Industrial Automation

IMI Norgren

AMT Rail Dryer

World Leading Technology for Compressed Air Applications

Breakthrough engineering for a better world

IMI Norgren

AMT Rail Dryer

World Leading Technology for Compressed Air Applications

Breakthrough engineering for a better world

We create solutions for our customers which enable smarter, safer, more productive and sustainable factories, production lines and warehouse operations. Our pneumatic and electric motion systems help machine builders and end users around the world automate and optimise manufacturing and warehousing processes.

We have partnered with customers in industrial automation for over a century, applying our experience and innovation to create lasting value for their businesses. Our solutions support critical industries such as automotive, food and beverage, pharmaceuticals and even the space industry. We support the automation of precision manufacturing, product assembly, testing and packaging.

We use the latest digital technologies in our automation products and constantly innovate in close partnership with our customers. By applying our deep expertise, we can solve their toughest automation challenges, today and tomorrow. Through increased productivity, efficiency and safety, our customers can serve their own customers better, creating sustainable competitive advantage and delivering growth.

Our world-class product portfolio includes IMI Norgren, IMI Bimba, IMI Bahr and IMI Buschjost.

Breakthrough engineering you can count on. NOTE:

The safe, cost-effective and trouble-free operation of so many critical rail applications depends on a reliable supply of clean, dry compressed air, free from moisture and contaminants.

Compressors, generally mounted underneath the body of the train, draw in large volumes of air from the surrounding atmosphere. This air typically contains water vapour and airborne contaminants. As the air is compressed, vapour and contaminants are heated up and compacted. After subsequent cooling by an after-cooler, water vapour condenses within the air system to form liquid.

With oil-lubricated compressors, the lubricating oil degrades with the heat of compression and combines with the condensing liquid to form acid condensate of varying viscosities.

Dryers and filters are used to remove this wet and dirty ‘liquid emulsion’ before it reaches downstream applications, such as door and brake systems, where it can cause erosion, corrosion, reduced performance, costly maintenance and safety implications – all of which affect the quality of rail service.

Historically there has been 2 types of compressed air dryers used in rail applications. These are desiccant dryers and membrane dryers. They offer different approaches to the issue of removing moisture and contaminants from the air.

• Collect and absorb water using special canisters filled with beads, held together with a clay substance

• The beads absorb moisture and contaminants from the air, so dry air flows out to the vehicle

• However, vibration can cause the beads to rub together, producing dust that contaminates the air

• As the beads erode their efficiency and performance is reduced, and the pressure drop can increase

• Over time the substance in the canister can become over saturated, and a chemical reaction causes irreparable damage to the beads, which means they cannot be used again

Each technology has its strengths, but it’s also acknowledged that neither option currently offers a wholly satisfactory or reliable solution

• Use special fibre tubes suspended between two potted ends to form a semi-permeable membrane

• Water vapour passes through the membrane wall via plasmolysis and is swept into a small vent, which releases it back into the atmosphere

• Contamination, such as oil, can clog and damage the fibres, causing them to break

• Membrane dryer fibres are delicate and can be easily damaged or broken in harsh applications

• If one fibre breaks, the others usually follow shortly after, causing a catastrophic failure

Working closely with customers in the rail industry, we understand the need for robust, durable solutions that improve reliability, increase energy efficiency and reduce weight, emissions and downtime.

Our patented IMI Norgren Adsorbent Media Tube (AMT) technology takes the best of the current desiccant and membrane systems, and eradicates the flaws associated with their short lifecycles, and the costs of regular replacement.

• Service life up to 10 years (30,000 hrs) (supported by actual installations in various rail environments)

• Compact and flexible design, horizontally or vertically mounted

• Typical dew point suppression of 40°C (up to 70°C available on request)

• Superior moisture uptake

• Energy efficient (low pressure drop)

