ENGINEERED TO MOVE:

Hydraulic Components In-stock and at great prices

Hydraulic Cylinders

starting at $462.00 (HP16150A1S)

AutomationDirect carries Peninsular NFPA hydraulic cylinders that are in stock and ready to ship to you. No long lead times for made-to-order cylinders. Many bolt-on mounting options allow for installation flexibility and replacement of existing cylinder installations.

• Interchangeable with other popular brand of NFPA cylinders

• Available bore sizes: 1-1/2”, 2”, 2-1/2”, 3-1/4”, 4”

• Wide selection of stroke lengths

• All models are double-acting

• Tapped end caps for mounting accessories

• 3000 psi working pressure

• Temperature range is −20° F to 200° F

• Made in the USA

starting at $1,713.00 (51045050002)

Hydraulic power units (HPUs) are the lifeblood of hydraulic systems. These all-in-one units generate the needed pressure for flow of hydraulic fluid through the system. HPUs from Bucher Hydraulics provide everything needed to supply fluid for proper hydraulic system operation.

• Totally enclosed fan-cooled Premium Efficiency electric motor, rated for 60 Hz (will also work with some 50 Hz voltages)

• Powder-coated reservoir plumbed for vertical mounting

• Adjustable safety relief valve preset at factory

• Return line spin-on type filter with visual by-pass indicator

• Two extra 1” NPT couplings through the top of the reservoir for electrical sensors if remote live data of level or temperature is needed

• ¾” NPT drain port on lower front/side of the reservoir

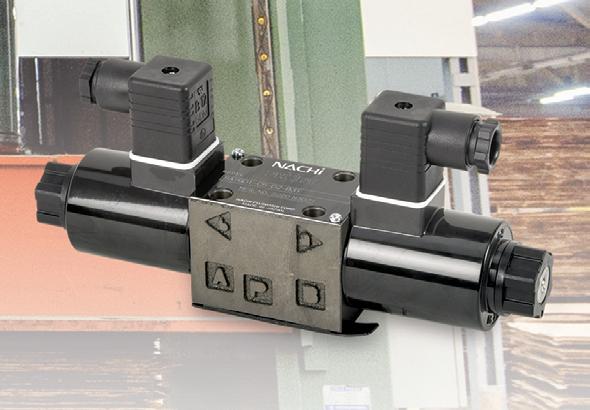

Hydraulic Solenoid Valves

starting at $288.00 (50020851098714)

Hydraulic solenoid valves control hydraulic fluid flow throughout the system and direct the fluid to where it is needed to operate actuators, which may include cylinders and hydraulic motors. Bucher hydraulic solenoid valves are available in a variety of configurations.

• 4-port, 4-way, 3-position, in NFPA D03 and D05 patterns

• Center configurations for D03 versions include tandem, closed, open, or float styles

• Center configurations for D05 versions include tandem or open styles

• 120 VAC or 24 VDC double solenoids

• Manual overrides

• Can be mounted directly on HPU or machine-mounted

price, buy at: www.automationdirect.com/hydraulic-components

Orders over $49 get FAST FREE SHIPPING

shipping policies

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Hydraulic Power Units

Canadian MedTech innovation is alive and well

When it comes to the development of cutting-edge, state-of-the-art MedTech innovations that improve and, indeed, save the lives of countless individuals, few countries in the world boast a legacy of achievement as healthy or as storied as Canada’s. From the discovery of insulin, advances in cancer treatment and the development of the cardiac pacemaker to portable defibrillators, robotic surgical systems and bionic eye technology, Canadian MedTech innovators are regularly lauded globally for their contributions and breakthroughs.

Within this edition of Design Engineering magazine, we explore some of the incredible advances currently impacting the Canadian medical life sciences and healthcare industries, patient outcomes and the future of medical device development.

Siamak Arzanpour and Chloe Angus from Human in Motion Robotics walk us through the engineering ingenuity behind the development of the company’s XoMotion self-balancing exoskeleton, while breaking down the technical complexities of the advancement that’s changing the lives of individuals with mobility challenges.

We sit down with David Van Slingerland, CEO of Sterling Industries - one of Canada’s leading medical device developers - to discuss the current state of the Canadian MedTech sector, some of the challenges and opportunities faced by medical device manufacturers, and the company’s philosophy and engineering culture that’s enabled its continued growth and success.

Beyond MedTech, we examine some of the latest fluid power trends and innovations, the testing and measurement involved in meeting high performance demands, and the robotics-driven construction initiative that’s set to address Canada’s growing housing crisis.

All of this and more is within this edition of Design Engineering magazine. I sincerely hope that you and your teams find the content insightful and informative and will look forward to receiving feedback that can help us enhance our industry coverage further. |DE

SEPTEMBER 2025

Volume 70, No.4

design-engineering.com

READER SERVICE

Print and digital subsciption inquiries or changes, please contact Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

EDITOR Sean Tarry (416) 510-5244 • starry@annexbusinessmedia.com

BRAND SALES MANAGER Trish Sutton (437) 995-4651 • tsutton@annexbusinessmedia.com

ACCOUNT COORDINATOR Cheryl Fisher (416) 510-5194 • cfisher@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick (416) 510-5248 • abeswick@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz (416) 510-5182 • bolechnowicz@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Design Engineering, established in 1955, is published by Annex Business Media, 5 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

Printed in Canada

Publications Mail Agreement #40065710

ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $58.65 for 1 year; $94.35 for 2 years;

Outside Canada: USA - $143.31; Overseas - $154.02; $10.00 for single copy.

All prices in CAD funds.

Add applicable taxes to Canadian rates.

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Officer: privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

SEAN TARRY Editor starry@annexbusinessmedia.com

Editorial Board

DR. MARY WELLS, P.ENG Dean, Faculty of Engineering, University of Waterloo

KEVIN

BAILEY CEO, Design 1st

MASSIMILIANO MORUZZI CEO, Xaba

JAYSON

MYERS CEO, NGen Canada

©2025 Annex Business Media. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

To build your financial future

The Engineers Canada-sponsored Group Savings and Retirement Program offers a range of plans with Canada Life to help you grow your savings then turn your savings into income for your retirement years.

Personalized guidance to help you reach new heights

As an engineer or geoscientist, you know that nothing should be built without a solid foundation. That’s where your personal health and wealth consultant comes in. They’re licensed professionals who can:

Meet with you online – when it’s convenient for you

Help guide you through all stages of your financial journey

Talk to you in more than 12 languages

Plus, being part of a group plan means you get to enjoy lower-than-retail fees* – which means more money for you!

Take it from those** who have met with a health and wealth consultant:

97% said they felt valued

98%

felt they were spoken to in a way that was easy to understand

98%

said all their questions were answered on their personal needs

AEROSPACE

AIRBUS HELICOPTERS OPENS ADVANCED DISTRIBUTION CENTRE IN ONTARIO

Airbus Helicopters Canada recently opened a 21,000 square foot integrated distribution centre in Fort Erie, Ontario, expanding its footprint in the Canadian aerospace sector.

The impressive new facility enhances spare parts storage, accelerates shipping timelines and supports helicopter completions, component repair and advanced composite manufacturing for the company. It’s a strategic move that should serve to optimize logistics and inventory management, while sustaining over 300 skilled jobs.

The expansion also enables increased capacity at the adjacent manufacturing centre, driven by demand for twin-engine helicopters like the H135. And it signals intent from Airbus to continue to strengthen its ties with Canadian suppliers, further reinforcing Ontario’s role as an aerospace manufacturing hub.

ENERGY

FLUOR JV SECURES FEED CONTRACT FOR LNG CANADA PHASE 2 EXPANSION

Fluor Corporation and JGC Corporation have been awarded the Front End Engineering and Design (FEED) contract for a proposed Phase 2 expansion of the LNG Canada facility in Kitimat, British Columbia.

Building on their success in Phase 1, which is now operational and exporting LNG, the joint venture will assess expanding

processing, storage and shipping capacity. This second phase would also bolster Canada’s position as a global low-carbon LNG supplier.

In addition, the project signals upcoming demand for modular systems, process equipment and infrastructure to support large-scale, energy-efficient gas liquefaction and export capabilities.

AEROSPACE

NSERC FUNDING BOOSTS HORIZON AIRCRAFT’S HYBRID EVTOL DEVELOPMENT AND COLLABORATION WITH CANADIAN INSTITUTIONS

Horizon Aircraft has received an additional $450,000 in federal funding through Canada’s Natural Sciences and Engineering Research Council (NSERC) Applied Research and Development (ARD) grant program, bringing the total NSERC support it’s received to more than $3.4 million.

The funding will support Horizon’s continued development of its hybrid-electric Vertical Take-Off and Landing (eVTOL) aircraft through a multi-year research and development collaboration with Fleming College and Ontario Tech University.

In addition, the funding also helps accelerate the design and engineering of Horizon’s Cavorite X7, a piloted, full-scale hybrid-electric

prototype capable of transitioning between vertical and fixed-wing flight using the company’s patented fan-in-wing technology. The aircraft aims to combine the operational versatility of a helicopter with the speed, range and efficiency of traditional aircraft, offering significant implications for emergency response, regional transport and military use.

The collaborative partnership with Fleming and Ontario Tech brings together expertise in applied engineering, electrified propulsion systems and advanced manufacturing - fields of growing importance as electric aviation gains momentum.

