SYMBOLS > DESCRIPTION > DESCRIPTION

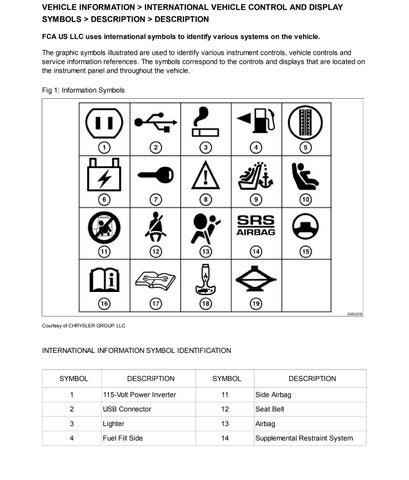

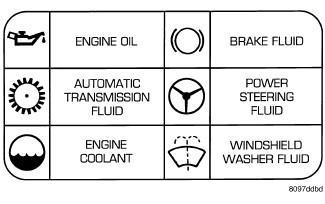

FCA US LLC uses international symbols to identify various systems on the vehicle.

The graphic symbols illustrated are used to identify various instrument controls, vehicle controls and service information references. The symbols correspond to the controls and displays that are located on the instrument panel and throughout the vehicle.

Courtesy of CHRYSLER GROUP, LLC

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

5Spare Tire Winch 15Power Steering Fluid

6Fuse 16See Owner's Manual

7Key Activate (Power Outlet)17 See Appropriate Service Information

8Warning 18Emergency Release Handle

9Child Seat Tether Anchor 19Jack/Jack Tools Location

10 Lower Anchors and Tether for Children (Latch)

Courtesy of CHRYSLER GROUP, LLC

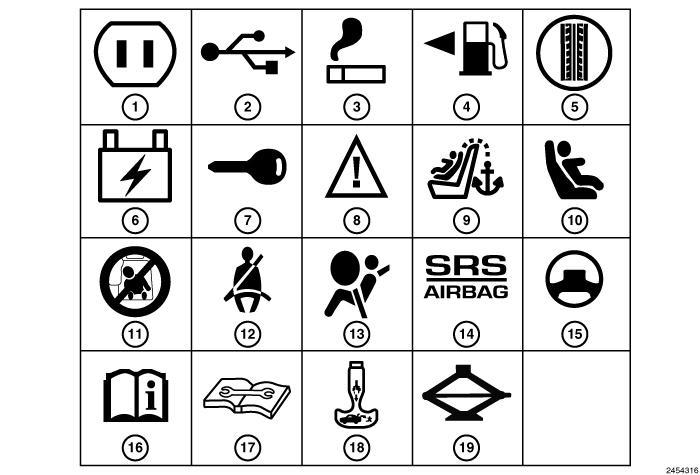

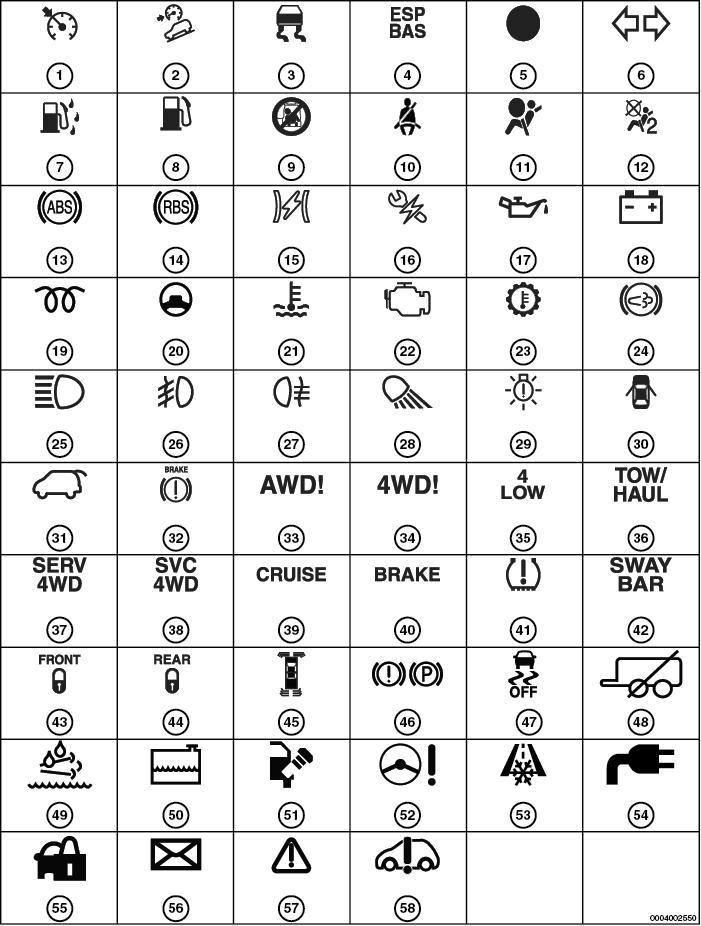

INTERNATIONAL INDICATOR SYMBOL IDENTIFICATION

SYMBOLDESCRIPTIONSYMBOLDESCRIPTION

1Electronic Speed Control30Door Ajar

SYMBOLDESCRIPTIONSYMBOLDESCRIPTIONSYMBOLDESCRIPTION

23Ventilated Seat50Trunk/Deck Release77Axle Lock Button

24Recirculation51Door Ajar78Traction Control Off

25 Heated Steering Wheel 52Liftgate Release79 Electronic Stability Control Off

26 Passenger Air Bag Off 53Sliding Door 80Trailer Brakes

27 Electronic Speed Control 54Sliding Door

VEHICLE INFORMATION > INTERNATIONAL VEHICLE CONTROL AND DISPLAY SYMBOLS > DESCRIPTION > DESCRIPTION > ENGINE COMPARTMENT

The graphic symbols illustrated are used to identify engine compartment lubricant and fluid inspection and fill locations. The symbols correspond to the caps located within the engine compartment.

VEHICLE INFORMATION > LABEL, VEHICLE EMISSION CERTIFICATION

INFORMATION (VECI) > DESCRIPTION > DESCRIPTION

NOTE:

The Vehicle Emission Control Information (VECI) label(s) must be in place for the life of the vehicle. When replacing the component in which the VECI label is adhered, a new VECI

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

label must also be adhered to the new component.

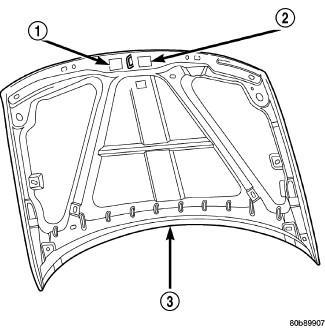

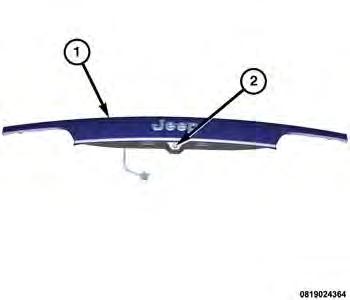

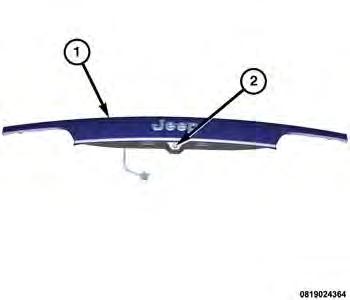

All vehicles are equipped with a combined VECI label(s). The label is located in the engine compartment on the vehicle hood. Two labels are used for vehicles built for sale in the country of Canada.

The VECI label(s) contain the following:

Engine family and displacement

Evaporative family

Certification application

Spark plug and gap

VEHICLE INFORMATION > VEHICLE CERTIFICATION LABEL > DESCRIPTION >

DESCRIPTION

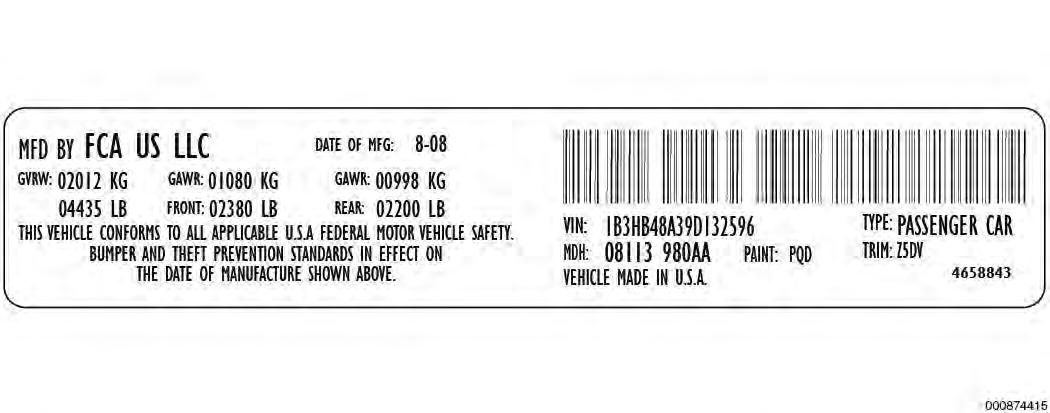

1: Vehicle Certification Label - Typical

A vehicle certification label is attached to every FCA US LLC vehicle. The label certifies that the vehicle conforms to all applicable Federal Motor Vehicle Standards. The label also lists:

Month and year of vehicle manufacture.

Gross Vehicle Weight Rating (GVWR). The gross front and rear axle weight ratings (GAWR's) are based on a minimum rim size and maximum cold tire inflation pressure.

Vehicle Identification Number (VIN).

Type of vehicle.

Type of rear wheels.

Bar code.

Month, Day and Hour (MDH) of final assembly.

Paint and Trim codes.

Country of origin.

The label is located on the driver-side door shut-face.

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION > DESCRIPTION

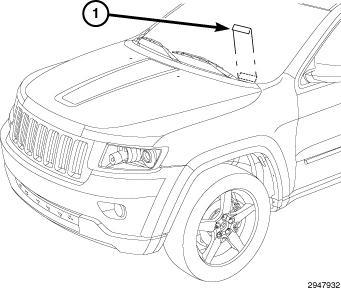

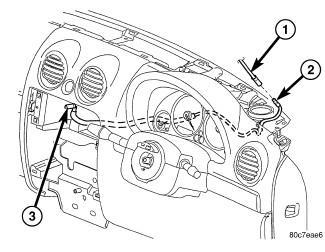

1: Vehicle Identification Number (VIN) Label

Courtesy of CHRYSLER GROUP, LLC

The Vehicle Identification Number (VIN) label (1) is attached to the top left side of the instrument panel. The VIN contains 17 characters that provide data concerning the vehicle. Refer to the decoding chart below to determine the identification of a vehicle.

