Global Technical Solutions

Global Coverage. Local Service.

Introducing EPC Groupe’s Global Technical Solutions (GTS) and the EPC ecosystem created to deliver mining and quarrying technical solutions for our clients.

Global Coverage. Local Service.

Introducing EPC Groupe’s Global Technical Solutions (GTS) and the EPC ecosystem created to deliver mining and quarrying technical solutions for our clients.

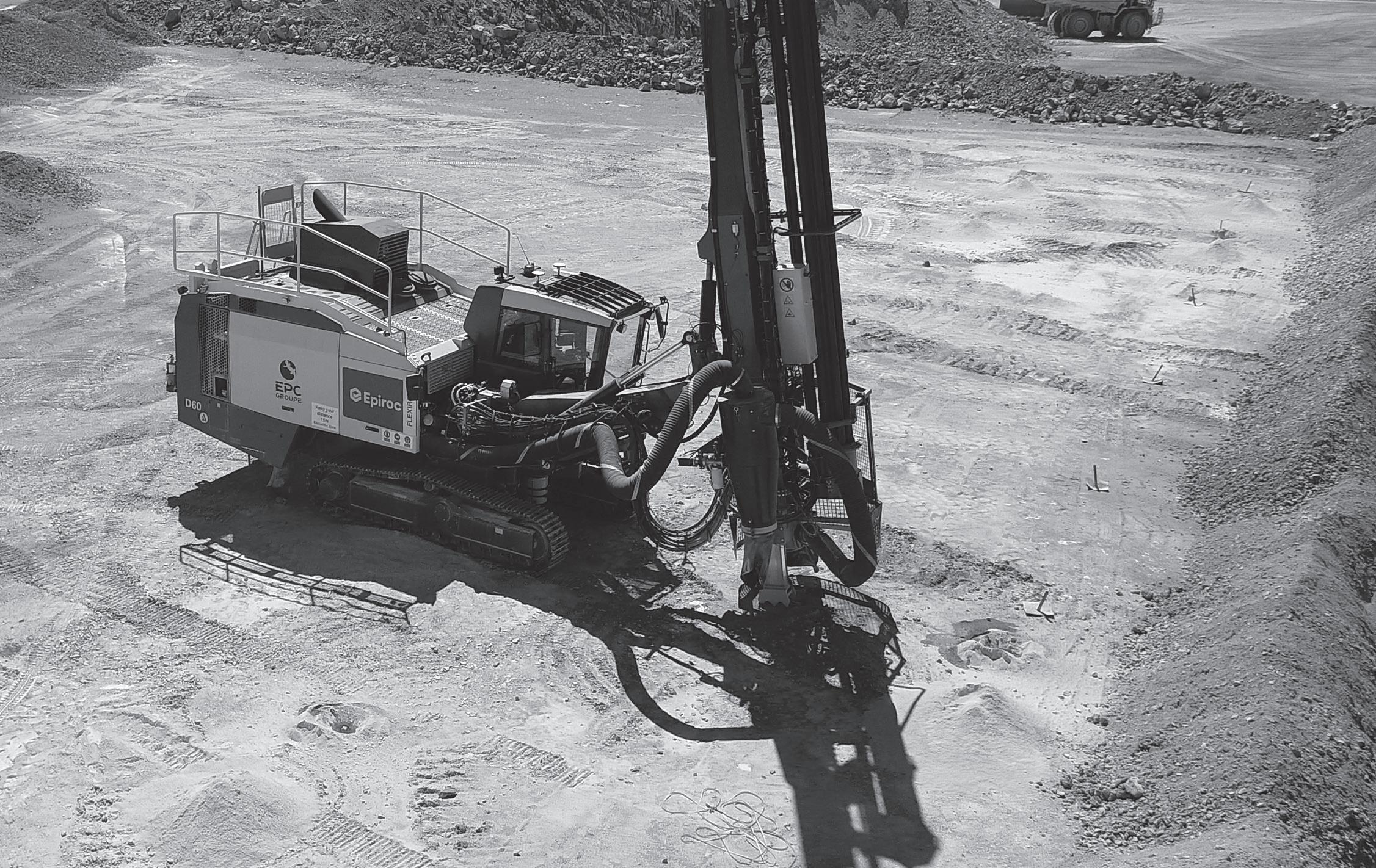

EPC Groupe’s Global Technical Solutions (GTS) has been created by explosives engineers, for explosives engineers. A revolutionizing, true journey of real time site implementation to deliver optimized results, GTS is powered by our own software house Diogen and is driven by EPC Groupe experience. GTS is an investment for our industry. It brings our VERTEX© software

solutions, proven hardware capabilities and extensive expertise into the EPC ecosystem, which when applied empowers customers’ projects and delivers value added results through partnership.

