Release Your Potential

It starts with the right software

A modern propane business presents unlimited opportunities for growth. Let ADD Systems help you realize all those possibilities as we meet today’s challenges of customer experience, speed, accuracy, mobility, and ever more important, scalability.

ADD Systems has been providing solutions to the energy distribution industry –retail and wholesale fuel, propane, convenience stores and more – since 1973.

Heads of Departments

Editor-in-Chief Carley Fallows editor@littlegatepublishing.com

Space Management Emlyn Freeman emlynfreeman@littlegatepublishing.com

Media Coordinator Andrew Williams andrew@littlegatepublishing.com

Lead Designer Alina Sandu Research Kristina Palmer-Folt Editorial Research Amber Winterburn

Corporate Director Anthony Letchumaman anthonyl@littlegatepublishing.com

Founder and CEO Stephen Warman stevewarman@littlegatepublishing.com

For enquiries or subscriptions contact info@littlegatepublishing.com +44 1603 296 100

ENDEAVOUR MAGAZINE is published by Littlegate Publishing LTD which is a Registered Company in the United Kingdom.

Company Registration: 07657236

VAT registration number: 116 776007

343 City Road 60 Thorpe Road London 79 Norwich EC1 V1LR NR1 1RY

Littlegate Publishing Ltd does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Copyright© Littlegate Publishing Ltd

Editor’s Note

When you think of the Asia-Pacific region, you would probably imagine beautiful beaches and forests, alongside amazing wildlife and marine animals. Although this is most certainly true from a tourism point of view, in a business mindset, all these specialised resources make it the perfect place for technological and industrial growth.

Consequently, across Asia and the Pacific region, what can be witnessed is the rapid increase in new technology, globalisation, and market-orientated reform. This points towards vast innovation and enhancement of industry. Thus, here at Endeavour, we have been very lucky to witness how such companies have drastically grown, as business advancements have swept across the vast region. This is also helped by the growing demands of a rapidly increasing population. This means that the Asia-Pacific region can afford a greater workforce and economic advancement.

It is for this reason that the Asia-Pacific region deserves its own specific publication. Within this issue, you will find out about brand new innovations in engineering, sailing and biscuits! Thus, we will not only discover the business behind the lavish and decadent Asian skylines but how such companies face the challenges of the ever-modernising world.

Solomon Islands Port Authority

Made up of a double chain of volcanic islands and coral atolls, the Solomon Islands is a country located in the southwest of the Pacific Ocean. Due to its vital location in the Pacific Ocean, the island’s main ports of Honiara and Noro are linked to key ports in Australia, as well as ports in New Zealand, Japan, China and Southeast Asia. Therefore, the shipping industry of the Solomon Islands is a vital aspect of the country’s economy, with the country’s main ports serving as a premier hub for port and maritime activities, providing the Solomon Islands as a gateway for international trade. To oversee such a vital aspect of the country’s economy, the Solomon Islands Port Authority (SIPA) was developed to oversee the development of the Island’s ports and deliver them as the South Pacific’s Strategic Gateway to the World.

Established in 1956, SIPA is a governmentowned authority responsible for overseeing the operation and development of the ports of Honiara and Noro for the Solomon Islands. The Authority is mandated to provide, maintain, and improve the port facilities of Honiara and Noro, whilst overseeing the maritime operations across the territorial waters of the Solomon Islands. Across these operations, SIPA is focused on harnessing the potential of the Solomon Islands’ shipping industry to deliver ports that can handle the cargo arriving and leaving its shores with seamless solutions.

In recent years, global cargo trade volumes have increased, and this has been seen across the port of the Solomon Islands. Therefore, a key part of SIPA’s role is to help support this growing demand and deliver vital commodity trade for the region, which will have knock-on benefits for the economy. However, SIPA achieves this, whilst also working to deliver this shipping capability in the most sustainable way possible. Therefore, in recent years, SIPA has been moving the ports across the country towards a more environmentally conscious future, helping them to lower their energy consumption and cost on the planet whilst still delivering the vital cargo services needed to support the Islands.

One of the central ports for the Solomon Islands is the Port of Honiara, which is the capital port for the Islands. The port is located on the northern side of Guadalcanal and deals largely with imports of consumer goods and machinery. For exports, the port is responsible for delivering copra, palm oil, fish and timber to international markets. Every year, around 190 vessels arrive at the port, and the majority of these are cargo vessels or tankers. As the main port for the Solomon Islands, SIPA has carried out works to ensure that the roadways around the port can maintain the delivery of cargo through the port and support the surrounding area. In February, SIPA helped deliver vital road upgrades around the Honiara port, focused on the Commonwealth Street entrance, and extended through the International Port Terminal, Yacht Club Mbokona bay Road and the entire Domestic Terminal area. The refurbishment was fully funded by SIPA and was completed by China Railway Construction Engineering Group.

However, one of the most significant new developments for Honiara is the development of the Millennium Terminal. In December 2024, SIPA opened the Millennium Terminal, which is the largest domestic seaport terminal in the South Pacific. The facility is a key milestone in the nation’s development, delivering a state-of-the-art terminal designed to cater to passengers and business. The terminal encompasses a three-story seaport terminal, offering amenities to passengers and is designed to improve efficiency and passenger service in the region. Thus, the Millennium Terminal is the largest of its kind in the region and is a beacon of growth and innovation, designed to bring enhanced connectivity for the people of the Solomon Islands and beyond.

The other major port for the Solomon Islands is Noro Port, located on a group of islands known as the New Georgia Islands, which are just southwest of the Solomon Islands Group. The port, under the management of SIPA, handled primarily copra and fish commodities; however, there is only 1 berthing wharf for all shipping vessels, whether travelling along domestic or international routes, and no designated wharf for landing craft. The Noro Port is vital to the Solomon Islands’ fishing and logging industries, whilst being a key asset to the Solomon Islands’ maritime infrastructure.

A Strategic Maritime Hub

SEAMLESS SHIPPING. SMART LOGISTICS. GLOBAL REACH.

For all your shipping and logistical needs- GS Agencies got you covered on time - every time

Port Agency Services

We handle it all — vessel coordination & communication, customs & Immigration clearance, pilotage, cargo supervision and other husbandry services for all types of vessels — commercial ships, luxury yachts, cruise liners, and special-purpose vessels. We ensure efficient port operations and quick turnaround of vessels calling our ports.

Cargo & Freight Forwarding

Air, sea, or land — we move your cargo effortlessly to and from the Solomon Islands with trusted global partners. From LCL/FCL shipments to breakbulk and air freight, we deliver tailored, cost-effective solutions.

Landside Logistics & Warehousing

Efficient delivery from port to point of sale. We offer trucking, warehousing, 6PL logistics, e-commerce fulfillment, and reverse logistics — keeping your supply chain running at peak performance.

Your Cargo, Our Commitment.

From pharmaceuticals to industrial and project cargo, we ensure safe, timely, and professional delivery — every single time.

Solomon Islands Port Authority

Over the years, various refurbishment works have been undertaken to help maintain the port and its role in developing the Solomon Islands maritime industry. A key development was outlined in 2024, when SIPA introduced a new terminal operating system at Noro, designed to enhance port operation efficiency and improve the overall efficiency of service delivery. The ‘OCTOPI’ system was implemented at both the Noro and Honiara ports, following months of rigorous preparation and training delivered in collaboration with SIPA staff and key stakeholders. The system is designed to optimise port terminal operations by ensuring the container movements are processed in real time, which will improve the overall management of cargo and vessels. This more detailed view of cargo and vessel movements allows the ports to provide enhanced container handling services, and in the process speed up turnaround times to help position the port as a competitive hub for global shipping.

Speaking on the launch of the new system. Mr Ellison Pade, SIPAS’s Chief Information Officer and Manager of Special Projects, outlines that “We are proud to be the first Port in the region to implement and use this system, which is also a modern and latest system designed for medium-sized port terminals, which suits us well”. Pade continues, “This is a significant investment by SIPA, which puts the Port of Honiara and Noro fast forward into the future in terms of Port Operation efficiency and online container movement processing, which I trust will certainly support the ongoing development expansion and growth of the Port”. Pade’s comments highlight just how valuable the development of such a system is in enhancing the port operation of both the Port of Noro and Honiara to allow them to develop the ports as key shipping hubs supported by the top technology for optimised shipping movements.

