Governor in the press conference did not suggest any enthusiasm to move away from this approach.

There was an emphasis on weighing up the data and information and assessing policy on a ‘meeting by meeting’ basis. At the same time, the Governor also watered down the prospect of back-to-back cuts.

In its updated forecasts published alongside August’s decision, economic growth was downgraded for 2025 from 2.1% to 1.7%. Growth was also revised lower in 2026.

Both downgrades to growth reflect softer productivity and a slower recovery in private demand, especially household consumption.

By December 2027, growth is projected to lift modestly to 2.0%, which is well down on Australia’s estimated potential rate.

The tepid economic recovery underscores the need for more rate cuts, especially as the RBA has grown more confident of underlying inflation returning to the target mid-point on a sustained basis.

The underlying inflation forecasts were unchanged from May. However, the extended horizon period shows underlying inflation reaching the mid-point in the second

The jobs market remains tight. The unemployment rate edged down to 4.2% in July, but a wider range of employment measures show there are subtle signs emerging of a modest loosening in jobs growth.

It includes the pace of employment growth slowing from earlier this year and business liaison that suggests employers are becoming more selective around hiring.

The manufacturing industry has experienced net job losses over the past year, according to the latest available data.

But the most recent rate cut will be supportive of conditions in manufacturing.

Recent business survey data published by NAB shows an improvement underway in business confidence and forward orders. Conditions have remained sluggish, but are likely to recover with the lift in forward orders.

However, the manufacturing industry locally is being disrupted by the speed and scale of US trade tariff announcements.

Global growth is set to slow this year and next, even if the most damaging tariff scenarios have been sidestepped.

Trade tensions have already dented confidence, disrupted supply chains and cooled investment. Sidestepping the worst will not halt the slowdown already in motion.

Making manufacturing connections, building thought leadership

Amanufacturing business is only as good as its connections - so any opportunity to get together and share experiences is invaluable.

That’s why the Manufacturing iLab conferences have proved so popular with businesses.

Organised by William Buck, St.George Bank, AON and Coleman Greig Lawyers, they provide guest speakers and networking opportunities to the industry.

The latest, held in Parramatta, featured a keynote address from William Buck’s new Chief Economist, Besa Deda, talking through the latest developments in global economics, including tariffs and geopolitical issues.

Through the discussion, manufacturers were able to ask questions directly of Deda, creating a steady dialogue that allowed complex global questions to be seen through the prism of Australian manufacturing and centred around practical outcomes for the sector.

“The iLab has been going for at

least five or six years now, and the purpose of doing this is around trying to create some thought leadership in the manufacturing industry,” said John Spender, Partner at William Buck.

“The collaboration with Coleman Greig, St.George and AON is designed to provide a better opportunity to help industry - particularly manufacturing - to provide quality services. If we do it as a collaboration, we can actually do things far better.

“You see today that the amount of discussion. It’s a small group, but there’s a lot of interaction, a lot of discussion and people are learning from it.

“Where else do they get an opportunity to get some time out of their office, learn something new, then have a discussion with people who are in a similar industry with similar issues, sharing ideas about how they’ve solved their problems or where their challenges are? We use this as a way for that discussion to happen.”

The diversity of the hosts, who bring together banking, accountancy,

insurance and legal, allows for expertise to be shared directly.

“You wouldn’t get that exposure elsewhere,” said Malcolm Campbell of Coleman Greig Lawyers.

“The diversity of clients, but also the diversity of service providersit’s just not something you’re going to come across at a regular workshop, seminar or conference. You can get that one-to-one interaction.

“We get some high-quality speakers that are right on the topical issues for the industry. I just think it’s not an opportunity that’s really replicated anywhere else within our space.”

St.George Bank were also able to add insights, particularly on the lending environment, as well as creating networking opportunities.

“I think one of the real values that it really provides is where it’s creating business opportunities for the people that attend,” said Matthew Kelly, Head of Manufacturing at St.George.

“I just saw a Kavanagh Industries person swap business cards with someone to do with lasers, because they’re now going to get together and talk about doing business together. I think that’s a real opportunity that people don’t get every day.”

Connection is everything in manufacturing

How MaXXlink is redefining integration for Aussie manufacturers

Industry 4.0 is everywhere in Australian manufacturing, and while it has certainly been a positive for the sector, it can be hard to navigate at times.

Digital transformation can often focus on the bigger systems, and simple but very important aspects, such as integrating what seem to be peripheral systems, can deliver significant benefits.

