https://ebookmass.com/product/electricity-for-refrigeration-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Refrigeration and Air Conditioning Technology – Ebook PDF Version

https://ebookmass.com/product/refrigeration-and-air-conditioningtechnology-ebook-pdf-version/

ebookmass.com

Essentials of Strength Training and Conditioning 4th Edition – Ebook PDF Version

https://ebookmass.com/product/essentials-of-strength-training-andconditioning-4th-edition-ebook-pdf-version/

ebookmass.com

Aerodynamic Heating in Supersonic and Hypersonic Flows: Advanced Techniques for Drag and Aero-heating Reduction Mostafa Barzegar Gerdroodbary

https://ebookmass.com/product/aerodynamic-heating-in-supersonic-andhypersonic-flows-advanced-techniques-for-drag-and-aero-heatingreduction-mostafa-barzegar-gerdroodbary/ ebookmass.com

Master Handbook of Acoustics, Seventh Edition F. Alton Everest

https://ebookmass.com/product/master-handbook-of-acoustics-seventhedition-f-alton-everest/

ebookmass.com

Chemistry for the IB Diploma Programme (Higher level) 3rd Edition Brown

https://ebookmass.com/product/chemistry-for-the-ib-diploma-programmehigher-level-3rd-edition-brown/

ebookmass.com

American Gun: The True Story of the AR-15 Cameron Mcwhirter

https://ebookmass.com/product/american-gun-the-true-story-of-thear-15-cameron-mcwhirter/

ebookmass.com

Principled Spying: The Ethics of Secret Intelligence David Omand

https://ebookmass.com/product/principled-spying-the-ethics-of-secretintelligence-david-omand/

ebookmass.com

Introduction to global studies Second Edition John Mccormick

https://ebookmass.com/product/introduction-to-global-studies-secondedition-john-mccormick/

ebookmass.com

The Trouble with Happiness and Other Stories Tove Ditlevsen

https://ebookmass.com/product/the-trouble-with-happiness-and-otherstories-tove-ditlevsen/

ebookmass.com

Strategy in the Age of Disruption: A Handbook to Anticipate Change and Make Smart Decisions 1st Edition

Henrik Von Scheel

https://ebookmass.com/product/strategy-in-the-age-of-disruption-ahandbook-to-anticipate-change-and-make-smart-decisions-1st-editionhenrik-von-scheel/

ebookmass.com

The refrigeration, heating, and conditioning industry has been going through a transitional period for the past 15 to 20 years or possibly even longer. Control systems are using more sophisticated electronic circuitry and doing more functions in system operation. Thermostats are moving from the old mechanical thermostats to digital, communicating, and wi-fi thermostats. The use of the mini-split heating-air-conditioning systems is increasing in their popularity; they are widely used in the industry. In Electricity for Refrigeration, Heating and Air Conditioning, 1Oth Edition, we have addressed these advancements:

1. The section on thermostats has been improved by decreasing the information on the old mechanical thermostat and increasing information on digital thermostats and communicating thermostats, along with adding wi-fi thermostats. Much of the graphics have been updated to show modern digital and wi-fi thermostats.

2 . A section has been added on troubleshooting integrated furnace controls.

3. A section on mini-split heating and air-conditioning control systems has been added

4. A section has been added on the type of DC motors that is used in the mini-split heating and air-conditioning systems

5. Arc flash has been added to the safety chapter.

6. Art has been updated to examples of electrical devices being presently used in the industry.

7. Revisions in the electric meter chapter have been made to shift the emphasis to digital meters instead of analog.

8 Additional practice service calls have been added to applicable chapters. Today's technicians face a difficult task because much of the equipment in the field is older equipment and has the older mechanical thermostats and other controls that technicians will have to be able to troubleshoot and stay up-to-date on the newer controls and systems that are being introduced each day. This text is written with a blend of theory and practicality suitable for vocational/technical and technical college students or for industry practitioners who wish to upgrade their knowledge and skills. The purpose of this text is to assemble concepts and procedures that will enable readers to work successfully in the industry

ORGANIZATION

It is difficult to organize an electrical text to be used in refrigeration, heating, and air-conditioning programs in educational institutions because of the many different types of programs and the variety of the delivery of information. The information covered in this text is organized from the very basics to the circuitry and troubleshooting of control systems in the industry. The organization is industry driven because of the correlation of industry standards and the many new developments that continue to be made. Electrical devices are covered in detail in a systematic order with the troubleshooting of the components following an explanation of how they work. Troubleshooting control systems should be the objective of most students and industry personnel using this text and is covered in detail.

FEATURES OF THIS EDITION

The features of this text are designed to enhance the learning experience:

• A chapter on Electrical Safety provides students with an awareness of the dangers of working with electricity, while Caution notes integrated throughout the chapters explain how to prevent and avoid accidents on the job.

• Examples walk students through important math equations and calculations essential to understanding how refrigeration, heating, and air-conditioning systems work.

• Green Technology features information relative to practices that technicians can implement to protect the environment and ultimately the health and safety of the communities they serve.

• Service Calls reinforce procedures that are commonly used in the industry, while Review Questions and Practice Service Calls provide students with the opportunity to evaluate what they have learned and hone their troubleshooting skills.

• Electricity for HVAC Online Training Simulation references are integrated throughout the text as helpful tools for those classrooms utilizing this enhanced supplement to the text. For more details on this training simulation, contact your sales representative or go to www.cengagebra in .com.

• Appendix A and Appendix B provide reference charts to review various types of motors, as well as to study electrical symbols commonly used in schematics, including switches, thermostats, contactors, relays, and other electrical devices.

NEW IN THIS EDITION

N ew t ec hn o logy has brought abou t rapi d chan g es in the thermostats and control syste m s used in t he heating an d air-condit i on in g i ndustry. As a resu lt, this h as prom p ted t he fo l lowing changes for this e dit ion:

• D ue to the rapid cha n ge in the design, technology, a n d ava i lab i lity o f e lect ro n ic ther m ostats, the the rm ostat sect i on has been complete ly revised, removing some of the material on the o lder the r mostats and focusing on the m ore adva n ced dig i tal, com m unicat in g, a n d w i-fi the r mostats.

• A sect i on o n DC motors an d contro ls has been added because of t heir use in the popu lar mini-spl i t heat i ng a n d cool i ng systems.

• A section o n min i-sp l it ai r condi t ioning a n d h eat pump system has been added.

• T he dangers of arc fl as h have been added to the sa f ety section, a l ong w i th how to p revent in j ury f rom an a rc flash.

ALSO AVAILABLE

COMPANION SITE

NEW! The Com p anion si te to accompany Electricity for Refrigeration, Heating and Air Conditioning fea t ures tools to support learning an d fac i litate teaching:

• Answers to Review Questions, appear in g at t he end of each chapter, allow teache rs to trac k and validate st u de n t learning.

• Answers to the Lab Manual p rov ide res p o n ses to the questions and pro bl ems found in the Complete HVAC Lab Manual applicable exercises.

• Lesson Plans provide an outl in e of the key top i cs i n each cha p ter and corre lat e to t h e accom p anying Powe r Po in t ® p resenta t ions.

• PowerPoin -r.® p resenta t ions a l ign w i th the Lesso n Pl ans a n d include photos and i llustrations t o visually reinforce t he key po i nts in each chapte r

• Testing powered by Cognero, a f lex i ble o n line system, p r ov i des chapte r-by chapte r quizzes and enables teachers to:

o Autho r, ed i t, an d ma n age tes t bank content from m u ltiple sources .

o Create multip le tes t versio n s in an in sta n t.

o D eliver tes t s from t eacher- / school-specifi c learn i ng ma n agement systems (LMS) o r cl ass rooms.

• Image Gallery offe rs fu l l-co l or pho t os a n d illustrat i ons f rom t he t ext to enable teache rs to further enhance class room prese n tations.

For these instructor-specific resources, please visit CengageBrain.com at http://login.cengage.com and follow the prompts for obtaining access this secure site.

MINDTAP FOR ELECTRICITY FOR REFRIGERATION, HEATING AND AIR CONDITIONING, 1OTH EDITION

NEW! The MindTap for Electricity for Refrigeration, Heating and Air Conditioning, 1Oth Edition, features an integrated course offering a complete digital experience for the student and teacher. This MindTap is highly customizable and combines assignments, videos, interactivities, lab exercises, and quizzing, along with the enhanced ebook to enable students to directly analyze and apply what they are learning and to allow teachers to measure skills and outcomes with ease.

• A Guide: Relevant interactivities combined with prescribed readings, featured multimedia, and quizzing to evaluate progress will guide students from basic knowledge and comprehension to analysis and application.

• Personalized Teaching: Teachers are able to control course contenthiding, rearranging existing content, or adding and creating own content to meet the needs of their specific program.

