T HE A R T OF P URP OSE

T HE A R T OF P URP OSE

PAID

T HE A R T OF P URP OSE

T HE A R T OF P URP OSE

PAID

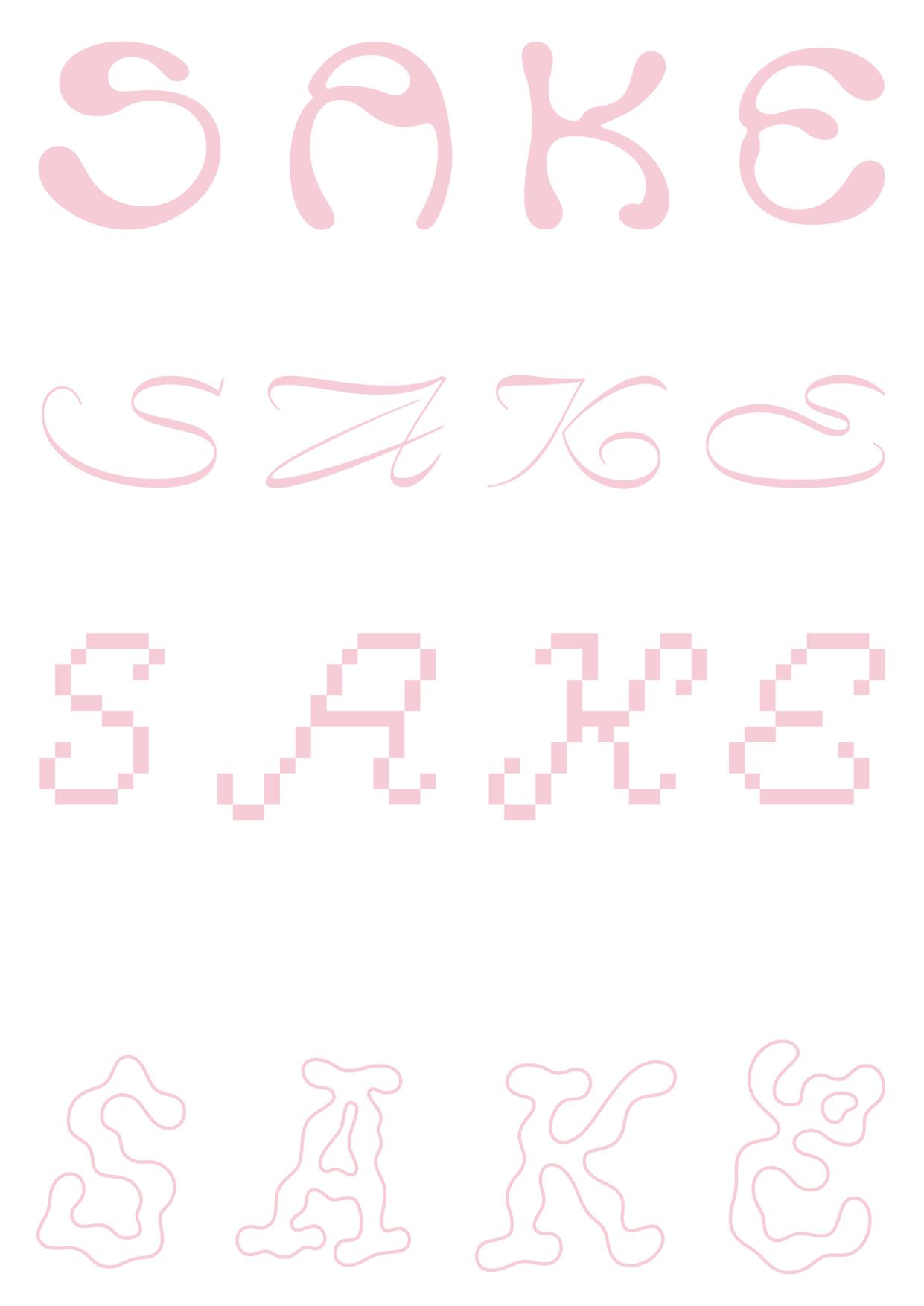

SAKE (pron. /se ɪk/, sayk) is an interdisciplinary art project led by Sadia Rafique together with Mohsin Sajid (ENDRIME® and Denim History) and artist Matt Duckett in collaboration with Tonello, alongside Susan Zheng and Leah Hoy. Supported by global industry leaders—Cone Denim®, Indigo Textile, Sharabati, Stella Blu, Tusa Denim, YKK and 496 Fabric Lab—with special thanks to Kingpins Show and Denim Days.

This summer, we had the privilege of returning to Italy to work on SAKE — THE ART OF PURPOSE with the wonderful team at Tonello.

Our journey has always centred on exploring Purpose — what it means to us as individuals, as businesses, and within the denim industry.

Purpose gives meaning to our work. We discover it where our passions, strengths, and professional skills meet the needs of the world. This is the essence of Ikigai: doing what we love each day and, in the process, uncovering our reason for being.

As part of this year’s project, I’d love for you to take the time to consider any (or all) of these questions:

What does Purpose mean to you — personally or within your business?

What could it mean for the denim industry if we chose to lead with Purpose?

How might a Purpose-driven approach transform the way we work?

With gratitude, Sadia

SAKE artist and graphic designer

Sadia Rafique is a visionary storyteller specialising in fashion projects and creative collaborations. As the co-founder of ENDRIME® and Denim History, she has made a mark as an Art and Creative Director, leading award-winning fashion shoots, films, and brand identity projects. Her expertise spans storytelling in marketing, social media, and creative direction for the denim and fashion industry, working with mills, brands, and fibre producers. Sadia’s background as an apparel graphic designer includes collaborations with global brands, where her hand-painted illustrations elevated leather jackets and premium sneakers, sold at more than 30 stores globally including Tokishirazu and United Arrows in Japan, Ron Herman and Fred Segal in LA, Boutique1 in Dubai, Harvey Nichols, Library Liberty, Matches and Browns in London, UK.

SAKE co-project manager, collection design and storytelling

Mohsin Sajid is a highly accomplished denim specialist, denim historian and educator. With more than 20 year’s experience working with a number of world-leading international denim brands and mills.

Mohsin has a keen interest in raising the next generation of denim designers reflecting on his role as MA Denim Lecturer at The Royal College of Art, and BA Denim Lecturer at Central St Martins and Ravensbourne University London.

SAKE artist and graphic designer

Matt joined us this year as a contributing artist and graphic designer. He is the ex Levi’s Print and Graphics Director and Creative Consultant at Alexander McQueen.

Matt Duckett is an experienced Graphic/Print Designer and Art Director with 19 years of expertise, primarily within the fashion industry. His extensive portfolio also includes work in illustration, animation, and video production. Having lived and worked internationally, he brings a global perspective to his projects. In addition to his creative work, he has shared his knowledge as a lecturer and tutor at leading universities and has had his work published in prominent journals.

AR Experience Developer

Susan Zheng is a software engineer and 3D fashion technical artist. Building on her master’s research in digitizing historical garments through 3D technology and gamified experiences, she continues to bridge fashion and technology through innovative digital fashion projects.

AR Experience Developer

Leah Hoy is a fashion designer who specialises in 3D digital interfaces. Her work -that merges the digital and physical- leans its emphasis on developing interactive experiences with animation, body tracking and real-time cloth simulation. She teaches as a digital garment specialist at London College of Fashion.

Founded in 1981, Tonello has become the global benchmark in garment finishing technologies, playing a key role in strengthening the worldwide reputation of “Made in Italy.”

But Tonello is more than a manufacturer of advanced machines: it is a true partner, working side by side with its customers and acting as a vital bridge between fashion designers, brands, and the companies in charge of manufacturing, dyeing, and finishing garments.

With more than 10,000 machines installed worldwide, Tonello has set the standard for the

industry. Its pioneering solutions have not only transformed garment finishing processes but have also redefined the very standards of the sector.

From its foundation to its position today, Tonello’s story is one of dedication to quality, innovation, and people. A journey that has helped shape the evolution of the fashion industry and secured Tonello’s place as a leading player on the international stage.

At Tonello, we design and develop technologies for garment treatment — from lasers, washing and dyeing machines, to dryers — created to deliver innovation, efficiency, and responsibility. But these same technologies also serve a greater purpose. By generating unique effects and aesthetics, they connect fashion and art, embodying our mission to inspire.

Art gives us the chance to step outside our usual boundaries and explore new perspectives, offering a fresh vision beyond daily work. As a company driven by innovation, we often need projects like these to help us look at things differently and spark new ideas.

For us, inspiration is where art and technology meet: where concepts take shape, and forwardthinking ideas become garments, prototypes, and even true works of art.

Inspiration is the heartbeat of Tonello: a reflection of who we are. We don’t just build machines; we create ideas that inspire change and drive the evolution of an entire industry.

ALICE TONELLO Marketing and R&D Director

As a member of the board and part of the Tonello family, Alice has revolutionized the company with her innovative vision, driving the company’s leadership in garment finishing technologies.

STEFANO ISONNI

Washing and Dyeing Expert

Stefano specializes in synthetic fiber dyeing and denim, always pushing boundaries to create sustainable results.

CARLO RENIERO

Washing and Dyeing Expert

Carlo brings expertise in washing and denim, crafting sustainable processes and vintage effects.

LUCREZIA SACCARDO

Digital Marketing Specialist

Lucrezia promotes marketing at Tonello, crafting creative and engaging multimedia content with a strong emphasis on digital and social media.

MARCO VISENTIN

Fashion designer and Laser Specialist

Marco mixes fashion and laser design with ease, creating unique, modern pieces that really catch the eye.

NICOLA CIOFFI

Laser Specialist

Nicola has evolved from a laser designer to a technical innovator, blending creativity and laser technology.

ALBERTO LUCCHIN

Marketing and Sustainability Manager

Alberto handles communication, media relations, and educational projects, while prioritizing social and environmental responsibility.

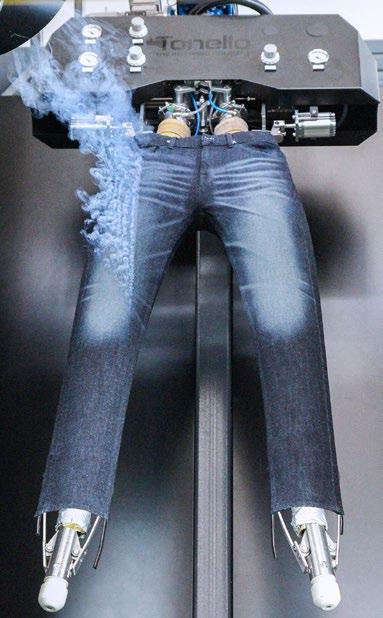

The Laundry (R)Evolution is Tonello’s groundbreaking concept that reimagines the laundry of today while shaping the one of tomorrow. It makes every process smarter, digital, and truly responsible. At its heart are two pioneering technologies that simplify, centralize, and oversee the entire garment finishing cycle, cutting down waste of water, energy, and time, while maximizing creativity, efficiency, and value.

THE Laser 2.0 — Forget tedious, manual abrasion. This technology transforms finishing into a space for creativity, efficiency and innovation. With Crea, developing new projects becomes faster, more flexible, and more accessible, turning what was once repetitive work into an opportunity for inspiration.

All-in-One System — The ultimate Tonello machine. Designed for both washing and dyeing, it combines four sustainable technologies (EGO, NoStone®, UP, and Core) into a single solution

that optimizes resources, production flows, and space, delivering unmatched versatility and performance.

Completing the ecosystem, Metro software provides full transparency by automatically tracking and certifying every consumption data. It creates a true environmental passport, reliable, authentic, and unalterable, offering brands and consumers proof of a smarter, leaner, and more sustainable process.

In short, the Laundry (R) Evolution maximizes efficiency while making operators’ work easier, safer, and more flexible. For example, it enables the washing of medium-tone jeans using just 10–15 liters of water, compared to the 150–300 liters normally required across multiple machines, with hazardous chemicals and heavy manual labor.

Responsible and lean, transparent and safe, flexible and accessible: this is Tonello’s Laundry (R)Evolution. Simple yet sophisticated. Here and now.

THANK YOU TO OUR MILL PARTNERS & KINGPINS SHOW

DESIGNER

Matt Duckett

Sadia Rafique

Mohsin Sajid

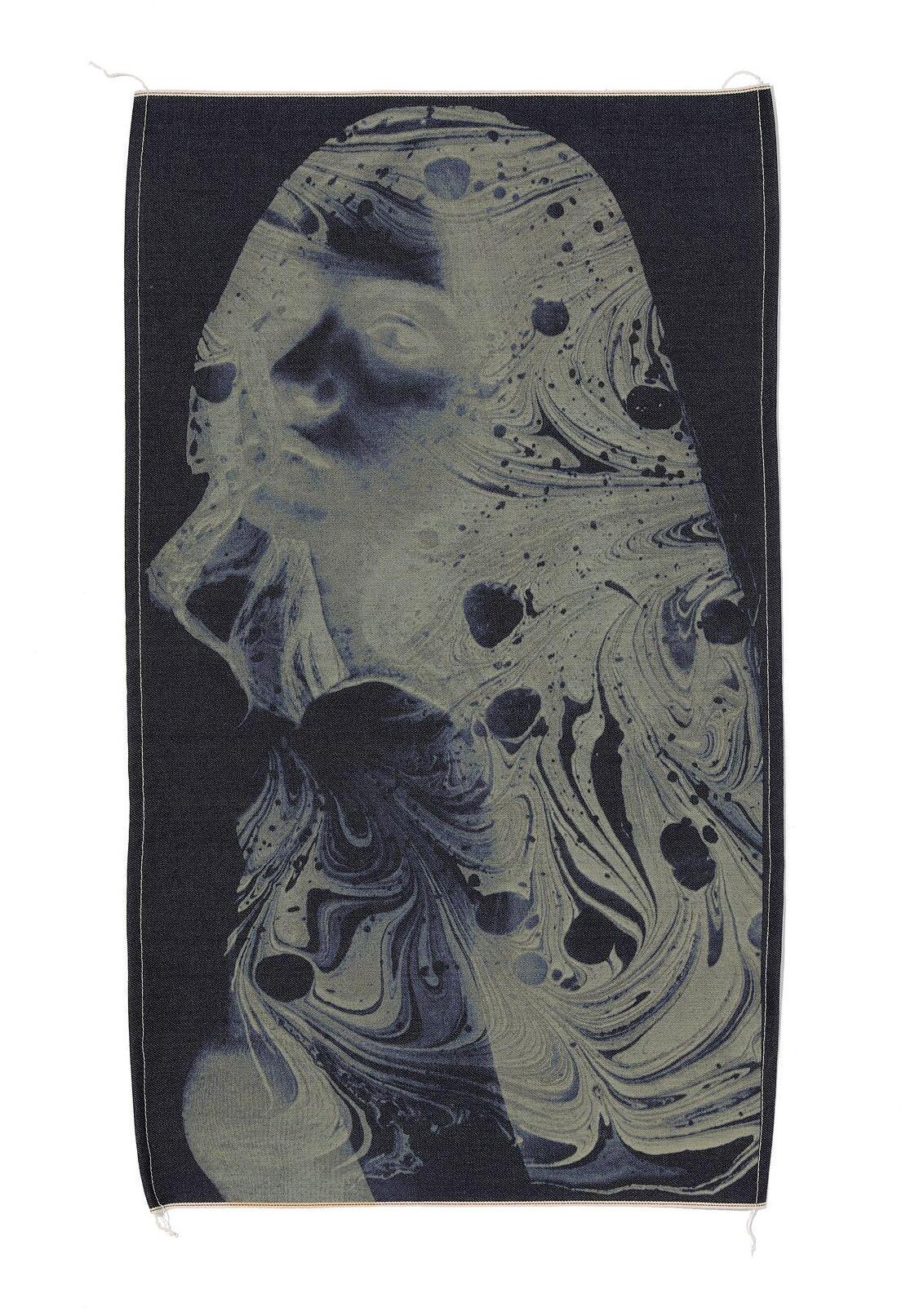

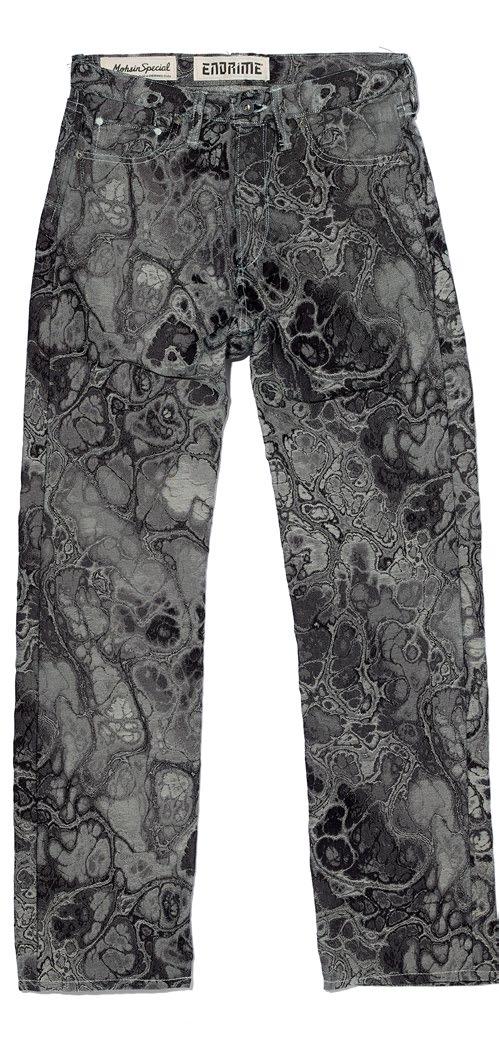

ARTWORK METAMORPHOSIS

DENIM MILL

Cone Denim®

Indigo Textile

Sharabati

Stella Blu

Tusa Denim

ARTWORK PROCESS

Matt Duckett created the METAMORPHOSIS animation for SAKE — THE ART OF PURPOSE 2025, an interdisciplinary art project led by ENDRIME® in collaboration with Tonello. Nicola Cioffi and Marco Visentin sustainably lasered 472 individual slides at Tonello. The slides were photographed and animated into a short film and made into a flip book.

