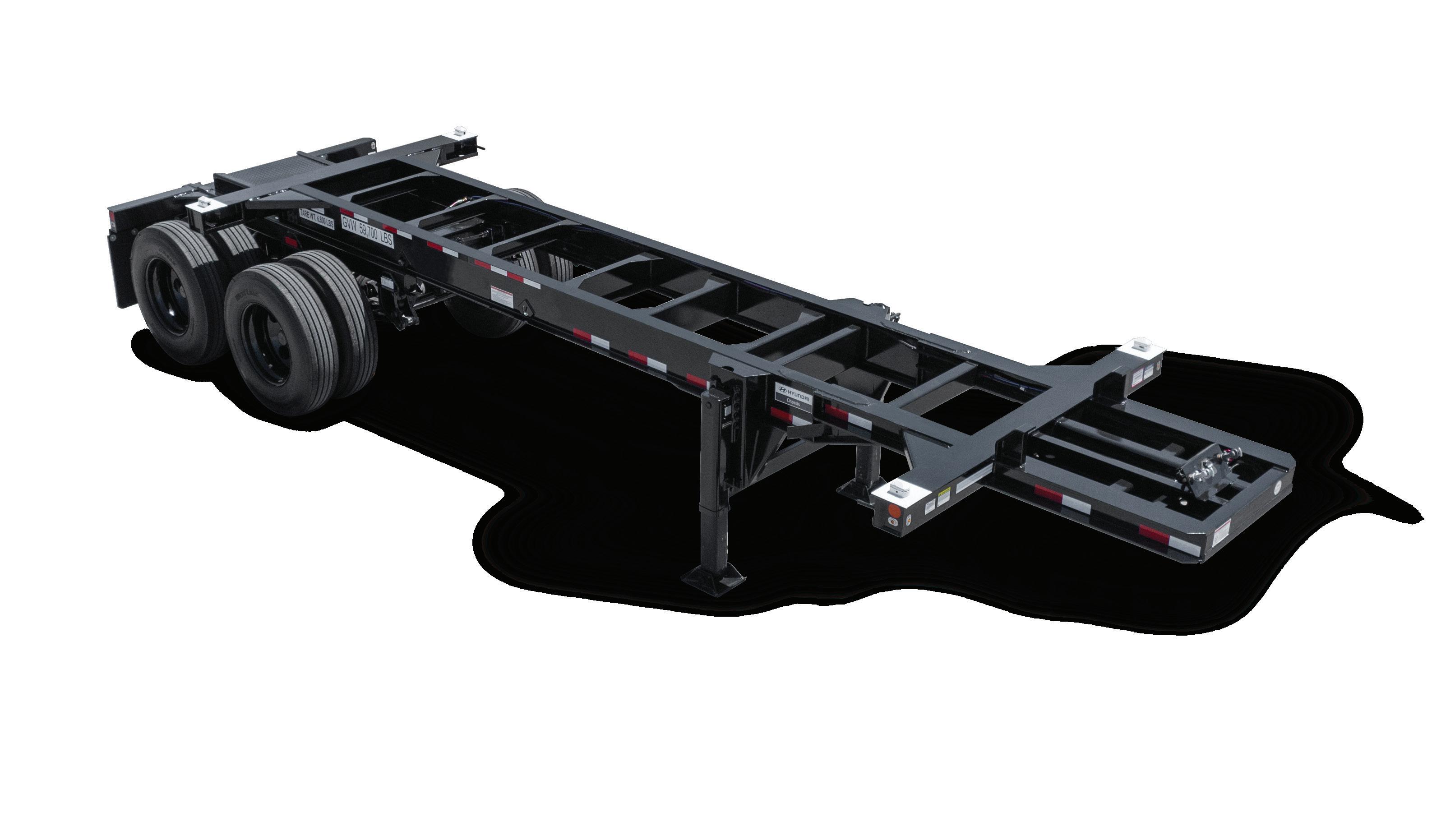

HYUNDAI FIXED CHASSIS

20’ Slider Tandem

The 20’ Slider Tandem offers superior strength and durability. Optimized for standard capacity 20’ containers, the sliding frame allows for a perfectly balanced haul.