And, according to Brandon Robinson, CEO of Horizon Aircraft, it’s a project that should secure a foundation for Canadian innovators moving forward.

“Canada’s continued support demonstrates the recognition of the strategic importance of cutting-edge aerospace development and that it is clearly looking to build upon that national strength,” he says. “This support has accelerated our ability to attract and retain skilled workers, develop world-class innovative technologies and bolster Canadian industry.”

With its recent milestone - the world’s first successful fan-in-wing transition flight - Horizon continues to lead in hybrid eVTOL innovation. Its next move is to complete testing and certification of the Cavorite X7 before entering scaled manufacturing.

Airbus’ new integrated distribution centre in Fort Erie, Ontario.

Precision Control Solutions

Designing efficient systems involves much more than simply understanding a few basic principles. There is a true art to balancing the specific requirements of an application in order to achieve the desired goals in the best possible way. Help us understand the unique needs of your application and together, we’ll develop something that surpasses what any of us could have done alone.

Contact wainbee.com to learn more, or visit clippard.com to request free literature.

FROM DIAL-UP TO ADVANCED CAD

The digital awakening of design engineering in the nineties and beyond the noughties.

BY SEAN TARRY

The 1990s and 2000s proved to be transformative decades for design engineers, marked by rapid technological advances and the integration of digital tools. One of the most significant breakthroughs was the widespread adoption of Computer-Aided Design (CAD) software, which replaced manual drafting and significantly improved design accuracy, speed, and collaboration. This digital shift allowed engineers to create complex 3D models and simulate real-world conditions before physical prototyping.

In the late 1990s, rapid prototyping technologies, including 3D printing, began emerging, enabling faster and more cost-effective iterations of product designs. These tools revolutionized product development cycles and opened new possibilities in customization and innovation.

The 2000 and into the 2010s witnessed a growing emphasis on sustainability and eco-friendly design, influenced by global environmental concerns. Engineers began integrating life-cycle assessments and energy-efficient materials into their projects. In addition, the rise of embedded systems and microelectronics during this time allowed for the integration of smart technologies into everyday products, giving rise to the Internet of Things (IoT).

Collaboration also became more global and streamlined due to the rise of internet-based platforms and Product Lifecycle Management (PLM) systems. These tools allowed teams across the world to co-develop and manage complex projects efficiently.

In short, the 1990s and 2000s served to lay the foundation for modern design engineering through the fusion of digital technologies, sustainability and globalization, setting the stage for the intelligent, connected systems seen today, and the advances of tomorrow.|DE

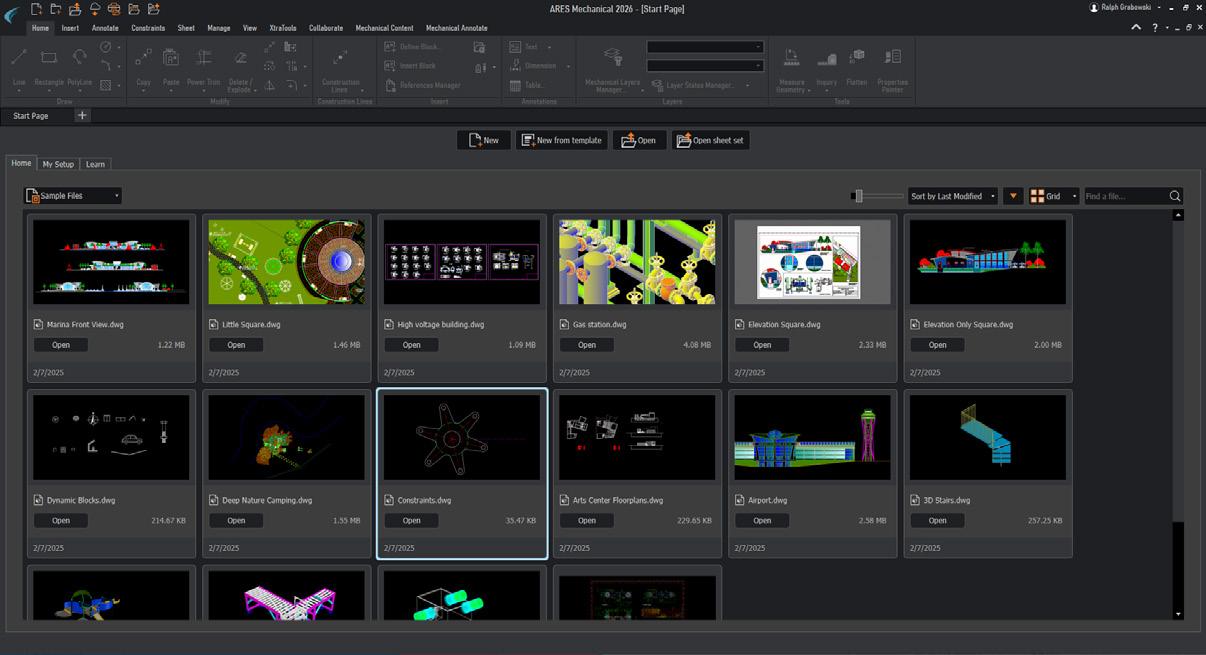

TWO DIRECTIONS IN MCAD

Examining two very different classes of CAD.

BY RALPH GRABOWSKI

This decade is witnessing two contrasting classes of CAD. One is based on the legacy code upon which we engineers place our trust for accuracy -- whether using AutoCAD or ViaCAD.

The other class of CAD software is always emerging - visionaries who spot a niche, get millions in funding, develop a new way to do CAD, and then hope someone buys them before the funding runs out. I recently counted three dozen newish CAD firms that I’d never heard of -- from Archonet to Vectary. Most run in Web browsers, and nearly all tout AI. Here I’d like to tell you about

ARES Mechanical starting with a tableau of sample files.

ARES Mechanical 2026 from Graebert

In 1983, Grabert GmbH became an Autodesk distributor for Germany. After its contract was taken away in 1994, the firm wrote a DWG editor to compete against AutoCAD. In

2005, it was rewritten with a new kernel and renamed ARES, after the Greek god of war. The company says its user base now is second only to AutoCAD’s. ARES runs on most operating systems: Android, iOS, Linux, MacOS, Windows, and Web

ARES Mechanical reporting the properties of a DIN part. The BOM is in the lower right corner.

Images courtesy of ARES.

browsers. The company also licenses it to other firms, such as PTC (used in Onshape) and Dassault Systemes (the basis of DraftSight).

In recent years, Graebert branched into verticals for 3D BIM/IFC files, ArcGIS maps, and 2D mechanical designs. (The verticals work on Windows only). When engineering firms move, say, from AutoCAD to NX or Catia, they still need to update and archive hundreds of millions of DWG files from the last 40 years. ARES Mechanical does this, but at a third of the cost of AutoCAD.

ARES Mechanical adds 2D mechanical functions to Graebert’s ARES DWG editor, handles AutoCAD Mechanical files up to v2022 (and up to v2023 within a few months) with full round-tripping, but does not do 3D modeling.

How Mechanical Differs from AutoCAD

I remember the first time I saw AutoCAD Mechanical. I was blown away by its automated design abilities and wondered out-loud why these functions weren’t in AutoCAD itself. (Autodesk no longer offers Mechanical separately; it is included with AutoCAD).

Drawings made with AutoCAD Mechanical are stored in DWG files but contain custom data for welding symbols and feature control frames. AutoCAD Mechanical attaches “part references” to objects - essentially attributes and balloon leaders attached to blocks, which generate bills of material effortlessly. Change a part, and the BOM updates automatically. (Because BOMs count parts, they are crucial for generating cost estimates and placing orders).

These features make it incompatible with other DWG editors, and so Open Design Alliance developed an API for firms like Graebert to read-edit-write the custom data. ARES Mechanical handles part references and BOMs in the same way as AutoCAD Mechanical.

A powerful function ARES offers is versioning, where it can record variations on designs, and then later merge the ones we want to keep. As well, ARES can compare differences

in two similar-looking drawings. We can coordinate with other designers through shared links and jump over to the Touch tablet and Kudo browser versions of ARES. It can also store drawings on cloud services, such as Dropbox and WebDAV.

ARES Mechanical includes parametric parts libraries based on American ANSI, British BSI, German DIN, international ISO and Japanese JIS

standards, as well as parts for architecture, civil and electrical drawings.

The AI in A3

These days, every CAD vendor needs to mention AI. For Graebert, it is A3 (ARES AI Assist). A3 gives industry-specific advice, shows users how to access commands and does calculations. A3 manipulates object selection through natural language input, such

Zoo Design Studio with 3D modeling commands in the toolbar along the top, the Variables panel on the left, and the split washer result in the center.

as “move the selected entities to layer doors.” At this stage, however, there is no AI-based design available.

ARES passes our queries to OpenAI for processing, which keeps them for OpenAI’s own training. Subscription users are limited to ten conversation threads a day, and permanent licenses users to two.

I tested A3 by asking, “Where is the attribute extraction command,” and it highlighted it in the ribbon. But when I asked it to “select all balloons” in the drawing, it couldn’t and suggested that I do it manually. Graebert tells me that support for Mechanical-specific objects will be added soon.

Pricing

ARES Mechanical is US$1,490 for a permanent license - something Autodesk itself has long proscribed - or else starts at $450 per year on subscription. You can run the software on

Zoo Design Studio with its Text-to-Part prompt at the top, the KCL code on the left, and the resulting part the center.

two computers at once. Download a 30-day trial from www.graebert.com/ cad-software/ares-mechanical.