• Promote Better Outcomes: Through relevant and engaging content, assignments and activities, students are able to build the confidence they need to ultimately lead them to success. Likewise, teachers are able to view analytics and reports that provide a snapshot of class progress, time in course, engagement, and completion rates.

LAB MANUAL

NEW! The Complete HVAC Lab Manual is a brand-new offering for the HVAC curriculum. Combining the content from Electricity for Refrigeration, Heating and Air Conditioning and Refrigeration and Air Conditioning Technology respective lab manuals, the Complete HVAC Lab Manual supports the concepts learned in these texts-and beyond. Divided by HVAC subject areas and correlated to specific content in companion texts, it features over 250 lab exercises including step-by-step procedures, questions, and problem sets to help students to evaluate their knowledge of the technical content and to practice essential skills.

DELMAR

ONLINE TRAINING SIMULATION: ELECTRICITY FOR

HVAC. Delmar Online Training Simulation: Electricity for HVAC is an immersive simulation that offers HVAC students a learning path from basic electrical concepts to real-world electrical troubleshooting in HVAC. The product includes dynamic interactive wiring diagrams with different settings including an open sandbox mode, allowing students to explore

and experime n t, and a tutorial mode providing students with the proper seq u e n ces required for so un d electrical pract i ce. Both modes are supported by an adapt i ve questio n eng in e that drives students down the learning path. In the culminat in g modules, students wi l l enter a 3D, i mmersive, l ifel i ke simu lation that lets them put into practice the e lectrica l t h eories and understanding t h at they h ave developed.

T he simu lation draws upon many wi rin g diagrams throughout th i s text. A si mulation i con w i ll be p laced in the marg i n next to t h e diagram where a si mulation act ivity ex i sts. Fo r mo re detai ls on De/mar Online Training Simulation: Electricity for HVAC co n tact your sales representative or go to www. ce n gag ebra in. com.

Printed Access Code ISBN: 978128S746289 Instan t Access Code ISBN: 978128S7 46296 (Ava i lab le for i nstant pu rchase on www.cengagebrai n .com.)

VIDEO DVD SET A t h ree-DVD video set address in g over SO top i cs is ava i lab le. Each DVD conta i ns four 20-m inu te videos. To o rder the t h reeDVD set, re f erence ISBN: 9781111038779.

ACKNOWLEDGMENTS

I would l ike to thank God f or the skil ls and knowledge He has give n me and the ab i lity and desire to write t his text. I thank my w i fe f or SO wonderfu l years of marriage and her encou r agement, wh i ch is priceless. I tha n k my f ami ly members fo r the i r encourageme n t and s u pport through each and every edition. I would like to t h ank my fel low col leagues, espec i al ly Carter Sta n fie ld, at Athens Technica l Co l lege fo r their support and encourageme n t. I would like to tha n k past and present students for suggestio n s that have made each edition easier to w ri te.

I, along with Cengage, would also l i ke to express our apprec i ation for the outstanding wo rk of the reviewers o f t h is edit i on:

Thomas Bush, South Florida State Col lege, Avon Park, FL

Brent Evans, Johnst on Community College, Smithfield, NC

Frank M Sylvester, Eri e Community College, Buffalo, NY

John Tecumseh, Drake Career College of Northern Nevada, Sparks, NV

In addition, we wo u ld l i ke to recognize t he part i c i pa t ion of t he fol lowing in dividuals in pr i or edit i ons, as their work has served as a form i dable foundat i on for this edi t ion:

Duane Bjornson, Seattle Area Pipe Trades, Renton, WA

Nea l Broyles, Rolla Technica l Inst i tute, Ro l la, MO

William Burk lo, Ind i an River State College, Fort Pie rce, FL

William H. Burklo, Indian River Community College, Ft. Pierce, FL

John Demree, Bu rl ingto n County Inst itute of Technology, Medford, N J

Gary M. DeWitt, Monroe Commun i ty Co ll ege, Roches t er, NY

Eugene C. Dickson, Ind i an River Comm uni ty Co l lege, Ft. Pie rce, FL

Herb Haushahn, Co l lege of DuPage, G len El lyn, IL

Russell K. Marcks, Sinclair Community College, Dayton, OH

James Mendieta, Western Technical Institute, El Paso, TX

Lawrence D. Priest, Tidewater Community College, Virginia Beach, VA

Robert Reynard, Western Technical Institute, El Paso, TX

Eugene Silberstein, Suffolk County Community College, Brentwood, NY

Greg Skudlarek, Minneapolis Community Technical College, Minneapolis, MN

Darius Spence, North Virginia Community College, Woodbridge, VA

Jerome Stahler, Jr., Fortis Institute, Jacksonville, FL

Richard Wirtz, Columbus State Community College, Columbus, OH

Lastly, I would like to thank each of the following manufacturers and manufacturers' representatives who have helped with the photographs and artwork:

Bill Johnson

EWC Controls Inc.

Robert Madden Industries

Schneider Electric USA, Inc.

Carrier Corporation

Chromolox, Wiegand Industrial, Division of Emerson Electric Co.

Honeywell, Inc.

National Fire Protection Association

Sealed Unit Parts Co.

A special thank-you goes to Carrier Corporation and Honeywell, Inc. for their extensive contribution of graphics to support the text.

ABOUT THE AUTHOR

Russell E. Smith is an air-conditioning technology Instructor Emeritus at Athens Technical College in Athens, Georgia. Mr. Smith also ran his own contracting and consulting firm for many years. He is a Certificate Member of the Refrigeration Service Engineers Society and holder of Conditioned Air Non-Restricted License in the State of Georgia. He holds an AE in airconditioning engineering.

OBJECTIVES

After completing th i s chapter, you shou l d be able to :

Explain the effect of electric current on the human body.

Understand the injuries that are possible from an electrical shock.

Know the basic procedures in the event of an electrical shock.

Understand the importance of properly grounding tools and appliances.

Arc flash

Ca rdiopu Imona ry resusc itation (CPR)

Circuit breaker

Circuit l ockout

Conductor

Double insulated

Safely use electri cal hand tools and electrical meters.

Follow the principles of safety when installing and servicing heating and air-conditioning equipment.

Electrical shock

Electromotive force

Fuse

Ground

Ground fau lt circuit

interrupter (GFC I)

Ground i ng adapter

Live electrical circuit

National Electrical Code® (NEC®)

Three-prong plug

INTRODUCTION

Electricity is very commonplace in our environment today; in fact it's hard for us to envision life without electricity. No matter what part of our lives we examine, electricity plays an important role, from our home life to our places of employment. Our homes are filled with personal electric appliances like toothbrushes and hair dryers, small electric appliances like mixers and toasters, major appliances like washers and refrigerator / freezers, and large equipment that heat and cool our living spaces. Many people work in environments that use large electrical equipment that are powered by an extremely high-voltage source. No matter what a person does, he or she is likely to come near electrical power sources that are dangerous.

The single most important element to remember when dealing with electrical circuits is to respect them. It is impossible for a service technician to adequately troubleshoot heating and air conditioning with the electrical power turned off, so it is imperative to use safe procedures when the power is on. Many troubleshooting procedures can be performed with the electric power to the equipment interrupted, such as checking the condition of electric motors, relays, contactors, transformers, and other electrical devices. However, there are other times when troubleshooting requires a connection to the power source-checking power available to the equipment, checking power available to a specific electrical device, or checking the voltage drop across a set of contacts in a relay, for example. The important thing for an HVAC/ R technician to know is when it is necessary to have the power to the unit on or off.

Always perform repairs with the power off.

One of the most important things that a service technician must learn is how to safely work around equipment when the power is being supplied to the equipment. Good service technicians cannot fear being shocked, but they must always pay attention to what they are doing and not get careless when they are working around live electrical circuits. A live electrical circuit is one that is being supplied with electrical energy.

It is possible for an installation technician to completely install a heating and air-conditioning system without the power being turned on until it is time to check the system for proper operation. No matter what part of the heating, ventilating, and air-conditioning industry a person works in, it is imperative that he or she respects electricity and knows how to properly work around it without being injured.

ELECTRICAL INJURIES

Electrica l shocks and burns are common hazards to personnel who are employed in the heating and air-conditioning industry. It is impossib l e to insta l l or troub l eshoot a i r-cond ition i ng equ i pment without worki ng close to electrical devices that are be i ng supp l ied with e l ectr i ca l energy. It i s the respons i b i l ity of the technician to develop a procedure for working around live e l ectric c i rcu its w ithout coming i n contact w ith conductors and e l ectrical components that are being supp l ied with electrica l power.

Electrical shock occurs when a person becomes part of an electrical c i rcuit. When e l ectr i city passes through the human body, the results can range from death to a slight, uncomfortable stinging sensation, depend i ng upon the amount of e l ectr i city that passes through the body, the path that the electr i c ity takes, and the amount of time that the electric ity f l ows. Technicians shou l d never a ll ow themselves to become the conductor between two wires or a hot and a ground in an electrical circuit.