LASER PROCESS

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

WASH PROCESS

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

DESIGNER

Matt Duckett

Sadia Rafique

Mohsin Sajid

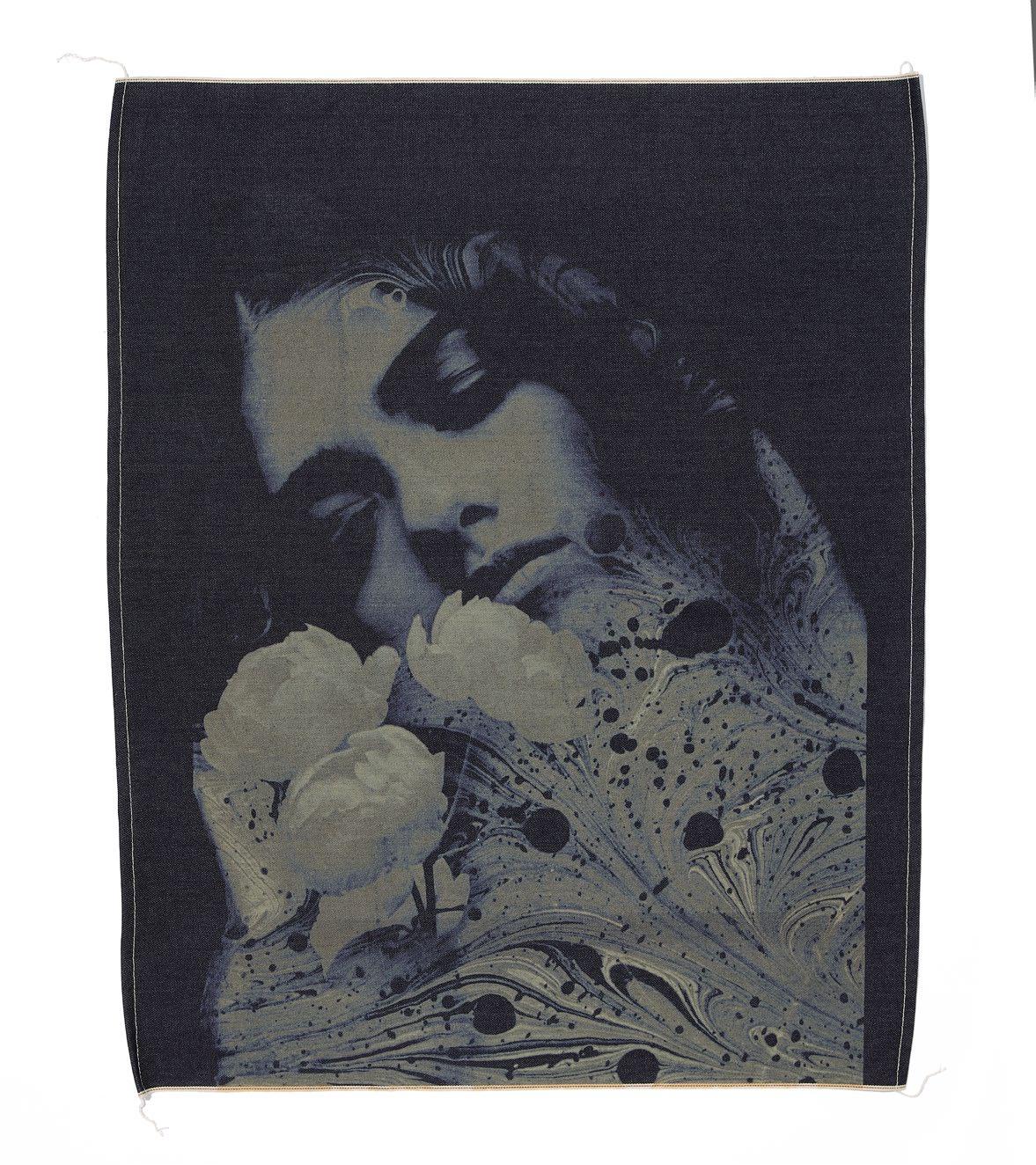

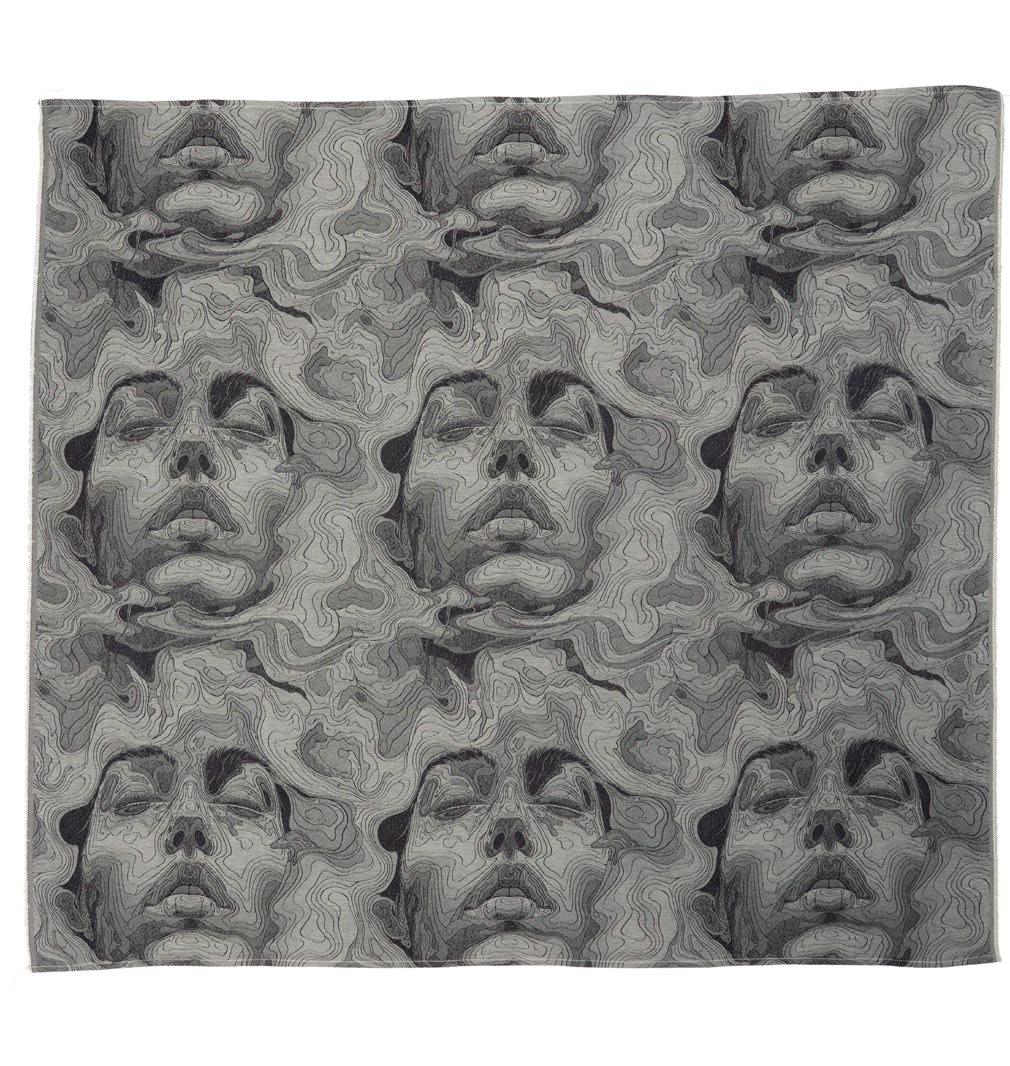

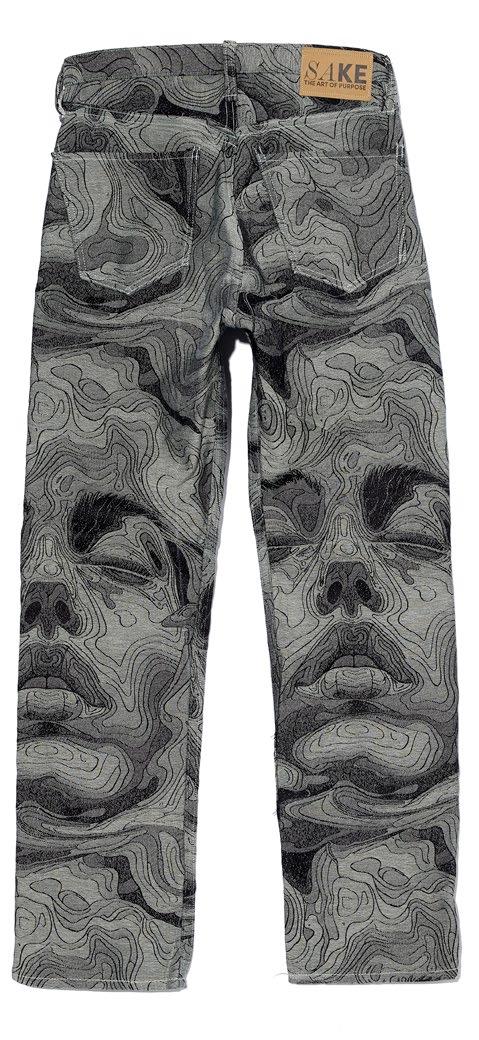

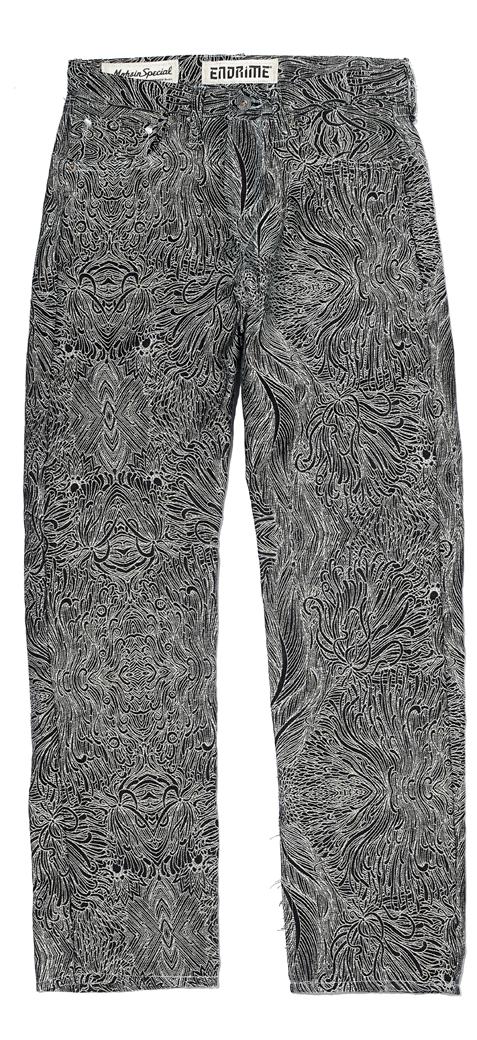

ARTWORK MOTIVATION

DENIM MILL

Cone Denim®

Indigo Textile

Sharabati

Stella Blu

Tusa Denim

ARTWORK PROCESS

Matt Duckett created the MOTIVATION animation for SAKE — THE ART OF PURPOSE 2025, an interdisciplinary art project led by ENDRIME® in collaboration with Tonello. Nicola Cioffi and Marco Visentin sustainably lasered 87 individual slides at Tonello. The slides were photographed and animated into a short film and made into a flip book.

LASER PROCESS

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

WASH PROCESS

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

DESIGNER

Matt Duckett

Sadia Rafique

Mohsin Sajid

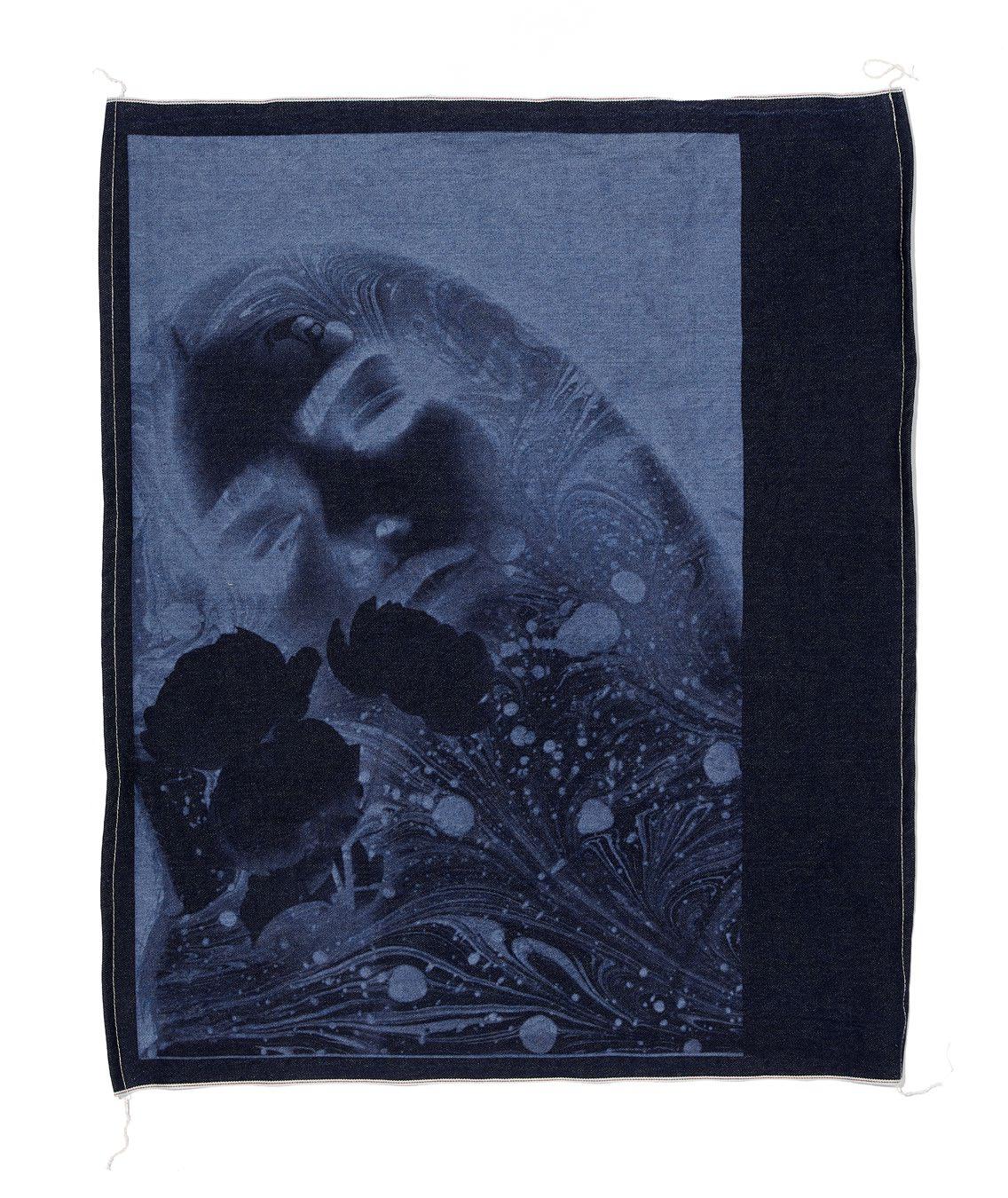

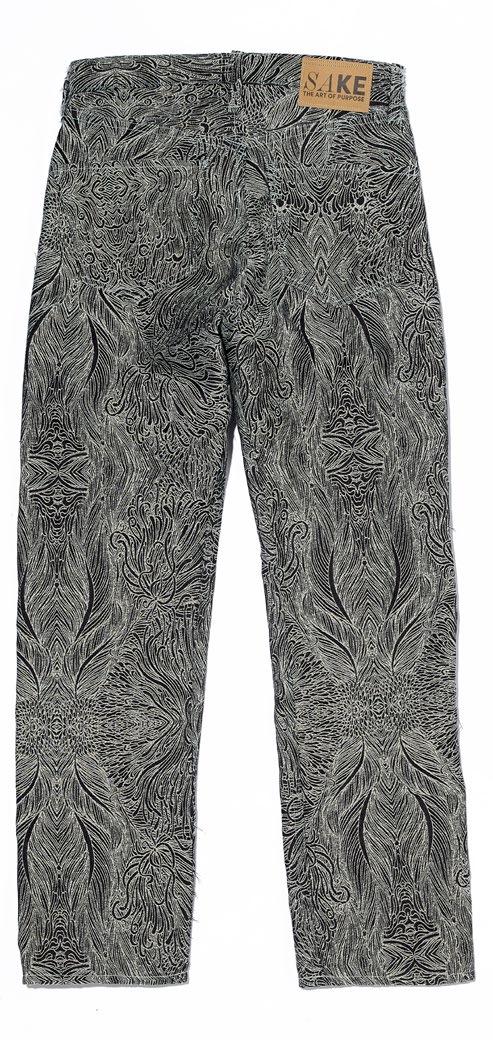

ARTWORK MOMENTUM

DENIM MILL

Cone Denim®

Indigo Textile

Sharabati

Stella Blu

Tusa Denim

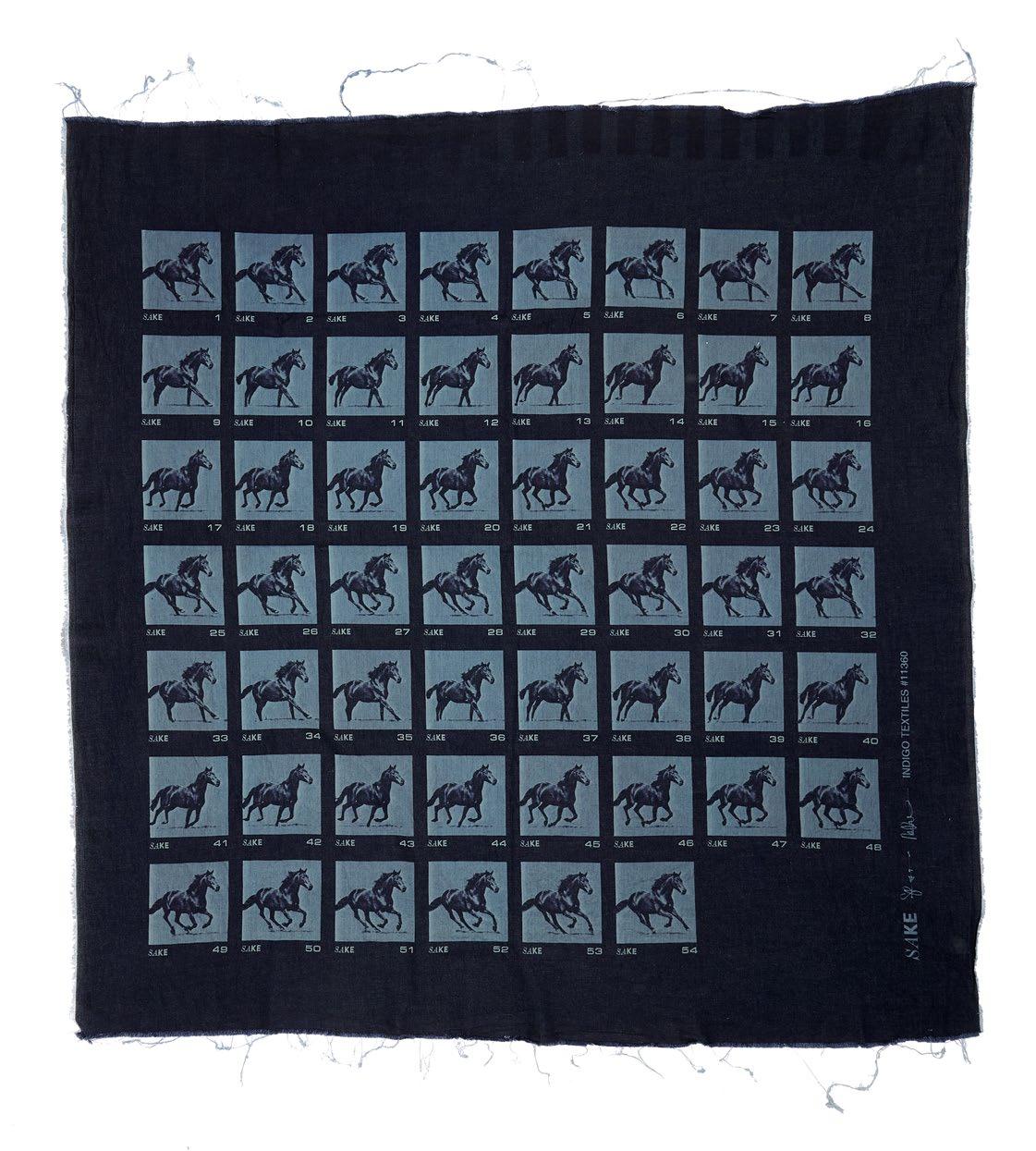

ARTWORK PROCESS

Matt Duckett created the MOMENTUM animation for SAKE — THE ART OF PURPOSE 2025, an interdisciplinary art project led by ENDRIME® in collaboration with Tonello. Nicola Cioffi and Marco Visentin sustainably lasered 54 individual slides at Tonello. The slides were photographed and animated into a short film and made into a flip book.

