ANNUAL 2025 FILTRATION INNOVATION ISSUE

GOVERNANCE

A Strategic Framework for Filtration, Trade, and Sustainable Governance

REVERSE OSMOSIS Environmental Challenges SHOW PREVIEWS World Filtration Institute AHR 2026 TM

Corporate Profile A2Z Filtration Specialities

Solution Center Epic Resins

Innovation in Action: Filtration for Today ... and Tomorrow

Compiled By Caryn Smith, Chief Content Officer & Publisher, IFN

Synergizing Clean Energy & Clean Air

38 / Excerpts from the Experts By Dr. Iyad Al-Attar, Global Correspondent, Technology and Innovation, IFN

Reverse Osmosis: Innovations for Environmental Challenges By Jason Chen, International Correspondent, IFN

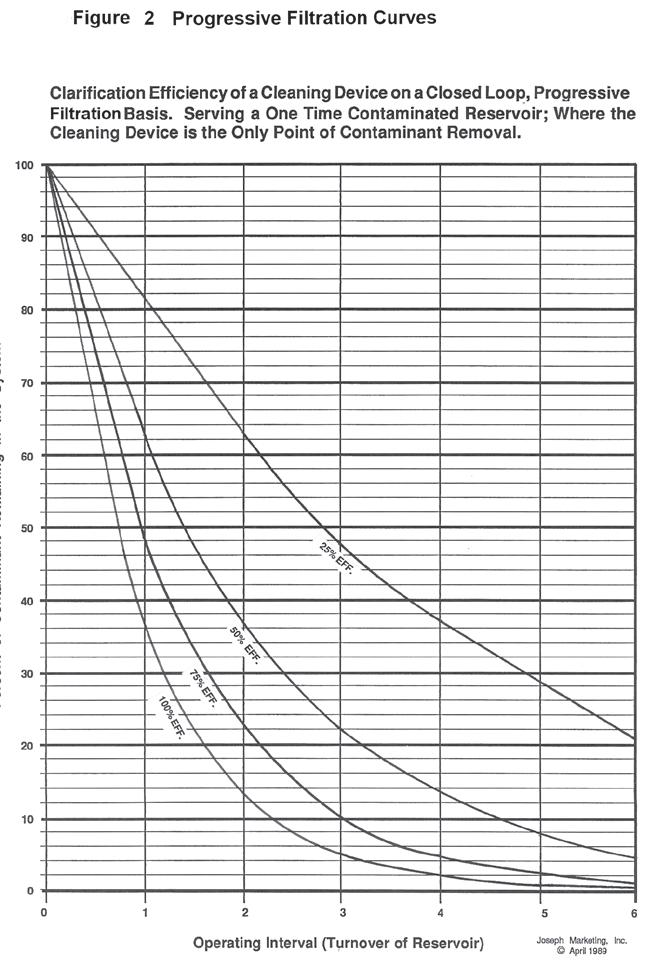

Progressive Filtration for Cleaning Metalworking Coolants

By James J. Joseph

Show Previews

47 / World Filtration Institute

48 / AHR 2026

COLUMNS & DEPARTMENTS

Viewpoint

Innovation Grows – And a Personal Note By Caryn Smith, Chief Content Officer & Publisher, IFN

Tech Spotlight

Keeping the Real World Out of Diesel Equipment

Tech Notes

New Technology Briefs Green Economy

Embracing Circularity in Filtration By Philippe Wijns, Principal, CleverSustainability Emergence

Trending University & Institutional Research

Compiled By Ken Norberg, Editorial & Production Manager, IFN Movers & Shakers

Industry News & Notes

Caryn Smith Chief Content Officer & Publisher, INDA Media csmith@inda.org

Dr. Iyad Al-Attar Global Correspondent, Technology & Innovation, Visiting Academic Fellow Cranfield University i@driyadalattar.com

Philippe Wijns Principal, CleverSustainability, Filtration Expert and Sustainable Business Development Advisor philippe.wijns@ cleversustainability.com

CALL FOR COLUMNISTS & WRITERS

Jason Chen International Correspondent jasonchen200501 @hotmail.com

James J. Joseph Author and Consultant Joseph Marketing +1 757.565.1549 josephmarketing120@ gmail.com

International Filtration News is actively seeking viewpoints from qualified industry professionals and those allied to the filtration industry for insightful columns on topics such as trends, innovation, equipment, processes, etc. Email Caryn Smith, csmith@inda.org with feature and column ideas.

Innovation Grows – and A Personal Note

“Creativity is thinking up new things. Innovation is doing new things.” — Theodore Levitt

Creativity is something I feel I excel at, and I must say that I am not shy about sharing my ideas with others, almost to a fault. I mean, why wouldn’t you want new ideas to shape the future of your widget? But I have found that, sometimes, people just want a slightly better version of status quo, not reinvention of the wheel. To each their own!

Yet, I am happy to report that what you will find in this issue of IFN are the folks that embrace ideas, and then DO SOMETHING about them. My kind of people. The Innovators.

On page 22, the Annual Innovation Roundup contains those in the filtration industry pushing the envelope in small and big ways. Four years ago, I started this annual tradition to highlight “the best of” in the last issue of the year. I found it interesting that submissions only trickled in, at best. This year, I think the idea has come into fullness, as we had many entries, and I love the vibe of this issue! I hope it inspires you.

Other big ideas in this issue include Embracing Circularity on page 14, IAQ Governance on page 34, Reverse Osmosis and the Environment on page 42. You have a chance to be inspired at two upcoming shows, as well – WFI ‘25, page 47, and AHR ‘26, page 48.

Speaking of new ideas, the Media Kit 2026 was just released and is found at https:// www.filtnews.com/advertise/. This year our theme is “New Dimensions Through Partnership & Collaboration.”

I strongly feel that from the editorial to the advertising of this publication, it is a true industry collaboration to benefit you, the reader. Ultimately, you want to learn about news and views that help you to stay ahead of the curve and, hopefully, be inspired to formulate your own innovative ideas!

In the Media Kit, we share an Editorial Grid, full of new and interesting issue topics for next year, such as a focus on Data Centers, Digitization and AI, Gas Turbine Filtration, Industrial Water Trends, Equipment and Machinery, Production Efficiency and more.

To discuss your ideas for an article in one of our issues, or to collaborate on marketing or advertising, email csmith@inda.org.

Let’s Talk Partnership & Collaboration!

Caryn Smith Chief

Content Officer

& Publisher, INDA Media, IFN

International Filtration News Editorial Advisory Board

R. Vijayakumar, Ph.D., Chair AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Jay Armstrong, MBA, PhD Mott Corp.

MS Teams #: +1 (860) 999-9035

Email: JArmstrong@mottcorp.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Email: josephmarketing120@gmail.com

Tom Justice, CAFS, NCT ZENE, LLC Filtration

Tel: +1 757-378-3857

Email: justfilter@yahoo.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Rishit R. Merchant Parker Hannifin

Tel: +1 805-604-3519

Email:rishit.merchant@parker.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

Philippe Wijns CleverSustainability

Email: philippe.wijns@cleversustainability.com

New Dimensions Through Partnership & Collaboration

MEDIA KIT 2026

SPOTLIGHT TECH

Keeping the Real World Out of Diesel Equipment

Industry-Standard Filtration Tests Aren’t Telling the Whole Story

By Greg Hoverson, Vice President and Chief Technical Officer, Atmus Filtration Technologies

Are industry standard tests keeping pace with evolving customer needs?

Standards play critical roles in keeping diesel equipment running, and they are needed. But when it comes to diesel fuel filtration, customer needs are evolving faster than standards can address.

Although standardized tests can provide insight into filter life and efficiency, they don’t always tell the whole story. Customers care about real-world performance and the bottom line. How well will their equipment be protected? How often will they need to service the filter? How will their filtration needs impact their total operating costs?

To enable our customers’ success, we must also go beyond industry testing to provide filtration solutions that more closely simulate the dynamic and real-world conditions our customers experience.

Old Standards Aren’t Keeping Pace With New Challenges

Technological developments and changing market needs are creating challenges that current standardized test methods aren’t equipped to handle.

For example, a trucking fleet in Brazil recently experienced widespread short service life or cycle issues. Everything from macroeconomic shifts in the biodiesel supply base to advances in fuel systems – two factors not easily identified through standardized testing – caused their filters to fill up with contaminants twice as fast, resulting in short service life while causing unplanned and unwanted maintenance.

Standardized methods run capacity tests with hard dust particles of a certain size for a set period. But this isn’t always representative of what plugs a filter in today’s operating

conditions. Today, filters are more likely to be plugged with soft, sticky organic material with smaller particles, especially if biofuels are blended in.

In Brazil, the customer needed to get to the root of the problem right away but knew it required more than standardized data. They turned to Atmus Filtration Technologies for help.

Atmus was able to deploy on-site fuel testing to analyze and understand the real-world fuel contamination. Then, recreating these conditions in the lab resulted in a more effective solution that captured smaller particles –protecting the engine, extending service life and delivering the expected service intervals.

Greater Fuel Variation Is the New Normal

A decade or two ago, it was possible to take a “one-size-fits-all” approach to filtration technology, in part because engine and fuel system designs provided more clearance. The same systems would deliver comparable performance, whether they were used in North America, South America, Europe or anywhere else. This approach doesn’t work anymore. The biggest factors our customers face include:

• Changes in diesel fuel-injection equipment – Most modern diesel engines use a high-pressure common rail (HPCR) fuel system or similar technology to meet stricter emissions standards. This type of equipment is extremely sensitive to small particles; it’s now necessary to protect the system from smaller particles than in the past (typically four microns, or smaller than a red blood cell). Filters today must capture more material, meaning they are at risk of plugging faster. Innovation is therefore necessary to extend service intervals.

• Modern pressurized fuel systems – Pressurizing fuel raises its temperature, creating more contamination as it moves through the system. As a result, filters are up against additional contaminants that weren’t generated by the mechanical or electrical fuel systems of the past.

• Aging infrastructure – Many of the world’s fuel pipelines are aging. Fuel delivered through aging pipes dislodges rust and other contaminants that have built up over time, carrying them into the distribution system. Each fill-up delivers fuel pumped through different pipelines, giving customers less control over what their systems are exposed to. Filters need to be ready for anything.

• Biofuel content – There’s significant variability in global biofuels, even in the U.S., where biodiesel blends up to B5 don’t have to be labeled. Although these fuels can often be used as drop-in replacements for ultra-low sulfur diesel, their chemistry can present different challenges to filter life and performance.

All these factors are driving the need for greater innovation to create more capacity in filters so that customers don’t have to settle for shorter service intervals. Going beyond industry standard testing can help us get there.

Protecting Your Equipment

Next time you are evaluating a filtration solution, ask yourself how it will perform for your application. Look for a provider who can demonstrate that they’ve gone beyond industry standard tests to test for real-world performance. www.atmus.com

For details on how to submit your company’s technology for consideration as a “Technology Spotlight” in IFN , contact Ken Norberg at ken@filtnews.com or +1 202.681.2022.

NOTES TECH

Crown Unveils

Patent-Pending Monarc Clean Oilseed ProcessingTM

Crown announces Monarc Clean Oilseed ProcessingTM, a revolutionary, patent-pending alcohol-based solvent extraction technology that is projected to have competitive operational efficiency to traditional hexane-based extraction systems while delivering key advantages in safety, environmental impact and consumer appeal. This makes it possible for alcohol-based solvent extraction to compete with hexane-based extraction at scale. Historically, oilseed processors have relied on hexane-based extraction as the most efficient and cost-effective method to produce the cooking oils, protein meals and ingredients that form the foundation of countless food products consumed worldwide.

Now, Monarc Clean Oilseed Processing allows producers to work with alcohol-based solvents, like ethanol, and take advantage of meaningful benefits:

• Alcohol is already present in or utilized to produce many foods and beverages.

• The use of an alcohol-based solvent enables companies to produce clean-label products that appeal to health-conscious consumers.

• Alcohol-based solvents significantly improve worker safety profiles at factories.

• Alcohol-based solvents reduce environmental impact compared to petroleum derivatives like hexane.

• Alcohol-based solvents better align with sustainability goals.

• Alcohol is a renewable source material, as ethanol can be produced from plants.

