Go from zero to hero in dental 3D printing in your clinic or lab in this comprehenive, systematic two day intensive

3D printing is everywhere in dentistry today, however the technology is far from plug and play. Understanding the key factors in the complex photochemical printing process that starts with optimal object design and material selection and extends through printing to washing to curing as part of a validated workflow is vital in order to achieve consistent, accurate results. This two day program delivered by industry experts is designed both for new users looking to upskill fast as well as current users who need to better understand every aspect of 3D printing.

• Overview of 3D printing technologies (FDM, SLA, DLP and MSLA printers), their applications, benefits, ROI.

• Printer and environment setup, calibration, resin tank installation, build platform alignment.

• How to calibrate resins to the printer.

• Selecting materials, types of dental resins; handling and storage to avoid contamination and premature degredation.

• Safety protocols: Ventilation, PPE, resin toxicity risks and disposal regulations.

• Types of software: design, mesh editing and slicers.

• File formats.

• Scanning and importing, converting intraoral and CBCT data to 3D models

• Design principles: Anatomy considerations, occlusion, margins and ensuring printability.

• Preparing for print: File import, orientation, supports generation in basic slicer software.

• Software tools for mesh repair, error detection.

• Monitoring print parameters like layer thickness, exposure time and print speed for dental accuracy.

• Washing techniques.

• Curing methods.

• Validated workflows.

• Common pitfalls.

• Printing more complex designs like surgical guides, aligners and implant models, etc.

• Optimisation for reducing material use.

• Slicer software deep dive.

• Troubleshooting common issues.

• Reasons why resin prints fail.

• Integrating 3D printing into a dental lab or clinic.

• Maintenance tips.

• Future trends: AI-assisted design, design outsourcing and new materials.

• Next steps – Advanced training, consultancy, where to get help.

And so much more...

Terry Whitty

Jeroen

Charlie

WITH PRINTED

By Joseph Allbeury

For the thirteenth time, almost in a row except for the COVID mess, I joined hundreds of other Australians and thousands - 135,000 to be exact - of dental colleagues from across the globe in descending on Cologne, Germany for the greatest show on Earth. And once again, it delivered and then some.

The 41st IDS concluded with 135,000 visitors from 156 countries having come together to see the latest and greatest from 2,010 exhibitors from 61 countries.

The exhibition - there is no accompanying education program - covered 180,000 square metres with stands big and small on show from every dental manufacturer you know and love and thousands you have never heard anything about at all and never will.

From a dentists’ perspective, the IDS is often a bucket list trip to see how big “dentistry” actually is [it’s massive]. Much of what is on show will never be available in Australia, however, it’s certainly the place to stay on trend with the latest in diagnostic technology, radiography, intraoral scanning and the like.

Dental technicians and prosthetists, conversely, flock to the IDS to keep up with the trends in manufacturing solutions. Big ticket items like milling machines are plentiful at the IDS as are 3D printing solutions and the exhibition is a great place to find out exactly what’s coming next. Manufacturing dentures digitally remains a key area of interest.

Most of all, however, IDS is where the dental industry comes together to deal. The dental trade from Australia meets with the agencies they represent to renew relationships and see what’s coming next. Equally, manufacturers are often on the look out for new distributors and distributors for new agencies. With everything all in one place, the event attracts dental dealers from across the globe.

Digital Dentistry & Dental Technology 2025 is coming up on August 1-2 and many of the new products from IDS 2025 will already be on show.

We’ve been working hard to firm up the education program and if you visit www.dentaltechnology.com.au, 80% of the sessions are now locked in with 30+ speakers confirmed presenting across six streams. Expect lots on full arch restorations, digital dentures, 3D printing, milling, CAD and CAM software, artificial intelligence, automation, intraoral scanning, 3D facial scanning, milling, orthodontics, photogrammetry, materials, smile design, implantology, CBCT, cosmetic dentistry, aligners and more.

The venue is looking pristine following the conclusion of renovations and the new ballroom will bring the exhibition together in a single location. The format is once again the same but there will be some changes we hope will enhance the delegate experience.

So register now and don’t miss out!

Enjoy the edition...