The amount of e l ectr i ca l energy needed to cause serious injury i s very sma l l. The electrica l energy supplied to an e l ectrical circuit is called electromotive force , and it i s measured in vo lts. In the heating and a i r-cond ition i ng i ndustry, the technician often is i n close proxim ity to 24 volts, which is used for the control circuits of most residential systems; 120 vo lts, which is used to operate most fan motors in gas furnaces; 240 volts, wh i ch is used to operate compressors in residentia l condensing units; and much h i gher voltages, which are used to operate compressors in commercial and industr i a l cooling systems. The heat i ng and aircondit i oning techn i c i an is often around vo ltages that can cause serious injury or even death.

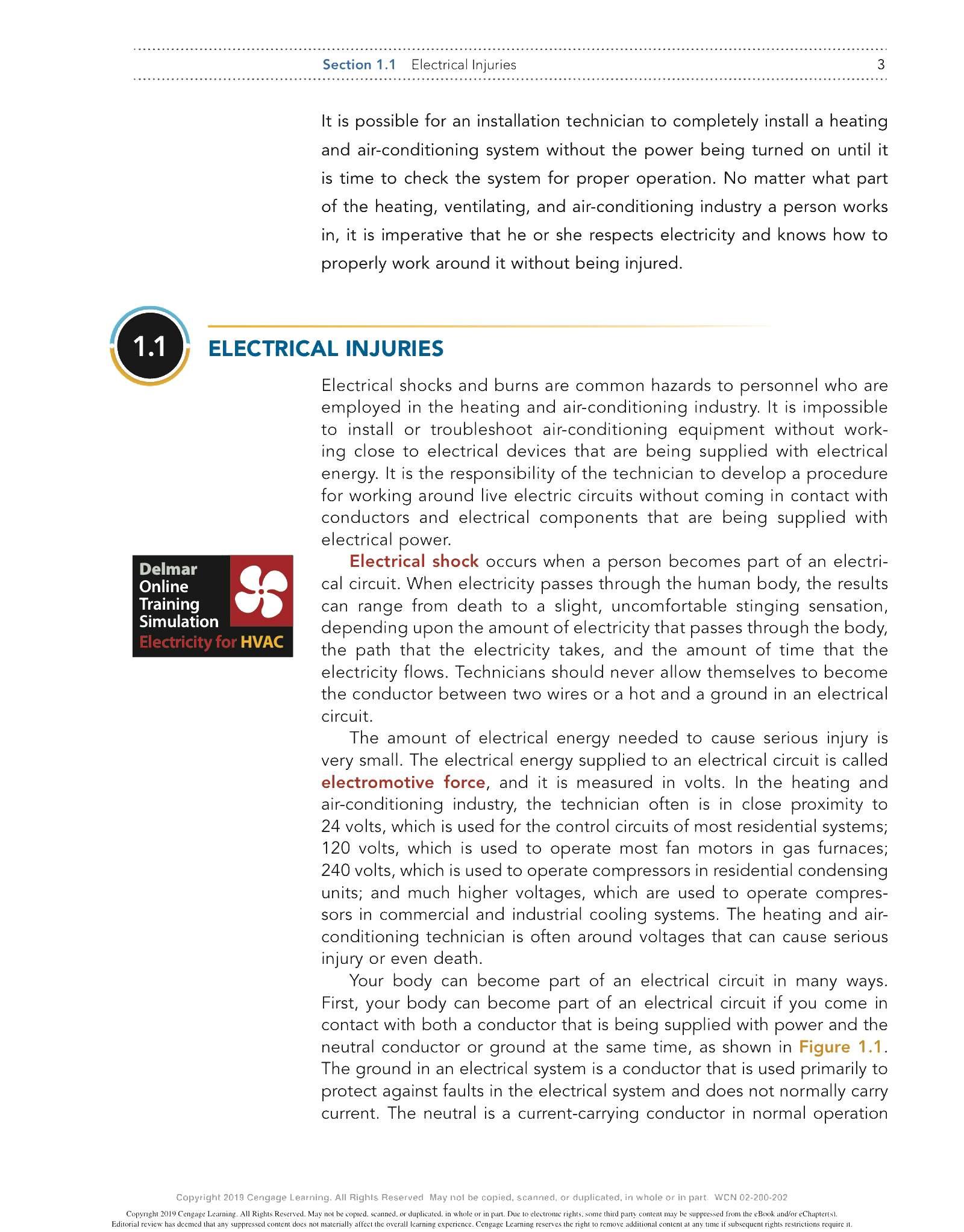

Your body can become part of an e l ectr i cal circu it in many ways. First, your body can become part of an electrical circuit if you come in contact with both a conductor that is be i ng supp l ied with power and the neutra l conductor or ground at the same t i me, as shown in Figure 1.1 The ground in an electr i ca l system i s a conductor that is used primarily to protect aga i nst faults i n the electrica l system and does not norma ll y carry current. The neutral is a current-carrying conductor in normal operation