STANDARD FEATURES

• Heavy duty construction

• All steel parts shot blasted, primer coated before and after fabrication with zinc rich primer

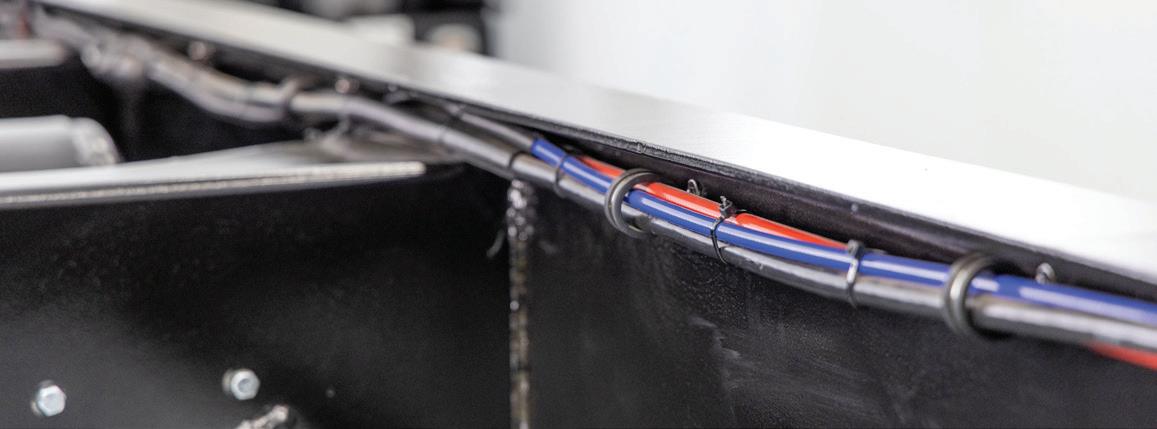

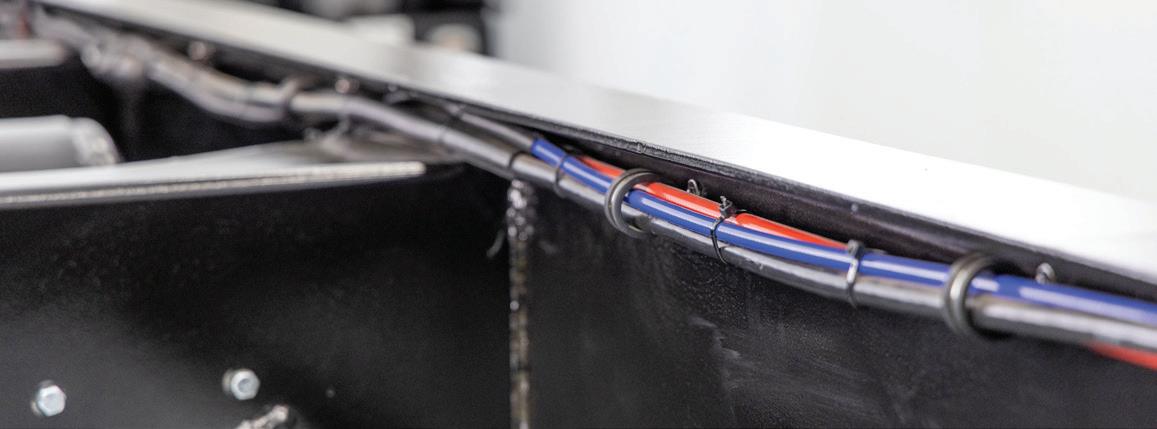

• Sealed wiring harness with integral ground

• A.A.R. Certified

• Straight type chassis with slider

Closed Length Extended Length Overall Width Capacity Tare Weight GVWR 23’ 6-1/4” 27’ 6-1/4” 96” 52,910 lbs 6,800 lbs 59,710 lbs HYUNDAI CHASSIS

20’ Slider Tandem Body Construction

Main Beam Hi-tensile steel, hot rolled 12” x 16 lbs/ft H-beam.

Kingpin Setting 18"

Crossmembers Fabricated channel

Upper Coupler

All hi-tensile steel construction with A.A.R. Certified cruciform style kingpin. All interior walls of closed sections coated for superior corrosion protection.