• Alcohol-based solvents facilitate easier permitting of new extraction facilities compared to hexane. https://onecpm.com

Pall Enables Sustainable Food Production at a Lower Cost with Membralox®

Pall Corporation, a leading provider of filtration, separation and purification solutions launched Membralox ® GP-IC ceramic membrane systems, a revolutionary ceramic membrane with graduated permeability along the length of the filter. This unique design increases processing efficiency, lowers capital and operating costs and has the potential to yield up to 95% recovered value-add products enhancing overall filtration performance.

With a high surface area and multi-channel geometry, the Membralox GP-IC membranes offer up to 45% more filtration capacity compared to conventional ceramic filters of similar size. This enables optimized system loop design with more compact filter modules, reducing capital and operational expense.

“The unique design of Membralox GP-IC pushes the boundaries of what’s possible for ceramic membrane solutions in order to meet the demands of food processors globally,” said Ankush Soni, Vice President & General Manager of the Food and Beverage business unit of Pall Corporation. “We are excited to launch this breakthrough solution and support our customers with a smarter, more efficient and sustainable solution.”

Pall has a long history of expertise and innovation in the ceramic membrane industry, which is poised for exponential growth ($21 billion by 2030). Through filtration expertise as well as a deep understanding of the unique challenges of the global food industry, Pall was able to design a solution enabling customers to be at the forefront of sustainable and efficient food production. www.pall.com

Transfilm Technology, a global leader in reverse osmosis and nanofiltration membrane research, development, and manufacturing, recently announced the launch of IonClear, a Silicon Valley-based company that supplies water filtration and resource recovery membranes for customers across North America and beyond. IonClear will serve American, Canadian and Mexican markets.

Transfilm Technology was established by a team of international scientists specializing in membrane research, development, and production for water filtration, reclamation, and reuse. The company operates a global network providing water purification solutions for markets around the world.

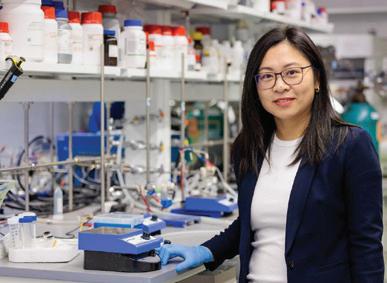

Cady Yu, CEO of Transfilm and IonClear, said: “The launch of IonClear in the United States marks an exciting new chapter for Transfilm. By combining our decades of scientific expertise with U.S.-based operations, we will be able to accelerate innovation, strengthen supply resilience, and deliver sustainable, high-performance water treatment solutions with closer-to-market innovations.” www.transfilmtech.com

Transfilm Debuts IonClear

TRANSFILM Reverse Osmosis Elements.

Pall Membralox GP-IC ceramic membranes

Monarc Clean Oilseed ProcessingTM, a revolutionary, patentpending alcohol-based solvent extraction technology. Crown

Blu Technology Launches ‘Camo’ Water Filtration System

Blu Technology, a leader in mobile water filtration solutions, has launched a limited-edition camo version of its AR3 3-Stage Water Filtration System.

The product was unveiled at America’s Largest RV Show in Hershey, Pa., and is designed to provide cleaner, safer water when traveling by RV and a custom option for the outdoor enthusiasts’ gear checklist, according to a release.

Blu Technology has already seen success with its original, bright blue version of the AR3 system (nicknamed “The Blu” by RV influencers and Blu Technology customers). The new product, with its camouflage detailing, seeks to pique the interest of campers, hunters and anglers as well. “Beneath its rugged exterior lies the same advanced RV water filtration technology trusted by thousands of RVers nationwide,” said Corbin Collet, Blu Technology’s CEO and founder.

“The AR3 is engineered and assembled in Kalamazoo, Michigan and features a smaller micron size, stage two filter for greater filtration,” Collet added. Standard RV inline water filters are able to filter out particles up to 20 microns in size. Blu Technology 0.2-micron filters provide filtration for particles that are up to 100x smaller.

The three-stage process includes:

• Longevity Filter: Captures larger particles, including dirt, sand, and rust.

• 0.2 Micron Filter: Reduces sub-micron contaminants including bacteria and viruses.

• Tasty Filter: Improves the taste and smell of water via its granularactivated filter.

Blu Technology’s AR3 camo version.

The limited-edition design is created for RVers who see the road as more than just a route to follow but rather a lifestyle to define instead. The Limited Edition AR3 3-Stage Water Filtration System Camo Version celebrates that adventurous spirit and has “collector’s piece” status for those who love the outdoors, off-grid camping, and fall travel. www.goblutech.com

Toray Launches Industry-Leading Reverse Osmosis Membrane

Toray Industries, Inc., announced the launch of the TLF-400ULD reverse osmosis (RO) membrane that was developed with Toray Membrane (Foshan) Co., Ltd., and Toray Advanced Materials Research Laboratories (China) Co., Ltd., for industrial wastewater reuse and sewage treatment.

The TLF-400ULD offers several advantages over conventional counterparts. It uses Toray’s proprietary membrane manufacturing technology and flow-channel design to improve permeability and chemical resistance while maintaining high salt rejection. It slashes differential pressure increases from fouling.

Toray’s innovative design doubles chemical resistance during cleaning while boosting permeability. This suppresses performance

ZwitterCo Launches Evolution Membranes, Transforming Dairy and Food Processing Efficiency

ZwitterCo, a global leader in membrane solutions for challenging liquid separations, has announced the commercial release of its Evolution membrane product family. These next-generation membranes are engineered to help food, dairy, and biotech processors increase productivity, reduce cleaning costs, and advance sustainability objectives – all without requiring changes to existing systems.

In dairy and food processing, every minute counts, but lengthy daily cleanings can consume valuable production time and significantly increase chemical consumption and water demand. Evolution membranes, built with ZwitterCo’s patented zwitterionic chemistry, are anti-fouling and fully recover performance with a simplified cleaning program. This enables processors to clean faster, use fewer chemicals, and reclaim over an hour per day for additional production or other high-value tasks.

Available in an ultrafiltration membrane for protein concentration (PCM), superfiltration (SF), and reverse osmosis (RO) membrane configurations, Evolution membranes are one-for-one replacements for conventional sanitary spiral membranes. They install easily in existing systems with no hardware changes needed to experience lower operational costs and time savings. zwitterco.com

deterioration and extends service life.

A clog-resistant element structure reduces fouling buildup and cuts chemical cleaning frequency. Together, these features enable stable long-term operation while consuming roughly 10% less energy. The TLF-400ULD should reduce membrane replacement frequency and simplify operational management.

Global water shortages are driving demand for water treatment technologies that handle diverse water sources, operate efficiently, and reduce environmental impact. As a nextgeneration solution, the TLF-400ULD will help build energy- and resource-efficient processes at water treatment sites worldwide.

China’s 14th Five-Year Plan for Circular

Economy Development (2021–2025) has accelerated the adoption of water treatment membranes to combat water pollution. Toray has established an integrated structure in China covering research, development, production, and sales through Toray BlueStar Membrane, Toray Membrane (Foshan), and Toray Advanced Materials Research Laboratories (China). These companies will collaborate to deliver optimal local solutions while working with Toray’s global water treatment group. Together, they will contribute to solving the world’s water challenges by providing advanced membrane technologies, including the TLF-400ULD, along with responsive technical services. www.toray.com

ZwitterCo’s Evolution membranes.

NOTES TECH

Nobel Prize for MOFs Developers

Svante Technologies Inc., headquartered in Canada is celebrating the recent announcement of the 2025 Nobel Prize in Chemistry, which honored scientists Susumu Kitagawa, Richard Robson and Omar Yaghi for their groundbreaking work in the field of metal-organic frameworks (MOFs).

The Royal Swedish Academy of Sciences awarded the prize for the development of MOFs, citing their “enormous potential” and unique molecular architecture that creates spacious, porous materials capable of capturing and storing specific substances, including carbon dioxide.

“The Nobel Committee’s recognition of the very class of materials we leverage here at Svante is a profound validation for the entire field of carbon capture and removal,” said Svante COO and President Richard Laliberté. “The cutting-edge work that is being done in the MOF space has been one of the fundamental building blocks of our success in this industry.”

t Svante’s CALF-20 MOFs. Svante

The Nobel announcement highlighted the incredible capability of MOFs for gas separation and high-capacity capture, which are central to Svante’s proprietary filter technology. Specifically, the scientific background documents referenced MOFs relevant to industrial carbon capture, including CALF-20, a MOF developed by Dr. George Shimizu at the University of Calgary, a valued collaborator, scientific advisor and inventor of the MOF used by Svante.

Svante manufactures structured adsorbent filters coated in solid sorbent materials at industrial scale, including CALF-20, a MOF that the company has successfully scaled up from gram to commercial quantities in collaboration with its partners in the materials sciences sector. Svante recently launched Svante OEM&D, a new business unit that helps customers with solid sorbents get gas separation technologies to market faster, leveraging Svante’s expertise, experience and equipment to scale up solid sorbents and coat them onto high-performance filters. www.svanteinc.com

