EROWA Robot Six

The flexible solution for all manufacturing technologies

Are you looking for a comprehensive smart factory solution for all your machining processes? At EROWA, we understand that your specific workflows and the type of parts to be machined are key factors.

Whether you need to handle palletized workpieces, raw parts, tools, or a combination of all three, EROWA will develop a solution tailored specifically to your smart factory.

COMPATIBLE WITH

• Hybrid solutions for raw parts, pallet, and tool handling

• Milling, turning, grinding

• Sinking, wire, and start hole eroding

• Engraving/laser marking

• In-process quality measurements

• Washing/drying of machined parts

• AGV/AMR connection

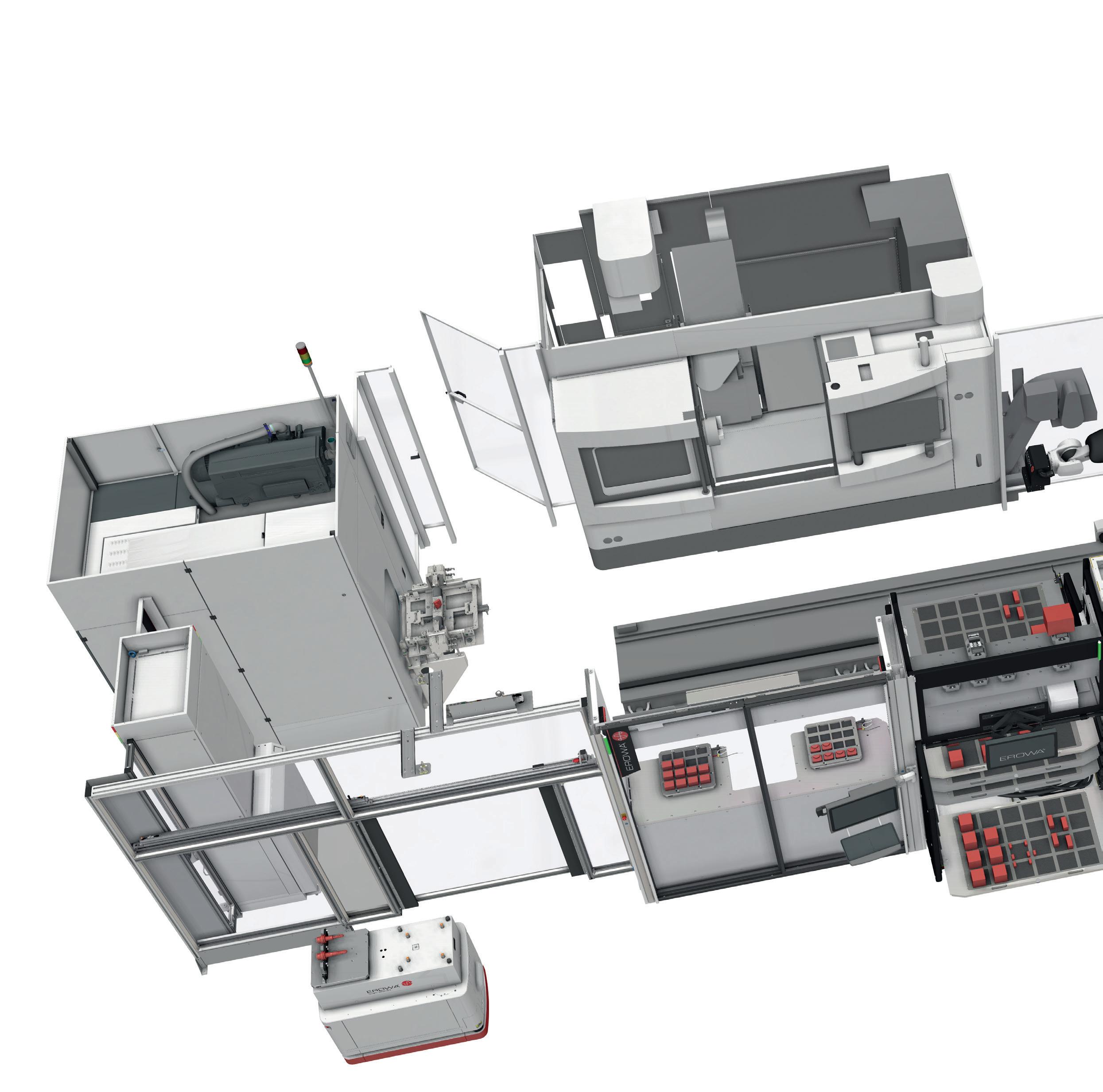

Compared to other automation solutions, the EROWA Robot Six offers an unparalleled advantage when handling a wide variety of workpieces. The sophisticated gripper system offers the option of handling not only conventionally palletized workpieces, but also unpalletized raw parts and tools.

