Our combi-versions feature four rear rubber tires in place of a traditional drum. Each pair is independently powered by separate drive motors, significantly reducing the risk of surface damage —especially during tight turns on freshly laid asphalt. The rubber tires also help achieve a denser, smoother finish, meeting the demands of high-spec paving jobs.

14 5 Tips to Ensure Your Workflows Are As Smooth As Your Roads

Asphalt contractors embracing construction software are finding gamechanging efficiencies across bidding, scheduling, field execution, and maintenance.

18 Waste Into Wealth

Even contractors who don’t own an asphalt plant can benefit, and profit, from setting up a crushing operation on the side.

OF THE

38 Women Advancing in Construction

The asphalt and construction industries offer diverse career paths, from editorial and marketing to association leadership.

PRESERVATION & SUSTAINABILITY

42 How Crawler Skid Excavators Are Revolutionizing Roadbuilding Efficiency

Discover how crawler skid excavators combine the functions of mini excavators, CTLs, and telehandlers in one compact machine — boosting productivity, cutting labor costs and transforming roadwork efficiency.

46 Sustainable Pavement Preservation: 100% RAP In Slurry Seals

Turning 100 % recycled asphalt into a highperformance slurry seal by cutting costs, carbon emissions, and waste without sacrificing durability.

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published ten times per year: January, February, March/April, May, June/July, August, September, October, November, December by IRONMARKETS, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, 201 N. Main St. Ste. 350, Fort Atkinson, WI 53538. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying

0 2 6

For over a half a decade Blaw-Knox has earned its reputation as the go to source of training and instruction on hot mix paving.

The Blaw-Knox University, is dedicated to training paver operators and foreman on proper Paver Operation and Maintenance and applied Best Paving Practices through classroom-style and handson application courses.

Blaw-Knox provides improved technical and problem-solving skills on a variety of paver operations and maintenance topics. Course instructors share decades of field and teaching experience with attendees, including training on the latest DOT requirements.

• January 12 - January 15

• January 19 - January 22

• January 26 - January 29

• February 2 - February 5 2026 DATES

All details can be found at www.blawknox.com/training or contact at (407) 290-6000 ext. 342 or training@blawknox.com

Introducing the core principles of compaction, why it’s important, and what key factors influence its success in construction today.

Watch the video at: https://asph.link/oci23ag0

Sustainable construction is growing rapidly in the U.S. An industry expert outlines five trends set to transform building practices, from low-carbon materials to circular, net-zero communities.

Read more at: https://asph. link/0pinidc9

Associated Builders and Contractors voiced opposition to the Faster Labor Contracts Act, saying it expands federal power over private labor agreements.

Read more at: https://asph. link/d6trz8qr

Caterpillar’s new articulated truck lineup adds smarter automation, upgraded safety features and redesigned bodies.

Read more at: https://asph.link/ nfs71gvn

The project modernized 22,560 square feet of shared spaces across the Bobcat Bismarck Manufacturing Facility, where more than 700 professional and production employees work and excavators and aftermarket parts are manufactured.

Read more at: https://asph.link/ t982q7b4

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

Brandon Noel, Editor

bNoel@iron.markets

234-600-8983

We are heading into the soon-tobe offseason for many in the industry, and when things kick back up again in the spring, it’s going to be a different place. There have been lots of signs during the second half of 2025 that the economy is weakening, and, according to some economists, those indicators which have been lagging are going to likely catch up with us.

Now, I will be the first person to celebrate me being wrong if, in fact, I turn out to be off the mark. That would be great news! But there have been some other troubling things this year that could also start to make a noticeable difference in 2026 for those in the asphalt business. But there’s also good news!

While the IIJA expires next September, there’s a good chance that a new infrastructure bill can be passed before that happens. The Transportation and Infrastructure Committee have already been at work on the language and priorities of the bill since session began earlier this year.

All that being said, I’ve talked to a lot of firms that are playing things safe for the time being, and I imagine that might continue to be the case until the new funding is set in stone by congress.

Every year we publish two industry spec guides. The first is our Roller Spec Guide, which we published in September, and for November we have the annual Paver Spec Guide. This has the most up-to-date information from all the trusted names and brands in the paver manufacturing industry.

Plus, we have a piece a on how a certain contractor added one piece of machinery to their lineup that completely changed the game for their business: a crusher. They shared about the additional income and moneymaking opportunities that came with it.

Also, we have an interesting interview with Dormie Weber who works for the Association of Equipment Manufacturers (AEM), but she actually once worked here as an editor for Asphalt Contractor magazine--covering and writing about the industry. After here, she took a position at Dynapac North America and eventually landed at AEM.

To round it out, we are covering how a 100% RAP based slurry seal might just transform the way that you look at road surface preservation. All this and there’s a whole lot more, as we get near the closeout of the year. See you on the road!

EDITORIAL

Editor-In-Chief Brandon Noel bnoel@iron.markets

Content Director, Marketing Services Jessica Lombardo jlombardo@iron.markets

Managing Editor Allyson Sherrier asherrier@iron.markets

AUDIENCE

Audience Development Director ......................... Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer.................................................. Ron Spink

Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Operations & IT .................................................... Nick Raether VP, Demand Generation & Education Jim Bagan Brand Director, Construction, OEM & IRONPROS Sean Dunphy

Content Director Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste. 350, Fort Atkinson, WI 53538 afranks@iron.markets

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2025 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR

@ASPHALTCONTRCTR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

The Quasar 360 patented unique latch and slide assembly comes in at only 16 lbs. and is the brightest, lightest and strongest on the market at the 300 Watt classification. It’s one push to rapidly deploy and another to de-latch the balloon has made it the simplest to set up. Robotically welded, nickel-plated latch and slide are built with rust protection for many years of service. The top and bottom assemblies are anodized billet aluminum to ensure the strength. This design was made to withstand the rigors of heavy construction.

The Wirtgen large milling machine W 210 XF is the ideal choice, no matter whether for milling work on freeways, state highways, airports, or other major construction projects. Its MILL ASSIST machine control system ensures absolute efficiency on every construction site. In automatic mode, it always ensures the most favorable working balance between performance and costs. It also allows the selection of three different working strategies that optimize the process with respect to cost, performance, or quality.

Powered by a John Deere engine with a maximum rated power output of 580 kW, the W 210 XF delivers powerful and efficient milling.

Caterpillar will introduce the next-generation Cat 140 LVR Motor Grader in early 2026. The new model adopts the cab design from Cat’s 120 nextgeneration graders, featuring larger windows for better visibility, a standard rearview camera, and a 10-inch touchscreen that integrates functions such as Cat Grade. A redesigned seat with additional adjustments aims to reduce operator fatigue.

The 140 LVR continues the series’ reputation for versatility in roadbuilding, snow clearance, ditching, and municipal projects. Caterpillar reports more than 40,000 testing hours on machines worldwide. The machine maintains a favorable power-toweight ratio and fuel efficiency while offering simplified maintenance through.

Weighing between 2.5 and 2.7 metric tons, the machines are intended for road and pathway construction, as well as gardening and landscaping. The rollers feature 3-point articulation for stability and even weight distribution, helping to produce smooth asphalt surfaces. Both models are equipped with a large drum diameter to support uniform compaction.

Operator-focused updates include a cab with improved visibility, an adjustable seat and simplified controls. Maintenance access points have also been streamlined around the 18.2 kW Yanmar engine. Options include LED work lights, a back-up alarm, anti-freeze filling system, automatic engine shutoff and connectivity with the John Deere Operations Center.

Both models feature a cab that is 28% larger than the PC210LC-11, with more legroom and improved visibility. The machines also deliver up to 20% greater fuel efficiency and up to 20% lower maintenance costs, along with performance increases of 7% in lifting capacity and 8% in bucket digging force, according to the company.

The PC220LCi-12 includes Komatsu’s Intelligent Machine Control (IMC) 3.0 technology with factory-integrated 3D boundary control.