LASER PROCESS

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

WASH PROCESS

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

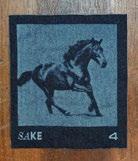

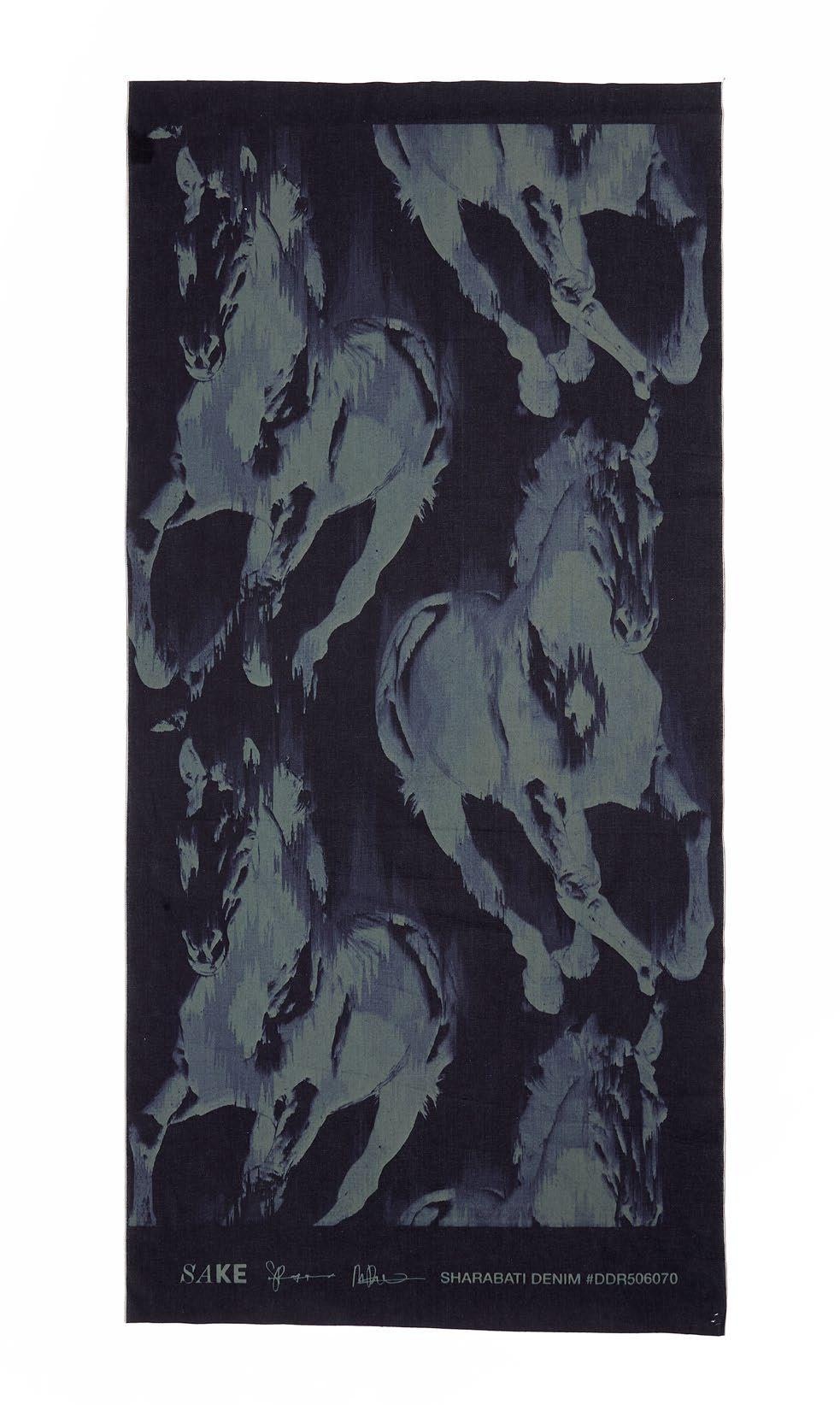

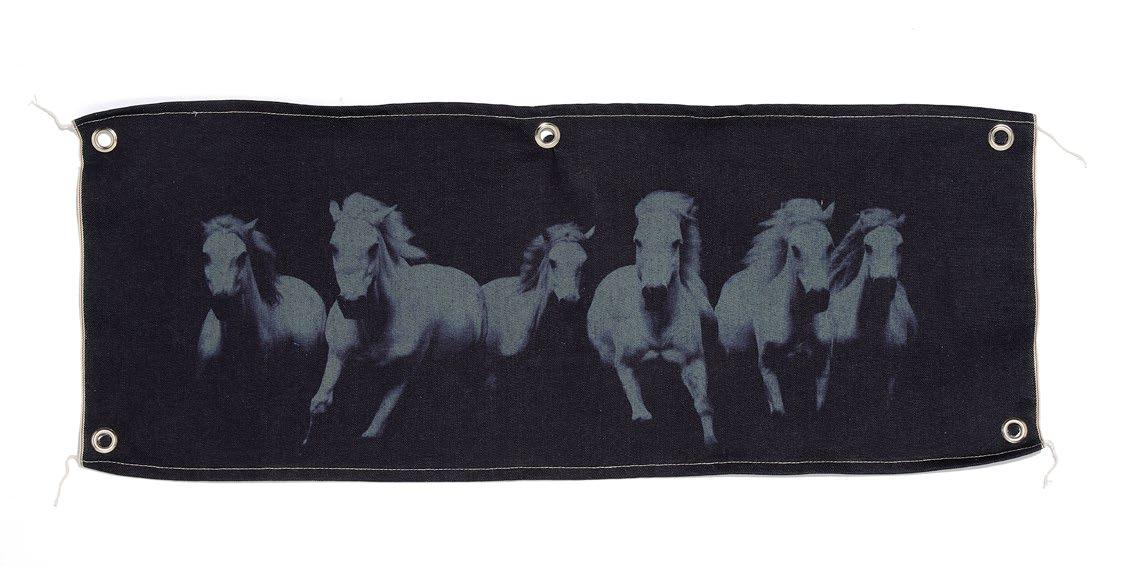

DESIGNER

Matt Duckett

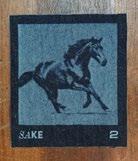

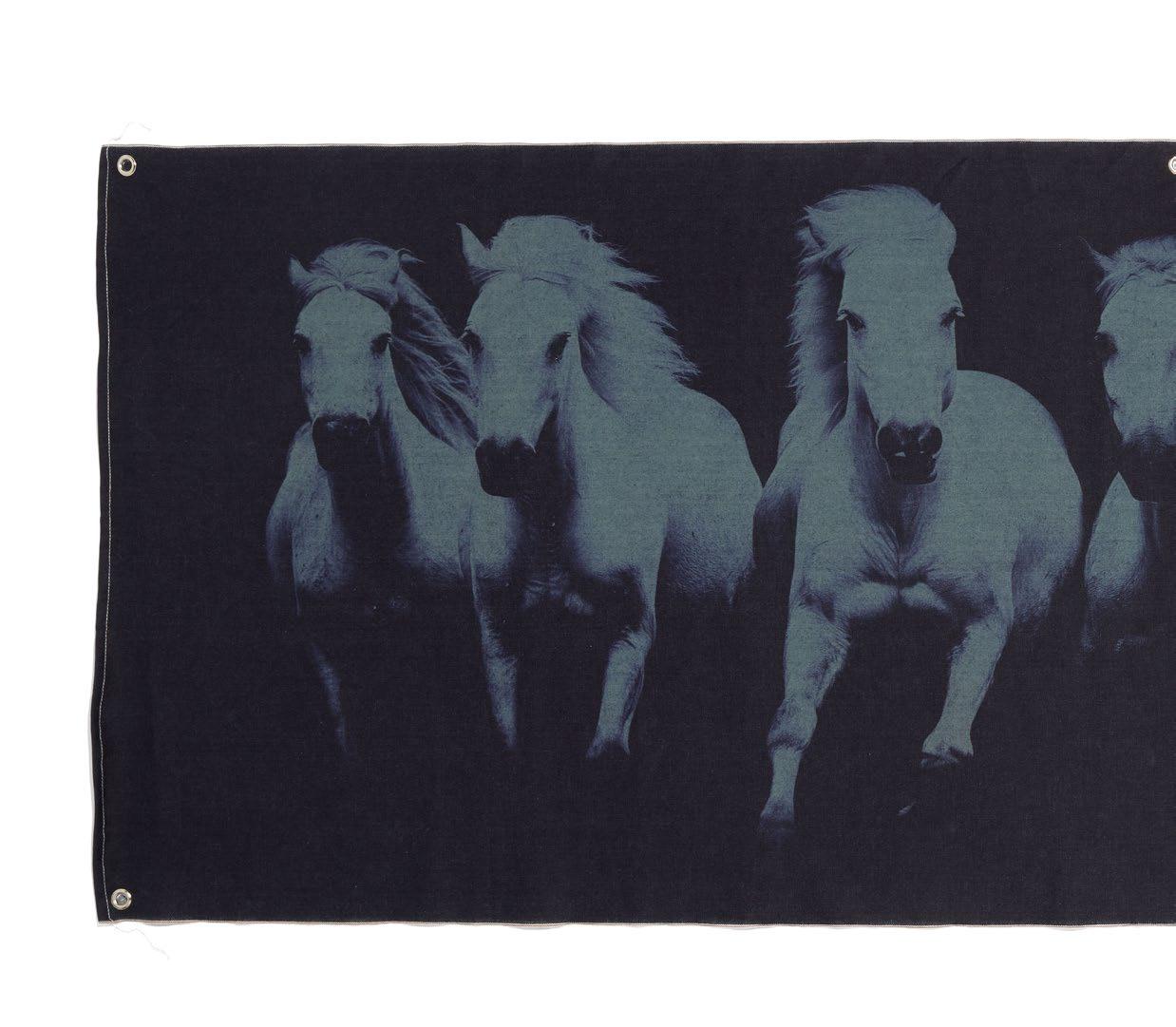

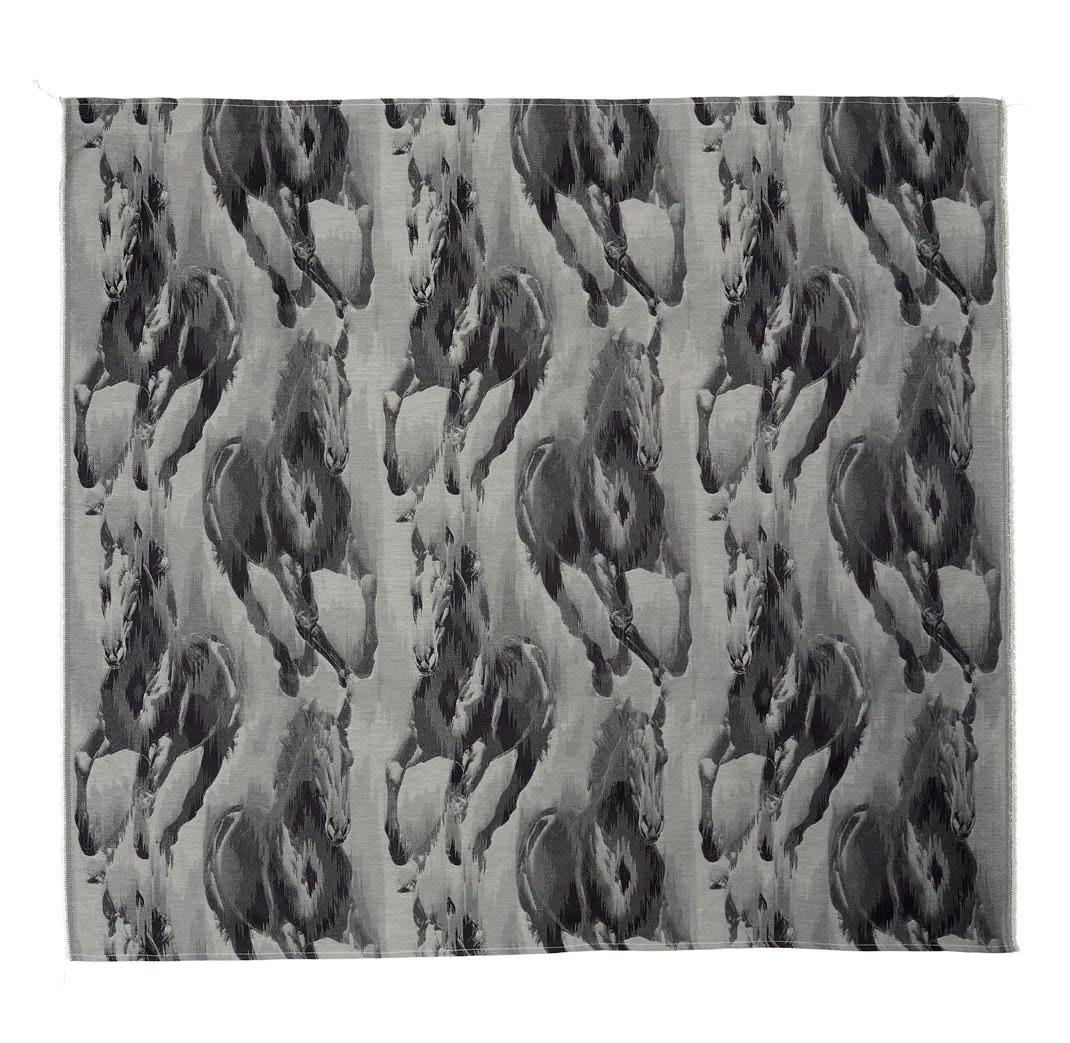

ARTWORK HORSE

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

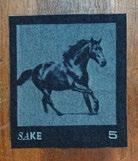

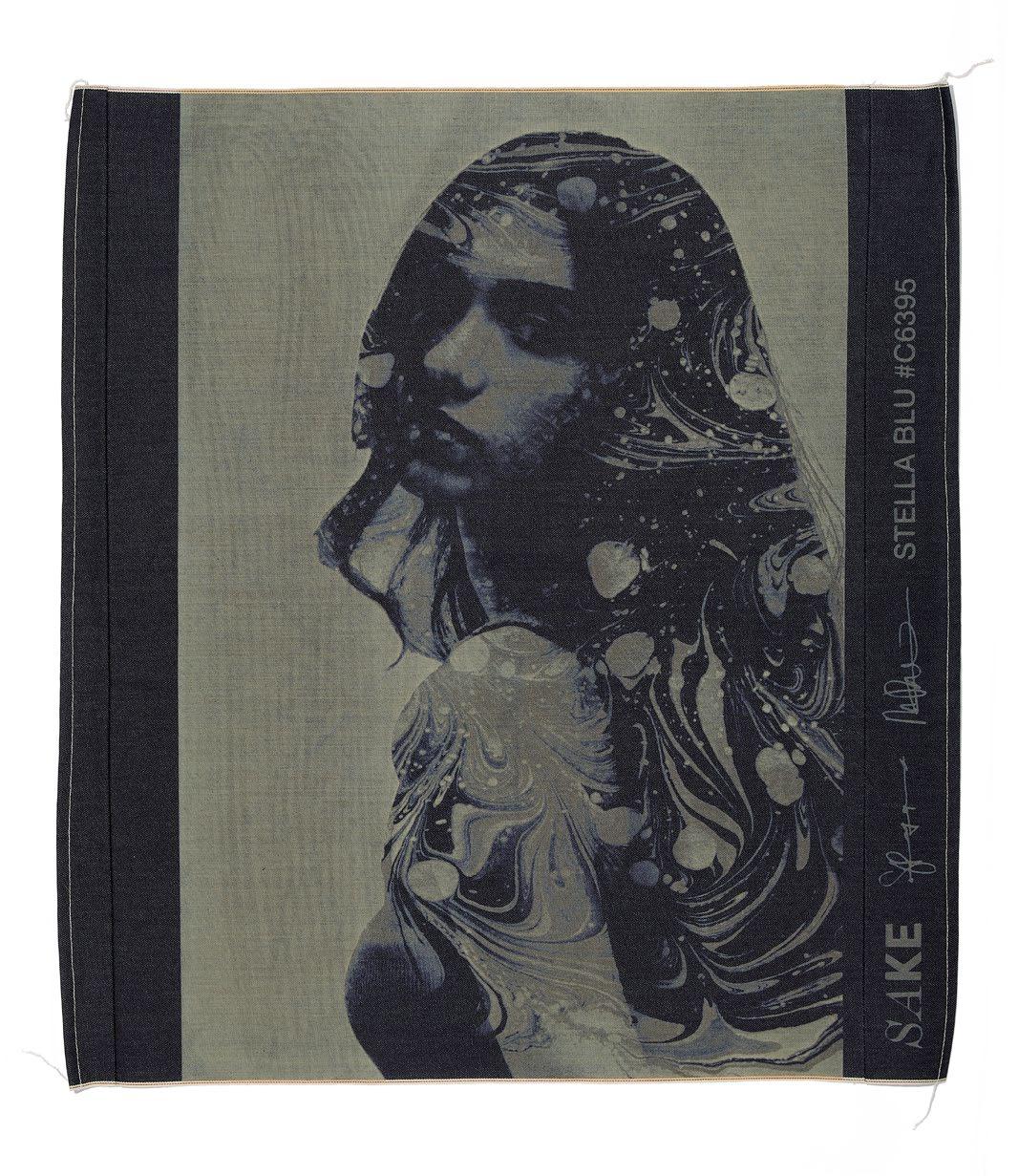

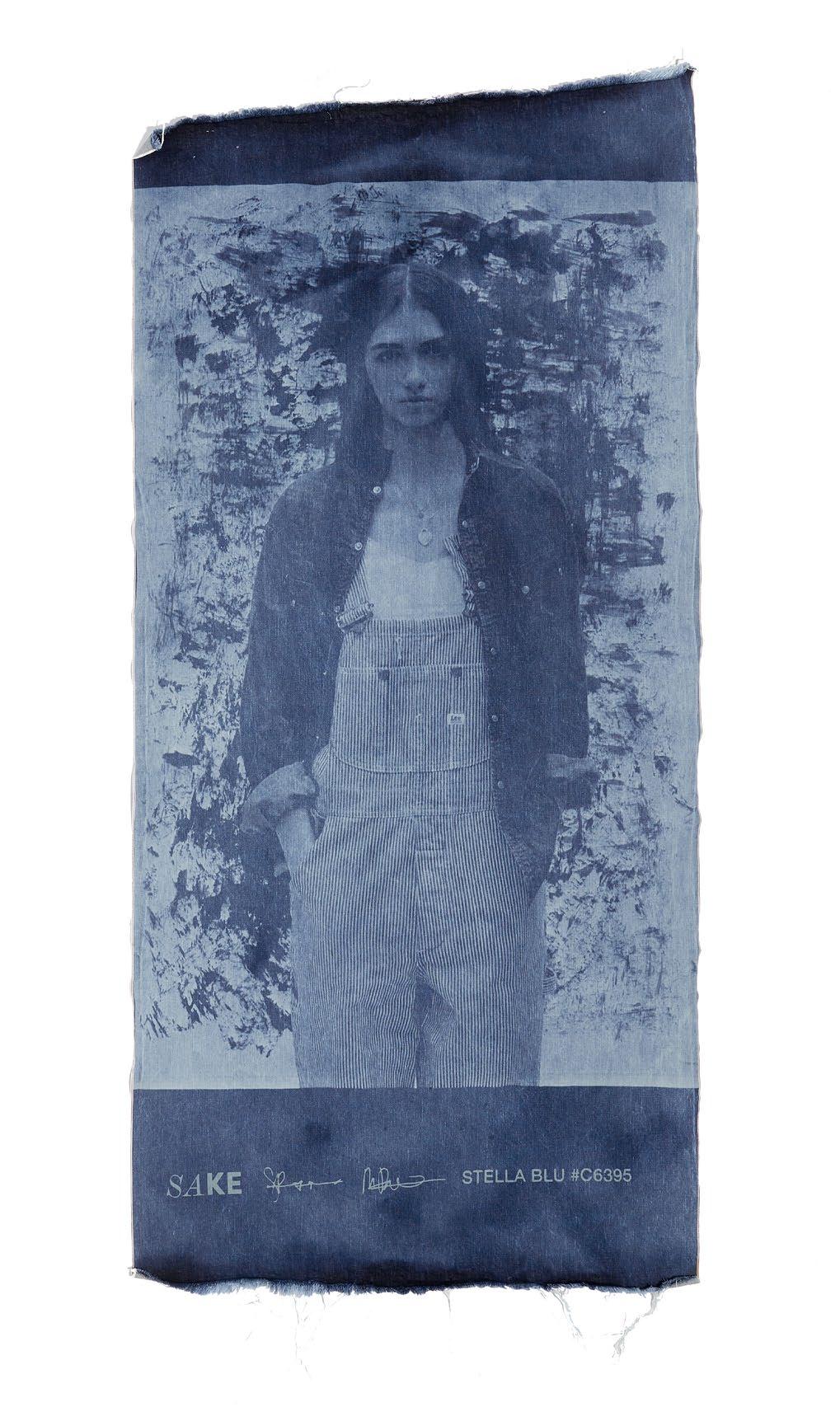

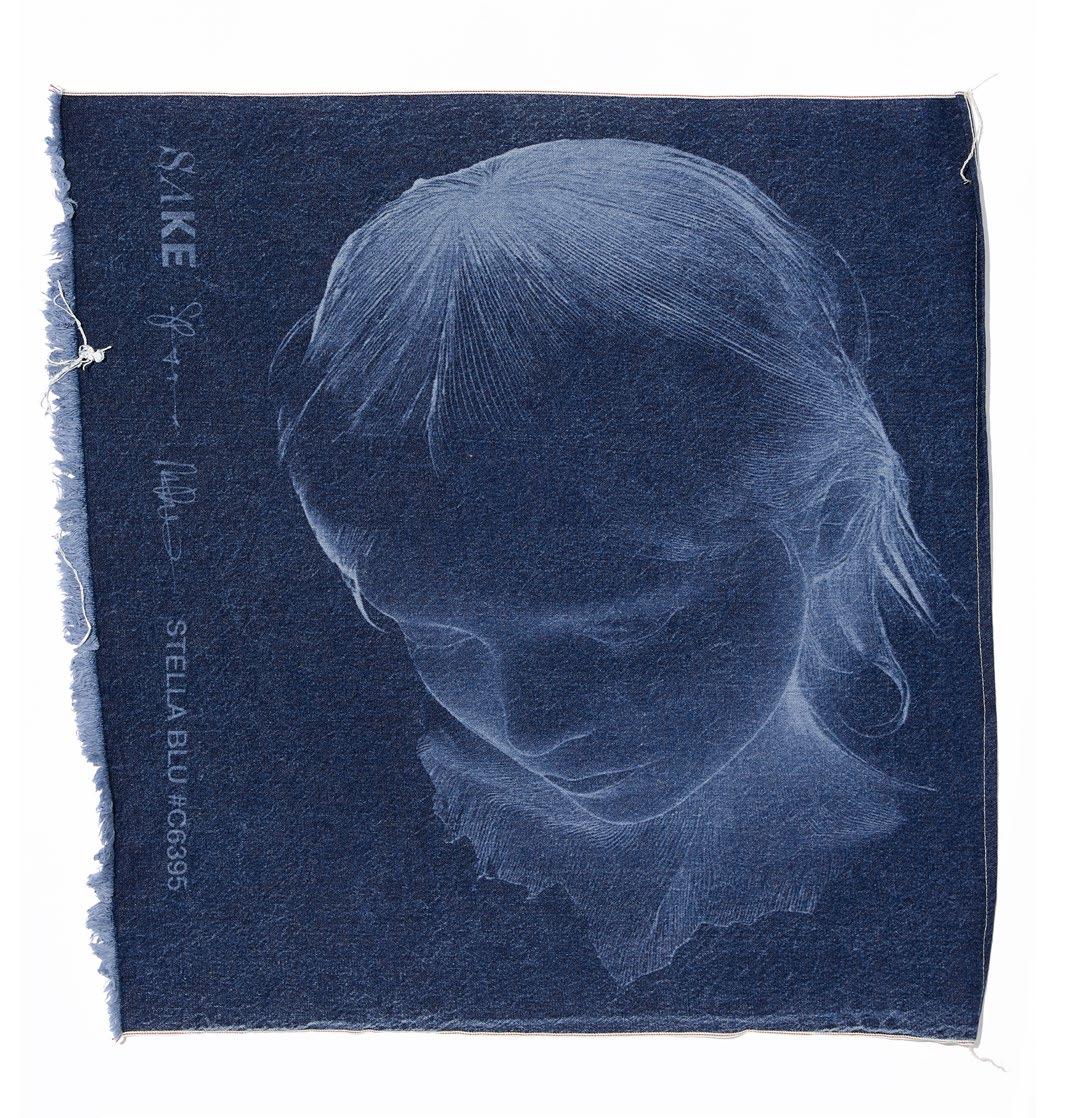

DESIGNER

Matt Duckett

ARTWORK HORSE

DENIM MILL STELLA BLU

FABRIC CODE # C6395 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

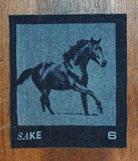

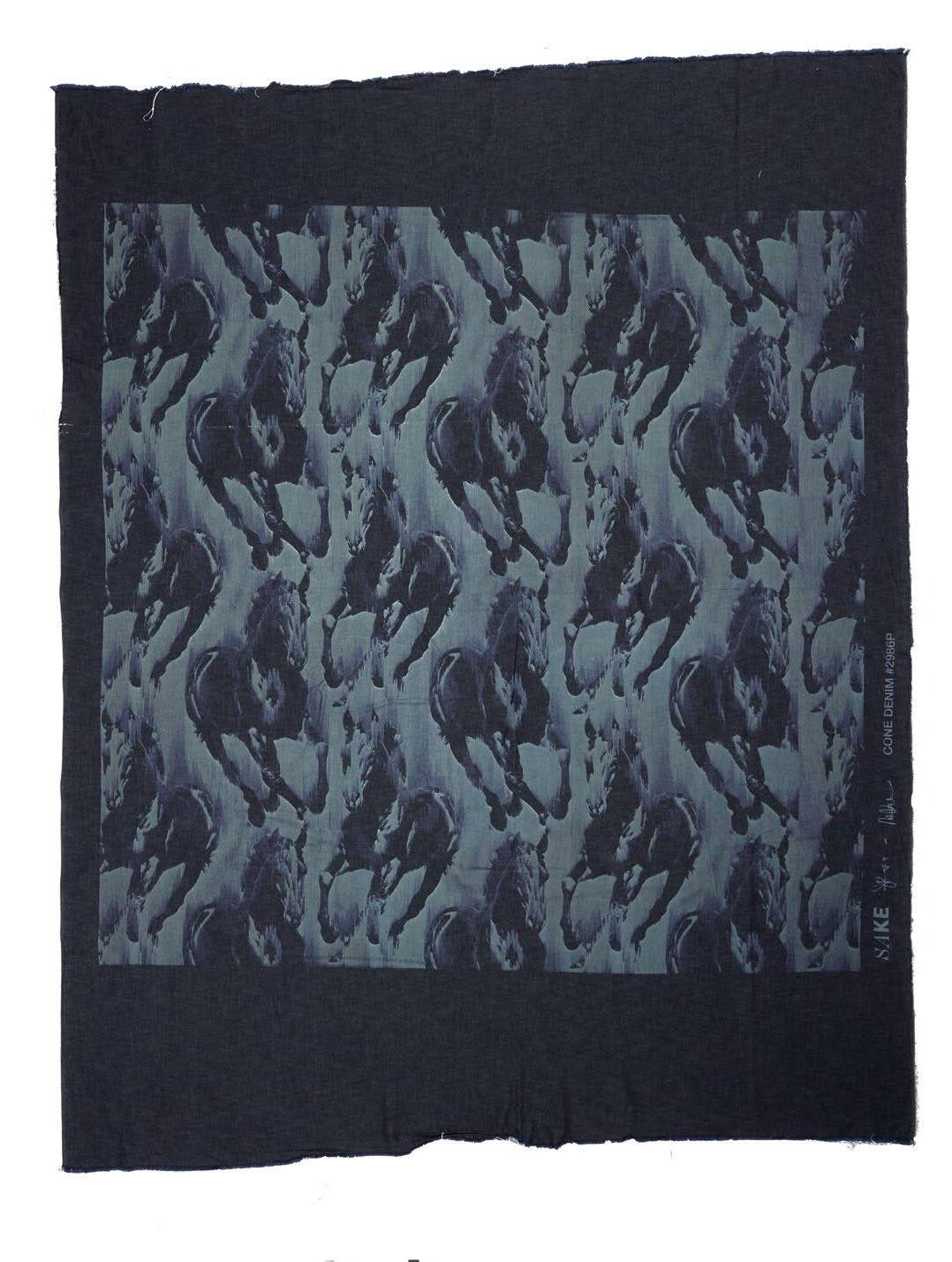

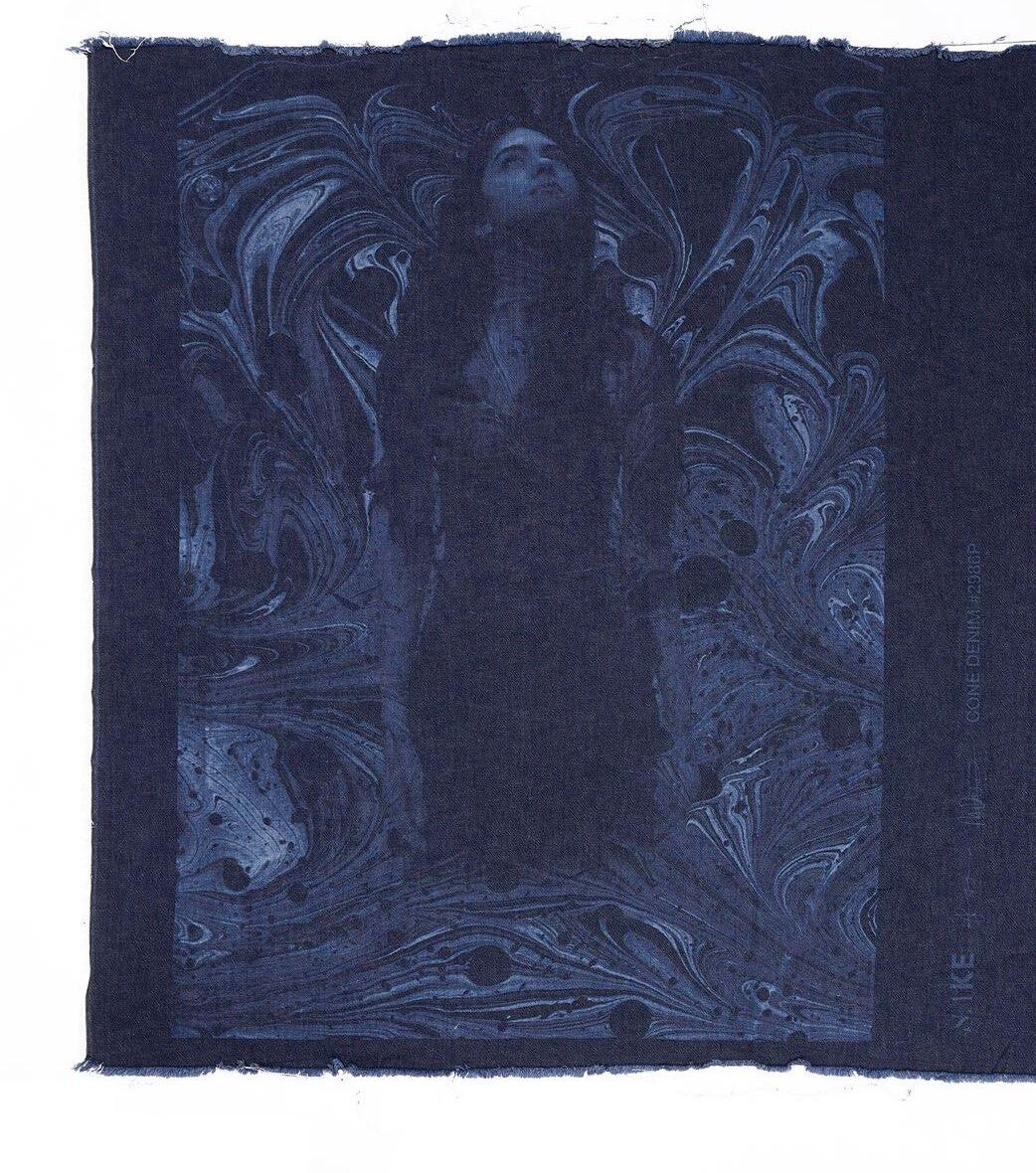

DESIGNER

Matt Duckett

ARTWORK

HORSE SMALL REPEAT

DENIM MILL

CONE DENIM

FABRIC CODE

2986P Horseshoe

FABRIC COMPOSITION

73% Cotton, 27% TENCEL™

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

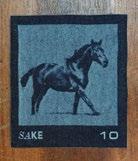

DESIGNER

Matt Duckett

ARTWORK

Horse Smaller Repeat No2

DENIM MILL

Tusa Denim

FABRIC CODE

10025 ALABAMA BLUE MOON

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Matt Duckett

ARTWORK

Running Horse

DENIM MILL

Indigo Textile

FABRIC CODE 11360 -Z 02

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

DESIGNER

Matt Duckett

ARTWORK

HORSE RUNNING

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures

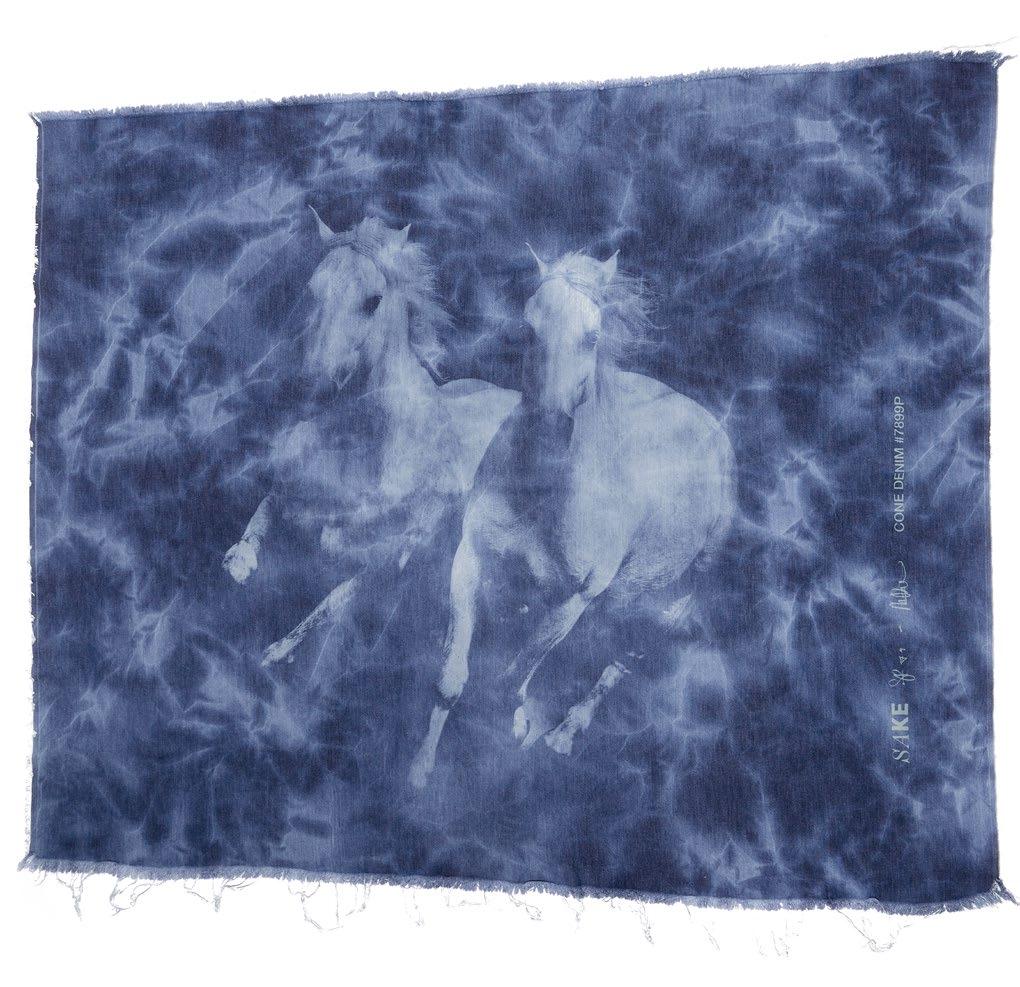