GTS is a natural evolution of EPC’s best in class performance. Its development has been made possible by a team that’s fluent

in the numerical modelling techniques, backed by the data in our Explore® platform, that measure and process blast impact and results. Supported by an engine room of service professionals that encapsulate our esprit d’équipe working methodology, GTS is EPC Groupe’s most important global development yet.

“Global Technical Solutions is EPC Groupe’s next step to enabling mineral extraction sustainability, inspired by the challenge to realize change within surface mining, quarrying and underground operations globally.”

Olivier Obst CEO & Chairman EPC Groupe

Designed by Engineers, for Engineers.

25 years ago, EPC Groupe recognized that digital tools for our changing industry would be essential to support mineral extraction more sustainably, adding value, heightening safety and delivering a greater return on investment. Through a revolutionary initiative devised by Dr. Ricardo Chavez, the first version of our blast design software, Expertir®, was created: a powerful digital solution that optimizes the energy of explosives to

achieve superior blasting results within mining & quarrying operations. Expertir® continues to be refined and in 2022 EPC Groupe’s dedicated software house, Diogen, was launched to further enhance our capabilities and reactively integrate engineer and customer data to achieve bespoke solutions for each application. As technologies and AI continue the journey to supporting sustainability, so too will Diogen’s expertise.

The Partnership based approach has always been the EPC-Way and it has proven to deliver real value for our clients.

Adding value, reducing operating / processing costs using our new technologies, whilst maintaining the EPCWay in our approach is the key feature and offering of the GTS team. Utilizing the key features within our QAQC (quality assurance and quality control) numerical simulation with AI enabled software and applying our blasting knowledge gained both locally and globally through our networks we can create real value.

This EPC Groupe ecosystem has been developed to ensure that we can create a be-spoke service to our customers’ operations in surface mining, underground and quarrying operations. EPC’s approach through GTS is to support our already successful global subsidiary structure to create valuable partnerships, implementing our technology and know-how to an operation to realize greater sustainability.

Ben Williams Head of Global Technical Solutions

Our approach to precision blasting

We understand that every site is unique. Our methodology begins with a thorough site assessment with the client including understanding the whole value chain of the operation. Following a complete assessment, it is through a partnership approach that we will benchmark the operation for an agreed period to ensure consistent evaluation.

An agreed plan of action with the client to implement the EPC ecosystem systematically to realise the value against agreed KPIs is put in place. The tools we use look to precisely control the energy distribution in the blast based on the prevailing conditions.

These technologies include blast simulation software and AI enabled analytics to refine blast parameters and maximise efficiency using a data driven approach.

Within our ecosystem we provide the metrology tools for various applications to ensure sustainability, compliance and environmental safeguards in every project.

The value of blasting solutions through successful partnerships

Our techniques ensure optimal rock fragmentation or mineral extraction to decrease the processing costs and energy consumption of the operation.

By improving the blasting efficiency in a holistic way the environmental impact of the whole operation is reduced, as we minimise dust, noise and vibration. Critically, safety is also heightened as controlling the energy released reduces the risk of flyrock and overbreak and ore dilution.

The success of the partnership approach has been the journey of EPC Groupe and is a proven path for GTS to continue to take as we continue to drive our sustainability goals within the minerals extractive industry implementing our experience, technological solutions, best practice methods and, most importantly, respecting local regulations and culture.

GTS partnered with a limestone quarry to implement advanced blasting techniques. The result was a 20% reduction in fines, together with a reduction in oversized material, reducing costs and improving overall efficiency.

By employing its advanced blasting processes , GTS is ensuring its civil engineering project clients meet environmental compliance regulations, whilst optimizing blast performance and reducing project costs.

Tailor-made approach to complex and unusual underground geology

Unique up-hole charging technology combined with tailored services has proven to be both safe & profitable for a Swedish underground gold mine.

Why choose GTS?

With decades of experience in blasting operations and extensive capabilities in using proprietary techniques to ensure precision in every blast, GTS is a reliable partner to drive operator savings and reduce downstream costs with an ever-present focus on sustainability and environmental responsibilities.