The extremely rugged street sweepers are built to last. Efficiency and productivity are the primary objectives in any industry, this couldn’t be more true with roadwork. Extreme efficiency and super productivity of the XBroom allows virtual single pass sweeping cleanup and considerably more sweeping time before dumping than other street sweepers on the market. More sweeping, less downtime and easy operating equate to larger profit margins.

• Week 1: January 12 - 15

• Week 2: January 19 - 22

• Week 3: January 26 - 29

• Week 4: February 2 - 5

Details can be found at www. gencor.com/training or call us at 407-290-6000 ext. 342.

CLASS SIZE IS LIMITED!

To secure your seat, please register before December 15, 2025

Improving overall plant production and efficiency are all common concerns for plant owners and operators. Having a well-trained technical crew is vital to maintaining plant performance and efficiency.

Gencor and its training staff represent the biggest concentration of knowledge and expertise in all the sciences and technologies involved in the production of asphalt plants. Customers who attend these seminars benefit by having the support and focused attention of the best specialists in the asphalt industry

Using Gencor’s state-of-the-art control simulators and actual equipment, our experts take you step-by-step through a comprehensive & intensive concentrated hands-on training program providing the latest techniques on optimizing production efficiency.

Command Alkon has launched Command Community, an online platform designed to give customers easier access to support resources and self-service tools. The platform allows users to submit, view and manage support cases, track order history and check delivery status through carrier websites. It also provides a Knowledge Base with articles, FAQs and troubleshooting guides to help customers resolve issues independently. New features include chat support, personalized list views for cases and orders and the ability to add comments within cases to streamline communication with support.

HCSS has integrated its Equipment360 fleet management system with Gearflow’s AI-powered parts procurement platform, enabling construction fleets to order parts directly within Equipment360 and automatically sync purchases with the purchase order system.

The integration streamlines workflows by reducing manual tasks, giving teams detailed visibility into all parts purchased, and helping lower costs by minimizing errors and unnecessary spending. Fleet teams have reported saving over 12 hours per week per person and reducing parts budgets by 10–15%, while eliminating the need for additional administrative staff.

RefrigiWear has expanded its lineup of insulated and high-visibility gear with new products built for extreme cold. The Frost Flex Heated Vest, rated for temperatures from 10° to -60°F, uses a rechargeable battery to power heating panels. It features waterrepellent fabric, stretch construction and insulated handwarmer pockets.

For crews working in milder cold, the Lightweight HiVis Work Overalls combine a waterproof softshell with a heat-reflective lining and reinforced knees. Available in orange or lime, the overalls meet ANSI/ISEA 107-2020 and CSA Z96 safety standards. The new Endurance Collection includes jackets and overalls rated to -30°F, plus mid-layer.

Caterpillar is adding built-in automation, safety features and operator-focused upgrades to the Cat 725, 730, 730 EJ and 735 models.

Topcon has announced the HiPer XR, its latest GNSS receiver for surveying, mapping and construction applications. The new receiver is designed to benefit a wide variety of users, including construction professionals, surveyors, GIS professionals, engineering firms and others. The HiPer XR supports all major satellite constellations, including GPS, GLONASS, Galileo, BeiDou, IRNSS, QZSS and SBAS. The new receiver features advanced Topcon Integrated Leveling Technology (TILT) compensation featuring a calibrationfree and magnetic interferenceimmune integrated IMU that provides up to 60 degrees of tilt for precision measurements in challenging positions. This keeps data reliable, even in areas with interference.

The trucks feature push-to-start ignition with operator ID, a redesigned cab with touchscreen controls and a Cat C13 engine that meets global emissions standards. Automatic traction control, engine overspeed protection and retarder control are now integrated to improve handling and reduce wheel slippage on difficult terrain.

Updated dump bodies provide easier loading and reduce carryback, while payload technology gives operators real-time weight data and external indicator lights.

A compact tool designed for tight spaces and trench work. Weighing under 70 lb (31 kg), the machine delivers high compaction force through a 5.5-in (140-mm) plate width, 1.8-in (45-mm) jumping height, and adjustable frequency up to 790 vpm (13.2 hz). The tamper’s lightweight, ergonomic design makes it easier to transport and maneuver around obstacles. Its variable frequency and large stroke allow it to handle a range of soil types — including clay, silt and mixed soils — for jobs such as trench backfilling, foundation prep, landscaping, and pipeline construction. Durability features include a Honda 4-stroke gas engine, engine cover for protection during transport, a two-stage self-cleaning air filter, and dual fuel filter system to reduce downtime. An isolated steering handle minimizes vibration for the operator and includes a single-point lift for easy handling.

FEATURES:

• All diesel power (both burner and engine) for maximu efficiency and performance.

• Industry’s fastest heat u time - less than 2.5 hour from cold start.

• Advanced plow-poin agitation for faster heat-u and material discharge.

• Heated discharge chut for uninterupted materia applicaton.

Asphalt contractors embracing construction software are finding game-changing efficiencies across bidding, scheduling, field execution, and maintenance.

The most successful paving contractors aren’t just skilled at laying asphalt - they’ve mastered the art of operational efficiency. While many companies rely on established manual workflows, forward-thinking firms are leveraging construction software to create competitive advantages that translate directly to their bottom line.

The technology exists today to create connected workflows that span every aspect of paving operations - estimating, bidding, scheduling, field execution, documentation, billing, and future project planning. Here are five ways technology is making a difference for asphalt contractors who refuse to settle for business as usual.

For many contractors, the bridge between estimating and field operations is a spreadsheet-driven process that creates delays and disconnects. When a project is won, the detailed assumptions, quantities, and resource allocations used to calculate the winning bid often live in static files that don’t communicate with field tracking systems.

Integrated construction software eliminates these bottlenecks by creating direct data flow from estimating to field operations. For instance, Minneapolisbased Bituminous Roadways implemented B2W’s connected platform, which allows bid data to automatically move to field tracking and resource scheduling applications.

“Once a project is won, bid data flows directly to B2W Track and B2W Schedule,” explains Nate Larson, construction technologist with Bituminous Roadways. “This allows managers to establish daily field logs and assign resources according to how the job was envisioned in the bid.”

The greatest value is that field crews work from the same assumptions used in bidding, eliminating manual re-entry and ensuring projects proceed according to plan.

Conventional grading methods rely heavily on operator skill and experience, often resulting in a time-consuming trial-and-error approach. The emergence of 3D machine control technology has reshaped traditional practices.

Jacob Buck, co-owner of Buck Brothers Asphalt Paving& Concrete in Toledo, Ohio, describes their former process: “We didn’t have graders or dozers at the time, so we would run stone through an old asphalt paver to achieve grade. While it worked, it was difficult to achieve a perfect grade. It became a’guess and check’ process that required considerable skill.”

A few years ago, Buck Brothers implemented 3D machine control

guided by Trimble’s SPS930 Universal Total Station with 3D modeling workflows, which immediately delivered millimeter-level precision guidance and eliminated guesswork.

“In the two short months before the season closed in 2023, Buck Brothers was able to fine grade over 300,000 square feet of stone base before paving,” Buck reports. “We literally cut our prep time in half and delivered effective drainage in every situation. Now I know that everything we pave is at the right thickness and is going to drain correctly.”

For many pavers, material coordination represents one of the most timesensitive challenges. Hot mix asphalt has a narrow temperature window for proper placement, making coordination between plant production, trucking, and paving crews absolutely critical. Conventional methods rely on phone calls and radio communication to manage deliveries, often resulting in costly delays when trucks arrive too early or too late.

Digital dispatching platforms transform material coordination through real-time visibility and automated scheduling. Bituminous Roadways dramatically increased its capacity using integrated software that connects scheduling data directly to truck dispatching applications.

“Our ability to dispatch over 200 trucks in a day, compared to 80 trucks in previous years, speaks to efficiencies we’ve gained,” according to Kim Scales,

Our UL asphalt tanks have properly sized normal and emergency venting as standard.

All structural attachments are OSHA approved and are af xed to our tanks per code.