To protect the consumer from theft and possible fraud the manufacturer is required to include a Check

Digit at the ninth position of the Vehicle Identification Number. The check digit is used by the manufacturer and government agencies to verify the authenticity of the vehicle and official documentation. The formula to use the check digit is not released to the general public.

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION >

DESCRIPTION > POSITIONS 1 - 3: WORLD MANUFACTURER IDENTIFIER

MANUFACTURER VEHICLE TYPE 1C4 Chrysler Group LLC (USA) MPV

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION >

DESCRIPTION > POSITION 4: BRAKE SYSTEM & GVWR

Brake System

PoundsKilograms

GVWR RangeActive Belts, Air Bags Active Belts, Air Bags, Side Bags-Front Row Active Belts, Air Bags, Side Bags-All Rows Active Belts, No Air Bags Active Belts, GVWR > 10, 000 lbs.

Hydraulic6001 - 7000 (2722 - 3175 KG) CJR--

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION > DESCRIPTION > POSITIONS 5 - 7:

Define the following: Brand, Marketing Name, Drive Wheels, Cab/Body Type, Drive Position, and Price Series.

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION >

DESCRIPTION > POSITION 8: ENGINE

CodeDisplacementCylindersFuelTurboSales Codes

M3.0 Liter6DieselYesEXF

83.0 Liter6GasolineNoEHD

G3.6 Liter6GasolineNoERB

T5.7 Liter8GasolineNoEZH

J6.4 Liter8GasolineNoESG

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION >

DESCRIPTION > POSITION 9: CHECK DIGIT

0 through 9 or X

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION >

DESCRIPTION > POSITION 10: MODEL YEAR

G = 2016

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION > DESCRIPTION > POSITION 11: ASSEMBLY PLANT Code Plant C Jefferson North Assembly

VEHICLE INFORMATION > VEHICLE IDENTIFICATION NUMBER > DESCRIPTION > DESCRIPTION > POSITION 12 - 17: PLANT SEQUENCE NUMBER

A six digit number assigned by assembly plant.

Cooling System

Engine Coolant (3.0L Diesel Engines)

Engine Coolant (3.0L/3.6L Gas Engines)

We recommend you use MOPAR® Antifreeze/Coolant 10 Year/150, 000 Mile Formula OAT (Organic Additive Technology).

We recommend you use MOPAR® Antifreeze/Coolant 10 Year/150, 000 Mile Formula OAT (Organic Additive Technology).

Engine Coolant (5.7L Engines without Trailer Tow Package)

Engine Coolant (5.7L Engines with Trailer Tow Package)

We recommend you use MOPAR® Antifreeze/Coolant 10 Year/150, 000 Mile Formula OAT (Organic Additive Technology).

We recommend you use MOPAR® Antifreeze/Coolant 10 Year/150, 000 Mile Formula OAT (Organic Additive Technology).

We recommend you use MOPAR® Antifreeze/Coolant 10

Engine Coolant (6.4L Engines)

Year/150, 000 Mile Formula OAT (Organic Additive Technology) hat meets the requirements of Material Standard MS.90032.

Engine Oil with Filter

Engine Oil (3.0L Diesel Engine)

Engine Oil (3.0L/3.6L Gas Engine- Domestic/Non-ACEA)

We recommend you use SAE 5W-30 Synthetic Low Ash Engine Oil meeting he requirements of Material Standard MS-11106 or 9.55535- S3 and approved ACEA C3 such as MOPAR or equivalent.

We recommend you use API Certified SAE 0W-20 Engine Oil, meeing the requirements of Material Standard MS-6395 such as MOPAR, Pennzoil, and Shell Helix. Refer to your engine oil filler cap for correct SAE grade.

8 Quarts 7.7 Liters

6 Quarts 5.6 Liters

Engine Oil (3.0L/3.6L Gas Engine- ACEA Categories)

Engine Oil (5.7L EngineDomestic/Non-ACEA)

We recommend you use API Certified SAE 0W-20 engine oil, meeting the requirements of Material Standard MS-6395 or 9.55535-CR1. Refer to your engine oil filler cap for the correct SAE grade.

We recommend you use API Certified SAE 5W-20 Engine Oil, meeing the requirements of Material Standard MS-6395 such as MOPAR, Pennzoil, and Shell Helix. Refer to your engine oil filler cap for correct SAE grade.

Engine Oil (5.7L Engine - ACEA Categories)

We recommend you use API Certified SAE 5W-20 engine oil, meeting the requirements of Material Standard MS-6395 or

6 Quarts 5.6 Liters

7 Quarts 6.6 Liters

7 Quarts 6.6 Liters

Engine Oil (6.4L Engine) Domestic and Export

9.55535-CR1. Refer to your engine oil filler cap for the correct SAE grade.

For best performance and maximum protection under all types of operating conditions, the manufacturer only recommends full synthetic engine oils that meet the American Petroleum Institute (API) categories of SN. The manufacturer recommends the use of Pennzoil Ultra 0W-40 or equivalent MOPAR engine oil meeting the requirements of Material Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter (3.0L Diesel Engine)

Engine Oil Filter (3.0L/3.6L Gas Engine)

Engine Oil Filter (5.7L/6.4L Engine)

We recommend you use MOPAR Engine Oil Filter or equivalent.

We recommend you use MOPAR Engine Oil Filter or equivalent.

We recommend you use MOPAR Engine Oil Filter or equivalent.

Diesel Fuel Filter

Fuel (approximate)

We recommend you use MOPAR Fuel Filter. Must meet 3 micron rating. Using a fuel filter hat does not meet the manufacturers filtration and water separating requirements can severely impact fuel system life and reliability.

Fuel Selection (3.0L Diesel Engine)

Use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle with Ultra Low Sulfur Highway Diesel fuel (15 ppm Sulfur maximum) and prohibits the use of Low Sulfur Highway Diesel fuel (500 ppm Sulfur maximum) to avoid damage to the emissions control system. For most year-round service, No. 2 diesel fuel meeting ASTM specification D-975 Grade S15 will provide good performance. We recommend you use a blend of up to 5% biodiesel, meeting ASTM specification D-975 with your diesel engine. This vehicle is compatible with biodiesel blends greater than 5% but no greater than 20% biodiesel meeting ASTM specification D-7467 provided the shortened maintenance intervals are followed as directed.

NOTE:

If the vehicle is exposed to extreme cold (below 20°F or -7°C), or is required to operate at colderthan-normal conditions for prolonged periods, use climatized No. 2 diesel fuel or dilute the No. 2 diesel fuel with 50% No. 1 diesel fuel. This will provide better protection from fuel gelling

24.6 Gallons 93.1 Liters

or wax-plugging of the fuel filters.

Fuel Selection (3.0L Diesel Engine - Europe)

Fuel Selection (3.0L/3.6L Gas Engine)

Fuel Selection (3.6L Gas EngineEurope)

50 Cetane or higher (Less than 10 ppm Sulfur)

24.6 Gallons93 Liters

87 Octane, 0-15% Ethanol.25 Gallons94 Liters

Minimum 91 Octane25 Gallons94 Liters

Fuel Selection (3.0L/ 3.6L Gas Engine) Flexible Fuel Ethanol E85 (ASTM D5798)25 Gallons94 Liters

Fuel Selection (5.7L Engine)

Fuel Selection (5.7L EngineEurope)

Fuel Selection (6.4L Engine)

Diesel Exhaust Fluid (DEF)

A/C Refrigerant System

89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

Minimum 91 Octane Acceptable - 95 Octane Recommended

Premium Unleaded 91 Octane Only or Higher, 0-15% Ethanol.

MOPAR Diesel Exhaust Fluid (API Certified) (DEF) or equivalent that has been API Certified to the ISO 22241 standard. Use of fluids not API Certified to ISO 22241 may result in system damage.

25 Gallons94 Liters

25 Gallons94 Liters

25 Gallons94 Liters

8 Gallons30.3 Liters

A/C RefrigerantR-134a1.375 Pounds623.7 Grams

(1)

System fill capacity includes heater and coolant recovery bottle filled to MAX level.

(2) (3)

SAE 5W-30 engine oil approved to 9.55535 may be used when SAE 5W-20 engine oil is not available

MOPAR® SAE 5W-30 engine oil approved to MS-6395 such as Pennzoil® or Shell Helix® may be used when SAE 5W-20 engine oil meeting MS-6395 is not available.

Vehicles equipped with a 5.7L engine must use SAE 5W-20 oil. Failure to do so may result in improper operation of the Fuel Saver Technology.

CAUTION:

Nominal refill capacities are shown. A variation may be observed from vehicle to vehicle due to manufacturing tolerance and refill procedure.

SPARK PLUGS

DescriptionType

Spark Plugs (3.0L/3.6L Engine)

Spark Plugs (5.7L Engine)

Spark Plugs (6.4L Engine)

TRANSMISSION Description

We recommend you use MOPAR® Spark Plugs. 0043 in 1.10 mm

We recommend you use MOPAR® Spark Plugs. 0043 in 1.10 mm

We recommend you use MOPAR® Spark Plugs. 0043 in 1.10 mm

HP45 - 8 Speed

Use only Mopar® ZF 8&9 Speed ATF™ Automatic Transmission Fluid or equivalent. Failure to use the 8.98 Quarts 8.5 Liters

HP70 - 8 Speed

correct fluid may affect the function or performance of your transmission.

Use only Mopar® ZF 8&9 Speed ATF™ Automatic Transmission Fluid or equivalent. Failure to use the correct fluid may affect the function or performance of your transmission. 8.77 Quarts8.3 Liters

* Dry fill capacity. Depending on type and size of internal cooler, length and inside diameter of cooler lines, or use of an auxiliary cooler, these figures may vary. Refer to the appropriate service information for the correct procedures.

CAUTION:

Nominal refill capacities are shown. A variation may be observed from vehicle to vehicle due to manufacturing tolerance and refill procedure.

TRANSFER CASE DescriptionType

MP2010

MP3010

MP3023

CAUTION:

We recommend you use Automatic Transmission Fluid 3353.

Liters

MOPAR® ATF+4 Automatic Transmission Fluid 1.4 Quarts 1.35 Liters

MOPAR® ATF+4 Automatic Transmission Fluid 2.0 Quarts 1.9 Liters

Nominal refill capacities are shown. A variation may be observed from vehicle to vehicle due to manufacturing tolerance and refill procedure.

