FIVE YEARS FIGHTING FOOD FRAUD

CELEBRATING FIVE YEARS BEING TRUSTED TO SET THE STANDARD FOR COMMODITY AUTHENTICATION, SPECIFICATION AND COMPLIANCE, RAPIDLY, RELIABLY AND SCIENTIFICALLY.

CELEBRATING FIVE YEARS BEING TRUSTED TO SET THE STANDARD FOR COMMODITY AUTHENTICATION, SPECIFICATION AND COMPLIANCE, RAPIDLY, RELIABLY AND SCIENTIFICALLY.

PUBLISHER

Planet Media & Design Ltd

Brooke’s Mill, Huddersfield HD4 7NR

MANAGING DIRECTOR

Jillian Evans

NATIONAL SALES MANAGER

Shazia Hussain

CHIEF EDITOR

David Barnett

SUB-EDITOR

Abigail Wears

CONTACT US: FACEBOOK @food&drinkmagazine

INSTAGRAM @foodanddrinknews

TWITTER @food_drink_news

CONTRIBUTE info@planet-media.co.uk

ADVERTISING advertising@planet-media.co.uk

EDITORIAL editorial@planet-media.co.uk

MAG SUBSCRIPTIONS subscriptions@planet-media.co.uk

It has been, certainly by recent standards, a glorious spring, and the hope is that this will lead to a warm, sunny summer.

This is, of course, good news for those whose business spikes during the summer months. In this issue we have been looking at trends in both the barbecue industry and the alcohol sector, with the latter highlighting a battle for the drinkers’ money between cider and a surprise new player in the younger consumer market, stout.

Of course, every sunny day has a cloudy lining, with already as we go to press ominous rumblings about what a prolonged period of hot weather might mean for the farming industry, should we not get rain soon.

Everything in the food and drink industry is a double-edged sword, with what’s good for some not so great for others. But, as the saying goes, you have to make hay while the sun shines, so those who do see a boost from warmer weather, here’s hoping it’s a great summer for you all.

David Barnett

CHIEF EDITOR

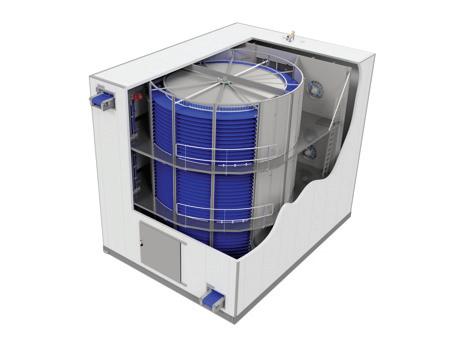

Pukka, a brand leader in the UK pie industry, is taking a major step to enhance its production capabilities by investing in a third Starfrost Helix spiral freezer at its Syston bakery in Leicestershire. This investment is part of the company’s ongoing strategy to integrate cutting-edge technology, meet rising demand, improve quality and consistency, and boost overall manufacturing efficiency.

Scheduled for installation later this year, the new spiral freezer follows the successful addition of two Starfrost systems in 2021, underscoring Pukka’s commitment to longterm growth and innovation.

The new Starfrost Helix spiral freezer will replace an older, less efficient freezing system, safeguarding continuity of supply.

The state-of-the-art technology offers several benefits, including reduced downtime and lower maintenance requirements, resulting in smoother and more reliable operations.

With the Helix freezer’s precision performance, Pukka can ensure consistent

quality across every batch, preserving the taste and freshness that has built the brand’s reputation.

Peter Gull, Engineering Manager at Pukka, commented on the importance of this equipment upgrade: “The new system will provide an automated and dependable freezing process, just like our other Starfrost equipment. This latest spiral freezer will enable us to increase production throughput while maintaining the high standards our customers expect.”

As Pukka continues to scale its operations, this new freezing system will play a vital role in meeting increasing consumer demand, all while maintaining both efficiency and product quality.

The Belfast Distillery Company, producer of McConnell’s Irish Whisky, has chosen Forterro’s manufacturing ERP solution, 123Insight, to help streamline its operations, support business growth and ensure compliance in a highly regulated industry.

Belfast Distillery is undergoing a period of significant expansion, and with operations ramping up, the team needed a powerful and scalable system to consolidate processes and data into one accessible platform.

“As part of our improvement programme, we needed a solution that would promote transparency, collaboration and efficiency across all departments,” said Joanne Paffey, Supply Chain Controller, Belfast Distillery Company. “123Insight’s features, especially its traceability and ability to handle complex units of measure, make it ideal for a business operating in the alcohol production sector.”

Joanne has 20 years’ experience using 123Insight in previous roles, and brought that understanding of the product and experience to her role at Belfast Distillery,

having seen firsthand the significant positive impact 123Insight has on business performance. That familiarity helped

accelerate the implementation process, with the company going live within just a few weeks.

The production of confectionery in Holešov, Czech Republic, has a long tradition dating back to 1863. At that time, Philip Kneisl started producing sugar whistles and sticks, and became one of the first manufacturers of sweets in the Bohemian countries. And just as it was in the 19th century, today the Holešov plant is the most important confectionery manufacturer on the Czech market. While the delicacies are still produced according to traditional recipes, the operating equipment meets the most modern standards. Thirteen EFAFLEX high-speed doors provide key functions for securing the production area.

The fastest door with the fastest service

“Our company’s priorities are safety and quality. We place great value on the safety of our employees and, of course, that of our customers. That’s why we chose EFAFLEX high-speed doors. They meet these high requirements and function reliably even in continuous operation. Last but not least, EFAFLEX offers flexible customer service that resolves problems in the shortest possible time”, explains Radek Ponižil, Industrial Engineer at NESTLÉ. The spare parts are produced in the Czech Republic and EFAFLEX can deliver most of them within 24 hours – an exceptional level of service.

Although production began in the 19th century, the Holešov plant now has cutting-edge equipment that meets all the requirements for modern food producers. Both raw materials and finished products pass through the high-speed EFAFLEX doors upon arrival and delivery.