Design Studio from Zoo Zoo began in 2021, with the name coming from the KittyCAD geometry and ML-ephant machine-language APIs. They are the foundation for Design Studio, launched earlier this year. The MCAD program is being

developed on Github and runs on Windows, MacOS, Linux and in Web browsers. The company has been financed through several rounds by investors, most recently for $5 million. By adding machine learning to a basic 3D mechanical CAD program, Design Studio lets us create and modify parts by typing descriptions like “16-tooth gear.” We might call that AI, but the company prefers to talk

Images courtesy of Zoo Design Studio.

instead about machine learning. It attempts to find appropriate formulas with which to draw parts.

The list of Design Studio commands is shorter than that of a 30-year-old program like Solidworks, but it has a powerful assistant in its Variables panel, which lists the parameters of objects as we create them. This is a straightforward way to modify every dimension of every part.

Another panel, named KCL, shows the KittyCAD programming code that generates the models. In fact, models are saved in ASCII-format .kcl files; we could make new 3D models just by writing KCL code. Other panels show the feature tree and linked files.

Testing machine learning

The halo function is Text-to-Part. It takes our written input and converts it to editable 3D parts. Early on, I found it slow and inaccurate. For instance, when I asked for a “universal joint for a 2-inch shaft,” it failed badly, return ing some rectangular blocks. When I asked for something simpler like a “1/2-inch lock washer,” it also failed, producing a washer sprouting blades. This one took about 40 seconds to generate; it might be faster to look up parts in a library.

Zoo told me updates would im prove things. So, when I asked for a “1/2-inch split washer,” it took just 20 seconds this time. However, instead of a helical split, it came up with an (incorrect) gap.

Once drawn, we can export parts in formats like STEP and STL. It imports the same formats, as well as Solidworks .sldprt files. I’ve suggest ed that DWG/DXF be added.

Design Studio is updated frequent ly, as new software programs need to be. It is free to use with 40 monthly credits for text-to-CAD operations, with one credit used for every minute of machine learning time. For more credits, monthly subscriptions start at US$99 per month.

With Design Studio, Zoo drags the future into the present. New CAD programs are taking advantage of the latest programming techniques to iterate rapidly.

From my experience with AI-enabled CAD programs, I’m asking, “Will AI like text-to-parts improve over time, or is it fundamentally flawed, unable to produce the human-level results we expect of CAD?”

In my opinion, I consider “AI” for the most part no more than a series of standard programming if-then statements.

ARES Mechanical is worthwhile checking out when you need an experienced CAD program to do general and mechanical drafting, while Design Studio is fun to play with, and to monitor as it develops better capabilities. |DE

Going forward

With ARES Mechanical, Graebert is preserving the past for today. Mature CAD programs remain compatible with legacy files, thanks to reverse-engineering by Open Design Alliance

ENGINEERED TO MOVE

Inside the self-balancing intelligence of Human in Motion Robotics’ XoMotion exoskeleton. BY SEAN TARRY

During a moment in time when wearable robotics are rapidly evolving from science fiction to everyday reality, Human in Motion Robotics has engineered a leap forward that blends mechanical sophistication with human-centred design. Its breakthrough innovation - the XoMotion exoskeleton – promises to redefine mobility for individuals with lower-limb paralysis. However, at its core, the XoMotion isn’t simply a robot that helps someone walk. It’s an intelligent, responsive system that integrates biomechanics, advanced sensing, high-performance actuation and fast deterministic control loops to mimic the innate agility of real human movement.

Bridging the gap between human and machine

Siamak Arzanpour, Co-CEO and Co-Founder of Human in Motion Robotics, who has been instrumental in translating research at Simon Fraser University into a commercial device now poised for clinical deployment, began his journey in the multidisciplinary realm of mechatronics - a hybrid of mechanical, electrical and software engineering designed for the complexity of modern robotic systems. It’s this education that Arzanpour credits when talking about the inspiration behind the development of the company’s engineering philosophies that not only underpin the XoMotion, but offer a blueprint concerning the

Regulating balance in real time was one of the biggest challenges faced by the engineering team.

Chloe Angus enjoying XoMotion’s ‘Dance Mode’.

way modern exoskeletons should be built - not just to assist, but to intuitively move with their users.

“When we formed the company, we realized that our engineers were going to need to understand a bit of everything,” he explains. “We didn’t want to be limited by silos, especially when the task we were undergoing was replicating human motion.”

The idea to begin creating a self-balancing, full-mobility exoskeleton donned on Arzanpour in 2014 when he witnessed a live demonstration of an early exoskeleton in action while attending a trade show. He was impressed, but with some caveats.

“It was really exciting to see it in operation,” he says. “But it could only stand up and walk forward, with crutches for support. I could

immediately see the potential technology of that sort promised. But its limitations were clear.”

Shortly after returning to Vancouver, he and Co-Founder Edward Park assembled a team to pursue a radically different design. Their goal was to create full-body mobility with self-balancing autonomy - a system that could operate without crutches or any external support.

The challenge of balance

Setting the XoMotion apart from nearly every other exoskeleton on the market is its breakthrough self-balancing capability. It’s a technical achievement that required Arzanpour and his team to understand human balance and the equation that permits us to remain upright and apply that to advanced technology.

“To understand balance, you first have to understand the interplay between center of mass (CoM) and center of pressure (CoP),” Arzanpour explains. “As long as CoM remains over CoP, you’re stable. However, when we walk, we’re constantly going in and out of balance with the movement of our feet. We needed to understand how our brain essentially supplements for this constant change.”

Translating this into robotics meant incorporating an entire suite of embedded sensors within the footplates and across the body to track these variables in real time. These inputs feed a motion generation algorithm capable of adjusting CoM in anticipation of movement. The XoMotion doesn’t just react, it predicts motion trajectories based on user intent and environmental conditions.

However, building a robot capable of processing this data at human speed was a

unique and complex challenge. Achieving balance is not just a matter of solving mathematical equations. It’s fundamentally about timing. Every motion the exoskeleton makes must happen within a few milliseconds, or the illusion of natural movement breaks., and with it, stability.

Real-time control loops

The necessity of rapid decision-making drove the development of a tightly integrated control system with fast, low-latency sensor integration becoming essential in order to ensure that the device could sense changes immediately. To meet this need, the team developed deterministic control algorithms which guarantees the control system responds within a fixed, predictable timeframe - critical for avoiding delays that could lead to instability or user discomfort.

“We don’t think about how we walk. It just happens,” Arzanpour observes. “As a result, we knew the robot had to work the same way. To replicate this intuitive, subconscious reaction, we built it to close its control loop in milliseconds, not seconds.”

Arzanpour goes on to explain that this tight feedback architecture is especially critical when compensating for unexpected motion, such as shifts in the user’s upper body. Unlike humanoid robots, which operate within a fully controlled, predictable mechanical system, exoskeletons like XoMotion must manage the dynamic and often unpredictable behaviour of a real human user. In order to do this the device continuously processes inputs from the user’s body and adjusts in real time to maintain balance, prevent falls and ensure a smooth gait.

LP500 Latch Pins for Plastics

• Designed specifically for use in plastic hinge applications

• Lightweight, lead-free aluminum

• Barb secures pin in place

• Smooth body facilitates easy alignment through multiple holes

• Conducive for automatic feeding

Regulating

When off-the-shelf isn’t enough

One of the most impressive engineering hurdles involved in the development of the XoMotion was actuation. Arzanpour says that the team initially spent six to nine months searching for commercially available actuators that met their stringent requirements for weight, speed, torque and reliability. However, every off-the-shelf actuator they tested proved too heavy, too slow, or simply lacked the necessary torque-to-weight ratio for real-world use.

Realizing the fact that no existing solution was suitable, the team pivoted to in-house actuator development. And it’s a pivot that proved to be a game-changer. The result was the engineering of a proprietary actuation system that, despite being similar in size and weight to early prototypes, delivers four times the torque and speed. Combining high-torque motors with custom gearheads and integrated sensors in a compact housing, these custom actuators have been built specifically for the exoskeleton’s anthropomorphic structure.

Durability and low maintenance were also priorities when developing the

XoMotion’s actuators. Arzanpour describes them as “the heart of the system” that have been designed not only to deliver power but to last, too. And, in efforts to confirm the durability of the actuators, the team is continuously logging performance metrics to predict wear and replace parts proactively, ensuring the device remains reliable over long-term use.

Modularity, adjustability and the rehab environment

The XoMotion is currently targeted primarily at rehabilitation clinics, where safety, ease of use and adjustability are paramount. The exoskeleton’s modular design allows it to accommodate a wide range of users, specifically those between 140 and 190 centimeters in height and weighing up to 100 kilograms. Recognizing that time is a precious commodity in clinical settings, the team engineered internal adjustment mechanisms that enable clinicians to reconfigure the device between sessions quickly.

“The XoMotion can be adjusted for a new user in less than five minutes,” Arzanpour says. “This rapid reconfiguration

capability means clinicians don’t have to spend an excessive amount of time swapping parts between patients. This in itself is a significant improvement over earlier devices that required cumbersome manual adjustments that took a long time.”

In addition to modularity, explains Arzanpour, the device has been designed to be intuitive and straightforward for clinical use. The system’s ease of handling and quick adjustability reduce the clinician’s physical burden and learning curve, improving overall adoption and patient throughput.