Joseph Allbeury, Editor and Publisher

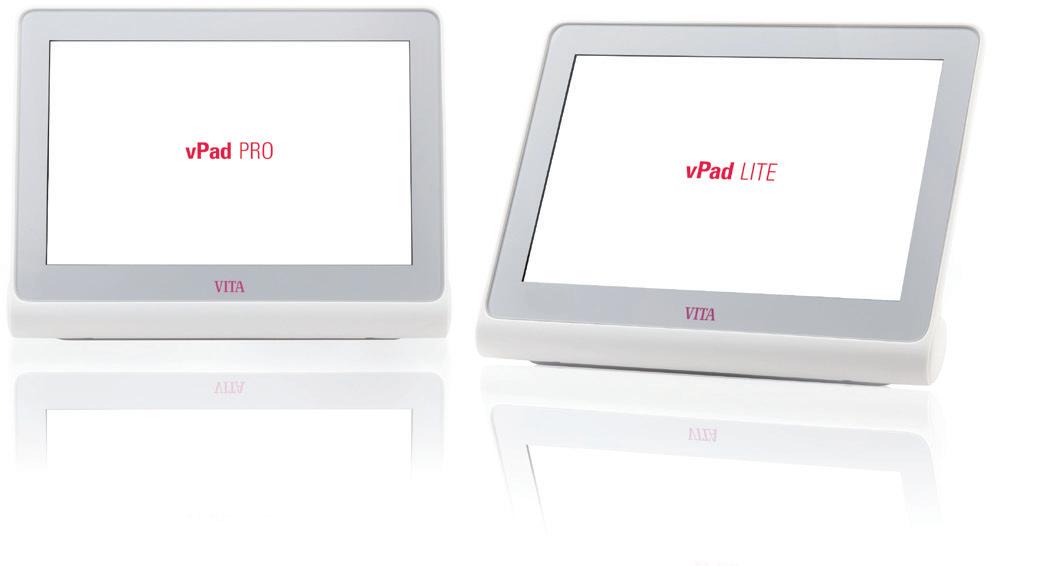

With the new VITA vPad LITE and VITA vPad PRO models, VITA Zahnfabrik is introducing two new control units for VITA firing and sintering furnaces that make everyday work in dental laboratories and dental practices even easier. The devices replace the previous models VITA vPad comfort and VITA vPad excellence and feature a clear, user-friendly interface and new, well-designed functions. VITA vPad LITE is designed for users who need a reliable device for standard applications. It offers impressive intuitive navigation, clear menu navigation and a solid technical foundation – ideal for everyday use. The VITA vPad PRO also offers advanced features such as a programmable start time and versatile connection options. This makes the VITA vPad PRO particularly suitable for more complex processes that require efficiency and control – without compromising on user friendliness. Both models were specially developed for the requirements of the firing and sintering process. They help streamline workflows, reduce operating times and focus on what matters most – a seamless process flow in the laboratory and practice. Whether it’s a standard application or more advanced control, the VITA vPad LITE and VITA vPad PRO provide dental practices and dental laboratories with the perfect solution to fit their needs.

VITA Zahnfabrik and UP3D now offer a fully validated workflow for dental milling applications. At the heart of this new partnership lies the successful validation of VITA’s complete CAD/CAM material portfolio on the UP3D milling machine series – including the models P42, P53 and P55D. This allows dental laboratories and clinics to work with a fully harmonised system – from material selection to final restorations. The validation covers the full range of VITA CAD/ CAM materials – from the million-times proven feldspar VITABLOCS, the high-performance VITA YZ zirconia, and the unique VITA ENAMIC hybrid ceramic to the VITA VIONIC materials for digital denture production. This ensures not only reliable results, but also restorations that meet the highest standards of esthetics and functionality. UP3D is known for delivering powerful yet attractively priced CAD/CAM systems with a strong and growing global customer base. In combination with VITA’s proven materials, this creates a forward-looking solution that is simple, efficient and validated.

Ivoclar has introduced IPS e.max Ceram Art, its new product line for the customisation of ceramic restorations. The ready-to-use stain, glaze and structure pastes open up new creative possibilities and integrate seamlessly into a variety of fabrication techniques, from press and CAD/CAM technology to monolithic and layered restorations. As the latest addition to the globally successful IPS e.max all-ceramic portfolio, IPS e.max Ceram Art sets a new standard in the finalisation of ceramic restorations.

In addition to conventional staining materials, the new line includes innovative glaze materials that feature a unique Magic Glaze effect with optimal viscosity for easy application without beading or running, delivering a brilliant natural shine. The pastes are also ideal for the one-shot technique, in which staining and glazing are combined in a single firing cycle.

Another highlight of the range is the inclusion of firing-stable, cadmium-free gingiva shades, designed to enable natural-looking gingival characterisation across diverse phenotypical variations. With its optimised consistency, IPS e.max Ceram Art is ideally suited for wet-on-wet staining (one-shot technique). Staining and glazing can be performed in a single firing cycle, saving time and simplifying workflows – a real advantage for modern, efficiencyfocused laboratories. A standout feature of the ready-to-use IPS e.max Ceram Art pastes is the self-glaze effect, which eliminates the need for an additional glaze firing.

In lifelike reconstructions, the design of the gingival area is becoming increasingly important. Colour, translucency and structure vary greatly among individuals and significantly influence the overall appearance of the restoration.

The new IPS e.max Ceram Art gingiva materials – cadmiumfree for the first time – are available in a wide range of shades to reproduce virtually all phenotypical variations. Reconstructed gingival areas blend seamlessly into their surroundings, delivering results that look very natural.

The new product line also delivers outstanding results in surface design. The form-stable structure pastes provide targeted 3D effects, such as natural tooth or gingiva textures – without the need for an additional layering step. Together, these advantages make IPS e.max Ceram Art a material that offers creative freedom in design and process reliability in application. The materials are perfectly matched to Ivoclar’s all-ceramic framework materials such as IPS e.max Press, IPS e.max CAD (lithium disilicate) and IPS e.max ZirCAD (zirconium oxide). They can also be used for the characterisation of Ivoclar’s metal-ceramics, as well as other framework materials with a compatible CTE.

A limited first edition of 750 exclusive kits of IPS e.max Ceram Art is now available, allowing dental technicians to purchase the new product range ahead of its official launch. The First Edition includes the complete range of pastes and is the ideal introduction to working with IPS e.max Ceram Art. Each kit comes with training materials and application tips, so users can make the most of the product from day one.

More info about the First Edition, the product selection and its scope of applications, see www.ivoclar.com/ips-e.max-ceram-art or call 1300-486-252 orders.au@ivoclar.com in Australia or in New Zealand, call 0508-486-252 orders.nz@ivoclar.com

A glimpse at Zirkonzahn’s new Premolaris production site

The principle of creating everything in-house has always guided Zirkonzahn since its first steps in the dental market. This principle is applied to almost the entire range of the Company’s products, which includes dental materials (such as zirconia, metals and resins), CAD/CAM systems, furnaces, implant prosthetic components, digital diagnostic technologies, tools and everything required to finalise patient-specific dental restorations. Products are studied, developed and produced in-house in close collaboration with the company’s Research and Development team, which constantly works to improve and fine-tune solutions to create a reliable planning and working environment, where hardware, software, tools and materials form an optimum match in the complete workflow.