Most of the doors are the EFA-SRT® Premium model. The main reason the customer chose these doors was their fast opening speed, which reaches up to 2.5m/s. This is particularly important in food processing plants: by opening and closing quickly and remaining open for as short a time as possible, the doors minimise the penetration of particles into the processing plants. This is important, for example, for the doors that separate the outdoor areas from the production areas.

In addition, the doors help to accelerate logistics processes, save energy and create a more pleasant climate for employees in the halls. Another advantage of EFAFLEX products is their long service life and reliable operation, as they can handle hundreds of load cycles every day without problems. For instance, the EFA-SRT® ECO can handle up to 150,000 load cycles per year.

Another door with a special feature, the EFA-SST®-L, is mounted in the shipping area. Due to the limited space, a low lintel version was used instead of a classic installation. This solution is used where the ceiling is low and other door leaf guides cannot be used. This also allowed a door with insulation laths to be installed in this location.

The Holešov plant has been in operation since 1863. However, much has changed since its founding back in the days of Austria-Hungary. The company successfully weathered two world wars and the nationalisation in 1949. It is now part of the multinational NESTLÉ corporation. The products are among the most widely sold brands of non-chocolate confectionery in the domestic market. The most famous are Linsen, BON PARI, JOJO jelly bonbons and Haslerky.

But it is not only locals who enjoy the sweets from Holešov: a significant portion of the products are shipped abroad. Another portion of the products bear the names of brands that are destined directly for the foreign market.

EFAFLEX produces high-speed doors for industrial applications. The company, which was founded in 1974, works for clients from industry, trade, food production, and the chemical and pharmaceutical industries, among others. As the only manufacturer in the field of high-

speed industrial doors, EFAFLEX is listed in the world market leader index and is therefore one of the top 461 companies in Germany, Austria and Switzerland. The family company employs more than 1,200 people worldwide. With its headquarters in Bruckberg, Bavaria, EFAFLEX is firmly anchored as the largest employer in the region. In addition, the company opens up international markets with 10 subsidiaries on five continents. EFAFLEX generates over 40% of sales abroad.

EFAFLEX Press Contact: Ms Jasmin Jobst Tel.: +49 8765 82-525

E-mail: Jasmin.Jobst@efaflex.com Web: www.efaflex.com

Bluewater, a global leader in cutting-edge water purification and beverage solutions, is making a bold return to the US market with the launch of its award-winning Café Station at the Specialty Coffee Expo – the largest B2B speciality coffee trade show in North America – taking place at the Houston, TX, Brown Convention Center from 25–27 April 2025.

Following critically acclaimed debuts in the United Kingdom, South Africa, and the Middle East, the Bluewater Café Station has already earned widespread industry recognition, including being honored as ‘Best New Product’ at Dubai’s World of Coffee Expo in February. Designed to revolutionise the coffee industry, the Café Station enables baristas to customise the mineral composition of water to enhance the unique flavour profiles of different coffee beans, thanks to its precision water

calibration technology.

This US launch marks Bluewater’s full return to the American market after the pandemic-related supply chain disruptions affected sales. With renewed momentum, the company is reintroducing its secondgeneration reverse osmosis technology, SuperiorOsmosis™, which has achieved independent thirdparty verification for its industry-leading ability to remove virtually all waterborne contaminants –including microplastics, heavy metals and other impurities – while maintaining exceptional energy efficiency and reducing service and maintenance demands.

Bluewater’s ommitment to the US Market Niklas Ivarsson, President of Bluewater USA, emphasised the significance of the launch:

“What better way to put the Bluewater brand front and

centre for American businesses and consumers than by launching a gamechanging product that brings joy to professional baristas serving the nation’s favourite drink, with around two-thirds of Americans reportedly drinking coffee daily,” says Ivarsson. “The Café Station has already been named a 2024 ‘Best Buy’ for speciality coffee shops by The Caterer Magazine, and we are excited to introduce it to the US coffee industry.”

Bengt Rittri, Bluewater Founder and CEO, recently recognised as a Top 2025 Ecopreneur by the UK’s Sublime lifestyle magazine, expressed his enthusiasm for the company’s US expansion:

“Building on our successful partnership with the New York Yacht Club’s American Magic team – based in Pensacola, Florida –during the 37th America’s Cup, where we helped the US team eliminate the need for over 88,000 single-use plastic bottles while training and competing in Barcelona, we are proud to champion a refill culture that reduces plastic waste and protects our oceans and marine life for generations to come. We aim to provide Americans with safe, great-tasting drinking water straight from their faucets while fostering a refillconscious mindset prioritising sustainability,” Rittri said.

Visitors to the Specialty Coffee Expo 2025 can experience the Bluewater Café Station firsthand and taste its difference in coffee brewing at Booth 958 at the George R. Brown Convention Center, 25–27 April 2025. Guest roasters on the Bluewater booth include Be Bright’s Frank La, 2024 US Barista Champion, who’ll be brewing up a storm for visitors between 10am–12 noon on Friday morning.

Bluewater, a global innovator in premium water purification and beverage solutions, will unveil its award-winning Café Station at the London Coffee Festival, running 15–18 May at the Truman Brewery. In partnership with UK distributor HTG, Bluewater will showcase its cutting-edge technology at Booth HP30.

Fresh off major debuts in Dubai and Houston, the Bluewater Café Station is transforming speciality coffee brewing. The unit has received multiple accolades, including ‘Best New Product’ at Dubai’s World of Coffee Expo and a 2024 ‘Best Buy’ rating from The Caterer Magazine.

Specifically engineered for the speciality coffee sector, the Café Station allows baristas to fine-tune the mineral composition of water, optimising flavour extraction for each bean type. “The market response has been phenomenal,” said Dave Noble (pictured), Bluewater spokesperson. “We’re thrilled to introduce this innovation to the UK’s rapidly expanding specialty coffee scene.”