The future of blasting optimization

As the mining and quarrying industries continue to evolve, GTS remains committed to driving innovation in

blasting technologies. Our future advancements will include the introduction of AI enabled real-time simulation blast design and the implementation of advanced monitoring systems with real-time blast performance technologies.

Precision blasting for superior

At GTS, we combine expertise, innovation and collaboration to deliver unparalleled, optimized blasting solutions. Our proprietary techniques are empowering mining and quarrying operations to achieve their goals safely, efficiently, and sustainably.

Let GTS redefine what’s possible with precision blasting. Together, we can achieve operational excellence.

Learn more about our partnerships.

Experience safe, more productive, and standardized operations with VERTEX©.

VERTEX© is a powerful solution for mining and quarry operations. It combines advanced 3D modelling, precise planning, and accurate drilling, all managed within the Explore® platform.

VERTEX© enhances safety by preventing flyrock, boosts productivity with high-quality drill & blast designs, ensures consistent results through rigorous document management and KPI monitoring.

• 3D Planning

• Pre-drill and Post-drill profiling

• Consistent energy distribution

• Optimized design

• Digitalization of drilling report

• Remote communication with MEMU

• Controlled hole loading

• Real time GPS positioning

• Environmental monitoring

• Blast localization in the pit

• Post blast measurement