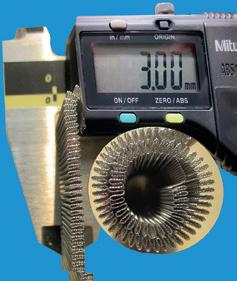

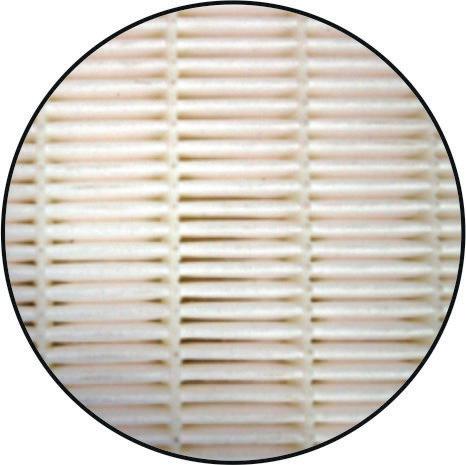

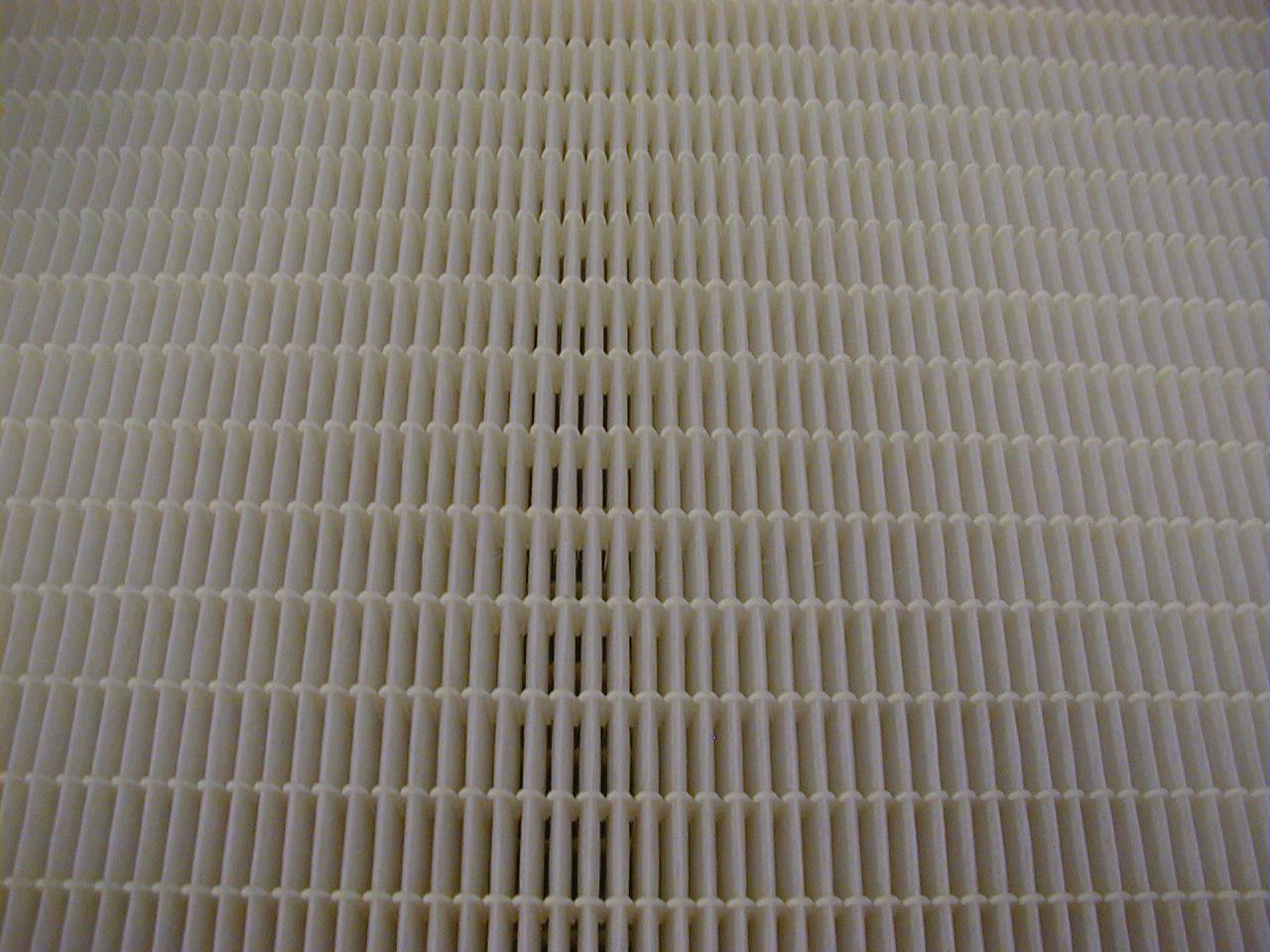

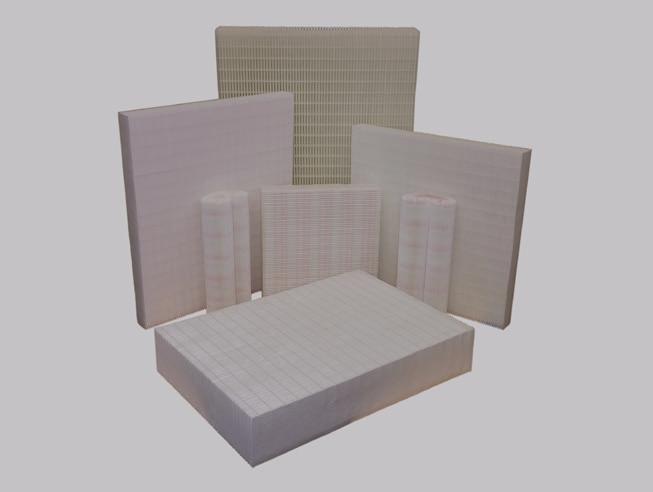

MINI-PLEAT-GLASS

Mini-Pleat: H.E.P.A., ULPA & ASHRAE

Pleat heights 1/2” to 12” upto 39” wide. Interrupted beads, many configurations.

Mini-Pleat: H.E.P.A. & ASHRAE

Pleat heights 3/4” to 4” upto 25” wide. Interrupted beads, many configurations.

Share Your Knowledge, Research, and Best Practices

This year's theme, Energy Transition & Regulatory Compliance, spotlights the pivotal role of filtration and separations in enabling cleaner energy systems and meeting increasingly complex global standards.

From renewable fuels and hydrogen production to carbon capture, battery technologies, and advanced manufacturing, innovations in filtration are driving efficiency, reliability, and sustainability across sectors.

And as emerging technologies and AI-driven design reshape the landscape, FILTCON26 offers a platform for scientists, engineers, and practitioners to share breakthroughs, discuss evolving regulations, and explore solutions that will define the next generation of clean technology.

Submit your abstract today and contribute to advancing the science and practice of filtration in a changing world.

www.afssociety.org/filtcon26/call-for-abstracts

Submission Deadline: Dec. 15

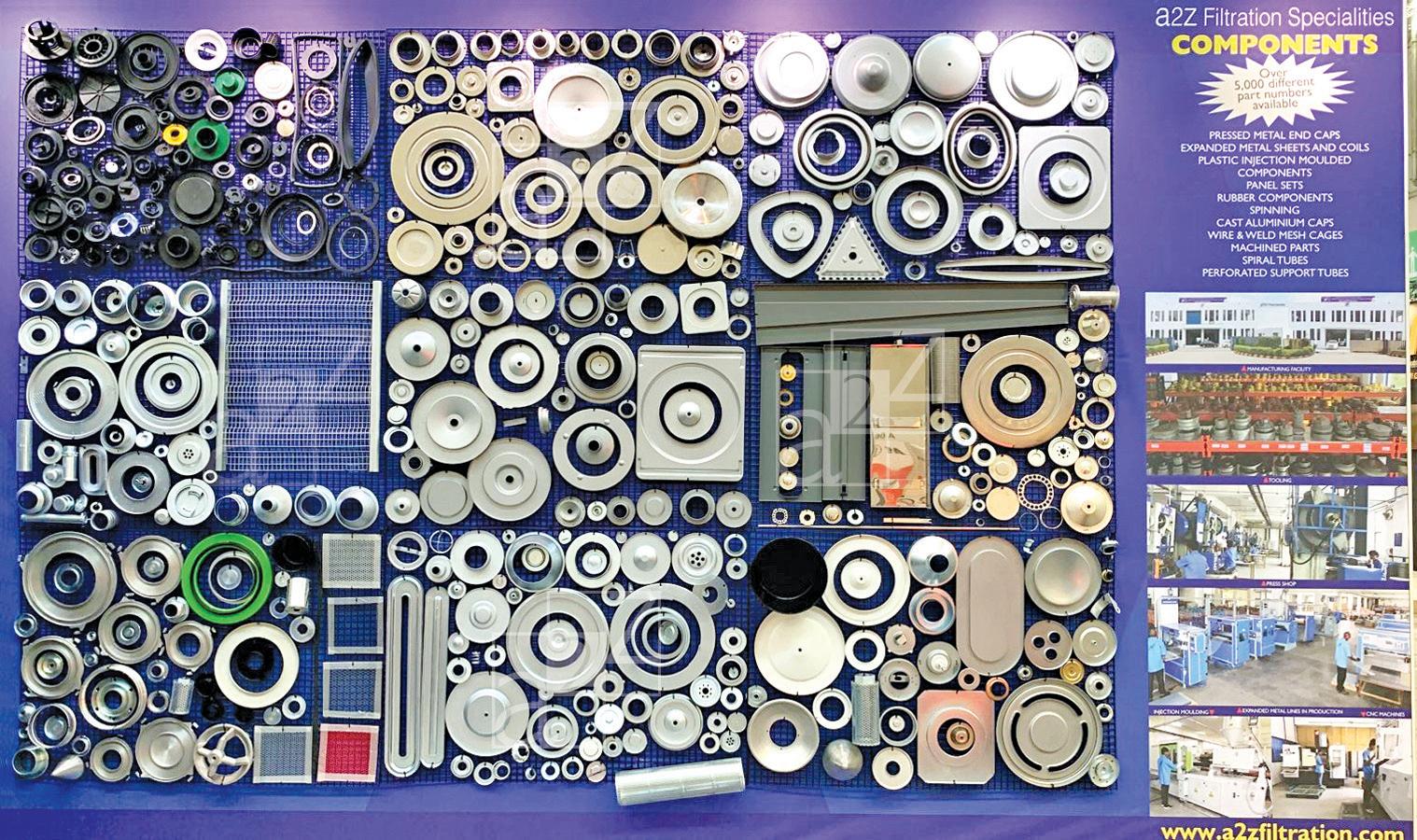

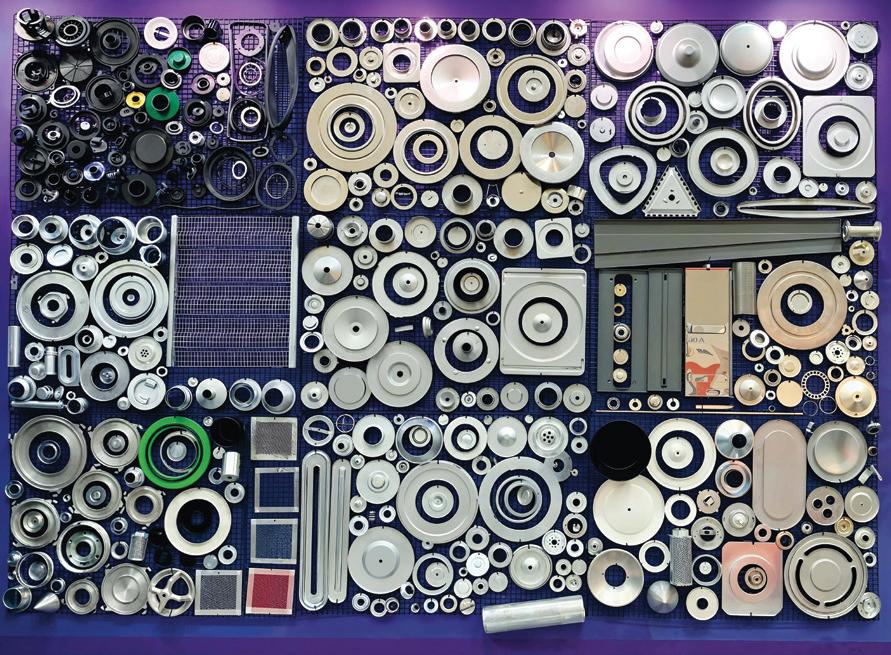

A2Z Truly Has The “Widest Range for End Caps & Components”

A2Z Filtration Specialities manufactures a large variety of end caps, components, and parts to suit the assembly of all types of filters. A2Z supplies products in sheet metal duly Stamped, Machined, Cast as well as Injection Molded parts. With a range of over 7,000-part numbers, we offer the broadest range of end caps on earth. Only the latest version of SolidWorks® is used to design all tooling. The ability to manufacture our own tooling with HAAS® CNC machines allow us to quickly turn around parts from concept to finished product in less than three weeks.

A2Z Supplies:

• End Caps – Stamped and supplied in Zinc, Tin, Nickel, Powder Coated. Also available in spun and fabricated.

• Expanded metal is available as cut-tosize sheets as per the specification of the customers or in coils in Galvanized steel, Stainless steel, Aluminum, and powder coated.

• Injection molded parts can be supplied in Glass-filled nylon (any grade), ABS, Polypropylene, Silicon, Polyester and Polycarbonate materials. The above components can be supplied in various grades materials including FDAapproved.

• CNC Machined Parts in materials such as Steel, Stainless Steel, Aluminum, Brass and Nylon.

• Synthetic Rubber Grommets, Gaskets, Sponge Rubber Air Filter Molded Sealing Rings (endless/jointless). Available in EPDM, Natural Rubber, Silicone among other materials as per requirement.

• Weld Mesh Cages of any size or configuration.

• Deep drawn housings and Threaded Top cover plates for spin-on filters.

• Perforated Sheets (Tin, Mild Steel, Zinc Plated or Paper Board)

• Panel Sets and Frames

The illustration showcases over 50,000 square feet of area used for storage of over 7,000 tools and dies.

A2Z Has the Infrastructure to Meet All Your Needs

1. With a total covered area of nearly 200,000 square feet.

2. Over 11 Solid workstations for Design.

3. A tool room is spread over 50 thousand square feet and consists of 11 Haas ® CNC Machines over 13 mechanical lathes, surface grinders, milling machines. At any given time A2Z carries over 500 tons of various grades and

thicknesses of stainless steel and steel materials.

4. We have spot welding, projection welding, MIG welding, TIG welding, capacitor discharge projection welding and stud welding machines.

5. Over 80 pneumatic power presses, hydraulic presses, double action presses with the range from 10 tons to 250 tons spread over 100,000 square feet. We can offer a quick turnaround of your orders.

6. We also have multiple turret punch press and CNC hydraulic press brake machines to manufacture a large range of frames and punched parts.

7. Five Dedicated High Speed Automated Expanded Metal Lines to produce expanded metal in various raw materials.

8. State of the Art Inspection System, such as Carl Zeiss – CMM – Mitutoyo Contracer and various measuring instruments from Mitutoyo.