That’s where Central Innovation can come in.

Their new MaXXlink product streamlines and digitalises the complex and often risky zone between the Engineering Bill of Materials (BOM) and the Manufacturing equivalent.

It automates the BOM creation process, delivering efficiency, accuracy, and when the BOM is issued to the production line and all parties are up to date with the latest, most accurate versions.

MaXXlink takes away the huge spreadsheets, confusing processes and crossed lines of communication that can cost manufacturers both time and money.

“Integration between systems in manufacturing is sporadic or even non-existent,” said Damien Davis, GM of Data Solutions at Central Innovation.

“Many of the solutions offered are extremely complex in nature and aimed at big businesses, but 72% of the industrial manufacturing market is actually made up of small businesses.”

Most manufacturers make use of an Enterprise Resource Planning (ERP) solution, but they are often disconnected from other parts of the manufacturing process.

Central Innovations are resellers of the Solidworks CAD product, which is already one of the most

popular in the industry. MaXXlink integrates your design files with your ERP systems seamlessly.

“The fact that manufacturers are using manual systems in many cases introduces risk - from an intellectual property, productivity and data integrity perspective. It’s an unacceptable risk in many cases.

“Case in point: if someone orders the wrong part for a line that’s going to produce 2,000 engines a month, and it’s the wrong version, then the impact of that error can be substantial.

“Costs are increased due to the rework required, and the purchased material must be restocked. There’s probably going to be a restocking fee. If it’s a custom part, it’s down the drain.”

For manufacturers with short lead times, fast change cycles or complex supply chains, the ability to unite CAD, E-BOM, M-BOM and ERP is a vital step forward for agile production.

This is particularly useful for high-volume manufactured products with flexible workflows, as the Manufacturing side is updated within seconds of a change on the CAD side, without a complicated communications pathway between humans.

“When we look at the value chain for manufacturing, it starts with the design which is then transformed into engineering drawings, then

engineering BOMs. But there are many other non-modelled items and processes that can go into a finished product,” said Davis.

“In some cases, some or all the data is entered manually into spreadsheets or other documents - it’s essentially a process where drawings and these manual spreadsheets are relied upon in the manufacturing stage in a disconnected system.

“But all the other elements needed to make a finished product must also be created using data from the ERP or from the production and operations engineering team, who design the final processes and understand what’s involved in assembling all those parts.”

Manual systems are labour intensive, lack an integrated collaboration or approvals process automation and inject unacceptable risk in materials requirements planning and procurement.

MaXXlink works with multiple CAD systems and ERPs, and Central Innovation can provide custom APIs should a connector not be available off the shelf.

“The product will extract information from the SolidWorks assembly - the 3D CAD design - and automatically explode that information so you get a three-dimensional, hierarchical relationship diagram of all components, their numbers, quantities and all associated metadata,” said Davis.

This visualisation of the BOM and the toolset provides for the addition of non-modelled items from the ERP system, and significantly reduces the time taken to create final bills of material that manufacturing and procurement can rely on to be accurate.

“This helps engineers quickly see relationships between components, and when they need to add other components - non-modelled items that aren’t designed in CAD but are either procured or already in stock - they can simply drag and drop them into the BOM from the ERP,” said Davis.

“MaXXlink not only closes the gap between two critical systems, integrating otherwise siloed data, but both sets of data become reliant on each other.”

Central Innovation are perfectly placed in the market to offer this product.

With 35 years in industry, they understand how vital the interplay between engineering, manufacturing and design can be in creating new products and delivering speed, agility, accuracy and profitability. They can boast an experienced, local customer support and engineering solutions team who have extensive industry and data management knowledge. Unlock the value in your data, with MaXXlink.

The new MaXXlink product from Central Innovation

MaxxLink can be a vital piece of middleware.

MA LINK

MaXXlink is an intelligent solution that unites CAD and ERP systems, closing the critical integration gap that slows manufacturing output and creates risk.

Unlike generic connectors, MaXXlink is purpose-built for manufacturing and engineered to integrate disparate or siloed environments—such as SolidWorks, Inventor, Epicor, and MYOB Advanced—without disrupting established workflows. It transforms engineering BOMs into fully validated manufacturing BOMs with precision, speed, and complete traceability.