• Export various data and reports

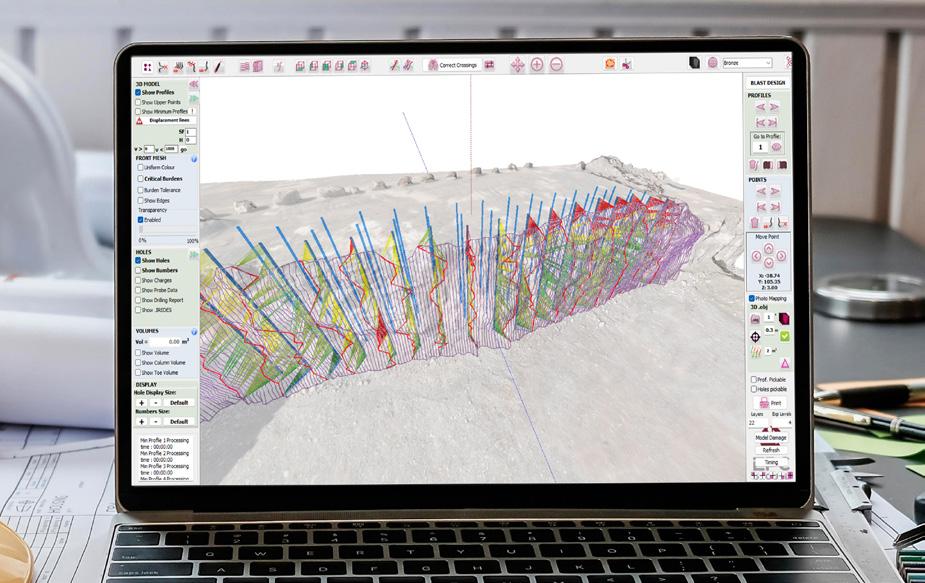

Blast design software

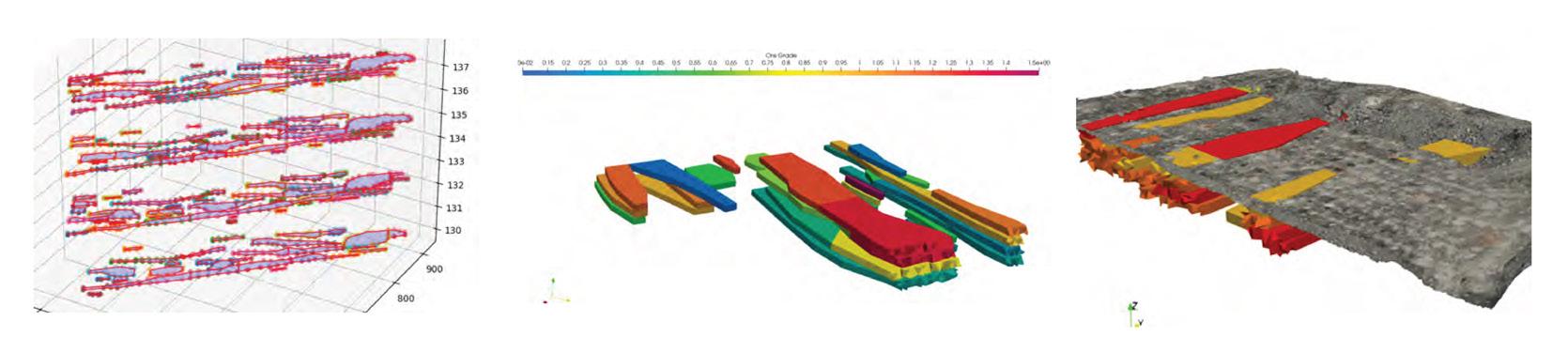

Expertir® optimizes mining operations with advanced services in drilling, loading, and firing sequences. Our drilling design features precise 3D model analysis from drone surveys, adaptive drilling geometry, and burden control visualization.

Our firing sequence module includes designing delay sequences for complex ore shapes and simulating vibrations from sequences and charges. Expertir® delivers innovative solutions for consistent energy distribution enhanced performance and sustainability.

In loading design, we ensure, damage and fragmentation control, and assess the blast carbon footprint.

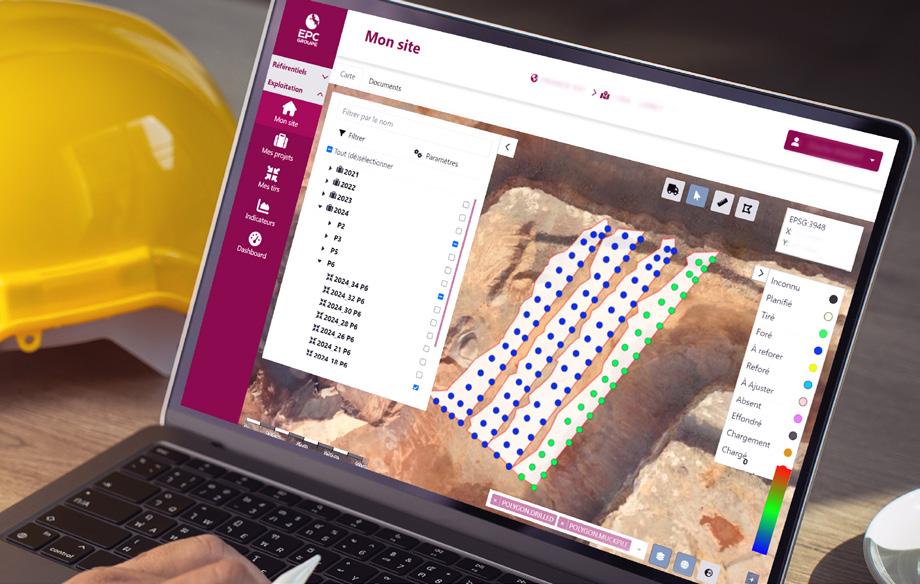

On-bench blast design assistant

Expertab® digitizes drilling reports for easy integration into Explore® and Expertir®. Our drilling Quality Control ensures accurate borehole measurements and identifies geological issues. For Loading Quality Control, Expertab® provides real-time loading data and remote communication with hole loading equipment.

Streamlined data management & visualization

Explore® offers a secure database to store and share files across sites, projects, and blasts, including blast locations in the pit. It provides customized workflows tailored to your methods and easy access to your documents. With Explore®, you can visualize a live dashboard of KPIs and statistics from multiple blasts, helping you learn from past data to optimize future blasts.

Learn more about Blast Design.