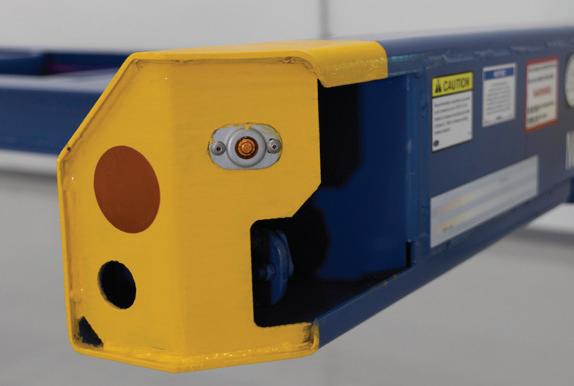

Front Bolster 8” wide x 6-3/4” deep U-channel with two non-retractable twist locks.

Rear Bolster

Landing Gear

Rear Impact Guard

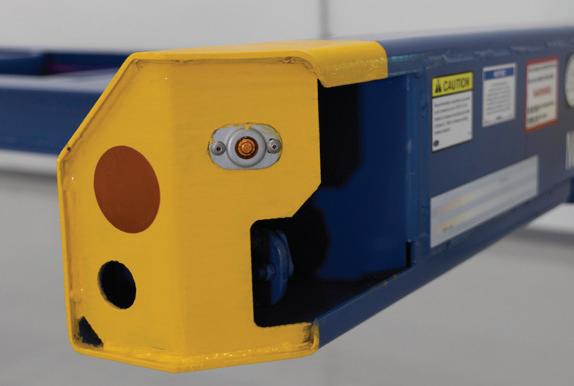

Bogie Slider

8” wide x 6-3/4” deep U-channel with two non-retractable twist locks.

55,000 lbs lift capacity with heavy-duty low profile sand shoe.

4” horizontal step U-channel designed and tested to conform to the Federal Motor Vehicle Safety Standards in effect at time of production.

4” x 6” A500 GRC rectangular tubing with spring loaded pins.

Suspension Hutchens overslung spring hangers with three leaf springs.

Wheel & Drums Heavy duty, 16-1/2” x 7” outboard mounted brake drums with 8.25” x 22.5” hub piloted disc wheels.

Tires 11R22.5 14 PLY (G)

Axles

Brakes

Lights & Wiring

5” round type, 22,500 lbs ratings, 71-1/2” track with 16-1/2” x 7” non-asbestos brake lining.

2S-1M ABS brake system. Meets Federal Motor Vehicle Safety Standards No. 121.

12V sealed system with molded connectors to accept sealed LED lamps.

Paint All steel parts shot blasted, coated with zinc rich primer, and finished with urethane topcoat.

Markings Customer markings installed. Conspicuity markings per Federal Safety Standards.