Purpose-built for Australian manufacturing environments:

Visual BOM Interface — Restructure assemblies with drag-and-drop speed

CAD to E-BOM Conversion — Native compatibility with SolidWorks and Inventor

E-BOM to M-BOM Mapping — Get from design to production-ready structures in minutes

Pull non-modelled parts from your ERP — Drag and drop these parts with full traceability

Local ERP Integration — Works with Epicor, MYOB Advanced, and custom systems

Full Change Control — Built-in version tracking, approval workflows, and audit trails

INDUSTRIAL FLOORING

From safety to style: The rise of epoxy floors in manufacturing

With over five generations of one family dedicated to coating, Cotewell has earned its reputation as one of Australia’s most trusted names in the manufacturing industry.

They remain one of the country’s premier providers of epoxy floor coating to the industrial sector, with a reputation for delivering quality floors that are built to last.

And when it comes to finding a floor for a manufacturing facility or warehouse, epoxy is only growing in popularity as safety, automation and cleanliness requirements grow.

“The benefits of epoxy are obvious,” explained Jacob Hiscock of

But in the modern age, form and function go hand in hand.

Workers work better in more pleasant environments, with demonstrable effects in productivity that come from investment in high-quality environmental elements such as floors.

“One of the other things we like to highlight - something that’s come from our customer feedback - is the unseen benefits. It lifts employee morale,” said Hiscock.

“They feel like they’re working in a high-quality environment. We use the analogy: people spend a lot of money making their offices nice and fancy - why don’t they do that in the

“Especially today, with psychosocial health being a big focus, it’s about making sure people feel looked after and included, and that they’re working in a positive space, that’s why we “Inspire Excellence””

Looking after mental wellbeing is important - and coated floors can also assist with safety elements.

They are easier to clean and, as a result, last longer in tougher

old floor that always looks dirty, even after sweeping, it doesn’t help. That’s why a lot of companies running 5S have coated floors. It makes a difference.”

“Concrete, when exposed to chemicals, will deteriorate over time. Coating the floor helps prevent that - it protects the concrete underneath from chemical damage.

“One of the biggest reported safety incidents in the workplace is slips, trips and falls. A coated floor with grip can help prevent slipping. And for trips, if your floor is old and

Cotewell provide first-class epoxy flooring options.

uneven, or has holes or damage, people can easily trip. A smooth epoxy coating fixes that.”

Looks matter, of course, and Cotewell can help on that front. Their floors can be adapted to fit corporate branding, or even to designate different zones of a facility for different safety standards, machinery or materials.

“You can choose whatever colour you want,” said Hiscock.

“There’s a project on our website from a company called Grillex. They did theirs in green, because their whole business is about outdoor spaces - park furniture, barbecues, things like that.

“They wanted to bring that outdoor feeling indoors, so they chose green flooring to reflect that environment for their employees.”

“Different colours tie into lean practices too. Different zones can be colour-coded for staging materials, processes and so on.”

Speaking to a specialist consultant will get you the best outcome.

Setting the standards for safety in manufacturing with Nilfisk vacuum cleaners

When it comes to cleaning in potentially explosive atmospheres, safety isn’t optional - it’s essential.

It’s why such situations are highly regulated, with the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres - that’s IECEx for short - covering every aspect of the process.

The IECEx is a globally recognised standard for equipment, services and personnel working in hazardous environments that

are sensitive to explosions, such as warehousing, manufacturing and food & beverage processing.

In Australia and New Zealand, IECEx is the benchmark for compliance in hazardous areas, providing maximum confidence that your workplace is both safe and compliant.

Finding an industrial vacuum cleaner provider who can satisfy the onerous requirements of the IECEx is a key aspect of WHS planning for these environments.

That’s why the Nilfisk VHS010 and VHS011 Mini Industrial Vacuums and VHS 210 models are fully third party IECEx certified, making them ideal for manufacturers who need to know that their cleaning equipment is IECEx compliant.

One might expect that this level of certification comes as standard, but it does not always.

Nilfisk Industrial IECEx-certified models can offer many benefits that go above and beyond the average in terms of safety compliance and operational efficiency, with both the

Small but mighty

Don’t let their size fool you. Nilfisk’s new range of Mini Industrial Vacuums are small but mighty and they pack a punch.

The Mini Industrial Vacuums (IVS) brings all the power, safety and durability one might expect from a larger model, only with a smaller, more flexible footprint.

The range consists of four distinct models, suitable for industries with specific needs and challenges.

They match any required level of safety needs for hazardous, combustible and conductive dust, securing a safe, dust-free environment, meeting all standards across food & beverage manufacturing, iron and metal manufacturing and pharmaceuticals.

