HOUSEWRAPS

OPEN JOINT CLADDING

Housewraps designed for use in open joints facade systems.

They provide high water vapour permeability, airtightness and water resistance. They protect building facades from wind and rain penetration preventing condensation and moisture.

They are characterized by extremely high resistance to UV radiation. These unique characteristics allow them to be exposed to partial UV radiation caused by the day light penetrating through the open joint cladding. They have undergone artificial aging testing - 5000 hours.

Their additional advantage is extreme flame retardancy, with a fire resistance classification of B-s1, d0. Makes them self-extinguishes when ignited.

FASSADE

ca. 210 g/m2 | Sd 0,02 m

FASSADE X

ca. 210 g/m2 | Sd 0,1 m

FASSADE PLUS

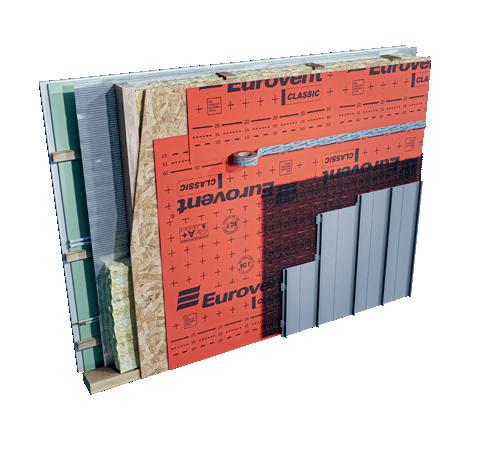

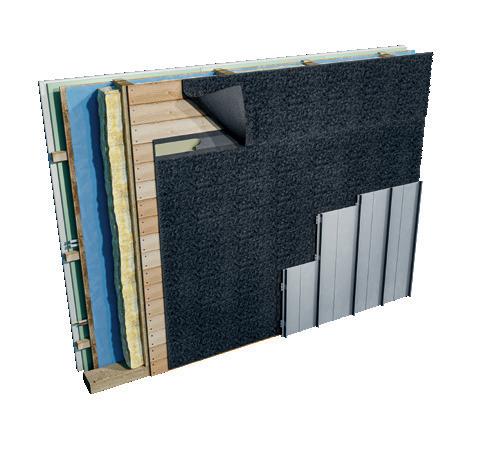

› Application of Eurovent® FASSADE in timber frame wall.

1 Eurovent® FASSADE

2 Eurovent® UNO COLD UV

3 Eurovent® STANDARD ALU

4 Plasterboard

5 Thermal insulation

6 OSB board

7 Open joints timber cladding

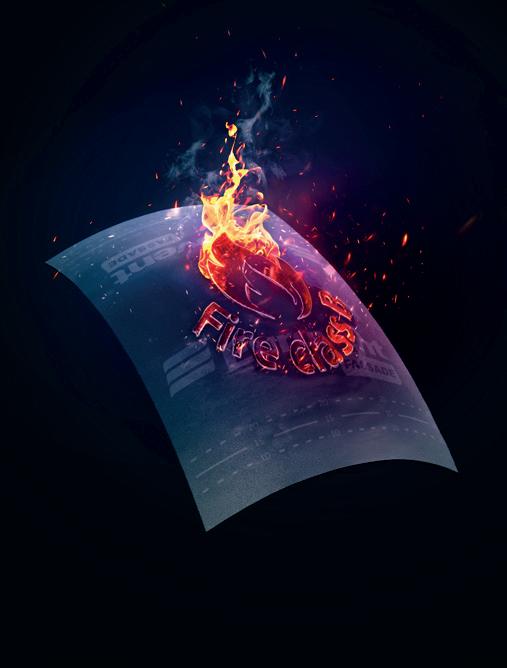

FIRE CLASSIFICATION

Fire classification of FASSADE housewraps.

An additional advantage is their fire resistance in class B-s1,d0 according to European classification and EN-13501-1 standard.

This means that these membranes are non-combustible.

B – Indicates non-combustible material. It does not ignite after removing the ignition source. It contributes a limited share to the fire.

s1 – The material has a very low smoke emission rate.

d0 – This means that the material does not generate flaming droplets/particles.

CLOSED JOINT CLADDING

Housewraps designed for use in closed joint cladding systems.

They provide high water vapour permeability, airtightness and water resistance. They protect building facades from wind and rain penetration preventing condensation and moisture.

Suitable for use in cladding facade systems for timber framing, log houses, modular, prefabricated and traditional construction.

Particularly recommended for facades cladded with siding and various types of external cladding such as metal, wood, stone, composite panels, and ceramics.