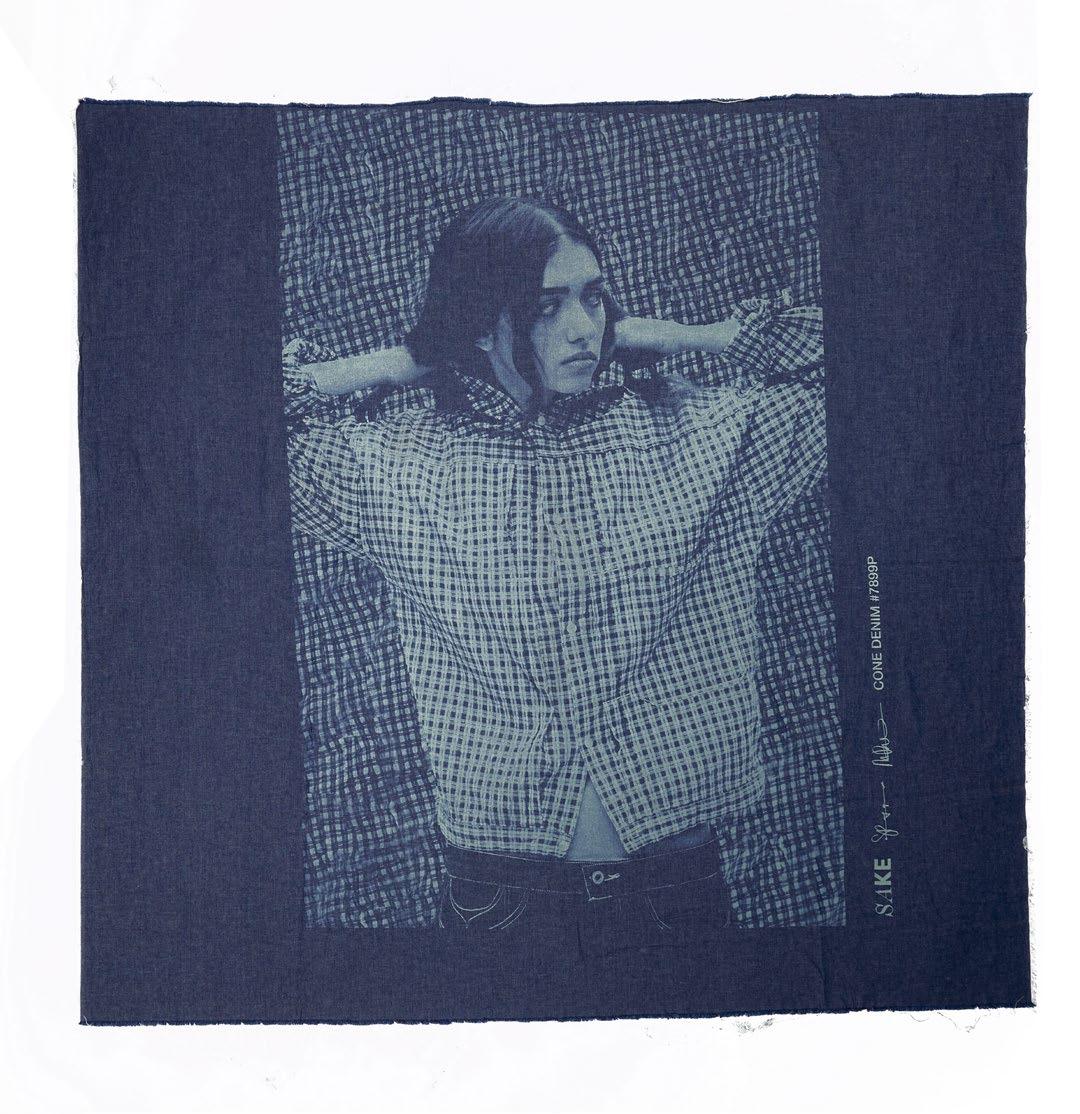

DESIGNER

Matt Duckett

ARTWORK HORSES

DENIM MILL CONE DENIM

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

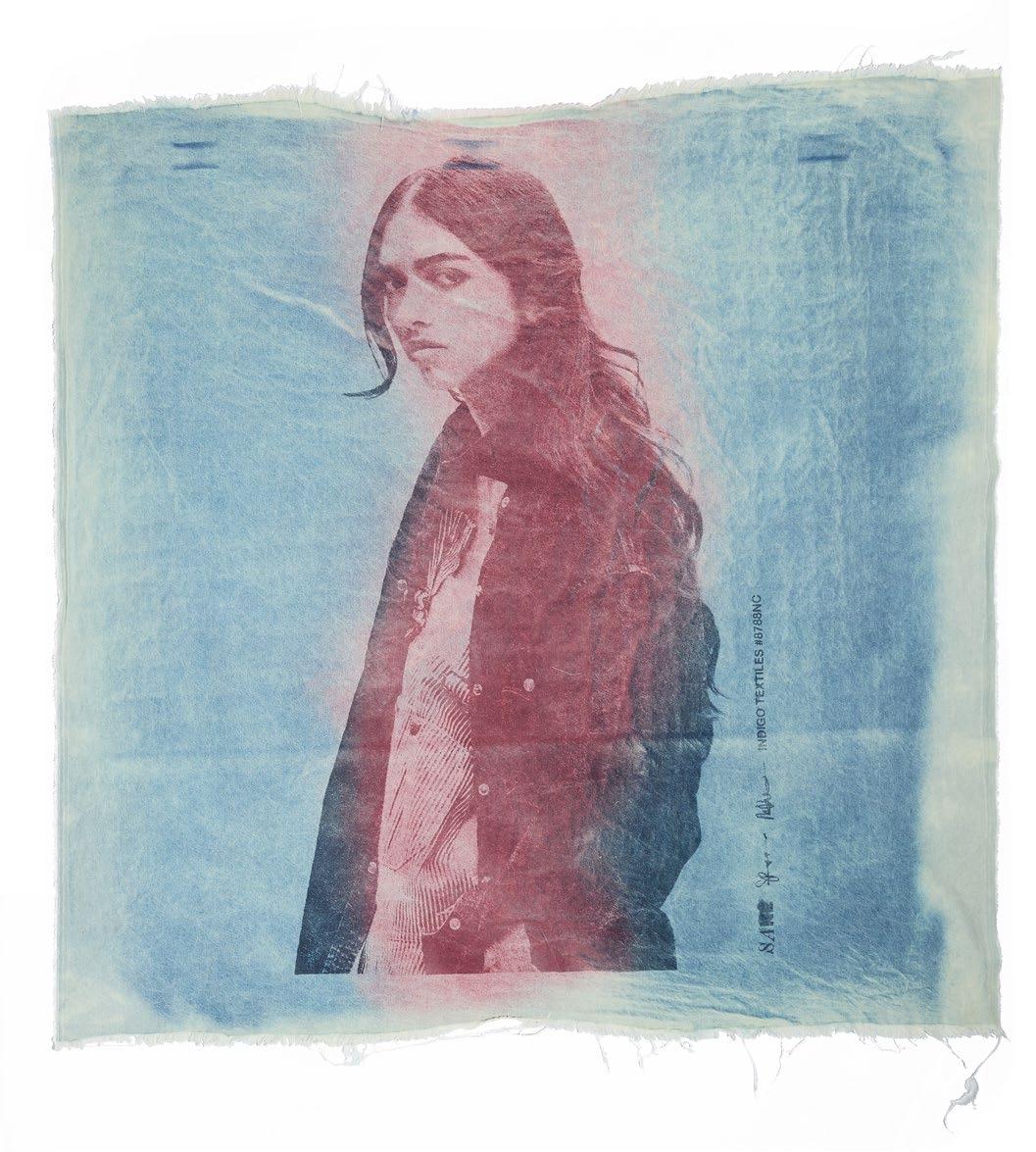

DESIGNER Matt Duckett

ARTWORK Horses

DENIM MILL Indigo Textile

FABRIC CODE 8788-NC

FABRIC COMPOSITION

COTTON 80% PIW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Matt Duckett

ARTWORK HORSEY

DENIM MILL Cone Denim

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

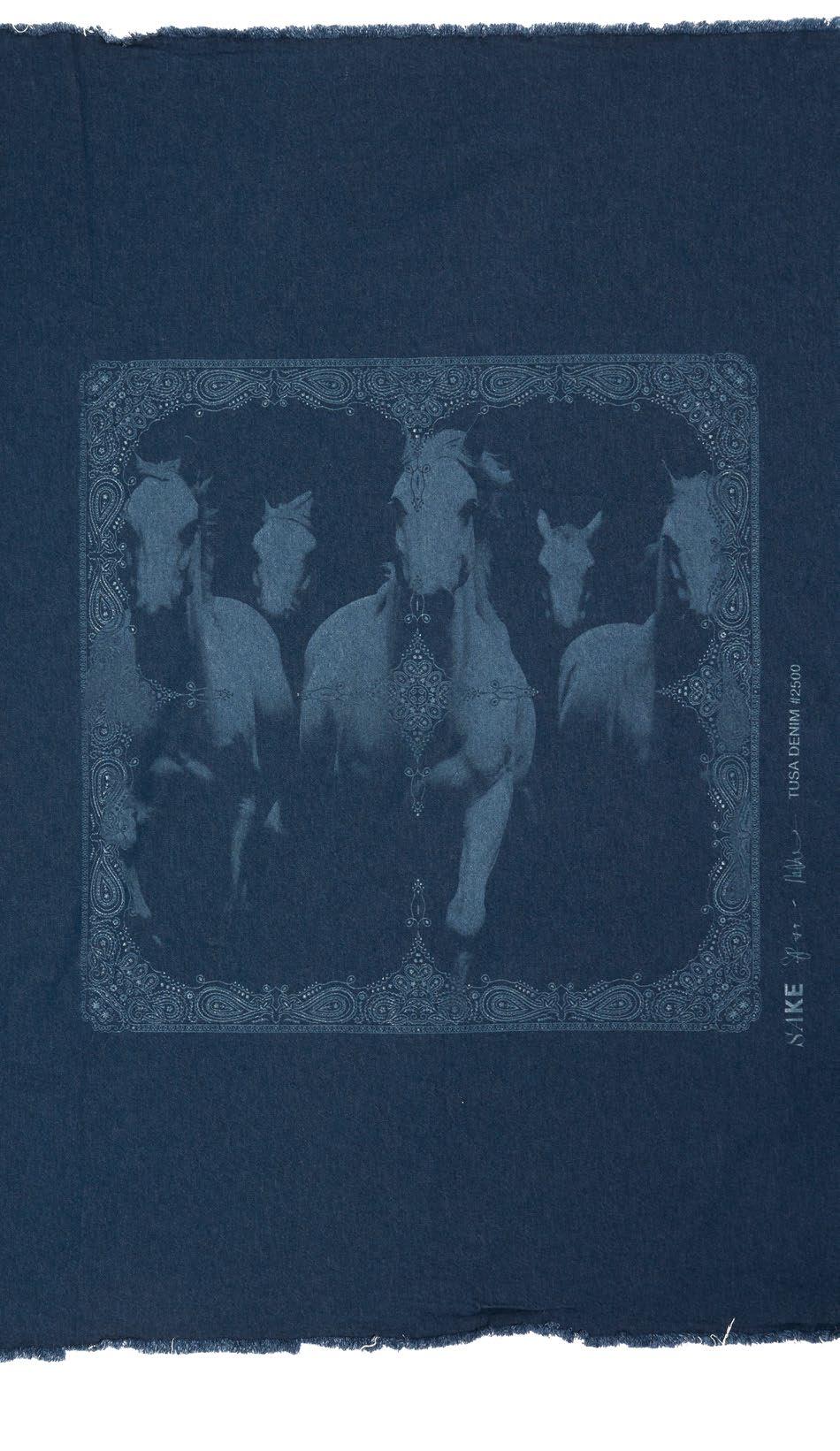

DESIGNER

Matt Duckett

ARTWORK HORSEY

DENIM MILL TUSA DENIM

FABRIC CODE DARKLY BLUE JASMINE 2500

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

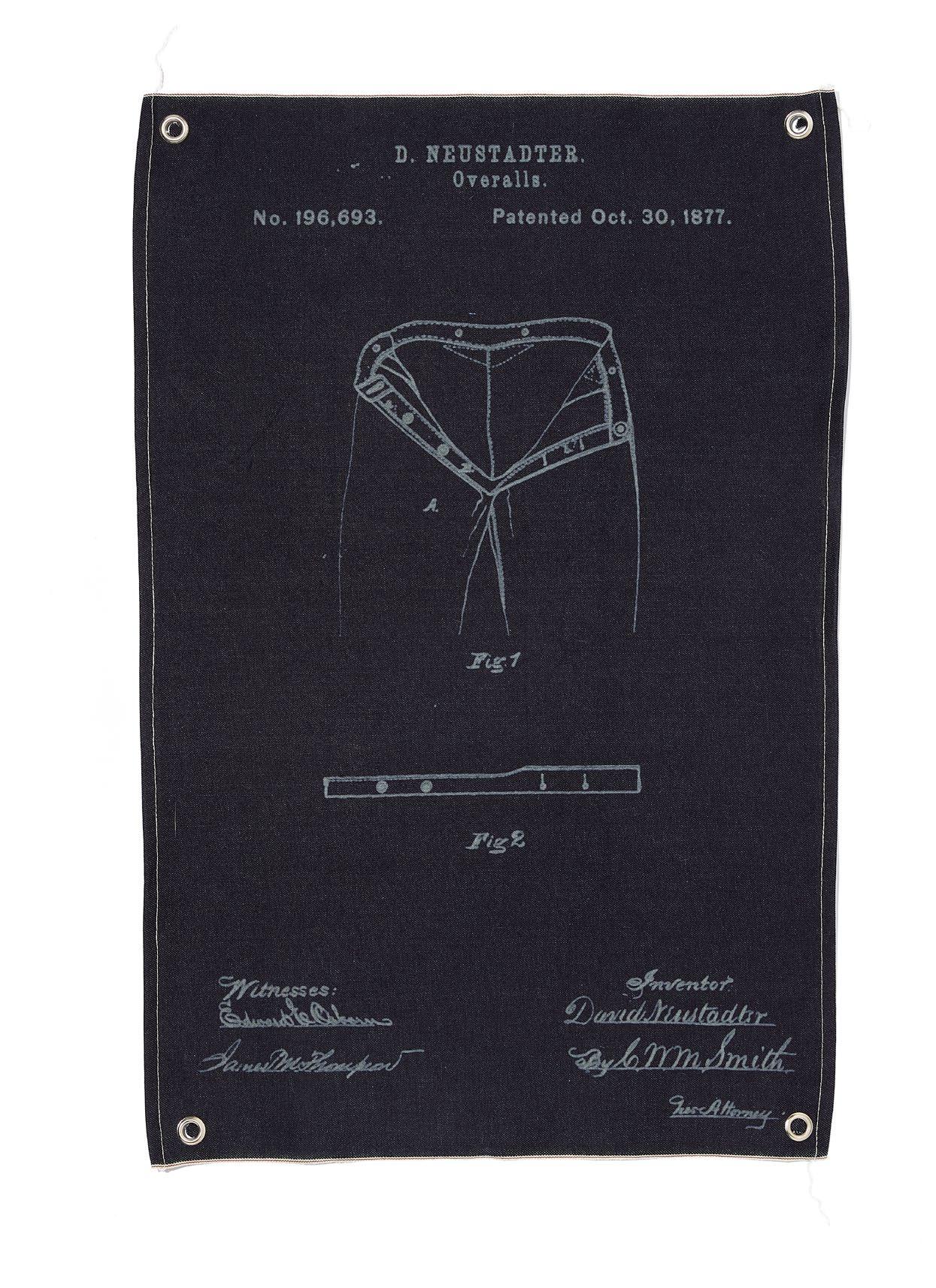

DESIGNER

Mohsin Sajid

ARTWORK

Continuous One Piece

Fly Patent

October 1877

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

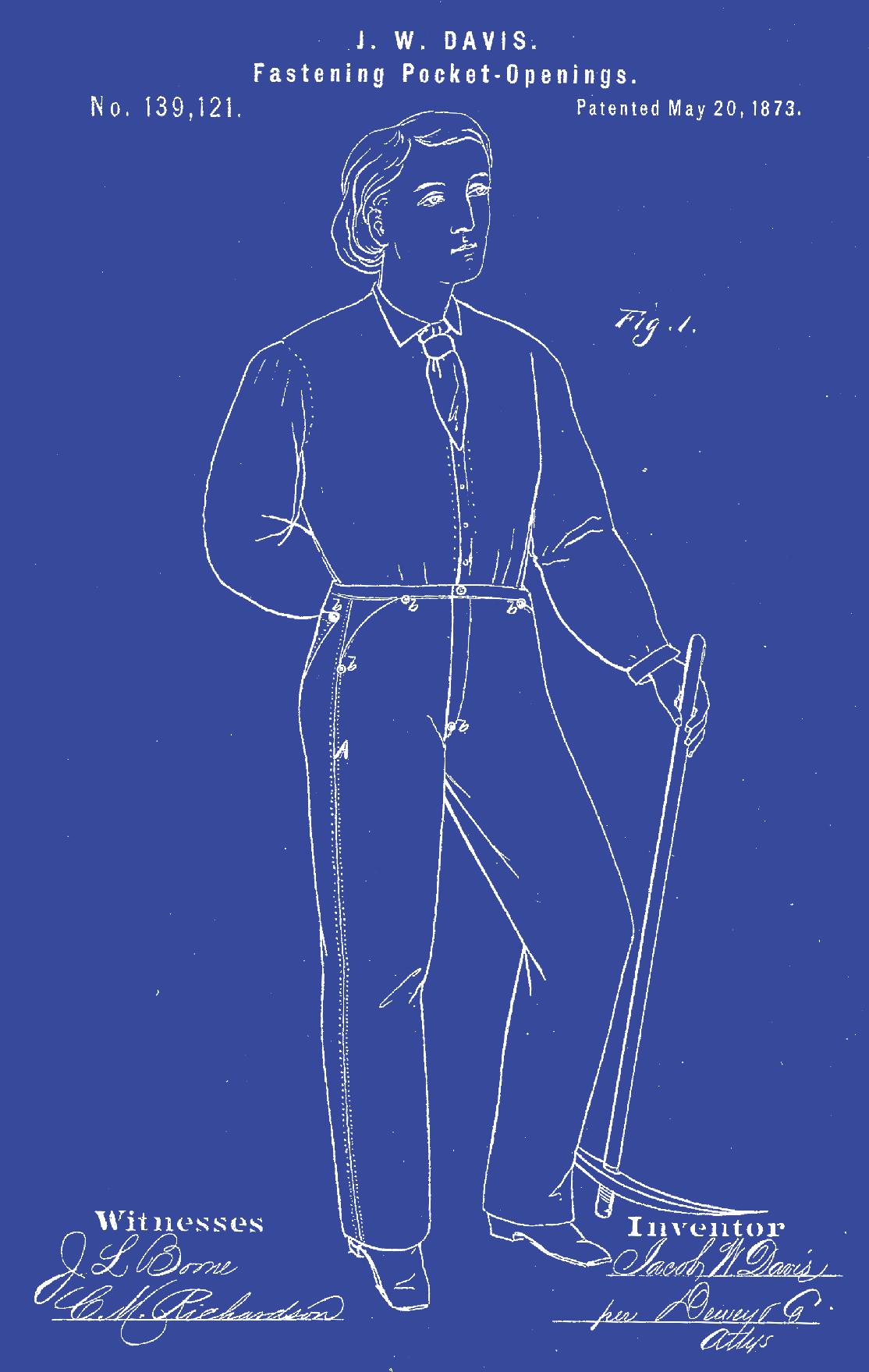

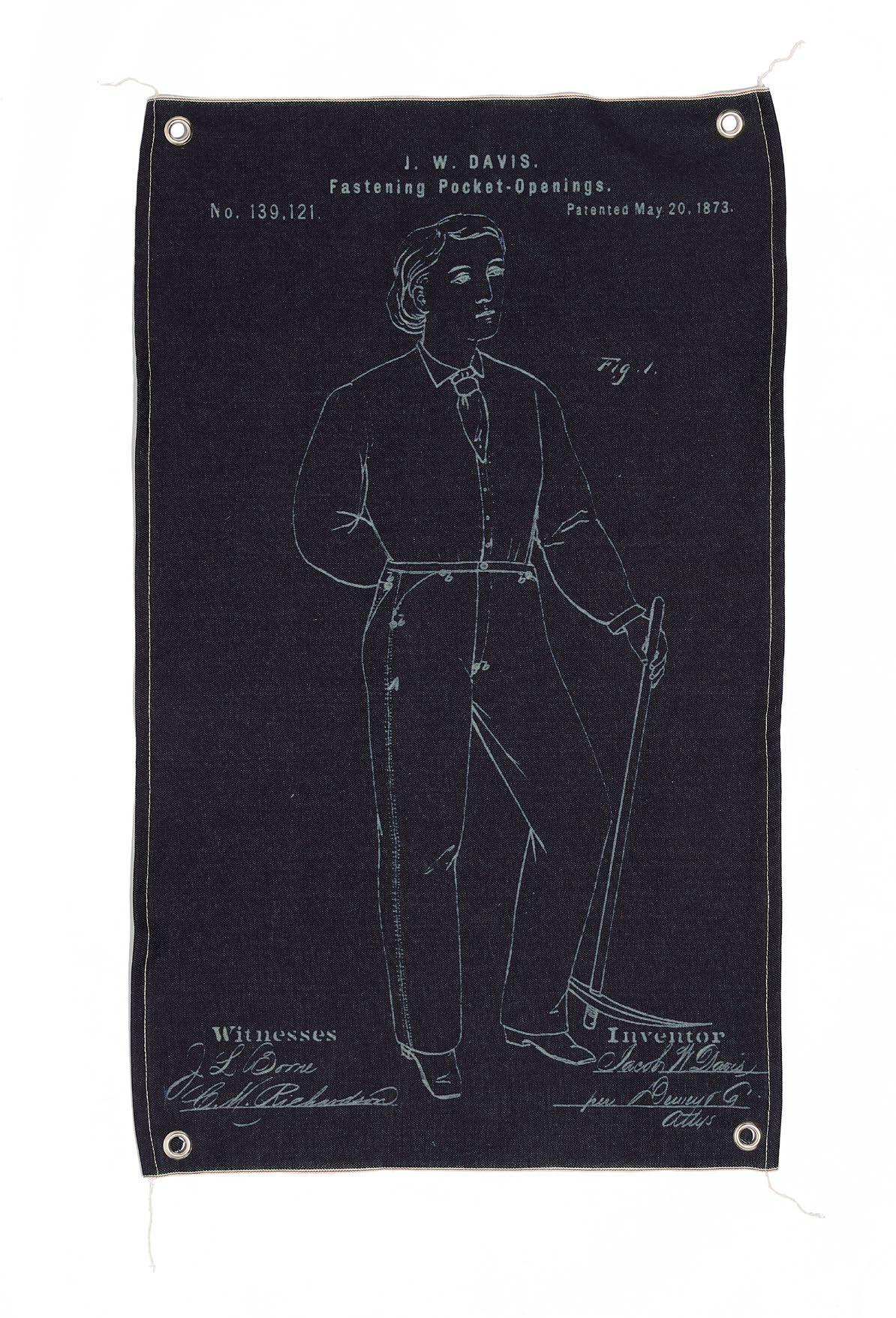

DESIGNER

Mohsin Sajid

ARTWORK

J Davies Rivet Patent May 20th 1873

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

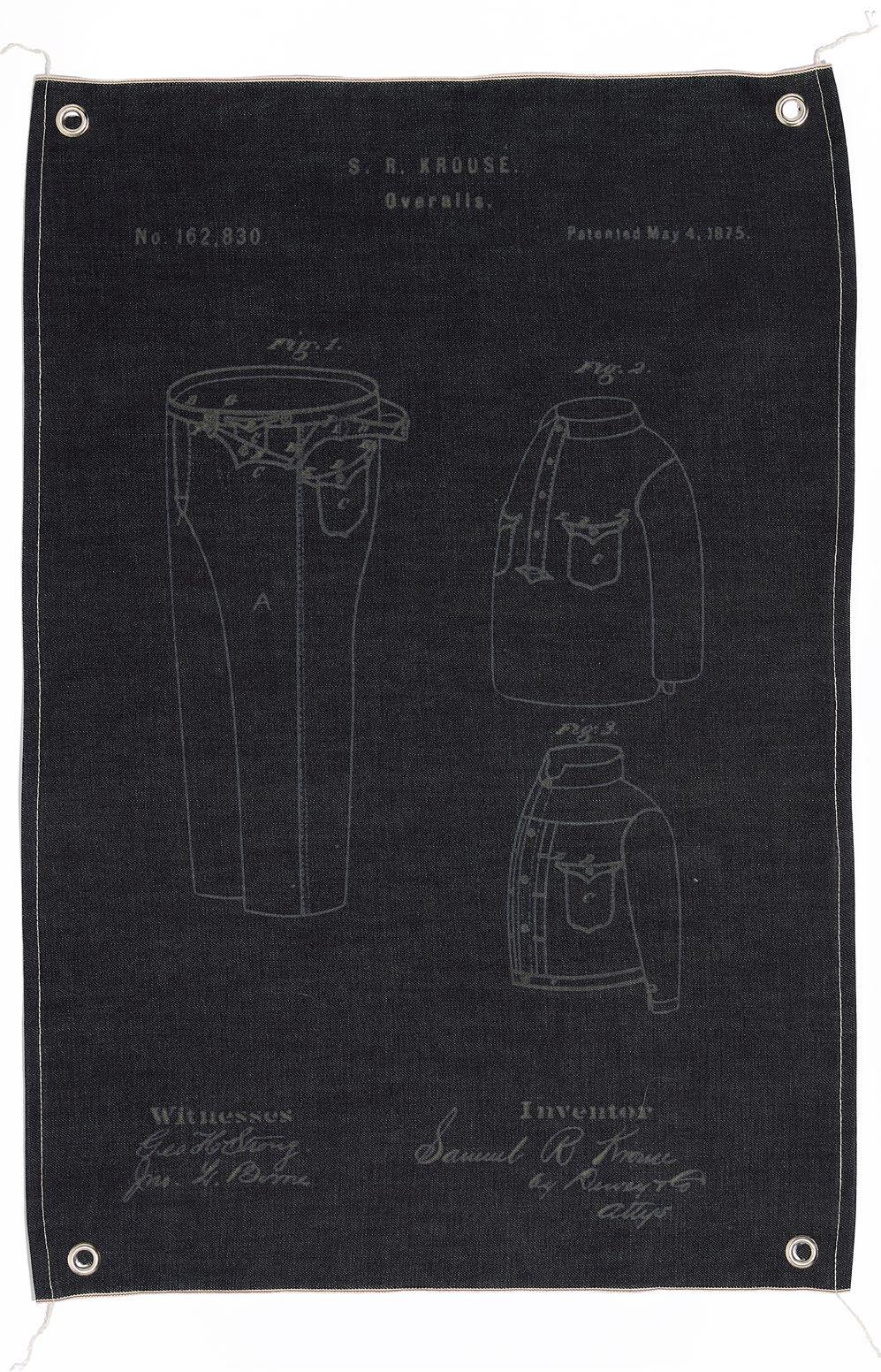

DESIGNER

Mohsin Sajid

ARTWORK

Krouse Overalls Patent

May 5th 1875

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

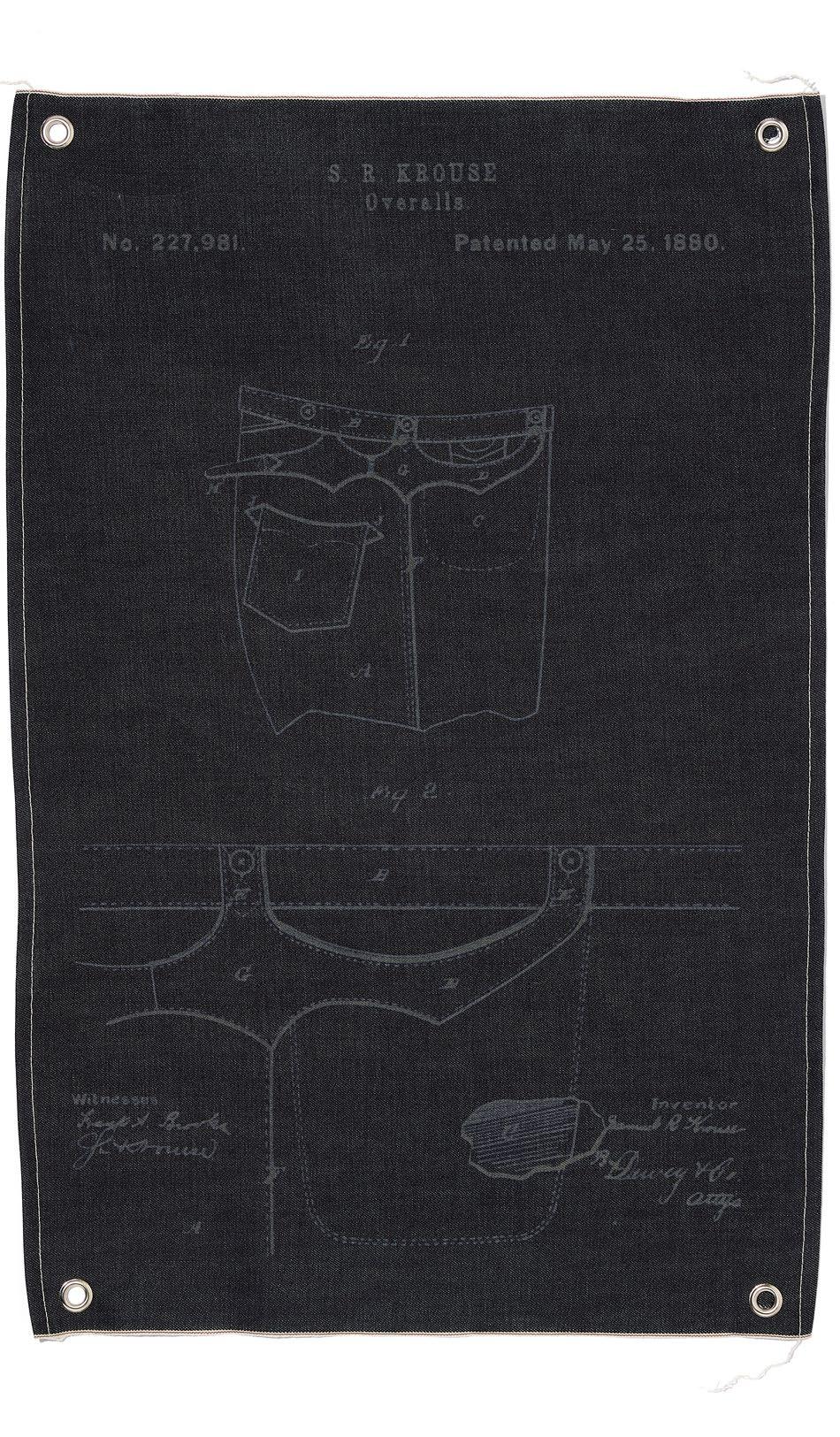

DESIGNER

Mohsin Sajid

ARTWORK

Krouse Overalls Patent May 25th 1880

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

DESIGNER

Sadia Rafique

ARTWORK

Feathers No20

DENIM MILL

Cone Denim

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

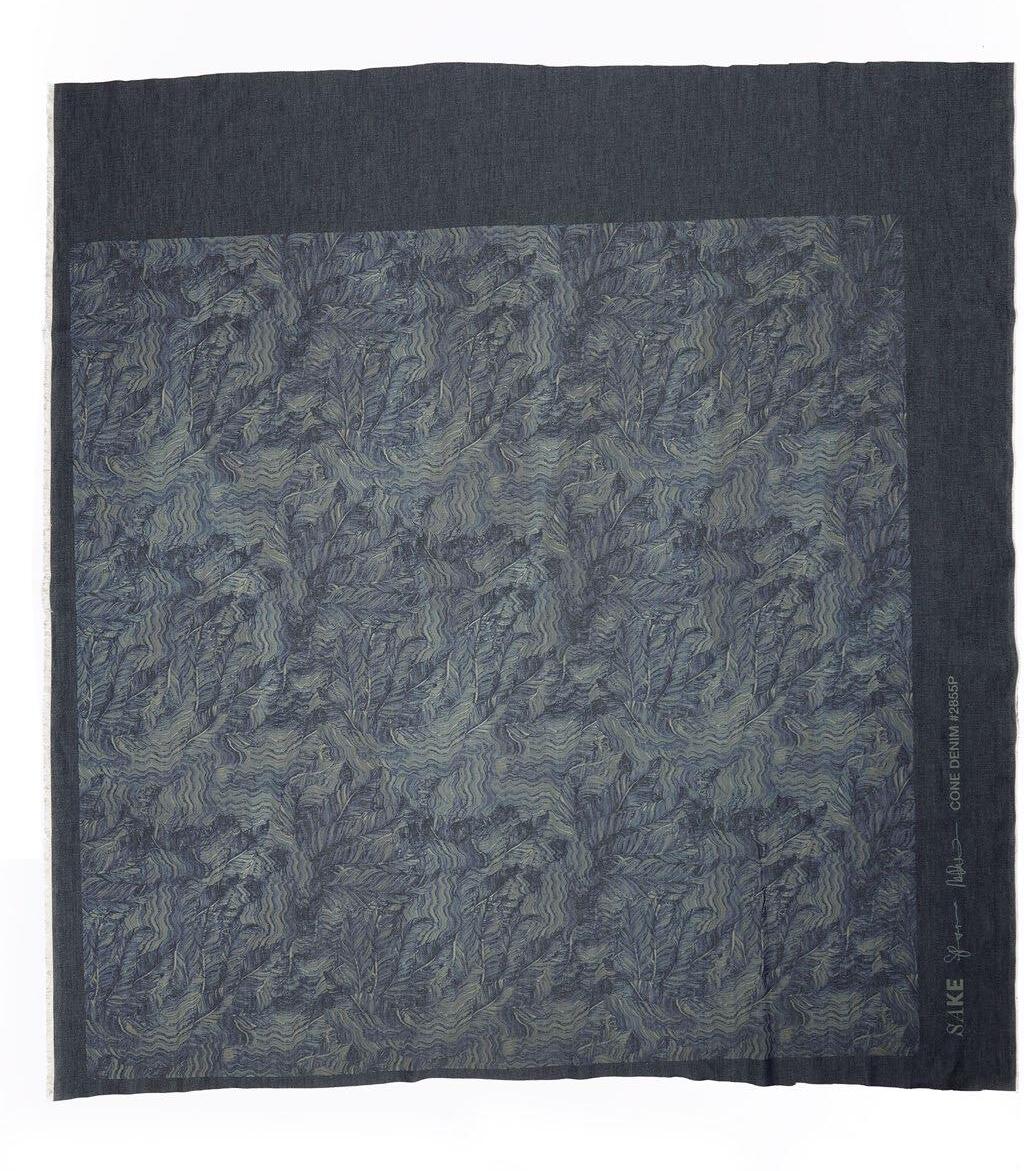

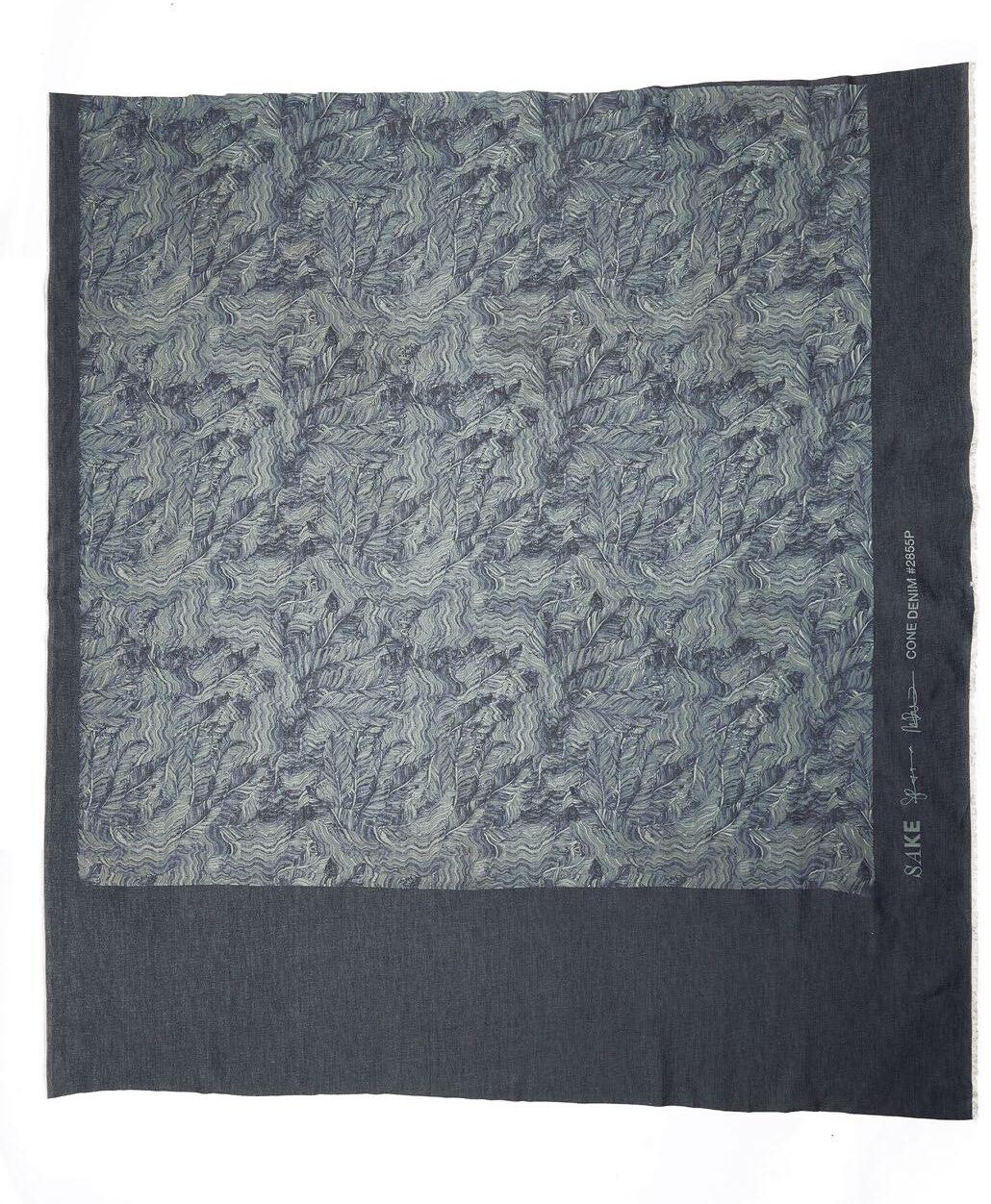

DESIGNER

Sadia Rafique

ARTWORK