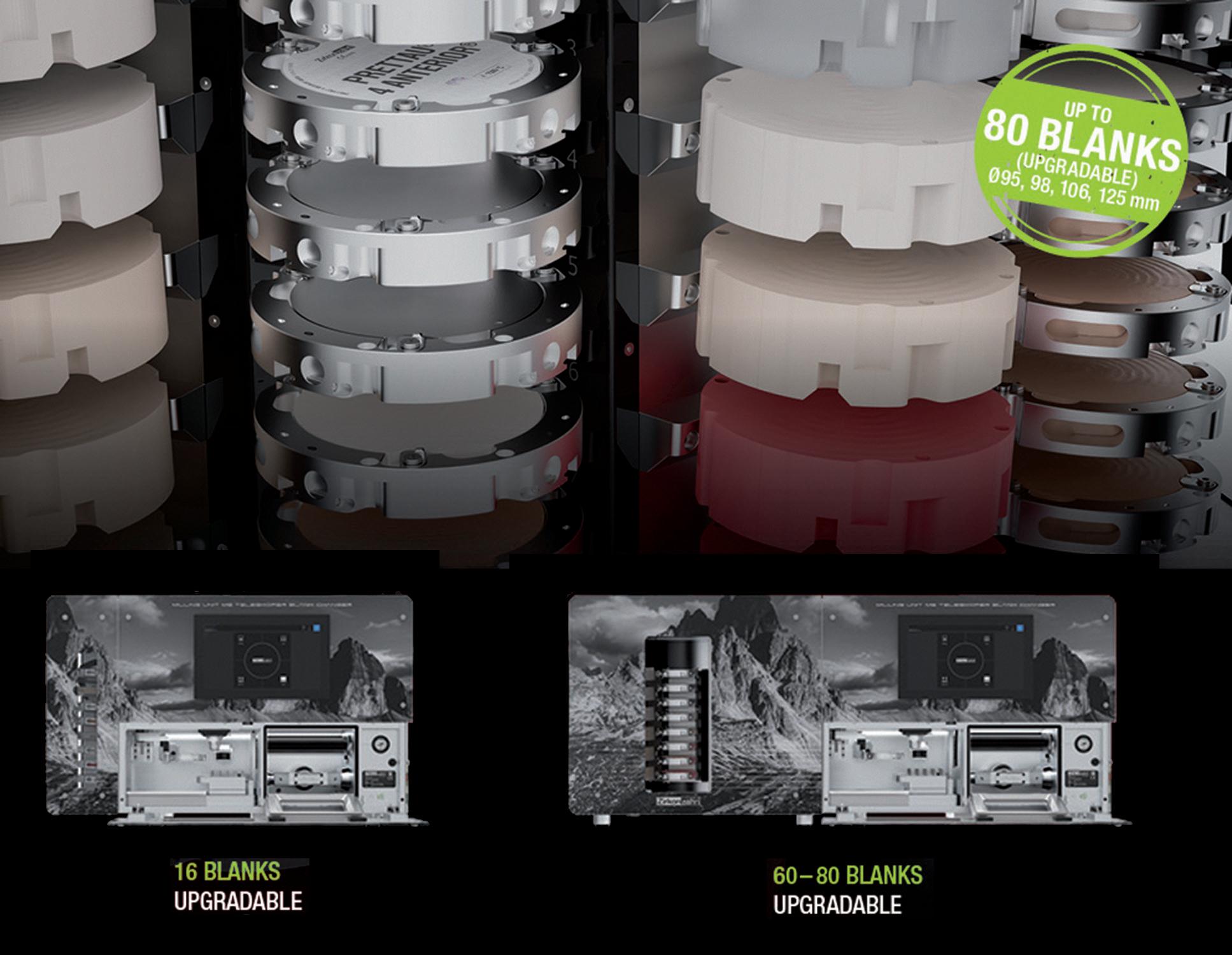

The full control over the entire production process allows Zirkonzahn to have a complete understanding of their products and to react very quickly to customers’ needs, not only through constant optimisation but also through a comprehensive technical and dental technical support at any workflow stage. The newest milling unit, the M6 Teleskoper Blank Changer, is namely the company’s answer to the increasing need for more automation as well as greater speed and performances. The 5+1 axis simultaneous milling unit is equipped with storage for 16 or 80 blanks (upgradable) as well as a Blank Changer that allows material blanks to be transferred autonomously from the storage to the orbit. Once the structure is milled, blanks are reinserted back in the storage in their correct slot. This means that restorations made of different dental materials, colours and heights can now be designed fully automatically without any manual intermediate steps.

r.zirkonzahn.com/0hz

The new Abro ® resin is characterised by excellent translucency values, high flexural strength as well as fracture and abrasion resistance. Specifi cally conceived for the production of single crowns, this resin is also well suited for long-term temporaries as well as different secondary and tertiary structures. It is available in two different types: monochromatic (Abro ® Basic Mono) or with natural colour gradient from dentine to enamel (Abro® Basic Multistratum®).

r.zirkonzahn.com/370

Gingiva-coloured resin with improved material properties in terms of flexural strength and fracture resistance, specifi cally conceived for the production of denture bases. The resin blank is also available in Ø 125 mm for the manufacturing of up to two denture bases in just one milling process.

r.zirkonzahn.com/63b

Liquid for bonding Abro ® Basic Mono, Abro ® Basic Multistratum ® and Denture Gingiva Basic Mono resins. It is also suitable for polishing Multistratum ® Flexible and Temp Premium Flexible resins.

The machine also features the Teleskoper Orbit SelfLock (Ø 125 mm) for processing blanks with a diameter of 95, 98, 106 and 125 mm and the newly developed Performance Spindle with Permanent Magnet Synchronous Motor (PMSM), permitting a maximum torque of 200 Ncm at speeds of 6,000 to 50,000 rpm with a peak power of 2.5 kW.

In addition, in the contamination-protected tool chamber, two magazines with 30 slots each ensure safe and tidy storage of up to 60 milling burs, which are automatically checked for type or damage before and after each milling process through the automatic tool changer function.

All milling machine components are assembled in-house in Premolaris (2021): the fourth of the five production sites owned by the company, all located within the vicinity of the firm’s headquarters in South Tyrol (Italy).

In Premolaris, the different parts of the M6 milling unit, e.g. spindle and orbit, are assembled with all hardware and software components. All parts such as ball screws, linear rails, motors and milling spindles are tested for precision before they are installed, and the resultant data is recorded and registered. Then, the machine is calibrated and fine-tuned at individual stations according to standardised production processes.