At the Festival, guest baristas such as Douglas Conde, Day Trip, Tom Sixsmith, Batch Baby and Mathew Harvey-Ingram will demonstrate the Café Station in action. They’ll brew with Bluewater’s super-purified water and LiquidRock®, a patented Swedish mineral blend designed to balance hydration, boost taste and enhance well –being.

LiquidRock® features a carefully calibrated calcium-to-magnesium ratio for optimal absorption and crisp flavour. Beyond taste and health benefits, it helps tackle hard water issues by preventing scale buildupessential for preserving equipment. With three customisable mineralisation levels –light, medium and bold – baristas can match their water to the specific profile of their beans.

The London Coffee Festival draws over 22,000 visitors and features more than 260 top artisan brands, tastings, workshops, live demos and industry networking. It’s a celebration of the UK’s booming coffee culture, with both trade days and consumer experiences.

With over 8,000 branded coffee shops and a market valued at £15bn, the UK’s coffee

industry is thriving. Despite not ranking in the global top 25 for per capita consumption, Brits now drink an estimated 98 million cups of coffee per day - a sign of growing demand for premium experiences.

“Water makes up more than 98% of a cup of coffee, yet it’s often ignored as a key ingredient,” added Noble. “The Café Station gives baristas complete control to brew with the purest, best-balanced water possible.”

Visit Bluewater and HTG at Booth HP30 to explore how water quality can redefine coffee excellence.

Swedish water purification and beverage innovator Bluewater turned heads at the London Coffee Festival with the launch of its precision-engineered Café Station, featuring patented Liquid Rock technology. Designed for speciality coffee, the system lets baristas fine-tune water mineralisation to match specific roast profiles — delivering exceptional control, flavour clarity and brew consistency.

The Bluewater stand at the Truman Brewery attracted crowds of roasters, cafe owners and baristas, with many calling the Café Station a game changer.

“There was a genuine buzz around the system and how it elevates coffee quality,”

said UK Sales Chief Antonio Tedeschi.

Top UK baristas from Daytrip, Batch Baby and Naked Ground Coffee showcased their signature roasts using Bluewater’s optimised water, receiving high praise for enhanced taste and aroma.

Bluewater also supplied purified water to other exhibitors, earning rave reviews for consistency and quality.

Founded in Stockholm in 2013, Bluewater wants to become the world’s most planetfriendly hydration brand. Already recognised with awards from Fast Company and the Chicago Athenaeum, its innovations are available across the UK to consumers, hospitality and education sectors.

With growing demand, Bluewater is ~redefining how water powers coffee excellence by empowering businesses to achieve unparalleled water and beverage excellence.

The days of traditional British picnic staples – such as pork, cheese sandwiches and chicken drumsticks – may be numbered. New research from Moorish suggests that many people are opting for lighter, more varied foods during the warmer months.

According to findings, hummus was the top choice for picnic-goers, with 21% of people selecting it as a preferred item. Fruit kebabs (20%) and charcuterie boards (20%) were also popular, along with summer rolls (13%) and chickpea salad (9%). When it comes to drinks, the proud nation of tea drinkers aren’t veering too far from home – with iced tea a refreshing crowd pleaser for summer picnics.

The survey also looked at dipping preferences and found that dips continue to be a common feature of picnic spreads. Garlic and herb was the most popular dip (24%), followed by sour cream and chive (18%), hummus (11%), tzatziki (11%) and guacamole (10%) as the top five UK dip choices for summer. Opinions diverged, however, on what people had with their dips. Some people liked a tortilla or bread stick in their favourite dip, whilst others went for carrots or cucumber sticks. Almost one in 10 (7%) said they would use their fingers to enjoy a dip –perhaps not ideal for a shared meal occasion.

The results suggest a broadening of picnic menus, with many people including a mix of traditional and newer food options. While

classic items remain popular, there appears to be a room for a wider range of tastes and dietary preferences.

In recent years, small sachet formats have received a lot of attention in the media for the environmental challenges that they present. These small plastic envelopes are widely used to dispense condiments, sauces, personal care creams and many other liquid products. While they are convenient for the consumers, they are often highlighted for the issues that they create at the end of their life.

Estimates* suggest that approximately 855 billion sachets were used globally in 2018. Most of these packs are produced with complex multi-layered packaging that can withstand the nature of the ingredients and preserve the products during the supply chain for their required shelf life. They are usually produced from three-layer structures including layers of polyolefin, aluminium and often polyester, making the packs extremely difficult to recycle as the components of the laminate structure are incompatible for recycling and not easily separated. Their very small size and the fact that they often remain contaminated by foodstuff, further add to the difficulties in recycling.

Compostable film producer Futamura, flexible packaging converter Repaq and machine producer GK Sondermaschinenbau have worked together to produce a compostable solution for this market segment. This has been a difficult challenge to resolve, one that has been taken many attempts to perfect.

Today, they are delighted to launch a fully compostable solution based on NatureFlex™ technology for this application, capable of wrapping ingredients such as ketchup or mustard, cooking sauces or hand cream. The new compostable laminate includes a barrier cellulose film layer from Futamura as well as another biofilm to provide hermetic seals. The structures have been certified as compostable, both in an industrial and home settings.

The new compostable packaging structures have been proven to make effective sachet solutions, when produced on the newly designed GK Sondermaschinenbau machinery. The demonstration packs delivered have confirmed the required shelf life and

protection for a range of sauces. The machineability of the new liquid sachet packs have been repeatedly proven, at scale, by the first brands implementing the compostable structure. There was no difference in efficiency when using this structure compared to a conventional one. That has been reported for all GKS machinery, whether small, medium or large size. The first commercial sachets will enter the market shortly.

Sven Seevers, Technology Manager at Repaq, confirmed: ‘It was very important for us to replace this non-recyclable packaging, which can pollute the environment, with a compostable solution. We succeeded after two years of development work with our great co-operation partners. Our packaging offers excellent product protection and significant ecological benefits at the same packing speeds. For liquids packaging we achieve an OTR of 0.5 at standard conditions of OTR: 23°C, 50% r.h with a shelf life of up to 12 months. In the long term, it is the best end-of-life scenario for this packaging and many others.’