In August, SIPA participated in the 47th Pacific Maritime Transport Alliance (PMTA) Conference, which brings together port stakeholders from across the region to discuss the shared challenges facing the sector and to find ways to improve these. CEO of SIPA, Georgia Rausi, was a key panellist at the opening session of the meeting, highlighting SIPA’s effort to address the challenges of the Solomon Islands’ ageing port infrastructure and the role of digitalisation and efficiency improvements for the ports. Rausi highlighted the importance of such events for PMTA; “This conference was an important platform for us to not only share our progress, but also to learn from the experiences of our regional partners. Collaboration is key to building stronger, more resilient Pacific ports that can withstand global challenges and drive economic growth for our island nations.” Rausi’s comments solidify the unifying role of SIPA in enhancing the role of the ports across the Solomon Islands, whilst working alongside key stakeholders of the Pacific maritime sector to deliver the entire region as a hub for global trade.

Overall, SIPA is a vital authority body working across the Solomon Islands to develop the ports of Honiara and Noro into hubs for global maritime development. With each port experiencing vital upgrades in recent years, from physical infrastructure to digital systems, SIPA has been able to position the port of the Solomon Islands as a key gateway from the Pacific region to the world. Therefore, in its mission to develop and promote the Solomon Islands as a premier hub for port and maritime activities in the heart of the South Pacific, SIPA has been largely successful with its delivery of world-class services in logistics, shipping and port management.

Seatrium Limited

With over 60 years of experience in the energy and marine design and construction sector, Seatrium Limited (Seatrium) delivers innovative engineering solutions that span across the development of offshore platforms, rigs, floating vessels, and specialised vessels, as well as in its delivery of repair, upgrading and conversion services. With these extensive solution offerings, Seatrium serves the maritime and oil and gas industries well, positioning itself as a premier global player offering solutions that are underpinned by the company’s commitment to high standards, safety, sustainability and performance. With such a pivotal reputation within the energy and maritime sectors, Seatrium is now a leading engineering company operating across the world.

The Seatrium we know today was formed when Sembcorp Marine and Keppel Offshore & Marine, two heavyweights in the engineering sector, came together to form a single group that would harness both companies’ extensive expertise and knowledge in the industry. Together, these companies hoped to deliver leading solutions that could better serve their customers and stakeholders by leveraging the synergies between the two companies. Thus, Seatrium was formed in 2023, delivering high-quality and high-performance engineering solutions that are purpose-built to meet its customers’ needs. This innovative approach ensures that Seatrium can continue to work with its clients to develop offshore and maritime solutions that meet their specific needs, enhancing global energy and maritime sectors, whilst solidifying Seatrium’s place as a leading engineering company across the world.

Today, Seatrium’s operations span across the world with the company operating shipyards, engineering centres and technology facilities in places such as Singapore, Brazil, China, India, Indonesia, Japan, Malaysia, the Philippines, Norway, Saudi Arabia, and the United Arab Emirates, the United Kingdom and the United States of America. Across these hubs of operations, Seatrium is set on delivering vital solutions that explore new spaces, technologies and applications even under the most challenging of circumstances. With innovation at the heart of its development, Seatrium’s key business segments include oil and gas new builds and conversions, offshore renewables, repairs and upgrades, and new energies, with a growing focus on sustainability.

For the oil and gas sector, Seatrium delivers complex rigs and turnkey solutions, which are designed to harness the global network to deliver vital energy developments. Its products include the new builds and conversions for Floating Storage and Offloading (FSO) units, Floating Production and Storage (FPSO) Units, Floating Drilling, Production, Storage and Offloading (FDPSO) units, and Mobile Offshore Production Units (MOPUs). In addition to this, Seatrium also delivers gas terminals, Floating Liquefied Natural Gas (FLNG) units, Floating Storage Regasification Unit (FSRU) and Gravifloat solutions, as well as Offshore Oil and Gas Fixed Platforms.

Your One-Stop Solution for Advanced Protection Needs

At Best Technology, we are passionate about innovation and committed to safeguarding life, assets, and the environment. With years of expertise, we’ve emerged as leaders in providing cutting-edge protective solutions.

PROUD SUPPLIERS OF ANCLOZ PRODUCTS:

Ancloz Armourflex: Flexible, removable Passive Fire Protection (PFP) Jackets

Ancloz Androflex: Flexible insulation covers for superior thermal performance

Ancloz Audioflex: Flexible acoustic insulation covers for noise reduction

Designed to protect ESDVs, flanges, and other critical components on FPSOs and industrial sites.

Why

Best Technology Pte Ltd?

Removable: Easy maintenance with hassle-free removal and reinstallation.

Lightweight & Intuitive: Simplified installation, reducing downtime.

Customisable: Tailored to exact site requirements and project needs.

Service & Quality: We pay attention to everything - our product, customers, engineering

CERTIFIED BY

DELIVERING BROAD SPECTRUM OF LNG SOLUTIONS

SSB Cryogenic Services delivers specialized marine and LNG solutions with precision and reliability. From N2 purging operations and Non-Destructive Testing to turnkey LNG project management, our expertise ensures vital operations run safely. Trusted since 2002 for LNG membrane carrier NDT services, we continue to support the region’s expanding LNG fleet with proven skill and commitment.

Backed by SSB Cryogenic Equipment, established in 1996, we operate the largest fleet of T-75 ISO tanks in Southeast Asia, providing complete cryogenic logistics solutions - from ISO tank leasing and maintenance to bulk liquid supply for the gas, marine, and offshore sectors.

SSB Cryogenic Services – Excellence in Service. Leadership in Innovation. Your Partner in Cryogenic, Marine & LNG Solutions

Engineering Excellence

Seatrium has already shown its expertise in this field, with the development of Shell Vito RPF (Regional Production Facility), a deep-water floating production unit that is delivering oil and gas in the Gulf of Mexico. The unit was delivered in late 2021 and is a compact and efficient solution that incorporates advanced technology. Shell Vito RPF was one of the first of two new build FPUs Seatrium has delivered and will provide a great model for future compact, efficient FPU developments within the deep-water sector.

In July, Seatrium further cemented its place as a leading FPSO provider across the world with the delivery of PETROBRAS 78 (P-78) to Brazil’s national oil company, Petróleo Brasileiro S.A. (Petrobras). P-78 delivers a production capacity of 180,000 barrels of oil per day (bopd), 7.2 cubic metres (mcbm) of gas per day, and provides storage capacity for 2 million barrels of oil. The FPSO will be deployed across the Búzios Field, which is one of the most prolific oil and gas deposits offshore Brazil, providing essential oil and gas production for Brazil’s energy sector. P-78 ranks among the largest in the global operating fleet of FPSOs, highlighting Seatrium’s engineering expertise and innovation in delivering the vessel

SSB Cryogenic Services Pte Ltd Precision In Every Test

Delivering reliable cryogenic and marine solutions for the global LNG industry.

SSB Cryogenic Services Pte Ltd (SSBCSPL) specialises in cryogenic and marine solutions, offering Non-Destructive Testing (NDT) for LNG vessels, Nitrogen Purging operations, and LNG project support. Since its inception, the company has completed over 280 onshore and offshore purging and coolingdown operations and conducted NDT on more than 300 LNG carriers worldwide.

SSBCSPL is the first Singapore company certified by Gaztransport & Technigaz (GTT) to conduct Global Testing for LNG membrane vessels. Supported by a skilled in-house engineering team and certified by GTT to perform testing in accordance with its methodologies, the company ensures the highest standards of safety and reliability.

OUR EXPERTISE INCLUDES:

• Global Test

• Secondary Barrier Tightness Test (SBTT)

• Helium Leak Test

• Acoustic Emission Test

• Vacuum Box Test

• Dye Penetrant Test

• Thermal Assessment of Membrane Integrity (TAMI) – in partnership with Actemium

SSBCSPL is also capable of performing Global Test and SBTT for Cargo Containment Systems in gassed-up offshore conditions.

BEYOND TESTING:

The company provides cryogenic bulk liquid supply and ISO tank leasing services, supporting industrial and marine operations with products such as LIN, LOX, LAR, CO2, Ethylene, Helium, Isopentane, Ammonia, Refrigerants and more.