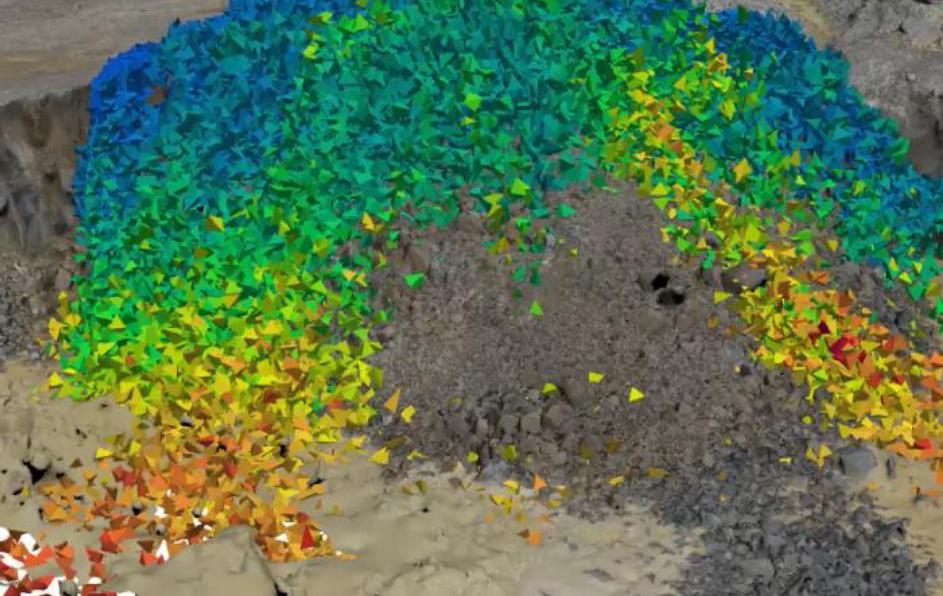

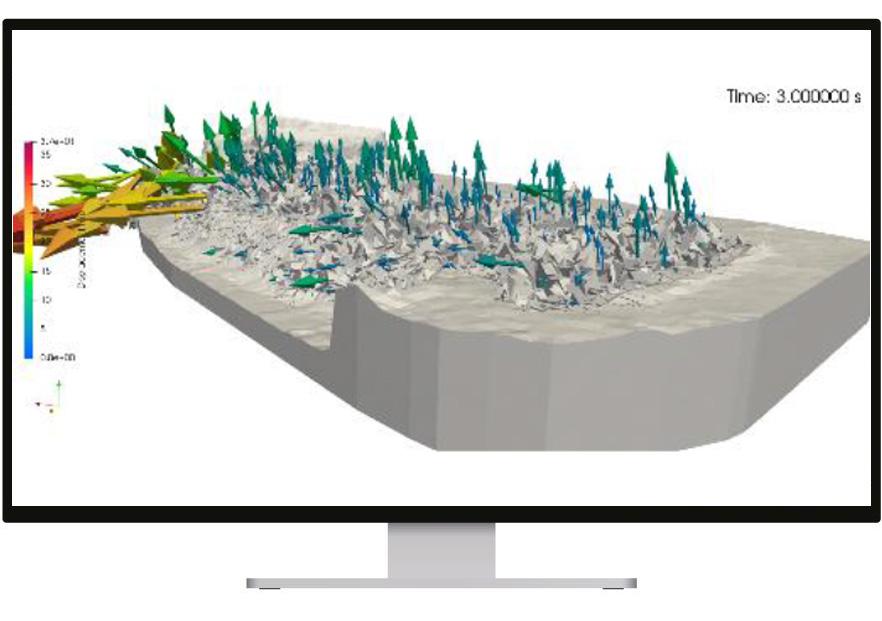

EPC Groupe’s technical capability in blast simulation is leading the industry’s way in enabling greater mineral sustainability for customers on a global level.