Nico Merkel, Sales Director at GK Sondermaschinenbau, added: ‘We are very pleased that our machinery has been involved in this project and shown to contribute to the production of these unusual and progressive packaging solutions. It has been a pleasure to produce samples in our facilities and participate in the extensive testing of these little packs, proving that they can withstand large pressure over the long term. The tests on our machinery have certainly shown that almost no adjustments were required to use the solution supplied by Repaq.’

Joachim Janz, Regional Sales Manager at Futamura stated: ‘This home compostable liquids sachet packaging is indeed a really exciting launch. Ultimately, it means a perfect match to the request for offering a full portfolio of demanding food and nonfood items to be packed in compostable packaging choices. Small-portion sachets have always been the tricky ones for recycling, so this success in compostability is good news to be shared.’

We’ve had an unusually wonderful spring, weather-wise, which means that some of us have been dusting off the barbecues a little earlier than normal.

For those companies providing either barbecue kit or food for grilling outside, it s very good news indeed.

And the general trend is that barbecuing is just soaring in popularity. In fact, according to a report this year by the Business Research Company, the expansion in the global barbecue market is forecasted to increase from $16.08bn in 2024 to $17.59bn in 2025, expected to reach $24.11bn by 2029.

The report says: The forecast period will also witness considerable trends such as the emphasis on inventive electric grills, advancements in technology, the emergence of new evolutions in outdoor grilling, product launches and the introduction of internetenabled grills.

Internet-enabled grills? More on that in a moment. But what do Brits like putting on their barbecues? According to a survey at the end of last year by YouGov, chicken skewers, bread rolls and chicken breast are the most liked barbecued items, but sausages are the most loved by Britons.

The report says: Britain s BBQ god-tier – items liked by more than eight in ten Brits who have tried them –is unsurprisingly dominated by staples of the garden table. Chicken skewers, bread rolls, chicken breast, pork sausages, beef burgers, garlic bread and baked potatoes are the seven items that every BBQ must have to ensure happy guests.

“What comes out on top overall, though, very much depends on how you are defining most popular.

Chicken skewers, bread rolls and chicken breast can all claim to be most broadly popular overall, liked to some degree by 82% of Britons who have tried them, with bread rolls the item that fewest people outright disliked (only 4% of Brits).

“But when it comes to the most loved part of a BBQ, it is pork sausages that more Brits (58%) say they ‘ like a lot than any other item, although beef burgers (57%) and chicken breast (56%) come in a very close second and third.”

Globaltic is a family-owned brand at the cutting edge of sustainable barbecue design. They say: BBQ is entering a bold new era, blending time-honoured traditions with cutting-edge innovations. From smoked desserts to AI-powered grilling, the landscape of barbecue in 2025 is more diverse and exciting than ever. Live fire cooking is making a comeback, while smoked cocktails and fermented flavours are elevating the experience beyond just food.”

So we re getting more inventive with our cooking outdoors, and according to Globaltic there’s a return to “ live fire cooking ”. They say: “Inspired by ancient techniques, this trend sees chefs and home cooks alike turning away from gas grills and even conventional smokers in favour of open flames, wood embers, and clay ovens.

“The appeal lies in the pure connection with fire. Cooking over live coals brings out deep, natural

flavours, whether it s a tomahawk steak seared over an open flame, whole fish roasted in banana leaves or rustic flatbreads cooked on hot stones.

Even the choice of wood becomes an art form, with pitmasters carefully selecting cherry, hickory, oak, and mesquite to impart specific flavours. This return to elemental cooking allows for an appreciation of simplicity — where smoke, time and fire are the only ingredients needed for culinary magic.

That said, we’ve already mentioned internet-enabled grills and even AI taking a role in our barbecuing.

Globaltic says: “As much as BBQ is returning to its roots, technology is also revolutionising the way we grill. AIdriven cooking is making BBQ more accessible, precise and foolproof than ever before.

The rise of smart grills means that achieving the perfect temperature is no longer a guessing game. AIpowered smokers can monitor internal meat temperatures, adjust airflow and even send notifications when it s time to flip or rest the meat. Some advanced models can even analyse humidity levels and adjust settings accordingly to maintain the ideal slow-cooking conditions.

Beyond hardware, AI is also influencing recipe development. Some platforms use machine learning to suggest optimal wood pairings, cooking times, and flavour profiles based on user preferences. Whether you re a seasoned pitmaster or a beginner, AI-driven BBQ technology is making it easier than ever to achieve consistent, restaurant-quality results at home.”

However we cook, though, what matters is what we put on our grills. And it s often something we can t agree on. The YouGov survey says: “Beef burgers are men’s favourite item, liked by 86%, while baked potatoes clinch the title with women, liked by 84%. When it comes to least popular, though, there is no disagreement – aubergine steaks are the least popular item polled among both men and women.

As is often the case, there are some age divides, but also many items that are able to successfully unite the generations. Items like beef steaks and beef burgers are widely liked on a similar level by all age groups, while between two-thirds and three-quarters (69-75%) of all generations like to see corn on the cob at the BBQ table and garlic bread consistently musters support from eight in 10 Britons (79-81%) across the ages.”