• Unaffected by water saturation

• Faster regeneration

• Resistant to vibration

• No by-products produced e.g dust

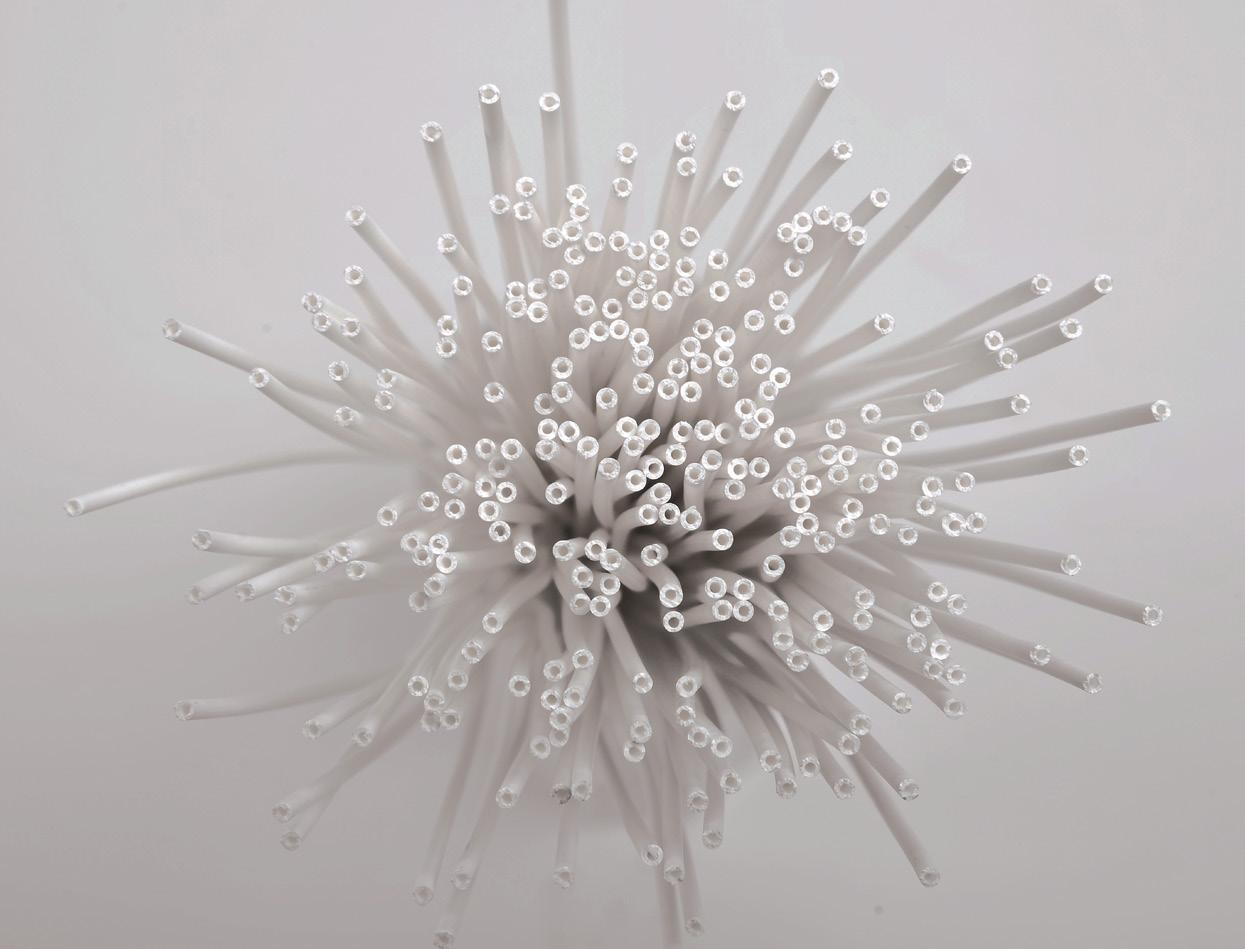

The AMT air dryer system uses Adsorbent Media Tube (AMT) technology.

Not to be confused with semi permeable membranes, AMT is totally resistant to bulk water and there’s no by-product or chemical reaction when saturated.

The open structure of the AMT allows maximum surface area for moist air to permeate, compared with the clay binder found in a regular desiccant dryer allowing faster adsorption and a more efficient drying performance.

AMT is tightly packed into a canister, where their uniform shape means they are unaffected by the vibration of rolling stock. This ensures a consistent flow of air through the dryer with minimal drop in pressure.

The AMT’s performance does not degrade over time, and as there’s no clay component, there’s no dust – a huge advantage over desiccant air dryer solutions.

The key features of AMT patented technology

• Adsorbent material packaged into a tube structure

• Unaffected by water saturation, whereas conventional clay beads dissolve if contaminated by bulk water

• Improved moisture uptake compared with standard beaded technology

• Independently validated for rail use

• Compact and lightweight design

• Flexible installation orientation (vertical or horizontal)

• Low lifecycle costs

• Fit and forget up to 10 years*

• Moisture uptake on AMT tubes is much faster than standard beaded technology (less energy required to regenerate)

• Can be completely saturated with moisture and recover to original performance levels

• Does not generate dust unlike desiccant beads (no post filter required)

• Test point fitted as standard

• Options include heaters, dew point sensing, pressure sensing and rock guards

* Providing required filter maintenance is followed

Anodised Aluminium Manifolds

Optional Rock & Side Guard (protects valves)

Anodised High Tensile Aluminium Extrusion (packed with AMT)

Integrated Control Valves with optional heater

Pre-wired electrical connector

Performance

• Air dryer service intervals: 30,000 operating hours (10 year service intervals)