© Cengage®

FIGURE

Technic ian coming in contact with a conductor (shorted fan motor) and ground

W iring d iagram

240 vo lts

=::::: ...--- Fan re lay

...--Frame of fur nace

Sma ll wire i n mo tor Pa t h

© Cengage®

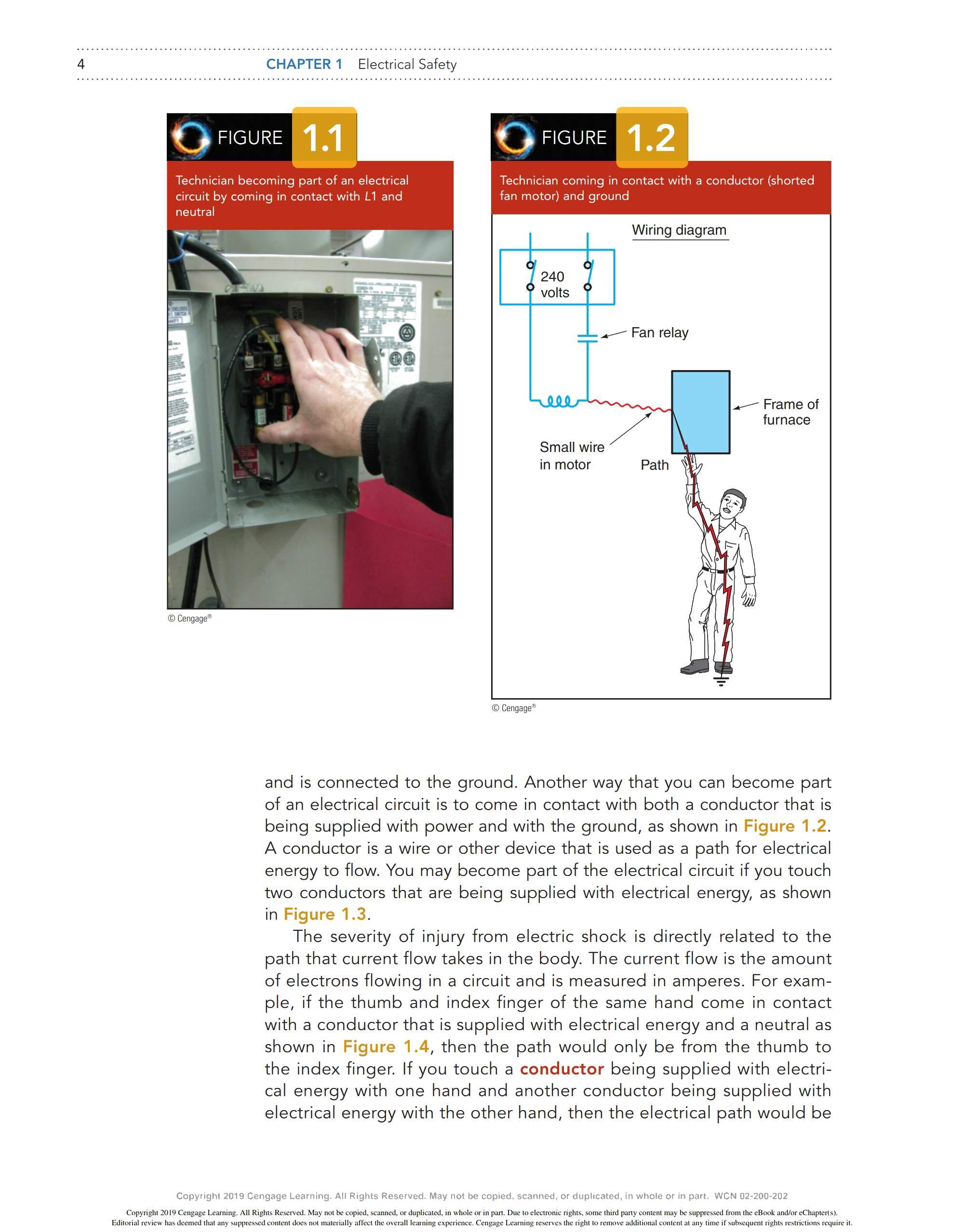

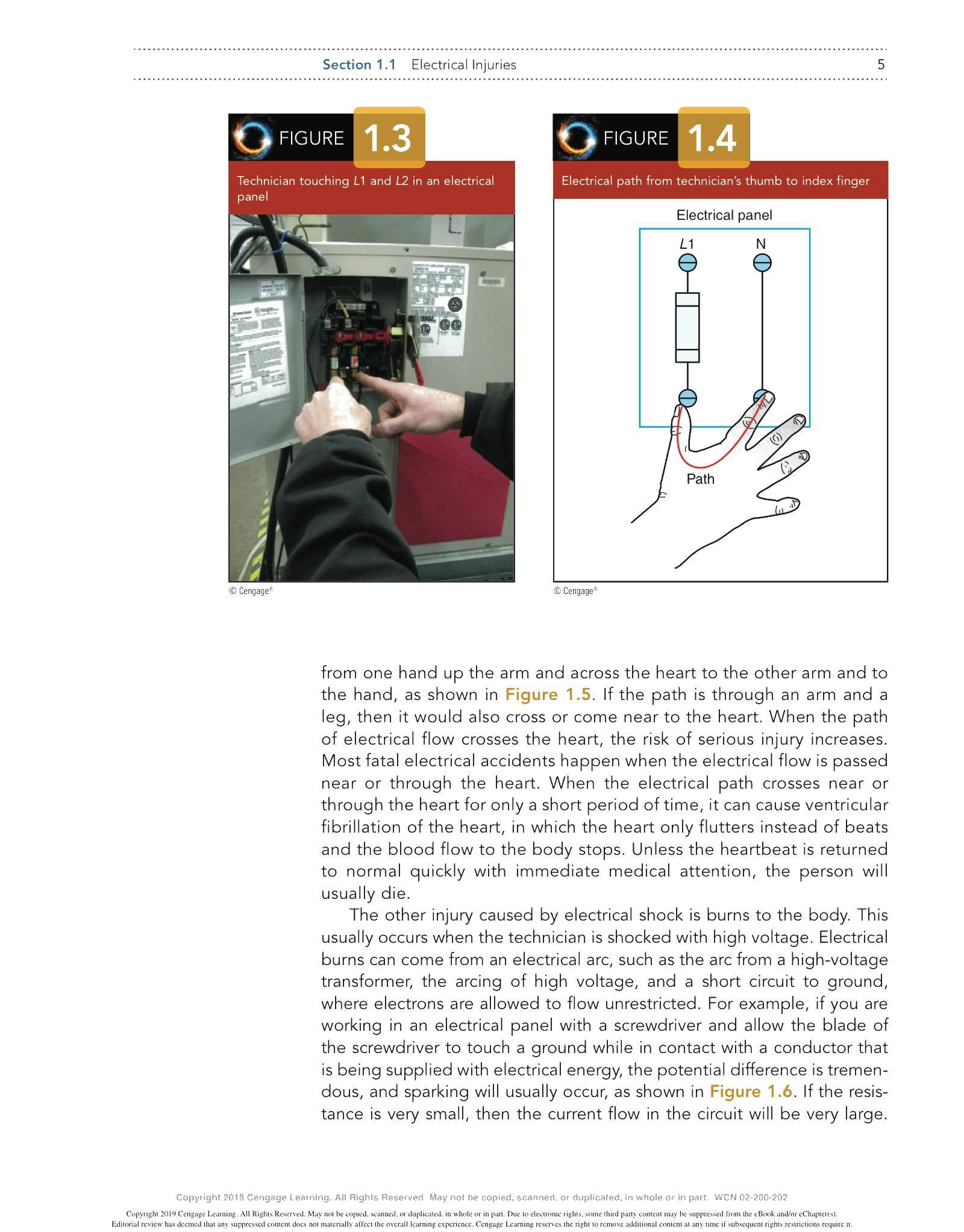

a nd is connected to the gro un d. Anot h er way t h at you can become part o f an e lectrica l c i rcuit is to come in contact with both a conducto r that i s being supp l ie d with power an d with the ground, as shown in Figure 1.2 . A conductor is a w i re or o th er dev i ce that is u sed as a p at h for e l ec t r i cal energy to flow. Yo u may become part o f t he elect ri ca l c i rcuit if yo u touch two conductors that a r e b eing suppl i ed w i t h e lectrica l ene rgy, as shown i n Figure 1.3

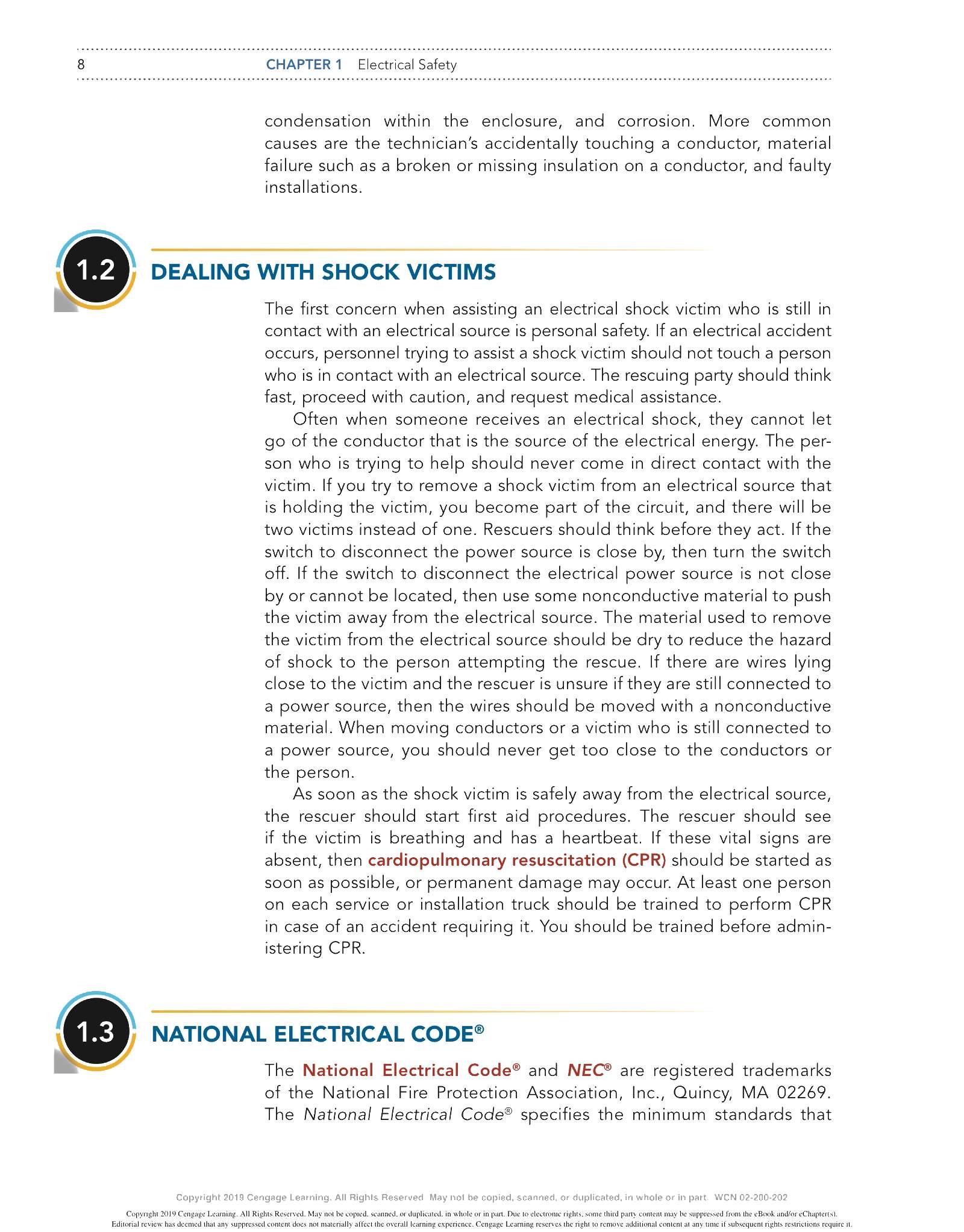

The severity of inj u ry from e l ect r i c s h ock i s d i rectly re l a t e d to the path t hat c u rrent fl ow t akes i n the b ody. T h e current f l ow is the amount of e l ectro n s flowi n g in a c i rcu i t and is measu r ed in amperes. For examp l e, if t he thumb an d index f in ger of t he same han d come in contact w i th a conducto r t hat i s supplie d wi t h e l ectrica l energy and a neut r a l as show n in Figure 1.4 , then the pa t h wo u l d on l y be from t h e t h u mb to the i ndex fi nger. If you touch a conductor being supp l i ed with electrica l energy w it h one h and and anothe r conducto r bei n g supp l i ed with e l ectr i cal energy w it h the o t he r hand, t hen t h e electrical path would be