Deterministic now, AI tomorrow

While the current rehabilitation model of XoMotion relies on deterministic control algorithms, which have been chosen for their reliability and simplification of safety validation needed for FDA approval, the Human in Motion Robotics team is already preparing for the next stage in exoskeleton evolution - the integration of artificial intelligence.

Arzanpour envisions a personal-use version of the device that incorporates AI-based control and environmental

Regulating balance in real time was one of the biggest challenges faced by the engineering team.

perception, stating that they’re similar in concept to self-driving cars. This future iteration will feature machine vision and AI inference to dynamically understand terrain, detect obstacles and climb stairs, all while adapting its gait accordingly. And, according to the Human in Motion Robotics Co-CEO, this is only the beginning.

“The AI components will go beyond obstacle detection,” says Arzanpour. “They will optimize energy efficiency, movement smoothness and torque allocation, which in turn will help reduce the size and weight of hardware components. This intelligent adaptation will enable the exoskeleton to respond more naturally and fluidly, creating an experience that approaches the responsiveness of the human body itself, which is our ultimate goal with this technology.”

Two brains, one machine

Designing an exoskeleton for human use is fundamentally different from building a humanoid robot, Arzanpour notes. While humanoid robots operate in fully controlled and predictable environments,

exoskeletons must coexist with the unpredictable dynamics of their human users. As a result, a number of special considerations needed to be made.

“The robot and the human user are effectively two brains working together,” he says. “The exoskeleton must constantly infer the user’s intent without controlling their upper body. For example, if the user leans or shifts unexpectedly, the system must respond immediately to maintain balance and safety without overriding the user’s natural motion.”

He goes on to explain that this requires a sophisticated interplay of biomechanical safety measures, FDA-certifiable materials - down to the adhesives - and fault-tolerant behaviours. As a result, the XoMotion is as much a marvel of human factors engineering as it is of robotics.

Lived experience

When Chloë Angus first stood up in the XoMotion, it wasn’t in a lab or on a stage. It was a deeply personal milestone - the kind that redefines what’s possible after a life-changing injury. For Angus, who

became paralyzed from the waist down a decade ago, it was also a vindication of years of vision, advocacy and collaboration with a team of engineers who shared her belief in changing the status quo of mobility technology.

“Ten years ago, I laid in a hospital bed wishing for something like XoMotion,” she says. “To now see it not only developed, but being used by others - it’s everything I hoped for and more.”

The future of mobility

What further differentiates XoMotion from previous exoskeleton generations is more than just the sum of its motors and microcontrollers. It’s a complete rethinking of how humans and machines move together - and how technology can restore not only function, but freedom.

“We’re not just talking about mobility,” says Angus. “We’re talking about independence, about empowerment, about joy.”

Built on Lived Experience

Angus serves as Human in Motion Robotics’ Director of Lived Experience - a

25_007029_Design_Engineering_SEP_CN Mod: June 18, 2025 4:09 PM Print: 07/23/25 page 1 v2.5

ORDER BY 6 PM FOR SAME DAY SHIPPING

ENGINEERING SPECS AT A GLANCE

Custom-built for self-balancing long life, the XoMotion is proving to be an optimized wonder among exoskeletons.

• User Height Range: 140–190 cm

• Max User Weight: 100 kg

• Actuator Design: In-house; high-torque, compact, 4x performance over initial prototypes

• Control System: Deterministic feedback loop (<5 ms cycle time)

• Sensors: Pressure, position, IMU; embedded throughout limbs and feet

• Balance Model: Center of Mass vs. Center of Pressure; push-recovery and gait-prediction enabled

• Clinical Status: Entering trials for FDA approval in the U.S.

role that isn’t ceremonial, but foundational. Having used earlier exoskeletons herself, she recognized their lack of balance, dependence on crutches, awkward gait, high clinician burden and inability to offer truly independent use.

“In the past, the technology was exciting,” she says. “But it just didn’t meet the needs of the user. I’ve seen and used devices that required multiple attendants to help or left people reliant on walkers. That’s not freedom.”

Her feedback, starting at the earliest stages of development, helped ensure the design of XoMotion went far beyond technical achievement. It had to match real-world expectations like maneuvering around tight spaces or standing up to greet someone.

“Unless you’ve spent a year or a decade in a wheelchair, it’s hard to fully grasp what the barriers are, including physical, emotional and social,” she says. “But that’s the lens I brought to this team.”

Natural movement, reimagined

And it’s a lens that has helped to shape everything, from mechanical design to software user experience. What’s more, XoMotion is constantly evolving, adding capabilities and ‘modes’ to its impressive list of commands. It’s a system that provides the user with an incredible range of customization, says Angus, adding further to the sense of freedom that the device offers.

“The closest analogy that I can think of is like giving someone an iPhone,” she says. “It starts as a platform, and then you can customize

it by adding the ‘apps’ you need for your life. XoMotion is similar. The team’s been amazing at considering just about everything possible for the end-user.”

Technology with a soul

While XoMotion’s technical achievements are remarkable, its emotional impact may be even more profound. The device is currently being used at Synaptic Neuro Rehabilitation Centre in Calgary, Alberta where it’s being integrated into intensive neuro-rehab protocols. Angus recalls its debut moment in the clinic being deeply emotional.

“There wasn’t a dry eye in the room when Ryan Straschnitzki, one of the Humboldt Broncos hockey players who was injured in the 2018 bus crash, stood up and started practicing hockey skills in the exoskeleton,” she says. “It’s a moment that reconfirmed all over again the reasons we set out to develop the XoMotion and the incredible possibilities it presents to those with mobility challenges.”

In fact, Angus also recalls the moment she was able to stand up and hug her husband to her chest for the first time since her injury.

“It still makes me choke up,” she says. “You don’t realize how much you miss the little things like standing eye-to-eye with someone and hugging them without a wheelchair between you.”

Another moment arrived when the Human in Motion Robotics engineering team surprised Angus with an XoMotion feature they called ‘Dance Mode.’ Knowing how much she missed dancing, they programmed the system to respond to her body’s natural movement

without a controller.

“At first, I thought the system had failed,” she says. “It dropped down quickly when I leaned forward, but then it moved with me, flowing with my rhythm. I immediately told the team that we had developed the coolest exoskeleton in the world. Come on. It has dance mode.”

Not just a device - a movement

From Angus’ perspective, the future of wearable robotics is not just about assisting people with injuries. It’s about preparing them for the inevitabilities of life. Human in Motion Robotics’ vision is to make wearable robotics as essential, and as common, as smartphones. From industrial exosuits that protect factory workers to assistive devices that enable independent aging, the applications are vast. And the need, according to Angus, is urgent.

“Everyone is going to experience a motion disability at some point,” she asserts. “Whether it’s due to injury, illness or aging, we’re all going to experience the same challenges at some stage. And none of us want a walker or a wheelchair.”

Still, barriers remain - especially in Canada, where Angus says the med-tech investment ecosystem is cautious. Financing, she says, has been the biggest challenge. But the company has persevered because, as Angus explains, everyone involved knew that it was what the world needed.

“That’s our legacy. We built a device that doesn’t just help people stand up and walk. We built a device that helps to restore an individual’s freedom. That’s worth everything. |DE

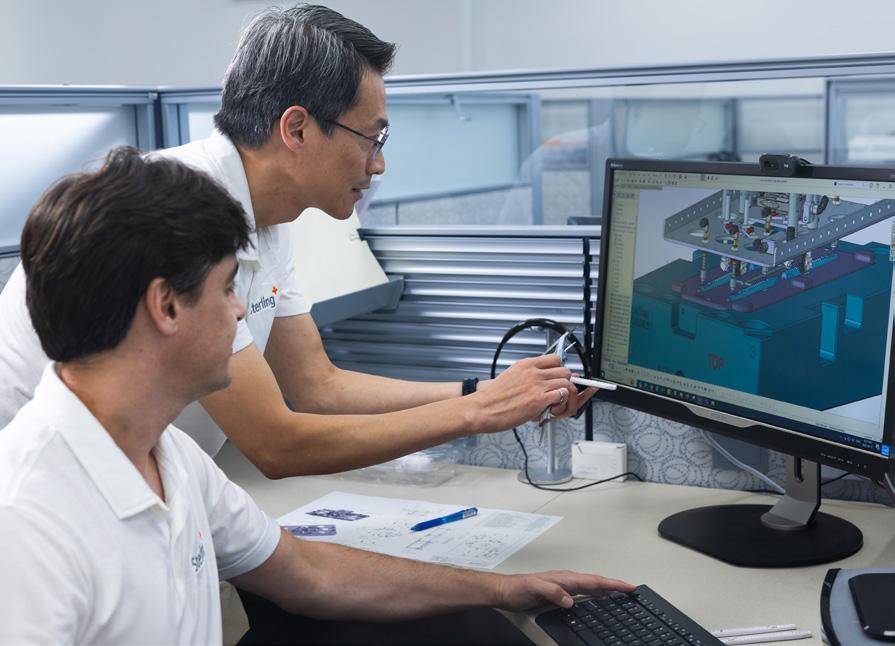

STERLING INDUSTRIES: UNLOCKING CANADA’S MEDTECH POTENTIAL

Inside the philosophy and engineering culture of one of the country’s leading medical device manufacturers.