For the right technology in terms of kinematics and peripherals, we use the standardized EROWA modular system with proven components.

Reliable loading and clamping of raw parts:

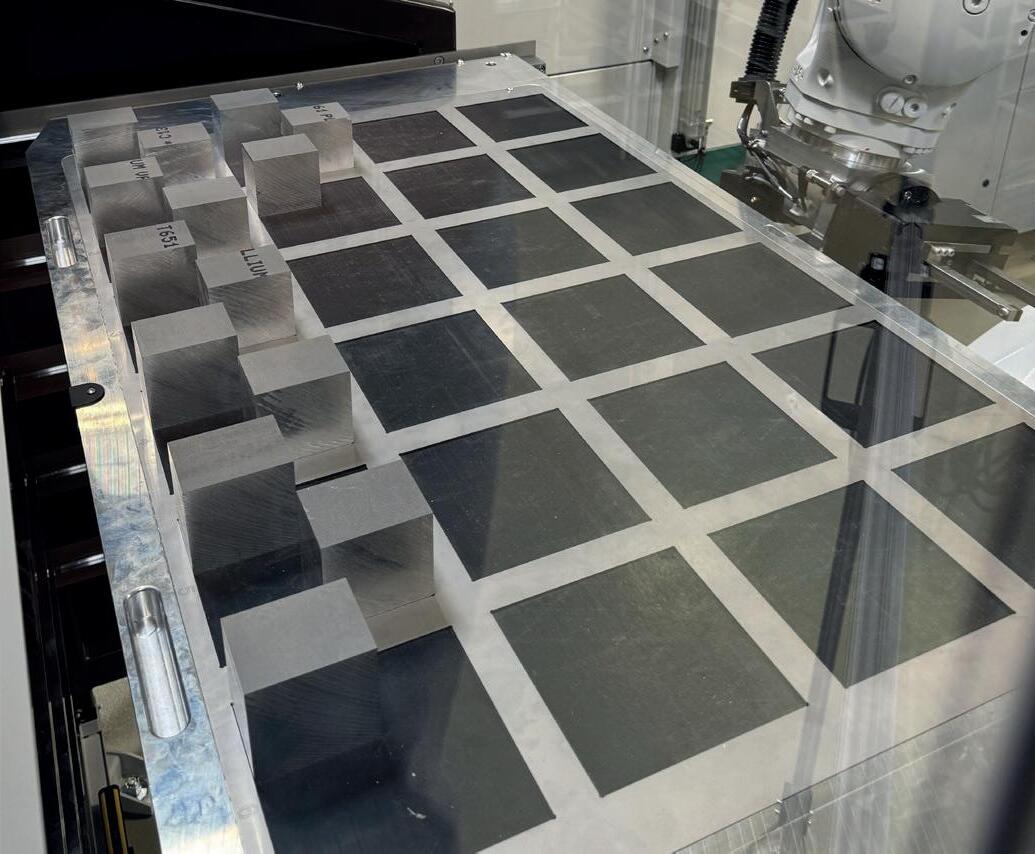

Non-palletized workpieces can be fed into the automation system easily and ergonomically via pull-out drawers. This means that workpieces can be securely gripped as raw parts in nonpalletized form, automatically set up for production, and reliably transported for machining.

Loading drawers for raw parts and semi-finished products: For the workpieces recorded in a specific order, free spaces in the drawers can be easily assigned directly at the magazine via a touch monitor. Up to nine drawers within a magazine can be flexibly configured with customizable grids, allowing for maximum part diversity. Customized insert grids make it possible to handle a wide variety of parts in the same drawer magazine. The electric clamping station autonomously clamps raw parts into the designated centric clamps for machining, and automatically unclamps and returns them to the drawers after the machining processes are completed. This provides an optimal solution for automating the setup of workpieces independently of the production machines.