CHASSIS

Axles (Front)

195FIA FE - Front Axle

Axles (Rear)

195RIA - Rear Axle (Aluminum)

230RIA With Electronic Limited-Slip Differential (ELSD)-Rear Axle (Aluminum)

230RIA Without Electronic Limited-Slip Differential (ELSD) - Rear Axle (Aluminum)

Chassis Systems

Brake Master Cylinder

We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE 75W-85. 0.9 Quarts 0.8 Liters

We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE 75W-85. 1.0 Quarts 0.9 Liters

We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE 75W-85 with friction modifier additive. 1.4 Quarts 1.3 Liters

We recommend you use MOPAR GL-5 Synthetic Axle Lubricant SAE 75W-85. 1.2 Quarts 1.1 Liters

We recommend you use MOPAR DOT 3 Brake Fluid, SAE J1703 should be used. If DOT 3, SAE J1703 brake fluid is not available, hen DOT 4 is

acceptable.

Power Steering Reservoir (Belt Driven Pump)

Power Steering Reservoir (Electric Pump)

(1) (1)

MOPAR® Power Steering Fluid +4

MOPAR® Hydraulic Fluid meeting the requirements of Material Standard MS-11655

N/A

N/A

N/A

N/A

If MOPAR® Power Steering Fluid +4 is not available, then MOPAR® ATF +4 Automatic Transmission Fluid, is acceptable.

CAUTION:

There is an Electro-Hydraulic Power Steering (EHPS) pump on some vehicles requiring a different fluid. Do not mix power steering fluid types. Damage may result to the power steering pump and system if any other fluid is used. The mechanical power steering pump systems on this vehicle require the use of Power Steering Fluid +4, which meets material specification MS-9602 or equivalent. The EHPS system uses fluid which meets material specification MS-11655 or equivalent. Do not overfill.

CAUTION:

Nominal refill capacities are shown. A variation may be observed from vehicle to vehicle due to manufacturing tolerance and refill procedure.

FUSE - RELAY LOCATIONS AND TYPES > SPECIFICATIONS > SPECIFICATIONS

NOTE:

Refer to the appropriate Wiring Application for Relay description and location information.

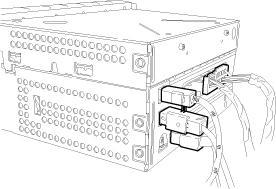

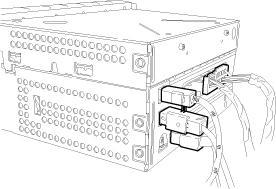

The Power Distribution Center is located in the engine compartment near he battery. This center contains cartridge fuses, micro fuses, relays, and circuit breakers. A description of each fuse and component may be stamped on the inside cover, otherwise the cavity number of each fuse is stamped on he inside cover that corresponds to the following chart.

POWER DISTRIBUTION CENTER

CavityCartridge FuseMicro FuseDescription

F0360 Amp Yellow-Radiator Fan

F0540 Amp Green-Compressor for Air Suspension - If Equipped

F0640 Amp Green-Anti-lock Brakes/Electronic Stability Control Pump

F0730 Amp Pink-Starter Solenoid

F0930 Amp Pink- Diesel Fuel Heater (Diesel engine only) / Brake Vacuum Pump

F1040 Amp Green-Body Controller / Exterior Lighting #2

F1130 Amp Pink-Trailer Tow Electric Brake - If Equipped

F1240 Amp Green-Body Controller #3 / Power Locks

F1340 Amp Green-Blower Motor Front

F1440 Amp Green-Body Controller #4 / Exterior Lighting #1

F1730 Amp Pink-Headlamp Washer- If Equipped

F1920 Amp Blue-Headrest Solenoid- If Equipped

F2030 Amp Pink-Passenger Door Module

F2220 Amp Blue-Engine Control Module

F2330 Amp Pink-Interior Lights #1

F2430 Amp Pink-Driver Door Module

F2530 Amp Pink-Front Wipers

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

F26 30 Amp Pink -Anti-lock Brakes/Stability Control Module/Valves

F2820 Amp Blue-Trailer Tow Backup Lights - If Equipped

F2920 Amp Blue-Trailer Tow Parking Lights - If Equipped

F3030 Amp Pink-Trailer Tow Receptacle - If Equipped

F3230 Amp Pink-Drive Train Control Module

F3430 Amp Pink-Slip Differential Control

F3530 Amp Pink-Sunroof - If Equipped

F3630 Amp Pink-Rear Defroster

F3725 Amp Clear-Rear Blower Motor - If Equipped

F3830 Amp Pink-Power Inverter 115V AC - If Equipped

F3930 Amp Pink-Power Liftgate - If Equipped

F40-10 Amp RedDaytime Running Lights/Headlamp Leveling

F42-20 Amp YellowHorn

F44-10 Amp RedDiagnostic Port

F49-10 Amp RedIntegrated Central Stack / Climate Control

F50-20 Amp YellowAir Suspension Control Module - If Equipped

F51-15 Amp Blue Igniion Node Module / Keyless Ignition / Steering Column Lock

F52-5 Amp TanBattery Sensor

F53-20 Amp Yellow Trailer Tow - Left Turn/Stop Lights - If Equipped

F56-15 Amp BlueAdditional Content (Diesel engine only)

F57-20 Amp YellowNOX Sensor

F58-15 Amp BlueHID Headlamps LH - If Equipped

F59-10 Amp RedPurging Pump (Diesel engine only)

F60-15 Amp BlueTransmission Control Module

F61-10 Amp Red Transmission Control Module/PM Sensor (Diesel engine only)

F62-10 Amp RedAir Conditioning Clutch

F63-20 Amp YellowIgniion Coils (Gas), Urea Heater (Diesel)

F64-25 Amp ClearFuel Injectors / Powertrain

F66-10 Amp Red Sunroof / Passenger Window Switches / Rain Sensor

F67-15 Amp Blue CD / DVD / Bluetooth Hands-free Module - If Equipped

F68-20 Amp YellowRear Wiper Motor

F69-15 Amp BlueSpotlight Feed - If Equipped

F70-20 Amp YellowFuel Pump Motor

F71-30 Amp GreenAudio Amplifier

F72-10 Amp RedPCM (If Equipped)

F73-15 Amp BlueHID Headlamp RH - If Equipped

F75-10 Amp RedDual Batt Control (If Equipped)

F76-10 Amp RedAnti-lock Brakes/Electronic Stability Control

F77-10 Amp Red Drivetrain Control Module/Front Axle Disconnect Module

F78-10 Amp Red Engine Control Module / Electric Power Steering

F80-10 Amp Red Universal Garage Door Opener / Compass / Anti-Intrusion Module

F81-20 Amp YellowTrailer Tow Right Turn/Stop Lights

F82-10 Amp Red Steering Column Control Module/ Cruise Control / DTV

F83-10 Amp RedFuel Door

F84-15 Amp BlueSwitch Bank/Instrument Cluster

F85 - 10 Amp RedAirbag Module

F86 - 10 Amp RedAirbag Module

F87 - 10 Amp Red Air Suspension - If Equipped / Trailer Tow / Steering Column Control Module