FRONT VIEW REAR VIEW

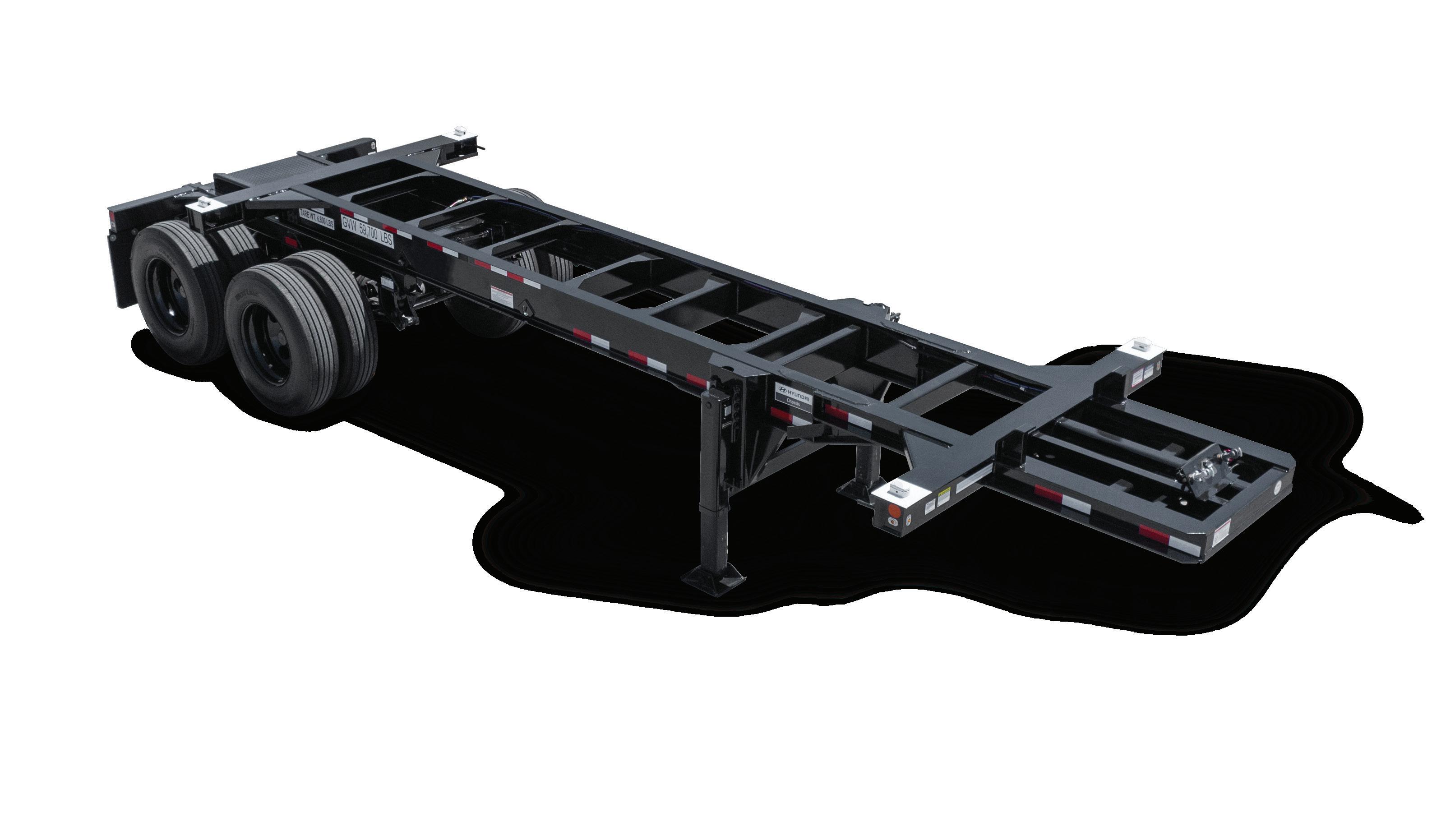

20’ Slider Tri-Axle

Built with high-strength alloy steel, the Tri-Axle Slider carries a 20’ container. This tri-axle configuration offers greater durability and stability with the tri-axle suspension allowing an increased load capacity.

STANDARD FEATURES

• Heavy duty construction

• All steel parts shot blasted, primer coated before and after fabrication with zinc rich primer

• Sealed wiring harness with integral ground

• A.A.R. Certified

• Gooseneck type chassis with slider

Closed Length Extended Length Overall Width Capacity Tare Weight GVWR 33’ 41’ 11-3/4” 96” 52,910 lbs 10,900 lbs 63,810 lbs HYUNDAI CHASSIS

20’ Slider Tri-Axle Body Construction

Main Beam Hi-tensile steel, hot rolled 14” x 38 lbs/ft H-beam.

Gooseneck Hi-tensile steel, hot rolled 10” x 19 lbs/ft H-beam.

Kingpin Setting 18”

Crossmembers Fabricated channel.

Upper Coupler

Front Bolster

All hi-tensile steel construction with A.A.R. Certified cruciform style kingpin. All interior walls of closed sections coated for superior corrosion protection.

8” wide x 6-3/4” deep U-channel with two non-retractable twist locks.

Rear Bolster 8” wide x 6-3/4” deep U-channel with two non-retractable twist locks.

Landing Gear

Rear Impact Guard

55,000 lbs lift capacity with heavy-duty low profile sand shoe.