It’s not just Nilfisk that back their products, either. Every vac they sell is third party certified to comply with global safety regulations such as IECEx, ATEX, ACD, L-H class.

The Mini IVS series is a perfect blend of safety, affordability and unparalleled suction capability, able to adapt to unique cleaning needs either as a standalone or as part of a

set of complementing larger vacuums. Each machine can also be completed with various accessories for selected applications.

Their highly mobile chassis makes the Mini IVS series ideal for spot cleaning and moving between departments, and the compact design enables effective cleaning in even the most hard-to-reach areas.

Nilfisk Global - nilfisk.com

Mini IVS and VHS 210 standing out from their range.

They excel in safely removing particles from the environment regardless of type, from combustible dust to fine powders, without restrictions on use.

All parts are compliant with IECEx regulations and standardswhich means the entire system and add-ons, from corresponding hoses, filters and tools to the machine itself.

The Mini IVS is designed for narrow areas, which enable use in facilities that maximise the use of floorspace.

This is particularly useful in manufacturing facilities where dust can congregate behind machinery, or in F&B applications with beltways and

The ultimate all-rounder

Nilfisk are taking industrial vacuums to the next level with unseen power with the VHS210 Z22 IECEx.

They bring high performance, superlative safety standards and a best-in-class filtration system, designed to work in the toughest conditions within classified zones.

They are explosion-proof and certified to the global IECEx standard, with third party approvals at all levels for both the core machine and all accessories.

Thanks to its functional compact design, the VHS210 Z22 IECEx is fully grounded, easy to use and easy to move.

It can go wherever high-level hygiene is required - including difficult to reach overhead areas and behind machinery.

Features include:

• A single-phase motor with high air volume and immense vacuum power

• A maintenance-free motor

conveyors which can limit access to larger machines.

The VHS 210 is well suited to general use around floors and machinery, as well as overhead and hard-to-reach areas. It is one of the most powerful on the market and can increase cleaning efficiency with high-pressure thanks to Nilfisk’s PullClean system.

These products are two from Nilfisk’s range that meet the IECEx standards, enabling complete peace of mind for manufacturers who need assurance that their workplaces and factories are safe, clean and compliant.

Nilfisk Global - nilfisk.com

The HS210 Z22 IECEx from Nilfisk

• Increased efficiency of the innovative PullClean system due to a high-pressure difference

• Highest safety standards on the market

• The highest filtration performance

Nilfisk Global - nilfisk.com

Nilfisk’s range are compliant with IECEx standards.

The machines are ideal for F&B manufacturing

The Mini IVS series from Nilfisk

One spark is all it takes.

When compliance is critical, choose IECEx certified.

Combustible dust is a silent threat in every production facility. An unprotected vacuum can spark an explosion. Trust in safety. Choose Nilfisk. IECEx-certified Mini IVS VHS010/VHS011 and VHS210.

Five questions manufacturers need to ask about industrial flooring

When you’re building a company, you start from the bottom up - so it makes sense to think long and hard about the best options in industrial flooring.

Fosroc ANZ provides custom industrial flooring solutions tailored to the unique requirements of every project, whether it’s resurfacing an underground car park, refurbishing a warehouse or renovating a research facility.

As Andrew Nelson, Fosroc ANZ’s Product Segment Specialist for Flooring and Coatings, explains, selecting the right flooring solution is paramount.

“Floors are the hardest working surfaces of any building,” he said.

“To ensure they last the distance, it’s critical to select a flooring system that is fit for purpose.

“We have a wide range of flooring products from sealers and densifiers to cementitious and resin-based flooring systems.

“It can be confusing for asset owners, builders and specifiers to know where to start.”

According to Nelson, there are five

key factors that should be considered before selecting a flooring solution.

• Project type - Are you undertaking defect rectification or producing an internal finish? What substrate are you working with?

• Expected traffic - What levels of traffic will the flooring have to endure? Heavy vehicle? Foot traffic? Does the surface need to be non-slip?

• Environment - Are aesthetics important? Will the flooring be exposed to a corrosive environment or harsh UV light? Will it be overlayed with tiles or carpet? Is waterproofing a requirement? Are VOCs a concern?

• Chemical exposure - Will the surface be exposed to harsh industrial chemicals or other corrosive substances?

• Hygiene - Are there particular hygiene requirements? Does the floor need HACCP certification for use in the food and beverage industry?

“By taking each of these factors into account, asset owners can be confident they’re getting the right

flooring system for them,” he said.