All tanks are tested to UL142 Section 42.2.1a 10th Edition.

All weld joints are per UL142 standards.

Your asphalt tanks will be properly labeled and registered with UL142.

IS technology manager at Bituminous Roadways. This 150% increase in dispatching capacity demonstrates how real-time solutions enable firms to coordinate material deliveries with precision, ensuring hot mix arrives when paving crews need it rather than when convenient for plants or trucking companies. Advanced dispatching platforms also incorporate geofencing technology, allowing dispatchers to verify equipment location before scheduling moves and eliminating costly trips to empty jobsites.

Conventional quality control in asphalt paving relies on post-construction testing and final inspection - a reactive approach that discovers problems after it’s expensive to fix them. Crews work with limited real-time visibility into project performance, making adjustments based on experience rather than quantifiable data. Manual documentation is time-consuming and often provides feedback too late to influence ongoing operations.

It’s a common practice that leaves firms hoping everything went right rather than knowing it did. Real-time data collection throughout the project lifecycle transforms quality control from reactive to proactive. Effective field documentation also improves communication between field and office teams.

At Palmer Paving Corp., a

Massachusetts-based asphalt producer and paving contractor, field crews provide detailed insights through digital logs. “They leave a lot of notes for us, because they’re basically our eyes and ears out there,” explains Palmer Paving’s contract administrator Mary Lessard. “What they enter in those field logs give me a picture.” That same data is used for future bidding on similar jobs.

Automated field documentation and integrated platforms can also help streamline equipment maintenance. For example, Bituminous Roadways replaced what Scales called”antiquated software” with B2W Maintain, which connects maintenance scheduling with job scheduling to minimize equipment downtime. “We now proactively schedule maintenance and track detailed equipment repair costs,” she says. “Mechanic hours also transfer automatically to Viewpoint Spectrum for payroll.” This integration ensures maintenance work happens during planned downtime rather than disrupting active projects.

It’s important to remember that technology adoption doesn’t require an all-or-nothing approach. The most successful firms identify their biggest operational headache and solve that first, then build from there.

Bituminous Roadways took this incremental path, transitioning from

spreadsheets to B2W Estimate as their bid volume increased, then gradually adding field tracking, scheduling, and maintenance modules to create their connected workflow over time.

Similarly, Buck Brothers’ Jacob Buck faced a choice: “It was either learn machine control or learn to manually operate a grader/dozer. It made more sense to go the machine control route.” He started with Trimble’s Universal Total Station for one specific challenge - fine gradingthen expanded his 3D capabilities as confidence and expertise grew.

These companies succeeded because they avoided the temptation to digitize everything simultaneously. Instead, they identified their most time-consuming manual processes and tackled those first. Whether your biggest challenge is equipment maintenance scheduling, crew coordination, or material dispatching, the key is picking one area and doing it well before expanding.

Subscription-based technology models can also ease adoption by reducing upfront capital investments while ensuring firms always have access to the latest features and updates.

The firms profiled in this story share a common thread: they didn’t view technology as a replacement for their expertise, but as a multiplier of their capabilities. By connecting previously isolated platforms - estimating, scheduling, field operations, and project documentation - they are creating workflows that eliminate waste, reduce errors, and maximize the value of every crew hour.

The industry landscape is shifting. Companies embracing these integrated approaches are winning more bids with accurate pricing, completing projects faster with better quality, and scaling operations without proportionally increasing overhead. As these advantages become standard practice, contractors who implement them will find their workflows become as smooth and efficient as the roads they build.

by Kevin Garcia, General Manager, Civil Specialty Solutions at Trimble, and John Sheedy, Sr. Product Manager at B2W Software, a Trimble

company.

By Brandon Noel, Editor-In-Chief

More asphalt contractors are adding crushing to their operations, and it’s becoming a boom for both profits and production.

For many asphalt and pavement maintenance contractors, the piles of leftover millings, broken concrete, and truck washouts that accumulate over a season are seen as waste, a problem to be dealt with, material to be hauled away somewhere. In some areas this waste even comes with its own costs associated with dumping it. But a growing number of forward-thinking contractors are realizing that these “waste” piles can become a profit center.

Crushing reclaimed asphalt pavement (RAP) and concrete isn’t just about sustainability. It’s about creating new material streams, cutting disposal costs, and building independence from third-party aggregate suppliers. As several contractors have discovered, adding a crusher to the yard can change a company’s financial picture in surprising ways.

In central North Carolina, Piedmont Paving made a move nearly six years ago that seemed risky and out of the ordinary at the time. What began as a side project on a small plot of land is now a full-scale material operation serving both their own needs, as well as other contractors who need materials or are just looking for a place to dispose of their waste.

What they demonstrated is that, even if you don’t own an asphalt plant, even by itself, crushing can be profitable, efficient, and a game changer for any size paving contractor.

Matt McGee of Piedmont Paving said the decision came from seeing value where others saw waste. “My dad, David

McGee, and Mark Rountree… always had people asking what we do with those millings. They wanted to buy them,” McGee explained. “They used [the millings] for driveways, paths, and other things, while most people in our industry, are trying to get rid of them.”

Rather than giving away RAP to local plants or paying to dispose of concrete, Piedmont decided to start processing it themselves.

“We started just feeding ourselves,” McGee said. “Instead of taking it to the asphalt plant, where we don’t get anything for it in return, we ended up acquiring this property, and it’s grown exponentially since we started.”

The operation now handles about 5,000 to 6,000 tons at a time. “We don’t charge for it, everybody dumps for free,” McGee said. “If it’s clean asphalt or clean concrete, we’ll take it.”

That free dumping policy ensures a steady flow of inbound material.

“We have two concrete companies that come and wash out all their trucks every day, so we’re getting ten, twenty,

thirty yards a day of concrete washout,” he added.

Each load that comes in becomes fresh inventory. The crushed product, which includes asphalt down to, “fiveeighths minus, by the size of your thumbnail,” McGee said, is sold for driveways, road projects, and even other asphalt plants call them up.

“Other contractors will buy the crushed concrete because it’s just as good as stone,” McGee said. “It takes more water to set up, but once you set it, I think it sets up better than stone.”

The company’s first customers were other paving plants that needed clean RAP. “We ended up actually selling it for the first two-or-three years to a paving plant out in the boonies that were having trouble getting RAP,” McGee recalled. “They would send ten trucks on the weekends, and we’d have somebody load them out, and they would buy every single lick of it.”

Once the word spread, Piedmont didn’t have to market much. For a while, McGee experimented with Facebook Marketplace. It turned out to be almost too successful.

All of this runs with a minimal crew. “I only see the two guys here,” Brandon noted in the interview. McGee confirmed, “That runs the whole operation… three days, and they’ll be done crushing this”. Despite the lean setup, the company can’t keep product in stock. “Even that pile right there that’s not crushed yet is already sold,” McGee said. “We can’t keep it in stock”.

The experience at Piedmont echoes what equipment manufacturers and producers are seeing across the asphalt industry.

“When I tell you I could not keep up with the orders and the messages,” he said, “I had to shut that down.” Today, the operation sells itself, with multiple trucking companies picking up and reselling crushed material.

“We just load them and charge them,” McGee said.

The company’s investment in crushing equipment also paid off in terms of efficiency. “It’s a Germanengineered machine. It’s like a Swiss watch,” McGee said, describing their Kleeman impact crusher. “It’s electrical over hydraulic… there’s a magnet that gets out any metals… and anything that’s too big gets filtered back through on the bottom conveyor to go through one more time to make sure it gets crushed all the way”.

Daniel Friedman, VP Marketing from leading crusher manufacturer Eagle Crusher explained in a Q&A that, “Having on-site crushing capabilities allows asphalt contractors the opportunity to both save money by recycling RAP as well as introduce new revenue streams by accepting RAP from third parties… and, if the business case supports it, charge to accept the materials.”

For paving contractors, this can mean transforming waste into wealth. Instead of paying fees or hauling offsite, every ton of crushed asphalt or concrete becomes inventory, usable base material for your own projects, or sellable aggregate. Beyond savings, there’s independence.