F88 - 15 Amp BlueInstrument Panel Cluster

F90/F91 - 20 Amp YellowPower Outlet (Rear seats) Selectable

F92 - 10 Amp RedRear Console Lamp - If Equipped

F93 - 20 Amp YellowCigar Lighter

F94 - 10 Amp RedShifter / Transfer Case Module

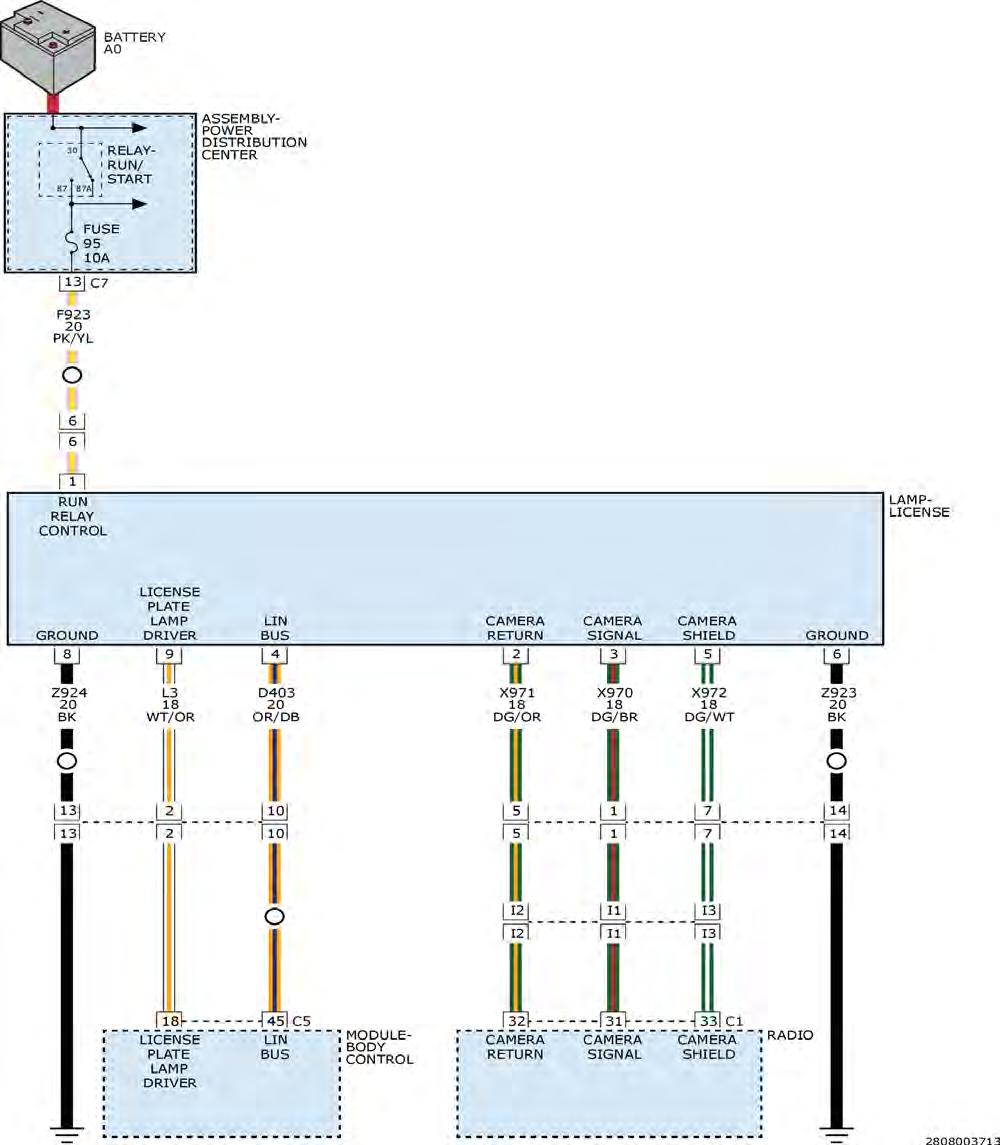

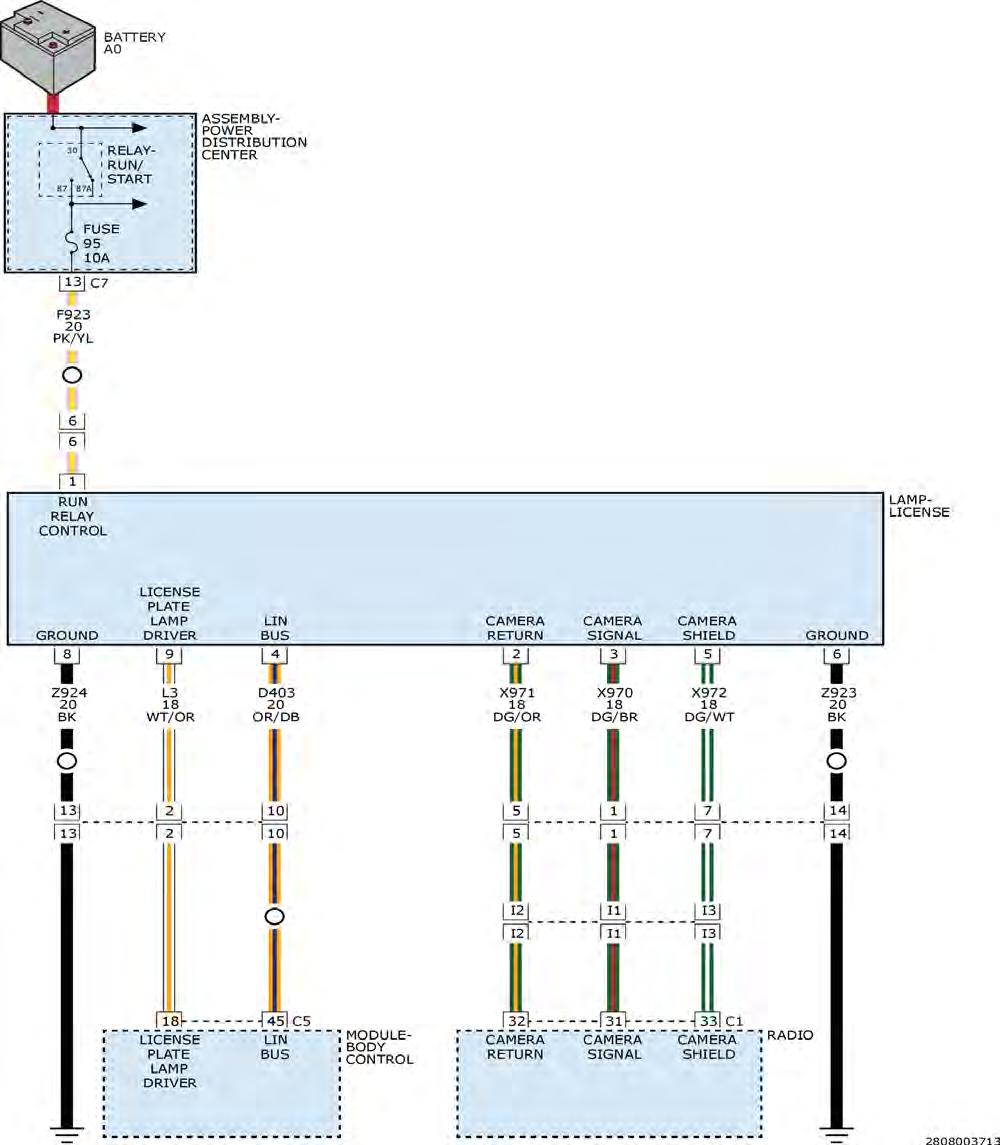

F95 - 10 Amp RedRear Camera / ParkSense

F96 - 10 Amp Red Rear Seat Heater Switch / Flashlamp Charger - If Equipped

F97 - 20 Amp Yellow Rear Heated Seats & Heated Steering Wheel - If Equipped

F98 - 20 Amp YellowFront Heated Seats - If Equipped

F99 - 10 Amp Red Climate Control / Driver Assistance Systems Module / DSRC

F100 - 10 Amp RedActive Damping - If Equipped

F101 - 15 Amp Blue Electrochromatic Mirror/Smart High BeamsIf Equipped

F103 - 10 Amp Red Cabin Heater (Diesel Engine Only)/Rear HVAC

F104 - 20 Amp Yellow Power Outlets (Instrument Panel/Center Console)

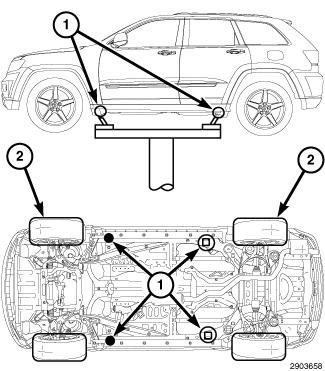

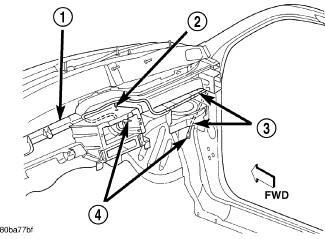

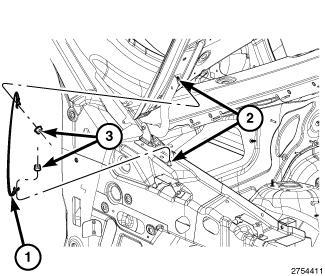

HOISTING > STANDARD PROCEDURE > STANDARD PROCEDURE - JACKING AND HOISTING LIFT POINTS

Courtesy of CHRYSLER GROUP, LLC

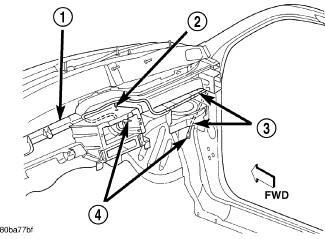

1 - FLOOR JACK, VEHICLE EMERGENCY JACK

1 - CHASSIS LIFT (DUAL POST)

1 - OUTBOARD LIFT (DUAL LIFT)

2 - DRIVE ON HOIST

Refer to Owner's Manual provided with vehicle for proper emergency jacking procedures.

WARNING:

The hoisting and jack lifting points provided are for a complete vehicle. When the engine or rear suspension is removed from a vehicle, the center of gravity is altered making some hoisting conditions unstable. Properly support or secure vehicle to hoisting device when these conditions exist. Failure to follow these instructions may result in personal injury or death.

WARNING:

Support the vehicle by supplemental means before performing any work on the air suspension system to prevent the vehicle from changing height. Before any given component is to be serviced it must be deflated. Servicing the air suspension system without supplemental su pport, or with pressure in the specific component, can cause possible serious or fatal injury.

NOTE:

The air suspension system will auto-disable when lifted on a frame hoist, or when jacking one corner of the vehicle. The air suspension may attempt to change height slightly prior to switching to auto-disable. A manual disable is also available by pressing the "Up" and "Down" switches of the terrain select switch simultaneously for more that 5 seconds. The air suspension system will return to normal operation when the vehicle speed reaches 25 kph (15 mph).

When properly positioned, a floor jack can be used to lift the vehicle and support the raised vehicle with jack stands.

A floor jack or any lifting device, must never be used on any part of the underbody other then the described areas.

CAUTION:

Do not attempt to lift a vehicle with a floor jack positioned under:

Aluminum differential.

A body side sill.

A steering linkage component.

A drive shaft.

The engine or transmission oil pan.

The fuel tank.

JUMP STARTING > STANDARD PROCEDURE > STANDARD PROCEDURE - JUMP STARTING

WARNING:

Review all safety precautions and warnings in the Battery System Service Information. Refer to BATTERY SYSTEM - SERVICE INFORMATION .

Do not jump start a frozen battery, personal injury can result.

If equipped, do not jump start when maintenance free battery indicator dot is yellow or bright color.

Do not jump start a vehicle when the battery fluid is below the top of lead plates.

Do not allow jumper cable clamps to touch each other when connected to a booster source.

Do not use open flame near battery.

Remove metallic jewelry worn on hands or wrists to avoid injury by accidental arcing of battery current.

When using a high output boosting device, do not allow battery voltage to exceed 16 volts. Refer to instructions provided with device being used.

Failure to follow these instructions may result in personal injury or death.

CAUTION:

When using another vehicle as a booster, do not allow vehicles to touch. Electrical systems can be damaged on either vehicle.

JUMP STARTING > STANDARD PROCEDURE > STANDARD PROCEDURE - JUMP STARTING > TO JUMP START A DISABLED VEHICLE:

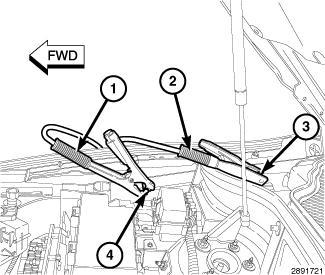

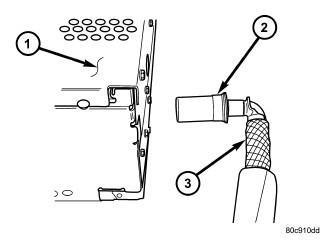

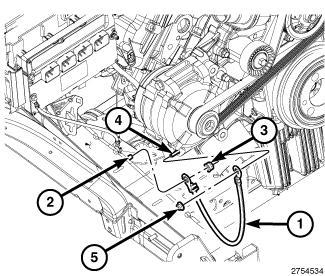

Courtesy of CHRYSLER GROUP, LLC

On the disabled vehicle, remove the battery compartment lid from under the passenger seat and inspect the battery.

1.

Inspect the battery cable terminal clamps for damage. Replace any battery cable that has a damaged or deformed terminal clamp.

2.

3.

Inspect the battery tray and battery hold down hardware for damage. Replace any damaged parts.

Slide the thermal guard off of the battery case, if equipped. Inspect he battery case for cracks or other damage that could result in electrolyte leaks. Also, check the battery terminal posts for looseness. Batteries with damaged cases or loose terminal posts must be replaced.

4.

5.

Inspect the battery thermal guard for tears, cracks, deformation or oher damage. Replace any battery thermal guard that has been damaged.

Inspect the battery built-in test indicator sight glass (if equipped) for an indicaion of the battery condiion. If the battery is discharged, charge as required. Refer to BATTERY, AGM, STANDARD PROCEDURE .

2.

Raise hood on disabled vehicle and visually inspect engine compartment for: Generator drive belt condition and tension. 1.