CLASSIC

ca. 120 g/m2 | Sd 0,02 m

ca. 90 g/m2 | Sd 0,02 m

ORANGE BLACK

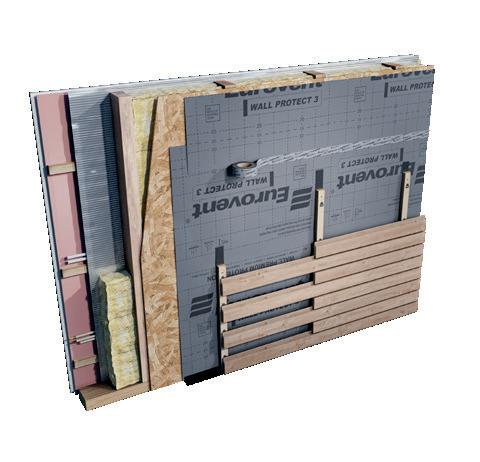

› Application of Eurovent® WALL PROTECT 3 in timber frame wall.

1 Eurovent® WALL PROTECT 3

2 Eurovent® TOPBAND

3 Eurovent® STANDARD ALU

4 Thermal insulation

5 OSB board

6 Facade cladding

SELF–ADHESIVE HOUSEWRAP

Effective waterproofing and house wrapping of walls, ceilings, and roofs with a self-adhesive membrane.

Eurovent® SUPER SA is a self-adhesive, three-layer membrane with an additional adhesive coating that covers the entire membrane surface. The membrane is specifically designed to adhere independently to a prepared substrate, providing a high-performance, waterproof and airtight barrier.

Eurovent® SUPER SA self-adhesive high-permeability membrane. Suitable for insulating pitched roofs, walls and ceilings.

The membrane adheres perfectly to wood-based surfaces such as CLT, OSB boards, MDF, and other wood-derived panels. Additionally, it provides adhesion to hard plastic, metal, plasterboard, and fibre gypsum board.

With the use of a Eurovent® PRIMER, it can also be applied to concrete, plaster, and fibre-cement boards.

› Advantages of Eurovent® SUPER SA

Perfect adhesion to walls and big surfaces.

The special adhesive formula ensures high vapour-permeability.

Air tight water and moisture protection. Time and thermal energy saving.

METAL SHEET CLADDING

Housewraps designed for use in closed joint metal cladding systems.

Highly water vapour permeable, air tight and water tight 4 layer house wraps, made of 2 layers of polypropylene fabric and a layer of microporous functional film, integrated with an 8 mm separation 3 dimensional mesh.

The applied mesh functions as a separation layer between the membrane and standing seam metal cladding, providing ventilation space, draining condensate and ensuring soundproofing.

They are used in facade systems made of metal cladding where the metal cladding is supposed to be installed directly onto the sheathing. In such systems the condensation prevention and permanent moisture prevention is required in order to avoid the metal cladding getting affected by the rust as well as especially wall substrate getting affected by the moisture.

METALLIC

8 mm | ca. 450 g/m2 | Sd 0,02 m

CERTIFICATES

EMICODE®

It is a quality control and classification system for building materials based on the level of hazardous substance emissions. Materials classified as „very low emission” carry the GEV EMICODE® EC1 PLUS label, which ensures the highest level of safety for healthy indoor air.

UV 1000 hour test

The UV 1000-hour test is a standard method for assessing the UV resistance of building products exposed to sunlight.

A 1000-hour test provides a baseline evaluation of a material’s resistance to UV degradation, allowing predictions of its longevity in outdoor use conditions.

UV 5000 hour test

This is an advanced test assessing the resistance of materials to ultraviolet (UV) radiation, simulating prolonged exposure to sunlight. The material is exposed to UV radiation for 5000 hours in controlled laboratory conditions, which corresponds to years of real-world exposure to sunlight in outdoor environments.

The test evaluates how the material responds to UV exposure, which is crucial for building products used outdoors, such as membranes, coatings, or roofing materials. The test assesses color changes, structural integrity, and mechanical durability.

A 5000-hour test is highly demanding, meaning that materials that pass this test exhibit high resistance to UV degradation, ensuring long-lasting durability and functionality in outdoor applications.

BLOWER DOOR TEST

It is an air-tightness test of a building that measures how well the building prevents uncontrolled airflow between the interior and exterior. It is primarily used to assess the building’s energy efficiency, particularly in terms of heat loss and insulation.

It identifies areas of air leakage, such as around windows, doors, the attic, and walls. This test helps assess the effectiveness of thermal insulation and ventilation systems. It is essential for energy-efficient, passive, and low-energy buildings.

During internal testing, we successfully evaluated a wide range of Eurovent brand products, including Vapor Control Layers, Adhesive Tapes, Window Tapes, and Roof Membranes.

ENVIRONMENTAL DECLARATION

The EPD declaration provides information about the environmental impact of the product.

The assessment covers:

Raw material consumption and emissions.

Energy consumption related to production. Usage, product life cycle.