SSBCSPL continues to advance precision, safety, and performance across the global LNG and cryogenic sectors, working with partners and adopting new technologies to strengthen its capabilities and deliver excellence across all projects.

swordtek.com.sg

With software, you can automate documentation to save time, lower risks, and quickly analyze data to make better decisions.

Calibration data is your most valuable asset and with calibration software you can ensure the quality and integrity of the data that your decisions will be based on.

Beamex has over 50 years of experience in developing and delivering calibration technology and expertise. Our world-leading experts and accredited calibration laboratories are here to support you.

Engineering Excellence

to support the energy sectors across the world. In fact, Seatrium has previously delivered FPUs, FPSOs, FSRUs, drill rigs and accommodation vessels to Brazil’s energy sector already, highlighting its robust relationship with the country as a leading engineering solution provider.

Another key sector of Seatrium’s business is focused on offshore renewables and delivering new energy. For this, the company delivers turnkey solutions including fixed platforms, offshore wind and new energy solutions that focus on being cost-effective and highly adaptable, whilst also meeting the highest of technical specifications for global clients. Seatrium delivers offshore wind farm fixed platforms, including High Voltage Direct Current (HVDC) converter stations, High Voltage Alternating Current (HVAC) substations and wind turbine foundations. In addition to this, Seatrium is also focused on delivering Wind Turbine Installation Vessels (WTIVs), Floating Offshore Wind Turbines (FOWTs) and Floating Wind-HVDC and HVAC stations. This focus on delivering engineering solutions for the offshore renewables and new energies sector highlights Seatrium’s commitment to delivering

designs that are helping customers across the world to meet their sustainability goals, and in the process, solidifying Seatrium’s role as a key provider of solutions that are designed with sustainability and emission reduction in mind.

Aside from its role in the offshore energy sector, Seatrium also provide specialised shipbuilding services to deliver high-performance specialised vessels that are designed with the global energy transition and decarbonisation in mind. These vessels are ‘future-proofed’ utilising Seatrium’s award-winning, high-performance and specialised expertise in vessel construction to deliver vessels that meet the highest of technical specifications for clients across the globe, both for today and for the future. However, alongside its development of new vessels, Seatrium is also passionate about repairing and upgrading existing vessels. For this, the company has developed strong relationships with its clients to repair, refurbish, retrofit and extend the life of existing vessels, including FPSOs, FSOs and FSU units. This focus on refurbishment and repairs to existing vessels helps to promote sustainability by utilising existing vessels rather

Seatrium Limited

than developing brand new ones. Ultimately, this helps to extend the lives of vessels already in operation or give them a new purpose to limit the necessity for new vessels to be made to support the planet, whilst saving its customers both money and resources.

In August, Seatrium signed a Letter of Intent (LOI) with Karpowership for the development of 4 New Generation Powerships, with the adoption of two additional units. Karpowership will deliver the hulls and key equipment for the powerships, where Seatrium will complete the bulk of the mechanical and electrical equipment integration, mechanical completion and pre-commissioning work. The agreement also outlines the conversion, life extension and repairs to three existing LNG carriers to deliver them as FSRUs. The LOI marks a milestone agreement between Seatrium and Karpowership and deepens the strategic partnership between the two towards delivering more sustainable, mobile and scalable energy solutions for the future.

Alvin Gan, Executive Vice President of Repairs and Upgrades at Seatrium, outlined the following announcement: “This LOI marks a pivotal step in our journey to build a global franchise in floating power infrastructure. Our successful collaboration with Karpowership goes beyond FSRU conversions – its about enabling energy access through innovative maritime platforms. With four FSRUs delivered, a fifth due later this months, and two more underway, we are proud to be a long-term trusted partner in delivering greener energy and sustainable solutions; through a variety of innovative solutions in new generation powerships, FLNGs, floating battery, floating data centres and water de-salination vessels. These projects demonstrate our engineering excellence

and our commitment to supporting the energy transition”. Gan’s comments highlight just how valuable this LOI is in strengthening Seatrium’s position as a leading engineering and development company for the energy sector. By working with other leaders in the maritime construction and engineering sector, such as Karpowership, the two can leverage their expertise to deliver more sustainable, efficient and reliable power ships for the future of energy development.

Across Seatrium’s operations, there is a primary focus on delivering engineering expertise that

can harness the energy and maritime sector, whilst working to do this in the most sustainable way possible. With sustainability taken into consideration across every single development or redevelopment, Seatrium can play a valuable role in helping its customers deliver the vital resources needed for operations, whilst meeting global sustainability goals. With a plethora of projects and developments under the company’s belt, it’s no surprise that Seatrium is now a leader in the global offshore, marine and energy sectors, focused on engineering for the future.

Hitachi Construction Machinery Co.,

On a mission to deliver innovative products, services and solutions across the construction sector, Hitachi Construction Machinery Co., Ltd. (Hitachi) is a globally expanding construction machinery manufacturer. The construction industry is vital to global infrastructure, with the sector responsible for building roads, houses and laying down waterpipes that are vital for supporting societal development. Therefore, the construction sector relies on innovative and efficient machinery that can help meet these needs across the globe. However, as the world moves towards a more sustainable future, Hitachi is focused on ensuring its products have a longer life cycle and are built with leading technology innovations to contribute towards a more sustainable future for the construction machinery manufacturing sector.

As a subsidiary of the global Hitachi Ltd., Hitachi is focused on bringing a leading worldwide manufacturer of construction equipment. Its role spans across the globe from its head office in Tokyo, to Europe, North America and South America. Today, Hitachi has roughly to 25,000 employees operating across the world who are key to bringing vital development, manufacturing, sales and service operations across the heavy machinery industry. The Hitachi we know today, began over 70 years ago following the start of its mass production of its cable operated shovels in the 1950s. This development was born from a mission to make construction work more efficient across Japan through the mechanisation of its construction machinery, to help rebuild the country and revitalise the economy. Therefore, Hitachi developed and delivered the first capable operated shovel using entirely domestic technology. This innovative spirit remains with the company today, and this is why the Hitachi brand remains a leader across the construction and mining machinery manufacturing sector.

Today, Hitachi’s machinery spans from mini excavators, mini wheel loaders, hydraulic excavators, wheel loads, compaction equipment, large hydraulic excavators, ultra large hydraulic excavators and rigid dump trucks.

Across these products, Hitachi is passionate about delivery top of the line manufacturing supported by leading solutions which maximise the value of its products. These solutions include its Autonomous Haulage System (AHS) which aims to address the challenge of safety across global mining and construction sites. AHS allows machinery to be safer, more productive and reduce costs over time by utilising Hitachi’s 24/7 system and field communication support that is integrated into its product lines. Therefore, Hitachi machinery can provide customers with low risk, staged implementation machinery that can operate efficiently alongside its customers’ existing fleet. AHS is then paired with Hitachi’s Fleet Management System (FMS) which is provided by Wenco International Mining Systems Ltd. under Hitachi. This solution ensures the real-time monitoring of each piece of machinery to enhance fleet management and utilise IoT platforms to optimise mining and construction processes, whilst utilising a wide range of data acquired through the integration of FMS across its product lines.

For construction machinery specifically, Hitachi has a Construction Machinery Solution Linage, which is an ICT/IoT system to help improve the safety and productivity of a product, whilst reducing its costs over its life cycle. It achieves this by bringing together the broad knowledge and advanced technologies from across Hitachi’s expertise, to deliver construction machinery that is designed to deliver results for its customers. Hitachi Construction Machinery ICT Solution is designed to fully support all ICT aspects of construction operations, taking projects from initial construction surveys to as-built data drive operations. A key development for this is the ICT Hydraulic Excavator ZX200X-7 which has been made with safety and construction efficiency in mind, to ensure that no matter the skill level of the operator, it will utilise its ICT system to deliver highly accurate, efficient and productive work every time.