CAUTION:

If the cause of starting problem on disabled vehicle is severe, damage to booster vehicle charging system can result.

3.

When using another vehicle as a booster source, park he booster vehicle within cable reach. Turn off all accessories, set the parking brake, place the automatic transmission in PARK or the manual transmission in NEUTRAL and turn the ignition OFF.

On disabled vehicle, place gear selector in park or neutral and set park brake. Turn off all accessories. 4.

5.

Connect jumper cables to booster battery. RED clamp to positive terminal (+). BLACK clamp to negative terminal (-). DO NOT allow clamps at opposite end of cables to touch, electrical arc will result. Review all warnings in this procedure.

6.

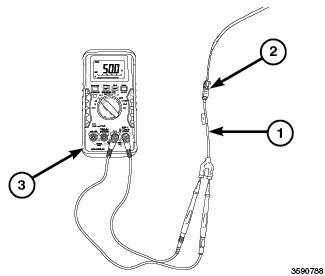

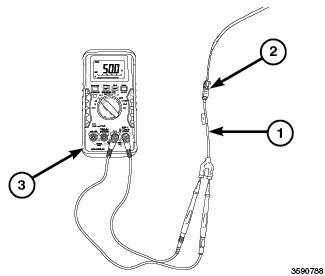

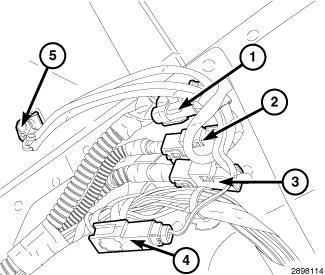

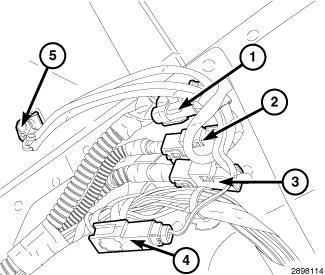

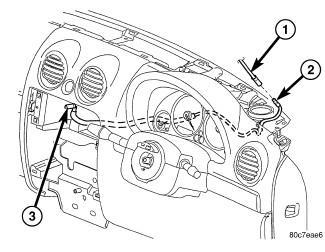

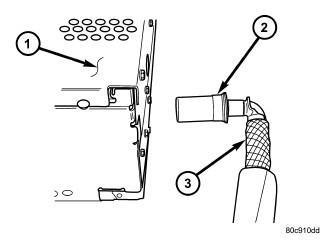

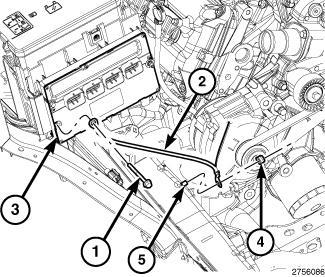

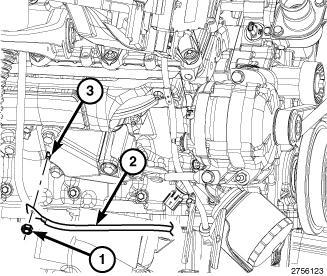

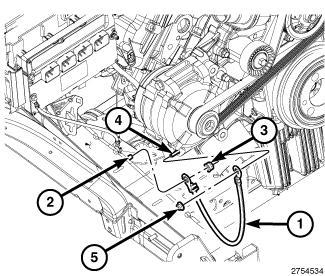

On the disabled vehicle, pull up and remove the protective cover over the remote positive (+) battery post (3).

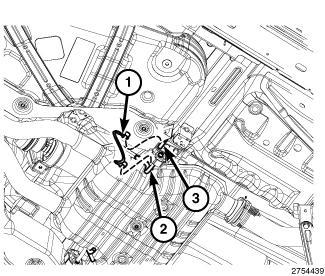

Connect he RED jumper cable clamp (2) to positive (+) terminal (3). Connect BLACK jumper cable clamp (1) to engine ground (1). 7.

8.

Start the engine in the vehicle which has the booster battery, let the engine idle a few minutes, then start the engine in the vehicle with the discharged battery.

9.

CAUTION:

Do not crank starter motor on disabled vehicle for more than 15 seconds, starter will overheat and could fail.

Allow battery in disabled vehicle to charge to at least 12.4 volts (75% charge) before attempting to start engine. If engine does not start within 15 seconds, stop cranking engine and allow starter to cool (15 min.), before cranking again.

JUMP STARTING > STANDARD PROCEDURE > STANDARD PROCEDURE - JUMP STARTING > DISCONNECT CABLE CLAMPS AS FOLLOWS:

Disconnect BLACK cable clamp (1) from engine ground on disabled vehicle.

When using a Booster vehicle, disconnect BLACK cable clamp from battery negative terminal. Disconnect RED cable clamp from battery positive terminal.

Disconnect RED cable clamp (2) from battery positive terminal on disabled vehicle.

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - NAFTA

Your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you hat it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This means that service is required for your vehicle. Operating conditions such as frequent short trips, trailer tow, extremely hot or cold ambient temperatures, and E85 fuel usage will influence when the "Oil Change Required" message is displayed. Severe Operating Conditions can cause the change oil message to illuminate as early as 3, 500 miles (5, 600 km) since last reset. Have your vehicle serviced as soon as possible, within he next 500 miles (805 km).

NOTE:

Under no circumstances should oil change intervals exceed 10, 000 miles (16, 000 km), twelve months or 350 hours of engine run time, whichever comes first. The 350 hours of engine run or idle time is generally only a concern for fleet customers.

Oil

Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

Severe Duty All Models

Change Engine Oil at 4, 000 miles (6, 500 km) if the vehicle is operated in a dusty and off road environment or is operated predominately at idle or only very low engine RPM's. This type of vehicle use is considered Severe Duty.

Once a Month Or Before a Long Trip

Check engine oil level

Check windshield washer fluid level

Check tire inflation pressures and look for unusual wear or damage.

Check the fluid levels of the coolant reservoir, brake master cylinder and fill as needed.

Check function of all interior and exterior lights.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change the engine oil filter.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect brake pads, shoes, rotors, drums, hoses and park brake.

Inspect engine cooling system protecion and hoses.

Inspect exhaust system.

Inspect engine air cleaner if using in dusty or off-road conditions.

MAINTENANCE CHART

or time

(whichever comes first)

Or Years:23456789101112131415

Kilometers:32,

Additional Inspections

Inspect the CV joints.

Inspect front suspension, tie rod ends, and replace if necessary.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off-road or frequent trailer towing.

Inspect the brake linings, parking brake function.

Inspect transfer case fluid.

Additional Maintenance

Replace engine air filter.

Replace the air conditioning filter.

Replace spark plugs.**

Flush and replace the engine coolant at 10 years or 150, 000 miles (240, 000 km) whichever comes first.

Change transfer case fluid.

Inspect and replace PCV valve if necessary.

** The spark plug change interval is mileage based only, yearly intervals do not apply.

MAINTENANCE

The Scheduled Maintenance services listed in this Service Information must be done at the times or mileages specified to protect your vehicle warranty and ensure the best vehicle performance and reliability. More frequent

maintenance may be needed for vehicles in severe operating conditions, such as dusty areas and very short trip driving. Inspection and service should also be done anytime a malfunction is suspected. The oil change indicator system will remind you that it is time to take your vehicle in for scheduled maintenance. The Driver Information Display (DID) will display an "Oil Change Required" message and a single chime will sound, indicating hat an oil change is necessary. Based on engine operation conditions, the oil change indicator message will illuminate. This means hat service is required for your vehicle. Have your vehicle serviced as soon as possible, within the next 500 miles (805 km).

NOTE:

The oil change indicator message will not monitor the time since the last oil change. Change your vehicle's oil if it has been six months since your last oil change, even if the oil change indicator message is NOT illuminated.

NOTE:

Change your engine oil more often if you drive your vehicle off-road for an extended period of time.

NOTE:

Under no circumstances should oil change intervals exceed 6, 000 miles (10, 000 km) or six months, whichever comes first.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

At Each Stop For Fuel

Check the engine oil level. Refer to "Maintenance Procedures/Engine Oil" in "Maintaining Your Vehicle" for further information.

Check the windshield washer solvent and add if required.

Once A Month

Check tire pressure and look for unusual wear or damage.

Inspect the battery, and clean and tighten the terminals as required.

Check the fluid levels of the coolant reservoir, engine oil, brake master cylinder, and add as needed.

Check all lights and other electrical items for correct operation.

At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

MAINTENANCE CHART

Or Months:6121824303642485460667278849096102108114120126

Change

oil filter. Rotate the tires, rotate at the first sign of irregular wear, even if it occurs before scheduled maintenance.

If using your vehicle for any of the following: dusty or off-road conditions.

Inspect the engine air cleaner filter; replace if necessary.

Inspect the brake linings; replace if necessary.

Inspect the CV joints.

Inspect the exhaust system.

Adjust the parking brake on vehicles equipped wih four wheel disc brakes.

Drain the transfer case and refill.

Inspect the accessory drive belts replace if necessary.

Inspect the front and rear axle fluid. Change if using your vehicle for any of the following: police, taxi, fleet, sustained high speed driving, off-road or frequent trailer towing.

Inspect front suspension, tie rod ends, and boot seals, for cracks or leaks and all parts for damage, wear, improper looseness or end play;

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

replace if necessary.

Replace the engine air cleaner filter.

Replace the air conditioning filter.

Inspect and replace the PCV Valve if necessary X

Replace the spark plugs ** X

Flush and replace the engine coolant at 120 months if not done at 150, 000 miles (240, 000 km).

** The spark plug change interval is mileage based only, yearly intervals do not apply.

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - EUROPEGASOLINE

The Scheduled Maintenance services listed in this Service Information must be done at the times or mileages specified to protect your vehicle warranty and ensure the best vehicle performance and reliability. More frequent maintenance may be needed for vehicles in severe operating conditions, such as dusty areas and very short trip driving. Inspection and service should also be done anytime a malfunction is suspected. The oil change indicator system will remind you that it is time to take your vehicle in for scheduled maintenance. On Electronic Vehicle Information Center (EVIC)/Driver Information Display (DID) equipped vehicles "Oil Change Required" will be displayed in the EVIC/DID and a single chime will sound, indicating that an oil change is necessary. The oil change indicator message will illuminate approximately 7, 000 miles (11, 200 km) after the most recent oil change was performed. Have your vehicle serviced as soon as possible, within 500 miles (800 km).

NOTE:

The oil change indicator message will not monitor the time since the last oil change. Change your vehicles oil if it has been 12 months since your last oil change even if the oil change indicator message is NOT illuminated.

NOTE:

Change your engine oil more often if you drive your vehicle off-road for an extended period of time.