Another major advantage is the flexibility. While mobile/portable crushing equipment usually isn’t directly tied into a HMA production system, well thought out plant layouts or crushing operations like Piedmont’s can mean minimal effort to feed RAP bins for asphalt production.

“Crushing on-site means that your operation isn’t beholden to contract crushing operations or third-party suppliers for your RAP,” Friedman said.

That control over supply can be critical when market volatility, trucking shortages, or high aggregate demand cause prices to spike. For higher-volume operations, the return on investment can come quickly.

“Higher-volume asphalt plants can easily see their RAP crushing system investment recouped within a single paving season,” Friedman said.

That kind of turnaround is rare for capital equipment, and it speaks to the high demand for RAP and crushed concrete in today’s roadbuilding market.

With that modularity also creates opportunities beyond asphalt. “When an asphalt plant utilizes mobile or portable crushers to process RAP for their own mix, if there is downtime, the crushers can be sent offsite to crush other materials,” Friedman explained. This can open a new business line and increase revenues.

For contractors who already manage milling, trucking, and site prep, this is a logical extension of their capabilities. Crushed material is always in demand. McGee put it plainly, “They just come wash out. It’s just money in the bank”.

While sustainability goals often drive recycling discussions, the business case is just as strong. Reusing concrete washouts, accepting millings from other contractors, and turning discarded material into a sellable product reduce landfill waste while improving community relations and meeting regulatory expectations. But for most contractors, the math is what seals the deal.

Every truckload that used to cost money to dump now generates revenue. Every crushed ton reduces the need to buy virgin aggregate. And every cubic yard of clean material reused on a jobsite shortens haul times, reduces fuel costs, and keeps crews working.

As the asphalt and pavement maintenance industries continue to navigate rising material prices and tightening environmental standards, the contractors who crush will be the ones who come out ahead, not just in sustainability reports, but on the balance sheet.

•

•

•

•

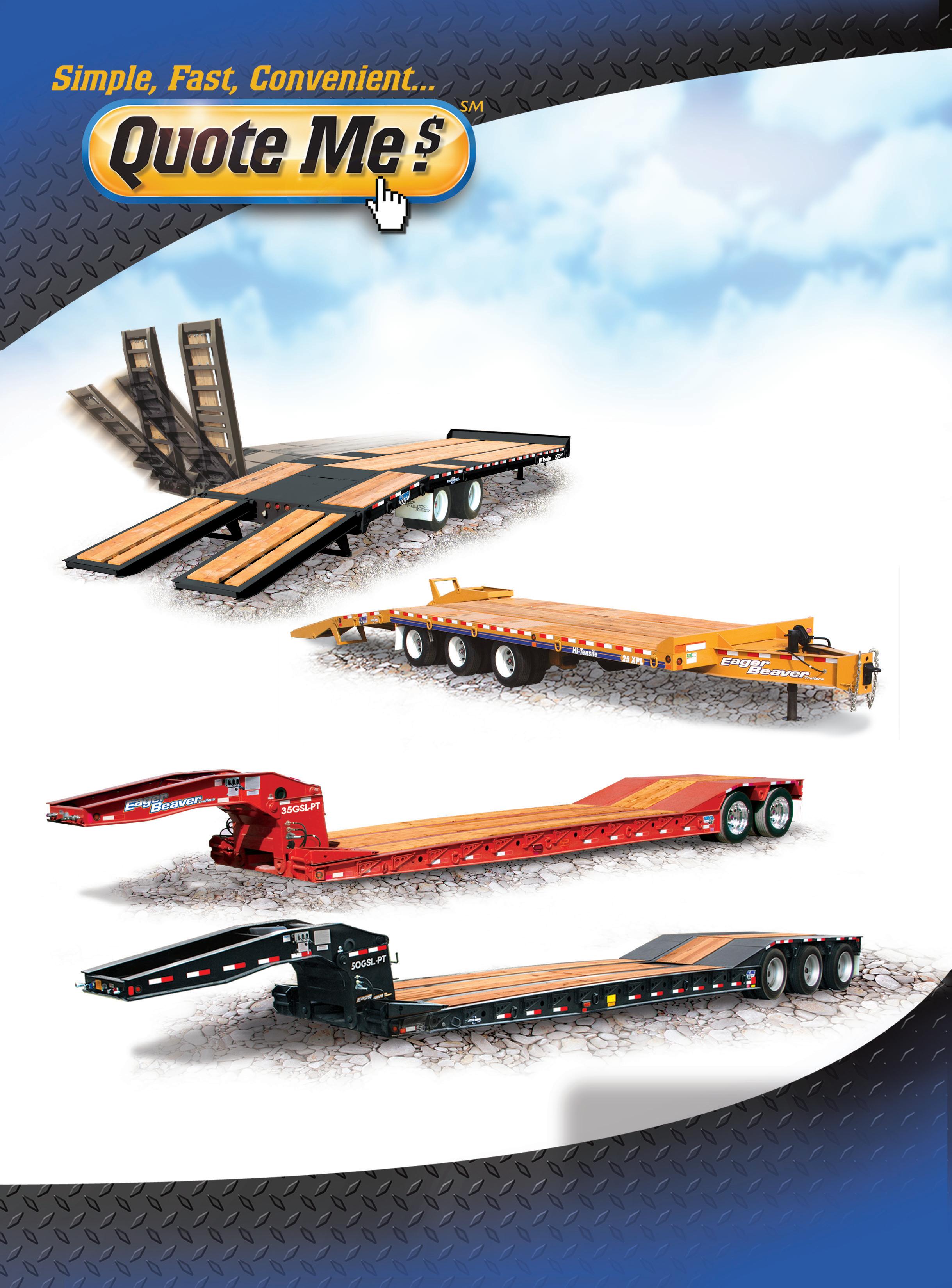

With so many options available, purchasing a new piece of equipment that meets your needs is not an easy decision. Research is an important first step to help you decide exactly what you’ll want to rent or buy. If you’re in the market for an asphalt paver, these next few pages are a great resource. Here, we’ve compiled the industry’s only Asphalt Paver Spec Guide where you can compare more than 75 models. For an even easier way, visit the exclusive, interactive and customizable version of this spec guide at http://www. forconstructionpros.com/specguide/asphalt-paver to sort and rank models based on the specific needs and requirements of your crew.

With the 10-ft. tracked Super 2000-3, the wheeled Super 2003-3i, the 8-ft. tracked Super 1700-3 and wheeled Super 1703-3i, Vögele is marketing four advanced technology pavers for North American highway and commercial markets. Now, a new app for smart phones, tablets and PCs helps users understand the intuitive and easy-to-use ErgoPlus 3 operating system via animations and step-by-step videos that provide an easy-to-grasp demonstration of work steps, including setting up the screed, varying pave widths, and comprehensive automatic functions. Download at Google Play or Apple store or search Vögele ErgoPlus 3 app.

For more information visit https://asph.link/lj2hak

BOMAG is dedicated to asphalt and compaction. While other companies supply products for multiple segments; dirt work, mining, agriculture, BOMAG expertise is solely dedicated to your work and what’s important to you. You’ll be able to rest easy knowing that the support you get with BOMAG products is laser-focused on what is most important to you.

Whether on compact city streets or vast highway projects, Dynapac offers solutions to meet all of your paving needs. Dynapac pavers are designed with paving quality, innovation, ergonomics, and innovative solutions in focus. Built with robust screed designs, top pre-compaction and solutions such as PaveManager, Truck Assist, and BPO.

The 8680 Asphalt Paver delivers high production capacity while maintaining a compact and maneuverable footprint meeting the needs of heavy commercial and main-line contractors alike.