9. In-house Sand Blasting facilities. A2Z is the go-to supplier for all your component needs. A2Z also has the ability to provide supplies through 3rd party warehouses in North America.

For further information, please visit our website –www.a2zfiltration.com or contact us at info@a2zfiltration.com

TURRET PUNCH PRESS MACHINE.

CNC HYDRAULIC PRESS BRAKE MACHINE.

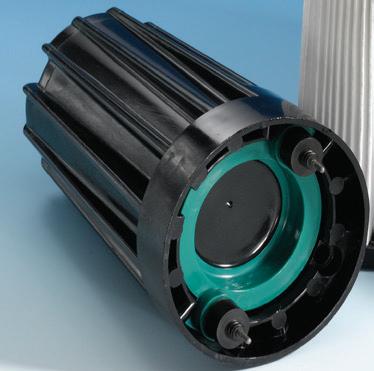

Improving Efficiency, Product Life and Production Without Compromising Performance

In high-performance filtration systems, choosing the right adhesive plays a crucial role in the integrity, durability and efficiency of the final product. As engineers and manufacturers face increasing demands for heat resistance, chemical resistance and production efficiency, selecting the right adhesive is more important than ever. Epic Resins, a global leader in epoxy and polyurethane technology, develops solutions tailored to meet these evolving challenges.

Epic Resins has formulated, manufactured and supplied high-quality epoxy resins and polyurethanes to a wide range of industries for over 65 years. Specializing in adhesives, potting and encapsulation compounds, Epic Resins delivers products to enhance customer profitability and performance.

Because Your Design Can NOT Be Compromised

The launch of Epic S7465 highlights Epic Resins’ commitment to helping customers:

• Improve manufacturing efficiency

• Extend product life in demanding environments

• Streamline production without compromising performance

Whether you’re a spa equipment supplier wanting a filter end cap material, an OEM supplier seeking an air filter potting compound or an automotive manufacturer looking for a chemical resistant filter adhesive, Epic Resins can formulate it.

S7465: A 3-in-1 Epoxy System

Epic’s S7465 is a two-component epoxy adhesive specifically designed for high-temperature applications that require good chemical resistance. With its unique rheological design, S7465 stands out in the marketplace as a truly multi-functional material.

Key Benefits:

• 3-in-1 functionality: Can be used for seam sealing, moldable end-caps and end-cap adhesive

• Reduced work-in-process (WIP): Pot both end caps and apply the seam seal in a single step

• Streamlined operations: Short setup time

High-Temperature & Harsh Environment Performance

S7465 delivers reliable performance in extreme conditions:

• Temperature resistance: Up to 177°C

• Chemical resistance:

Excellent when immersed in harsh fluids, including:

- Automatic transmission fluid

- Synthetic hydraulic oil

- Synthetic water-free fluids (HFD-U)

- Water glycol fluids (WGF)

Above: S7465 is a multi-functional adhesive, it can be used in seam sealing, moldable end-caps and as an end-cap adhesive. Left: The chemists at Epic Resins work directly with your engineering and manufacturing departments, enabling us to provide you with effective solutions to fit your demanding needs.

Exceptional Bonding & Versatility

S7465 provides strong adhesion across a wide range of substrates:

• Excellent adhesion to end cap substrates

• Customizable viscosity: Available in multiple flowability options to suit various applications and dispensing methods

Production-Friendly Formulation

Designed with manufacturing efficiency in mind:

• Simple 4:1 volumetric mix ratio

• Short setup time: Speeds up filter production

• Reduced material changeovers: Supports lean manuacturing goals

Epic Resins: A Partner in Filtration Innovation

Epic Resins has a long-standing reputation for:

• Customized formulation support: Work directly with application chemists

• Responsive technical service: On-site troubleshooting and process guidance

• Consistent quality: Trusted materials that meet exact specifications

To learn more about Epic S7465 or to request a sample, visit www.epicresins.com.

By Philippe Wijns Principal at CleverSustainability, Filtration Expert and Sustainable Business Development Advisor

Embracing Circularity in Filtration

A Practical Framework and the New EU Circular Economy Act (2026)

Why is circularity suddenly featured in so many sustainability strategies, webinars, and conference discussions? Is it simply a buzzword, or does it have genuine regulatory and commercial backing? In Europe, much of this drive comes from new legislation commonly referred to as the EU Circular Economy Act, a blanket term for multiple enforceable laws that emphasize product design, encourage reuse and recycling, and demand transparent reporting throughout production and consumption. Start-ups are experimenting not only with repair services, refurbishment, and take-back schemes but also with innovative recycling and collecting initiatives. At the same time, chemical and polymer companies are shifting their focus from purely virgin raw materials to more sustainable and circular alternatives. Large filtration companies are adapting too – offering full-service models such as “Filtration as a Service” (BaaS), integrating recycling, product recovery, and lifecycle optimization. Across the industry, CO₂ footprint documentation and tracking of Scope 1, 2, and increasingly Scope 3 are becoming standard, or even mandatory, as part of CSRD, ESG, and financial disclosures. The filtration sector might be wellpositioned for these changes. The challenge now is to make circularity more than just a concept by applying it in measurable ways that enhance performance, reduce risks, and comply with regulatory frameworks – while also embedding it into the core of corporate sustainability strategies.

The EU “Circular Economy Act” –What It Is and What It Will Be

The European Commission launched a public consultation on August 1, 2025, for a new Circular Economy Act (CEA). The initiative aims to accelerate the EU’s transition to a circular economy with a central objective: Creating a single market for

Philippe Wijns is Principal at CleverSustainability, and serves as a Filtration Expert and Sustainable Business Development Advisor. He is a Certified Expert in Sustainable Finance, Climate Finance, and Renewable Energy from the Frankfurt School of Finance and Management. He began with global leaders in the nonwovens industry before transitioning to the filtration sector, where he specialized in filtration technologies across a wide range of applications and markets – including industrial and automotive systems, HVAC, household appliances, medical and life sciences, as well as power storage solutions such as fuel cells, hydrogen systems, and battery separators.

Wijns recently founded CleverSustainability, a consultancy dedicated to sustainable business development to help companies develop and implement sustainability strategies, ensure compliance with the EU legal reporting requirements, and enhance their sustainable business growth, product portfolio and development, and market positioning.

secondary raw materials, increasing the availability of high-quality recycled inputs, and stimulating demand across industries. According to the Commission’s timeline, a legislative proposal is expected in 2026. The Act is positioned within the broader Clean Industrial Deal and the EU Competitiveness Compass.

Relationship with existing legislation. The CEA will not replace existing rules such as the ESPR or the PPWR. Instead, it is intended to complement and build on measures already adopted under the 2020 Circular Economy Action Plan – including the ESPR (ecodesign and Digital Product Passports), PPWR (packaging), the Right-to-Repair initiative, waste shipment regulations, and more. The explicit goal is to ensure that markets for secondary raw materials can scale across borders, with the CEA acting as the connecting framework. This includes:

• Create a real single market for recycled materials.

• Pull demand and improve product design via existing levers.

• Target key product/value chains and close waste policy gaps.

• Tie circularity to EU competitiveness. The Commission opened the consultation window from August 1 to November 6, 2025, as part of the “Have Your Say” process, which feeds into its impact assessment. A legislative proposal for the Circular Economy Act is expected in 2026, after which it will move to Parliament and Council negotiations. Until the draft text is published, the exact targets, obligations, and standards remain open.

Practical implications of the EU Circular Economy Act (What This Likely Means for Operators and OEMs)

• Materials strategy: expect more straightforward rules and quality signals for recycled polymers/metals across borders.

• Product information & design: stricter use of Digital Product Passports under ESPR, including CO2 footprint information and tracking

• End-of-life systems: updates to waste/product-stream laws.

• Competitiveness & procurement: stronger demand-pull from public procurement and

private buyers for circular designs and verified recycled content as part of competitiveness policy.

An Operational Circularity Framework for Filtration

Across industries, circularity programs often organize work around four pillars spanning the full life cycle: Prevention (1), Preparing for reuse (2), Collection & Recycling (3), and Disposal (4).

• Prevention: reducing waste and emissions. Filtration products can reduce waste and emissions by utilizing single materials, safe chemicals, and designs that facilitate disassembly. Reusable frames, recyclable packaging, and intelligent monitoring extend product life while ensuring efficiency in HVAC, air, and water filtration systems.

• Preparing for Reuse: extending filter lifecycles. Extending filtration product lifecycles through reusable housings and frames that facilitate simple media replacement and cleaning enables reuse, adaptability, and a longer service life.

• Collection & Recycling: closing the loop. To promote circularity in filtration, companies should implement incentive-based take-back systems, design for easy product separation, and reuse plastics, metals, and fibers. When recycling isn’t feasible, safe energy recovery minimizes landfill use, while incorporating recycled materials into new products sustains demand and closes the loop.

From Today’s Practices to Collective Action

Today, many filtration companies are advancing circularity by focusing on prevention, preparation for reuse, collection and recycling, and responsible disposal. They are integrating design for longevity, modularity, and recyclability into products, embedding circular practices into daily operations, and aligning these with regulatory compliance. These steps strengthen operational efficiency, reduce environmental impact, and build long-term resilience. However, to accelerate progress and achieve scalability, the industry must not operate in isolation. Companies should standardize data and definitions for media, additives, and material IDs, enabling digital product passports and seamless service histories. They should also work toward unified systems for product returns, with consistent labelling, documentation, and return hubs co-funded by OEMs, media producers, and service networks. Joint research on material separation, safe decontamination, and refurbishment can make recycling and reuse more reliable in sensitive applications.

• Disposal: responsible end-of-life management. Some waste, such as biohazard filters or highly contaminated media, is unavoidable. Use strict handling, specialised treatments like energy-recovering incineration, and design feedback to continually reduce leftover waste.

Implementing a Circularity Score Model: Simple, Credible, Useful

Learning from other industries, we see that a circularity score model can be applied in any sector to turn complex sustainability data into clear, actionable insights. At its core, such a model is a measurement system that consolidates many data points – like return rates, recycled content, reuse volumes, and landfill avoidance – into a single score with drill-down KPIs. Instead of tracking dozens of isolated indicators, companies can group key performance indicators into a few KPIs aligned with their ESG strategy. Tracking these consistently over time makes it possible to demonstrate progress, identify gaps, and build trust with stakeholders. A consolidated score provides management focus, cross-functional alignment, and comparability across business units and markets – while giving customers, investors, and regulators a credible and transparent view of circularity performance.

This is where industry organizations have a crucial role: coordinating shared data standards, facilitating training programs, and creating frameworks for cross-border refurbishment, recycling, or energy recovery pathways. By adopting standard metrics such as a circularity score, the sector can track progress, benchmark reasonably, and ensure comparability. Drawing inspiration from other industries – such as electronics or apparel – filtration can tailor proven solutions in returns management, grading, and secondary use to its specific needs, including sterility, efficiency, and regulatory validation. The message is clear: Companies are already taking necessary steps, but industry-wide coordination will be the real accelerator for circularity in filtration.

Conclusion – Making Circularity Everyday Business

Circularity is transitioning from a side project to an integral part of our everyday practice, woven into our strategies, budgets, and customer promises. The road ahead is complex, challenging, and at times uncertain. Still, we don’t need to make it more complicated than it is: A clear, simple measuring system – a practical scorecard with a handful of indicators – helps everyone see where we stand, where we’re improving, and where we need to adjust. If companies, partners, and industry organizations align around this shared view, we can steadily expand return systems, trusted refurbishment and recycling routes, and reliable supply chains across regions and markets. Different sectors and geographies will start from various points, yet the direction is the same: Keep learning from one another, focus on what works, and show progress year over year. By staying pragmatic and collaborative, our industry won’t just keep pace with circularity – it will help set the pace for our customers.

EMERGENCE

Compiled by Ken Norberg, IFN Editorial & Production Manager

International Filtration News Explores Trending Innovation

IFN highlights significant research from universities and institutions around the world. If you are a part of a project you would like to highlight, email csmith@inda.org. Please write “IFN Emerging Research Submission” in your subject line in order to apply. Please send a completed press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution photographs/charts/graphs, short researcher bio(s). All selections could be edited for length.