BY SEAN TARRY

Canada’s medical technology sector is currently at a crossroads. From one perspective, the country boasts an impressive legacy of world-class research institutions and a vibrant pool of talent.Through another lens, though, the journey from innovation to commercial success remains riddled with unique systemic and operational barriers. As global healthcare demands continue to grow increasingly complex, Canadian MedTech companies face the critical challenge of scaling innovative medical devices while navigating a fragmented healthcare system, evolving regulatory frameworks and limited access to capital and talent.

One company that seems to have figured these complexities out is homegrown Canadian MedTech leader Sterling Industries. It operates locations in Kalamazoo, Michigan, Concord and Barrie, Ontario and is headquartered in Woodbridge, Ontario. And with over four decades of experience in precision manufacturing, the company has established itself as a trusted partner for OEMs and MedTech innovators across North America. Specializing in the production and assembly of complex components and finished devices, Sterling

delivers scalable solutions for regulated industries including medical, life sciences and advanced industrial markets. From early-stage prototyping to full-scale production, the company offers vertically integrated services - from design for manufacturability and sourcing to machining, assembly, testing and logistics.

However, what sets the company apart is its commitment to collaboration and operational agility. The company doesn’t just manufacture components - it helps bring ideas to life through a strategic, customer-centric approach. Whether supporting a startup with rapid iterations or enabling a multinational OEM to scale production efficiently, Sterling adapts its capabilities to meet diverse needs without compromising on quality or speed. With in-house engineering, automated production lines and a data-driven quality management system, Sterling helps reduce time-to-market and mitigate risk for its clients.

As a result, Sterling serves as a beacon of sorts on the oft-clouded Canadian MedTech landscape, signalling a way forward for other Canadian MedTech companies attempting to find success and growth among the complexities of the industry.

So, to better understand all the dynamics at play and explore how Canadian companies can unlock their full potential and accelerate their strategic and technical efforts in order to drive innovation, we spoke with Sterling Industries’ CEO, David Van Slingerland, about some of the broader challenges the sector must overcome.

Promise and pitfalls

Despite Canada’s strong foundation and storied history in medical innovation, which the MedTech CEO acknowledges, he suggests that one of the core issues impacting the industry is the way in which Canada’s publicly funded healthcare system is structured. Unlike in the United States, where healthcare is largely privatized, and cost-benefit analyses can support the adoption of new, higher-priced devices that reduce overall patient costs, Canada’s budget allocations are highly siloed. As a result, explains Van Slingerland, innovation can be stifled.

“We have incredible research talent across the country and a history of introducing breakthrough ideas,” he says. “But translating those ideas into market-ready

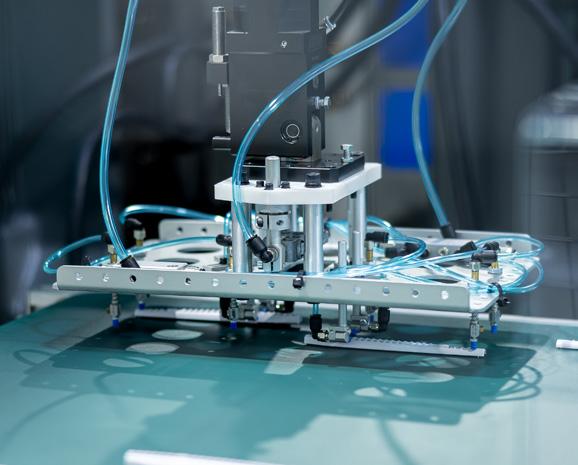

Sterling Industries has developed an engineering culture that ensures operational excellence.

products that actually improve patient care is a different story. In Canada, operating room budgets are separate from budgets for hospital stays or infection management. So, if a device is expensive in the operating room but leads to fewer infections or shorter hospitalizations, the operating room decision-makers may still reject it because they don’t control the savings downstream.”

He goes on to explain that most medical device companies rely heavily on reimbursement pathways to recoup investments. The lack of clear billing codes in Canada, he says, and the complexity of regulatory approval processes, contribute to extended timelines and heightened risks. What’s more, Canada’s capacity for clinical trials and diagnostic validation is limited, which, explains Van Slingerland, places even more strain on those operating within the industry.

“Rigourous clinical studies are necessary for regulatory approval,” he recognizes. “But they are expensive and require specialized infrastructure and expertise. That puts a lot of pressure on startups and smaller companies who are already facing an incredible number of challenges.”

This budget fragmentation, he explains, discourages the adoption of advanced technologies that could improve outcomes and reduce total healthcare costs. As a result, promising devices and innovations developed in Canada often gain traction in the U.S. private market before they even make headway at home. It’s an outcome that can be incredibly frustrating for Canadian companies, he says, but one that’s also an economic reality.

Reimbursement and regulation complexities

Van Slingerland goes on to explain that reimbursement and regulatory challenges also serve as bottlenecks that stall and impede medical device innovation in the country.

“Many innovations don’t have an existing billing code, so hospitals and providers have no clear way to pay for them,” he says. “Without reimbursement, commercialization stalls and both short- and long-term innovation suffers.”

He points to recent efforts to harmonize regulatory standards globally as a positive step. Canada’s adoption of the Medical Device Single Audit Program (MDSAP) and alignment with ISO standards help streamline market access internationally. However, developing an intimate understanding of and working within diverse frameworks, including the FDA’s evolving requirements in the U.S. and the European Union’s stricter Medical Device Regulation (MDR), remains a challenge.

The rise of integrated MedTech ecosystems

Despite these challenges, Van Slingerland stresses the fact that there are currently just as many opportunities for those operating within the MedTech industry. And, he says, much of the opportunity is being driven by advanced technologies and the wherewithal of companies to leverage their capabilities to the fullest.

While the development and use of traditional medical devices remains crucial, Sterling’s CEO believes that the future of MedTech lies in integrated, connected systems. Devices that seamlessly exchange data with electronic medical records (EMRs), like surgical devices which

automatically upload clinical notes and images during procedures, are presenting massive potential. In fact, according to Van Slingerland, they offer transformative capabilities to improve clinical workflows and patient care.

“This kind of connectivity doesn’t just enhance device function - it transforms the entire care pathway,” he asserts. “Doctors used to dictate into tape recorders or do voice-to-text after their shifts. Now, with real-time voice integration, documentation is finished the moment the procedure ends. That’s a game-changer for productivity, enhancing accuracy and reducing errors.”

Home healthcare and combo devices

Van Slingerland also highlights the growing demand for home healthcare devices. Driven by Canada’s aging population and a desire to reduce hospital visits, it’s another area of innovation that the Canadian MedTech leader believes is rife with opportunity.

“There’s huge interest in ‘combo devices’ that merge drug delivery with medical devices, allowing patients to administer precise doses at home safely,” he explains. “Pharma companies are investing heavily in this space, and it’s a tremendous opportunity for MedTech innovation. By developing user-friendly, accurate devices for unsupervised home use, companies can tap into a growing market while improving patient independence and outcomes.”

Manufacturing as a strategic advantage

One of the ways in which Sterling Industries has set itself apart from most of its competitors within the industry, explains Van Slingerland, is its commitment to inhouse manufacturing, serving as a critical part of the company’s strategy to ensure agility and quality control. Over the past five years, Sterling Industries has built injection molding facilities and acquired laser fabrication equipment, producing about 70 per cent of device components internally.

“Vertical integration shortens time to market and gives us greater control over materials and biocompatibility,” he says. “These outcomes are crucial for the development of invasive devices and allow us the greatest possible level of control over our processes and production.”

In addition, the company invests in clean rooms for sterile product manufacturing, further ensuring compliance with regulatory standards. And advances in 3D printing, especially using metal additives, have also allowed rapid prototyping and quick design iterations. Although not yet scalable for mass production, these capabilities enable Sterling to test and refine designs efficiently, helping to introduce cutting-edge innovations within shorter timeframes.

Accelerating innovation with advanced tools and collaboration

Another way by which Sterling Industries separates itself from other companies

working within the Canadian MedTech industry is the culture of engineering that it’s built which influences the practices it employs, powering the company’s accelerated development cycles. Leading the way is Sterling Industries’ Senior Engineer andTeam Lead, Project Manager, Sanjesh Yasotharan, who understands just how important his team’s work is and the critical nature of the devices and components that they design and manufacture.

“Medical device development is a significantly important, high-compliance environment,” he says. “We need to deliver innovative solutions rapidly but with zero compromise on safety and reliability. As a result, it’s our responsibility to not only ensure that our processes are maintained, but to also make sure that we’re considering everything at our disposal in order to enhance and improve our practices. For instance, we’ve been leveraging artificial intelligence to automate repetitive tasks such as documentation and data transfer. Our goal with this is to free engineers from administrative burdens so they can focus on creative problem-solving.”

Yasotharan points out that Sterling’s engineering teams also extensively use simulation tools like mold flow analysis, finite element analysis (FEA) and computational fluid dynamics (CFD) to validate designs early, minimizing costly late-stage changes.

“We want to get the design right the first time,” he stresses. “This upfront rigour reduces risks and shortens time-to-market.”

Design for manufacturability

Another hallmark of Sterling’s success is its commitment to design-for-manufacturability concerning every project it embarks on, considering it from the earliest stages possible. Yasotharan contrasts this approach with his earlier industry experiences where manufacturing was often an afterthought, which inevitably caused delays.