210 hp (157 kW) Kubota Tier 4 Final Diesel Engine

Weight: 33,600 lbs. with LB5 Screed; 36,000 lbs. with LB7 Screed

Paving Widths Variable Up To 15’ 6”

High Speed Smooth Rubber Tracks

Actuator Driven Hood Lift to Aid in Maintenance

The Roadtec and Carlson paver lines by Astec combine power and functionality with nimbleness and maneuverability. Our highway class tractors can be combined with a variety of reliable screeds that will serve you well for a wide range of applications. The commercial class line provides contractors with reliability and unmatched performance in a compact package. Regardless of your project, Astec pavers produce a quality mat with efficiency and productivity.

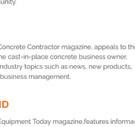

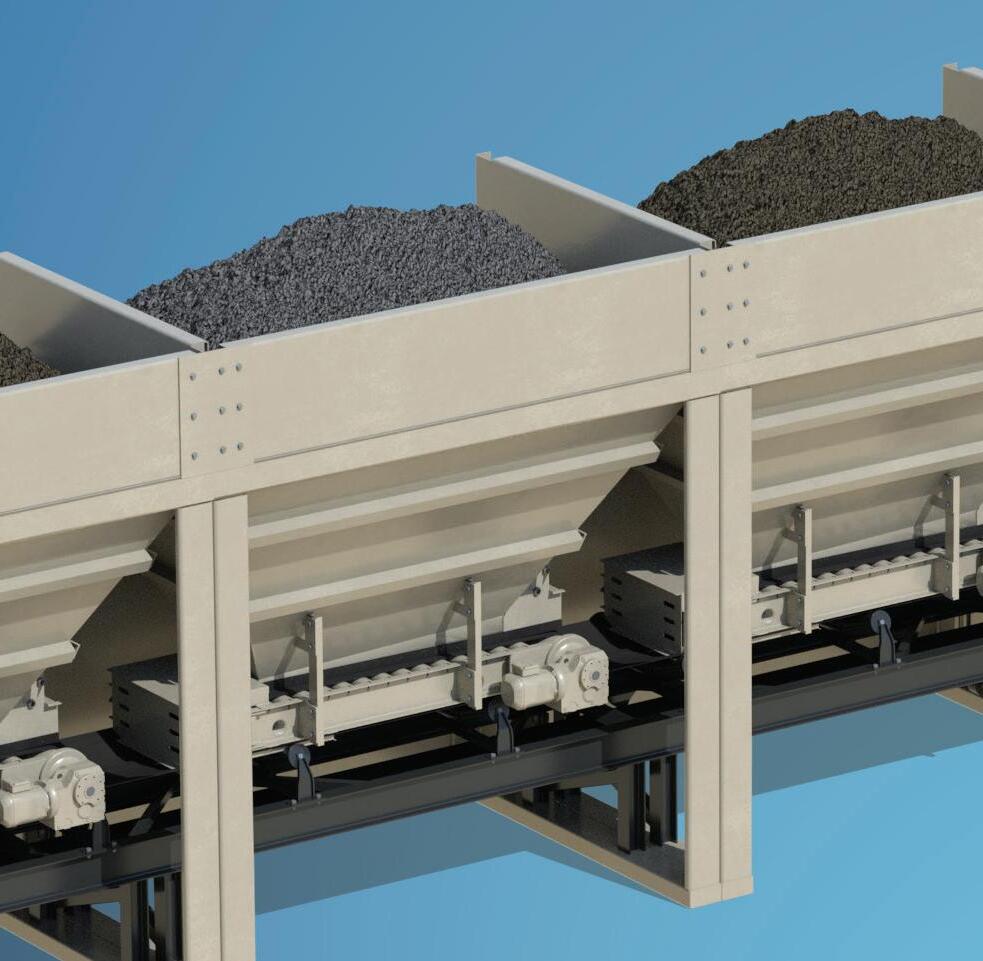

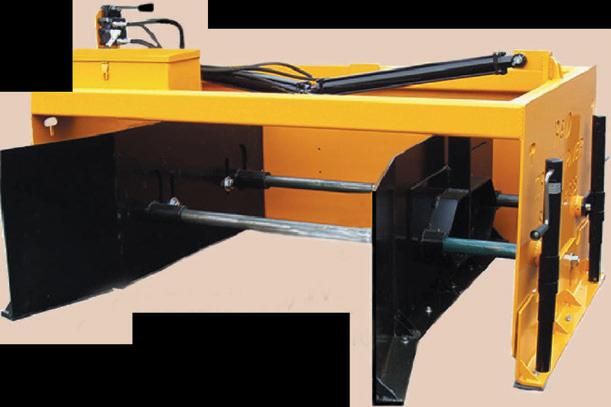

Discover the MaxRap® 25 Portable specially designed for the asphalt industry. Featuring Eagle’s UltraMax® 25 impactor with its high reduction ratio and North America lifetime rotor warranty, the MaxRap 25 Portable provides the same precision crushing of the stationary MaxRap, allowing operators to crush RAP at multiple locations with ease.

Experience the benefits of multi-feature deck selection, blending, and bypass; sampling to verify the mix-design spec requirement is correct, and ability to use the system for screening, direct to stockpile. Discover even more RAP benefits. Plus, this versatile plant may be used as a secondary unit for recycled concrete and aggregate by removing the diverter chutework to become two plants in one.

Engineered and built to exceed the demands of commercial paving, Weiler pavers incorporate proven designs with new innovations to provide performance, reliability, and outstanding mat quality. Weiler offers six pavers to meet contractor’s needs in a wide range of applications. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America.

Mauldin Paving Product’s line of commercial pavers ensure superior performance due to three strategic approaches to design. Proven productivity, screed design, and a commitment to quality are the key elements that sets a Mauldin Paver apart. Mauldin Pavers have been trusted for decades by contractors to produce lasting results.

The all-new Blaw-Knox PF-7110C tracked paver combines all-around visibility, ease of operation and a new powerful Cummins 235hp engine for the ultimate in dependability and efficiency. The turbo-charged diesel engine provides more torque and less weight in a more compact package, letting you power through steep grades with confidence. Coupled with the proven Blaw-Knox durable track and automatic tensioning system, the 7110C ensures smooth and consistent paving power on any terrain.

Blaw-Knox, The Legacy lives on.

Blaw-Knox

Whether paving pathways or interstates, meeting performance targets is the expectation of all contractors. With a complete line of paver/ screed combinations, Caterpillar makes it easy for contractors to deliver on their promises. And with cleaner burning, more fuel-efficient engines, great parts and service support, application expertise, and outstanding training solutions, Cat dealers offer a one-stop-shop that helps paving contractors meet the needs of their customers.

Any source of heat that requires a burner — including natural gas, propane, diesel, or fuel oil — also exhausts emissions into the air.

Replace your tank heaters, hot oil heaters, fuel oil preheaters, and distributor truck heaters with our zero-emission, 100% efficient, Lo-Density® drywell-style electric heat. Sustainable PHCo heaters not only operate without combustion or emissions, they also eliminate a source of fuel spills. Find out more:

LeeBoy features a broad range of commercial class pavers to meet any contractor’s needs. All the models are simple to operate, maintain and service while offering top mat quality provided by the Legend Screed.

Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine.

Modular conveyor drive and sealed chain case increase feeder system reliability and life.

Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

By Allyson Sherrier, Managing Editor

Dormie Weber laughs when she talks about her path into the construction and asphalt industries. It wasn’t a direct route, and she’s the first to admit it.

really share their voice with others. I thought that was awesome.”

That passion eventually led her to Dynapac, where she became a marketing manager overseeing brand voice, trade shows, and advertising. Today, Weber is four months into her new role as Construction Services Manager for the Association of Equipment Manufacturers (AEM).

“My career path hasn’t been a straight line,” Weber said. “Even dating back to my college days, I would go to school in the morning until noon and work retail from noon to seven, and then I milked cows in the evening. So, I’ve done a lot of interesting things.”

The asphalt and construction industries offer diverse career paths, from editorial and marketing to association leadership.

After college, Weber worked her way through a farm store retailer’s manager trainee program before moving into public relations and event coordinating. That experience opened the door to marketing communications and editorial — the roles that first connected her with asphalt and paving contractors.