NOTE:

Under no circumstances should oil change intervals exceed 7, 500 miles (12 000 km) or 12 months, whichever comes first.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds. Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

At Each Stop for Fuel

Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark.

Check the windshield washer solvent and add if required.

Once a Month

Check tire pressure and look for unusual wear or damage. Rotate tires at the first sign of irregular wear.

Inspect the battery and clean and tighten the terminals as required.

Check the fluid levels of the coolant reservoir, brake master cylinder, and power steering; add fluid as needed.

Check all lights and other electrical items for correct operation.

At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

MAINTENANCE CHART

Mileage or time passed (whichever comes first)

Kilometers or time passed (whichever comes first):

If using your vehicle for any of the following: Dusty or off-road conditions. Inspect the engine air cleaner filter, replace if necessary.

Inspect the brake linings, replace if necessary.

Inspect exhaust system.

Inspect CV Joints.

Inspect the front suspension, tie rod ends and boot

seals, replace if necessary.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off road or frequent trailer towing.

Change brake fluid every 24 months if using DOT 4 brake fluid.

Replace the air conditioning filter.

Adjust parking brake on vehicles equipped wih four-wheel disc brakes.

Replace engine air cleaner filter.

Replace spark plugs *

Replace accessory drive belt(s).

Flush and replace the engine coolant at 120 months or 240, 000 km whichever comes first.

Inspect or change the transfer case fluid if using your vehicle for any of the following: police, taxi, fleet, or frequent trailer towing.

Change Transfer Case Fluid.

Inspect and replace PCV valve if X

necessary.+

* The spark plug change interval is mileage based only, yearly intervals do not apply.

+ This maintenance is recommended by the manufacturer to the owner, but is not required to maintain emissions warranty.

Severe Duty Condiions

++ Change the engine oil and engine oil filter at every 4500 miles (7, 500 km) or 12 months if using your vehicle under any of the following severe duty conditions:

Stop and go driving.

Driving in dusty conditions.

Short trips of less than 10 miles (16 km).

Trailer towing.

Taxi, police, or delivery service (commercial service).

Off-road or desert operation.

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - EUROPEDIESEL

Your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you hat it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This means that service is required for your vehicle. Operating conditions such as frequent short-trips, trailer tow, extremely hot or cold ambient temperatures will influence when the "Oil Change Required" message is displayed.

NOTE:

Under no circumstances should oil change intervals exceed 12, 500 miles (20 000 km) or 12 months, whichever comes first.

NOTE:

Flush and replace the engine coolant at 120 months or 150, 000 miles (240, 000 km) whichever comes first.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

At Each Stop for Fuel

Check the engine oil level about 5 minutes after a fully warmed engine is shut off. Checking the oil level while the vehicle is on level ground will improve the accuracy of the oil level reading. Add oil only when the level is at or below the ADD or MIN mark.

Check the windshield washer solvent and add if required.

Once a Month

Check tire pressure and look for unusual wear or damage. Rotate tires at the first sign of irregular wear.

Inspect the battery and clean and tighten the terminals as required.

Check the fluid levels of the coolant reservoir, brake master cylinder, and power steering; add fluid as needed.

Check all lights and other electrical items for correct operation.

At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

MAINTENANCE CHART

or time passed (whichever comes first):

Or Months:1224364860728496108120132144

Change engine oil and oil filter.

Completely fill the AdBlue tank.

Rotate tiresXXXXXXXXXXXX

If using your vehicle for any of the following: Dusty or off-road conditions. Inspect the engine air cleaner filter, replace if necessary.

Inspect the brake linings, replace if necessary.

Inspect exhaust system.XXXXXXX

Inspect CV JointsXXXXXX

Inspect the front suspension, tie rod ends and boot seals, replace if necessary.

Change brake fluid every 24 months if using DOT 4 brake fluid.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off road or frequent trailer towing.

Replace the fuel filter.XXXXXX

Adjust parking brake on vehicles equipped with four-wheel disc brakes.

Replace engine air cleaner filter.

Replace air conditioning/cabin air filter

Replace accessory drive belt(s).

Flush and replace the engine coolant at 10 years or 150, 000 miles (240, 000 km) whichever comes first.

Inspect or change the transfer case fluid if using your vehicle for any of the following: police, taxi, fleet, or frequent trailer towing.

Change the transfer case fluid

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - PUERTO RICO

Your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you hat it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This means that service is required for your vehicle. Operating conditions such as frequent short trips, trailer tow, extremely hot or cold ambient temperatures, and E85 fuel usage will influence when the "Oil Change Required" message is displayed. Severe Operating Conditions can cause the change oil message to illuminate as early as 3, 500 miles (5, 600 km) since last reset. Have your vehicle serviced as soon as possible, within he next 500 miles (805 km).

NOTE:

Under no circumstances should oil change intervals exceed 10, 000 miles (16, 000 km), twelve months or 350 hours of engine run time, whichever comes first. The 350 hours of engine run or idle time is generally only a concern for fleet customers.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

Severe Duty All Models

Change Engine Oil at 4, 000 miles (6, 500 km) if the vehicle is operated in a dusty and off road environment or is operated predominately at idle or only very low engine RPM's. This type of vehicle use is considered Severe Duty.

Once a Month Or Before a Long Trip

Check engine oil level

Check windshield washer fluid level

Check tire inflation pressures and look for unusual wear or damage.

Check the fluid levels of the coolant reservoir, brake master cylinder and fill as needed.

Check function of all interior and exterior lights.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change the engine oil filter.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect brake pads, shoes, rotors, drums, hoses and park brake.

Inspect engine cooling system protecion and hoses.

Inspect exhaust system.

Inspect engine air cleaner if using in dusty or off-road conditions.

MAINTENANCE CHART

or time passed (whichever comes first)

Or Years:23456789101112131415

Additional Inspections

Inspect the CV joints.

Inspect front suspension, tie rod ends, and replace if necessary.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off-road or frequent trailer towing.

Inspect the brake linings, parking brake function.

Inspect transfer case fluid.

Additional Maintenance

Replace engine air filter.

Replace the air conditioning filter.

Replace spark plugs.**

Flush and replace the engine coolant at 10 years or 150, 000 miles (240, 000 km) whichever comes first.

Change transfer case fluid.

Inspect and replace PCV valve if necessary.

** The spark plug change interval is mileage based only, yearly intervals do not apply.

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - NAFTADIESEL FUEL UP TO B5 BIODIESEL

Your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you hat it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This means that service is required for your vehicle. Operating conditions such as frequent short trips, trailer tow, extremely hot or cold ambient temperatures will influence when the "Oil Change Required" message is displayed. Severe Operaing Conditions can cause the change oil message to illuminate as early as 3, 500 miles (5, 600 km) since last reset. Have your vehicle serviced as soon as possible, within the next 500 miles (805 km).

NOTE:

Under no circumstances should oil change intervals exceed 10, 000 miles (16, 000 km) or twelve months, whichever comes first.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position. To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

Engine Oil Filter Replacement

Residual oil in the housing may spill from the housing when the new filter is installed if the residual oil is not either removed from the housing or enough ime has not elapsed to allow the oil to drain back into the engine. When servicing the oil filter on this engine, carefully remove he filter and use a suction gun to remove any residual oil left in he housing or wait about 30 minutes for the oil to drain back into the engine.

Once a Month Or Before a Long Trip

Check engine oil level

Check windshield washer fluid level

Check tire inflation pressures and look for unusual wear or damage.

Check the fluid levels of the coolant reservoir, brake master cylinder, and power steering and fill as needed

Check function of all interior and exterior lights.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Completely fill the Diesel Exhaust Fluid tank.

Drain water from fuel filter assembly.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect brake pads, shoes, rotors, drums, hoses and park brake.

Inspect engine cooling system protecion and hoses.

Inspect exhaust system.

Inspect engine air cleaner if using in dusty or off-road conditions.

MAINTENANCE CHART - DIESEL FUEL UP TO B5 BIODIESEL

comes first)

Additional Inspections

Completely fill the Diesel Exhaust Fluid tank.

Inspect the CV joints.

Inspect front suspension, tie rod ends, and replace if necessary.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off-road or frequent trailer towing.

Inspect the brake linings, parking brake function.

Inspect transfer case fluid.

Additional Maintenance

Drain water from fuel filter assembly.

Replace fuel filters and drain water from the fuel filter assembly.

Replace engine air filter.

Replace the air conditioning filter.

Flush and replace the engine coolant at 10 years or 150, 000 miles (240, 000 km) whichever comes first.

Replace accessory drive belt(s).

Change transfer case fluid.

MAINTENANCE SCHEDULES > DESCRIPTION > MAINTENANCE SCHEDULES - NAFTA - B6 TO B20 BIODIESEL

Your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you hat it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This means that service is required for your vehicle. Operating conditions such as frequent short trips, trailer tow, extremely hot or cold ambient temperatures will influence when the "Oil Change Required" message is displayed. Severe Operaing Conditions can cause the change oil message to illuminate as early as 3, 500 miles (5, 600 km) since last reset. Have your vehicle serviced as soon as possible, within the next 500 miles (805 km).

NOTE:

Under no circumstances should oil change intervals exceed 10, 000 miles (16, 000 km) or twelve months, whichever comes first.

Oil Change Indicator - RESET

Unless reset, this message continues to display each time you turn the igniion switch to the ON/RUN position.

To turn off the message temporarily, press and release the Menu button. To reset the oil change indicator system (after performing the scheduled maintenance) perform the following procedure:

Turn the ignition switch to the "ON" position (Do not start the engine).

Fully depress the accelerator pedal slowly three times within 10 seconds.

Turn the ignition switch to the "LOCK" position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator system did not reset. If necessary repeat this procedure.

Engine Oil Filter Replacement

Residual oil in the housing may spill from the housing when the new filter is installed if the residual oil is not either removed from the housing or enough ime has not elapsed to allow the oil to drain back into the engine.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

When servicing the oil filter on this engine, carefully remove he filter and use a suction gun to remove any residual oil left in he housing or wait about 30 minutes for the oil to drain back into the engine.

Once a Month Or Before a Long Trip

Check engine oil level

Check windshield washer fluid level

Check tire inflation pressures and look for unusual wear or damage.

Check the fluid levels of the coolant reservoir, brake master cylinder, and power steering and fill as needed

Check function of all interior and exterior lights.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter.

Completely fill the Diesel Exhaust Fluid tank.

Drain water from fuel filter assembly.

Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system turns on.

Inspect battery and clean and tighten terminals as required.

Inspect brake pads, shoes, rotors, drums, hoses and park brake.

Inspect engine cooling system protecion and hoses.

Inspect exhaust system.

Inspect engine air cleaner if using in dusty or off-road conditions.