To ensure the operational efficiency of machinery, Hitachi has developed ConSite, a solution which monitors the operational status of machinery and its alarms through operations reports. These reports and notifying alarms, ensure

The Future of Construction Machinery

that machinery can continue to run optimally and meet it customers needs. The entire ConSite report, is designed to keep customers continually informed about the operational status of a machine, which can then be easily accessed with a smart phone. In fact, ConSite has the ConSite app which helps customers oversee daily inspection and help with both owned and rental machinery. Then Hitachi operates ConSite Air, which is a remote service helping Hitachi keep an eye on its customers machinery remotely, to more effectively meets customers’ needs and deliver operational support. All of these solutions highlight Hitachi’s

WE ARE YOUR ONE STOP SOLUTION FOR PRECISION SHEET METAL PARTS AND ASSEMBLIES

Manufacture sheet metal parts and assemblies for Air Compressors, Earth Moving machines, Image and video processing machines, Power Generators, Medical equipment, Architectural signages and furniture, Banking Kiosks and ATM’s and Machine Tool Guardings etc.

Hitachi Construction Machinery Co., Ltd.

Edbro are proud to work in partnership with Hitachi supplying cylinders for some of the toughest mining trucks in the world.

The world’s toughest mining trucks demand the world’s toughest cylinders. Edbro, a UK based cylinder manufacturer part of the Orsan group of companies, have been a key partner to Hitachi on that front for more than 30 years.

Edbro and Orsan are proud to work in partnership with Hitachi supplying cylinders for some of the toughest mining trucks in the world.

Hitachi works with key suppliers such as Edbro to ensure ongoing product development of the hydraulic cylinders used on its mining trucks allow the Hitachi dump truck range to meet the toughest challenges.

Long term partnerships lead to market leading products, Edbro have supplied Hitachi dump truck cylinders for more than 30 years. Ongoing development and field experience has refined the designs and material used to provide the highest levels of reliability.

goal to deliver machinery products that focused on delivering safety, efficiency, management and optimised performance to keep project sites running smoothly.

As Hitachi moves towards the future, it has set out a Bulidng the Future 2025 plan, which began in April 2023. The plan outlines how Hitachi wants to grow as a true solutions partner, and over the last 2 years this has been the foundation for the company’s machinery and solution development. These developments are outlined in the plan to be innovative and customer-oriented, and through this adding to the expansion of its operations. A key part of this has been in Hitachi’s value chain business which consists of parts and services, remanufacturing of used parts and machinery and the rental of equipment. Plus, with the evergrowing issue of climate change, Hitachi has been set on expanding the life cycle of its products and contributing towards a more safe and sustainable society by extending the life of its machinery through remanufacturing, and the ability to rent machinery rather than purchase them. This

World class cylinders for world class trucks

prevents unnecessary machinery from going to waste, enhancing the performance of mahcinery whilst in operation, and then when parts go wrong, remanufacturing to extend the life of the machinery to reduce over production and in turn help keep its customers costs low.

In April, Hitachi announced that it had launched LANDCROS Connect Insight Solution, which aims to analyse the operational data of mining machinery collected in near-real time to help customers increase the efficiency of their operations. The solutions build on Hitachi’s experience and then utilises real-time data to support further detailed analysis backed by data scientists, mechanical engineers and other consultants in the mining field, to assist customers and dealers in proposals to help maximise the performance of its machinery.

LANDCROS Connect Insight, will allow Hitachi to build a digital platform that is capable of centrally managing and interlinking data with customers, group companies and collaborating business partners to deliver solutions that will continue to optimize its machinery, particularly in the mining sector.

The Future of Construction Machinery

Across Hitachi’s manufacturing developments, there is a real passion for the planet in delivering the vital machinery and tools to make infrastructural developments possible, all whilst achieving these in the most sustainable way possible. With a range of leading solutions under its belt that help to enhance its machinery and almost 70 years of expertise in the construction sector, Hitachi construction is delivering vital machinery that can deliver the future of the construction sector. We look forward to seeing how Hitachi will continue to expand its innovative solutions to optimise its machinery offerings, and deliver products that meet the needs of today without compromising the world of the future.

Mr. Ashok Punjani – Director +91 9350186940 admin@carrierengineers.com ak.punjani@yahoo.com www.carrierengineers.com

MANUFACTURERS OF

Thai International Freight Forwarders Association

On a mission to deliver Thailand as a key logistics hub operating across Asia, the Thai International Freight Forwarder Association (TIFFA) brings together the key players within the country’s freight forwarding industry under one governing body to build regional growth and strengthen the country’s role as a cargo shipping partner of choice. With operations spanning more than 35 years, TIFFA focuses on networking, education and industry development to ensure that every member operating under the association meets the highest standards in the freight forwarding sector to deliver Thailand as a leading logistics hub operating across the Association of Southeast Asian Nations (ASEAN).

TIFFA was established in March 1987 by a group of freight forwarders operating across the country who saw the need for a fixed body that could help deliver more regulation, structure and reliability for the country’s freight forwarding industry. This need for a governing body was so crucial, as previous to the establishment of TIFFA, Thailand had seen a vast surge in cargo imports and exports across the country; however, the freight forwarding activities were not well recognised and instead were viewed as a kind of brokerage service from the perspective of the government and private sectors. Therefore, the original members of the association submitted the proposal for a freight forwarders association to the Board of Trade in Thailand (BoT), which was fully supported and then registered with the Ministry of Commerce. After this registration, TIFFA was officially inaugurated in March 1987 and saw an increase in members joining the association over the coming years.

The establishment of TIFFA was vital for many industries across Thailand, including the electronics, agriculture, furniture, and manufacturing sectors, which all relied heavily on the reliable movement of goods both across Thailand and international markets for the country’s economy. However, one of the most vital industries that TIFFA benefited is the

automotive industry of Thailand, which saw many car parts arriving in the country from overseas, which would then be assembled in Thailand and sent throughout the country via freight links to ports for international shipping. Therefore, as the automotive industry was so lucrative for Thailand, the founding freight forwarding companies of TIFFA needed a way to ensure that the movement of such valuable cargo was supported by the same regulatory standards seen across the world, to ensure its exports remained competitive in global markets.

Today, TIFFA is home to over 250 members, ranging from ordinary to association members. TIFFA members all have the same combined goal of developing the country’s freight forwarding industry to keep cargo moving throughout Thailand and onto end markets through seamless supply chains. Since its establishment, TIFFA has continued to benefit Thailand, providing essential structure, regulation and support to its members. Ordinary members gain access to utilisation of the TIFFA logo to signify their role with the association, as well as things such as

Thai International Freight Forwarders Association

WCAworld

With over 12,800 member offices in 196 countries, WCAworld is the largest network of independent freight forwarders. Our members work together across borders and industries, sharing resources, expertise, and opportunities. It’s not just about moving cargo, it’s about building lasting partnerships. In WCAworld, independence doesn’t mean going it alone. It means going further, together.

www.wcaworld.com

group liability insurance, logistics news, networking, training and education. For TIFFA, education and training are some of the most valuable aspects of its membership, because through these, TIFFA can help shape the future of Thailand’s freight forwarding industry.

To support education and training across the Association, TIFFA has established the International Transport and Business Academic Institute. The school provides essential education on both practical and theoretical training, which is vital to helping its members grow within both the local and global freight forwarding industry. Thus, by delivering expertise, education and knowledge across its members, TIFFFA can create a more experienced workforce for the country that is ready to transform the future of Thailand’s freight forwarding industry.

In recent years, TIFFA introduced the TIFFA MARK certification, which outlines a standard assessment to develop the quality of its member services by assessing logistics business quality standards. The role of the TIFFA MARK is to help raise

Uniting Thailand’s Freight Forwarders

the quality of management of international freight forwarding, set a foundation for freight forwarding to operate on both locally and internationally, and to help promote recognition from both government and private sectors across the world of a member’s international freight forwarding business. Members with this certification highlight their expertise in the freight forwarding space, and so these businesses gain international recognition for their excellence within the sector.

When we last covered TIFFA, we highlighted its work across the Inland Container Depot (ICD) Lat Krabang, where the Association had been granted a 10-year concession from the State Railway of Thailand to operate and manage the facility. The ICD is one of the most active terminals in Bangkok, and so TIFFA’s role in managing the facility is pivotal for the country’s freight forwarding operation, providing its members with access to international markets via the ICD’s integrated service offerings. In recent months, TIFFA launched a new ICD station in the Lat Krabang area named the TIFFA Logistics Centre. The Logistics Centre will help TIFFA enhance its network and offer more options for connecting freight transport between the central region and Thailand’s major container port.