IN THE NEWS

German Students Awarded 2025

Stockholm Junior Water Prize for Flood Warning Innovation

Niklas Ruf and Jana Spiller from Germany received the prestigious Stockholm Junior Water Prize 2025 for their work on developing a scalable flood warning system for small streams. H.R.H. Crown Princess Victoria of Sweden presented the winners with their award during a ceremony at Stockholm City Hall as part of World Water Week in Stockholm.

Flooding is an increasing concern worldwide, with more frequent and larger floods affecting communities. Yet on smaller streams, real-time data is often lacking, limiting the possibility of early warnings. Over four years of work, Ruf and Spiller created a network of sensors linked to an app that provides live alerts to both experts and the public. Their system is already being scaled up across their region in consultation with multiple partners.

The jury noted that the project “addresses a critical challenge we are seeing around the globe: more frequent and bigger floods. Yet on smaller streams, we often lack the data needed to provide real-time warnings. The students have not only built a functioning system and an app that notifies experts and the public, but they are also already working to scale this system across their region in consultation with numerous partners.”

Diploma of Excellence – Türkiye

The Diploma of Excellence was awarded to Kagan Mehmet Ozkok from Türkiye for pioneering work that combines AI and

water efficiency. By training artificial intelligence on the sound of leaking water, Ozkok built and deployed two prototypes to detect leaks in public spaces. Tested under real conditions, the prototypes demonstrated significant water savings and are now being developed further in collaboration with local government for possible city-wide implementation.

The Jury stated: “This year’s Diploma of Excellence recognizes how data, AI and action come together. Training AI based on the sound of leaking water, this student has demonstrated a powerful and practical approach to tackling urban water loss.”

People’s Choice Award –United Kingdom

The People’s Choice Award, voted on by the global public, went to Divyasri Kothapalli from the United Kingdom for her project, sun-based water distillation system.

This research project presents the development of a low-cost solar water distillation system designed to improve access to clean drinking water in off-grid and

rural communities. Using a Fresnel lens to focus sunlight onto a metal boiling pot, the resulting steam passes through foodgrade silicone tubing and condenses into clean water. The system operates without electricity, avoiding additional carbon emissions.

Kothapalli conducted three experiments where the independent variables included initial water volume, light intensity, and natural weather conditions. The system produced consistent yields even in moderate climates such as the UK, showing its promise for broader application.

A Year of Flood-Focused Excellence

This year, both Water Prizes highlighted flooding: the Stockholm Junior Water Prize went to German students Niklas Ruf and Jana Spiller for their innovative flood warning system, while the Stockholm Water Prize will be awarded to Austrian professor Günter Blöschl, the world’s leading flood hydrologist. Together, their work underscores the urgency of addressing flood risks – from local innovations to global science.

About the Stockholm Junior Water Prize

The Stockholm Junior Water Prize is an international competition for students between the ages of 15 and 20, encouraging innovative solutions to major water challenges. Every year, thousands of young people from more than 40 countries take part, with the national winners competing in the global final in Stockholm.

The Stockholm Junior Water Prize has been organized annually since 1997. It is hosted by the Stockholm Water Foundation, with Xylem as Founding Partner.

Niklas Ruf and Jana Spiller from Germany received the 2025 Stockholm Junior Water Prize for their scalable flood warning system for small streams. The award was presented by H.R.H. Crown Princess Victoria of Sweden at Stockholm City Hall during World Water Week. Jonas Borg

MASSACHUSETTS INSTITUTE OF TECHNOLOGY (MIT)

Palladium Filters Could Enable Cheaper, More Efficient Generation of Hydrogen Fuel

The novel design allows the membranes to withstand high temperatures when separating hydrogen from gas mixtures.

By Jennifer Chu

Palladium is one of the keys to jumpstarting a hydrogen-based energy economy. The silvery metal is a natural gatekeeper against every gas except hydrogen, which it readily lets through.

Palladium-based membranes are used at commercial scale to provide pure hydrogen for semiconductor manufacturing, food processing, and fertilizer production, among other applications in which the membranes operate at modest temperatures. If palladium membranes get much hotter than around 800 kelvins, they can break down.

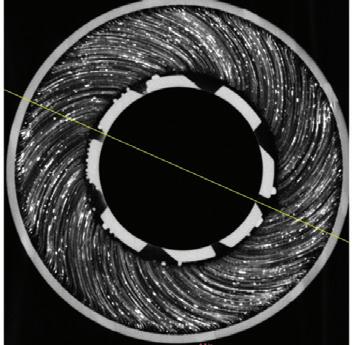

Engineers at MIT have developed a new palladium membrane that remains resilient at much higher temperatures. Rather than being made as a continuous film, the new design is made from palladium that is deposited as “plugs” into the pores of an underlying supporting material. At high temperatures, the snug-fitting plugs remain stable and continue separating out hydrogen, rather than degrading as a surface film would.

The thermally stable design opens opportunities for membranes to be used in hydrogen-fuel-generating technologies such as compact steam methane reforming and ammonia cracking – technologies that are designed to operate at much higher temperatures to produce hydrogen for zero-carbon-emitting fuel and electricity.

“With further work on scaling and validating performance under realistic industrial feeds, the design could represent a promising route toward practical membranes for high-temperature hydrogen production,” said Lohyun Kim PhD ’24, a former graduate student in MIT’s Department of Mechanical Engineering.

Kim and his colleagues report details

of the new membrane in a study appearing in the journal Advanced Functional Materials. The study’s co-authors are Randall Field, director of research at the MIT Energy Initiative (MITEI); former MIT chemical engineering graduate student Chun Man Chow PhD ’23; Rohit Karnik, the Jameel Professor in the Department of Mechanical Engineering at MIT and the director of the Abdul Latif Jameel Water and Food Systems Lab (J-WAFS); and Aaron Persad, a former MIT research scientist in mechanical engineering who is now an assistant professor at the University of Maryland Eastern Shore.

Compact Future

The team’s new design came out of a MITEI project related to fusion energy. Future fusion power plants, such as the one MIT spinout Commonwealth Fusion Systems is designing, will involve circulating hydrogen isotopes of deuterium and tritium at extremely high temperatures to produce energy from the isotopes’ fusing. The reactions inevitably produce other gases that will have to be separated, and the hydrogen isotopes will be recirculated into the main reactor for further fusion.

Similar issues arise in a number of other processes for producing hydrogen, where gases must be separated and recirculated back into a reactor. Concepts for such recirculating systems would require first cooling down the gas before it can pass through hydrogen-separating membranes – an expensive and energy-intensive step that would involve additional machinery and hardware.

“One of the questions we were thinking about is: Can we develop membranes which could be as close to the reactor as possible, and operate at higher temperatures, so we don’t have to pull out the gas and cool it down first?” Karnik said.

The researchers looked for ways to improve the temperature resistance of palladium membranes. Palladium is the most effective metal used today to separate hydrogen from a variety of gas mixtures. It naturally attracts hydrogen molecules (H2) to its surface, where the metal’s electrons interact with and weaken the molecule’s bonds, causing H2 to temporarily break apart into its respective atoms. The individual atoms then diffuse through the metal and join back up on the other side as pure hydrogen.

Plugging In

Karnik, Kim and their colleagues took a different design approach. They observed that at high temperatures, palladium will start to shrink up. This gave the team an idea: If a supporting material’s pores could be “plugged” with deposits of palladium – essentially already forming a droplet with the lowest surface energy – the tight quarters might substantially increase palladium’s heat tolerance while preserving the membrane’s selectivity for hydrogen.

To test this idea, they fabricated small chip-sized samples of membrane using a porous silica supporting layer (each pore measuring about half a micron wide), onto which they deposited a very thin layer of palladium. They applied techniques to essentially grow the palladium into the pores and polished down the surface to remove the palladium layer and leave palladium only inside the pores.

They then placed samples in a custombuilt apparatus in which they flowed hydrogen-containing gas of various mixtures and temperatures to test its separation performance. The membranes remained stable and continued to separate hydrogen from other gases even after experiencing temperatures of up to 1,000 kelvins for over 100 hours – a significant improvement over conventional filmbased membranes.

Illustration of the membrane showing selective permeation of hydrogen (green) from a mixture of hydrogen and helium (blue) gases. Lohyun Kim

These conditions are within the range of hydrogen-generating technologies such as steam methane reforming and ammonia cracking.

Steam methane reforming is an established process that has required complex, energy-intensive systems to preprocess methane to a form where pure hydrogen can be extracted. Such preprocessing steps could be replaced with a compact “membrane reactor,” through which a methane gas would directly flow, and the membrane inside would filter out pure hydrogen.

Ammonia cracking is another way to produce hydrogen, by “cracking” or breaking apart ammonia. As ammonia is very stable in liquid form, scientists envision that it could be used as a carrier for hydrogen and be safely transported to a hydrogen fuel station, where ammonia could be fed into a membrane reactor that again pulls out hydrogen and pumps it directly into a fuel cell vehicle.

This work was supported by Eni S.p.A. via the MIT Energy Initiative.

ARIZONA STATE UNIVERSITY

Student Engineers Join Forces with Kenyan Communities for Clean Water

By Joe Kullman

Driven by the belief that access to clean water and reliable infrastructure can transform lives, Engineers Without Borders USA tackles complex challenges in communities around the world.

Through these efforts, a growing number of Arizona State University students are getting hands-on education in the technological, logistical, organizational and management skills needed to meet such challenges.

Among them are 22 members of the organization’s ASU student chapter who

are helping the East African nation of Kenya provide clean water to the rural village of Naki by designing, testing and implementing a water filtration system, funded in part by donation from ASU’s Change the World initiative and an ASU Global Education Office Go Global grant awarded to the Ira A. Fulton Schools of Engineering.

Over the past several semesters, successive groups of ASU students have contributed to the project in Kenya, a nation of more than 50 million people, each building on the work of the last. Last year, the ASU team helped restore a 20,000-gallon water tank, but after finding the water unsanitary, they developed a water filter using easily accessible materials like sand.

The team’s plans include implementing solar-powered well and rainwater catchment systems over the next two years to provide filtered water to as many as 2,000 people across three communities. A future well project will bring year-round access to clean water for more than 3,000 members of one community.

Engineer Jack Moody, a water resources services leader with Westwood Professional Services in Phoenix, and Jason Reynolds, a project engineer with Jett Civil Engineering based in Scottsdale, Arizona, serve as mentors for the ASU Engineers Without Borders chapter and have been guiding the students on their work for the Kenya project.

Moody pointed to the students’ exemplary work in helping construct a 70,000-liter, in-ground storage tank to collect water from rooftop runoff collection systems, repairing two earthen dams, and building a hydraulics laboratory at the Jaramogi Oginga Odinga University of Science and Technology in Kenya.

Community members in Kenya expressed appreciation for the students’ role

t A team of Arizona State University students poses with a scalable water filtration system they built for a secondary school in Naki, Kenya. The ASU student chapter of Engineers Without Borders, an international community service organization, contributed significantly to the project, along with another vital water infrastructure project in Kenya. Engineering Without Borders, ASU chapter

in strengthening local infrastructure and access to essential resources.

“The collaboration between ASU’s Engineers Without Borders chapter and local communities in Kenya has demonstrated the profound impact of student-led engineering initiatives on global development,” said Noah Okidia, a community volunteer partner in Kenya. “As a volunteer working with the ASU team, I have witnessed firsthand how technical expertise, coupled with cultural exchange and community engagement, can generate lasting solutions. Despite our vastly different cultures, the ASU Engineers Without Borders team has always fit into our communities and carried out their planned projects.”

These pursuits not only expand students’ engineering knowledge and problem-solving skills, but also give valuable experience in working with people from other cultures, said team leaders.

THE UNIVERSITY OF ARIZONA

Researchers Developing Water Reuse Solutions for Military and Civilian Communities

By Leslie Hawthorne Klingler

University of Arizona’s Water and Energy Sustainable Technology Center’s (WEST) expanding partnership with the U.S. Army Engineer Research and Development Center (ERDC) is driving new research on practical water reuse solutions for both military and civilian communities. “Water reuse is, of course, an important response to water scarcity,” said Andrea Achilli, principal investigator for two of the center’s largest current grants, “but we can’t forget it’s also about national security.”