Fosroc’s vast flooring product range is the key to delivering tailored, durable and fit-for-purpose flooring solutions.

Fosroc’s flooring products include:

• Nitoflor - a range of urethane cementitious flooring products

• Cemtop - polymer modified, cement-based, floor levelling compounds

• Patchroc - fast setting floor and pavement patch repair mortar

• Paveroc - large area, internal and external pavement repair mortar

Fosroc partners with builders, asset owners, applicators and specifiers at every stage of a project to work through the performance requirements and deliver a complete industrial flooring solution.

“We provide tailored solutions for projects of any size and scale, making sure that all aspects of design and performance are factored in from the start,” said Nelson.

“Our sales and technical teams focus on solutions, not products. Everyone is dedicated to providing the best possible solution for the end user.”

are industrial flooring experts

Dominated by the Nitoflor and Cemtop ranges, Fosroc’s flooring products are formulated with advanced compounds and additives ensuring they can satisfy even the most demanding performance requirements.

“We have an industrial flooring solution for every conceivable situation,” said Nelson.

“Whether it’s an airport hangar, clean room, car park or bakery, if it’s industrial flooring you need, we can deliver.”

Fosroc - fosroc.com.au

FOSROC. FUTURE PROOF.

Fosroc

The hidden costs of dirty floors that manufacturers need to know

Manufacturing and warehouse floors take a daily beating and cleaning them often comes as an afterthought.

Between forklifts, foot traffic and the constant movement of goods and machinery, dirt builds up fast.

From workplace injuries to equipment failure and product contamination, the impact of neglected floors can ripple across operations in ways many businesses don’t initially see.

What are the real costs of dirty floors?

Dust, spills and debris aren’t just unpleasant, they pose serious safety risks and can impact operations.

Slips, trips and forklift skids on slick or cluttered floors can bring parts of your facility to a halt, delay critical shipments and result in costly injury claims or regulatory penalties.

Dust may seem harmless, but when it consists of metal shavings, pallet splinters or fine powders, it can quickly become a serious problem. This buildup can clog machinery

filters, accelerate wear on forklift wheels and overall shorten the lifespan of your equipment.

Beyond damaging assets, unhygienic floors risk contaminating raw materials and finished products, leading to spoiled inventory and costly rework or disposal.

Compliance is crucial

Regulatory bodies like Safe Work Australia enforce strict safety standards in industrial settings to protect employees.

Failing to comply, including maintaining proper cleanliness, can lead to hefty fines, legal action or even facility shutdowns.

Smart floorcare isn’t just about appearances - it’s about keeping your operation running safely, smoothly and in full compliance.

When every minute counts, your floor cleaning equipment needs to be built for the challenge.

Designed with industrial-scale cleaning in mind, the T16 Battery Ride-On Scrubber delivers

Trade show celebrating after 2,000 attendees turn out in Brisbane

The team at ARBS are celebrating after a successful completion of their first trade show in Queensland.

Now, they are already looking forward to the next date on the calendar, the national event next year, which is scheduled for the Melbourne Convention & Exhibition Centre on 5 - 7 May 2026.

This edition, the inaugural ARBSQLD, closed on August 28 after two days at the Brisbane Convention & Exhibition Centre (BCEC) that brought the best in HVAC&R to the Sunshine State.

Attendances were strong, with over 2,000 coming through the gate to see the future of air conditioning, refrigeration, heating and building services in Queensland.

A total of 20 talks on subjects such as indoor air quality, fire safety systems, energy performance, seismic safety and digital innovation were held at the BCEC, as well as the ever-popular Women in HVAC&R networking event.

“We’ve been delighted with the response to ARBSQLD. To see the industry come together in Brisbane

impressive scrubbing performance with up to 114 kg of down pressure and a run time of up to 4 hours.

Its robust steel frame and productivity make it ideal for production lines, expansive warehouse floors and high-traffic zones that require consistent, thorough cleaning.

But before you scrub, you need to sweep and that’s where the S20 Compact Ride On Sweeper shines. Designed to pick up everything from fine dust to bolts and packaging debris, the S20 delivers high-performance sweeping in a

for the very first time, connect with new audiences and showcase the expertise in HVAC&R and building services is an incredible milestone for our sector,” said Amanda Searle, CEO of ARBS Exhibitions.

ARBS - arbs.com.au

compact, easy-to-navigate form. Its multi-stage dust control system makes it ideal for both indoor and outdoor use, while its easy-toservice design keeps downtime to a minimum.