The introduction of the new TIFFA Logistics Centre follows the expansion of manufacturing

sectors across the country, with the introduction of the Eastern Economic Corridor (EEC) project. The data from this project highlighted that the central and nearby regions were vital for importing and exporting, and so the development of the new Logistics Centre would meet these needs. The new Logistics Centre will help TIFFA deliver even greater opportunities for its members to serve international and local markets, operating as a new strategic hub for multimodal transport operating between Thailand and neighbouring countries. Equipped with comprehensive services, the TIFFA Logistics Centre has the capacity to handle up to 25,000 Twentyequivalent units (TEUs) per month or 300,000 TEUs per year.

Across TIFFA’s operations, there is a real focus on enhancing the country’s freight forwarding business to deliver it as a vital hub serving marketing across the ASEAN and beyond. With the development of education, the TIFFA MARK certification, and the introduction of new ICD facilities, TIFFA is continually striving to provide its members, and in turn, the country’s freight forwarding industry, with the vital tools and resources to thrive. We look forward to seeing how TIFFA will continue to expand its offering across the country, to further position the Association and its members as a leading logistics hub.

Newmont Corporation Australia

Home to substantial gold reserves, Australia is the third-largest gold producer in the world with a long history in the gold mining sector. For this reason, Newmont Corporation, the world’s leading gold company, has been operating within the Australia’s gold mining sector since 2002. Now with over 20 years of experience within Australia’s mining sector, the bulk of its operations here can be broken down into three distinctive mine operations: Boddington, Cadia, and Tanami. Across these mines, Newmont utilises the company’s over a century of expertise in the global mining sector, to deliver vital gold and metal resources for the Australian metals market.

Some of the most lucrative deposits of gold in Australia are found in the West, where there are a plethora of greenstone belts. Here, Newmont operates the Boddington mine, the largest gold mine in the country based on production, within the Saddleback Greenstone Belt. The mine is a large-scale gold and copper surface mine just 30km from Perth. Commercial production at the mine began in 2009, with the operation reaching 1 million ounces of gold by March 2011. Since it began production, the mine has consistently produced more than 800,000 gold equivalent ounces (GEOs) a year. By 2022, the mine had reached more than 1 million GEOs for the first time in its history, largely thanks to its fully autonomous fleet, which operates within the mine. The fleet, which Newmont invested $150 million in as part of its Autonomous Haulage Project, works across the south pit, which is currently the deepest open pit in the world to deploy such automation technology. However, it is this focus on technological innovation that has long made Newmont a heavyweight in the mining sector.

The development of automation across Newmont’s fleet has significantly reduced the fleet size at Boddington from 46 trucks to just 41 automated vehicles, allowing for a non-segregated haulage network with shorter and more optimised haulage distances. The introduction of automation was part of Newmont’s wider Full Potential program which is designed to encourage new ways of thinking that could push its mines to deliver greater value utilising best practices. The program set out to reduce costs whilst generating productivity improvements, and since 2013, it has generated more than $700 million in value for the mine. Through the program, Newmont has been able to push beyond Boddington’s nameplate capacity of 35 metric tonnes and has processed more than 40 million metric tons whilst adding another 2 years to the mine life. Alongside its significant productivity output, the automated system greatly improves safety and productivity at the mine, making it both an efficient and safety-focused mine delivering significant resources for the future.

The Cadia Mine is another of Australia’s largest gold mining operations and encompasses an underground mine producing both copper and gold. The mine has ore reserves of 15 million ounces (Moz) of gold and 2.6 mega tons (Mt) of copper. The mine site includes the Cadia East Underground Mine, as well as the Cadia Hill Pit Tailing Storage Facility and the Ridgeway Underground Mine, but the latter two are currently on current in care and maintenance. Mining in Cadia East commenced commercial production in 2013, and

PARTS ENGINEERED TO PERFORM IN HARDROCK MINING

SURFACE PARTS SPOTLIGHT

MASPRO is a leading provider of cutting-edge engineering solutions for underground and surface operations in the hard rock mining industry. What sets us apart is our unwavering commitment to optimising the parts we produce to increase safety and reliability. Our team works closely with customers to ensure that their machinery performs at its peak, even in the harshest mining conditions. If you’re looking to drill deeper, move more ore, and push your equipment to the limits while maintaining the highest standards of safety and operational reliability, talk to the MASPRO team today!

UNDERGROUND PARTS SPOTLIGHT

Newmont Corporation Australia

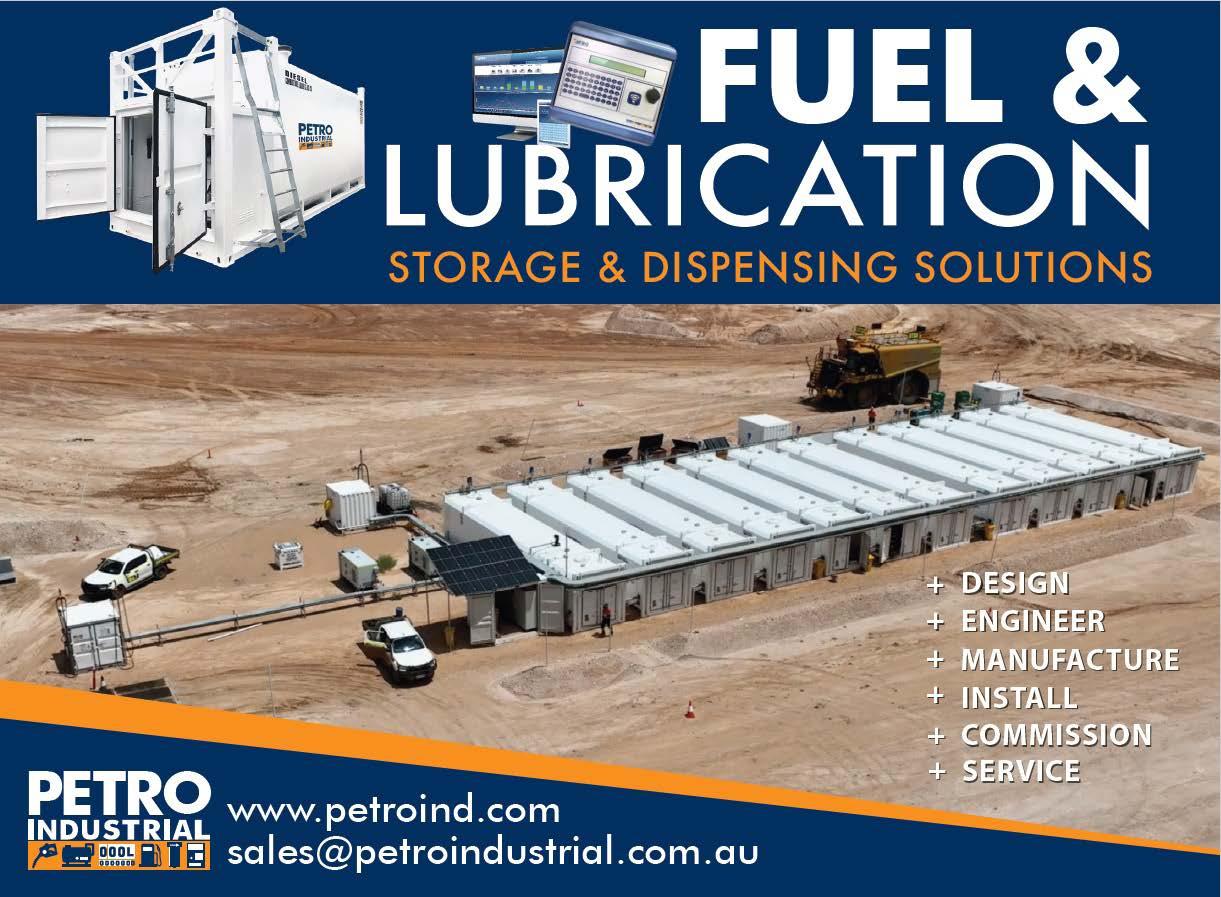

PETRO Industrial – Proven Fuel & Lubrication Expertise

PETRO Industrial delivers world-class fuel farm and lubrication storage & dispensing solutions, engineered for the demands of major mining operations. From design and manufacture to installation, commissioning, and ongoing service, we provide turnkey systems backed by advanced fuel management and secure cloudbased data storage.