Achilli, associate professor of chemical and environmental engineering, leads the U of A’s work in a four-year, $38M ERDCfunded Water Reuse Consortium – which also includes the University of Southern California and the University of Nevada–Reno. The U of A’s $10M portion of the grant supports research on smart treatment systems, sustainable brine management technologies, and improved virus

detection. It also invests in training and public engagement to encourage wider adoption of water reuse.

In 2024, the U of A and ERDC strengthened ties further by signing an Educational Partnership Agreement, enabling WEST to host postdoctoral researchers at its facilities. The first to participate, Luke Presson – an ORISE scientist with the Army Corps of Engineers – conducts research and connects partners across the Consortium to align its work with military needs. "This partnership shows how the federal government and universities

can work together to advance the research and better the nation. Using both of our strengths we can accomplish so much more than going at it alone. We hope this EPA is an example that we can replicate at other universities," said Nicholas Josefik, Presson’s supervisor at the U.S. Army Engineer Research Development Center.

One area of investigation where Achilli and Presson see big potential benefits is moving communities from massive water and wastewater treatment plants to smaller, mobile and semi-mobile advanced water purification systems. Traditional facilities are costly, built to last decades, and risky to upgrade. In contrast, decentralized systems are easier to adapt. For forward operating military bases, onsite reuse – particularly processes using

only electricity, without chemicals – could reduce the dangers of resupply missions. For civilian communities, these smaller systems would lessen dependence on large, centralized plants that leave entire communities vulnerable if they fail.

These concepts have already been put to the test through an earlier ERDCfunded effort, the ESTCP Demonstration Project. Completed in 2025, the project piloted a semi-portable, containerized advanced water purification unit.

The system performed well during trials at WEST and Tucson’s Tres Rios Water Reclamation Facility, but when deployed to Fort Huachuca it clogged due to excess solids in the water. Presson said the challenge was disappointing, but they were glad it showed up during testing.

“It’s better to find out that the system needs a simple mechanical screen before it’s sent to a forward operating base that’s relying on it to work,” he said. “That’s why what WEST does is so important.”

Andrea Achilli (left) and Luke Presson (right) at the ESTCP Demonstration Project semi-portable, containerized advanced water purification unit.

UNIVERSITY OF CHICAGO

Bio-Inspired Membrane Opens New Possibilities for Water Purification, Extraction

Taking lessons from biology, UChicago researchers develop system that controls chemical transport at atomic scale.

By Paul Dailing

In every living cell, there are membranes – and in every membrane there are proteins, each of which acts as a chemical gatekeeper.

Rather than passively letting ions pass in and out of the cell, these biochemical bouncers control access as needed. They let more of life-sustaining materials like potassium or sodium through the cells’ biological ion channels when the cell needs them but shut off the flow before the chemical concentration gets too high.

“It will advance technology greatly if we can understand ion transport in biological systems and creatively manipulate it in artificial ones,” said Asst. Prof. Chong Liu, of the University of Chicago Pritzker School of Molecular Engineering (UChicago PME).

This is a process biologists have studied and engineers have envied for years. The ability to tune membranes to let more of a material in sometimes and keep them out at other times could revolutionize how people make water safe to drink and remove harmful – or valuable –chemicals from oceans, lakes and rivers.

“Naturally, it becomes of interest to see whether you can build artificial systems that would, in some way or another, mimic those biological properties,” said Northwestern University chemistry Prof. George Schatz.

UChicago PME and Northwestern teams are behind a new paper in Nature Communications that both solved this mystery and revealed new insights into ion transport.

By using advanced simulations, the teams added different amounts of lead, cobalt or barium ions and found they could vastly increase or limit the amount of potassium passing through an artificial membrane – mimicking cells’ abilities to

mind their own biological membranes. Among the team’s more remarkable findings was that just a 1% increase in the presence of lead ions doubled the amount of potassium coming through the channels.

John Zich

“The most exciting part of our research is that we show how dramatically ion transport in angstrom-scale 2D channel can be changed in the presence of other ions, even with a tiny fraction,” said cofirst author Mingzhan Wang, who was a postdoctoral researcher in Liu’s UChicago lab at the time of the research and is now a research assistant professor at City University Hong Kong.

The research represents an advance in pure science, helping physicists and biologists understand better why ions and cells behave the way they do.

Opening the Door

Ion transport channels are exactly what they sound like – tunnels for ions.

In cells, these nanoscale tunnels run through the cell membranes; in devices, through plastic filters or other membranes. Positive charged potassium plods slowly through the negatively charged tunnel used in the present study, while negative charged chloride, ions containing the element chlorine, zip past.

Wang and Liu conceived the project and connected with Schatz through the Argonne-led Advanced Materials for Energy-Water Systems Center, which also funded the research. The mechanism behind it was not clear until co-first author Qinsi Xiong, a research associate in Schatz’s theoretical group, built an entirely new model from the ground up – in Schatz’s words, “from scratch.”

“We designed a non-equilibrium molecular dynamics simulation to incorporate an ion-induced dipole interaction and simulate ion transport through this 2D nanochannel,” Xiong said. “Our results aligned well with the experiments, suggesting that the physics we included were on the right track.”

Ions have either a positive or a negative charge, which means that any charged at-

t Researchers led by UChicago Pritzker School of Molecular Engineering Asst. Prof. Chong Liu and Northwestern University Prof. George Schatz have developed a tunable system that mimics cells’ abilities to mind their own biological membranes.

oms or molecules in the ion channel walls will push or pull on the travelers.

But when lead ions are added, those ions bond to acetate groups in the tunnel walls. The positively charged lead ions pull on the negatively charged chloride – not enough to stop the chlorides, just to slow them down to the potassium ions’ speed.

Once the chlorides and potassium ions are moving through the tunnel at the same rate, they form potassium chloride pairs. These are neutrally charged and so flow unimpeded through the channel, increasing the amount of potassium coming through the membrane.

“There’s nothing charged that it wants to interact with, and so that makes it so that the new molecule can flow through quicker than would occur if the two ions were just separately flowing through the channel,” Schatz said.

Cutting Off the Flow

The team also discovered an inhibitory effect, meaning a way to limit rather than enhance the potassium flowing through the channels. When they added small amounts of cobalt or barium ions, those metallic ions competed with lead ions for spots where they could bond to the acetate groups in the tunnel walls. This limits the effect of lead on these ions, and at the same time, reduces formation of neutral ion pair that would otherwise enhance transport.

The next steps for the research include seeing what other materials than lead can generate this effect, and if it can be expanded to control the flow of elements rather than potassium. One target would be lithium, valued for its use in batteries but currently harvested from water through environmentally damaging methods.

Funding: This work is supported by Advanced Materials for Energy-WaterSystems (AMEWS) Center, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences.

October 27-29, 2026

Minneapolis Convention Center Minneapolis, Minnesota

Step Into the Spotlight at FiltXPO™ 2026

FiltXPO™ 2026 is where breakthrough filtration technologies, industry leaders, and new business opportunities converge.

Whether you’re looking to showcase your innovations or discover the next big thing, FiltXPO is where filtration moves forward.

Why Exhibit at FiltXPO?

Grow your business by connecting with decision-makers across diverse industries who are actively sourcing advanced filtration and separation solutions.

• Engage with 1,200+ filtration professionals from around the world

• Expand your North American market reach

• Generate leads across high-impact sectors, including:

• Automotive & Aerospace

• Biotech & Pharmaceuticals

• Food & Beverage Production

• HVAC & Indoor Air Quality

• Water & Wastewater Treatment

• Power Generation, Oil & Gas, and more

Minneapolis offers direct flights from major international and domestic cities, making it the ideal location to meet top-tier prospects.

Reserve your space on the show floor today and make your mark at FiltXPO 2026.

INNOVATION IN ACTION Filtration for Today ... and tomorrow

Filtration industry companies are investing in research and development to bring new ideas to the world for enhanced filtration solutions. Innovation requires intentional changes to generate long-term social and environmental benefits and improve the quality of solutions.

Innovations range from efficiency and effectiveness in design, durability and attributes, to responsible sourcing with materials that are bio-based or feedstocks that draw on regenerative, and/or sustainable agriculture principles to advance circularity; to advancements that extend product life, and more. Needless to say, the supply chain is changing, and offering up new and improved solutions.

We asked companies to submit their most recent advancements and we are pleased to highlight the following companies and their achievements.