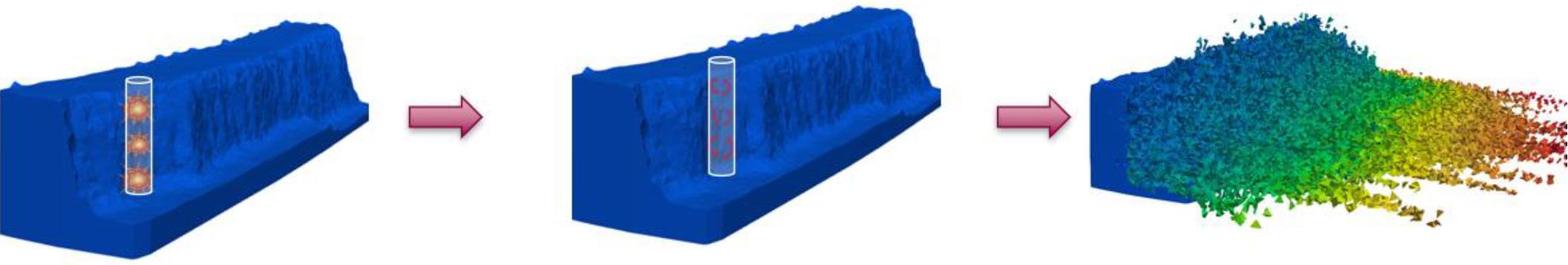

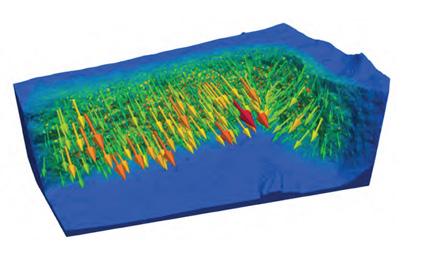

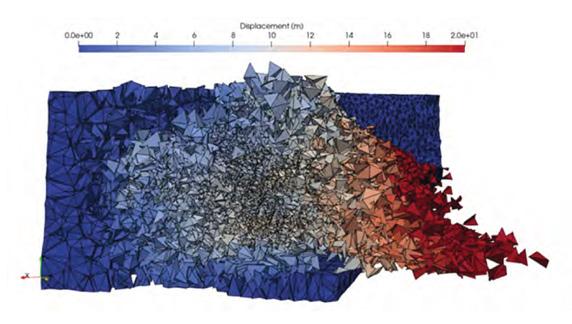

Our engineers’ use of numerical modelling techniques is helping us to better predict blast movement, fragmentation and damage so we can provide optimal designs, reduce future costs and waste, create greater value, and improve sustainability.

Using data gathered from seismic sensors, blast monitoring equipment and geological surveys, our team can develop a comprehensive view of a customer’s geological environment, then design the most cost-effective blast possible.

Our extensive understanding of the scientific interactions between explosive gas pressure and rock properties is industry leading, and our comprehensive use of numerical modelling allows quarry and mine customers to achieve full optimization with every blast performed.

By using state-of-the-art blast movement modelling, our engineers can predict the path of rock fragments that will follow the blast based on explosive type and quantity, blast hole placement and rock properties.

Our digitalized modelling techniques significantly improve safety on site, as rock landing points can be predicted ahead of the blast.

Subsequent mining and quarrying operations, such as loading, can be made more efficient, as muck pile shapes can be predicted before the blast is performed.

Using state-of-the-art modelling our engineers design the most costeffective blast possible.

Our team’s numerical modelling capabilities enable us to simulate the exact quantities of waste and ore within the rock. Using this information, we can adapt the blast sequence to optimize dilution.

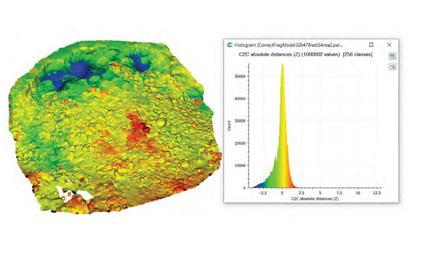

Fragmentation prediction

The digitalized models we create through numerical simulation can be cut into layers so we can predict the digging operations needed following the blast and calculate ore grades, volumes and cost benefit in advance.

Learn more about Blast Simulation.

Powered by

By capturing key data using processes influenced and controlled by the EPC Groupe ecosystem, GTS can unlock value through precision measurement solutions.

A crucial differentiator for GTS is our ownership and implementation of precise blast measuring device solutions, designed using Vibraquipo hardware and powered by Diogen software. Created in-house by engineers for engineers to simplify operations and ensure relevant data is accurate, our measuring solutions capture multiple data points from different areas to analyze environmental impact and assure hole layout and blasting precision.

EPC Groupe’s reputation for driving industry innovation is renowned. Historically, our research and development instigated the industry wide implementation of drone profiling in the field. The continuous investment in and evolution of GTS will realize the sector’s next developmental stage globally, as our ecosystem evolves to incorporate AI for the future to enhance customers’ sustainable capabilities yet further.

In the quarry environment, vibration data recorded can be transferred to our VERTEX© platform, or alternative software.

By realizing and combining our three key software systems, our teams can apply drone photogrammetry technology, fragmentation analysis techniques and 3D modelling solutions to achieve more successful and optimized blast outcomes, focused on delivering significant cost improvements to the entire quarry and mining process.