“I found my passion for learning about the asphalt and pavement industry and really getting to tell the stories of contractors,” she said. “I got to be on the job sites, learn what they did and

At AEM, Weber describes her role as being equal parts communicator and connector.

“I realize that I get to be a connector, which I love,” she said. “Whether it’s helping members, navigating industry challenges or just making sure their voice is heard to a larger audience, building that momentum for the equipment manufacturing space and the markets.”

Weber also works internally, ensuring AEM staff have a clear understanding of the realities of the construction and asphalt sectors. “We’re all aligned to support the members,” she added. “It makes it kind of a cool role that I get to be with members and staff and kind of connect us.”

stories that really matter — that’s what energized me,” she said. “Marketing really gave me that platform to do that in a creative and strategic way.”

That ability to listen and amplify industry voices has become a throughline in her career. From editorial to OEM marketing to association work, Weber has built her reputation on fostering relationships and elevating contractor perspectives.

Looking back, Weber says what drew her into work in editorial and marketing was simple: people.

“The opportunity to connect with people, with their ideas, solutions and

The construction industry has long been male dominated, and Weber acknowledges that her career required persistence and trust-building.

“Early on I had to earn trust and prove my capabilities, but that goes for anybody in a new industry or a new job,” she said. “So, I would strive to be first in and last out, especially in my marketing role at the OEM attending trade shows. Visiting job sites, I would just be a sponge and try to learn

everything and anything that they were doing.”

Weber often relied on research and preparation, even Googling industry terms, lingo and equipment questions, to make sure she could speak knowledgeably with contractors. Over time, consistency and genuine care helped her earn credibility.

“I always made sure people knew I cared about them and their businesses, and it’s not just a job to me,” she said. “Remembering those small details like sending a birthday message or asking about families — that builds the trust I want.”

With workforce shortages and diversity challenges looming large across construction, Weber sees a need to reframe the industry’s image.

“Changing the narrative over what the construction industry is and does is key,” she said. “It’s not this dirty, lowtech, crummy place to work. The goal is to get those everyday people excited about what the construction industry is and all the opportunities to do good.”

She also believes workforce

development looks different across regions, which means solutions must be flexible and locally focused.

Weber has spent much of her career on the road at trade shows like World of

Belt Designed for multiple materials

Truck mounts Available

Standard electric front to rear Shurco tarp

Optional bin extensions for more cubic yard capacity

Large range of standard capacities/lengths available.

Optional washout tanks with electric pump or system air pressure

Built for durability with 450 Hardox bin walls & heat retention with 1” Thurmax insulation panels

Multiple axle configurations & capacities

Several rear door options: twin, hi-lift, hilift/bi-fold

Think safety- No tipping of box eliminates overhead obstructions and potential rollover

42" wide belt helps prevent segregation (trailer)

36" wide belt (truck mounts)

sales@etnyre.com

888-586-1899 888-586-1899

1333 South Daysville Road Oregon, Illinois 61061 Illinois 61061 Sales: Sales: 815-732-2116

facturer relationships.

“Trade shows go a long way in bridging that gap, giving contractors,

CON/AGG, experiences that gave her a unique perspective on contractor–manu-

OEMs and dealers a chance to connect

face to face, which is huge,” she said.

feedback, kick the iron. And now that

I see how much they’re listening and trying to build those partnerships.”

For Weber, one of the biggest lessons of her career has been adaptability — a skill honed in fast-paced roles where plans could change at a moment’s notice.

“When I was working on the OEM side, it was clear that contractors valued that time — being able to ask questions, give I’m supporting manufacturers at AEM, know and trust,” she said. “These trade further relationship building down the

She added that those in-person connections often extend beyond the show floor. “At the end of the day, people do business with people they shows really help open the doors to road.”

“Things don’t always go as planned. I’ve learned to pivot, troubleshoot, and stay calm,” she said.

She recalls one instance at Dynapac where an event changed capacity limits at the last minute. After briefing her company president, his parting words were: I trust you.

“I’ve learned to invest in people, invest in relationships and just show up consistently.”

At the core of Weber’s career is a passion for the people who make construction run.

for people,” she said. “It’s really cool seeing on the manufacturing side that these people are incredibly skilled, and they just value what they do. They have this legacy and this strong sense of purpose. The collaboration aspect really excites me.”

Advice for the Next Generation

“I’m definitely the most passionate about the connections I make with and

As Weber looks ahead, she hopes to encourage others — especially women — to consider careers in asphalt and construction.

“There’s room for all different types of skill sets and backgrounds in this industry, and there are so many areas to start with,” she said. “Confidence comes from preparation. And curiosity is a valuable thing in construction, so don’t be afraid to step in places where you might be the only one asking questions.”

Her message is simple but powerful: “It’s okay to ask questions. People respect that. And know that your contributions do matter.”

Discover how crawler skid excavators combine the functions of mini excavators, CTLs, and telehandlers in one compact machine.

For roadbuilding projects, there’s one thing contractors can likely agree on – doing more with less is critical to maximize efficiency and profits. Tight project deadlines, limited worksite space, ongoing labor shortages and the drive to stand out in a competitive landscape demand smart solutions. In terms of an operation’s bottom line, imagine the impact of one machine that could do the job of a mini excavator, compact track loader and a telehandler.

Traditionally, the risk with multitools is that they seldom deliver high-quality results across the board. They can be adequate at several functions but won’t stand out in any. However, with these machines, contractors can harness the speed and agility of a compact track loader (CTL), the maneuverability and digging ability of a mini excavator and the reach of a telehandler, all in a single machine.

Like traditional mini excavators, crawler skid excavators offer 360-degree cab rotation. In this sense, both the mini excavator and crawler skid excavator provide excellent space management and productivity, letting contractors dig, break or perform a number of other functions in any direction without constantly repositioning the machine. However, one significant factor limits

the conventional mini excavator’s overall maneuverability — its boom.

The majority of excavators on the market today use a mono-boom design. While this configuration provides ample power for digging and other applications, its rigid nature limits overall range of motion. The main arm of a mono-boom is only able to move up and down, and the design relies on the dipper stick portion of the boom to reach, pull and dig. This limited range of motion does not prevent mono boom excavators from doing what they are made to do, but it does restrict their ability to work close to the machine and requires more room to operate.

On today’s crowded jobsites, where space is at a premium, contractors would be better served with a side-mounted, two-piece boom that offers greater compactness and range of motion. This design features an articulated arm, similar to a finger, with a total of five joints, including one between the second and third sections that allows for limited side to side motion. Bending or straightening each joint in sequence results in a boom that can extend almost straight in any direction or fold back in on itself for maximum compactness.

What does this look like on the jobsite, though? In terms of productivity,

the side-mounted, two-piece boom offers an increased working envelope over mono boom excavators, while also limiting the need to reposition the machine. For example, a mono boom excavator and a similar-sized crawler skid excavator with a side-mounted, two-piece boom are both tasked with digging a roadside trench. Both machines start their trench at a similar distance. However, as the bucket works back toward the machine, the mono boom excavator must stop and reposition while the crawler skid excavator is able to continue digging — until the bucket is under the machine if necessary. By working more from a single position, contractors save time and effort while also reducing their carbon footprint.

The crawler skid excavator’s twopiece boom also needs less space to operate, opening up the use of powerful machines even in tight spaces and limiting the need for large work crews. Working against the blade with a mono boom excavator, for example, requires laying the main part of the boom almost straight out with the dipper stick and bucket folded under. This position nearly doubles the overall length of the machine and requires a lot of clearance around the excavator for working or swinging. In a situation where work is being conducted in close proximity to

with your peers, while participating in daily networking receptions, and our annual golf outing. This event includes corn hole, golf, signature drinks and more!

∏ A STAY AT AN AWARD-WINNING PROPERTY - Staying at the OPAL SOL in Clearwater Beach, Florida will allow the perfect mix of relaxation, fun, and education!