“Right from the start, we discuss how the part will be made, feasible tolerances, draft angles and parting lines,” he explains. “Because we produce everything ourselves, building it right the first time is critical. This early alignment between design and manufacturing not only helps avoid costly redesigns, but it also helps to build and maintain customer confidence in our delivery timelines and the quality of the product.”

Inside the Sterling Industries facility in Woodbridge, Ontario.

Supporting early-stage startups through close collaboration

Yasotharan also highlights Sterling’s riskbased approach, collaboratively setting inspection criteria and process controls with clients to ensure smooth transitions from prototype to production. Early-stage startups often come with tight budgets and evolving product definitions, he explains. Sterling’s collaborative culture helps bridge these gaps.

“What’s challenging is extracting the ‘tribal knowledge’ clients hold about their own technology,” He notes. “To facilitate this, we visit their facilities, review prototypes and watch operators to understand nuances that may not be documented. This iterative, open process builds trust and allows us to tailor manufacturing solutions for small production runs, a growing need among many companies operating within the MedTech sector.”

Ensuring reliability – nonnegotiable

It may very well be understood without mentioning, saysYasotharan, but reliability is paramount in devices used in surgical and diagnostic contexts. In fact, he points out that failure rates must be well below one per cent in order to be deemed accurate and functional within the MedTech industry. It’s a challenge that Sterling’s engineering team lead recognizes, stating that it’s the reason for their unwavering commitment to testing and verification, especially early on in the process.

“You can’t test tens of thousands of pieces before launch,” he says. “Simulation tools and risk analysis like failure modes and effects analysis help us predict and design out failure points early. It’s an approach that ensures that our products meet ISO standards and function flawlessly when patient safety is on the line. You need to think like the user and anticipate every possible misuse or failure. It requires a mindset shift for some in order to begin using risk management tools as ways to improve the product, not just to fulfill paperwork requirements.”

A vision for Canada’s MedTech future

The convergence of Sterling Industries’ leadership and culture of engineering has to this point resulted in nothing less than an example for other companies working within the Canadian MedTech industry

to look to as a blueprint of sorts – one that seems to guide a path forward, promising the unlocking of potential.

As Van Slingerland points out, the industry in Canada possesses the ideas, talent and capabilities to be a global leader in the development and manufacturing of medical devices. However, in order to realize those capabilities, he suggests that enhanced strategic investment in manufacturing, the embracing of digital

integration and the fostering of a collaborative ecosystem are all necessary.

“The opportunity is clear. With the right kind of investments, combined with the proper nurturing of resources, we can create an environment in Canada where innovative medical devices not only get developed but thrive commercially. And, in the end, the greatest benefit of this result is in better patient care and a strengthened Canadian MedTech industry.”|DE

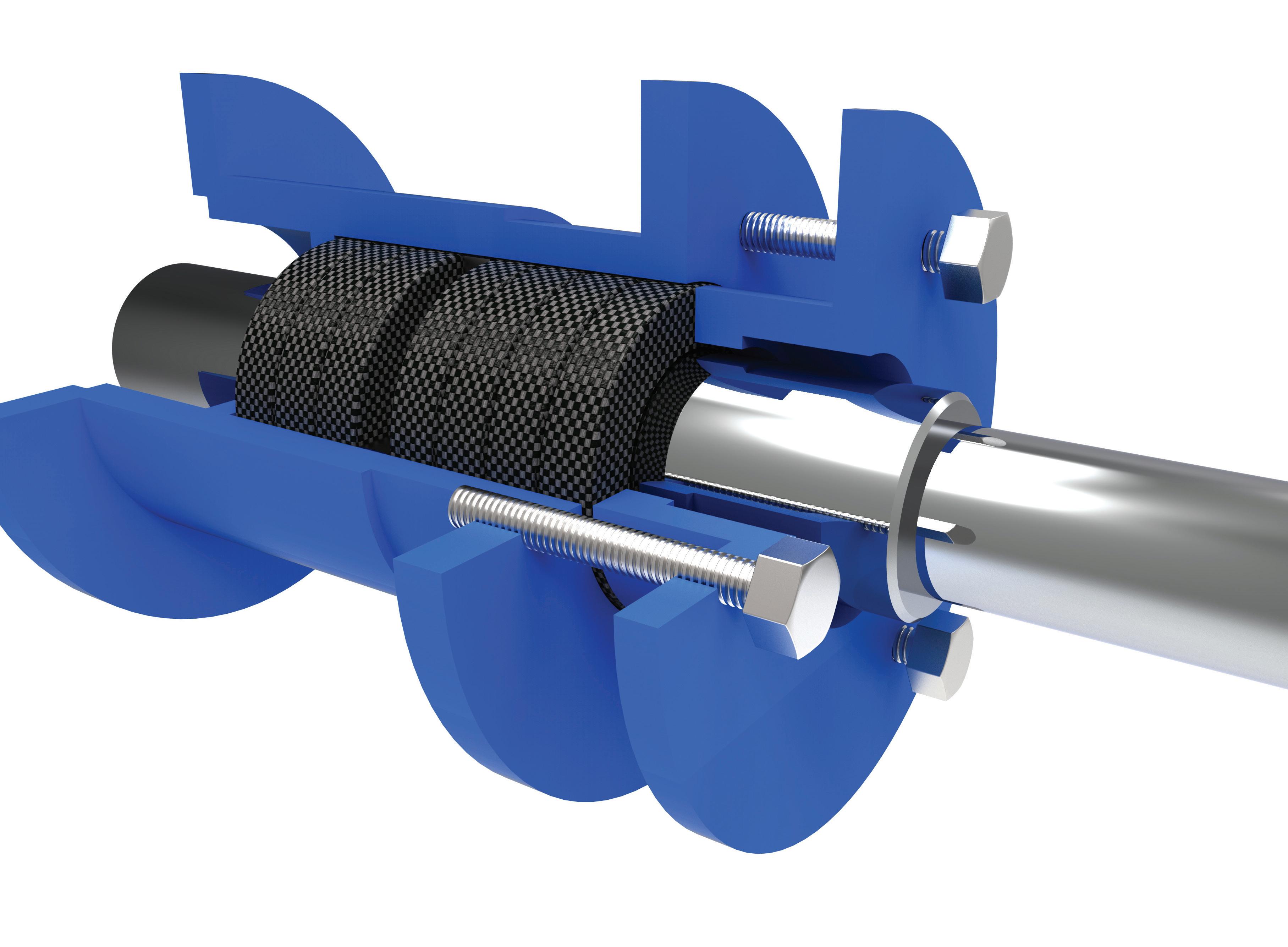

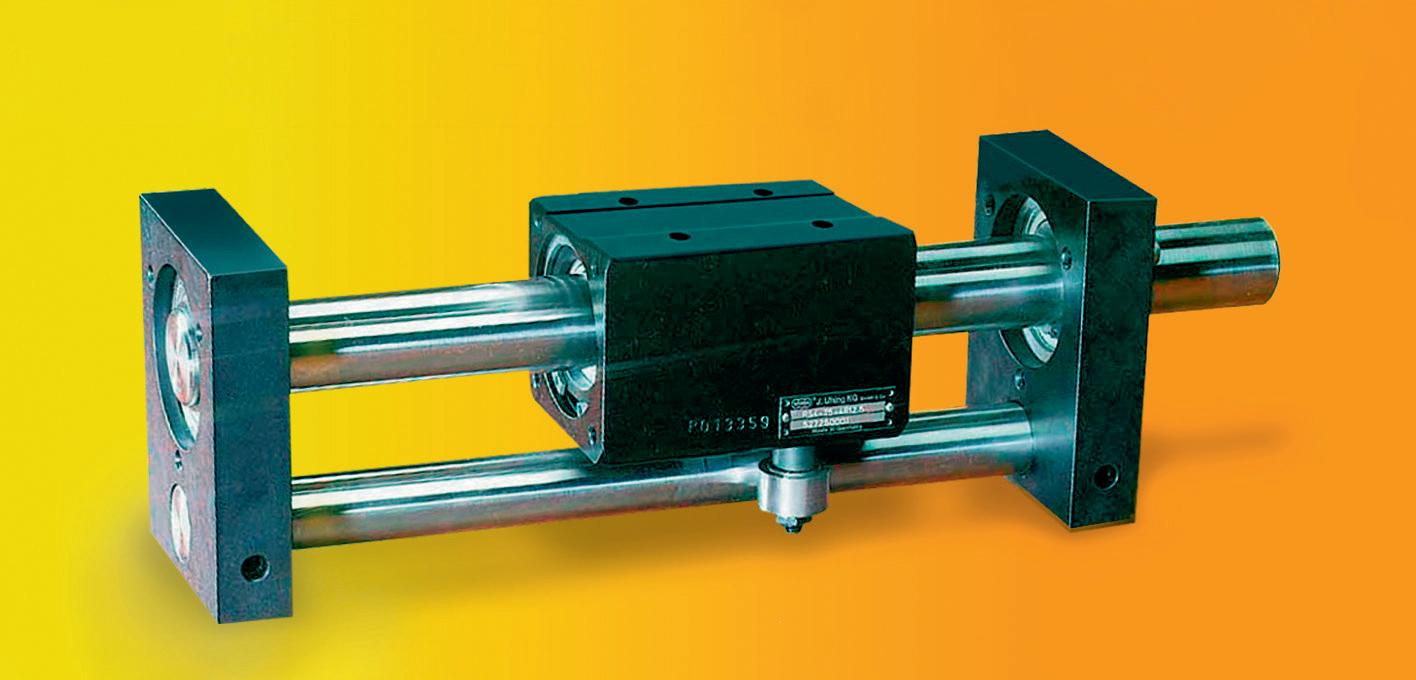

Rolling Ring LINEAR DRIVES

Canadian MedTech innovation, compliance and collaboration

Navigating design challenges in Canada’s complex

MedTech industry. SEAN TARRY

The Canadian MedTech sector occupies a unique position at the intersection of strict regulation, technical innovation and global health impact. For design engineers tasked with developing medical devices in this space, the job is anything but routine. It demands not only technical prowess but also an ability to navigate shifting supply chains, evolving compliance standards, as well as the growing role of AI and connectivity. According to Christian McMechan, Principal Electronics Engineer at StarFish Medical, engineering in this field is an exercise in innovation under pressure.