Premolaris is the place dedicated to the assembly, testing and customisation of all of the company’s milling units, furnaces and scanners as well as the surface treatment of their own-produced implant prosthetic components. Premolaris also hosts the company’s chemistry labs where, for instance, colours and resins are developed or burs are diamond-coated.

Machine assembly is a very complex procedure and employees have to comply with strict checklists, which serve to coordinate the different working steps and ensure safety. The new milling unit must pass through numerous quality stations before it reaches the final inspection and each employee is responsible for a specific assembly step, becoming an expert in what he or she does.

The first milling process is also performed in this location: only after the execution of the final checks and tests is the equipment ready to leave the production site, moving on to the onsite logistic department. A selection of glass cases, which the clients can choose from to personalise their equipment, is also available.

To discover the new M6 Blank Changer Teleskoper, scan the QR code or visit www.zirkonzahn.com

+ Fully automatic blank changer

+ Blank storage for up to 16 or 80 blanks (upgradable)

+ Tool magazines (2x30) with automatic tool changer function

NEW! MILLING UNIT WITH FULLY AUTOMATIC BLANK CHANGER FUNCTION FOR UP TO 16 OR 80 BLANKS (UPGRADABLE)

+ Teleskoper Orbit SelfLock (Ø 125 mm) for processing material blanks with Ø 95 mm, 98 mm, 106 mm and 125 mm

+ Performance Spindle with max. torque of 200 Ncm at speeds of 6.000 to 50.000 rpm with a peak power of 2.5 kW r.zirkonzahn.com/g3t

Dental technician Eelco van Wort has owned the milling centre Dental Design Centrum (Haarlem, Netherlands) together with his brother Martijn van Wort for 13 years and is an aspiring prosthetist. Along with their 12-person team, they exclusively offer CAD/CAM-supported dental technology for laboratories, dental practices and prosthetists. The focus is on design and subtractive manufacturing. Compared to crown and bridge work, digital full denture prosthetics is still a very young field, but it has been part of their portfolio for five years. In the following interview, Eelco talks about his experiences and the developments he has observed during this time.

QWhat are the reasons digital full dentures are becoming more and more established in the Netherlands?

AWe offer a dental technology service with our milling centre. We have noticed that more and more practitioners are able to design their own complete dentures in CAD software, but are not equipped to manufacture them with CAD/ CAM support. And that's where we come in. Of course, the lack of specialist staff is also a key reason for the rise in digital full dentures. Automation means that the milling unit can also work independently overnight. There have been great leaps in development in terms of quality, so we have decided that our clients should benefit from this too.

QWhere do you see decisive differences, perhaps also advantages and disadvantages, between analog and digital fabrication of removable full dentures?

AI don't think the time factor is even that decisive. If someone has a lot of total prosthetic experience, they may even be a little faster than the digital workflow if they move quickly. But if they've had a bad weekend, for example, the result on a Monday morning may not be as successful as usual. In the digital workflow, the quality will always be the same. Regardless of the human element, two millimetres will remain two millimetres. The setups are always reproducible. For me, this is the decisive reason as to why I produce complete dentures in the digital workflow.

Q

Who are your customers and how have they accepted digital full dentures? Are there price differences between analog and digital fabrication?

A

We generally do not make analog prosthetics. We have focused on producing digital full dentures with VITA VIONIC VIGO. We then only have to

bond the ready-to-use premium teeth into the base with VITA VIONIC BOND. This enables us to offer better quality than other milling centres that mill the teeth from unfilled PMMA, for example. Our clients are mainly prosthetists who can't use CAD/ CAM. So once I'm a prosthetist, I'll become my own client (laughs). I then order the complete dentures from my own company.

Q

Is there a price difference between analog and digital full dentures and if so, how big is it?

AWhen we started producing CAD/ CAM-supported full dentures around six years ago, the material components were still a little too expensive compared to analog production.

However, we have observed that the material prices for digital full dentures have become lower and lower over time, making it more and more economically attractive. The classic wax set-up is probably a little cheaper in terms of materials, but the time required is significantly higher in most cases. The bottom line is that digital full dentures are now comparable in price to analog full dentures.

Q

What experience have you had with the VIONIC DENT DISC multiColor so far? For which removable restorations do you mill your teeth yourself?

AThe VITA VIONIC DENT DISC multiColor has closed a gap in our portfolio. The composite disc is a real advantage, especially when space is limited. With a very low vertical bite height, the material gives us the functional leeway we need. We will also use it for immediate dentures. It offers high-end quality in the subtractive fabrication of dental material,

as the composite formulation is the same as with all other VITA premium teeth. It can therefore be assumed that the quality is better than that of conventional, unfilled PMMA blanks. I am very pleased that VITA VIONIC DENT DISC multiColor is available.

QHow do you assess the development of additive manufacturing in removable full denture prosthetics? Are you planning to work with this technology?

A3D printing is certainly the future of full denture prosthetics. Even as a milling centre, we cannot close our eyes to it. It is cheaper and will probably also be faster. A single-coloured denture base can already be printed easily today. This does not yet apply to robust teeth with a colour gradient and translucency in the right places. Sustainability is now also a major issue in dentistry and dental technology. Only the material that is really needed is used as an additive. This is

much better for the environment than milling from a blank and throwing away the leftovers.

QIn your opinion, how will the technology and the job profile of dental technicians and prosthetists change in the future?

AI think digitalisation will become mainstream in the future. Materials will continue to improve and processes will become faster and more consistent. Digitalisation will definitely prevail in the technical fabrication of dental restorations. VITA VIONIC VIGO and the VITA VIONIC DENT DISC multiColor are already helping us to produce functional and aesthetic complete dentures in a digital workflow to give patients their teeth back and make them happy. As a dentist, however, you should always bear in mind that the option for analog treatment of patients will continue for the forseeable future.

Experience effortless performance and higher ROI with the DWX-43W wet milling solution

Achieve faster production and flawless accuracy with the DWX-53DC dry milling solution

By Prof. Russell Giordano, DMD

With the American Dental Association redefining ceramics to include printed materials with at least 50% inorganic filler, many new products have been promoted for permanent restorations. With this in mind and noting that there are no ISO standards for printed restorations, this article details a scientific evaluation of several materials’ mechanical and physical properties.