Whether you’re managing a production floor, a distribution centre or a multi-shift facility, Tennant has the tools to help you clean smarter and cleaner.

Tennant Company tennantco.com

Tennant offer a large range of industry floor sweepers and scrubbers

ARBS in Brisbane was a success

FLOORING

How additive manufacturing has transformed a global F&B giant

Global food powerhouse Nestlé have greatly advanced their additive manufacturing capabilities thanks to a link-up with 3D printing experts Markforged.

The F&B giants have implemented Markforged’s technology in the UK, utilising the additive capabilities to create spare parts and components for their machines, reducing costs and downtime.

Moreover, the wider adoption of additive manufacturing processes has enabled Nestlé to reduce their carbon footprint and achieve sustainability goals, as 3D printed parts require less transportation and thus create fewer emissions, while also creating less waste.

“Nestlé has advanced its use of additive manufacturing in production line maintenance by creating a clear, standardised process to evaluate and scale its impact,” said Alan Yu, Senior Application Engineer at Markforged.

“It’s been great to support their team along the way and see how they laid the foundation for Nestlé’s broader adoption.

“Looking ahead, Nestlé is dedicated to further advancing its 3D printing capabilities, with plans to expand this technology to include food-safe components in the future.

“The roadmap for the next two–five years aims to enhance autonomy in 3D printing, ensuring that each

site can independently meet demand while maintaining high standards of quality and efficiency.”

The tech involved in the processes in England is also available in Australia and New Zealand and is being used by leading companies like Australian Meat Processing Corporation, Danone and PepsiCo

to enhance operational efficiency, reduce costs, and improve sustainability.

Nestlé are looking to find further efficiencies thanks to their partnership with Markforged.

“As we continue to embrace 3D printing technology, we are not only enhancing our operational efficiency

but also paving the way for sustainable manufacturing practices that will define the future of our industry.” said Simon Billington, Head of Technical & Production at Nestlé UK and Ireland.

Markforged - markforged.com

How stainless steel Line Vacs tackle dust, debris and high heat

Exair’s 3/8 NPT High Temperature Threaded Line Vacs convert hose, tube or pipe into a powerful in-line conveying system suitable for use with high temperature materials or in areas of high heat up to 482ºC (900ºF).

Fitted with NPT threaded ends, it is easily mounted onto threaded pipe and offers an efficient solution for fine material conveyance, sampling hot flue gases, exhausting fumes, conveying soot, ashes, salts and other hot debris.

The High Temperature Line Vacs utilise a small amount of compressed air to produce a strong vacuum and flow.

This model offers a durable construction from either Type 303 or Type 316 stainless steel to resist high temperature, corrosion and contamination while maintaining a compact design for fitting into tight areas.

Regulating the compressed air pressure provides infinite control of the conveyance rate and allows for precision when planning applications.

Exair’s High Temperature Line Vacs feature no moving parts to ensure performance over extended use.

Available from Compressed Air Australia, High Temperature Line Vacs are CE compliant and available in nine sizes from ⅜” to 3”.

Other larger models for hopper loading, scrap trim removal, small part transfer and packaging are available in both smooth ‘clamp type’ options or NPT threaded versions.

Compressed Air Australia caasafety.com.au

The new Line Vacs from Compressed Air Australia

Markforged have helped Nestle to utilise additive manufacturing in their processes

COMPRESSORS

Generate independent nitrogen on-site and significantly lower energy consumption

Maximum-purity nitrogen is required as a process and inert gas is not only in the chemical industry but also in other sectors such as food and beverages.

Companies have the choice to procure the gas from third parties or to generate it themselves.

The benefits of generating it independently are obvious: the quantity, purity and pressure can be easily controlled and adapted to requirements.

This also avoids costs for delivery and storage, and means the gas is available when needed. Purity is monitored continuously – another advantage of onsite generation.

Combining a modified PN nitrogen generator (PNK) and an H2KAT hydrogen converter, Inmatec, which is part of the Boge Group, offers an efficient system for the independent generation of maximum-purity nitrogen (0.001 per cent O2 [degree of purity 5.0]).

The compressed air is filtered and dried before the nitrogen

is separated from the ambient air using PSA technology and a high-quality carbon molecular sieve.

The generated nitrogen, which has a purity of 0.1 per cent O2 (degree of purity 3.0), is first stored in a buffer receiver, then enriched with tiny quantities of hydrogen in the H2KAT.