FIGURE n.l

Electrica l path from technician's thumb to index finger

Electrical panel

L1 N

© Cen gag e®

from one hand up the arm and across the heart to the other arm and to the hand, as shown in Figure 1.5 . If the path is through an arm and a leg, then it wou l d a l so cross or come near to the heart. When the path of electr i ca l f l ow crosses the heart, the risk of serious in j ury increases. Most fatal electrical accidents happen when the e l ectrica l flow i s passed near or through the heart. When the electrical path crosses near or through the heart for on l y a short per i od of time, it can cause ventricu l ar f i bri ll ation of the heart, in wh i ch the heart only flutters i nstead of beats and the blood flow to the body stops. Un l ess the heartbeat i s returned to normal quick l y with immediate medical attent i on, the person wi l l usua l ly die.

The other i n j ury caused by electrica l shock is burns to the body. This usua l ly occurs when the techn ician is shocked w ith high vo ltage. Electrical burns can come from an electrica l arc, such as the arc from a high-voltage transformer, the arcing of high voltage, and a short circuit to ground, where electrons are allowed to f l ow unrestricted. For example, if you are working in an electrical panel with a screwdriver and a l low the blade of the screwdriver to touch a ground wh il e in contact with a conductor that is be i ng supp l ied with electrical energy, the potent i a l difference i s tremendous, and sparking will usually occur, as shown i n Figure 1.6 . If the resistance is very sma l l, then the current flow in the c i rcuit w il l be very large.

A current flow through the body of 0.015 ampere or less can prove fata l. By comparison, the current draw of a 60-watt light bulb is on ly 0.50 ampere.

The fol l ow i ng values can be associated with the fee l of e l ectrical shock: (1) 0.00 1 ampere (1 milliampere), a person can fee l the sensation; (2) 0.020 ampere (20 milliamperes), a person might not be able to let go; (3) 0. 100 ampere (20 milliamperes) can cause ventricular fibr ill at i on; and (4) 0.200 ampere and above (> 200 mi lli amperes) can cause severe burns and respiratory paralysis.

Another danger of electr i cal shock is a person's reaction when shocked. For examp l e, if you are working on a l adder and get shocked, you could fall off the ladder. If you are using an e l ectr i ca l -powered hand tool and a short occurs, then you might drop the tool, causing persona l i njury to yourself or others. Techn i cians shou l d keep in mind that their reactions when getting shocked could endanger others, so they must be cautious and attentive when working near l i ve electr i cal circuits.

Technicians should be aware of the danger of electrica l shock when using ladders that conduct electric ity, such as aluminum l adders. If at a l l poss i ble, the technician should use nonconductive ladders on a l l jobs. The two primary types of nonconductive ladders used today are wood and f i berg l ass. Nonconductive l adders work as we l l as the aluminum l adders, except that they lack the same ease of hand li ng because of their added we i ght. Whenever you are using a ladder, you shou l d make sure that you do not posit i on the ladder under electrica l conductors that you m i ght accidenta l ly come in contact with when climbing the l adder.

In an arc flash , an e l ectr i c current leaves its intended path and travels through the air to an unintended path. For example, an arc from the line voltage source from li ne 1 in an enclosed switch to li ne 3 in the same sw itch or even to a ground outside the enclosure. See Figure 1.7 Arc f l ashes generally occur in higher-voltage applications (480 volts and above) but can occur at much lower voltages. The result of an arc f l ash i s often violent i n nature and can cause serious injury or even death to a technician. The refr i geration and heat i ng and a i r condit i on i ng technician occasionally i s ca ll ed on to work with electrica l systems and equipment using higher vo ltage. The technician should wear personal protective equ i pment in the form of g l oves and safety glasses. A pair of recommended safety gloves to be used around high voltages i s shown in Figure 1.8 .

Arc f l ashes can cause ser i ous i njury due to the vio l ent nature of the arc flash explosion. The injuries can range from life-threatening to m i nor. The typica l resu lts of an arc flash are burns to the technician, often molten meta l pieces thrown from the conductor, hear i ng damage due to the sound blast, and high heat. The proximity of the technician to the f l ash w il l determine the severity of injury. The most effect i ve and foo lproof way to prevent injury from an arc flash is to eliminate the risk by d i sconnecting the power source go i ng to the equipment. Of course, this is not a l ways possible, so in rare cases technicians are required to work around l ive equ i pment, at which time they shou l d check with a supervisor, use persona l protective equ i pment, and work w ith insulated too l s.

Arc flashes can be caused by the s i mp l est and overlooked reasons, such as dust and other impurit i es on the conductors, dropp i ng tools,

condensation within the enclosure, and corrosion. More common causes are the technician's accidentally touching a conductor, material failure such as a broken or missing insu lation on a conductor, and faulty installations.

DEALING WITH SHOCK VICTIMS

The first concern when assisting an electrical shock victim who is still in contact with an electrical source is personal safety. If an electrical accident occurs, personnel trying to assist a shock victim should not touch a person who is in contact with an electrical source. The rescuing party should think fast, proceed with caution, and request medical assistance.

Often when someone receives an electrical shock, they cannot let go of the conductor that is the source of the electrical energy. The person who is trying to help should never come in direct contact with the victim. If you try to remove a shock victim from an electrical source that is holding the victim, you become part of the circuit, and there will be two victims instead of one. Rescuers should think before they act. If the switch to disconnect the power source is close by, then turn the switch off. If the switch to disconnect the electrical power source is not close by or cannot be located, then use some nonconductive material to push the victim away from the electrical source. The material used to remove the victim from the electrical source should be dry to reduce the hazard of shock to the person attempting the rescue. If there are wires lying close to the victim and the rescuer is unsure if they are still connected to a power source, then the wires should be moved with a nonconductive material. When moving conductors or a victim who is still connected to a power source, you should never get too close to the conductors or the person.

As soon as the shock victim is safely away from the electrical source, the rescuer should start first aid procedures. The rescuer should see if the victim is breathing and has a heartbeat. If these vital signs are absent, then cardiopulmonary resuscitation {CPR} should be started as soon as possible, or permanent damage may occur. At least one person on each service or installation truck should be trained to perform CPR in case of an accident requiring it. You should be trained before administering CPR.

NATIONAL ELECTRICAL CODE ®

The National Electrical Code ® and NEC® are registered trademarks of the National Fire Protection Association, Inc., Quincy, MA 02269. The National Electrical Code® specifies the minimum standards that

must be met for the safe installation of e l ectrica l systems. The NEC® is revised every four years. Technicians shou l d make sure when using the NECID that the l atest edit i on is being used. The i nformat i on in the NECID and l oca l codes must be followed and adhered to when making any type of e l ectrica l connection in a structure. The NECID i s made up of n i ne chapters, with each of the first eight chapters d i v i ded i nto articles. Chapter 9 conta i ns miscellaneous tables used in the design of electrica l systems. The following is a l ist of the main topics of the eight chapters:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Genera l

W i ring and Protection

W i ring Methods and Materials

Equ ipment for Genera l Use

Special Occupancies

Special Equ ipment

Special Cond itions

Communications Systems

Tab l es

Chapters 1 through 4 are directly related to the electrical standards of the refr i geration, heating, and air-conditioning industry. Art i cles in Chapter 4 that app ly directly to the industry i nclude:

Article 400 Portable Cords and Cables

Article 422

Article 424

Article 430

Article 440 Appliances

Fixed Electric Space-Heating Equipment

Motors, Motor Contro l s, and Contro ll ers

Air-Condit i on i ng and Refrigerat i on Equipment

ELECTRICAL GROUNDING

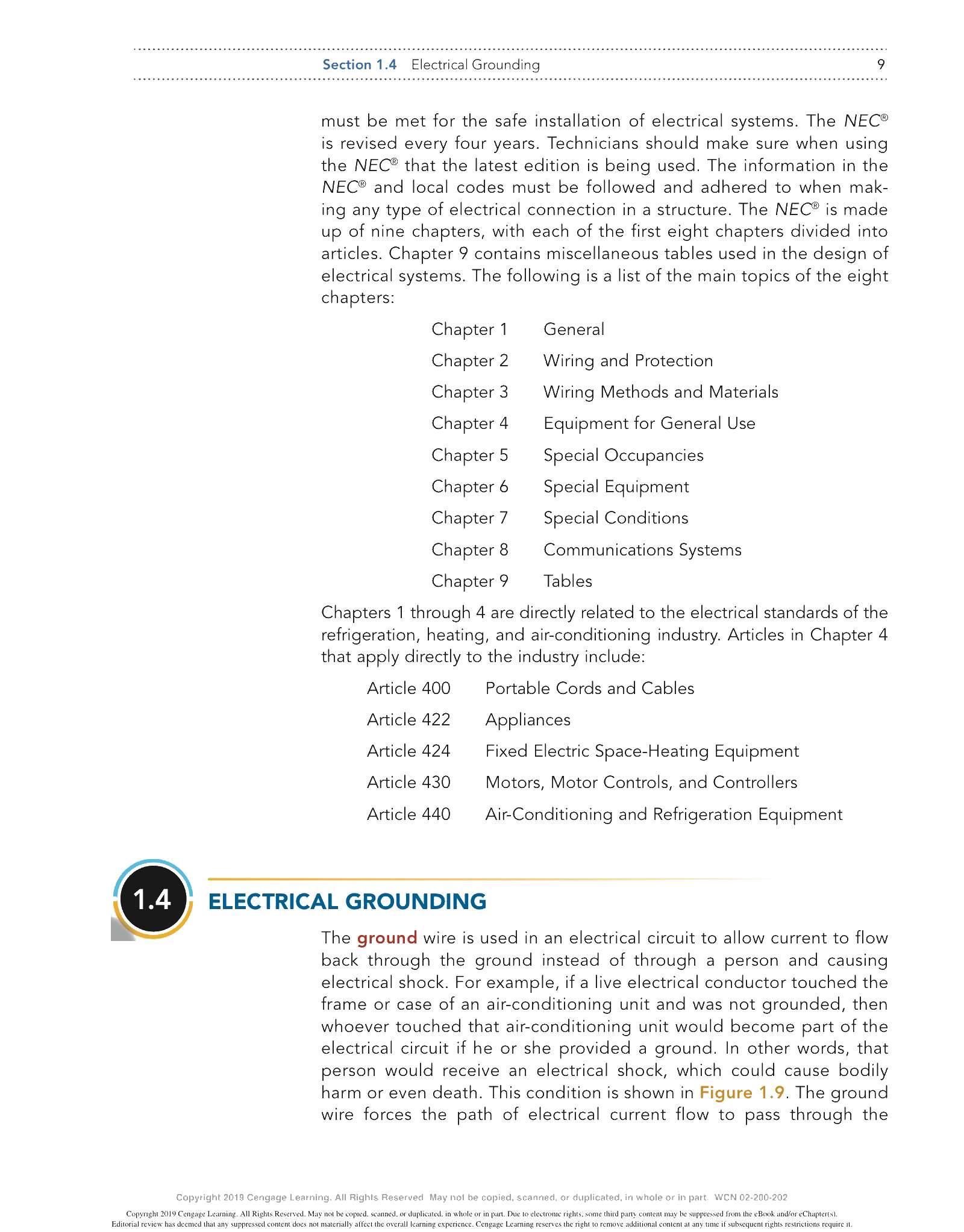

The ground wire i s used i n an e l ectrica l circuit to allow current to flow back through the ground i nstead of through a person and causing electrica l shock. For examp l e, if a l i ve electr i cal conductor touched the frame or case of an a i r-cond ition i ng un it and was not grounded, then whoever touched that a i r-condition i ng unit wou l d become part of the electrica l circuit if he or she provided a ground. In other words, that person would receive an electrica l shock, which cou l d cause bodily harm or even death. This condition is shown in Figure 1.9 The ground wire forces the path of electrica l current flow to pass through the

© Cengag e® Junction

Ungrounded circuit

Fan relay

Unit suspended from wooden structure (not grounded)

in motor touching frame

Concrete floor and damp shoes

electrical device that is used to protect the circuit, such as a fuse or circuit breaker. The ground wire is identified by the color green in almost al l cases.

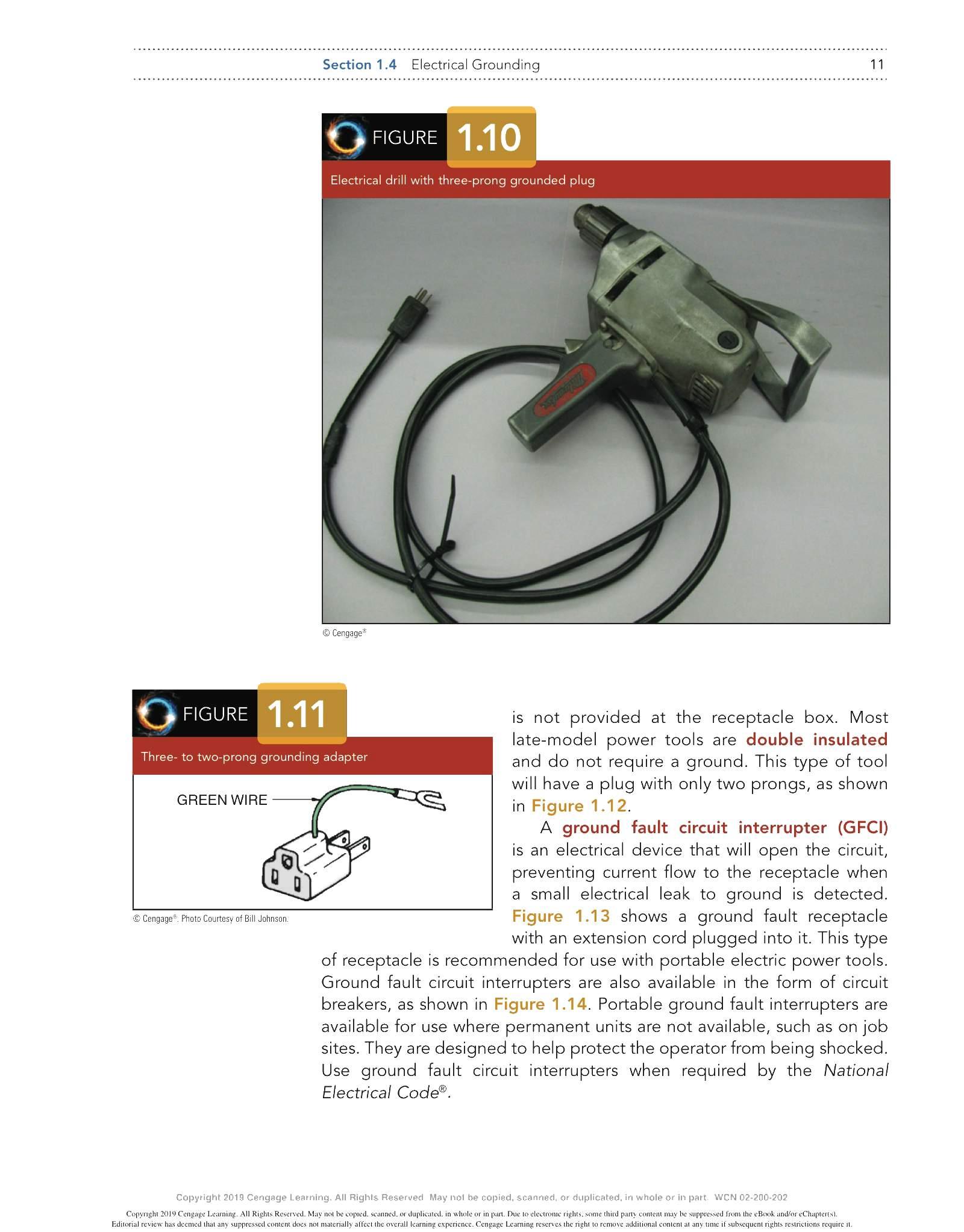

If an e l ectrically powered tool requires a ground, it is equ i pped with a three - prong plug , as shown in Figure 1.1 0 On this type of plug, the semicircular prong is the grounding section of the p l ug and shou l d never be cut off or removed. The same goes for extension cords; the grounding prong should never be removed for convenience. It is important when using a power tool that requires a ground that the technician make certain that the receptacle is grounded. Electrical too l s or cords with a ground prong that is a ltered shou l d be taken out of service unt il replaced or repaired. A grounding adapter shown in Figure 1.11 is a device that permits the connection of a three-prong plug to a two-prong receptacle. A grounding adapter should not be used on a power tool w ith a three-prong p l ug unless there is a sure ground that the grounding wire can be attached to. The techn i cian shou l d use caution when using grounding adapters, because in many older structures grounding

is not provided at the receptacle box. Most late-model power too l s are double insulated and do not require a ground. This type of too l wi ll have a p l ug with only two prongs, as shown in Figure 1.12