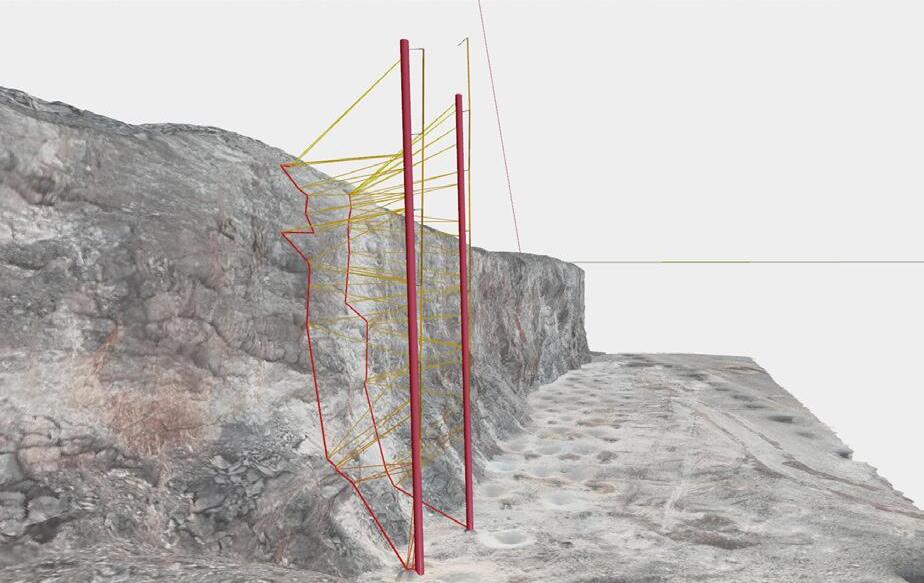

Drone surveying

We use drones in quarrying environments for two key purposes: The first is to gather data for the blast design process, or profiling; whilst the other is to perform whole quarry mapping flights to aid in planning and material reconciliation. Our drones can acquire more detailed face profiles than achievable using traditional

Fragmentation monitoring

The SMARTFRAG tool makes it possible to measure the fragmentation curve of muck piles using drone images. It was developed by EPC using deep learning technologies dedicated to computer vision. This makes it possible to correctly identify complex objects, such as fines, which are difficult to detect by conventional image analysis techniques.

measuring techniques. This data allows us to create 3D models of a quarry blast for analysis which, used alongside additional information generated through our VERTEX© software system, enables us to produce increasingly tailored, efficient blast designs to meet individual site requirements.

Vibration monitoring equipment

Vibracord Tellus is a latest generation vibration meter manufactured by equipment specialist, Vibraquipo, and managed, supplied and calibrated locally by your EPC Groupe team. It features a GPS function to provide the position of and synchronize all the precise timing analysis equipment used in a quarrying environment to enable users to remotely access and operate equipment.

In addition to a renowned level of consultancy expertise, our team can effectively control and optimize blasting environments. This enables planned and delivered blast parameters to be stored and the performance assessed against incremental changes in design so results can consistently be optimized.

Vibracord Gaia is an advanced ground borne blasting vibration monitoring solution designed for use in challenging quarrying conditions. Contained within a strong aluminium case and manufactured by equipment specialist, Vibraquipo, Gaia features a hi-contrast illuminated LCD screen, designed to be effective under all light conditions. It is user friendly and recommended for portable vibration measurement applications.

Our POLAREX© probe resolves customers’ down-the-hole measurement issues and has been built directly by EPC Groupe. This effective borehole deviation monitoring tool measures and reads the orientation and angle of blast holes enabling the control of energy and reduce the risk of flyrock.

Vibracord Hermes is the first data logger designed for mining applications, with different working modes to make the device configuration easier. The unit is portable and resistant, for open pit and underground operations.

• Data logger mode

• Near field vibration

• Under water pressure

• Velocity of detonation (VOD)

• Pressure of detonation

The EPC Groupe built probe can be supplied, serviced, calibrated and maintained by our team. In addition, the android compatible POLAREX© app perfectly supports the probe’s efficacy. It is easy to use and enables data to be transferred to EPC’s Expertir© software, or other blast design software package, on a phone or tablet.

Learn more about Measuring Solutions.

Creating bespoke solutions for our customers with quality assurance and quality control (QAQC) from within the EPC ecosystem, and providing a supportive and enabling link between the customer and their project.

GTS’s consultancy services can be driven locally or globally for customers. Our passion to excel leads us to continuously develop and enhance our digital and technical expertise and customer centric services, so we can add greater value and further reduce costs.

Key to our success are the valued relationships we invest in, and by providing site-based consultancy services we can build full and effective partnerships from understanding our customers’ businesses.

The experienced personnel on the ground worked proactively, meaning problems could be solved before they even became problems!

Superintendent Underground mine - Sweden

Dr Ricardo Chavez Group Technical Manager

The training was rich in information especially the practical which helped a lot. Very interesting and productive, the explanations were clear.