4” horizontal step U-channel designed and tested to conform to the Federal Motor Vehicle Safety Standards in effect at time of production.

Bogie Slider Hi-tensile steel, hot rolled 10” x 30” lbs/ft H-beam with spring loaded pins.

Suspension

Wheel & Drums

Hutchens underslung spring hangers with three leaf springs.

Heavy duty, 16-1/2” x 7” outboard mounted brake drums with 8.25” x 22.5” hub piloted disc wheels.

Tires 11R22.5 14 PLY (G)

Axles

Brakes

5” round type, 22,500 lbs ratings, 71-1/2” track with 16-1/2” x 7” non-asbestos brake lining.

2S-1M ABS brake system. Meets Federal Motor Vehicle Safety Standards No. 121.

Lights & Wiring 12V sealed system with molded connectors to accept sealed LED lamps.

Paint

All steel parts shot blasted, coated with zinc rich primer, and finished with urethane topcoat.

Markings Customer markings installed. Conspicuity markings per Federal Safety Standards.

40’ Gooseneck

The 40’ Gooseneck chassis is strong and effective. Built for hauling a single 40’ container, this chassis features corrosion resistant construction for greater longevity.

STANDARD FEATURES

• Heavy duty construction

• All steel parts shot blasted, primer coated before and after fabrication with zinc rich primer

• Sealed wiring harness with integral ground

• A.A.R. Certified

• 4-3/4” Gooseneck height

Closed Length Overall Width Capacity Tare Weight GVWR 40’ 8-1/2” 96” 67,200 lbs 6,600 lbs 73,800 lbs HYUNDAI CHASSIS

40’ Gooseneck Body Construction

Main Beam

Hi-tensile steel, hot rolled 12” x 19 lbs/ft H-beam.

Gooseneck Fabricated I-beam with 1/2" top and bottom flanges, and 1/4” web all GR50.

Kingpin Setting 30”

Crossmembers Fabricated channel with gussets integrated every other crossmember.

Upper Coupler

Front Bolster

Rear Bolster

Landing Gear

Rear Impact Guard

All hi-tensile steel construction with A.A.R. Certified cruciform style kingpin. All interior walls of closed sections coated for superior corrosion protection.

8” wide x 10” deep U-channel with two locking pins.

8” wide x 7-7/8” deep U-channel with two non-retractable twist locks.

55,000 lbs lift capacity with heavy-duty low profile sand shoe.

4” horizontal step U-channel designed and tested to conform to the Federal Motor Vehicle Safety Standards in effect at time of production.

Suspension Hutchens overslung spring hangers with three leaf springs.

Wheel & Drums

Heavy duty, 16-1/2” x 7” outboard mounted brake drums with 8.25” x 22.5” hub piloted disc wheels.

Tires 11R22.5 14 PLY (G)

Axles

Brakes

Lights & Wiring

Paint

Markings

5” round type, 22,500 lbs ratings, 71-1/2” track with 16-1/2” x 7” non-asbestos brake lining.

2S-1M ABS brake system. Meets Federal Motor Vehicle Safety Standards No. 121.

12V sealed system with molded connectors to accept sealed LED lamps.

All steel parts shot blasted, coated with zinc rich primer, and finished with urethane topcoat.

Customer markings installed. Conspicuity markings per Federal Safety Standards.

REAR VIEW FRONT VIEW

40’ Lightweight Gooseneck

This model uses a lightweight, durable construction. The 40’ Lightweight Gooseneck features increased freight capacity by utilizing lightweight components such as aluminum wheels and a ported main beam.

STANDARD FEATURES

• Durable construction

• All steel parts shot blasted, primer coated before and after fabrication with zinc rich primer

• Sealed wiring harness with integral ground

• A.A.R. Certified

• 4-3/4” Gooseneck height

Overall Length Overall Width Capacity Tare Weight GVWR 40’ 8-1/2” 96” 67,200 lbs 5,550 lbs 72,750 lbs HYUNDAI CHASSIS

40’Lightweight Gooseneck Body Construction

Main Beam Hi-tensile steel, hot rolled 12” x 16 lbs/ft H-beam.