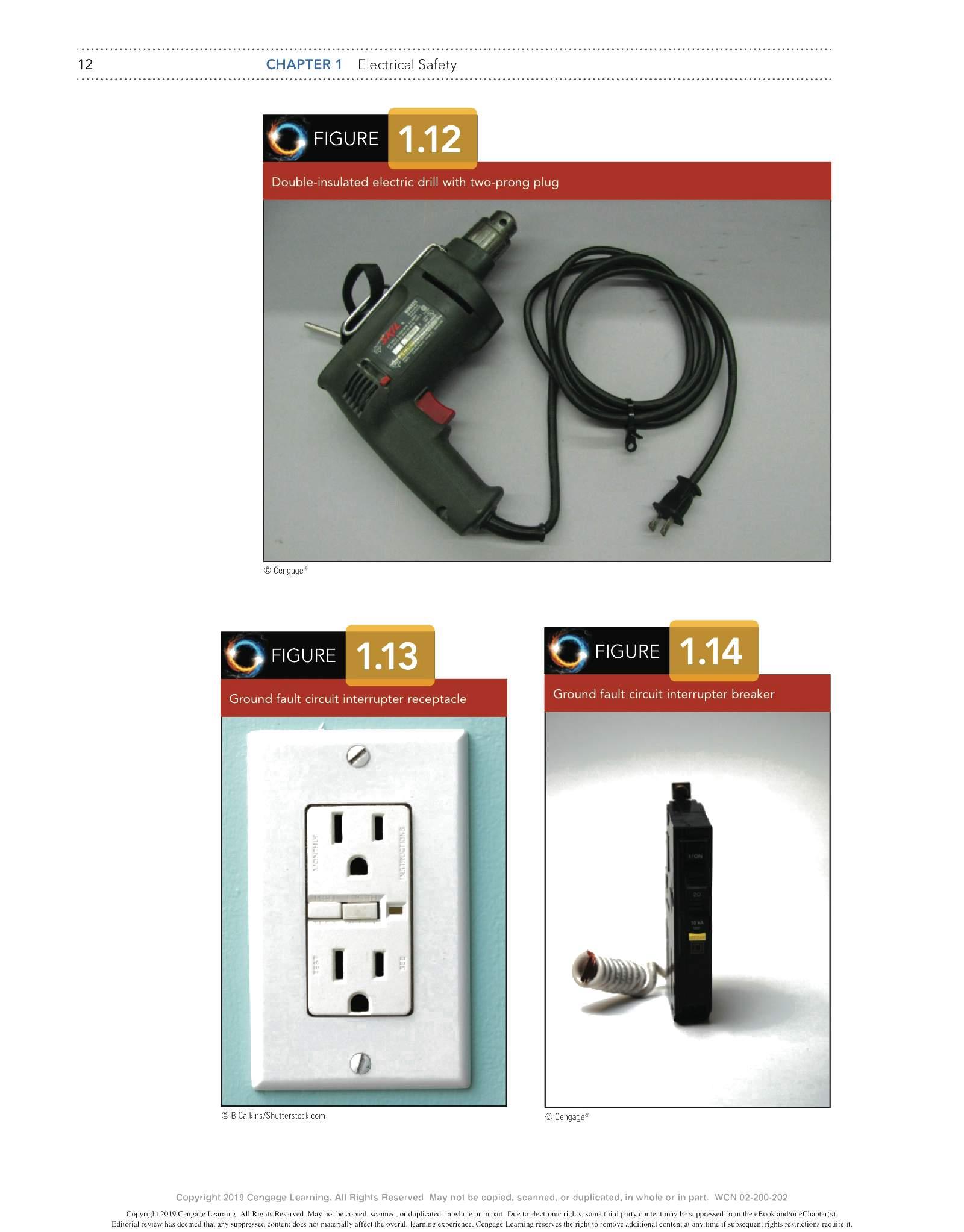

© Photo Courtes y of Bi ll John so n. A ground fault circuit interrupter {GFCI} is an electrica l dev i ce that will open the circu it, preventing current flow to the receptacle when a small electrical leak to ground is detected. Figure 1.13 shows a ground fau lt receptacle with an extens i on cord plugged i nto it. This type of receptacle is recommended for use w ith portable electr i c power too l s. Ground fault circuit i nterrupters are also availab l e in the form of c i rcu it breakers, as shown i n Figure 1.14 Portab l e ground fau lt interrupters are ava i lab l e for use where permanent un its are not availab l e, such as on job sites. They are designed to he l p protect the operator from be i ng shocked. Use ground fault circuit i nterrupters when required by the National Electrical Code®.

CIRCUIT PROTECTION

Electrical circuits in structures are designed to operate at or below a specific current (ampere) rating. Each electrical circuit shou ld be protected, according to the NECID. The wire or conductor of each c i rcuit should be protected to prevent a higher current than it is designed to carry. The electrical components in the circuit are also a consideration when protection is a concern. The standard wire used for receptacles in most residences is #12 TW. The maximum current protection for this type of wire according to the NECID is 20 amperes. However, if there is an electrica l component in the circuit that requires protection at 10 amperes, the c i rcuit protection should be at 10 amperes. If the current i n the circuit becomes greater than the rating of the protect ive device, the dev i ce opens, disrupting the power source from the c i rcuit.

The most common methods of circuit protection in structures are fuses , as shown in Figure 1.15 , and circuit breakers, as shown in Figure 1.16 . These dev ices protect the circuit by interrupt i ng the flow of electrica l energy to the circuit if the current in the circuit exceeds the rating of the fuse or circu it breaker. There are many types of fuses available today with special designs for part icu l ar purposes, but the primary purpose of any fuse is protection. Fuses are made w ith a short str i p of metal alloy ca l led an e l ement that has a low melt i ng po i nt, depending on the rating of the fuse. If a l arger current f l ow passes through the fuse than is designed to pass through the element, the element wi l l melt and open the circuit. Circuit breakers look a lot like ordinary l ight switches placed in an electrical panel. If the current in

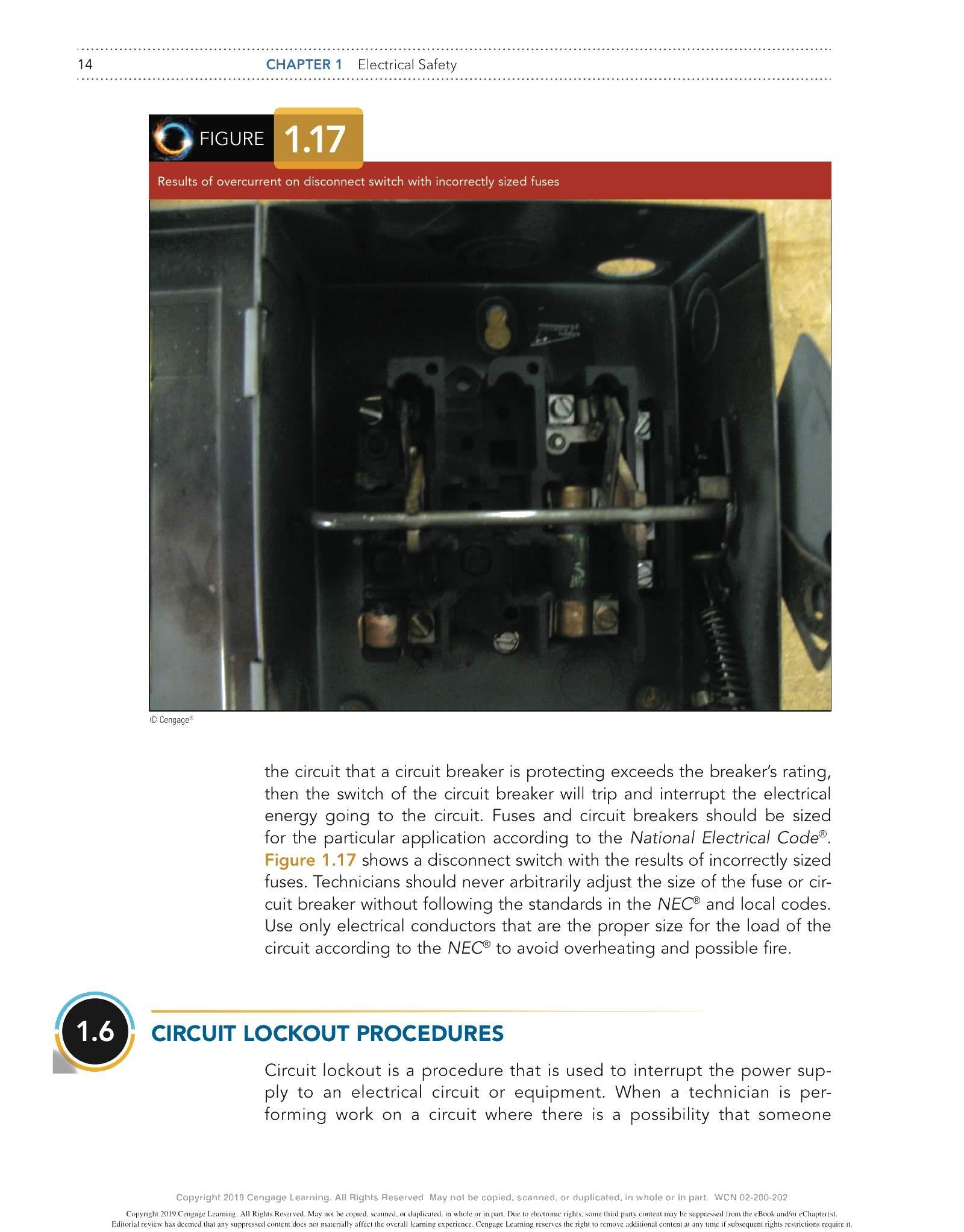

the circu it that a circuit breaker is protecting exceeds the breaker's rat i ng, then the switch of the circuit breaker wi ll trip and interrupt the electrical energy go i ng to the c i rcuit. Fuses and c i rcuit breakers shou l d be sized for the particular app l ication according to the National Electrical Code®