π EDUCATION LASER-FOCUSED FOR THE FUTUREGain access to information and tactics that you can put to use as soon as you get back to the office. Hear from industry experts and receive the resources you need to succeed. - Engage in Conversations

an existing structure or roadway, the excavator’s required footprint is too large. With a side-mounted, two-part boom, on the other hand, the bucket can be positioned directly in front of the blade or along the tracks for a compact 360-degree footprint that is only slightly wider than the body of the machine. .

Additionally, a tunnel’s low ceiling or other overhead obstacles can limit the use of mono-boom excavators, since repositioning the inflexible boom might require additional height. When working in tunnels or close to overhead obstacles, the crawler skid excavator boom can open up for above grade work with only slightly more headroom than the top of the cab.

The crawler skid excavator’s innovative boom design provides increased power and range of motion compared to other excavators, but that’s only the first part of the equation. A variety of tools for applications from material handling to trenching for utility lines allow operators to truly capitalize on the equipment’s versatility.

By angling the first part of the boom back along the cab, operators create a compact profile that maximizes lifting power and increases overall stability. This design allows for the use of larger skid steer buckets — up to.98 cubic yards — and enables the crawler skid excavator to operate as a CTL or skid steer as well as an excavator. The boom design also allows for the loader bucket to be braced against the blade for applications such as grading and ground leveling. This innovative feature stabilizes the bucket, distributing the forces to the frame of the crawler skid excavator and reducing stress on the boom, prolonging component life.

Switching out the bucket attachment for a set of forks, the crawler skid excavator essentially becomes a highly maneuverable material handler. Unlike mono-boom excavators, the two-part boom provides a greater range of motion while maintaining level forks. With a reach of around 14.5 feet for six-ton class

models and up to 18 feet for 10-ton class units, contractors can rely on the crawler skid excavator in a variety of situations, reducing the need for additional equipment, such as a telehandler. Here again, the dexterity of the boom provides a unique advantage since a fork-equipped crawler skid excavator can reposition the pallet left or right without moving the whole machine, unlike a telehandler.

The true beauty of using the crawler skid excavator as a material handler, though, is its ability to easily place material below grade. Using forks or a lifting hook, the crawler skid excavator can retrieve pipe, stone or other materials from the staging area, quickly and safely transport them to the work area and place them exactly where workers need them. There’s no need for wheelbarrow brigades, manually loading or unloading pallets or other time and labor intensive methods.

However, optimizing efficiency when it comes to attachments relies not only on the boom, but also the quickcoupler. Some advanced systems allow operators to quickly transition between attachments without leaving the cab, decreasing downtime between tasks and increasing overall productivity. Being able to use attachments in reverse is also key to increasing versatility. This feature ensures buckets and other attachments are in the ideal position for the job at hand, taking full advantage of the crawler skid excavator’s extended range of motion.

To offer a suitable replacement for an excavator, CTL, skid steer or other equipment, a crawler skid excavator must also provide the speed to effectively perform these tasks.

For the majority of operations, the crawler skid excavator’s speed can provide a significant boost to productivity and efficiency. Some models are capable of speeds up to 6.2 mph — twice that of a mini excavator and on par with most CTLs on the market. Given that approximately 15% of an excavator’s time is spent traveling around the

jobsite, being able to get from point A to point B in half the time means work can start sooner and proceed more quickly.

But sometimes slow and steady is what’s required for high-quality results — in ditch clearing, sweeping or snow removal applications, for example. To help operators focus on the job at hand, rather than constantly worry about maintaining the ideal speed, a speed management system is necessary. Here again, innovative manufacturers have provided game-changing technology that allows crawler skid excavators to excel. These units feature an advanced speed control system that acts as a limiter, keeping the machine at the desired speed even with the throttle wide open. Operators simply select a desired top speed to best suit the job at hand. Some systems offer up to 20 speed settings for maximum versatility. In this way, an operator can easily perform, say, a flail-mowing job at minimum speed then switch to a digging bucket or loader bucket and zip around a construction site at top speed.

For complex, space-restricted roadwork, the need for adaptable, highly productive equipment continues to grow. Crawler skid excavators directly meet this demand with a powerful combination of versatility, compactness and performance. Replacing multiple machines with one simplifies logistics, cuts costs and increases productivity to revolutionize the jobsite. While staying in a single position, a crawler skid excavator can dig and then swing up and dump into a truck within a compact 9-foot radius. With a range of attachments available, these machines can be tailored to fit the specific requirements of any roadbuilding project. Utilizing the crawler skid excavator can pave the way for a smarter method for roadwork and make an operation stand out as an industry innovator.

by Peter Bigwood, general manager at Mecalac.

By Brandon Noel, Editor-In-Chief

Turning 100% recycled asphalt into a high-performance slurry seal by cutting costs, carbon emissions, and waste without sacrificing durability.

In an industry often defined by incremental improvements, VSS Macropaver has taken a bold step: combining a production-grade slurry/ micro surfacing paver with fully recycled asphalt (RAP) to deliver high-performance pavement preservation solutions.

In a recent interview, Jeff Roberts, President of VSS International, walked me through how their Macropaver equipment works in a slurry seal application, the challenges and payoff of 100% RAP use, and what this could mean for the future of pavement preservation.

When I asked how the Macropaver functions in a typical slurry seal application and how it measures up to industry standards, Roberts didn’t hold back praise for his product.

“The Macropaver is the most durable and efficient micro surfacing machine in the world. It has been engineered by operators for operators and has been tested around the globe.”

The machine was recognized earlier this year in Asphalt Contractor’s Top 30 Products for 2025.

Roberts points to the 12-EX model’s fixed gate design, which, “Not only speeds up the calibration process but

also ensures precise material flow control and enhanced consistency of the finished product being placed on the road.”

In other words, the gating ensures that the aggregate, water, and emulsion are metered strictly, reducing variation in the mix and increasing consistency across the pavement surface.

Importantly, the Macropaver is fully compatible with RAP aggregates in slurry seal and micro surfacing mixtures. It doesn’t require any retrofits or extensive machine conversions. This means crews familiar with traditional Macropaver operation can adopt RAP formulations with minimal additional training or cost.

Supplemental materials from VSS reinforce Macropaver’s reputation as a rugged, fast, and flexible piece of equipment suited for high production slurry and micro surfacing work. My real curiosity, however, became fixated on this efficient use of old millings.

Switching from conventional virgin aggregates to 100% RAP in slurry or micro surfacing is not a trivial shift. When I asked what motivated VSS to experiment and implement 100% RAP mixes (and what obstacles the team encountered), Roberts said, “What initially led us to using RAP in our mixes was that we had several agency customers who had mountains of RAP materials that were not being utilized. We recognized that there could be potential cost savings to all stakeholders

if we could utilize these materials since RAP is significantly cheaper than virgin aggregates and asphalt binder.”

This is something I hear quite frequently from contractors and DOTs around the country. There’s more than enough RAP laying around, and never enough effective uses to go around.

He cites a dual benefit: cost savings on materials and hauling, and conservation of natural resources. In many cases, agencies already own the RAP material but lack strategies to put it to use. However, the switch is not fully plug-and-play.

“The biggest challenge with getting the mix right is making sure that we isolate consistent piles of RAP materials that we can use for mix design purposes and make sure that the materials being used on site are representative of the materials we designed around for our job mix formula. Once that is done it is important to make sure that all machines have been properly calibrated with these same materials.”

In practice, this means tight quality control on stockpiling, sampling, and ensuring that the on-site RAP matches the laboratory feedstock. Without that match, the risk of off-spec performance rises. This isn’t too different from what we’ve heard from our friends at Green Asphalt, who produce batches of 100% RAP asphalt for use on public roads in New York City.

One natural concern, and one I raised, is whether a 100% RAP slurry seal can

Featuring a robust educational program that is unlike any other learning experience in the market. The educational program will feature 60+ hours of education covering business management, paving, sealcoating, preservation, sweeping, striping and more.

Over the three-day event, there will be an incredible amount of opportunities for nextlevel networking that will create and strengthen the relationships that are vital to the success of business owners working to grow.