Our engineering capability ensures reliability, compliance, and efficiency in every project. Whether buying outright or hiring, PETRO offers flexible options tailored to site requirements. Trusted in the mining industry.

PETRO is your partner in powering productivity.

utilises panel caving mining techniques to access one of the largest gold and copper deposits in the world. Gold is produced in the form of gold doré bars via a gravity circuit and gold-rich copper concentrates from a flotation circuit. In the 2023 fiscal year, Cadia produced 597 thousand ounces (Koz) of gold at an allin sustaining cost of $45 per ounce.

Developing the Cadia mine has been of high importance to Newmont in recent years, with the Panel Cave (PC) 1-2 Feasibility Study approved for execution in November 2022. The project’s PC1 and PC2 are currently being developed to recover a substantial portion of Cadia’s ore reserves, with the first ore from PC 2-3 already delivered. The entire PC1-2 project aims to recover approximately 5.9 million ounces of gold services and 2.9 billion pounds of copper services. This development is expected to continue into the second half of 2026 to deliver significant resources for Newmont from the Cadia mine.

Image credit: PETRO Industrial

Creating Value in Australia’s Mining Industry

One of the central missions of Newmont Corporation is to create value and improve lives through sustainable and responsible mining. This focus can be clearly seen at the Cadia Mine, as it was awarded both The Copper Mark and The Molybdenum Mark in October 2024. These certifications are awarded to companies to recognise responsible production. For Newmont, this is the first mine site for the company that has received the award. The certification is awarded based on an operation meeting more than 30 criteria in critical areas such as environment, community, human rights, and governance.

Cadia is also the only mine in Australia producing molybdenum, and so is the only mine in the country to be awarded The Molybdenum Mark. In the announcement of the awarding to Cadia, Suzy Retallack, Newmont Chief Safety and Sustainability Officer, outlined, “We take great pride in being at the forefront of the copper industry with The Copper mark, which highlights our dedication to responsible production and transparency. Retallack continues, “This means our global customers can now choose to source copper concentrate from an independently evaluated mine that meets the highest standards in environmental, social, and governance practices, responding to the increasing demand for sustainable supply chains”. Retallack’s comments highlight just how vital this mark and The Molybdenum Mark are for the competitiveness of Newmont’s copper and molybdenum resources for global markets. Customers across the world can source these resources from a mine that is known for operating with sustainability and responsibility at the forefront. This makes Cadia’s resources highly valuable for global supply chains and, in turn, develops Australia’s minerals industry.

The final mine operated by Newmont in Australia is the Tanami mine, where the company has been delivering vital gold resources since 2002. The mine is located in the remote Tanami Desert of Australia, within the Aboriginal freehold land that is owned by the Warlpiri people and managed on their behalf by the Central Desert Aboriginal Lands Trust. The mine is in one of the most remote locations in Australia, and so access to Tanami is via a fly-in-flyout basis. The mine began operation more than 20 years ago as an open-pit operation, which over the years has been transformed into one of the largest underground gold mines in Australia, with more than 12 million ounces of gold produced.

Like with the other mines operated by Newmont in Australia, the Tanami mine is undergoing expansion

works to increase the gold production of the mine. Newmont is currently working on the second expansion of Tanami, with investment towards constructing a 1.5-kilometre-deep production shaft. Tanami Expansion 2 aims to increase the average gold production of the mine from roughly 150,000 -200,000 ounces a year to 600,000 ounces per year for the first five years. Whilst expanding the production capacity, the development also hopes to reduce operating costs by around 10%. The main scope of the expansion involves the construction of a headframe and vertical hoisting shaft to a depth of 1,460m to transport people and ore out of the mine.

As part of the expansion, Newmont entered into a strategic alliance with Caterpillar in 2021 to help deliver a fully connected, automated, zerocarbon-emitting, end-to-end mining system. Thus, with this partnership, Newmont can deliver a more technologically advanced mine to optimise production. Newmont’s partnership with Caterpillar aims to develop new battery electric haulage technology for its underground mining, and following the introduction of battery autonomous technology, which will be an industry first for the mine.

Across all three of Newmont’s mine sites in Australia, the company is focused on delivering vital mineral resources in a sustainable and communityfocused way. Newmont is committed to building respectful and mutually beneficial relationships with the communities that surround its operations. By working with local communities, the mines can help deliver long-term economic and social growth. Each mining operation under Newmont has a dedicated community relations team, and through these, Newmont is passionate about maintaining an ongoing dialogue between all stakeholders to ensure positive community growth.

What we can see from Newmont’s operations in Australia is a firm commitment to delivering value through responsible, efficient and communityfocused mining operations. Across Boddington, Cadia and Tanami, there is a keen sense of growth to harness the production of gold and copper for today, whilst delivering the infrastructure and techniques to optimise production for many years to come. With some of the largest mining operations under its portfolio in Australia, Newmont is set to deliver vital resources for the country, supported by its expertise on a global scale, to make its supply chains competitive and mining operations technologically advanced.

MODEC Offshore Production Systems Pte Ltd.

MODEC has been operating as a leading provider of solutions to the floating offshore oil and gas market for more than 50 years. Across this vast history, MODEC has been on a mission to unlock the potential of the ocean and deliver vital resources that will benefit humanity. MODEC achieves this through its delivery of engineering, procurement, construction, and installation (EPCI) services to the offshore sector, supported by innovative technologies which work together to help meet the challenges of the energy sector across the globe. In recent years, Singapore has remained a valuable market for the company’s development, with MODEC Offshore Production Systems (Singapore) Pte Ltd. working to provide valuable support to energy developments across Singapore and the surrounding regions.

Since 1968, the global MODEC Group has been a leader in the floating solutions market for the offshore oil and gas industry. Many of these solutions include Floating Production Storage and Offloading (FPSO) or Floating Storage and Offloading (FSO) vessels, which are essential for supporting the delivery of energy to markets by enabling oil and gas companies worldwide to extract resources from wells and transfer them through pipelines to these vessels, where they can then be distributed across the local region. However, with most wells situated in deep offshore waters, they are often exposed to harsh conditions. Therefore, MODEC is dedicated to providing solutions that address the unique and challenging conditions of its clients’ deposits to supply vital energy, and with it, ensure customer satisfaction.

In Singapore, MODEC Offshore Production Systems is committed to providing EPCI services and, with it, the delivery of FPSOs and other floating production systems. MODEC Offshore Production Systems often works alongside Offshore Frontier Solutions Pte Ltd., a MODEC Group Company, to handle the EPCI aspects, whilst the wider MODEC group offers engineering support for oil and gas extraction and offshore exploration in Singapore. MODEC’s operations through these two subsidiaries bring vital offshore solutions to the energy sector in Singapore, and through this to the wider region.

In fact, in recent months, MODEC Offshore Production Systems announced that it was opening a new execution centre in Kuala Lumpur. The centre will be facilitated by Offshore Frontier Solutions, part of the MODEC Group, who will be responsible for supervising subcontracting detailed engineering activities, whilst overseeing the hull and module construction works. These will be completed at local shipyards, which will help manage offshore installation and commissioning activities. The centre will be the heart of MODEC’s Front-End Engineering Design (FEED), Pre-FEED execution, project proposals, research and development, as well as digital analytics. Through this execution centre, MODEC will be able to deliver innovative and efficient solutions for the benefit of its clients both in Malaysia and across the world.

The first project to be achieved by the Execution Centre will be the FPSO Gato do Mato project. The project will be delivered for Shell Brasil Petróleo Ltda, which awarded the development to MODEC in March. Whilst the final project will be located offshore Brazil, the development and construction of the FPSO will be facilitated by MODEC via the execution centre in Malaysia. Thus, the centre serves as a vital development hub in the heart of Kuala Lumpur, strategically positioned and supported by the necessary facilities to become a key driver of MODEC’s growth across the region. Through the leveraging of MODEC’s skilled workforce across the facility, the company is well-positioned to meet the evolving needs of its clients and the global energy industry.