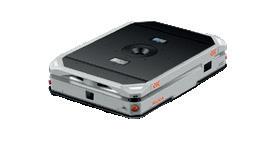

Interchangeable gripper technology

An attached servo gripper enables flexible gripping of workpieces by allowing the gripper fingers to be precisely prepositioned for each gripping action and closed with the desired force.

For further operational steps, such as secondary machining, pre-machined parts can be clamped in the traditional manner on EROWA system carriers. Thanks to the Robot Six‘s automatic gripper change, pallets can also be brought to the machines in a “on-the-fly change.”

The workpieces and tools are fed in and out via the various loading stations, which can also be used as setup stations. This means that finished parts are unloaded at an ergonomically ideal height directly at the cell and replaced with new raw parts. The integrated robust clamping features of the pallets withstands high loads, even when working with high torques during rough re-clamping operations.

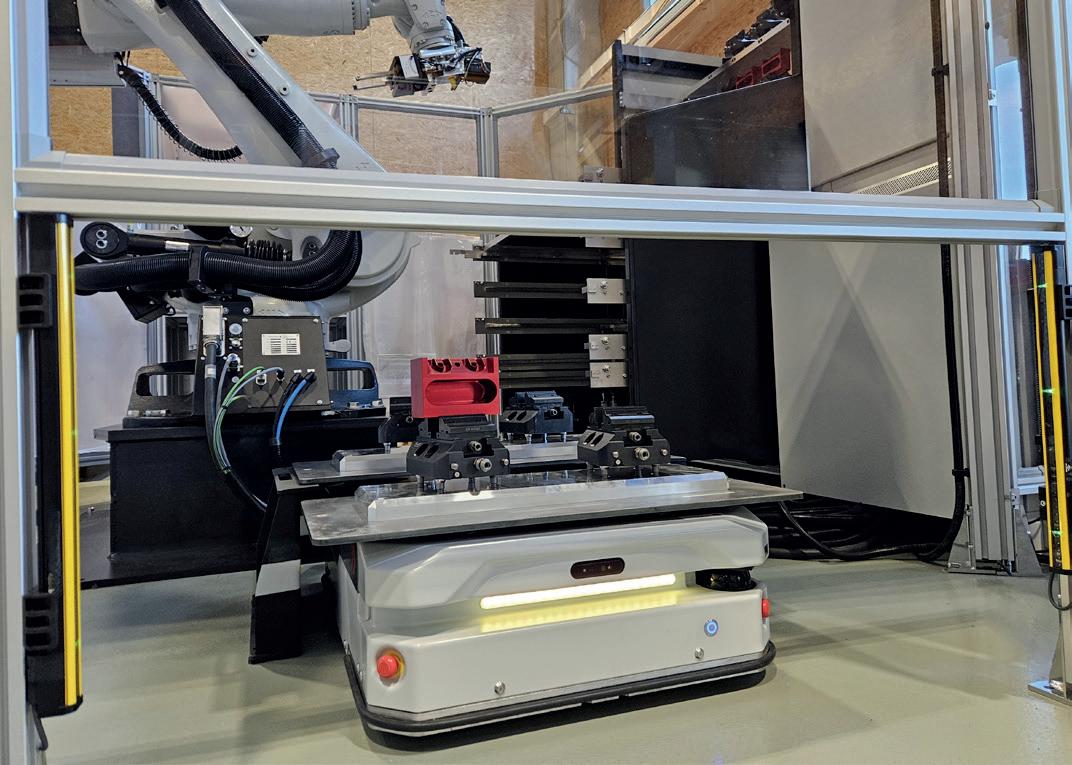

Docking and feeding or removing workpieces

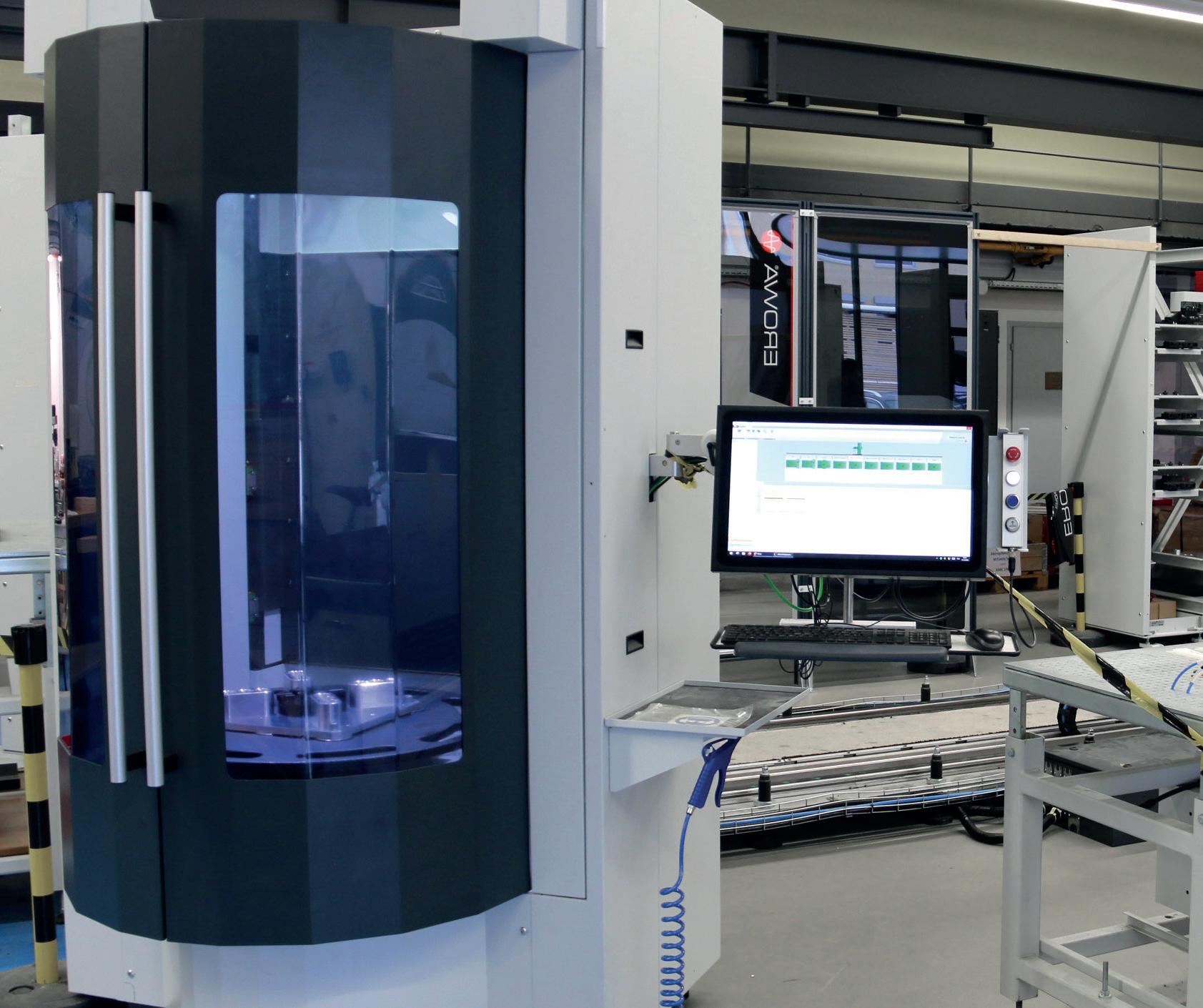

In order to link several individual robot cells and enable the exchange of parts to be processed even during unmanned shifts, docking stations for driverless transport vehicles (AGV/AMR) integrated into the robot cell are suitable. For example, processed workpieces can be picked up by autonomous vehicles and transported to a centrally used measuring cell in a climate-controlled cabin for intermediate inspection.