Asimple ash method was used to determine filler content of several printed full contour restorative materials. The polymer component was burned off, leaving the inorganic filler behind, Figure 1.

lexural strength is one property that the dental community often uses as a criterion for material selection. While this might be important, other properties such as fracture toughness, elastic modulus, material wear and colour stability all factor into a comprehensive evaluation.

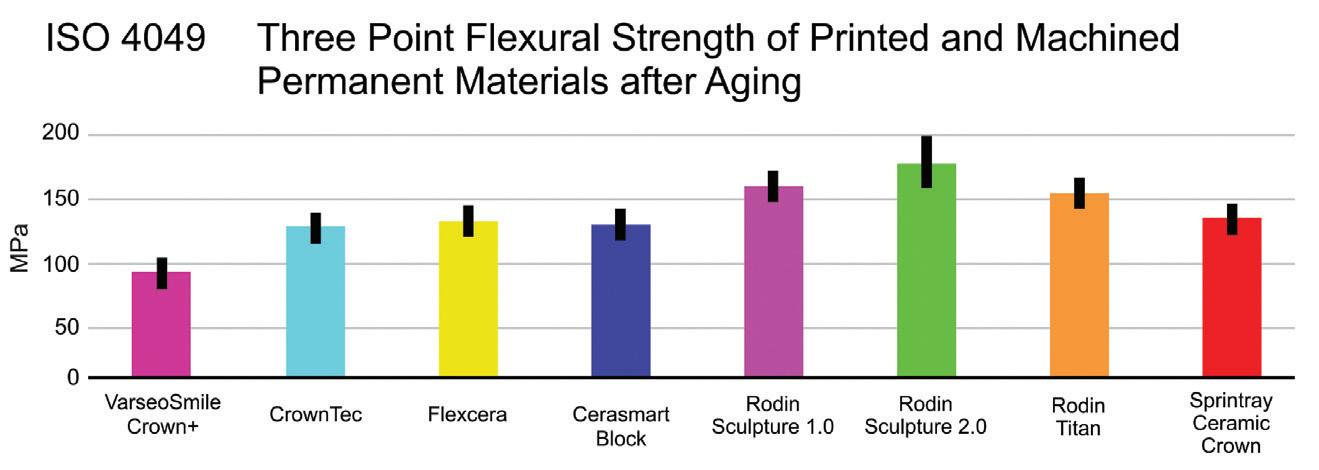

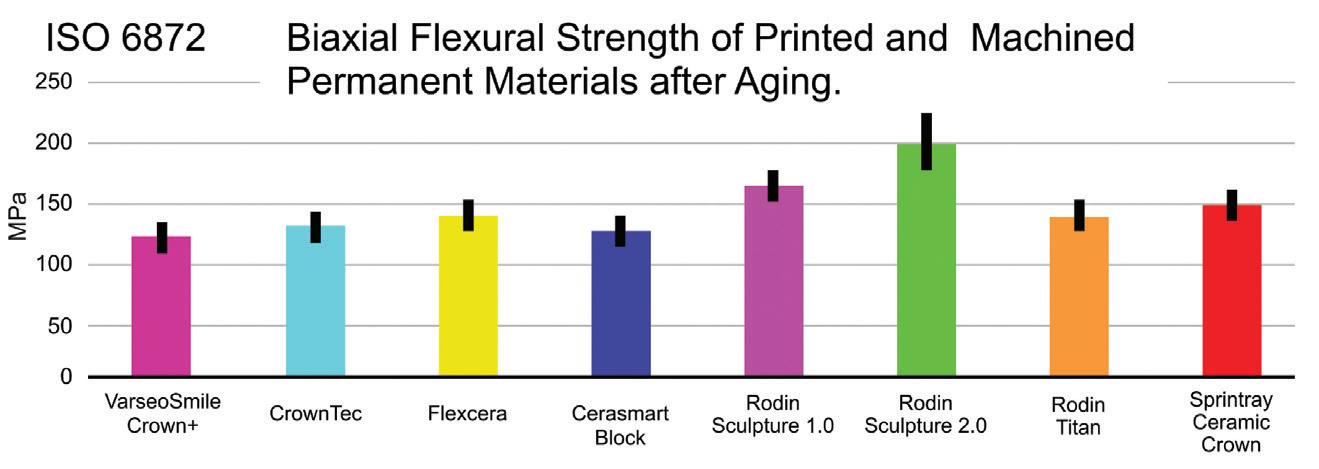

In this study, two different methods determining flexural strength were used. One followed ISO 4049 “Dentistry - Polymer-based restorative materials” to measure three-point flexural strength that involves testing bars of materials. Another used biaxial flexure strength that uses discs of materials. The biaxial test usually gives higher values but also is generally easier to conduct and many manufacturers reference biaxial strength of their materials. However, there currently is no biaxial strength standard for polymer-containing materials; therefore, ISO 6872 on Dental Ceramics was used as a guideline for the biaxial flexure strength specimens.

Athree-point bend test following ISO 4049 methodology was used. Bars were printed for each test material per

manufacturer’s recommendations. Parts were washed using isopropyl alcohol and cured using an Otoflash system under Nitrogen. The bars were tested on an Instron 5566A at a crosshead speed of 1.0 mm/min. Load at break was used to calculate flexural strength in MPa. A clinically successful composite resin block material was included for comparison in the strength tests. Results are shown in Figure 2.

In addition, a biaxial flexure strength test following ISO 6872 methodology was used. Discs were printed for each test material per manufacturer’s recommendations. Parts were washed using isopropyl alcohol and cured using an Otoflash system under Nitrogen. The discs were tested on an Instron 5566A at a crosshead speed of 1.0 mm/min. Load at break was used to calculate flexural strength in MPa. Results are shown in Figure 3.