Gooseneck Fabricated I-beam with 5/16" top and bottom flanges, and 1/4” web all GR80.

Kingpin Setting 30”

Crossmembers

Upper Coupler

Front Bolster

Fabricated channel with gussets integrated.

All hi-tensile steel construction with A.A.R. Certified cruciform style kingpin. All interior walls of closed sections coated for superior corrosion protection.

8” wide x 10” deep x 3/16” thick U-channel GR80 with two locking pins.

Rear Bolster 8” wide x 7-7/8” deep U-channel GR80 with two non-retractable twist locks.

Landing Gear

Rear Impact Guard

Suspension

Wheel & Drums

Tires

Axles

Brakes

Lights & Wiring

50,000 lbs lift capacity, ultralight series, with heavy-duty low profile sand shoe.

4” horizontal step U-channel designed and tested to conform to the Federal Motor Vehicle Safety Standards in effect at time of production.

SAF Holland overslung spring hangers with two leaf springs.

Heavy duty, 16-1/2” x 7” outboard mounted brake drums with 8.25” x 22.5” hub piloted aluminum disc wheels.

255/70R22.5 16 PLY (H)

5” round type, 22,500 lbs ratings, 71-1/2” track with 16-1/2” x 7” non-asbestos brake lining.

2S-1M ABS brake system. Meets Federal Motor Vehicle Safety Standards No. 121.

12V sealed system with molded connectors to accept sealed LED lamps.

Paint All steel parts shot blasted, coated with zinc rich primer and finished with urethane topcoat. Markings Customer markings installed. Conspicuity markings per Federal Safety Standards.

53’ Gooseneck

The 53' Gooseneck is reliable and sturdy. Featuring a sliding suspension for weight distribution, this chassis is a perfect solution for fleets carrying 53' domestic containers.

STANDARD FEATURES

• Heavy duty construction

• All steel parts shot blasted, primer coated before and after fabrication with zinc rich primer

• Sealed wiring harness with integral ground

• A.A.R. Certified

• 4-3/4” Gooseneck height

Overall Length Overall Width Capacity Tare Weight GVWR 53’ 8” 96” 67,200 lbs 7,500 lbs 74,700 lbs HYUNDAI CHASSIS

53’ Gooseneck Body Construction

Main Beam

Hi-tensile steel, hot rolled 12” x 16 lbs/ft H-beam.

Gooseneck Fabricated I-beam with 5/8" top and bottom flanges, and 5/16” web all GR80.

Kingpin Setting 36"

Crossmember

Upper Coupler

Front Bolster

Rear Bolster

Landing Gear

Rear Impact Guard

Suspension

Wheel & Drums

Tires

Axles

Brakes

Lights & Wiring

Paint

Markings

Fabricated channel with gussets integrated every other crossmembers, and diagonal braces throughout rear bolster to landing gear section.

All hi-tensile steel construction with A.A.R. Certified cruciform style kingpin. All interior walls of closed sections coated for superior corrosion protection.

8” wide x 10” deep x 3/16” thick U-channel GR80 with two locking pins.

8” wide x 7-7/8” deep x 3/16 thick U-channel and 5/16” thick top plate, all GR80 with two non-retractable twist locks. all GR80 w/ two no retractable twist lock.

55,000 lbs lift capacity with heavy-duty low profile sand shoe.

4” horizontal step U-channel designed and tested to conform to the Federal Motor Vehicle Safety Standards in effect at time of production.

Hutchens overslung spring hangers with three leaf springs.

Heavy duty, 16-1/2” x 7” outboard mounted brake drums with 8.25” x 22.5” hub piloted disc wheels.

11R22.5 14 PLY (G)

5” round type, 22,500 lbs ratings, 71-1/2” track with 16-1/2” x 7” non-asbestos brake lining.

2S-1M ABS brake system. Meets Federal Motor Vehicle Safety Standards No. 121.

12V sealed system with molded connectors to accept sealed LED lamps.

All steel parts shot blasted, coated with zinc rich primer, and finished with urethane topcoat.

Customer markings installed. Conspicuity marking per latest Federal Safety Standards.

hyundaitranslead.com