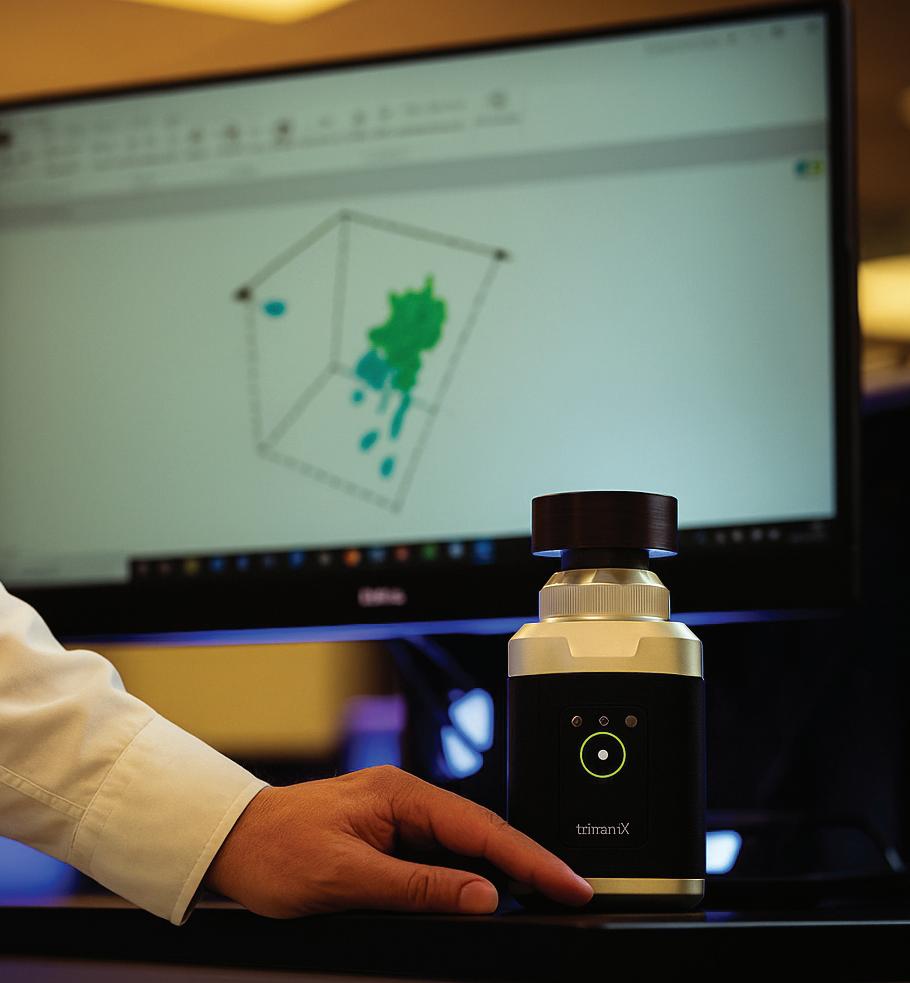

In just five years, Bia Analytical has gone from a university spin-out to a trusted name at the forefront of the fight against food fraud. Now a leader in rapid integrity testing, the Belfast-based company has built a reputation for science-backed innovation and industry collaboration that’s changing how we think about food authenticity and specification conformance.

As the company marks its five-year milestone, it’s clear that Bia Analytical is not only responding to the challenges of food fraud, it s actively shaping the future of how the industry detects and prevents it.

The origins of Bia Analytical lie in one of the food industry ’s most high-profile scandals: the 2013 horsemeat incident. This event served as a wake-up call for businesses, regulators and consumers alike, revealing just how vulnerable complex supply chains had become to economically motivated food fraud.

Researchers at Queen’s University Belfast were among those working to find a solution. Their answer? A faster, more accessible way to test food authenticity

using near-infrared (NIR) spectroscopy and advanced data analytics. What began as a research project evolved into a commercial venture in 2020 when Bia Analytical began testing samples in its own lab.

From day one, the mission was clear: protect the food supply chain by making authenticity testing faster, more affordable and scalable.

Food fraud isn’t new, but the risks it poses have grown significantly. Globalised supply chains, economic pressure and the increasing demand for “100%,” “premium,” or “single origin” labels have made food products more vulnerable to adulteration and misrepresentation.

What sets Bia Analytical apart is its ability to provide

near-instant results without the need for destructive testing or complex lab infrastructure. By applying infrared spectroscopy and chemometric modelling, the company can detect subtle differences in product composition, flagging potential signs of adulteration, low quality, non-compliance with specification or ingredient substitution.

This innovation means businesses can screen incoming goods in real time, rather than waiting days or weeks for lab results. And with a continually expanding portfolio of models, Bia Analytical can now test almost any commodity, from herbs and spices to powders, oils and liquids.

Since its founding in 2020, Bia Analytical has grown from a small team of researchers into a recognised industry player. Today, the company supports clients across the UK, Europe, North America and beyond.

Its services are now used by a wide range of stakeholders, from food manufacturers and ingredient suppliers to retailers and food safety authorities. These organisations turn to Bia Analytical not only for testing, but for strategic support helping integrate authenticity testing into broader quality assurance and compliance frameworks.

Key to this success has been the company ’s ability to respond to real-world risks. When herb and spice fraud surged during the Covid-19 pandemic, for example, Bia Analytical developed and validated new models rapidly to meet demand. That agility continues to define its approach.

The food authenticity landscape has evolved rapidly in the past five years. What was once seen as a niche concern is now recognised as a significant strategic and reputational risk. Frameworks like VACCP (Vulnerability Assessment and Critical Control Points) have become mainstream, and new regulations such as the incoming EU Deforestation Regulation (EUDR) place even greater emphasis on due diligence and traceability.

Importantly, fraud isn’t limited to the food itself. Mislabelling and misrepresentation are also affecting non-food commodities such as plastic and paper packaging. These components, often overlooked, can carry false claims about origin, composition or sustainability. This exposes the limitations of relying solely on paper-based certificates or small sample

checks and highlights the need for high-throughput, data-driven verification across larger volumes.

Food fraud is more than a financial issue it s a question of public safety, regulatory risk and consumer trust. Adulterated ingredients can lead to allergic reactions, undermine health claims and damage brand credibility. For businesses, the consequences include recalls, fines and long-term reputational harm.

Bia Analytical’s technology helps companies detect fraud before it becomes a crisis. By empowering quality control teams to verify authenticity at the point of receipt, the risk of fraudulent materials entering production or reaching consumers is significantly reduced.

In an industry where a single incident can cause widespread disruption, that kind of assurance is invaluable.