• Significant weight reduction compared with conventional dryer

• Reduced pressure drop across the dryers

• Reduced air purge requirement

• Total flexibility in mounting orientation – horizontal or vertical

• Robust and durable

• Dryer performance is not affected by orientation

• Dryer performance is not affected by shock and vibration

• Operating pressure range: 6 bar (72 psig) to 12 bar (188 psig)

• Ambient operating temperature range: -40°C to +80°C (-40°F to 176°F)

• Typical dew point suppression: 40°C (104°F)

Standard Description

EN61373: 2010 Shock and Vibration Category 1 Class B

MIL-STD-810G: 2008 Shock and Vibration Category 11, Fig 514.7C

EN45545-2: 2013 Fire protection on Railway Vehicles

NFPA 130, 49 CFR: 2007 Fire and Smoke

EN50155: 2007

> EN60068-2-1

> EN60068-2-2

> EN60068-2-30

Electronic Equipment used on Rolling Stock

Test A Cold Temperature

-50°C, 80cc/min external leakage @ 10 bar

-20°C, 10cc/min external leakage @ 10 bar

Test B Dry Heat

+80°C, 10cc/min external leakage @ 10 bar

Damp Heat, Cyclic

+55°C, @ 95% RH. 10cc/min external leakage @ 10 bar

Electromagnetic Compatibility

EN ISO 9227: 2012 Salt Spray Test to 1000 hrs

EN 60529: 2013 Ingress protection to IP65

N/A

N/A

Low Temperature Park Test (7 day @ -50°C)

Life cycle 30,000 hours of compressor flow

Compressed air travels through the high efficiency filtration system where particles, bulk water and oil are removed from the air before it reaches the AMT dryer itself, which is then free to remove the water vapour for an extended period of time.

The IMI Norgren AMT dryer system is a complete air filtration and drying solution designed for the harsh environment of the global rail industry.

water and oil 40 micron 5 micron

Capable of operating within a range of -40°C to +80°C, the full system consists of:

• 40 micron and 5 micron filters for bulk water and solid particulate removal

• Coalescing filter for oil/water aerosol removal and sub micron particulate removal

• 2, 3 and 4 stage filtration options available depending on incoming air quality

We help you achieve your goals by working with you as a partner, not just a supplier. Our dedicated rail team is connected worldwide to ensure close, continuous support no matter what the size and extent of your organisation. We have the reach and capability to work alongside you on complex, global projects or to simply offer local spare part supply.

We work closely with our customers to achieve tailored solutions. During development and testing, the focus is placed on designing products that can withstand anticipated loads and consistently perform their tasks. It is this thorough and detailed testing and validation in accordance with the relevant standards that reduces early failure of components. In addition, a comprehensive valuation under realistic conditions helps avoid high consequential costs caused by failures of components in the end application.

Complete product testing and valuation is done in our state of the art testing centres.

The laboratories have an extensive range of test equipment, operated by a neutral expert team working independently of the development departments. Their experience and expertise enables quick implementation of tests, the design of test programs tailored to the needs of real applications and operating conditions in the various sectors, and a guarantee of the neutrality and accuracy of test results.

We have extensive experience in the field of environmental simulation, with a focus on climate, temperature, thermal shock, corrosion, vibration and mechanical shock.

Prototyping and material laboratories are additional, important resources that contribute to our targeted and rapid product development.

Specific tests we undertake for the rail sector include:

• EN 45545

• EN 50155

• EN 50121-3-2

• DIN 5510-2

• EN 61373

• NFPA 130

• EN 60068

• ISO 9227

We help you achieve your goals by working with you as a partner, not just a supplier. Our dedicated rail team is connected worldwide to ensure close, continuous support no matter what the size and extent of your organisation. We have the reach and capability to work alongside you on complex, global projects or to simply offer local spare part supply.

Across manufacturing, sales, innovation centres and offices

Africa

Our Industrial Automation sector operates four global centres of technical excellence and a sales and service network in 50 countries, as well as manufacturing capability in Europe, Americas and Asia Pacific.

Supported by distributors worldwide.

For further information, scan this QR code or visit www.imiplc.com/industrial-automation

The information in this brochure is provided for informational and promotional purposes only and is provided “as is” and without warranties of any kind, whether express or implied, including but not limited to implied warranties of satisfactory quality, fitness for a particular purpose and/ or correctness.

Any specifications, features, pricing, or availability contained in this brochure are subject to change without prior notice. IMI plc does not represent or warrant that the information and/or specification in this brochure are accurate, complete, or current and therefore make no warranties or representation regarding the use of the content. IMI plc or one of its subsidiaries own all images, logos, product brands, and trademarks mentioned in this brochure. Unauthorised use, reproductions, or modification of this content is prohibited.

© Copyright IMI plc. All rights reserved. z10458BR en/12/25

Selected Images used under license from Shutterstock.com