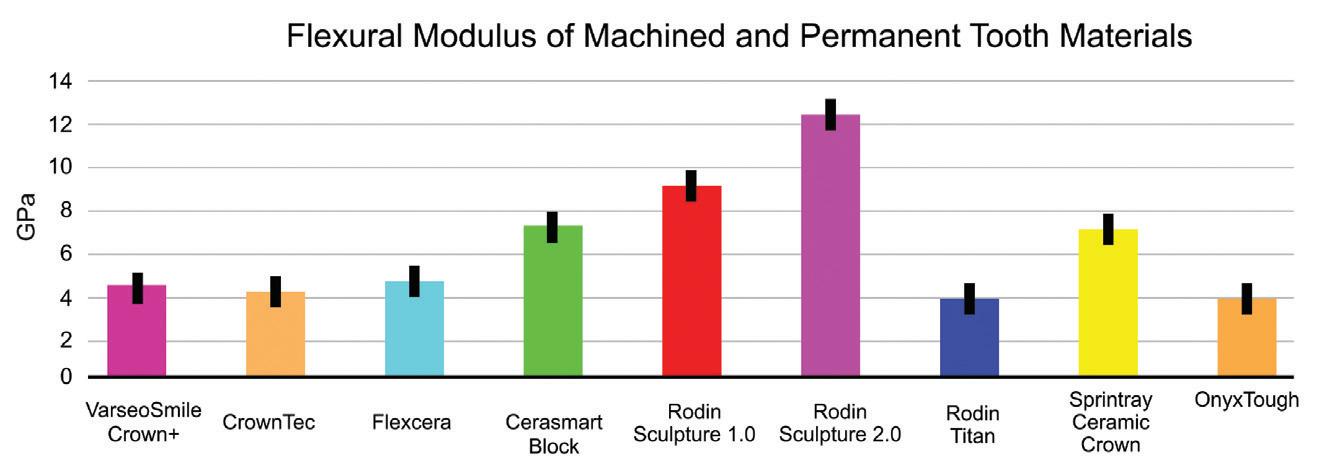

Flexural Modulus was determined from the three-point bend test. Modulus values are important in evaluating a material’s resistance to deformation under stresses developed during clinical use. Several years ago, a polymer-based material with a low modulus of about 2 GPa was widely used for crowns; failure rates were very high due to excessive wear sensitivity and debonding. Thus, we have some idea of what might be problematic with respect to modulus values. These values are presented in Figure 4.

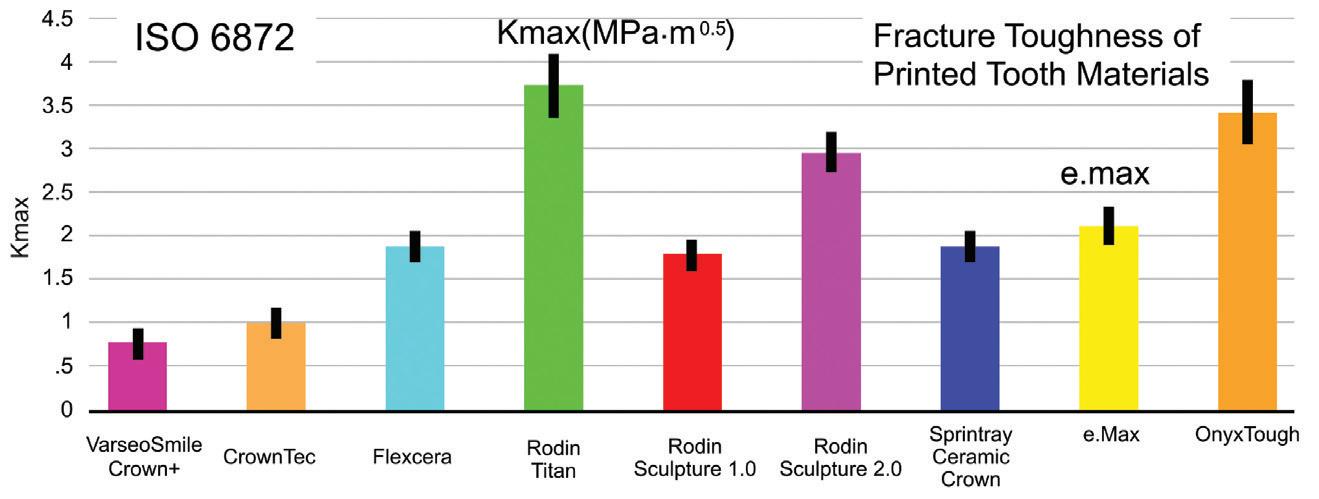

Fracture toughness is a measure of a material’s resistance to crack propagation. Ideally, we would like restorative materials to be able to sustain damage and remain intact and function even after the damage has been sustained. This is one advantage of materials like 3Y mol% zirconia. Fracture toughness was determined using a single edge notched beam on materials fabricated according to the manufacturer’s recommendations. Methodology for the polymer-based materials used ISO 20795 “Denture base materials” as ISO 4049 does not include fracture toughness testing. IPS e.max machinable ceramic was included for comparison with fracture toughness determined as described in ISO 6872 shown in Figure 5.