Feathers No19

DENIM MILL

Cone Denim

FABRIC CODE

2855P Wonderwall

FABRIC COMPOSITION

38% Cotton, 29% Regenerated Viscose, 27% TENCEL™, 6% Recycled Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Feathers No21

DENIM MILL INDIGO TEXTILES

FABRIC CODE 10291 - SHW 02

FABRIC COMPOSITION

REGENERATIVE COTTON 69%

TENCEL 31%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

DESIGNER

Sadia Rafique

ARTWORK

Feathers No21

DENIM MILL INDIGO TEXTILES

FABRIC CODE 10291 - SHW 02

FABRIC COMPOSITION

REGENERATIVE COTTON 69% TENCEL 31%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

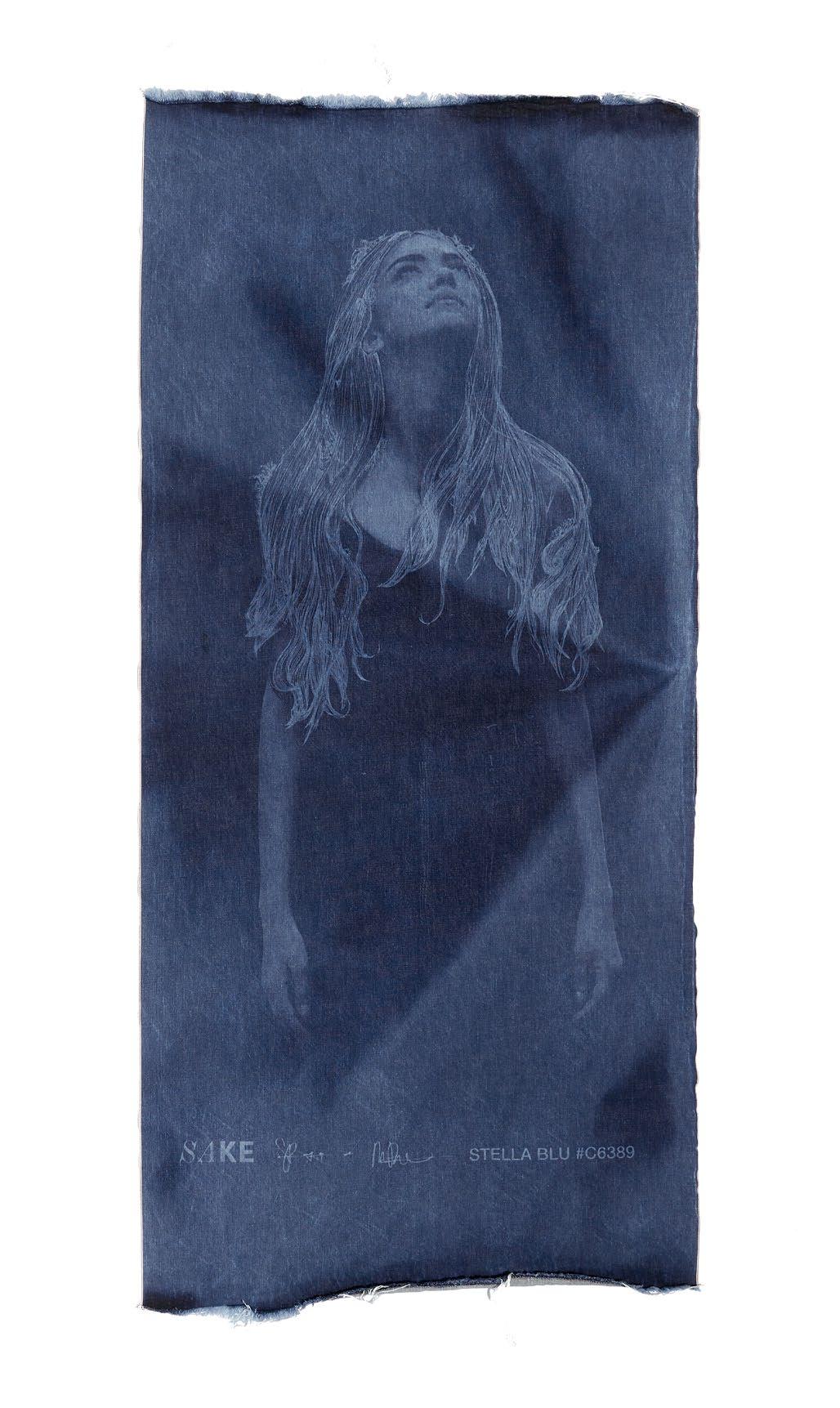

DESIGNER

Sadia Rafique

ARTWORK

Feathers No20

DENIM MILL STELLA BLU

FABRIC CODE # C6389 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Feathers No21

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506067 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather Smaller Repeat No1

DENIM MILL Indigo Textile

FABRIC CODE 11360 -Z 02

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather Smaller Repeat No2

DENIM MILL Cone Denim

FABRIC CODE

2855P Wonderwall

FABRIC COMPOSITION

38% COTTON

29% REGENERATED VISCOSE

27% TENCEL™

6% RECYCLED COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather Smaller Repeat No3

DENIM MILL Indigo Textile

FABRIC CODE 11360 -Z 02

FABRIC COMPOSITION

COTTON 80% PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather Smaller Repeat No4

DENIM MILL Cone Denim

FABRIC CODE

2855P Wonderwall

FABRIC COMPOSITION

38% Cotton / 29% Regenerated Viscose / 27% TENCEL™ / 6% Recycled Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather No2

