THE AMERICAS www.littlegatepublishing.com

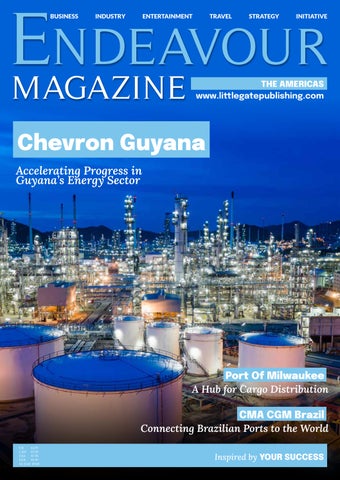

Chevron Guyana Accelerating Progress in Guyana’s Energy Sector

Port Of Milwaukee A Hub for Cargo Distribution CMA CGM Brazil Connecting Brazilian Ports to the World UK £4.95 CAN $7.95 USA $7.95 EUR €5.95 SA ZAR 69.00

Inspired by YOUR SUCCESS