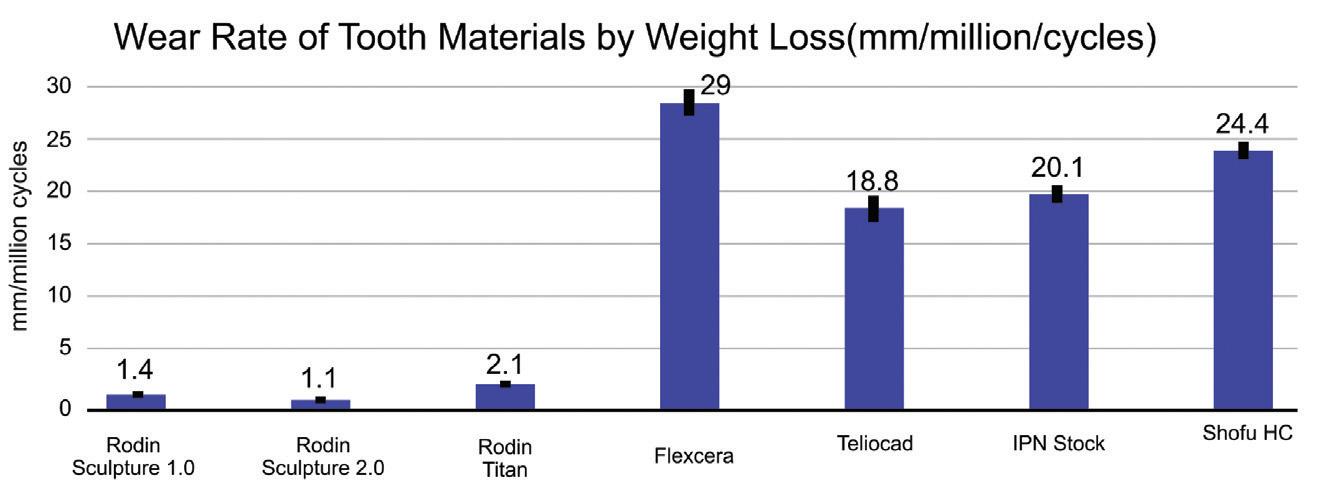

Rapid wear of restorative materials may create numerous clinical problems, as proper occlusion that was created with the restoration may rapidly change due to excessive wear of the material. Although this is an important property, there are no standardised wear tests. One of the most widely used methods follows one developed at the University of Alabama, Birmingham. Our laboratory fabricated a wear device based on this design and it has been used to determine wear rates for a variety of materials and even was accepted by the FDA to support wear kindness claims about fine particle veneering porcelains.

n this wear test, a pin of the test material is fabricated and then this is run against a plate of Vita MKII that has been shown clinically and in lab testing to have similar wear properties as tooth enamel. Plates of the tooth analog material are on the bottom of the device and pins of the test material are on the top and weighted. A continuous flow of water is used to remove wear debris. Weight and height loss are measured for the pin. The pins are bonded to metal rods that are weighted with a 400gm load. The pins are moved on a 39 mm path across the plates. A linear wear rate was determined for the test materials and weight and height loss per million cycles. Conventional composite resin as well as denture teeth were used for comparison. Height and weight loss per million cycles are shown in Figures 6 and 7.

Initial tests on colour stability were performed following an initial ISO standard (ISO 7491) on colour change. Specimens were printed as discs 20 mm x 2 mm thick according to manufacturer’s recommendations. These were polished using a Buehler Ecomet polisher in sequence finishing with a 1-micron diamond paste. Materials were subjected to toluidine blue dye and UV light. The Lab* values and the change in E values were determined before and after treatment using an X-Rite I7 spectrophotometer. Specimens were also stored in de-ionised water and in the dark (control group) for 7 days. Clinically, colour differences are seen by most people when there is a difference of 2 to 4 E (Figure 8).

In summation, many 3D printing materials do not meet the American Dental Association definition for a ceramic due to low filler content. Overall, the material properties of several of the printed materials compare favourably with machinable composite resins and conventional ceramics with respect to mechanical and physical properties.

Dr Russell Giordano, DMD is currently Professor, Director and Assistant Dean of Biomaterials and Biomaterials Research with a joint appointment as a Professor in the Division of Materials Science and Engineering, Henry M. Goldman School of Dental Medicine at Boston University. He received specialty training in prosthodontics at Harvard School of Dental Medicine and performed research at the Ceramics Processing Research Laboratory at the Massachusetts Institute of Technology leading to a DMSc degree in 1991 and a Certificate in Prosthodontics. Dr Giordano’s research involved novel ceramics processing techniques as well as analysis of stress developed during finishing procedures. His research paper won the Arthur R. Frechette Award presented by International Association of Dental Research Prosthodontic Group. Giordano presently has several private and federally funded projects. A major research focus is ceramics and ceramic matrix composites.

dentevents presents...

SYDNEY 29-30 MAY 2026

NOVOTEL SYDNEY BRIGHTON BEACH

TWO DAYS OF LECTURES AND WORKSHOPS ON DIGITAL DENTISTRY FOR DENTISTS, SPECIALISTS, DENTAL TECHNICIANS AND DENTAL PROSTHETISTS

BEFORE 29 NOVEMBER 202 5 (SAVE 75%)

Join us again or for the first time at Digital Dentistry & Dental Technology No 7 for a fun, exciting and fully immersive learning experience with the best of the best in the new age of dentistry. This year’s program will again cover Digital Smile Design • Digital orthodontics • Intraoral scanning • AI • 3D Facial Scanning • Digital implantology • Digital full arch restorations and full mouth rehabilitations • Digital Dentures • 3D Printing • Milling • CBCT • Materials and applications • Software and more with MORE Hands-on Sessions • MORE Advanced Sessions • MORE New Products • NEW Masterclasses... and more!

REGISTRATION FEES

$880 inc gst

EARLY BIRD PRICING

$220 before 29 nov 2025 price increases $110 on the 2nd of every month

VENUE DETAILS

INCLUSIONS

Registration fee includes participation in TWO full days of education (12 CPD hours), all catering and Friday drinks. Multiple lectures and workshops are being run concurrently to allow you to build your own program to suit your specific interests. Price is all inclusive.

PROGRAMME DETAILS

FRIDAY 29 MAY 2026

9.00am - 5.00pm - education 5.00pm - 7.00pm - drinks SATURDAY 30 MAY 2026 9.00am - 5.00pm - education

Novotel Sydney Brighton Beach - The Grand Parade, Brighton-Le-Sands NSW 2216 - Close to Sydney Domestic and International Airports Check the website for details of discounted accommodation rates for the conference • Ample parking available at the hotel

Answer the questions online at www.dentalcommunity.com.au To retrieve your FREE Dental Community Login, Call (02) 9929 1900 or email joseph@dentist.com.au

Question 1. What is one major advantage of modern intraoral scanners used for edentulous cases?

a. They eliminate the need for any clinician input.

b. They are smaller, lighter and more ergonomic than earlier models.

c. They automatically design and print dentures.

d. They require multiple cables and external computers.