DENIM MILL INDIGO TEXTILE

FABRIC CODE

10291 - SHW 02

FABRIC COMPOSITION REGENERATIVE COTTON

69% TENCEL 31%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather No1

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

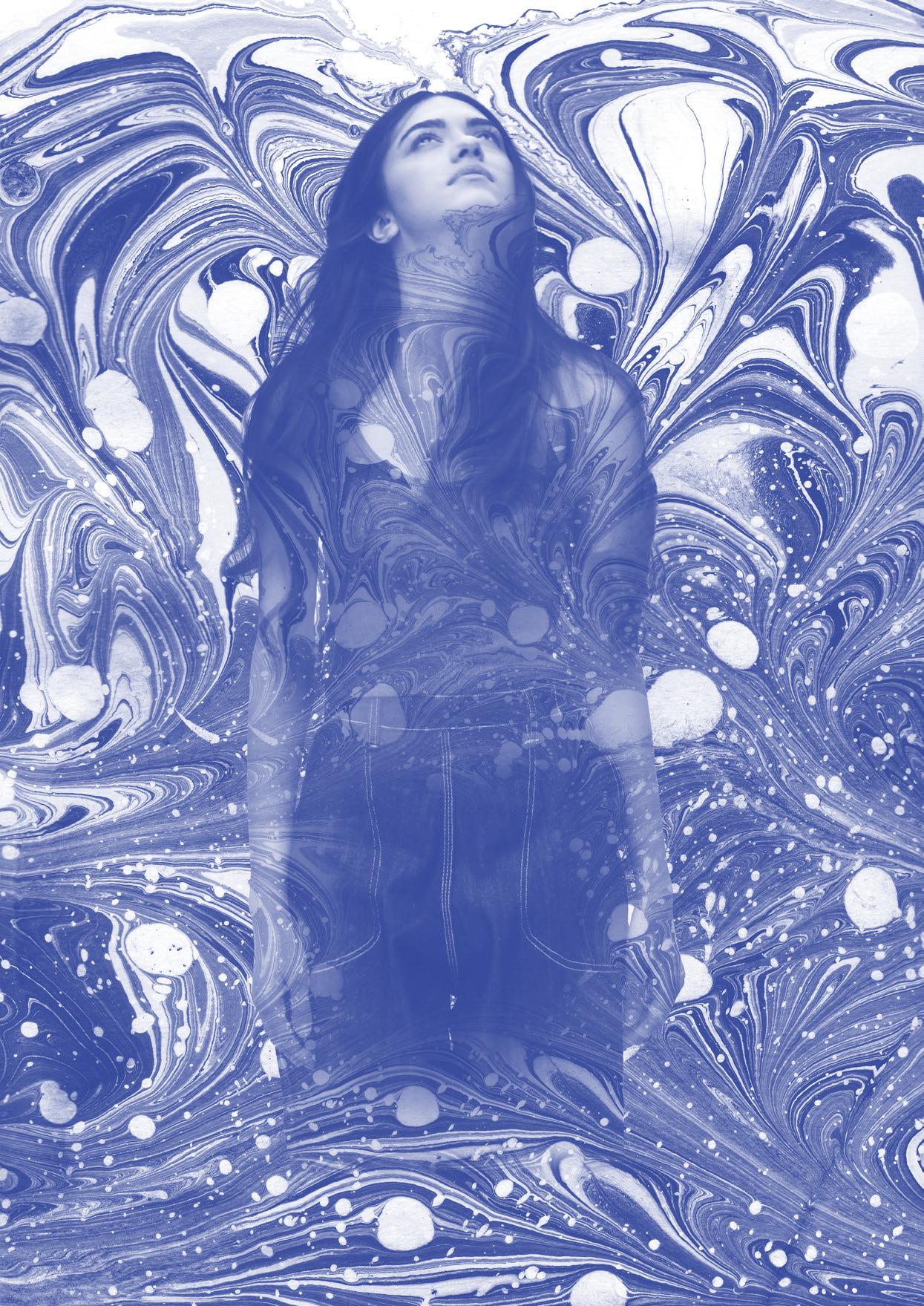

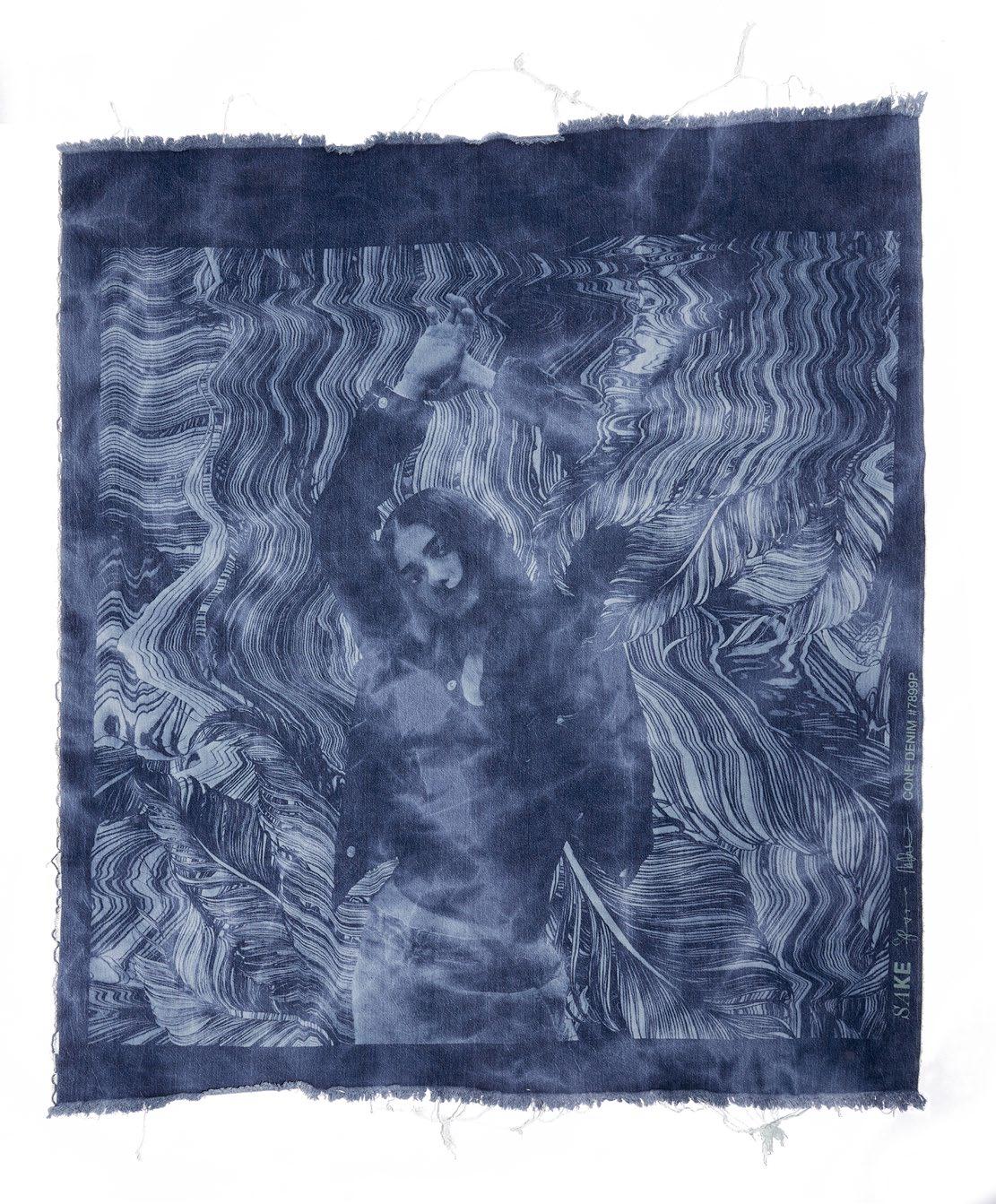

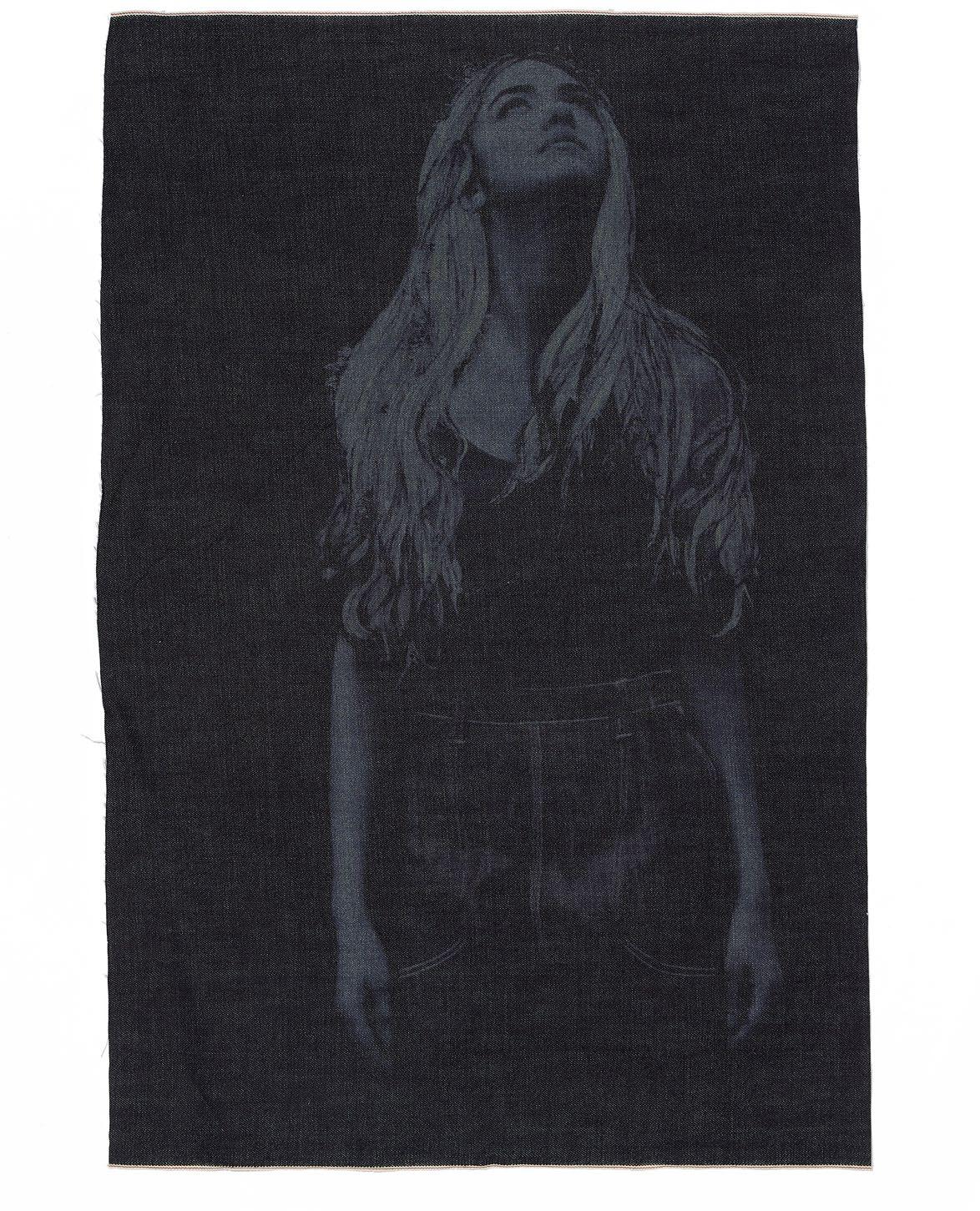

DESIGNER

Sadia Rafique

ARTWORK

Feather Girl No1

DENIM MILL

CONE DENIM

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

DESIGNER

Sadia Rafique

ARTWORK

Feather Girl No2l

DENIM MILL

TUSA DENIM

FABRIC CODE

Darkly Blue Jasmine 2500

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

DESIGNER

Sadia Rafique

ARTWORK

Feather Girl No1

DENIM MILL

TUSA DENIM

FABRIC CODE

2500 Darkly Blue Jasmine

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + O-Zone — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used O-Zone, the new static cabinet that, using only ozone, allows to obtain unique and customizable aesthetic effects, such as localized discolorations and lightenings.

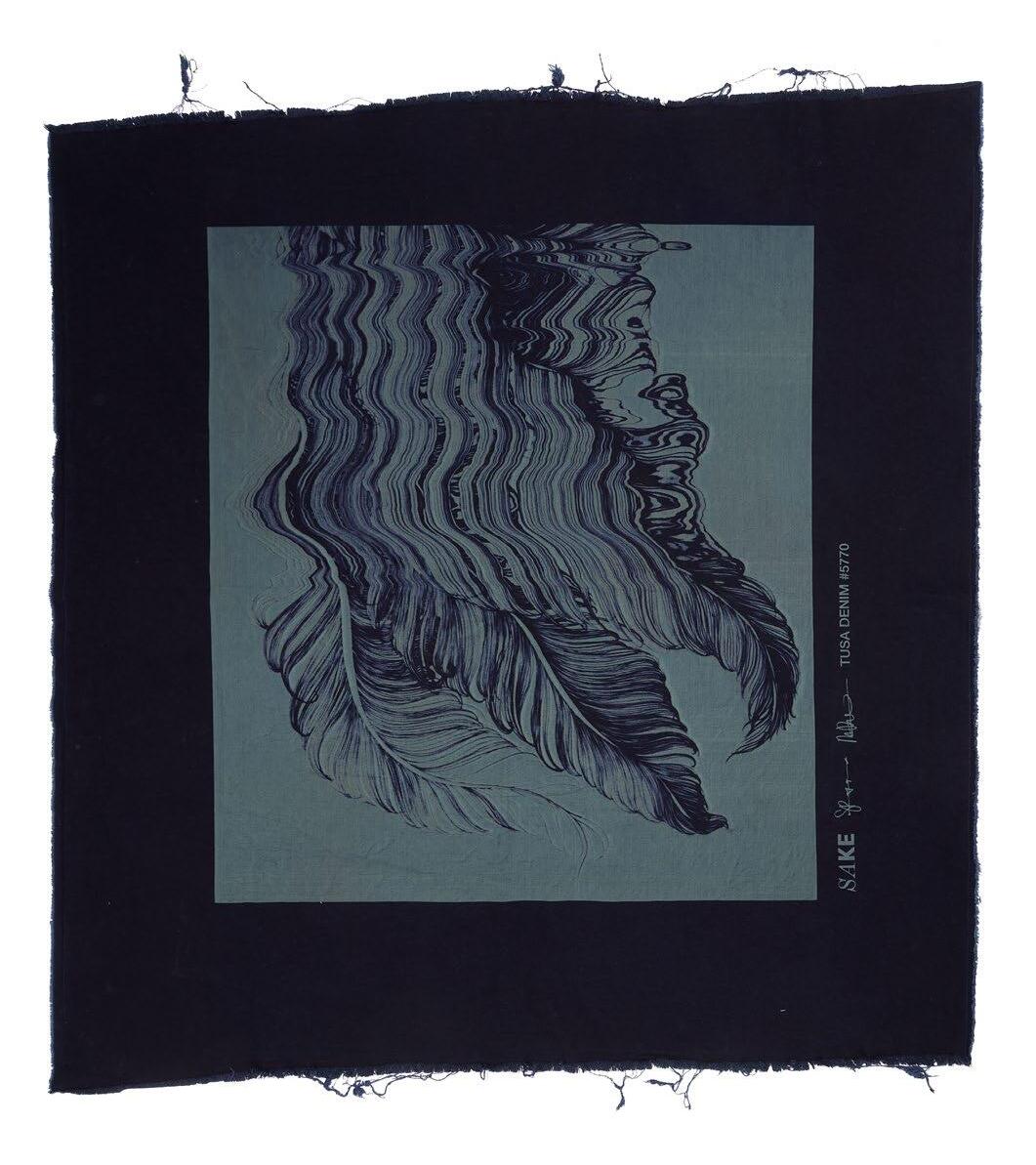

DESIGNER

Sadia Rafique

ARTWORK

Warped Feather No1

DENIM MILL

TUSA DENIM

FABRIC CODE

5770 Hempstead King Blue

FABRIC COMPOSITION

10%Hemp 90%Co, lighter weight

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK

WARPED FEATHER

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

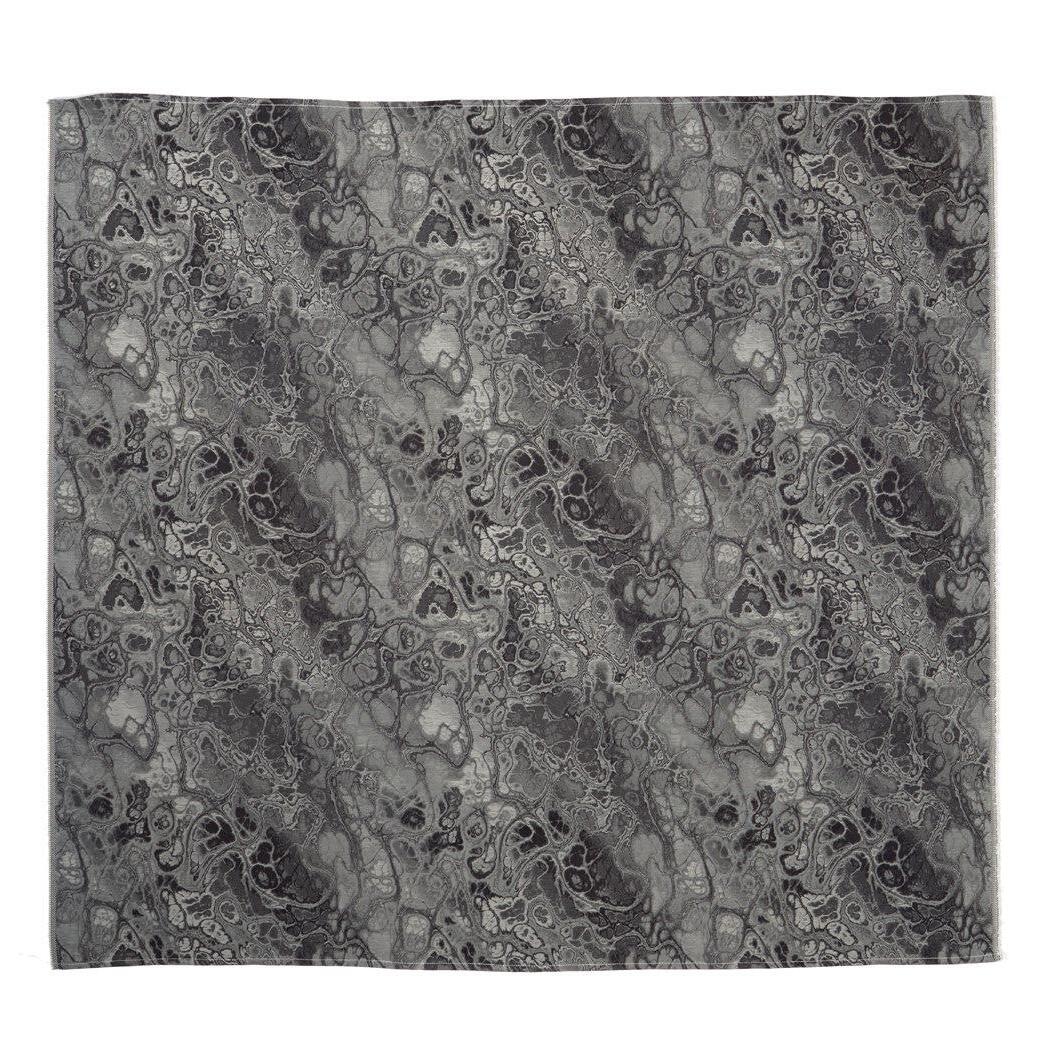

DESIGNER

Sadia Rafique

ARTWORK

Earth Element No4

DENIM MILL TUSA DENIM

FABRIC CODE

5770 Hempstead King Blue

FABRIC COMPOSITION

10%Hemp 90%Co, lighter weight

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Sadia Rafique

ARTWORK Earth Element No3

DENIM MILL INDIGO TEXTILES

FABRIC CODE 10291 - SHW 02

FABRIC COMPOSITION REGENERATIVE COTTON

69% TENCEL 31%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + DyeMate — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used DyeMate, the first-ever indigo garment dyeing technology suitable also for sulfur and VAT dyes.

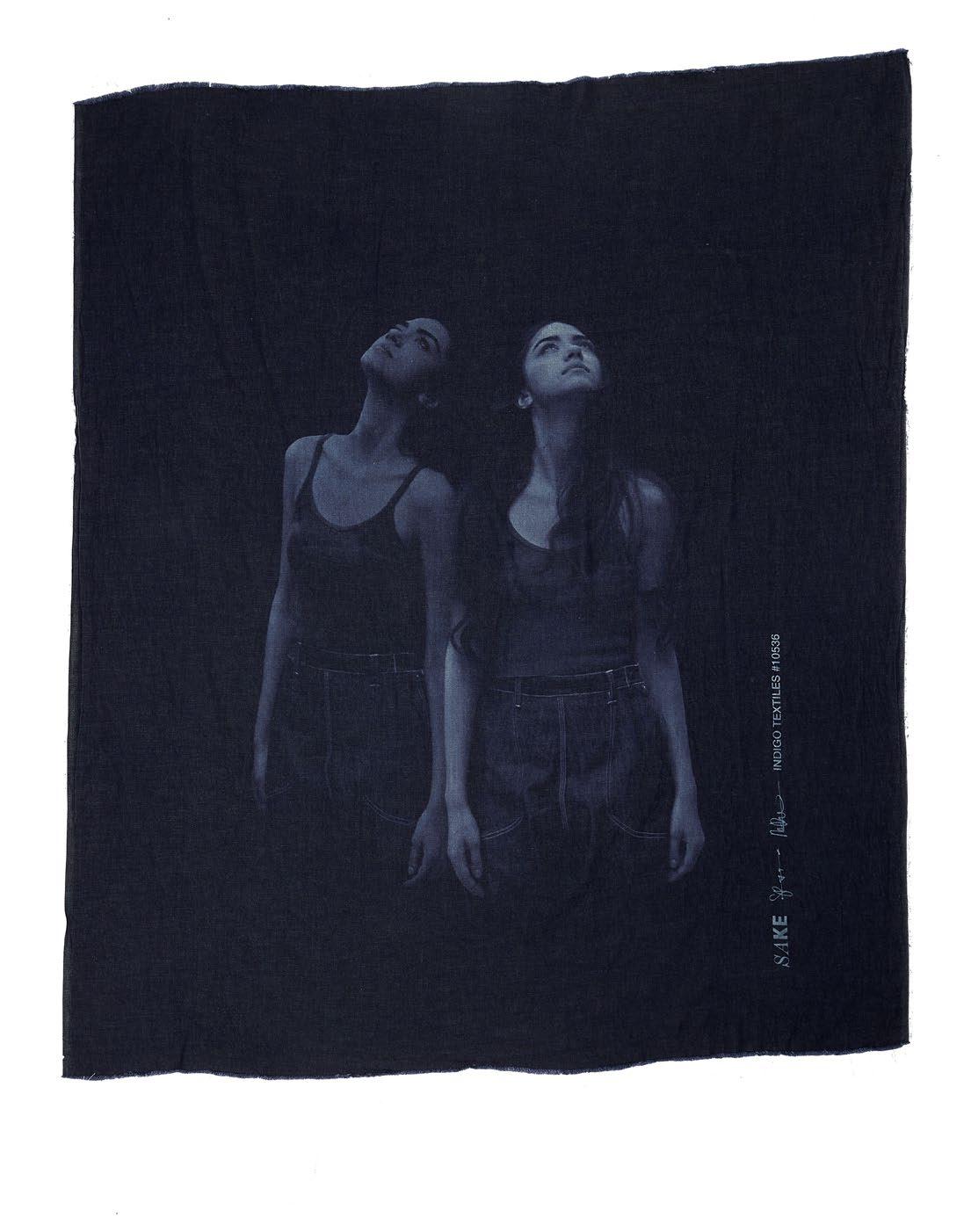

DESIGNER

Sadia Rafique

ARTWORK

Duality

DENIM MILL

Indigo Textile

FABRIC CODE 10536-NCJ

FABRIC COMPOSITION

COTTON 50%

TENCEL 32%

HEMP 17%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK

Hope No1

DENIM MILL STELLA BLU

FABRIC CODE # C6389 SELVEDGE

FABRIC COMPOSITION 100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Hope No2

DENIM MILL

Cone Denim

FABRIC CODE

2986P Horseshoe

FABRIC COMPOSITION

73% Cotton, 27% TENCEL™

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects..