COMPILED BY CARYN SMITH, CHIEF CONTENT OFFICER & PUBLISHER, IFN

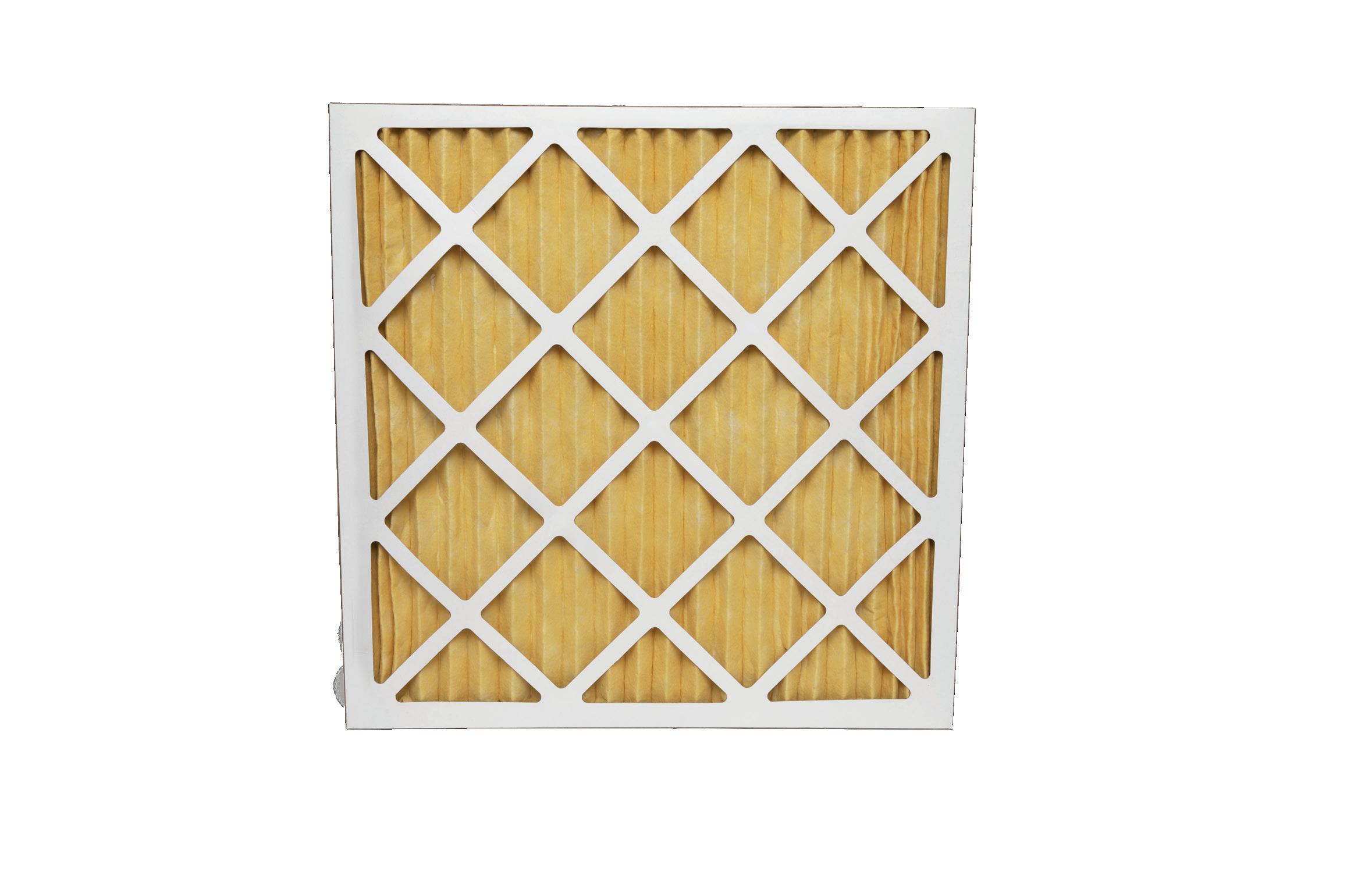

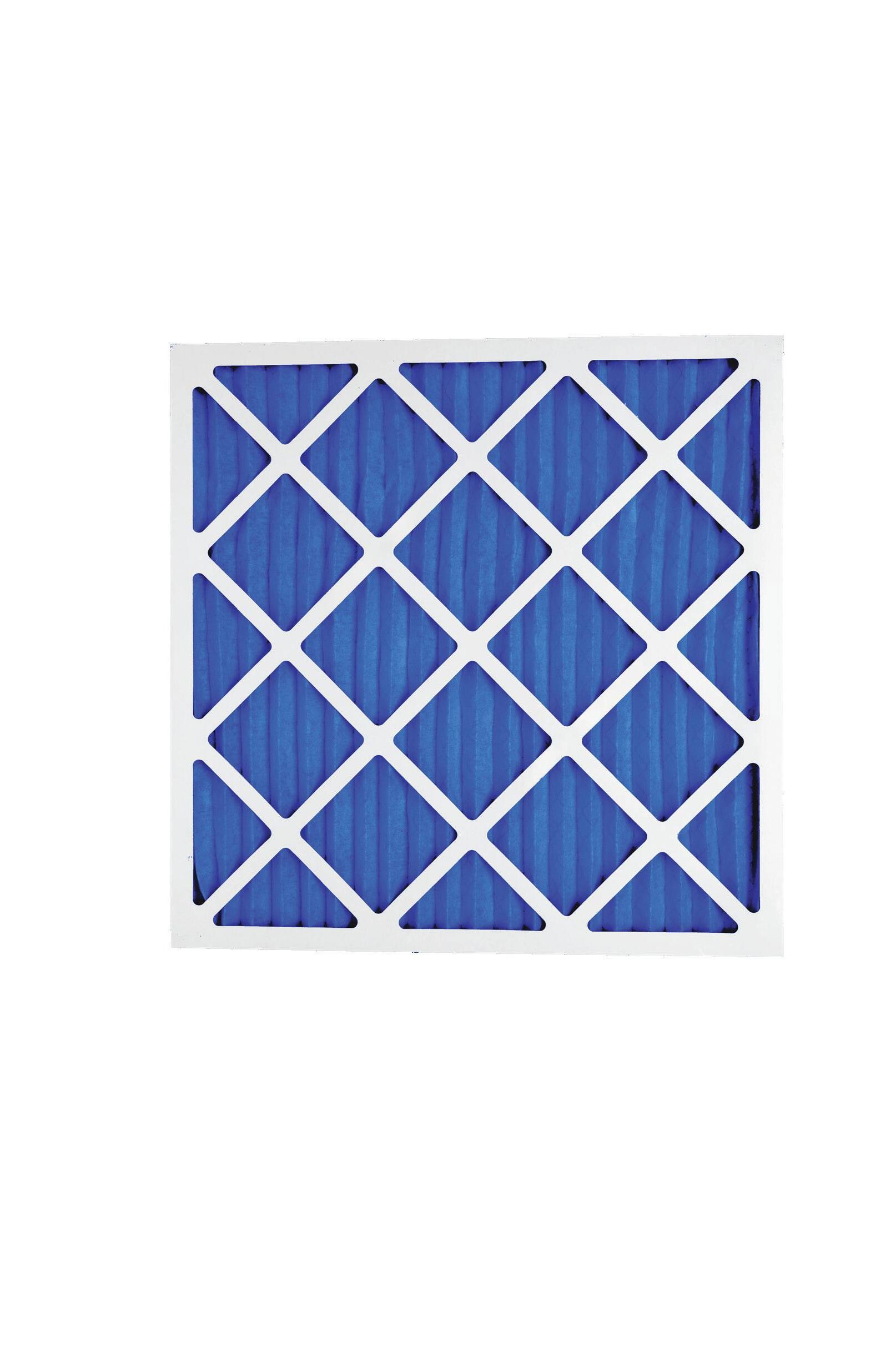

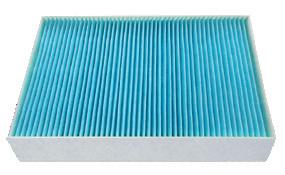

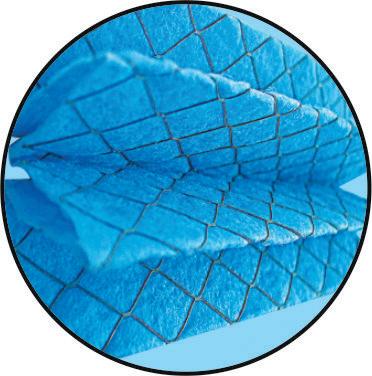

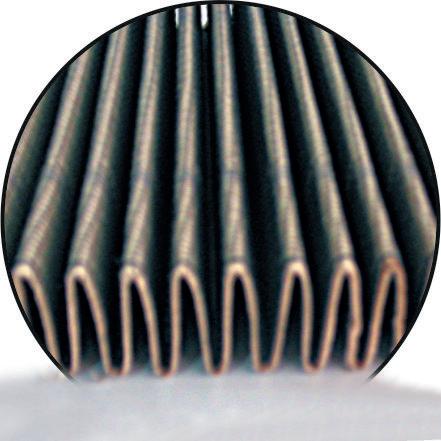

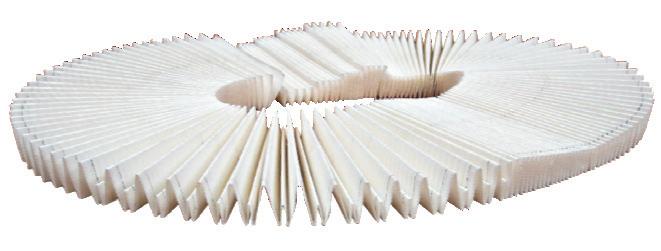

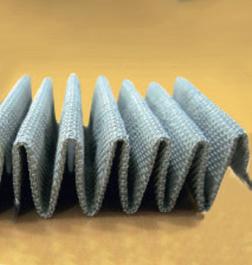

A Unique Solution to the Die Cut Problem in HVAC Filters

The HVAC filter industry has long relied on die cut frames to meet the diverse needs of customers. These filters are available in a wide range of sizes and variants, tailored for specific applications across residential, commercial, and industrial environments.

However, this very diversity creates significant challenges for filter manufacturers.

The Manufacturing Challenge

Producing HVAC filters with die cut frames involves:

• Managing a large variety of die cuts to match product dimensions.

• Printing unique branding and specifications for each size.

• Carrying high inventory costs for die cut frames.

• Coping with long changeover times on the shop floor.

• Coordinating multiple independent processes such as frame making, pleating, assembly, and packing – each of which creates additional inventory, manpower needs, and risks of rejection.

• Relying on a large workforce to keep production running smoothly.

In short, the traditional approach is labor-intensive, costly, and inflexible.

What Manufacturers Want

Filter producers have been clear about their needs. They are looking for:

• Higher productivity

• Minimal human intervention

• Quick changeovers and greater flexibility

• The ability to cover a wide size range (10” to 30” filters, pleat heights of 1”, 2”, and 4”)

• Compatibility with both laminated wire-backed media and self-supported media

• A cost-effective solution that reduces waste and improves efficiency

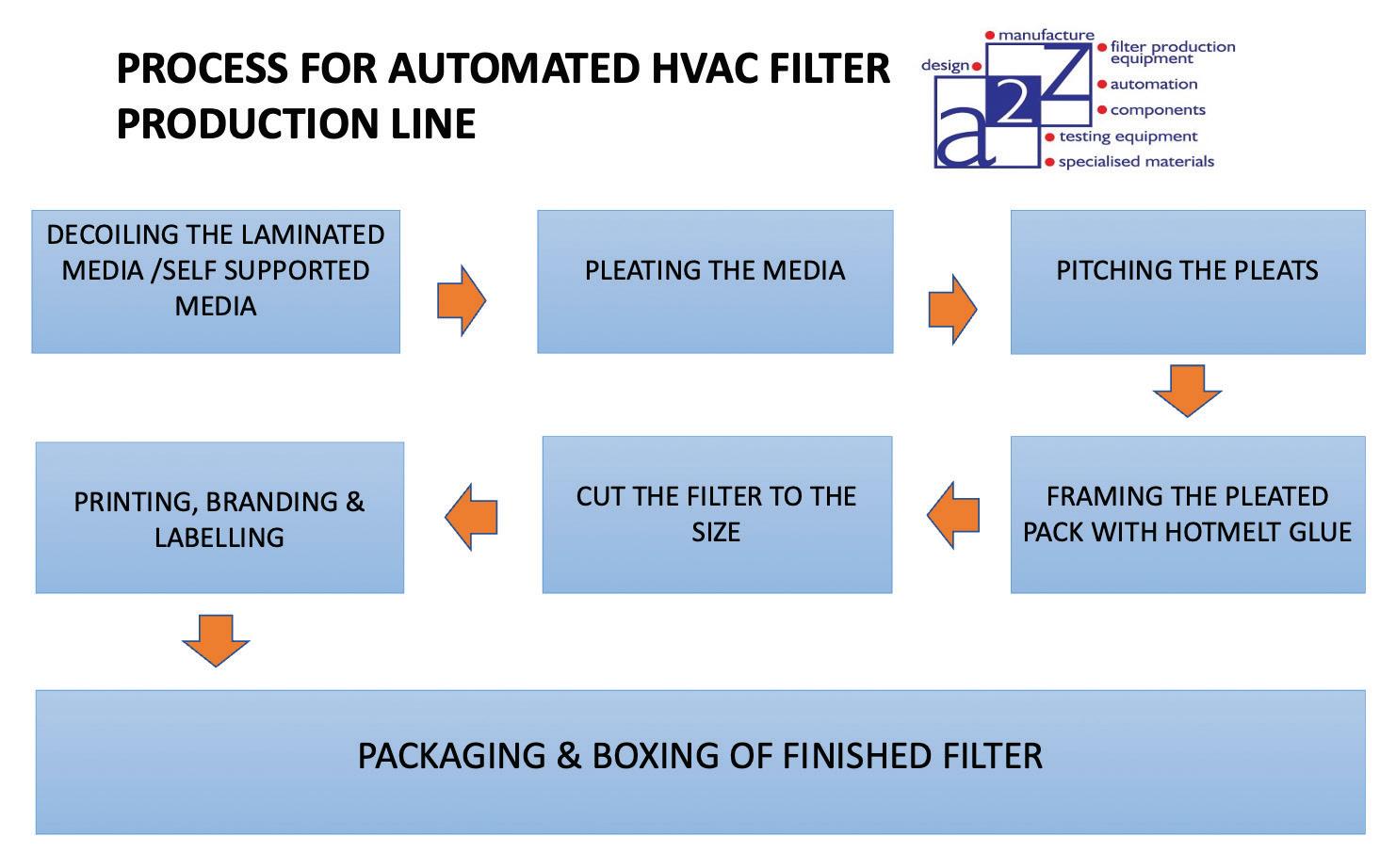

A2Z’s Solution: The HVAC Production Line

Recognizing these challenges, A2Z’s design and product development team set out to reimagine the process. The result is a fit-to-purpose production line that combines flexibility, efficiency, and cost-effectiveness

– the A2Z HVAC Production Line

This innovative system streamlines filter manufacturing with just three inputs:

1. Filter media

2. Side frame and top/bottom band material in rolls

3. Hotmelt glue

With this simplified approach, manufacturers gain full flexibility to produce a wide range of filters without the burden of managing hundreds of die cut variants.

The A2Z HVAC Production Line: A Streamlined Workflow

The production process is designed to minimize complexity while maximizing efficiency. Starting with laminated or self-supported media, the system automates pleating, framing, cutting, assembly, and finishing – all the way to boxing the final product.

A Smarter Way Forward

The HVAC industry is under constant pressure to balance customer expectations with operational efficiency. With the A2Z HVAC Production Line, filter manufacturers finally have a solution that addresses both – reducing costs, streamlining workflows, and empowering them to adapt quickly to market needs.