See equipment pushed to the limit in a fast-paced, real-world competition at PAVE/X — the ultimate way to evaluate performance before you buy. Watch the action, ask the questions, and discover what equipment truly delivers under pressure.

match or exceed the performance of conventional mixes. Roberts’s response is cautiously confident:

“The performance of a RAP slurry seal should be the same as a conventional slurry mixture with virgin aggregates as long as the base RAP materials are properly tested to ensure that the finished RAP product being used in consistent with the job mix formula provided for the job.”

In effect, the key caveat is “if managed well.” Proper testing, consistent stockpiles, and strict adherence to mix design are nonnegotiable. If those controls are in place, he contends that ride quality, curing times, and long-term integrity need not suffer.

Beyond the technical performance, Roberts emphasized that sustainability and cost efficiency are core to VSS’s pitch to clients.

“We like to communicate to project owners that reusing RAP reduces the environmental footprint by conserving natural resources using an asset that, in most cases, they already own and most likely are underutilizing,” He said. “RAP use also decreases the need for landfill disposal of old asphalt and reduces greenhouse gas emissions from production and transport of new materials.”

This is a strong message. Many agencies struggle with stockpiled RAP or limited landfill capacity. By converting that waste into a functional treatment layer, agencies gain not just cost avoidance but also a narrative advantage in lifecycle stewardship.

I pressed on whether the VSS team ran into unexpected problems during production or placement. Were there any issues related to material handling, moisture sensitivity, calibration issues, or machine limitations.

Roberts acknowledged that RAP is more commonly used in hot mix applications but said that the Macropaver handles slurry mixes just fine.

“RAP is more commonly used in hot mix asphalt (HMA) than slurry seals and micro surfacing now due to several factors,” he said. “When utilizing RAP in cold mixes, you don’t necessarily achieve the same benefits due to the lack of heat in the system. Otherwise, we have had very few problems with slurry mixtures as long as the stockpiles are managed to limit inconsistencies and mix design sensitivity. The Macropavers themselves handle the RAP aggregates just fine and require no modifications to produce a high-quality mixture using RAP materials.”

One operational best practice, however, stands out. For RAP slurry seal mixes, they require the use of a pneumatic roller after placement which is not necessary for all slurry seal or micro surfacing mixtures. That pneumatic roller step helps place the aggregate before initial cure, and it’s particularly useful when working with less-than-perfect RAP gradations or moisture fluctuations.

Given the novelty of 100% RAP slurry, I asked how client agencies and DOTs react to it, and whether interest in it is growing.

“Sustainability is and always has been a major advantage for buying agencies and private clients in that preservation techniques typically require less materials, heat and energy to produce, transport and place on the road.”

He predicts a natural evolution in the way things are done. He also sees the broader context: pavement preservation provides a strong life-cycle cost argument against more capital-intensive overlays or reconstruction. Used judiciously, preservation with recycled materials can strengthen that argument.

Finally, I asked whether Roberts believes that recycled slurry or micro surfacing treatments could become standard—and what it would take to scale adoption across the industry.

“I believe that recycled treatments will become a standard in pavement preservation applications in the future. The equipment required to do this work is already working in the market. The key is stockpile availability and the proper management of those stockpiles.”

For higher-volume roadways or state DOT work, he expects that a blend of RAP and virgin material may be required to smooth variability.

“We may find that we need to utilize an aggregate source that contains more of a blend of RAP and virgin materials to ensure better consistency in our stockpile sources. This may require greater interest from local aggregate suppliers to provide these products.”

Roberts underscored the ongoing need for data, standards, and training going forward.

“There is still a lot that our industry needs to learn about using RAP in these techniques but much of this work is being done today throughout the United States. Industry Associations like the International Slurry Surfacing Association (ISSA) have made RAP use part of their strategic plan and they are working hard to collect the data from its members and ‘connect the dots’ for the benefit of the entire industry and the agencies they serve.”

By aligning innovation with association efforts and real-world trials, he envisioned a future where recycled slurry is not niche but routine. The use of a 100% RAP slurry strategy represents one of the more aggressive sustainability pivots in pavement preservation.

The construction industry faces one of the highest suicide rates of any profession.

Discover the risk factors, resources, and steps leaders can take.

According to the Centers for Disease Control and Prevention, construction has one of the highest suicide rates of any industry. In 2022, roughly 1,000 construction workers lost their lives on the job, with OSHA’s “Fatal Four” hazards accounting for a significant share. Yet suicide claimed more than 5,000 construction workers that same year, nearly five times higher, and far less discussed. While most of those tragedies occurred off the jobsite, the impact is felt deeply across teams, families and communities.

Nationwide has partnered with the Construction Industry Alliance for Suicide Prevention (CIASP) to shine a light on the unique pressures construction workers face and the risk factors that contribute to mental health struggles. Construction is a high-stress, highdemand industry. Long hours, physical strain, job insecurity and a culture that often values toughness over vulnerability all contribute to elevated risks.

The workforce is also predominantly male – about 90% – and includes a significant number of veterans, both groups statistically at higher risk for suicide. As a Navy veteran, I know the transition to civilian life isn’t easy.

We also need to acknowledge the role of chronic pain and substance use. Injuries are common in construction, and pain management often involves prescription opioids. That can lead to dependency, which in turn can deepen feelings of depression and isolation.

One of the most powerful things we can do is simply start the conversation. As

leaders, we need to create environments where people feel safe – not just physically, but emotionally. That means training front-line supervisors to recognize the warning signs of mental distress, such as changes in behavior, absenteeism and performance issues, and to respond with empathy rather than discipline.

It’s easy for a foreman to see a worker struggling and assume it’s a motivation issue. But what if it’s something deeper?

And we need to bust the myths that still surround suicide. Talking about it doesn’t plant the idea in someone’s head. Asking someone if they’re okay doesn’t make you weak. In fact, it might be the strongest thing you do all day.

How we talk about mental health matters. We’ve come a long way, but there’s still work to do. Just as we wouldn’t shame someone for having a heart condition, we shouldn’t shame someone for living with depression.

Organizations like CIASP are leading the way in this space. They offer free, industry-specific resources – from toolbox talks and podcasts to training modules – that help companies start these conversations and build a culture of care. Their Start Training platform is a great place to start for front-line managers.

This isn’t just an HR issue or a safety issue – it’s a leadership issue. It belongs in every part of the organization. Whether you’re a project manager, a foreman or a business leader, you have the power to influence the culture of your team. You don’t need a degree in psychology to listen, to care or to connect someone with help.

And help is available. The 988 Suicide& Crisis Lifeline is a critical resource, and CIASP’s website – preventconstructionsuicide.com – offers a wealth of tools tailored to our industry.

At Nationwide, our mission is to protect people, businesses and futures with extraordinary care. That includes supporting the mental health and well-being of the industries we serve. We believe that safety isn’t just about preventing falls or wearing PPE – it’s about protecting the whole person.

That’s why we’re proud to host conversations like our “Safety as a Culture” roundtable series. These discussions aren’t always easy, but they’re necessary. When we talk openly about mental health, we reduce stigma. When we share stories, we build connections. When we lead with empathy, we save lives.

The construction industry is built on strength, resilience and teamwork. But true strength includes the courage to be vulnerable. True leadership includes the willingness to listen. And true safety includes mental health.

It’s important to keep it going year-round to make sure every worker knows they’re not alone. Mental health awareness is an important puzzle piece in building a work culture where safety means getting home whole.

by Jason Ragsdale, CSP, CIC, CHST

leads risk management technical specialization for Nationwide

Astec revolutionized the paving industry with the introduction of the Shuttle Buggy, and now the SB-3000 sets a new standard in material transfer vehicles. Effortless maintenance, unmatched performance, and four steering modes for ultimate agility keep paving seamless. Experience groundbreaking innovation with the patented Ground Crew Control Station for the ultimate user experience and protection. The SB-3000 isn’t a machine, it’s a revolution in material transfer, built on Astec’s legacy of industry firsts.