MAINTENANCE CHART - DIESEL FUEL B6 TO B20 BIODIESEL

Mileage or time passed (whichever comes first)

Or Years:123456789101112131415

Additional Inspections

Completely fill the Diesel Exhaust Fluid tank.

Inspect the CV joints.

Inspect front suspension, tie rod ends, and replace if necessary.

Inspect the front and rear axle fluid, change if using your vehicle for police, taxi, fleet, off-road or frequent trailer towing.

Inspect the brake linings, parking brake function.

Inspect transfer case fluid.

Additional B6 to B20 Maintenance

Drain water from fuel filter assembly.

Replace fuel filters and drain water from the fuel filter assembly.

Replace engine air filter.

Replace the air conditioning filter.

Flush and replace the engine coolant at 10 years or 150, 000 miles (240, 000 km) whichever comes first.

Replace accessory drive belt(s).

Change transfer case fluid.

NEW VEHICLE PREPARATION INSTRUCTIONS > STANDARD PROCEDURE > STANDARD

PROCEDURE - NEW VEHICLE PREPARATION

VEHICLE READINESS

NOTE:

Note: This document is for reference purposes only. The instructions are not VIN-specific, and it is not required to print or retain this document for each New Vehicle Prep performed.

Description Action

Keep All Protective Transit Film and Wheel Covers & Films on vehicle until sold, or up to 180 Days

Keep All Protecive Transit Film and Wheel Covers & Films on vehicle until sold, or up to 180 Days.

Turn the igniion key on (No engine cranking or running required) 1.

Turn on the hazard lamp (a/k/a/ emergency flashers) 2.

Place vehicle into Customer Mode

Inflate tire pressure to max side wall pressure (except Viper)

Verify vehicle is built as invoiced

Press the "Up Arrow" button on the steering wheel and hold for 5 seconds. 3.

4.

Mode is switched from "Shipping Mode" to "Customer Mode" - the EVIC display will update.

Turn off he hazard lamps 5.

Increase he tire pressure to maximum sidewall pressure if vehicle is going into lot storage.

Verify vehicle is built as invoiced

Install all "Shipped Loose" items (except Viper)Install all "Shipped Loose" items.

Install Front License Plate Bracket (if required)Install Front License Plate Bracket.

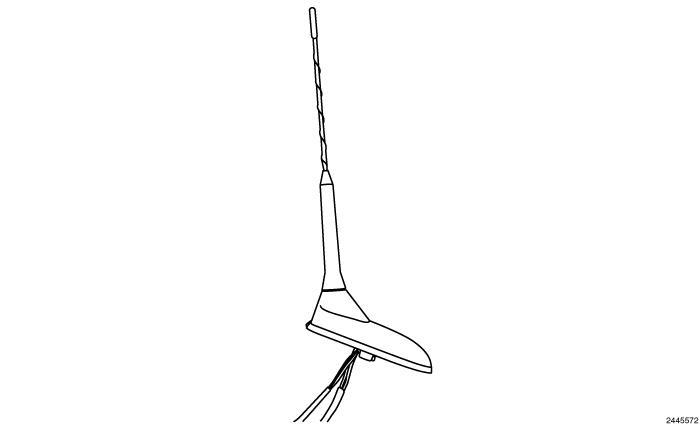

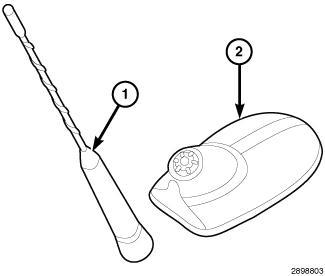

Install Antenna

Install Antenna.

Perform all Incomplete Recalls and RRTs Perform all Incomplete Recalls and RRTs

Install Wheel Center Caps

UNDERHOOD

Install Wheel Center Caps.

Description Action

Hood Latch and Safety Catch - Adjust as Needed

Verify the operation of the hood release system including the inside hood release lever and the outside hood secondary safety catch. Adjust if necessary. The safety

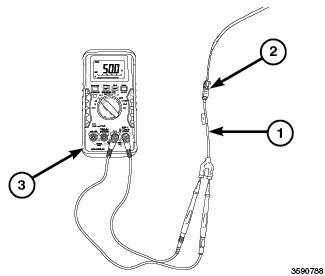

Battery State-of-Charge - document voltage

Loose Attachments, Routing and Clearance

All Fluid Levels

Top-Off Diesel Exhaust Fluid Reservoir (diesel equipped)

No Fluid Leaks present

UNDER VEHICLE

catch prevents the hood from going to the full open posiion until it is manually released. To test the safety catch, unlatch the hood with the interior hood release lever and attempt to raise the hood without operating the safety catch.

Check the battery state of charge by connecting a digital voltmeter at the jump-start locations. The battery voltage should be at least 12.4 volts (Fiat 500 BEV -100%). If charging is necessary, follow the service informaion procedures and recharge the battery. Record voltage on New Vehicle Prep (NVP) form.

Inspect the following for routing, loose attachments, connections, and clearance. Reroute and tighten as required: Brake Lines, Fuel Lines, Power Steering Hoses, Vacuum Hoses, Clutch Lines, Refrigerant Lines, Wiring, Belts.

Refer to the owner's manual or service information for proper fluid level inspection locations. Vehicles equipped with the eight-speed automatic transmission do not require the fluid to be checked. In addition, it is also not necessary to check the fluid of the manual transmission on Vipers and Challengers.

"Fill he DEF reservoir with DEF (diesel equipped). NOTE: TOP OFF THE DEF RESERVOIR PRIOR TO ANY ECU FLASH THAT MAY NEED TO BE PERFORMED. NOTE: DEF IS REIMBURSABLE DURING NEW VEHICLE PREPERATION"

Visually inspect the underhood area to ensure absence of fluid leaks. Check clamps for tightness an full engagement.

DescriptionAction

No Fluid Leaks present

All Fluid Levels

Loose Attachments, Routing, Clearance, Damage

ROAD TEST/OPERATIONAL TEST

Raise the vehicle on an appropriate hoist and check the following: Loose Attachments, Routing Clearance and Damage, Absence of Fluid Leaks. Refer to HOISTING for proper lift points. Check clamps for tightness and full engagement.

Refer to the owner's manual or service information for proper fluid level inspection locations. Vehicles equipped with the eight-speed automatic transmission do not require the fluid to be checked. In addition, it is also not necessary to check the fluid of he manual transmission on Vipers and Challengers models. Also, do not top off the axle fluid on Ram 1500, Challenger, Charger, 300, Durango, and Grand Cherokee models.

Raise the vehicle on an appropriate hoist and check the following: Loose Attachments, Routing Clearance and Damage, Absence of Fluid Leaks. Refer to HOISTING for proper lift points. Check clamps for tightness and full engagement.

DescriptionAction

Perform Road Test, Mileage: Before ______ After ______ NOTE: NOT REQUIRED ON VIPER.

Perform road test (8-10mile, 10-15km guideline) on a variety of road surfaces. Record mileage before and after road test.

Engine Starts with All KeysStart vehicle with all sets of keys.

All Warning Lights and Gauges / No DTCs Verify all warning lights and gauges are operating properly, and no fault codes exist.

Keyless Go

Engine Starts Only in Park & Neutral

Service and Parking Brakes

Ensure vehicle starts with push button, when key is inside vehicle.

Verify engine will only start while automatic transmission is in park or neutral.

Apply the service brakes while the car is in motion. Be sure the brake operation is smooth and positive. Make sure the vehicle stops in a straight line and wihout pulling to one side. Ensure there is no shudder or vibration when braking. Ensure that the parking brake is easy to operate. Make sure the parking brake does not drag.

Brake Transmission Shift Interlock

Automatic Transmission Shifting

Engine Performance - Cold

Steering and Handling

Noise, Vibration, Squeaks, or Rattles

Heater / Defrost- Front

Air Conditioning

Defrost - Rear

Blindspot Monitoring System (if equipped)

Cruise Control (if equipped)

Set Compass Variance / Calculaion (if equipped)

Transfer Case (if equipped)

Load Leveling Air Suspension (if equipped)

Tire Pressure Monitoring System

Engine Performance - Warm

Park Assist (if equipped)

Back-Up Camera (if equipped)

INTERIOR

Ensure hat the vehicle will only start when the brake is depressed on vehicles with automatic transmission.

Make sure that the park lock mechanism holds the vehicle. With the vehicle on a grade, put the automatic transmission in park and slowly release the service brake to check the operation of the park mechanism. Make sure the shift lever operates easily and smoothly. Check for smooth shifting. Check for proper upshifting and downshifting.

The engine should: start properly, idle smoothly and at proper speed, be free from stumbling or hesitation, produce sufficient power, be free of unusual noises, operate within the proper temperature range, and stop when the ignition key is shut off or stop button is depressed.

Check that he power assist works properly. Make sure that the steering wheel does not vibrate abnormally at idle or road speed. Ensure that the steering wheel is centered when traveling in a straight line. Check that the vehicle does not drift to either side on flat road surfaces. Make sure that the vehicle does not vibrate or shake abnormally.

Check that he vehicle is free of noise, vibrations, squeaks, or rattles. Tighten any loose fasteners.

Check the heater operation after the vehicle has reached operating temperature. Operate blower motor at all speeds. Operate the system in all modes. Check for hot air at all appropriate outlets. Check for temperature control operation.

Ensure hat the A/C system cools properly. Operate blower motor at all speeds. Check for cool air at all temperature outlets. Operate the system in all modes.

Ensure hat the electric heated rear defroster operates correctly. Turn on and feel for warmth.

While on road test, verify that the visual warning indicators located on the side view mirrors are operating properly when an object is within the detection zone.

Check the "on/off" switch. Check he "set" operation. Check the "resume" function. Check the "accelerate" and "decelerate" function. Check the "cancel" button. Check the brake/clutch release function. If equipped, verify operation of Adaptive Cruise Control function.

Refer to the service information on TechCONNECT for information regarding compass setting procedures.

Shift the transfer case through all ranges to make sure all shifting is smooth and operates properly.

Use the terrain select switch to change the ride height during normal driving conditions. Cycle through each selecion and verify proper operation of the air suspension system.

Verify that Tire Pressure Monitoring Indicator Light is not illuminated when tires are above minimum inflation recommendations. Ensure that indicator lamp is not flashing/chiming.

The engine should: start properly, idle smoothly and at proper speed, be free from stumbling or hesitation, produce sufficient power, be free of unusual noises, operate within the proper temperature range, and stop when the ignition key is shut off or stop button is depressed.

Put vehicle in reverse and slowly back up toward an object. Verify that Park Assist warning icon, lights and chimes operate properly as object is approached.

Put vehicle in reverse, verify that screen provides a clear and visible image from rear of vehicle.