Supply chain stresses

With 14 years of experience and a strong background in both electrical engineering and medical compliance, McMechan understands the challenges faced by design engineers when developing medical devices in Canada. And, in his estimation, one of the most difficult hurdles to overcome today is one that’s shared by engineers just about everywhere.

“The biggest technical challenge isn’t necessarily unique to Canada,” he explains. “Supply chain instability is huge, especially when your device relies on components originally developed for fast-moving consumer electronics.”

Consumer components like processors, sensors and displays drive much of the technological advancement in wearables and mobile devices. However, these parts often have short life cycles - replaced by newer, faster, smaller iterations every 12 to 18 months.

“That’s great for smartphones,” says McMechan, “but a nightmare for medical devices, which often need to be supported, manufactured and maintained for five to ten years. If a

Concept

sketch of the arc device – a non-invasive medicasl device.

major component becomes obsolete, you’re suddenly facing requalification, re-certification and possible design overhaul.”

Future-proofing devices

Adding another layer to these challenges, says James Henderson, Senior Mechanical Engineer at Design 1st, is the complexity of mechanical design constraints under regulatory pressures.

“Medical devices aren’t just mechanical puzzles; they have to be biocompatible, sterilizable and designed for repeatable manufacturing,” he points out. “Every material choice and assembly process must be validated, which limits your options but also ensures patient safety.”

Beyond the challenges associated with hardware, McMechan notes that regulatory burdens have evolved to reflect modern connectivity and cybersecurity concerns, particularly when it comes to electromagnetic compatibility.

“There’s greater emphasis today toward future-proofing the devices that are being designed and manufactured,”

he says. “Regulators are pushing manufacturers to conduct risk analyses that consider emerging emitters like 5G and new frequency bands. The burden’s now on the manufacturer to prove their device will be immune - or at least safe - in tomorrow’s environment.”

Designing for adaptability

Henderson echoes McMechan’s concern about future-proofing, emphasizing the importance of designing with adaptability in mind.

“When you design a device today, you need to anticipate the technology landscape three to five years out,” he says. “This means modular designs, upgradable firmware, and even considering how AI integration might evolve in the device’s lifecycle.”

Ensuring cybersecurity is no longer optional, either, explains McMechan. Devices are expected to connect to hospital networks, smartphones and cloud platforms. However, this expectation brings with it increased risk for manufacturers.

“We’re now needing to deal with

authentication protocols, encrypted data transmission, software versioning and endpoint security,” he says. “The design isn’t just about hardware anymore. It’s about designing trust.”

Henderson adds that this shift even influences mechanical design elements.

“Physical security - like tamper-proof enclosures and secure ports - has become just as critical as software defences. If a device is physically compromised, no amount of encryption can save patient data.”

Regulatory landscape

When it comes to the regulatory level, Gerry Frenette, Vice President of Public and Member Relations at MedTech Canada, offers critical insights into how the regulatory environment shapes product development timelines, especially for small- to mid-sized organizations.

“One of the most significant regulatory hurdles has been the transition to the Medical Device Single Audit Program (MDSAP),” Frenette explains.

“Canada was the first jurisdiction to implement MDSAP, which has posed challenges but ultimately offers significant benefits, particularly in enabling single audits to cover multiple regulatory jurisdictions.”

Frenette goes on to highlight how this international audit harmonization not only simplifies compliance but also increases access to Canadian markets for Class II-IV devices.

“The work that we conduct at MedTech Canada involves educating members on the program and advocating for further adoption globally,” he says. “This reduces duplication and streamlines product commercialization.”

Advocacy and support

With respect to the maintenance of regulations, including the development of or revising of existing ones, in collaboration with Health Canada and other bodies, MedTech Canada facilitates regular bilateral meetings, conferences and consultations to ensure ongoing dialogue. It’s an important

role to play says Frenette, advocating for the ongoing success and viability of Canadian MedTech companies while also guaranteeing patient health and safety.

“These forums allow both industry and regulators to address concerns and identify areas for alignment,” he explains. “Over the past three years, we’ve seen progress in reducing regulatory burdens while maintaining safe and effective devices in Canada.”

Proactive engagement

With these challenges in mind, Frenette emphasizes the importance of proactive regulatory engagement for OEMs and machine builders, especially amid evolving standards and supply chain pressures. He advises early and ongoing interaction with Health Canada in order to help clarify requirements, reduce risks and minimize costly surprises during development. In addition, he also recommends leveraging external resources such as regulatory consultants, industry

associations and government guidance programs as a means to remain current and compliant.

He goes on to explain that accelerated pathways like MDSAP and international recognition pilots are also important strategies that can be used to reduce certification burdens and speed time-to-market. In fact, Frenette suggests that organizations should aim to communicate and engage with as many points of reference as possible to ensure they are keeping up with the demands of medical device regulations.

“We also encourage collaborative development models - partnering with academic institutions or contract research organizations - to share compliance costs and foster innovation,” he says. “And participating in consultations and advocacy activities keeps industry perspectives front and centre in regulatory updates. This collaborative approach benefits the whole ecosystem.”

Embedding compliance and innovation

Design constraints in the Canadian MedTech space reflect global realities, explains McMechan, noting that compliance isn’t just a paper exercise - it’s deeply embedded in every design decision, especially when regulatory bodies like the FDA, Health Canada, or the EU’s MDR are involved. Every decision must be validated, he says,

documented and often simulated before any hardware is tested. As a result, budgets can sometimes grow unmanageable.

“Cost is always a major constraint,” he admits. “The level of documentation and design rigour needed in medical device development means timelines and budgets are never light.”

Despite these challenges, however, McMechan still finds room for innovation - particularly in how regulatory awareness can help shape better designs from the start.

“When I was a junior engineer, I didn’t know what I didn’t know,” he says. “And in some ways, that helped me create unconventional solutions to common problems. Now, I can embed safety principles, compliance factors and usability concerns into the earliest phases of design. That saves time and cuts down on rework.”

Interdisciplinary collaboration

It’s a sentiment that’s shared by Henderson. He recognizes the unique complexities involved in the development of medical devices from design to manufacturing, believing that adherent practices and procedures should not only be part of a company’s approach, but it should also be engrained in just about everything that it does. And he also suggests that interdisciplinary collaboration can be critical in determining the success of any given device.

“The regulatory landscape is

complex and ever-changing,” he asserts. “You can’t treat compliance as a checklist at the end. It has to be baked into your design workflow from day one. And a strong interdisciplinary approach definitely helps. Engineers need to collaborate closely with clinicians, human factors specialists and regulatory experts to ensure that the device they’re developing is safe, effective and user-friendly.”

Communication is key

Communication is also a central pillar of successful MedTech development, says McMechan, especially in a consultancy environment like StarFish Medical, where teams regularly engage with clients, clinicians and regulatory experts in the design to manufacturing journey.

“It’s one of the most interesting parts of the job,” he says. “Every project is different, and every stakeholder has a different level of technical fluency. Sometimes the client leans entirely on us for technical direction. Other times, they have their own engineering team, and we need to prove our competence quickly to build trust. Either way, the collaboration hinges on clear, respectful communication.”

In most instances, this communication and consultation, says Henderson, often requires engineers to become experts in the client’s core domain - be it a diagnostic system, a surgical tool or a wearable therapeutic. And then, he explains, they have to disseminate the information and knowledge they’ve gained in a number of different ways in order to achieve success.

“You have to be a translator sometimes,” he says. “You’ve got to take clinical needs and turn them into engineering requirements, then explain those requirements in layman’s terms back to stakeholders. This iterative dialogue can at times be onerous, but it’s absolutely crucial for success.”

In addition, Henderson says that clinicians, in particular, can offer engineers crucial insight into how devices are actually used in the field. He suggests engaging with them to better understand user behaviour in order to inform aspects of development including risk analysis, interface design and the physical form factor of the device.

The telehealth pre-production prototype.

“Understanding the clinical workflow and environment can reveal constraints engineers might never see in the lab,” he asserts. “For example, a device might be used in emergency settings where time and dexterity are limited. That drastically influences design priorities.”

AI and data-driven devices

Looking forward, McMechan cites significant opportunities in the area of emerging technologies, especially those involving machine learning and AI. In fact, he believes that the technology could hold the key to harnessing information that most engineers and organizations didn’t even know existed.

“There’s a lot of work being done on cloud-connected devices that collect standard measurements, like ECGs, but tag them with additional metadata that could be used for training AI models,” he explains. “These systems can discover patterns or correlations that are invisible to human analysts.”