The development of the Execution Centre in Kuala Lumpur adds to MODEC’s global capability centre, which it developed in Bengaluru in India. MODEC announced in October 2024 that Offshore Frontier Solutions has partnered with Toyo Engineering India Private Limited. The joint venture company, TOTO MODEC OFS India Private Limited (OFS India), will execute the FEED and detailed engineering and provide procurement support for the topsides of FPSO projects among its primary business activities. The Global Capability Centre opened officially in June 2025, and both the capability centre and execution centre highlight MODEC’s growing role across the region to enhance the delivery of energy solutions across the world.

INNOVATION BEHIND EVERY VALVE

Trusted Valve & Piping Solutions for FPSO Projects

Since 2006, Valves & Piping Asia (VPA) has been a leading supplier of highperformance valves, piping products, and engineered components for Offshore/ Onshore & FPSO applications. With a proven track record of over 40,000 valves on major Petrobras projects (FPSO P-Series) 2021-2025, VPA delivers certified, reliable solutions built to withstand extreme offshore conditions.

• API & ISO Certified • Up to 10,000 PSI & ANSI 2500

• Carbon Steel, Stainless Steel, Super Duplex & Inconel Options

• Strategic Partnerships with Top Chinese Manufacturers

MODEC Offshore Production Systems Pte Ltd.

This growing role was highlighted by Soichi Ide, President and CEO of Offshore Frontier Solutions,

“These strategic moves are part of the company’s expansion plan to continue to extend our capability and services to support our global clients. Besides enhancing our global footprint, OFS India and OFS Malaysia allow us to adapt quickly to changing business needs and market demands. They also provide access to a diverse pool of skilled professionals that we can tap into to boost our expertise and innovation”.

Ide’s comments bring into focus the vital and comprehensive role that MODEC can provide to the offshore energy industry, and through such vital developments across Malaysia and India, reinforced Singapore’s role as a leading energy solutions provider.

At present, the global MODEC Group currently has 20 FPSOs and FSOs in operation at offshore fields in places such as West Africa, Asia, Oceania, the Gulf Coast of Mexico, South America, Brazil and the North

Sea. Across these projects, MODEC delivers the best services possible through turnkey solutions that harness the energy potential across the world. By ensuring that its vessels are equipped to manage the often-harsh conditions, MODEC ensures that each project’s life cycle is maximised to deliver significant returns for the customer and the global energy industry in the process.

To remain ahead of its competition, MODEC continues to develop its FPSO and FSO solutions, and in recent years has developed two new types of hulls that are designed to optimise the future of offshore energy development. These vessels bring together MODEC’s best-in-class design and construction technology to deliver top-of-the-line FPSO and FSO projects that will see the next generation of energy production. One particular development of note is the M350™ and the MODEC NOAH™, which will help it take its energy development potential to the next level through their innovative hull designs. However, aside from its development of new hull designs, MODEC also has a key role in converting oil tankers into FPSOs and FSOs. The company has been redeveloping oil tankers for over 40 years and has built a strong reputation within the global market as a leading oil tanker conversion company.

In achieving its delivery of new and redeveloped FPSO and FSO vessels, MODEC relies on its network of shipbuilders and shipyards around the world to fully implement its EPCI works on its projects. Across its global network, MODEC has more than 6000 employees across 15 countries worldwide who help it to achieve its project visions. In addition to this, MODEC also relies on outsourced shipyards and companies that help it achieve its projects using local knowledge and expertise. Through this network, MODEC can maintain its competitive lowprice points and achieve greater flexibility across its operations by building and developing FPSO and FSO vessels utilising its connections on both a local and international scale.

What we can see across MODEC operations, both on a global scale and specifically in Singapore, is that the delivery of high-quality and innovative floating solutions is allowing the company to position itself as a leading offshore floating solutions provider for the oil and gas industry. Through the execution of facilities, cutting-edge technology and innovative FPSO/FSO vessels, MODEC is set on delivering a world where the oceans’ potential is harnessed to support humanity, aided by global subsidiaries that are vital in expanding its network across the world.

WHEN FIRE STRIKES, SECONDS MATTER

Malaysia Rail Industry Corporation

The railway network of Malaysia is vital to the country’s infrastructure, helping both people and materials move across the country and beyond to adjoining networks in neighbouring countries. With this network being vital to Malaysia’s interconnectivity, the need to bring together vital stakeholders and governmental figures has long been essential to maintain the railway network so it can remain efficient, safe and sustainable. Therefore, the Malaysia Rail Industry Corporation (MARIC) was formed in 2017 to contribute to the development of engineering across the Malaysian railway system through the support, unification and network provided by its members.

MARIC began operations in 2017 following the formation of the incorporated association to provide membership to all companies operating across Malaysia’s railway systems engineering and associated works sector. MARIC currently has 60 member companies spanning the country’s railway engineering sector. However, some members also include public transportation companies, communication companies, transitoriented development companies and services, as well as those within the railway infrastructure construction sector. These additional members are vital in helping the core engineering companies to facilitate the development of the country’s railway network. Across the company’s network, there are more than 5,000 personnel who are engaged across all aspects of the railway engineering network from construction, rehabilitation, maintenance, repair and overhaul (MRO), and public-private partnerships (PPP). These members are vital in helping MARIC achieve its goals to deliver a cohesive, developed and comprehensive rail network for the country.

For MARIC, it is particularly focused on engineering clusters, which include Rolling Stone, Signalling Systems, Telecommunication Systems (including SCADA), Power Supply and Distribution Systems (PSDS), Trackwork, Depot Equipment, and Automatic Fare Collection (AFC) systems. These systems are vital to helping MAIRC continue to improve Malaysia’s railway reliability and sustainability. In fact, across these, MAIRC is passionate about developing relationships with local suppliers and vendors to help manage the MRO and construction, rehabilitation, mid-life refurbishments and component supplies for activities in the future pertaining to the rail network.

The central mission of MARIC is to foster collaboration across all levels of the rail supply chain network and, through this collaboration, enhance productivity and deliver great value for the country’s railways. The importance of Malaysia’s

Enhancing Malaysia’s Railway Network

MANUFACTURER FROM CONCEPT TO COMPLETION - PRECISION IN EVERY LAYER

At DK Composites Sdn Bhd, we turn bold visions into reality with cutting-edge technology, advanced engineering, and world-class craftsmanship. Since 1997, we've been at the forefront of highend composite manufacturing, proudly operating from Composites Tech City, Batu Berendam.

From awe-inspiring architectural domes to high-performance marine vessels and next-gen transport solutions, our expertise spans:

• Design, Development & Installation

• Composite Structures – Cladding & Domes

• Marine Composites – Racing Yachts & Power Boats

• Modular Housing

• Rail, Transport & Electric Vehicles

Trusted by clients across Europe, the Middle East, the USA, Asia and Australia, we deliver precision, durability, and innovation — every time.

Malaysia Rail Industry Corporation

network and its local supply chains to enhance the system is outlined by Anthony Loke, Minister of Transport in Malaysia, with his message, “Every rail project presents unique opportunities to further the capacity and capabilities of the local rail industry. Whilst the primary goal is to develop infrastructure and systems that enable efficient rail services, these projects must also serve as a catalyst for advancing innovation, developing talent, and empowering local players”.

Loke also outlines in his message on the MARIC website, “implementing a partnership model between local players and like-minded foreign OEMS will ensure a win-win outcome and help create a sustainable rail industry ecosystem that can effectively support the operations and maintenance of these systems throughout their life cycle”. Loke’s message outlines how the rail industry is behind vital development for Malaysia, and through its collaboration with local and international like-minded companies and governmental figures, MAIRC can deliver these projects for the benefit of Malaysia and its supply chains overall.

A key way that MARIC is sharing its mission to enhance and develop Malaysia’s railway engineering network is through education and networking events. To achieve this, MAIRC hosts seminars, symposiums, exhibitions, familiarisation programs, Export Acceleration Missions (EAMs), and business match operations to grow the company’s network and member sphere. This focus on education and networking was highlighted in March with the announcement of MARIC partnering with the University of Kuala Lumpur.