One of Bia Analytical’s biggest achievements has been the rapid expansion of its testing capabilities. Initially focused on high-risk herbs and spices such as oregano, turmeric and paprika, the company is focused on a range of ingredients including soyabeans, cocoa, animal feed and palm oil.

This flexibility is essential to staying ahead of fraudsters, who are constantly shifting tactics to exploit new vulnerabilities,” says Dr Terry McGrath, Chief Scientific Officer and Co-Founder at Bia Analytical. “But it also opens up opportunities for broader applications, such as verifying claims about origin, variety or breed, and even supporting batch-level quality control in manufacturing.”

Where no model exists, the company offers bespoke development, allowing clients to test proprietary or novel commodities, blends or formulations with the same speed and reliability, but with a focus on detecting consistent formulations, rather than on adulteration.

Looking ahead, Bia Analytical’s focus is on scaling innovation through merging scientific technologies with AI and machine learning to further enhance automation, model accuracy and predictive capabilities. The launch of its portable testing solution in 2024 marked a significant step forward, bringing authenticity screening out of the lab and directly to the production floor or warehouse for realtime decision-making.

Now, the company is preparing to launch its cloudbased testing portal in 2025, giving customers with their own laboratory the ability to manage testing, access reports and monitor supply chain risk in one secure, digital platform. This move supports greater accessibility, traceability and insight for food businesses across the world.

Perhaps most importantly, the company is advocating for a cultural shift: one where integrity testing is not just a regulatory requirement, but a standard practice embedded throughout the food industry.

In just five years, Bia Analytical has earned the trust of some of the biggest names in grocery retail,

ingredient supply and food manufacture. Its success is rooted not just in science, but in collaboration, responsiveness and a clear commitment to integrity.

As one client remarked “They don’t just test our products. They help us protect our reputation.

The risk of food fraud will always be there, but the tools to detect and prevent it are stronger than ever. Thanks to companies like Bia Analytical, the industry is better equipped to confront one of its most complex challenges and ensure that what reaches consumers is exactly what it claims to be.

Five years in, Bia Analytical has proven that innovation, trust and a mission-driven mindset can transform the way we protect product integrity.

They separate manual workstations from robotic areas and moving parts along transport routes. And they open from the bottom up. EFAFLEX’s EFA-SRT® MS USD (Upside-Down) machine safety doors offer outstanding safety for employees at manual workstations that are located directly in front of moving machine parts. AuE Kassel has designed and installed this version of the doors for a new production hall for Hexagon Purus, in which type-4 hydrogen pressure vessels are produced.

“It’s not difficult to explain why we chose these doors”, explains Dennis Sommer, Technical Project Manager at AuE. The Kassel-based mechanical engineer is responsible for the entire project planning and installation of the systems in the new Hexagon Purus production hall. “In front of the automatic cells are manual workstations where employees install valves on hydrogen tanks or attach or remove adapters for testing. We therefore needed a barrier of at least one metre in height so that no one could enter the automatic area. That’s the regulatory requirement for these workstations.” The EFA-SRT® MS Upside-Down machine safety doors open from the bottom up. At the workstations for Hexagon Purus, the doors run to a height of one metre. This means that employees cannot access the robot track. If the containers – which are up to four meters long – are then introduced into the robot track or removed from it, the door provides access to the track only for the shortest time necessary for this operation and then immediately moves back to a height of one metre.

Safe and can be installed any way

“The machine safety doors are located at critical points in the production area. They are an important safety interface between robots and manual workstations”, explains Dennis Sommer. “This means that they must be perfectly coordinated with the work cycle of the machine.”

The EFA-SRT® MS USD is the first EFAFLEX machine safety door that closes from the bottom up. The functionally safe, space-saving and lowmaintenance upside-down high-speed door has been specially designed for intensive industrial applications. A particularly powerful pulling device which pulls the end-shield upwards is installed in the door cases of the roll-up door.

Thanks to integrated floor supports in the side frames, the roll-up door is self-supporting and can be easily bolted to the floor. Securing buttons on the outer edge of the door curtain secure it within the guide rails. The door dimensions can be configured with widths ranging from 600 to 6,000mm and heights ranging from 1,000 to 4,500 mm. The flexible door curtain is available in several designs and colours.

The EFA-SRT® MS USD has an interlocking device in accordance with DIN EN ISO 14120 and thus serves as a single-acting, power-operated, movable guard and as a personnel restraint device.

In combination with the machine’s control system, the door guarantees the highest level of safety for people working at plants and with machinery in the industrial and commercial sector. A safe limit switch serves as an electric locking mechanism between the door and the machinery/equipment. To ensure protection against reaching into the door mechanism, both the winding shaft and the drive are completely covered with sheet metal profiles.

The Kassel-based machine manufacturer AuE supplies technology for modern production plants as well as for logistics solutions. It seamlessly integrates and optimises the mechanics, electrics and control technology of mechanical systems and plants, in addition to superordinate IT and logistics systems – without time and information losses due to external interfaces, and always tailored to the production requirements of the customer. AuE thinks in terms of processes and implements each system with a view to the overall process. As a member of the global STRAMA

GROUP, AuE is firmly rooted in the region and cooperates regionally with other medium-sized companies that are as close as possible to the production sites. “This was another plus for EFAFLEX”, says Dennis Sommer. “Two company fitters are stationed here in the region, and they are with us very quickly if we need them.”

Global and regional: Hexagon Purus company profile Hexagon Purus enables emission-free mobility for a clean energy future. The company is a leading global supplier of type-4 hydrogen highpressure cylinders and systems, battery systems and vehicle integration solutions for fuel cell and battery-powered electric vehicles. Hexagon Purus products are used in a wide range of applications, including light, medium and heavy commercial vehicles, buses, block stacking, distribution, refuelling, shipping, rail transport and aerospace.