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Hope No3

DENIM MILL

Cone Denim

FABRIC CODE

2986P Horseshoe

FABRIC COMPOSITION

73% Cotton, 27% TENCEL™

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects..

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Universe No1

DENIM MILL

CONE DENIM

FABRIC CODE

2986P Horseshoe

FABRIC COMPOSITION

73% COTTON

7% TENCEL™

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK

Universe No2

DENIM MILL INDIGO TEXTILES

FABRIC CODE 8788-NC

FABRIC COMPOSITION

COTTON 80% PIW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK UNIVERSE

DENIM MILL

SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK

Universe No2

DENIM MILL STELLA BLU

FABRIC CODE

2986P Horseshoe

FABRIC COMPOSITION

73% Cotton, 27% TENCEL™

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK

Four No1

DENIM MILL

Indigo Textile

FABRIC CODE

10291 - SHW 02

FABRIC COMPOSITION

REGENERATIVE COTTON 69% TENCEL 31%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Sadia Rafique

ARTWORK FOUR No2

DENIM MILL INDIGO TEXTILES

FABRIC CODE 10536-NCJ

FABRIC COMPOSITION COTTON 50% TENCEL 32% HEMP 17%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Distance No1

DENIM MILL INDIGO TEXTILES

FABRIC CODE 8788-NC

FABRIC COMPOSITION

COTTON 80% PIW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Dual Vision No1

DENIM MILL

Indigo Textile

FABRIC CODE

11360 -Z 02

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Dual Vision No2

DENIM MILL

Indigo Textile

FABRIC CODE

8788-NC

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK

Hope No4

DENIM MILL

Indigo Textile

FABRIC CODE

11360 -Z 02

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

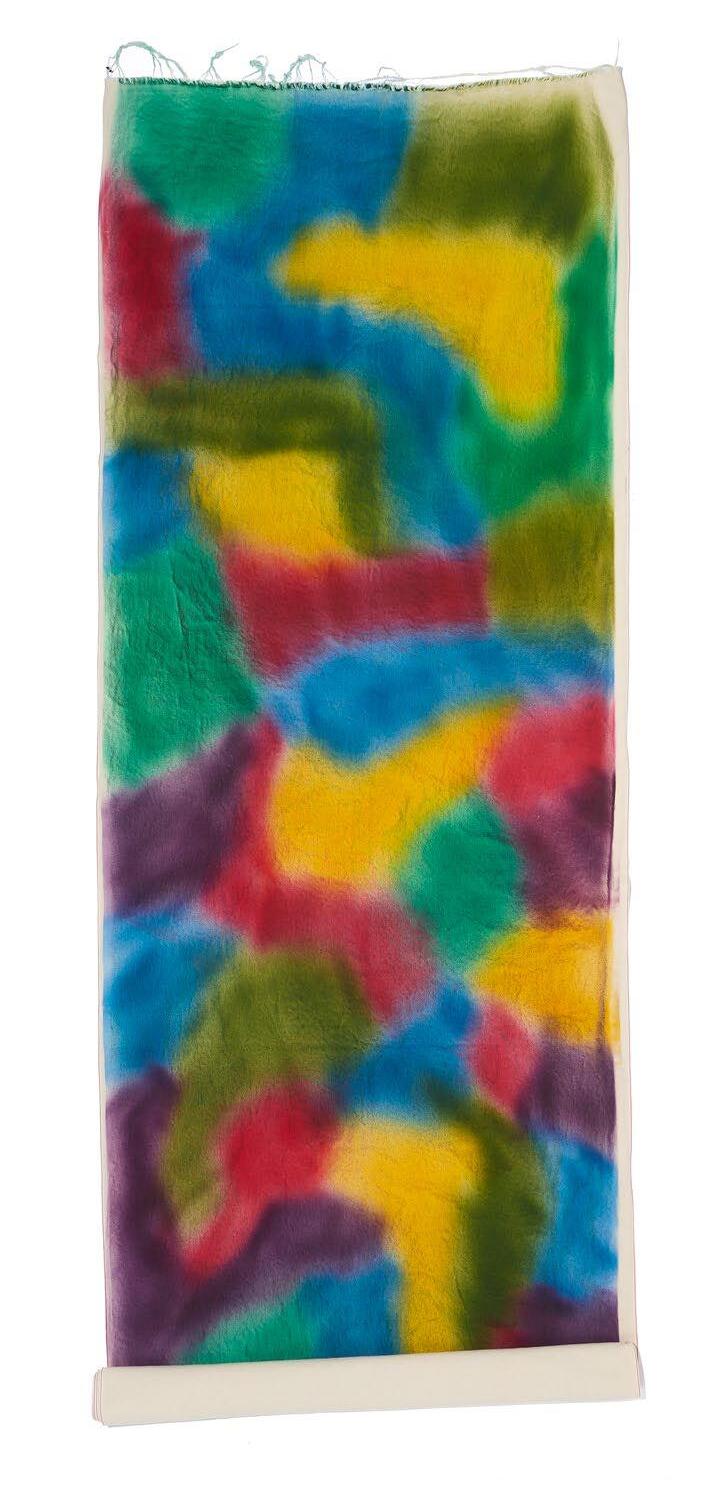

DESIGNER

Sadia Rafique

ARTWORK

Colours No2

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK Horse

DENIM MILL INDIGO TEXTILES

FABRIC CODE 8788-NC

FABRIC COMPOSITION

COTTON 80% PIW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

DESIGNER

Sadia Rafique

ARTWORK Pattern Girl NO2

DENIM MILL TUSA DENIM

FABRIC CODE

#2500 Darkly Blue Jasmine

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone ® , UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

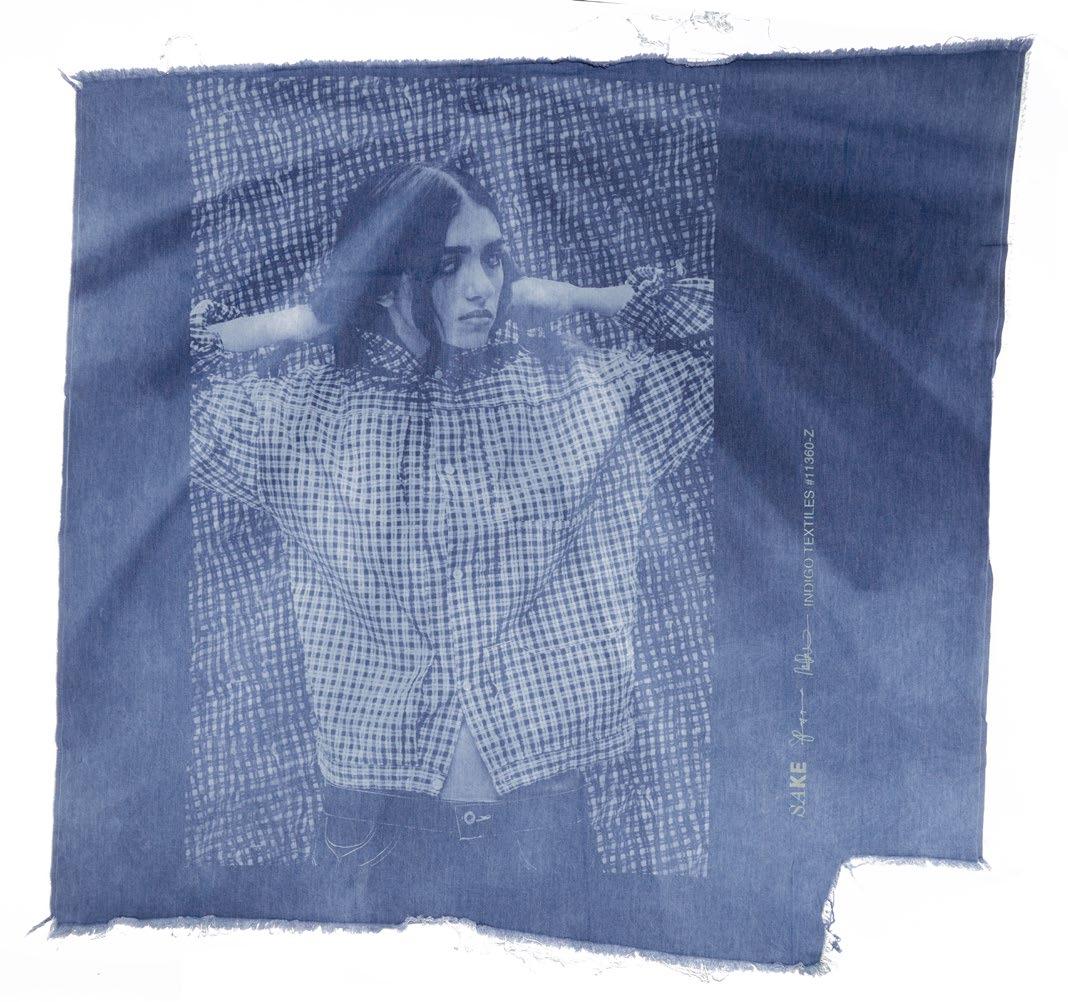

DESIGNER

Sadia Rafique

ARTWORK

Pattern Girl NO1

DENIM MILL INDIGO TEXTILES

FABRIC CODE 11360 -Z 02

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

DESIGNER

Sadia Rafique

ARTWORK Pattern Girl NO3

DENIM MILL CONE DENIM

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

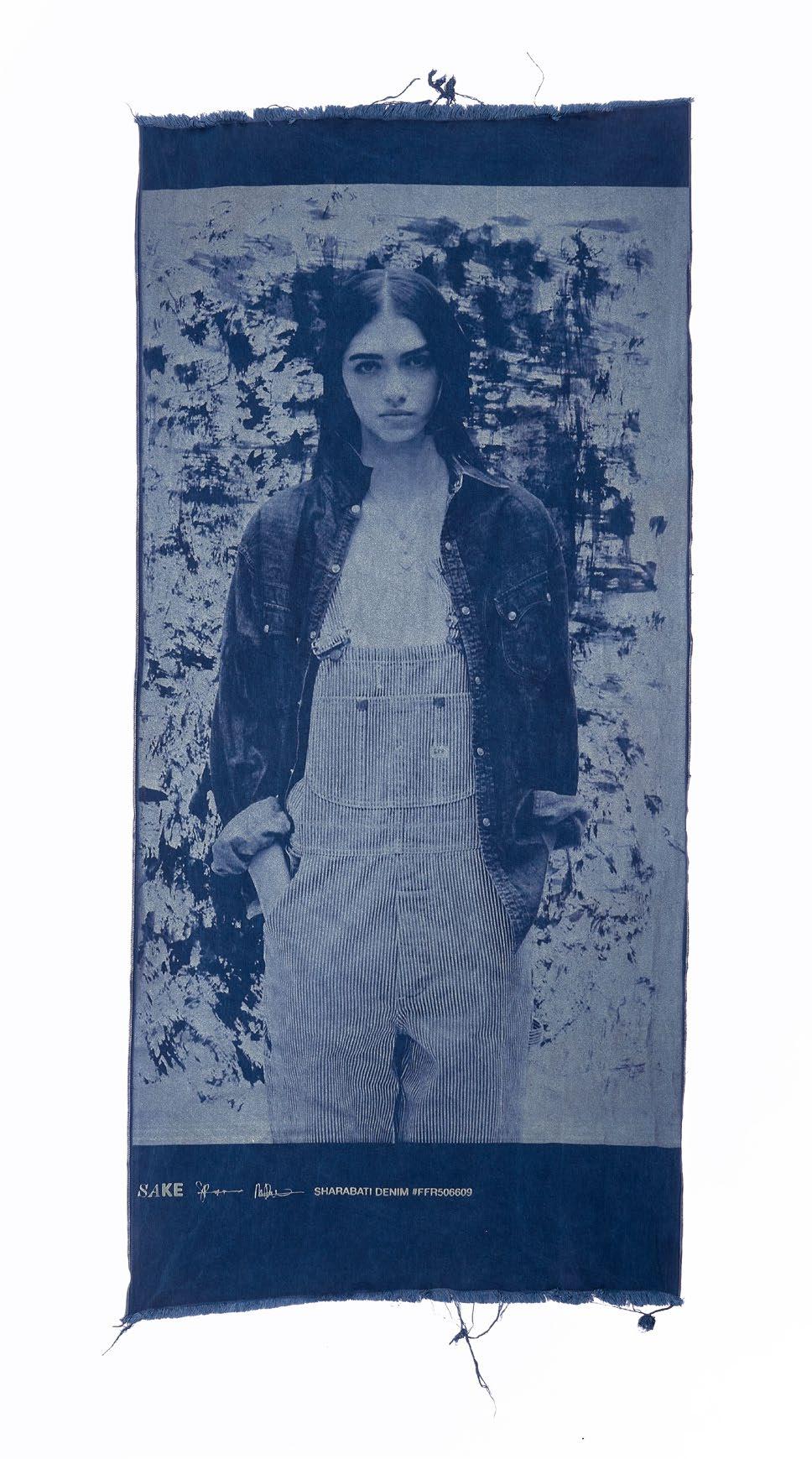

DESIGNER

Sadia Rafique

ARTWORK Paint Girl No2

DENIM MILL SHARABATI DENIM

FABRIC CODE

FRR506609 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system + DyeMate — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have also used DyeMate, the first-ever indigo garment dyeing technology suitable also for sulfur and VAT dyes.

DESIGNER

Sadia Rafique

ARTWORK Paint Girl No1

DENIM MILL STELLA BLU

FABRIC CODE # C6395 SELVEDGE

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, we have used EGO, the new ozone treatment system which incorporates ozone in air, ozone in water, and the patented OBleach process into a single technology. Enhancing performance and reducing consumption.