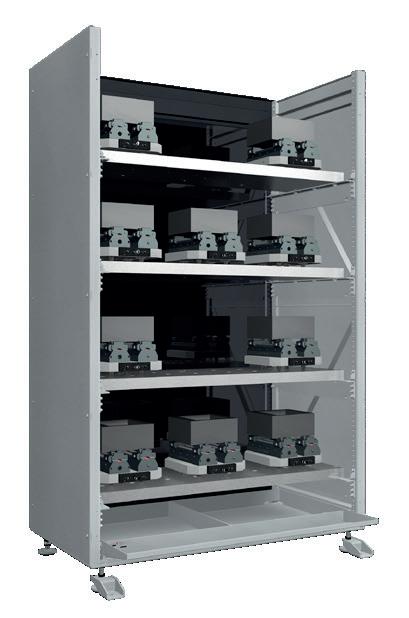

Magazines and parts storage

EROWA parts storage systems offer the ideal combination of standardized components and customized configuration to suit your range of parts. The individually configurable boards provide space for raw parts, pallets, and tools.

At EROWA Automation Solutions, we focus on creating the optimal interface between humans and machines. Control elements are arranged so that they are intuitive and easily accessible. The integrated EWIS part identification system ensures the necessary security in the workflow.

Another important factor is a clear and high-contrast software user interface: orders can be created or evaluated with just a few clicks.

FACTS

• Ergonomic control panels

• Hardware and software optimally coordinated

• Productivity evaluation using OEE dashboard

• Alarming and reporting

• Live status via mobile app

Your key EROWA advantages

• Everything from a single source

• Experience with over 5000 robots installs

• Standardized interfaces to machines

• Durable systems

• Independent partner

• Short installation times

• Integrated safety system

• Worldwide service and support

Technical facts about EROWA Robot Six

• Specified production automation tailored precisely to your requirements

• Standardized and proven peripherals

• Scalable robot kinematics depending on application

• Standalone, portal version, and/or linear with rail lengths up to 30 m

• Transfer weight up to 800 kg

• Precision in positioning across all axes and orientations.

• Handling of raw parts in combination with pallets

• AGV / AMR connection

• Automatic gripper change depending on pallet or part size

Expansion options

• Additional machines

• More magazine spaces

• Cleaning or loading stations

• Setup station with operator guidance

• Tool management

• Connection to CAD/CAM and PPS systems

• Fixture management

• Alarming and reporting functions

• OEE Dashboard

Step 1

Manufacturing processes

- Cutting: milling, turning, grinding

- Erosion: die-sinking, wire erosion

- Multi-sided machining

- Mixed operation / multi-stage work processes

- Number of machine tools

Step 2

Feeding and removing parts

- Manually into the magazine

- Via loading station/loading trolley

- Via autonomous transport systems (AGV/AMR)

Supporting processes

- Quality measurement / in-process measurement

- Washing / drying

- Laser marking / engraving

- Separating / merging / re-clamping

Parts storage / magazines

- Rotary magazines: For large quantities

- Rack magazines: For large and heavy parts

- Configurable shelves according to part size and weight

- Drawer magazines: For non-palletized workpieces

- Automatic identification

Parts handling

- Unpalletized raw parts / pre-machined parts

- Pallets or workpiece clamps

- Electrodes

- Tools

Software user interfaces

- Process control system

- Evaluation options via dashboards

- Tool management

- Central order management

- Oversize management

Step 3

Interfaces

- Connection of all machines from any manufacturer

- Cross-cell networking

Robot kinematics

- Based on part weight and system size

- Stand-alone, linear, and gantry versions

- Gripper concepts

Options

- Overall compliance

- Maintenance and servicing contract

We would be happy to design a customized solution with a machine layout for you from the countless modular options available.

EROWA AG, founded in Switzerland in 1971, is now a global organization for the development, production, consulting, and distribution of state-of-the-art manufacturing technology in tool and mold making as well as in production and precision mechanics. EROWA is one of the world‘s leading companies in its main areas of activity, clamping technology and automation. EROWA‘s headquarters are located in central Switzerland. With its 13 subsidiaries and 22 agencies, EROWA offers international contacts and worldwide customer service.

The next step toward greater efficiency, precision, and productivity starts now. With EROWA, you have a partner who will optimize your entire production process - from clamping technology and automation to process control. Our innovative solutions adapt flexibly to your requirements and grow with you - for production that is ready for tomorrow.

Get in touch with us - we will be happy to assist you.