Company information EFALEX

EFAFLEX produces high-speed doors for industrial applications. The company, which was founded in 1974, works for clients from industry, trade, food production, and the chemical and pharmaceutical industries, among others. As the only manufacturer in the field of high-speed industrial doors, EFAFLEX is listed in the world market leader index and is therefore one of the top 461 companies in Germany, Austria and Switzerland. The family company employs more than 1,200 people worldwide. With its headquarters in Bruckberg, Bavaria, EFAFLEX is firmly anchored as the largest employer in the region. In addition, the company opens up international markets with 10 subsidiaries on five continents. EFAFLEX generates over 40% of sales abroad.

EFAFLEX Press Contact: Ms Jasmin Jobst

Tel.: +49 8765 82-525

E-mail: Jasmin.Jobst@efaflex.com Web: www.efaflex.com

Being named best retailer in Scotland in the Farm Shop and Deli Show Awards was a vindication of Marshall Farms’ efforts to diversify its business — with amazing results. Based in Kintore, Aberdeenshire, the businesses’ diversification programme has actually been going on since the 1990s.

Originally a mixed farming enterprise with livestock, potatoes and arable land, Marshall Farms is now a second- and third-generation business, and the mixed nature of the farm meant the business was able to spread the risk and maintain a solid cash flow all year round.

Although the farm is still a major part of the business, it has a contender in the shape of the farm shop, which has grown steadily from a business selling produce out of a trailer to now a massive retail hub that attracts people from miles around.

Diversification began back in the 1990s with a selfservice trailer, followed by portacabins at each side of the A96 dual carriageway, 10 miles west of Aberdeen.

Selling potatoes initially, the offering grew to include vegetables and free-range eggs. Customers were able to help themselves and pay based on trust at this point, but as the produce offering grew, they needed a better

business plan than an honesty box!

In 2010, they opened a purpose-built farm shop and 40-seater cafe with the aim to cut out the middleman and promote their own farm produce while selling direct to the general public.

With Kenneth and Moira running the farm and their three daughters all interested in farming, the growing shop was the perfect opportunity to create something bigger and give the daughters the chance to work in the family business.

And what a business it is. The shop is thriving and the farm is as busy as ever: they run a 500 suckler cow herd and a flock of 600 ewes. The herd consists of mainly Aberdeen Angus, to produce what is known as some of the best beef in the world that can be sold directly from the farm shop.

Marshall Farm hens lay the eggs for the farm shop and restaurant, with around 2,000 hens laying at any one time. Most recently, they started up the outdoor rare-breed pig herd to produce their own pork, rearing piglets from 20 breeding sows, with 180 pigs and piglets on the farm.

Each year they grow 800 acres of barley, of which 70% is processed for malting, the remaining is kept on the farm for feeding. In addition, they grow 35 acres of

their own potatoes (eight different varieties) and vegetables for retailing in the farm shop, including turnips, broccoli, carrots, cabbage, cauliflower, beetroot and kale.

Marshall s embodies the idea of from field to fork and with both sides of the business thriving, it’s easy to see why they were voted the best in Scotland.

After 103 years in business and now run by the fourth generation of the same family, Sidoli’s certainly know their ice cream.

When founded in 1922 by Benedetto Sidoli in the South Wales town of Ebbw Vale, there was only one product on offer: vanilla ice cream produced daily in two-gallon batches, that sold for a halfpenny for a cone.

Fast-forward more than a century, with Benedetto’s great-grandson Stefano Sidoli at the helm for almost two decades, and the company now produces more than 50 flavours of ice cream and sorbet. Benedetto would find the business he founded unrecognisable now, but still working on the family-run principles of quality and expertise that he put into place so long ago.

Sidoli s is well-known all around South Wales, but a new deal signed with one of the UK’s fastest-growing food distribution companies, Harlech Foodservice, is set to see their reach expand significantly.

Stefano said: This is a huge opportunity which will allow us to reach completely new markets. It’s great to work with Harlech Foodservice because they are a company a lot like us, a family business with the same values.

“It’s very exciting for us to work with a company of their size and with their resources to expand our business to many more areas.

When Stefano joined the family business in 2006 he brought with him fresh ideas, a major rebrand and a plan to move the company forward, hugely growing the number of flavours on offer.

Welsh-Italian ice cream manufacturing has a long and illustrious history, and Sidoli’s is a prime example of that — so much so that in 2012 the company featured on TV, when famous comedian Ade Edmondson fronted a series called Ade In Britain, looking at the UK’s

manufacturing history.

It’s been a good start to 2025 for Sidoli’s and the ice cream industry in general, with a record-breaking warm spring, which they are hoping will continue through the summer months.

Sidoli’s is a continuous producer rather than a batch producer — their machines are running constantly, with a maximum output possible of 2,600 litres of ice cream every single hour.

They pride themselves on using three main ingredients in their ice cream: fresh whole milk, fresh double cream and real unsalted butter, which makes their product really creamy.

The company employs around 15 full-time workers, though this can go up considerably during the prime seasonal highs of ice cream production. And staff tend to stay; the factory manager is just entering his 50th year of employment!

Stefano said: “Our workforce is hugely important to us. Behind every great business is an even greater set of employees, and at Sidoli s we have the best.

www.sidolis-icecream.co.uk

When Perrys of Eccleshall won the Best Butcher Award at the Farm Shop and Deli Show Awards, it wasn’t just a victory for this highlythought of retailer… it was a victory for their entire community.

Located in a small, traditional Staffordshire market town, Perrys was established in Eccleshall just short of a century ago, and over the years they have established themselves as not only a thriving business, but one that supports local suppliers and outlets as much as they can.

Ben Deakin, Marketing Manager at Perrys, said: “This was not necessarily an award just for us, although we are the recipients of it. It takes a lot more than our shop to win an award like this.

“We’re surrounded by farmland and all of our meatbased produce our beef, lamb and pork - is sourced within five miles of the shop.

“Our lamb, for instance, that we have just been buying, our spring lamb, comes from a farmer that is just over a mile away. It s 1.4 miles up the road from us. You could walk to the farm they were reared at.

“We supply the local pub next door. We supply the local Italian restaurant, probably about 100 yards as the crow flies.