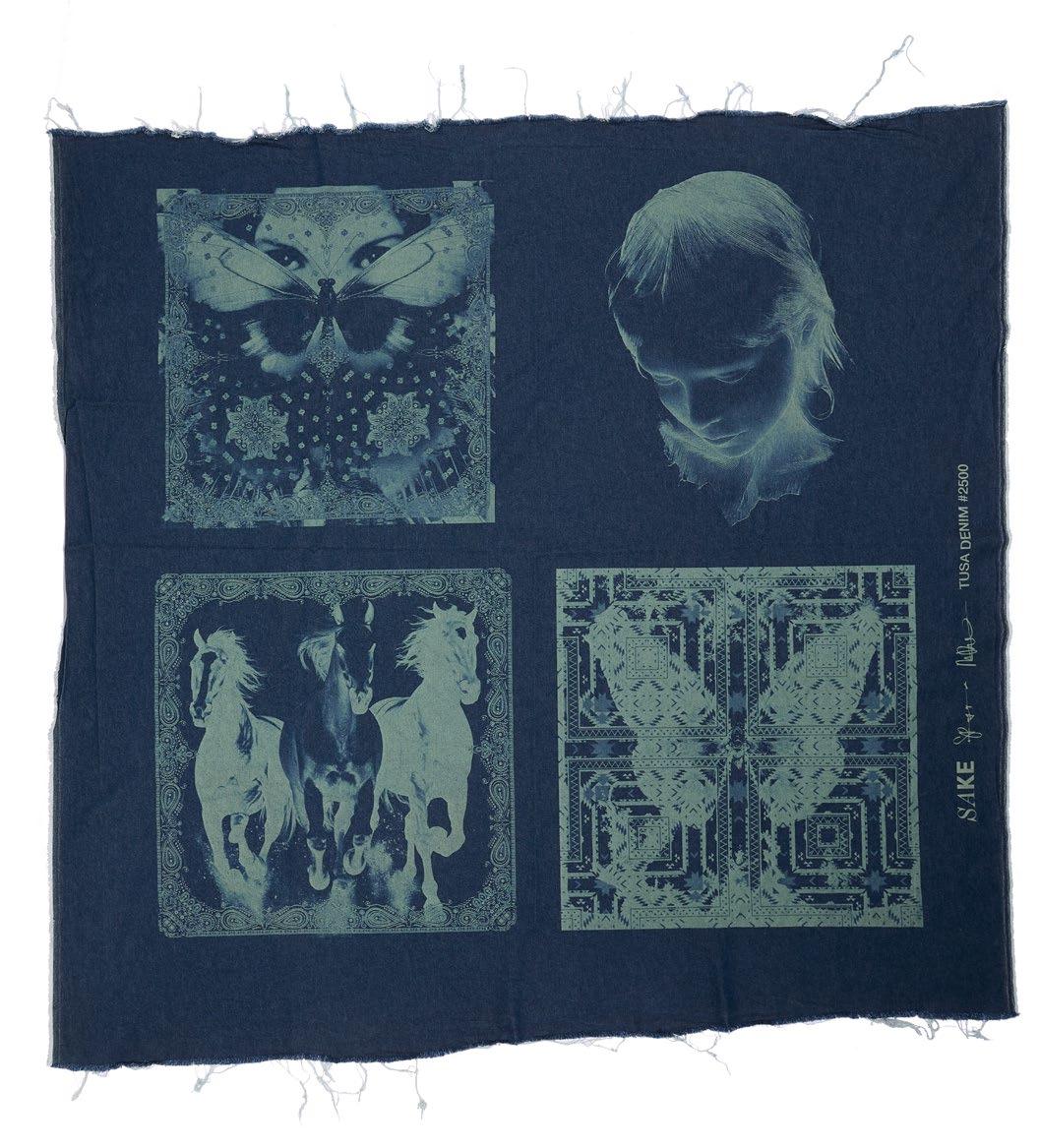

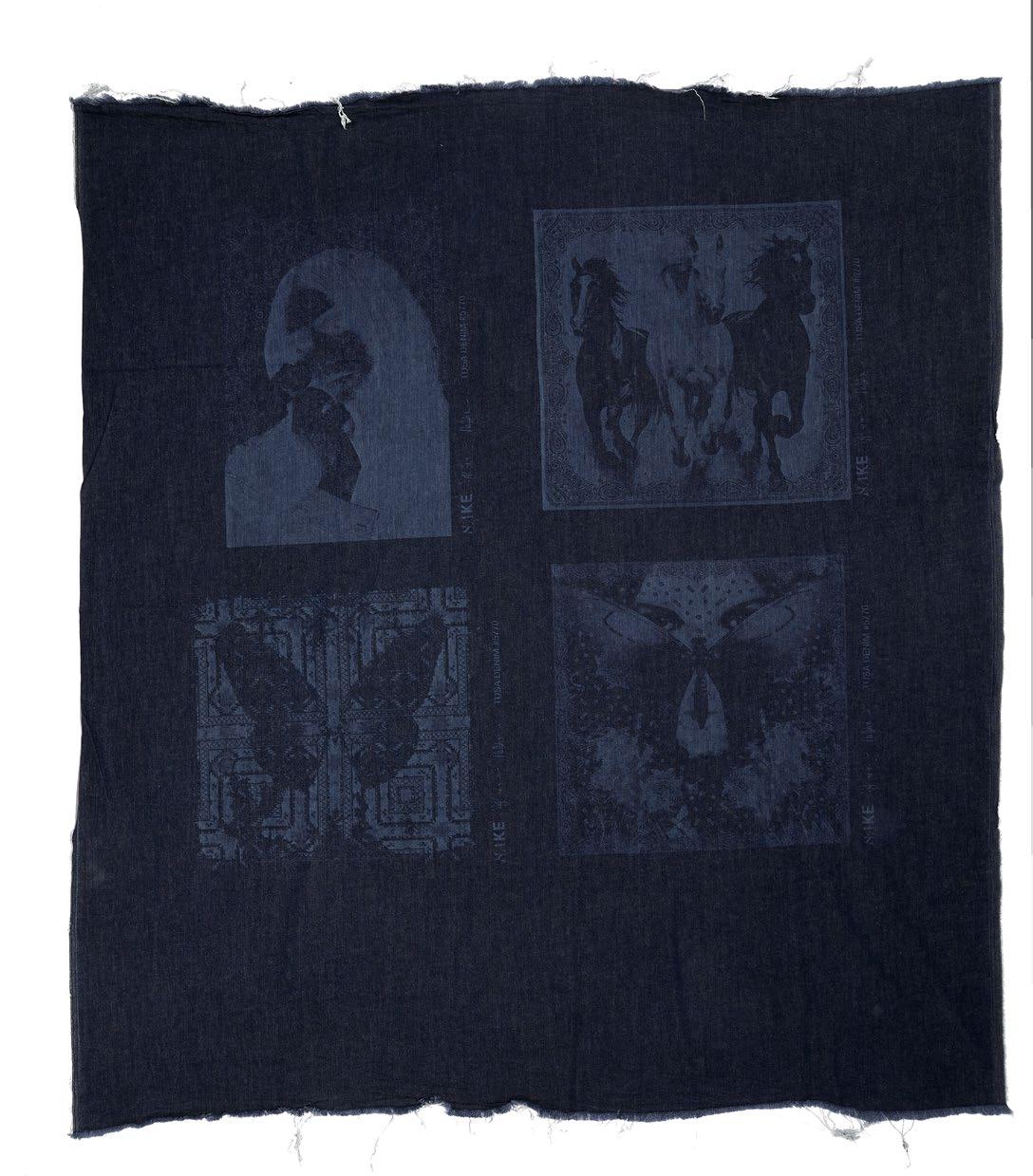

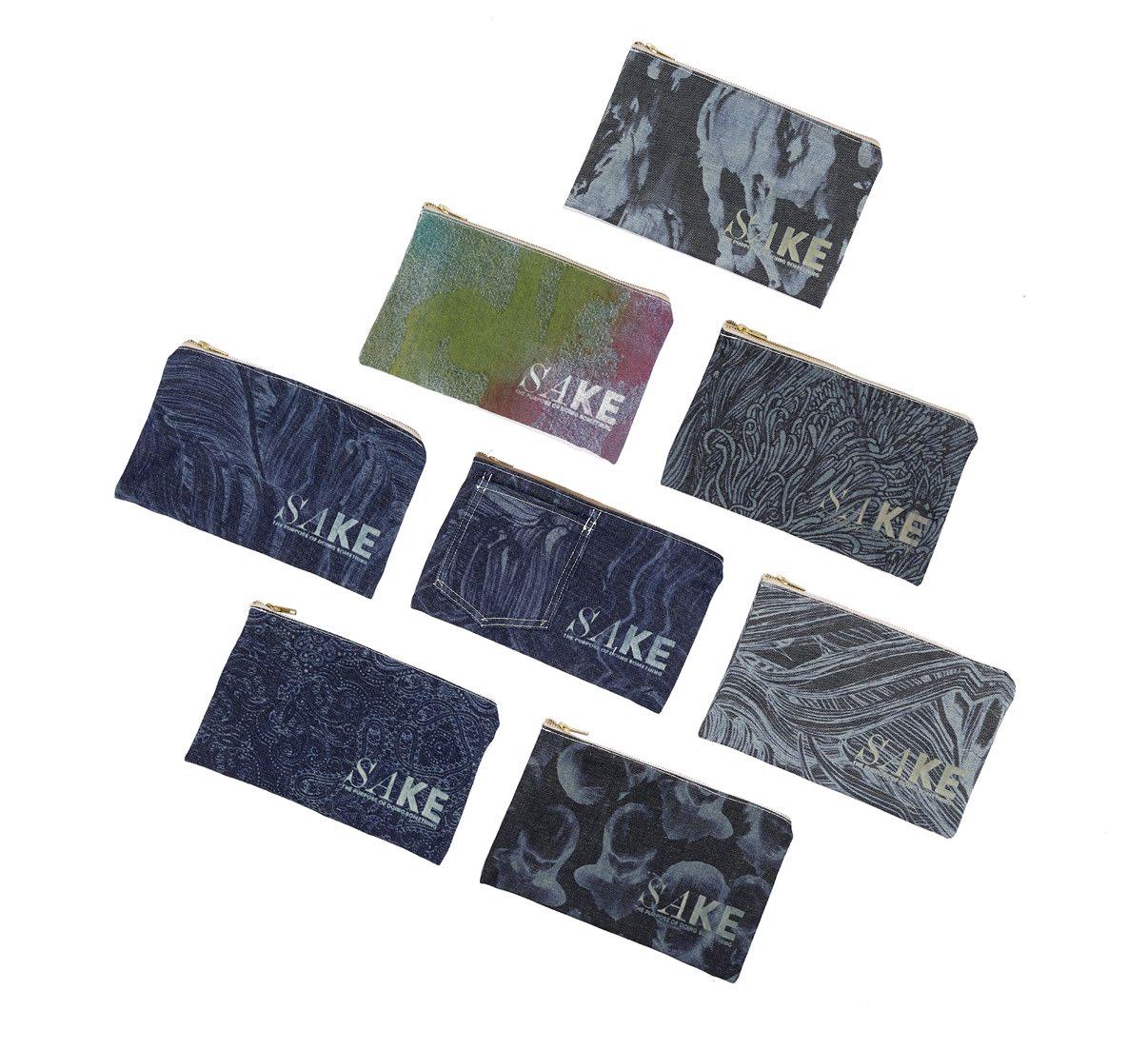

DESIGNER

Matt Duckett

ARTWORK

Bandana Butterfly, Face No3, Horsey, Butterfly Pattern

DENIM MILL

Tusa Denim

FABRIC CODE

2500 Darkly Blue Jasmine

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

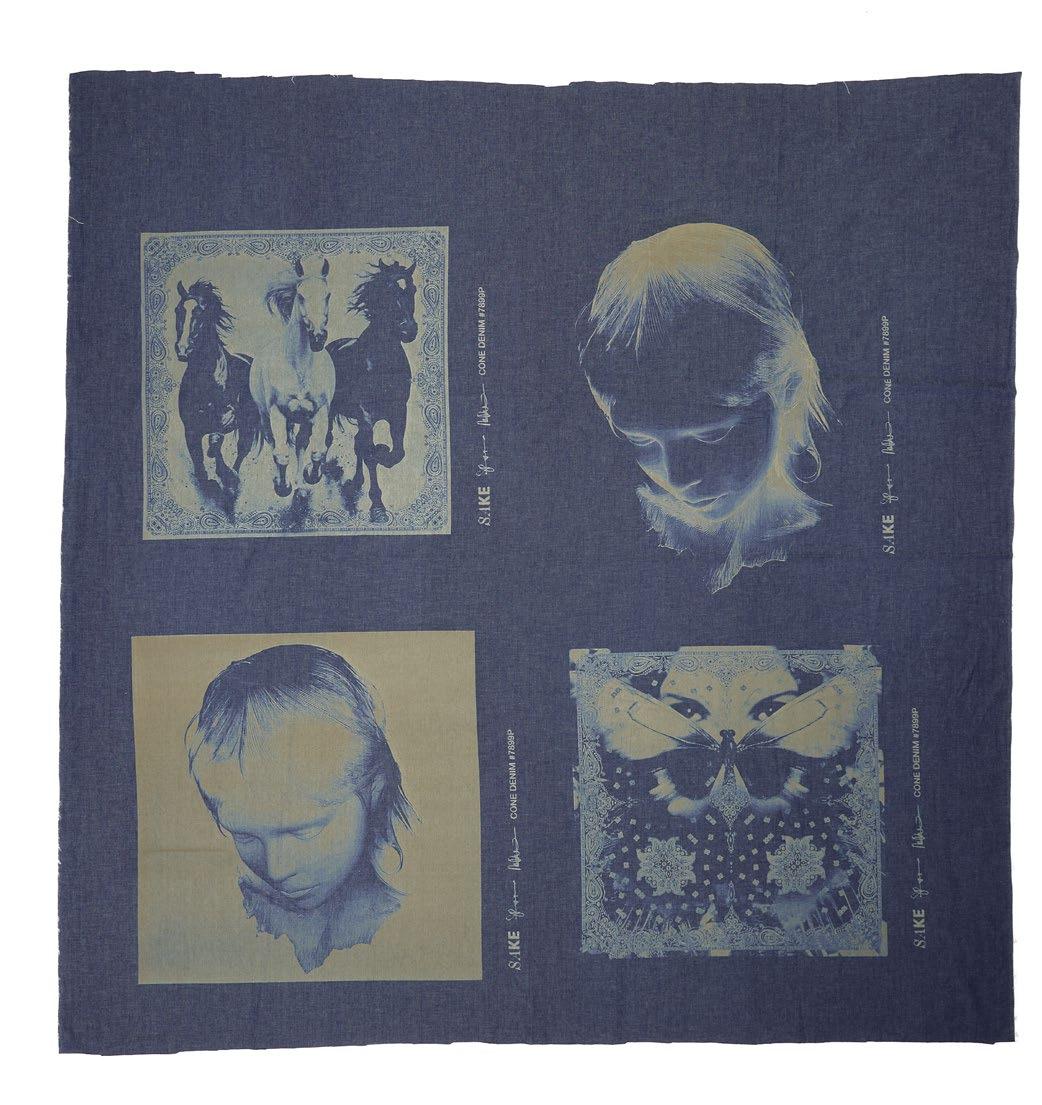

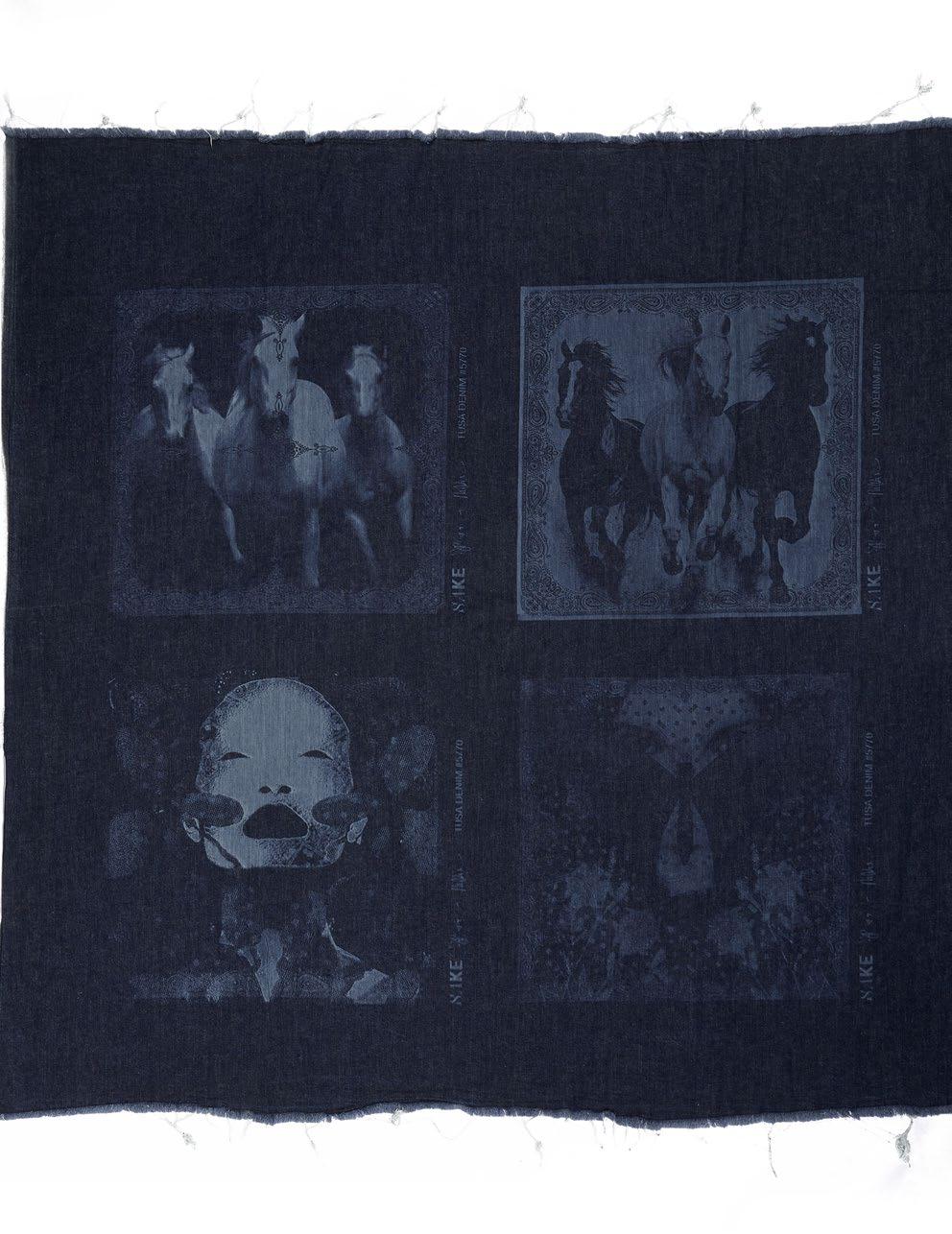

DESIGNER

Matt Duckett

ARTWORK

Horsey, Face No3, Bandana Butterfly

DENIM MILL

Cone Denim

FABRIC CODE

7899P Two Step

FABRIC COMPOSITION

100% COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

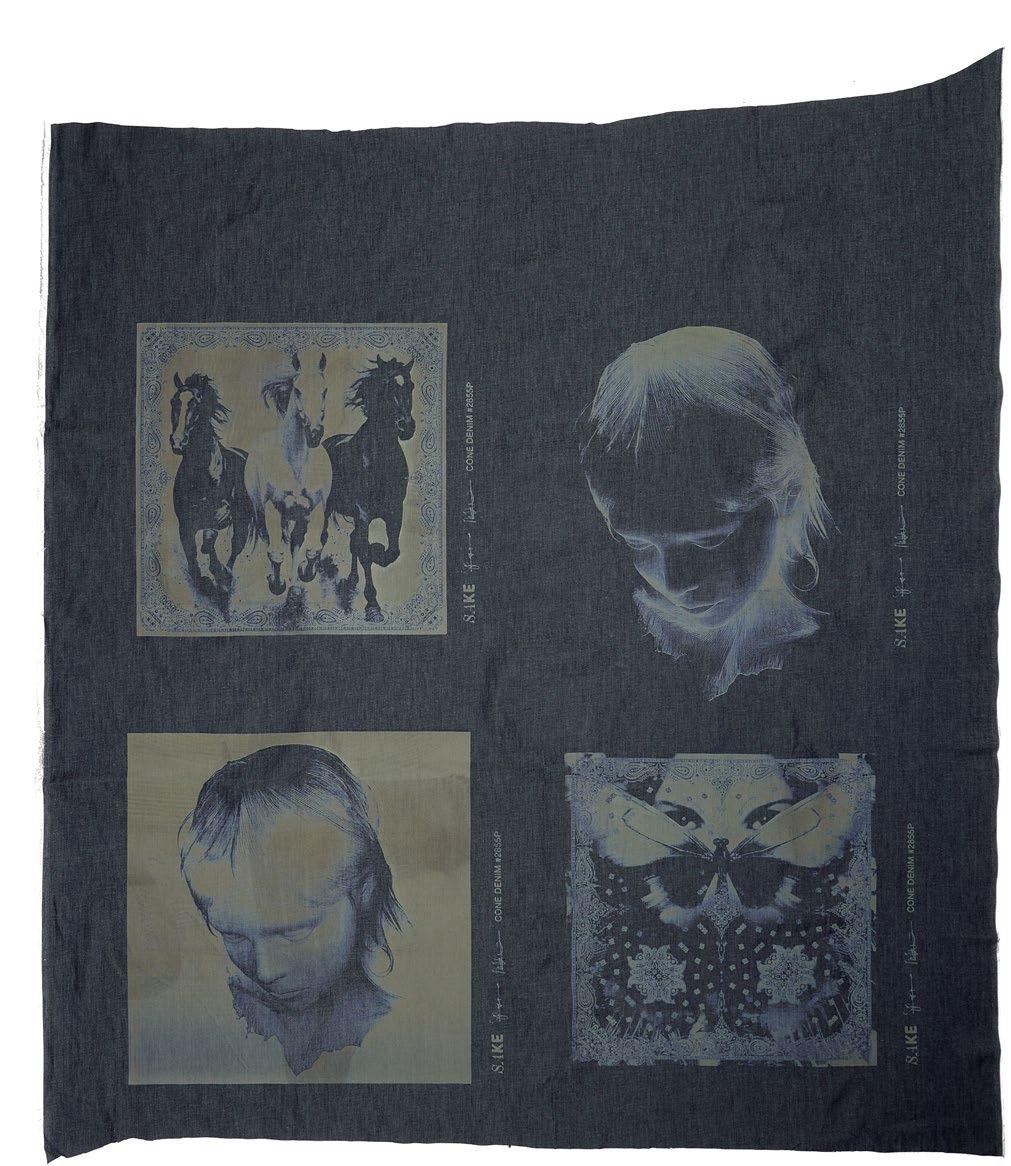

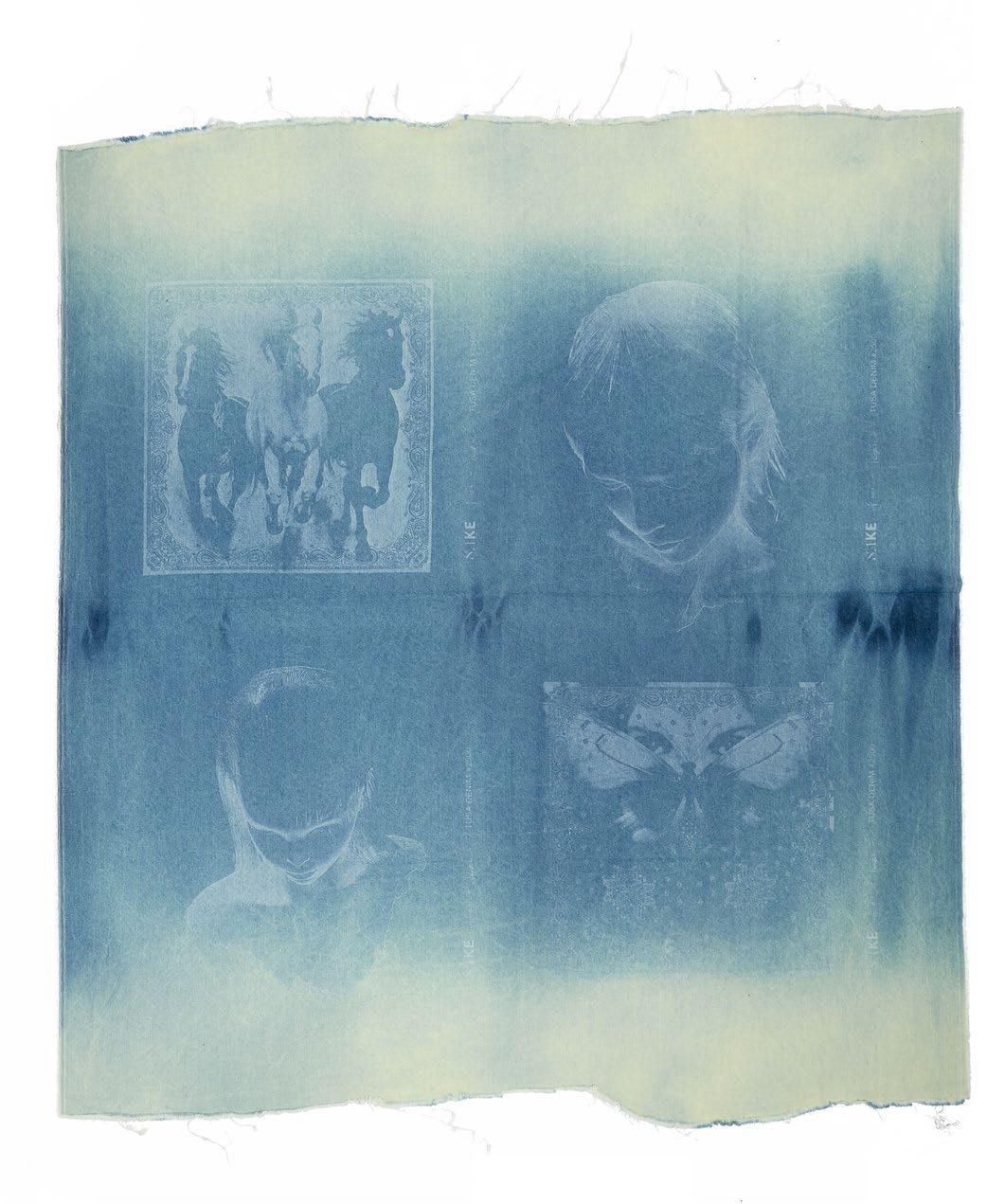

DESIGNER

Matt Duckett

ARTWORK

Bandana Butterfly, Face No3, Horsey, Butterfly Pattern

DENIM MILL

Cone Denim

FABRIC CODE

2855P Wonderwall

FABRIC COMPOSITION

38% COTTON

29% REGENERATED VISCOSE

27% TENCEL™

6% RECYCLED COTTON

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment.

DESIGNER

Matt Duckett

ARTWORK

Motivation, Metamorphosis, Bandana

DENIM MILL

TUSA DENIM

FABRIC CODE

5770 Hempstead King Blue

FABRIC COMPOSITION

10%Hemp 90%Co, lighter weight

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Sadia Rafique Matt Duckett

ARTWORK

Universe, Horsey, Butterfly Pattern, Bandana Butterfly

DENIM MILL

Tusa Denim

FABRIC CODE

5770 Hempstead King Blue

FABRIC COMPOSITION

10%Hemp 90%Co, lighter weight

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Matt Duckett

ARTWORK

Horsey, Butterfly, Bandana Butterfly.

DENIM MILL

TUSA DENIM

FABRIC CODE

5770 Hempstead King Blue

FABRIC COMPOSITION

10%Hemp 90%Co, lighter weight

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Matt Duckett

ARTWORK

Motivation, Face, Butterfly Bandana, Butterfly Pattern

DENIM MILL

TUSA DENIM

FABRIC CODE

2500 Darkly Blue Jasmine

FABRIC COMPOSITION

100% Cotton

Machine used: THE Laser T — This laser, designed by Tonello, allows for horizontal working on a table that can be divided into 2 sections and equipped with B.O.P., the automatic garment detection system. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

Machine used: All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Sadia Rafique

ARTWORK

Hope No5

DENIM MILL INDIGO TEXTILES

FABRIC CODE

11360 -Z 02

FABRIC COMPOSITION

COTTON 80%

PCW COTTON 20%

Machine used: THE Laser 2.0 — This next-generation laser, developed by Tonello, is equipped with a fully digital laser source and high-performance electronic boards that enable extremely high marking speeds. The system includes Turbo and Hyper modes, reducing processing times by up to 40% while maintaining excellent quality standards. Its dynamic focusing system ensures uniform results across the entire work area, allowing precise reproduction of even the finest details on every garment. In this specific case we have also used the Multicolor Laser process to obtain print out effects.

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core. In this specific case, the garment was also previously sprayed with indigo dye to achieve an intricate design.

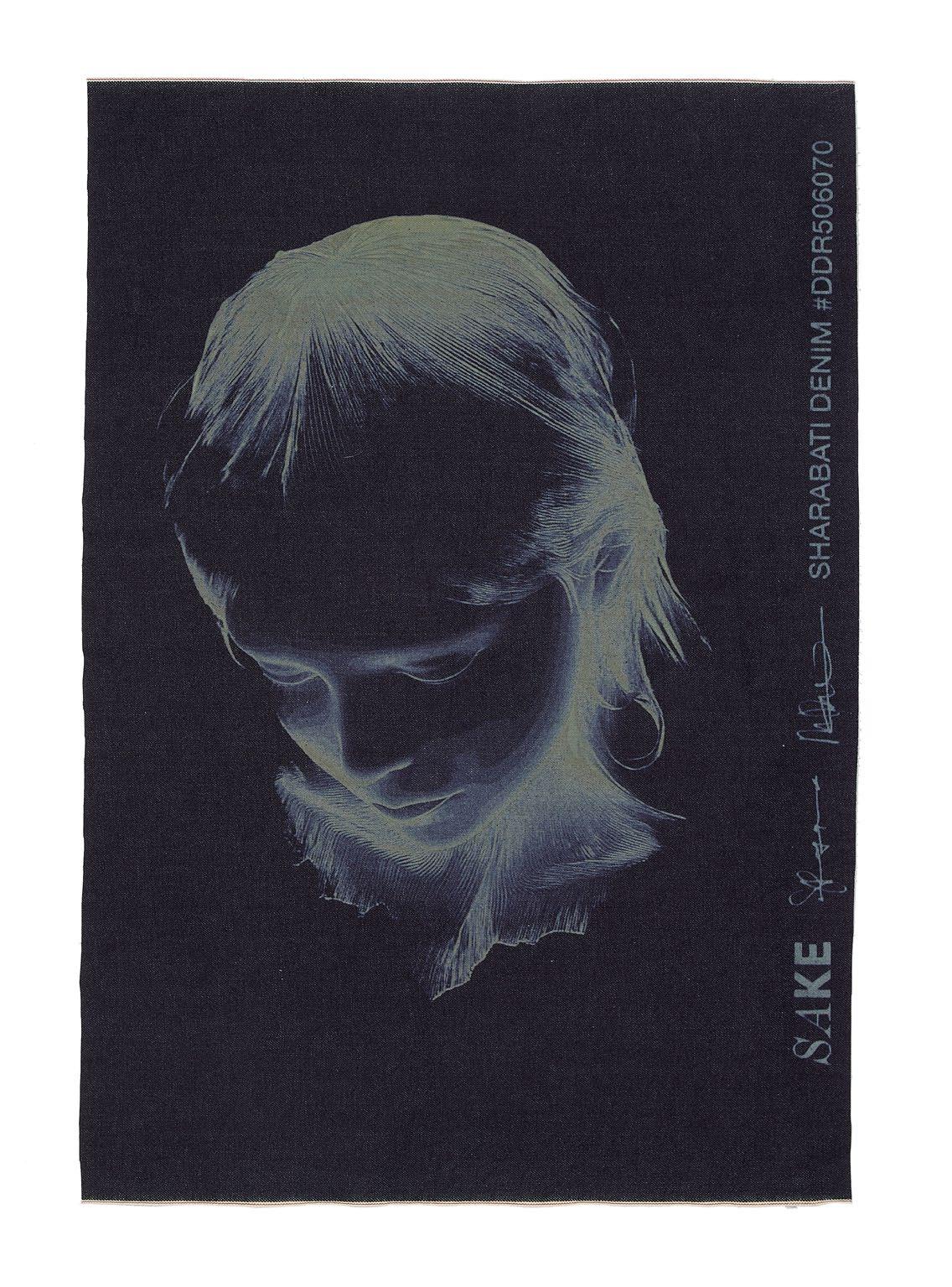

DESIGNER

Matt Duckett

ARTWORK FACE

DENIM MILL SHARABATI DENIM

FABRIC CODE

DRR506070 SELVEDGE

FABRIC COMPOSITION

100% REGEN COTTON ORGANIC

Machine used: THE Laser Lab — This laser, designed by Tonello, is specifically for stores and labs, and allows for horizontal working on three different levels. It is perfect for detailed and high-definition applications. It has an innovative and extremely compact design that facilitates operations in different contexts, even in small operating spaces. It is controlled by CREA, the laser software that offers endless creative solutions and makes every processing simple, intuitive, and fast.

DESIGNER

Matt Duckett

ARTWORK

Face No1

DENIM MILL

Stella Blu

FABRIC CODE # C6395 SELVEDGE

FABRIC COMPOSITION 100% COTTON

LASER PROCESS N/A

WASH PROCESS

Machine used: Spray Robot + All-in-One system — The All-in-One system performs all washing operations by combining 4 integrated sustainable technologies in one machine: EGO, NoStone®, UP, Core.

DESIGNER

Matt Duckett

ARTWORK FACE

DENIM MILL STELLA BLU

FABRIC CODE

C6395 SELVEDGE

FABRIC COMPOSITION

100% COTTON