Figure 1.17 shows a disconnect switch w ith the resu lts of incorrect ly sized fuses. Techn i cians should never arb itrar i ly ad j ust the size of the fuse or circuit breaker w ithout fo ll owing the standards in the NECID and local codes. Use on ly electr ica l conductors that are the proper size for the load of the circuit according to the NE CID to avoid overheating and possible fire.

CIRCUIT LOCKOUT PROCEDURES

Circuit l ockout i s a procedure that is used to i nterrupt the power supp l y to an e l ectrical circuit or equipment. When a technician is performing work on a circuit where there is a possib i lity that someone

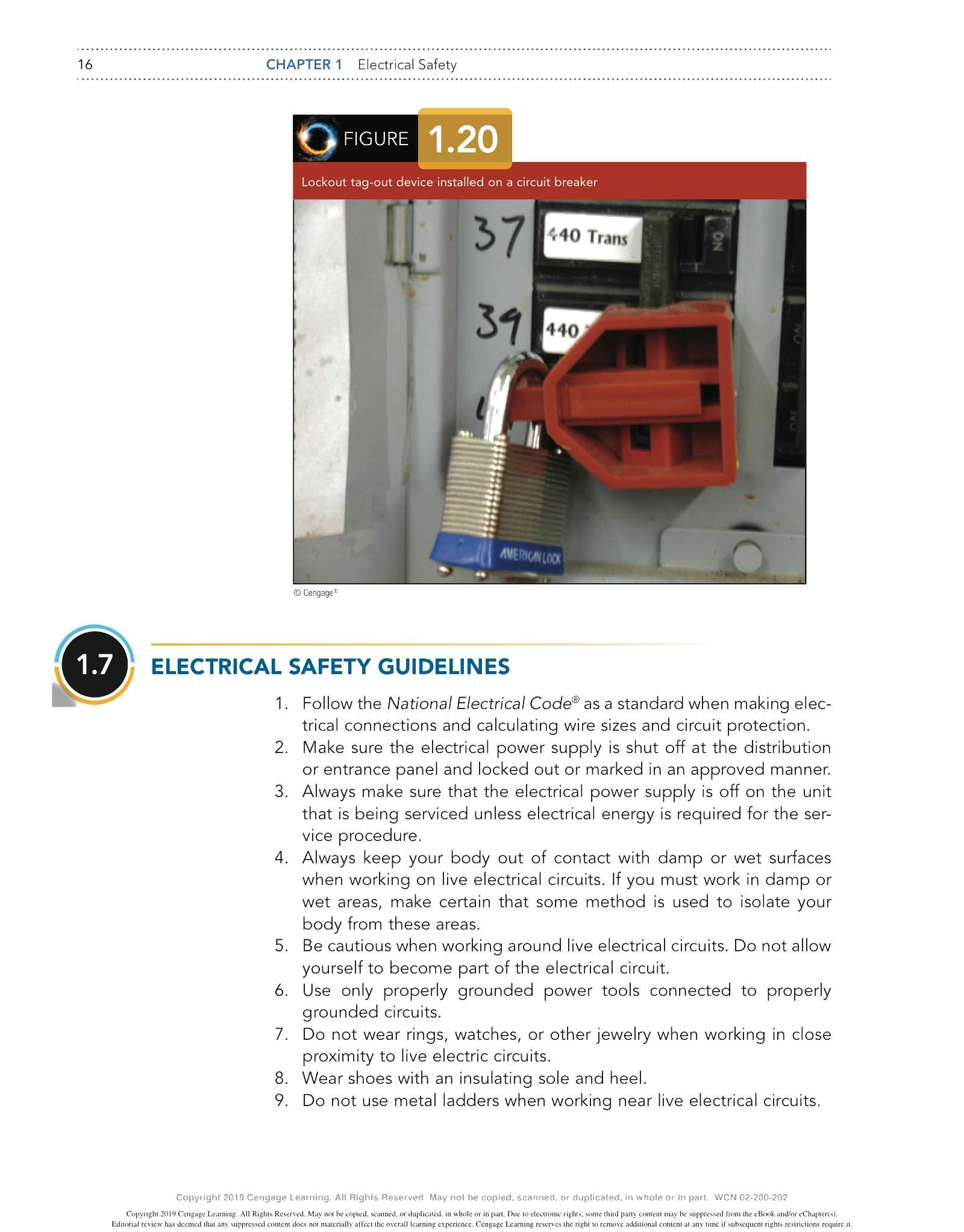

might acc i denta l ly restore e l ectrical power to that circuit, the technician shou l d place a padlock and/ or a warning labe l on the app l icable switch or circuit breaker. When you are working i n a res i dence, the chance of the homeowner closing sw itches that might affect your safety is remote but st i l l possible, so use some type of warning tag or verba l ly inform the homeowner. When working i n a structure where there are many people who could open and close switches, you should make absolutely certain that the electrica l energy is disconnected from the c i rcuit. Once the circuit is opened, mark the circuit so that others wil l not turn the c i rcu it on while the repair is under way. In a commercia l and industrial setting, this can be accomp l ished by using safety warning tags, pad l ocks, or l ocking devices made for that purpose. Figure 1.18 shows a p i cture of a l ockout tag-out k it used to safe ly disable an electr i cal device. Figure 1.19 shows a disconnect switch with a lockout tag-out device i nsta l led. Figure 1.20 shows a circuit breaker with a l ockout tag-out device i nsta l led.

ELECTRICAL SAFETY GUIDELINES

1. Follow the National Electrical Code®as a standard when making electrica l connections and calcu lat i ng wire sizes and circuit protection.

2. Make sure the electr i ca l power supp ly is shut off at the d i str i but i on or entrance pane l and locked out or marked in an approved manner.

3. Always make sure that the electrica l power supply i s off on the unit that is be i ng serviced unless electrica l energy is required for the service procedure.

4. Always keep your body out of contact w ith damp or wet surfaces when work i ng on live electrica l circuits. If you must work in damp or wet areas, make certain that some method is used to iso l ate your body from these areas.

5. Be cautious when working around live e lectrical circuits. Do not allow yourself to become part of the e l ectrical c i rcu it.

6. Use on ly properly grounded power tools connected to properly grounded circu its.

7. Do not wear rings, watches, or other jewelry when working in close prox i mity to li ve electric circuits.

8. Wear shoes with an insulating sole and heel.

9. Do not use metal ladders when working near l ive e l ectr i ca l circuits.

10. Examine all extension cords and power tools for damage before USing.

11. Replace or close all covers on receptacles that house e l ectrical wiring and controls.

12. Make sure that the meter and the test leads being used are in good condit i on.

13. Discharge all capacitors with a 20,000-ohm, 4-watt resistor before touching the terminals.

14. When attempting to help someone who i s being electrocuted, do not become part of the circuit. Always turn the electrical power off or use a nonconductive material to push the person away from the source.

15. Keep tools in good condition, and frequently check the insulated handles on tools that are used near e l ectrical circuits.

SUMMARY

Electricity cannot be seen but it certainly can be felt. It takes only a small amount of electricity to cause injury or even death. It is imperative that heating and air-conditioning technicians respect and be cautious around electrical circuits. It only takes a slip or careless move to find oneself in danger of electrocution or injury. The technician must be careful and cautious around live electrical circuits.

It would be ideal if you never had to work in close proximity with live electrical circuits, but that is not possible, especially when you are called on to troubleshoot heating and air-conditioning systems and equipment. You will be responsible for your own safety, and you should learn to respect and work carefully around live electrical circuits.