MARIC and the University signed a Memorandum of Agreement (MoA), which will focus on the Peneraju Skil Plus Professional Rolling Stock Maintenance program at the university, which is aligned with the national workforce development initiatives. It is hoped that through the partnership, the University will provide essential academic and technical training in the knowledge and practical skills needed to maintain and develop the railway sector. Thus, the program will promote the future leaders

Enhancing Malaysia’s Railway Network

of the rail network and bridge the gap between academics and the railway industry. Therefore, the partnership shows MARIC’s investment in the next generation of rail engineering to ensure that the railway will remain the mode of transport of choice across Malaysia.

What we have seen across the operations of MARIC is a firm commitment to investing in the development of Malaysia’s rail engineering sector. The railway engineering industry is so vital to keeping the railway network running smoothly, and so MARIC’s work is invaluable in keeping transportation links and supply chains on track. Therefore, by focusing on networking, education, and unification with other vital stakeholders within the industry, MARIC is able to promote the vital work of the sector and help keep Malaysia’s railways safe, reliable and sustainable. We look forward to seeing MARIC continue work with the government, local stakeholders and international OEMS to deliver a more enhanced rail network for Malaysia.

On a mission to deliver engineering operations to build a more sustainable future, Saipem is a leader in the design, construction and operation of a range of complex infrastructures and plant facilities for the energy sector. Saipem is passionate about overcoming engineering challenges to deliver essential solutions that help move its customers’ operations, and the world to a more sustainable future. Therefore, across its operations, technical innovation remains at the forefront, and it is through this that the company can deliver the most efficient and sustainable engineering solutions possible.

Saipem has been in operation since 1957 when the company delivered its first offshore platform as an independent company in Scarabeo. From this very first platform, Saipem exemplified its expertise in construction and engineering, and it is with this foundation that the company continues to develop today. Over the last 65 years, Saipem has only continued to build its portfolio of engineering and construction projects and now has played a vital role in many projects across the globe. Today, Saipem is a global leader in engineering with operations with its business broken down into 6 central business lines. These business lines include drilling, asset-based services, energy carriers, offshore wind, suitable infrastructure, robotics and industrialised solutions. Throughout its portfolio, Saipem works across every stage of project development, taking these operations from process and structural engineering, all the way to procurement and construction. Then, once constructed, Saipem offers maintenance, modification, and daily operations services which help to keep its customers’ projects running smoothly. Beyond the construction and delivery of such projects, Saipem also provides decommissioning services across plants and

platforms when they are no longer in use. By staying so close to every project, Saipem can ensure that it is delivering the maximum economic return of offshore field development whilst maintaining high levels of safety, reliability and performance.

Saipem employs over 30,000 employees spanning more than 50 countries of operation. Across the world, the company’s operations are often split into various region and country-wide divisions, for example in Singapore where Saipem’s operations are run by Saipem Singapore Pte Ltd. Saipem has been operating in Singapore since 1988 providing the company’s essential engineering services across the country and the surrounding region. Here, the company offer a vast array of services and solutions that help its customers in Southeast Asia design, procure, engineer and construct their energy projects.

Projects in Singapore include the expansion of the Singapore LNG (liquified natural gas) Terminal, which spans 40 hectares on the southernmost tip of Jurong Island. The terminal is vital to Singapore’s energy security and has been operating since

Leading Engineering Services

2013. The facility currently covers two jetties, three 180,000m3 storage tanks, and a further 260,000m3 tank. The terminal is currently responsible for close to half of Singapore’s total natural gas demand for power generation and so its expansion remains vital to supporting the country’s energy development. Saipem was awarded the initial construction agreement and has continued to play a vital role

DISCOVER

Best Technology Pte Ltd.

If you work on an FPSO, petrochemical plants, or any offshore or onshore installation where hydrocarbons flow and temperatures soar, you’ve likely seen our solutions in action.

At Best Technology Pte Ltd, we deliver Ancloz Engineering’s highperformance removable jacketing system - trusted for insulation, passivefire protection, and acoustic insulation on ESDVs, piping, valves, and more.

Our jackets are engineered for rapid removal and reinstallation, giving you fast access for maintenance without sacrificing safety.

Tested to withstand jet fires and hydrocarbon pool fires for up to 120 minutes, and certified by Lloyd’s Register, DNV, and ABS, Ancloz jackets protect your people, your plant, and your uptime.

Removable by design, our jackets allow rapid maintenance access - without ever compromising protection. Unlike traditional fireproofing, Ancloz jackets are engineered for fast installation and removal, reducing downtime and maintenance costs.

With over a decade of field-proven experience, we bring world-class solutions to your site - delivered promptly and backed by engineering expertise.

Discover why leading operators trust Ancloz. Contact Best Technology today for a consultation or technical demonstration.

T: +65 6747 5688 E: besttech@besttech.com.sg besttech.com.sg

of energy for Nigeria, it highlights the company’s role as a leader in the global engineering service sector providing the essential design, construction and operations services to support energy developments on an international scale.

Across Saipem’s operations in Singapore, there is a real focus on enhancing the region’s energy sector through its vital engineering services. From its role in the expansion of Singapore LNG to working across the Peninsular Gas Utilisation pipeline development, the company continues to invest in Singapore’s energy sector, whilst expanding its portfolio in delivering innovative, sustainable and reliable energy infrastructures across the globe. With the company’s global portfolio only continuing to grow, we look forward to seeing how Saipem will continue to expand its role across Singapore’s energy sector to help deliver vital energy resources across the country now and for many years to come.

in signing further contracts for the continued expansion of the SLNG Terminal. Saipem’s work on the fourth phase of the project expansion included engineering, procurement and construction

Another key energy development serving Singapore today is the Peninsula Gas Utilisation (PGU), which is located offshore the west coast of the Malaysia Peninsular but serves end users in both Malaysia and Singapore. The pipeline project has undergone many development stages, with Saipem appointed the main contractor in 1991 for Phase III of the development. Phase III was completed by Saipem in 1998, and saw the pipeline extended northwards along Malaysia’s west coast from Meru, Klang to Arau, Perlis. The entire pipeline spans 184km and is focused on delivering natural gas from offshore platforms to customers in Malaysia and Singapore. One of the major feats of the development was the use of PASSO Welding, which is an innovative system that utilises the automatic welding of pipes. Saipem’s role as the main contract for the third phase of the development highlights

in Nigeria. The unit was designed by Saipem and fabricated in the Singapore region, focusing its design on delivering a unit that can produce 210,000 barrels per day (bpd) of oil and 540,000 million standard cubic feet per day (mmscfd) of gas, whilst also delivering significant water and gas reinjection capacities. In addition to its production, it aims to store 2,200,000 barrels of oil. The design and construction of the FPSO included 18 modules that would come together to deliver a topside weight of 31,000 tons. Saipem will continue to oversee the management of the project until the offshore commissioning phase. With Saipem being awarded such a vital contract to help support the delivery

WHEN FIRE STRIKES, SECONDS MATTER

Arm your critical assets with Ancloz Armourflex

removable Passive Fire Protection (PFP)

Certified by DNV, ABS and Lloyd’s Register.

Engineered for rapid deployment.

No tools, no delays.

Rapid access. Zero downtime.

Trusted by the 30+ FPSOs worldwide

BP Indonesia

BP is a leading integrated energy company providing accessible, costeffective and diversified energy solutions across the world. Over the years, BP has expanded its offering from oil to gas, and now into onshore deepwater, and towards the development of new and renewable energy offerings that will help move the world towards a lower carbon energy future. This full range of energy offerings is evident across the Indonesian division of the company, BP Indonesia, where it has been operating for more than 55 years. Across Indonesia, BP is working to expand gas developments across the Ubadari gas field and deliver vital energy resources for the people of Indonesia.

In Indonesia, BP is present across almost every aspect of the gas development pipeline, with operations spanning from mainstream, upstream, downstream, integrated services, trading and even petrochemical sectors. For this reason, BP is one of the largest investors in the country and has delivered vital employment opportunities for local people to work across its various projects spanning Indonesia’s energy sector. However, one of the primary developments for BP in Indonesia is the exploration and production of the Tangguh LNG plant. The plant spans 6 gas fields across the Wiriagar, Berau, and Muturi production sharing contracts in Bintuni Bay in Papua Barat. In this region, the first gas reserves were discovered in the mid-1990s by Atlantic Richfield Co. (ARCO), but today are 100% wholly operated by BP Berau Ltd., BP’s Indonesia subsidiary.