“It’s all part of the story and it’s all part of the community because I could be sat in the King ’s Arms next door or Olive Italian on a Wednesday. And I could be sitting on a table next to the farmer who s reared the animal that I’m eating. The award is collected by us, but it wouldn’t be possible without the community.”

Perrys has a processing facility on site, so they deal directly with farmers. There s no middleman, helping to minimise food miles.

said: It helps with the welfare of the animal, not only because we know the farmers and we have interactions with the exact animal that we end up purchasing, but we also know that during transit, their stress is limited to as little as possible and we can ensure legislation is always adhered to”

Although still running on the same communityminded principles it was founded on 98 years ago, Perry ’s has certainly moved with the times. Ben said: “We’ve evolved because you either evolve or you die, don’t you? And so we’ve got a website now that is ever evolving where we do click and collect orders or we do home delivery, which is free of charge within a 10-mile radius of the shop if the customer spends £25 or more, and delivered personally in our electric van.”

www.perrysofeccleshall.co.uk

Wenzel’s bakers is celebrating its 50th anniversary this year — not only of providing quality baked goods from a growing number of stores, but also of making a difference in their communities.

The first Wenzel s was established in 1975 in Sudbury Hill, northwest London. The business was started by Peter Wenzel, who had previously trained as a masterbaker in the art of bread making.

Peter says: This is where my love for baking started, and I opened the first Wenzel’s with a simple mission: to provide my local community with high-quality, freshly baked goods.

Still to this day that s what we look to deliver on every day. Since starting out in Sudbury Hill, we’ve opened more than 100 stores and our range now includes everything from sandwiches to coffee to pasta pots.

“Whilst we’ve expanded our product offering hugely – we’ve always stayed true to our roots and will always prioritise creating delicious, high-quality food, served with a smile.

Wenzel’s offers a wide range of handcrafted, highquality baked goods, all made with traditional methods. Their core range includes freshly baked breads, sandwiches, paninis, wraps, pastries, sweet treats, celebration cakes, hot savoury items such as sausage rolls and pizza slices.

Their watchword is great value: their stores serve freshly made hot drinks for under £3. And their meal deal includes a properly-filled, freshly made bloomer sandwich, a drink and a snack for less than £6.

Peter says: The ability to offer fresh, quality products at accessible prices is where we really stand out. It’s an

artisan approach without the price tag.

The clientele is wide-ranging — families, officer workers, tradesmen. Wenzel’s attracts a diverse customer base to match its product range, taking customers through from early morning coffee to postwork sweet treats.

And it’s not just serving the communities food and drink. Last year the company established The Wenzel s Foundation to champion community causes, building on their work in that area that is almost as longrunning as the business itself.

Peter explains: We ve been working within the community, supporting some amazing, local initiatives across the past 50 years. I’m especially proud of our ‘Baking a Difference’ campaign, launched last year, which introduced substantial price reductions and multibuy offers to support customers during what has { Wenzel’s The Bakers }

been a tricky time to navigate with the rising cost of living.

“Beyond our stores, we’ve always done what we can to give back to the community whether it be our training programmes for apprentices, sending freshly baked goods to a local hospital or offering free school visits.

For example, at the end of last year, Wenzel s Southbourne offered emergency community, support when a local school oven broke down, swiftly preparing cheese and tomato sandwiches to ensure the children could still enjoy their lunch. It s these small moments that we re really proud to be a part of.

What makes Wenzel’s stand out is that they have remained true to their heritage, and the values Peter had when he set up the company half a century ago.

He says: “We still bake everything from scratch, using traditional methods and stone-baked ovens to create that deliver the rich, crusty texture and flavour customers love.

“While many chains prioritise convenience, we focus on quality and authenticity. Our blend of new flavour profiles with heritage products, regular product development and investment in new talent through our apprenticeship programme, means that we’re the perfect pairing of traditional quality meets innovation.”

It’s also a family business, with Peter ’s daughter Sarah the CEO and various other family members involved in the company.

Peter says: We re very tight knit even for a large team, and we still put the same craft and care into every loaf that we did 50 years ago.”

Wenzel s now operate 109 stores across the UK. Until 2020, they mainly operated in Greater London and the Home Counties, but they ’ve since expanded to the southeast, and southwest, and have recently opened stores in Poole, Essex, Southampton and Portsmouth.

The stores range from high street outlets to larger cafes, with 80% of their products being prepared in their central bakery in Watford, to ensure consistency and quality. At that location, they recently opened a dedicated sandwich making facility here due to the demand they were seeing for freshly made sandwiches.

Peter says: “We now employ more than 1,200 people, and staff training and retention are vital to us. Many of our team, including our COO Karl Spinks, started decades ago and have progressed throughout the years, so it’s wonderful to have so many staff that have a really in-depth view of our operations. Our Production Manager Colin, for example, has been with us for more than 30 years, and one of our shop managers joined the company in 1988!

Excitingly, this year, we launched the Wenzel s Academy as a dedicated training space to support new team members to develop their skills, further embodying our commitment to progression for our team members.

“We also recently hired a dedicated Learning &

Development Manager, Laura, who we ve brought on to really spearhead this side of the business. We are really passionate about supporting career progression and her appointment as well as the Wenzel’s Academy is really reflective of our ongoing commitment to staff training and retention. We want to be a business in which people can really grow.”

Wenzel’s 2024 turnover highlighted an increase of more than 10% year on year, following a number of investments – most notably a digital transformation in 2024, modernising the operations with new tech platforms and delivery systems. And there’s more to come.

Peter says: “We have lots of exciting expansion plans that bring Wenzel’s into new regions, which we’re looking forward to announcing in the coming months. Our mid-term aim is to achieve 200 stores in the next three to five years.

“Our vision is to make Wenzel’s a household name, synonymous with handcrafted and affordable baked goods. We aim to continue our expansion, grow our store network to different parts of the UK, and deepen our community impact, all while staying true to our family-run roots and traditional baking values.

www.wenzels.co.uk

Kings Fine Cooked Meats