DescriptionAction

Visually Inspect Interior Parts for Damage, Fit, etc.

From the interior of the vehicle, open and close all doors to ensure ease of operation. Fully open and close the

All Interior Lamps and Horn

Rear View Mirror

Front and Rear Wipers and Washers

All interior Door Locks including Child Locks

glove box to ensure proper operation. Fully open and close the console door to ensure proper operation. Check interior panels for proper fit and free from damage.

Operate and visually inspect all interior lights and switches, including: Dome/Map lamps, and if equipped the following: vanity mirror lamps, glove box lamps, ash tray lamp, cigar lighter lamp, radio lamps, door mounted lamps, illuminated entry system. Ensure hat the horn operates properly.

Check that the rearview mirror's day/night function Is operating properly.

Acivate front windshield wipers, and if equipped, rear window wipers and check for proper operation at all speeds. Activate the front and if equipped, he rear washer. Check the spray pattern for proper operation and aim. Check the intermittent wipe feature for proper operation.

Check all interior door locks for proper operation, including rear child safety door locks if equipped. Place in the unlocked position.

Steering Wheel Mounted ControlsCheck all steering wheel controls for proper operation.

Memory Mirror / Seat

Verify the proper operation of the memory mirror, radio (if equipped), adjustable pedals (if equipped), and seat system.

Cigar LighterCheck cigar lighter for proper operation.

Power Windows and Window Lock Switch

Fully open and close all power windows to ensure proper operation and sealing. Ensure that the windows operate properly at each door. Verify that window lock button is operating properly. Verify the operaion of the "One Touch Up/Down" feature if equipped.

Outside Power MirrorsCheck power mirrors for proper operation.

Power Folding Outside Mirrors

Press Power Folding Mirror button on driver side door trim panel. The switch is located between the Left and Right Power Mirror buttons.

Power Heated Mirrors (if equipped)Check power heated mirrors for proper operation.

Seats and Seat Belts - All Adjustments

Power Sunroof (if equipped)

Set Clock(s)

Audio System

Check for correct installation and operation of seat and shoulder belts, and retractors. Check that the restraint system safety labels regarding the use of seatbelts and airbags are in place. Fully cycle the seats for proper adjustments and verify that each seat is securely mounted. Fold down and latch the rear seats. Pull forward to check that the latches operate correctly. Check for proper head restraint operation. NOTE: ON GRAND CHEROKEE MODELS, MAKE SURE THE SECOND ROW SEATS ARE UNBUCKLED.

Cycle sunroof. Ensure that the sunroof opens and closes easily. Verify proper operation of one touch open/close feature if equipped.

Set all clocks to correct time. Refer to Owner's Manual for information regarding clock setting procedures.

Turn the radio on and check reception in both AM and FM modes. Check that the CD player operates properly. Check for good sound quality from all speakers.

Satellite Radio (if equipped)Turn on satellite radio and verify reception.

Confirm UCONNECT Language Set To Market Refer to User Guide to perform any radio updates/settings.

Confirm EVIC Set To Market Unit and Language Refer to User Guide to perform any radio updates/settings.

GPS NavigationVerify GPS Funcions.

Cycle Glovebox Lock

Video System (if equipped)

Using the key, ensure the Glovebox Lock operates properly.

Test the DVD player to ensure that a DVD will load properly and display on the screen.

Heated Steering Wheel (if equipped)Verify that heated steering wheel is functioning properly.

Power Outlet(s)Check all power outlets for proper operaion.

Integrated Child Seat / Belt

Check the child restraints and child seats for proper operation.

Storage bins properly seated around the spare tire

(Grand Cherokee only)

Heated Seats (if equipped)

Power Cooled Seats (if equipped)

Cargo Compartment Cover (if equipped)

Fuel Door Release

Tilt/Telescoping Steering Column

EXTERIOR

Verify that storage bins are properly seated.

Check for proper operation of heated seats on all power levels, on all equipped seats.

Check for proper operation of ventilated seats on all power levels, on all equipped seats.

Check the rear cargo compartment cover is operating properly.

Acivate the remote fuel door release to verify the fuel door will open.

Acivate the manual/power tilt mechanism. Activate the telescoping feature of the steering column.

DescriptionAction

Inspect Body and Paint for Damage and Fit/ Finish

Remove door edge protector for all doors (if equipped)

Exterior Lamps - Headlamps, Turn Signals, Hazards, Park/Tail/License Plate, Trunk Lights, etc.

Lock and Unlock all doors with all mechanical keys

Inspect the body exterior for damage, loose or missing items. During the inspection, ensure that no vehicle damage occurred from the time the vehicle was received and he beginning of the New Vehicle Preparation. Note: DO NOT TOUCH UP MATTE PAINT OR CUSTOM COLORS.

Pull the door edge protector off from each door (if equipped)

Operate and visually inspect the following: Headlamps (High/Low Beams), turn signals, hazard warning flashers, parking/tail/license plate lamps, reverse/back up lamps, fog lamps, stop lamps including center mounted stop lamp, daytime running lamps (if equipped), clearance lamps, cargo bed lamps, any oher lamps.

Verify all doors lock and unlock with all mechanical keys including the liftgate, tailgate, or trunk as equipped. In addition, verify that both Ram Boxes lock and unlock with all mechanical keys (if equipped).

Doors, Liftgate and Tailgate- Adjust Strikers as Needed

Power Liftgate - Inspect for fit and operation (if equipped)

Security Alarm Test (if equipped)

Open each door/liftgate/tailgate from the outside to check outside door handle operation. Check the door detent. Partially close all doors to check the open-door detent. Close all doors/liftgates/tailgates to check the operation of latches and strikers. Adjust strikers as required. Verify liftgate/tailgate ease of operation.

Verify all modes of operation of the power liftgate, including operating the liftgate using the inside switches and he Remote Keyless Entry transmitter.

Lock doors using the Remote Keyless Entry Transmitter. Verify the operation of the Vehicle Security System warning lamp.

Remote Keyless Entry (if equipped)Verify that doors unlock properly using all key FOBS.

Passive Entry/Keyless Go/Remote Proximity (if equipped)

Remote Start (if equipped)

VEHICLE STORAGE

Verify that the Keyless Enter-N-Go feature is operating properly, by grabbing the door handle of the locked vehicle, while the Remote Keyless Entry transmitter key is within 5 feet of the vehicle. The door should unlock automatically.

Verify that engine starts with all keys when using Remote Keyless Entry Transmitter.

DescriptionAction

Keep all protective transit film, wheel covers and films on Vehicle Until Sold or Up To 180 Days

Keep all protective transit film, wheel covers and films on Vehicle Until Sold or Up To 180 Days

Inflate tire pressure to max side wall pressure

Inflate ire pressure to max side wall pressure (except heavy duty trucks.) Periodically move vehicles to prevent Flat Spotting on tires

Periodically move vehicles to prevent Flat Spotting on tiresPeriodically move vehicles to prevent Flat Spotting on tires

Place vehicle into Ship Mode Turn the igniion key on (No engine cranking or running required)

Turn on the hazard lamp (a/k/a/ emergency 2.

FINAL DETAIL & INSPECTION

Inspect paint and body, touch up as needed

Perform all incomplete recalls and RRT's (Print a current VIP Report)

Place vehicle into Customer Mode

Test and record battery state of charge

flashers)

Press the "Up Arrow" button on the steering wheel and hold for 5 seconds. 3.

4.

Mode is switched from "Customer Mode" to "Shipping Mode" - the EVIC display will update.

Turn off he hazard lamps. 5.

Make sure that the body is free from paint chips or scratches. Touch up any chips/scratches using thin layers of paint. Ensure that the body is free from dings and dents. NOTE: ON VIPERS, DO NOT TOUCH UP MATTE PAINT OR CUSTOM COLORS.

Perform all incomplete recalls and RRT's (Print a current VIP Report).

Turn the ignition key on (No engine cranking or running required) 1.

Turn on he hazard lamp (a/k/a/ emergency flashers) 2.

Press the "Up Arrow" button on the steering wheel and hold for 5 seconds. 3.

4.

Mode is switched from "Shipping Mode" to "Customer Mode" - the EVIC display will update.

Turn off the hazard lamps 5.

Check the battery state of charge by connecting a digital voltmeter at the jump-start locations. The battery voltage should be at least 12.4 volts (Fiat 500 BEV -100%). If charging is necessary, follow the service information procedures and recharge he battery. Record voltage on New Vehicle Prep (NVP) form.

Adjust tire pressures including spare to door placardAdjust tire pressures including spare to door placard.

Ensure Center Caps are InstalledEnsure Center Caps are Installed

Top off Diesel Exhaust Fluid Reservoir (DEF Fluid IS reimbursable)

Remove interior and exterior Transportation Protective Covers

Wash and clean vehicle exterior

Clean vehicle interior

"Fill the Diesel Exhaust Fluid Reservoir located behind the cab on the driver's side of truck or behind the fuel filler door (DEF cap is clearly marked in blue) wih Mopar Diesel Exhaust Fluid prior to customer delivery. NOTE: TOP OFF DEF PRIOR TO PERFORMING ANY REQUIRED PCM FLASH."

Remove exterior protective coatings/coverings from vehicle, remove interior protective covers, grease markings on door jambs, unnecessary labels, etc.

Wash the entire vehicle. Clean the ire sidewalls and wheel/wheel covers (use non - acidic wheel cleaner). Clean exterior/interior glass surfaces.

Inspect the interior trim, seats, carpeing, and moldings. Clean as necessary. TOWING >

CAUTION:

DO NOT use sling-type equipment when towing. When securing the vehicle to a flatbed truck, do not attach to front or rear suspension components. Damage to your vehicle may result from improper towing.

CAUTION:

Towing this vehicle in violation of the below requirements can cause severe transmission damage. Damage from improper towing is not covered under the New Vehicle Limited Warranty.

NOTE:

This Service Information describes procedures for towing a disabled vehicle using a commercial wrecker service.

NOTE:

Vehicles equipped with Quadra-Lift must be placed in Transport mode, before tying them down (from the body) on a trailer or flatbed truck. Refer to the Owner's Manual section on Quadra-Lift for more information. If the vehicle cannot be placed in Transport mode (for example, engine will not run), tie-downs must be fastened to the axles (not to the body). Failure to follow these instructions may cause fault codes to be set and/or cause loss of proper tie-down tension.

Towing Condition Wheels OFF the Ground Two-Wheel Drive Models Four-Wheel Drive Models Without 4-LO Range

Four-Wheel Drive Models Wih 4-LO Range

See Instructions

Transmission in PARK

Transfer case in NEUTRAL (N)

Tow in forward direction

Towing A Disabled Vehicle