Henderson shares McMechan’s optimism concerning the promise of AI-driven technologies and the possible outcomes that they represent for engineers and machine builders. However, he cautions those who are venturing into its use to be mindful of the obligations and requirements that come along with its potential.

“AI isn’t just a buzzword,” he asserts. “The processing infrastructure from big data companies is making it easier than ever to use machine learning techniques in real-time medical contexts. It’s already affecting how new devices are conceived, how data is gathered and

how diagnostic feedback is provided to clinicians. However, integrating AI means ensuring data integrity and addressing regulatory concerns around algorithm transparency. It’s new terrain that demands collaboration across data scientists, engineers and regulators.”

Advice for new engineers

For engineers new to the Canadian MedTech industry, McMechan offers both encouragement and practical advice. He suggests that aspiring engineers tailor their school projects toward medical applications, stressing the need for them to study the basics of medical device regulations early.

“If you join a consultancy, expect to learn fast,” he says. “You’ll touch a wide variety of projects in a short time. Recognize the recurring design patterns. They’ll save you time down the road. And always test early, simulate everything and use your calculations to predict behaviour before the parts ever arrive.”

In a sector as demanding, and as vital, as MedTech, there are few shortcuts. But for engineers driven by impact, collaboration and the chance to solve hard problems that matter, Henderson says that the path is rich with opportunity.

“MedTech is a demanding field, but it’s incredibly rewarding. The impact on patient outcomes is tangible. When the device you’re designing might improve or save a life, it gives everything more meaning. So, to engineers exploring a career in MedTech: stay curious, be persistent and never underestimate the power of good communication.” |DE

BUILT TO WORK. DESIGNED TO LAST.

From OEM systems to demanding industrial environments, Gast compressors and vacuum pumps deliver the long-lasting, low-maintenance performance engineers trust - even in Canada’s toughest conditions.

• Oil-less, lubricated models for all applications

• Compact, quiet, energy-efficient design

• Trusted in automation, packaging, lab & medical

• Coast-to-coast support from Wainbee experts

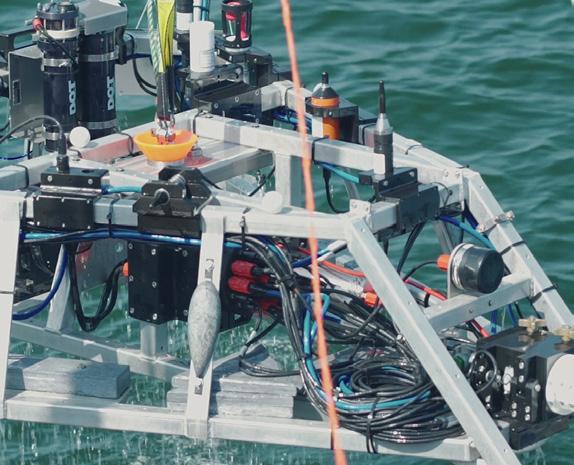

Meeting high performance demands

How metrology, design and collaboration drive resilient engineering.

BY SEAN TARRY

Within today’s industrial landscape, the standards associated with acceptable, and even expected, performance continue to rise. Machines need to function longer, operate faster and endure harsher environments - all without failure. Whether designing aerospace systems meant to withstand extreme thermal cycles, building semiconductor tools requiring nanometer-level precision, or crafting medical devices deployed in corrosive, remote settings, the challenge remains the same – to consistently meet and exceed the standards for the parts and products that are being developed.

This level of engineering excellence isn’t ensured by any single source. To achieve it, a holistic integration of data-driven metrology, strategic material choices, validated simulation and cross-functional collaboration is demanded, all fostered at the earliest stages of design.

Considering these things, and to better understand what’s required of design engineers who are responsible for meeting the demands of high-performance parts and components, we spoke with three leading experts - Gary Peacock, General Manager of Metrology Software at Hexagon; Gregory Reain, Dimensional Metrology Expert at Canada’s NRC; and JeanMarc Guindon, Director of Engineering at Enginuity. Combined, their insights offer some tips and inspiration for engineers developing for harsh or challenging environments, underscoring the fact that the best-performing machines are built not by guessing, but by measuring, iterating and working together.

From measurement to intelligence

For Gary Peacock, metrology has

evolved far beyond inspection and is quickly becoming a facet of any engineering and manufacturing company, feeding into decisions and direction outside of simple measurement.

“Metrology software is not just about measuring dimensions anymore,” he asserts. “It’s about transforming raw data into actionable intelligence - from information to context, to knowledge, and ultimately to wisdom.”

He describes this as a spiral of maturity, with each layer building on the last, converting reactive insight into predictive control. It’s a shift from detecting defects to preventing them.

And it’s made possible by integrating data across every domain, from CAD to machining to inspection. At Hexagon, the Nexus platform embodies this unified approach.

“When design intent, virtual inspection data and real-world feedback all live in one shared digital twin,” Peacock explains, “then designers understand how what they draw will actually be manufactured and checked. That transforms the entire design process.”

Peacock highlights how Hexagon’s Autonomous Metrology Suite helps design engineers, machine builders and OEMs achieve this level of data

Ensuring parts and components meet the demands of high-performance requires a holistic integration of engineering practices.

integration and consistency. For instance, Hexagon generates inspection routines automatically from CAD and PMI, fine-tuned to different CMMs across multiple sites, resulting in a level of consistency that used to take weeks. Nexus allows it to happen nearly instantaneous. And, as a result, explains Peacock, remote or disparate teams and colleagues can share in the same knowledge.

“One of Hexagon’s clients told us that their junior engineers learned much faster because the Autonomous Metrology Suite visualized inspection metrics virtually,” he explains. “They didn’t need a physical part to see what worked and what didn’t. This isn’t just about efficiency. It’s about democratizing quality and shifting inspection insight to the entire engineering team.”

A central role for AI

When it comes to the latest tools offering the greatest potential to enhance measurement and testing, Peacock immediately points to the use of AI as revolutionary. He recognizes the technology’s incredible capabilities to automate and predict. However, he suggests that we may be on the cusp of a whole new level of inspection and quality assurance.

“We’re already using AI to predict out-of-tolerance conditions and to suggest process adjustments,” he explains. “The next frontier is systems that not merely alert engineers to defects but automatically adapt tools and process parameters to prevent them. That’s what true resilience looks like.”

Designing with measurement in mind

With respect to ensuring the reliable performance of any given part, component or machine, Gregory Reain suggests that it begins with traceable, credible measurements. At Canada’s National Research Council, ensuring calibration traceability to SI units is foundational. Or, as Reain puts it, it’s something that’s entrenched in the NRC’s practices and processes because of the valuable purpose it serves.

“For high-performance systems, measurement isn’t optional, it’s part of the design itself,” he says. “Complex geometry is great, but if your feature

isn’t accessible by a probe, whether tactile or optical, then you lose traceability. It’s effectively un-measurable, and that creates enormous risk. Engineers should design with inspection in mind. If you can’t trace your result to SI units confidently, or if your measurement uncertainty dwarfs your tolerance, then you don’t know what your machine does in reality.”

To mitigate these types of issues,

he stresses clear and open early-stage communication across departments, urging engineers to share information and nuances about the projects they’re working on in order to improve efficiencies, reduce late-stage errors and confusion and accelerate timelines.

“A quick alignment between design and metrology can make a big difference,” he asserts. “Sometimes a part is perfectly manufacturable but

Next level hydraulic control

RMC200 Standard

Fast, precise, simple and elegant.

Use Delta RMC motion controllers and graphical RMCTools software to simplify and improve complex motion. 1-50 axes of synchronized position, velocity and pressure/force control.

Visit our website for videos, case studies, and specifications. Find a case study of your industry and application.

Discover simple, fast, and precise electro-hydraulic motion at deltamotion.com

PATTERNS FOR TRUE RESILIENCE

While superior quality assurance involves a range of different perspectives and considerations, including software insights, measurement science and practical engineering, a set of basic principles converge, directing design engineers developing high-performance parts and components:

• 1. Metrology as a design driver: Start with quality in mind. Engineering isn’t complete unless measurements confirm performance. And those measurements must be planned at the beginning, not left up to QA at the end.

• 2. Data integrated across workflow: Centralized platforms like Nexus allow inspection results to inform design and machining decisions, enabling a truly predictive cycle.

• 3. Designing for inspectability: Features and datum schemes must be accessible to measurement tools. And measurement uncertainty must align with tolerance intent.

• 4. Virtual modeling and real testing: Powerful simulation tools allow early failure-mode analysis, but must be complemented with test hardware, especially when environmental conditions or long-life wear matter.

• 5. Material and design simplicity: Match materials for thermal compatibility, minimize unnecessary constraints and validate tolerances in collaboration with machinists and metrologists.

• 6. Future-ready practice: Emerging trends like embedded digital metrology and AI-assisted inspection are becoming central, but only if they’re grounded in validated unit standards and accessible data.

impossible to inspect, because the datums or datum scheme were designed for aesthetics rather than accessibility.”

Reain also shares his views on measurement uncertainty and the challenges that it can pose, urging engineers to think beyond the nominal tolerance. He explains that if a component tolerance is ±5 microns and the measurement uncertainty is ±3 microns, then the user is operating dangerously close to ambiguity. The difference between a pass and a failure in that instance can be statistical and no longer deterministic. It’s the reason he advocates documenting and communicating uncertainty as a design metric.