Training Supervisor Contract Mining - Africa

Key locations

Delivered in collaboration with our global subsidiary network.

Learn more about Consultancy. With over 130 years of underground and surface mining and quarrying experience, EPC Groupe carries field leading expertise in its DNA.

Effective, knowledge led training, driven by field specialists, is essential to equipping operatives and engineers with the technical skills to realize mineral extraction more sustainably.

EPC Groupe’s commitment to ensuring excellence, quality, safety and reliability at every stage of training is evident and experience backed. We design and deliver globally recognized training courses, in collaboration with industry and leading educational institutions, enabling us to

‘build tomorrow’s skills together’. Our team of trainers are themselves distinguished industry contributors, published researchers (ISEE), conference speakers (EFEE) and institute board members with significant experience covering all disciplines of the extractives sector.

Eric Krolop Groupe Key Account Manager

Our Engineers

Dr Ricardo Chavez Group Technical Manager

Ricardo brings over 25 years of experience to EPC Groupe and is a Council Member of the European Federation of Explosives Engineers.

A Mining Engineer-PhD and blasting expert, he performs the role of Technical Manager taking charge of EPC Groupe’s ROG methods, innovation, and blasting software development. Throughout his career, Ricardo has been involved in projects across Europe, Africa and South-America and his implementation of optimized Mineto-Mill systems in mines and quarries has continuously achieved improvements in productivity and value.

Enabling mineral sustainability

Iván del Castillo Head of Seismic & Acoustic Metrology

Iván is a highly accomplished mining engineer who harnesses more than 35 years of experience within the blasting industry.

An expert in his field, his knowledge and expertise enabled him to become founder of a Spanish mining consulting firm which provides blasting services to the industry. From here he went on to become founder of companies Vibraquipo and Vibratesting, two businesses that specialize in the manufacture and supply of ground borne vibration measurement and calibration. Iván currently works for EPC Groupe as Head of Seismic and Acoustic Metrology.

Jean François Couvrat Equipment & Measurements Development Manager

Jean François is an experienced mining engineer and graduate of Ecole des Mines de St Etienne.

The current Head of Equipment and Measurement at EPC Groupe, he has previously performed at Director level within the quarrying and drilling-mining industries, and as a Mining Technical Advisor in Africa. His technological and programming expertise, together with invention capabilities, have led Jean François to develop EPC Groupe’s metrology products including POLAREX© deviation probes and EXOFUME© gas sensors.

The demanding nature of our business and the standards we set mean we have to guarantee a high level of qualification for our operatives and engineers to meet current changes and challenges, and those that lie ahead.

• 2500 professionals trained each year

• 95% success rate at state exams

• 3 training centres

• Explosives Awareness

• Shotfiring - Underground / Surface

• Refresher Courses

• Advanced OP Blasting

• Drift / Tunnel and Demolition Blasting

• Advanced blasting Diploma

Learn more about our Global Training & Support Solutions.

Antoine is a proven business leader with 15 years of experience in the software and materials industry, specializing in digital transformation.

As COO of Diogen, Antoine spearheads the company’s growth and oversees its development. Diogen, the software division of EPC Groupe, brings together a team of drill and blast experts and software professionals who together are building the future of drilling and blasting software. Antoine is passionate about transforming the mining and quarrying industry to realize more sustainable practices.

Sam Taoum

Head of R&D - digital technologies for blasting solutions

Sam holds a PhD in Applied Mathematics, enhanced with 12 years of experience from various physical industries.

A passionate professional with extensive expertise, Sam is realising his ambition to deliver engineering solutions through advanced algorithms and software. Currently he directs the numerical simulation department for EPC Groupe, with responsibilities including leading the Innovative Technological Solutions R&D project. He also works closely with clients to address their industry-specific challenges using optimization strategies and tailored engineering consulting services.

Chief Technical Officer (DIOGEN)

Pierre has 17 years of experience in software engineering and a solid background in physics.

An expert within the aeronautics industry, his natural curiosity and passion for innovation have led him to become a notable contributor to cutting-edge projects in system design and software solutions. Transitioning to the mining sector, he’s played a key role in developing innovative technologies that have enhanced operational efficiency and safety. Pierre now leads the development team at Diogen, driving forward impactful solutions and shaping the future of engineering with precision and creativity.

Contact

Global Technical Solutions gts@epc-groupe.com www.epc-groupe.com

Diogen support@diogen.com www.diogen.com