In an industry where flexibility is key, A2Z has delivered a unique, cost-effective, and efficient solution to the age-old die cut problem.

For further information, please visit

• Our website – www.a2zfiltration.com

• Or contact us at corporate@a2zfiltration.com

Automated HVAC Filter Production Line – From media decoiling to packing, the process ensures precision, reduced labor, and consistency across every filter produced.

Redefining Filtration Intelligence: FA-TCO Software Evolves with Real-Time IoT Monitoring

and ASHRAE 52.2-Standardized Performance

In an industry where assumptions still guide filter replacement and performance expectations, FA-

TCO Software continues to redefine HVAC filtration management through standards-based intelligence and real-world data. Recognized as a 2025 FiltXPO™ Awards finalist, the software has now taken a major leap forward by integrating real-time IoT monitoring across pressure, flow, and particle metrics – closing the gap between theoretical performance and field reality.

FA-TCO is the result of over 35 years of technical development, built on a foundation of engineering excellence from the Universidad Simón Bolívar (USB) in Venezuela, with a track record of innovation in the oil & gas sector. This expertise later expanded into the U.S. filtration industry, contributing to cutting-edge advances in media formation and filter manufacturing technologies. Together, this dual legacy shaped a solution that bridges scientific rigor with industrial practicality.

From the beginning, FA-TCO has championed ASHRAE 52.2 as the cornerstone standard. Now in 2025, it enhances this commitment with embedded IoT sensors that bring continuous visibility into how filters perform – not just in the lab, but inside real HVAC systems.

The upgraded monitoring suite includes:

• Differential pressure sensors to detect clogging, bypass, or early degradation across filter stages.

• Airflow sensors to track actual system flow and fuel accurate TCO calculations.

• Particle matter sensors (PM1, PM2.5, PM10)

positioned after filtration, to monitor the true quality of air returning to occupied spaces.

This comprehensive monitoring architecture enables filter manufacturers, distributors, and facility managers to move from assumptions to measurable performance. FA-TCO now delivers live validation of filtration effectiveness, revealing trends in filter efficiency, early warning signs of failure, and IAQ results that matter.

Complementing this real-time view is a curated filter database – where each product is benchmarked against ASHRAE 52.2 test data at 492 CFM, ensuring every comparison is grounded in independent labtested values. This alignment enables users to detect performance gaps between certified expectations and real-world results, improving both decision-making and accountability.

Crucially, FA-TCO is not just about cost optimization. By focusing on air quality at the output of the filtration system, it guarantees that clean air is not only intended but delivered. This positions FA-TCO as both a TCO management engine and an IAQ assurance tool.

As environmental and performance standards grow more demanding, the HVAC industry faces increasing pressure to evolve. FA-TCO answers that call, empowering the sector to adopt data-driven filtration strategies that reduce waste, control energy use, and verify air quality with confidence.

Smart filtration is no longer optional. With FA-TCO, it’s measurable.

https://www.filtrationadvice.com

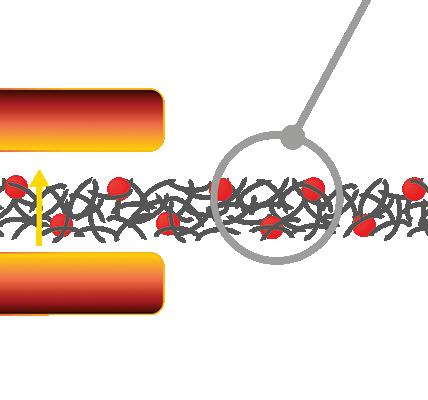

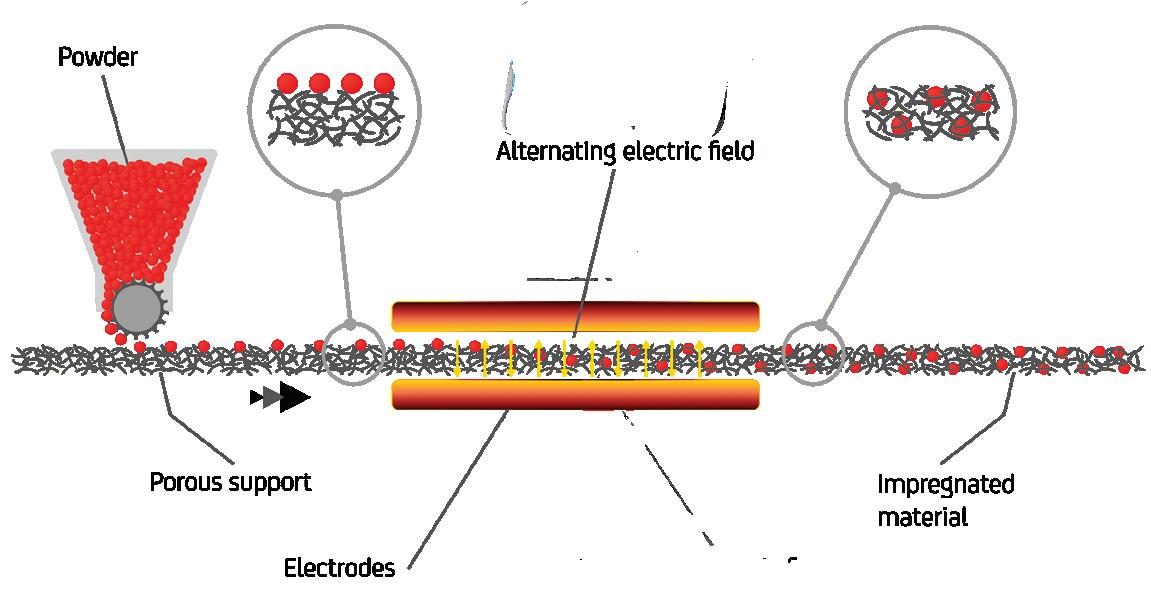

Next-Generation Filtration: Fibroline’s Expertise in MOF Functionalization

Fibroline is an engineering company based out of Lyon, France. With more than 50 patents worldwide, it is a world leader of ecofriendly impregnation technologies. It also has an innovation lab in the United States, in North Carolina. The company has developed dry powder impregnation solutions: this process uses high intensity alternating electric fields to enable the distribution of any form of powders into porous structures. Fibroline’s R&D team has unique know-how with dedicated knowledge for various sectors such as medical, filtration, composites or technical yarns.

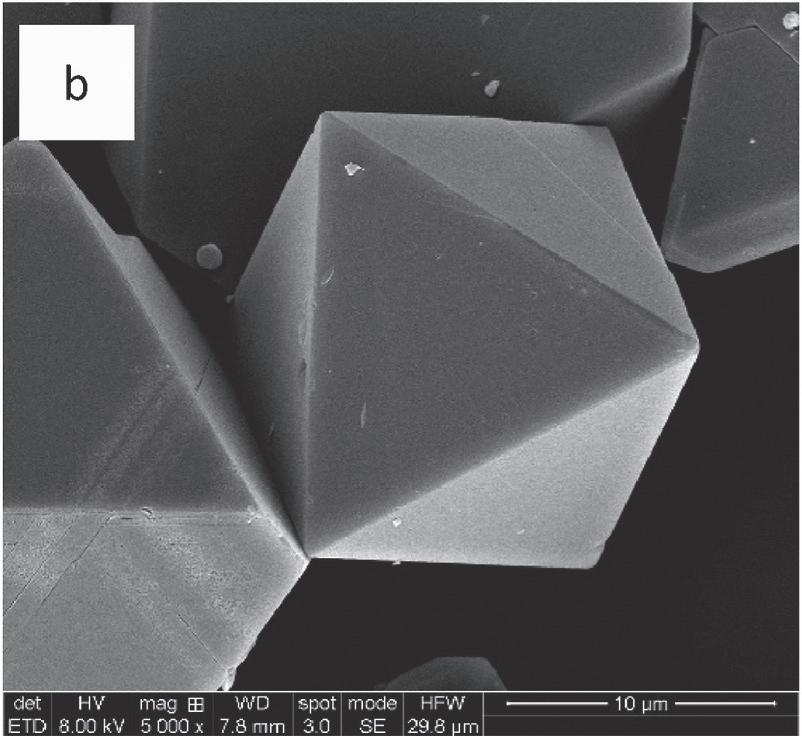

In the filtration sector specifically, Fibroline has jumped on the emergence of a new material; Metal Organic Frameworks or MOFs. These are powders of controlled geometries composed of metal centers connected by organic linkers. They have a very large specific surface area (1700m2/g for MOF HKUST-1 for instance), extra-high porosity and highly adjustable pore size from microporous (< 2nm) to mesoporous (2-50nm).

These unique properties render them promising candidates for various high-tech applications: water treatment, gas adsorption, catalysis, drug delivery, dehumidification, etc. They are in fact created to target specific molecules: each MOF has a different structure for this purpose. The capacity of MOFs to pick molecules out is a real advantage in comparison to activated carbons, which are much less selective and therefore quickly oversaturated. MOFs can also realize several adsorption-desorption cycles: thanks to this, the media they are a part of does not require frequent replacement, thus increasing product lifetime.

Fibroline’s technologies are particularly suitable for the impregnation of MOFs to develop functionalized filter media. Indeed, by nature dry impregnation does not require any liquid binder, which results in the elimination of the clogging effect. Thanks to this, the active in powder form is made fully available and it all results in much higher overall efficiency of the impregnated products.

Fibroline has continuously grown its own expertise with these materials, and has developed impregnation processes for various types of MOFs. The company has worked on different types of filtration systems using MOFs such as carbon capture, gases capture, odor adsorption, and water depollution.

Fibroline has notably taken a significant part in large project involving several companies to develop several types of products. This project focuses first on a medical application to impregnate MOF for the capture of organosulfur gases present in ostomy pouches. It also aims to develop a military application with the impregnation of MOFs into foams, which will then become CBRN-suits’ linings, in order to capture war gases espe-

This illustrates the principle behind Fibroline’s technology, using alternating electric fields to impregnate materials.

cially organophosphorus gases such as sarin gas. These improvements lead to better protection for soldiers on the battlefield from all these risks.

For both of these products, present-day solutions use activated carbon. As mentioned earlier, activated carbon molecules are not as selective as MOFs. The use of MOFs-based solutions as those developed by Fibroline aims at greatly improving these products’ performances, and the results of these developments tend to prove the efficiency of MOFs compared to activated carbons.

This project highlighted significant number of potential applications for MOFs. There are indeed plenty of other topics to be explored for further developments. With the research on MOFs continuously growing, other innovations are to be expected. There will be opportunities for Fibroline to hop on, based on its unique technology and its expertise acquired over the years. https://www.fibroline.com

This picture depicts the HKUST-1 MOF, used for the capture of organosulfur gases.

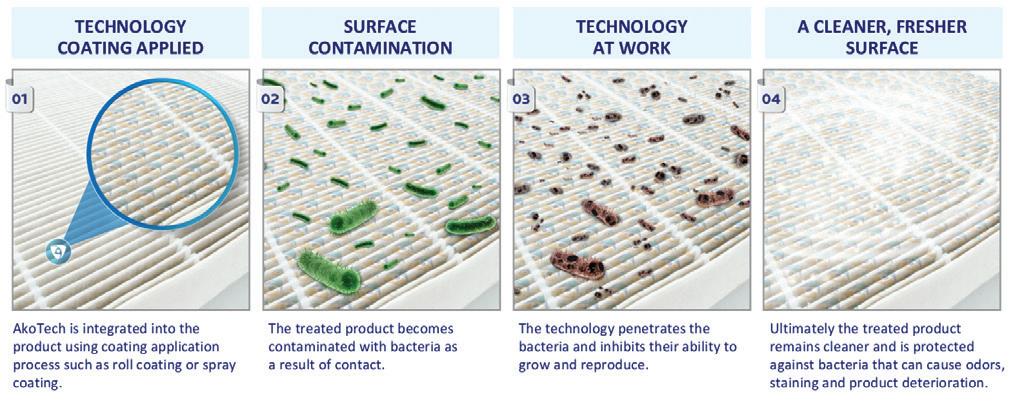

Greentech Unveils 2025 HEPA Media with Embedded ODOGard® Technology: Revolutionizing

Clean Air Through Molecular Odor Elimination