Question 2. Why are special scanning tips used when capturing fully edentulous arches?

a. They reduce light reflection from soft tissues.

c. They limit the scanning area to improve detail.

b. They allow capture of a larger area of data per pass for better accuracy.

d. They prevent overheating during long scans.

Question 3. If a direct intraoral scan is not possible, what alternative method can still be used in a digital workflow?

a. Taking traditional impressions and scanning them.

b. Photographing the mouth with a DSLR camera.

c. Using an old denture without modification.

d. Skipping the impression stage completely

Question 4. Why might an existing denture be relined before using it for jaw relation records?

a. To restore the surface gloss before scanning.

b. To update the internal surface to match current oral anatomy.

c. To make it more aesthetically pleasing in photos.

d. To increase the denture’s occlusal vertical dimension.

Question 5. In a complete digital denture workflow, what is typically the final step before design begins?

a. Exporting the aligned scans into denture design software.

b. Performing a border moulding with compound.

c. Polishing and finishing the printed denture.

d. Taking a facebow record.

INSTRUCTIONS:

Question 6. Why is printing dental appliances directly on the build plate usually avoided?

a. It wastes more resin and time.

b. Most appliances lack flat surfaces suitable for build-plate adhesion.

c. It reduces accuracy due to excess support structures.

d. The printer’s software cannot process flat surfaces.

Question 7. What is the main reason angled printing improves success in resin 3D printing?

a. It reduces resin curing time by using thinner layers.

b. It helps resin drain efficiently and lessens peeling forces on each layer.

c. It shortens the print file size for faster slicing.

d. It makes the model easier to remove from supports.

Question 8. What type of supports are typically recommended for printing dental appliances?

a. Very light supports with minimal density.

b. Randomly spaced supports for flexibility.

c. Medium to heavy supports with dense distribution for stability.

d. No supports are needed when angled correctly.

Question 9. What is the best approach when supports must touch critical fitting surfaces?

a. Use large supports for stronger adhesion.

b. Avoid supports on fitting areas entirely.

c. Use the smallest possible contact points and finish carefully after printing.

d. Increase print speed to compensate for surface damage.

Question 10. Before starting a full production build, what step is strongly advised to prevent failures?

a. Running the printer’s cleaning cycle.

b. Checking every layer in the slicer preview and testing smaller prints first.

c. Printing multiple copies of the model to improve adhesion.

d. Increasing exposure time on all layers.

Whether you need assistance with complex cases or during busy periods, just Plug in Dentmill, our purpose-built milling centre based right here in Melbourne. Using the latest CAD/CAM technology and Australia’s only Röder’s High-Speed Dental Milling Machines, Dentmill can seamlessly manufacture a variety of top-end quality dental products for your lab.

and learn more

By Terry Whitty

Full dentures as we know are not a replacement for natural teeth but are a great alternative for not having teeth. Taking records and overall construction can be challenging for practitioners at any level of expertise. The standard method of primary/ secondary impressions, wax rims for MMR then “try-in” setups and ultimately, the finished denture is a well-known standard we are all familiar with and currently still in use. Some people have dabbled with intraoral scanning for impression and record taking but in reality, up until now, it has been known to be plagued with issues and to be frank the hardware, software and techniques were yet to evolve enough to be consistent, accurate and repeatable.

Recently, a product from Shining 3D, the Aoralscan Elite, has added groundbreaking technology to a new compact intraoral scanner which makes it ideal for use in edentulous cases such as full dentures; in fact it’s made with exactly that feature built-in.

At first look, the Elite scanner is very different to anything on the market. It has a one piece seamless aluminium alloy body with special medical grade coating. This is the smallest, lightest intraoral scanner of its kind–ever, not by a few grams but by almost a whopping hundred grams to the nearest competitor. It weighs in at an incredible 124 grams and a size of 245 x 30 x 26 mm and surprises everyone who picks it up at how light, small and ergonomic it is.The Elite is amazingly easy to manipulate and no-one will ever have any fatigue after using this scanner for many reasons but the weight and size are more than groundbreaking. It will be the new benchmark for intraoral scanner size and weight.

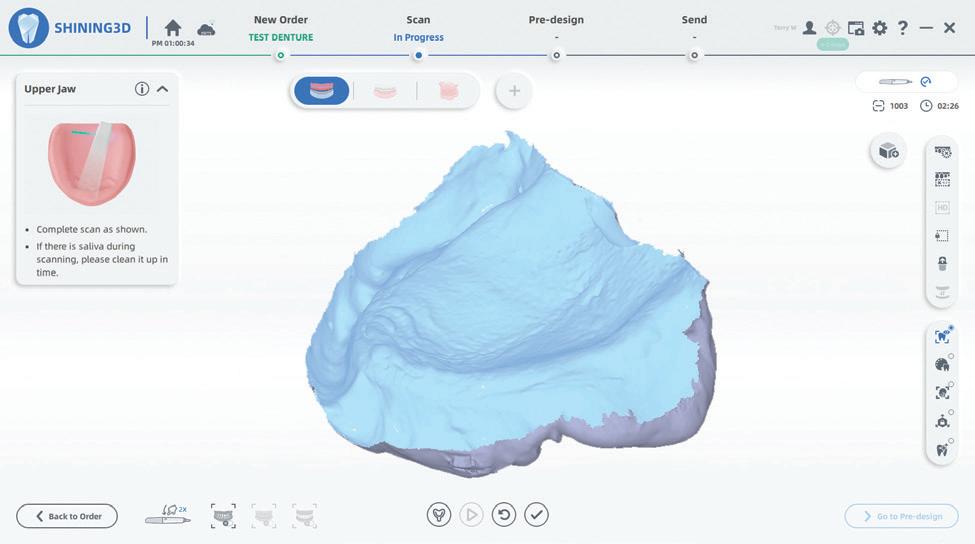

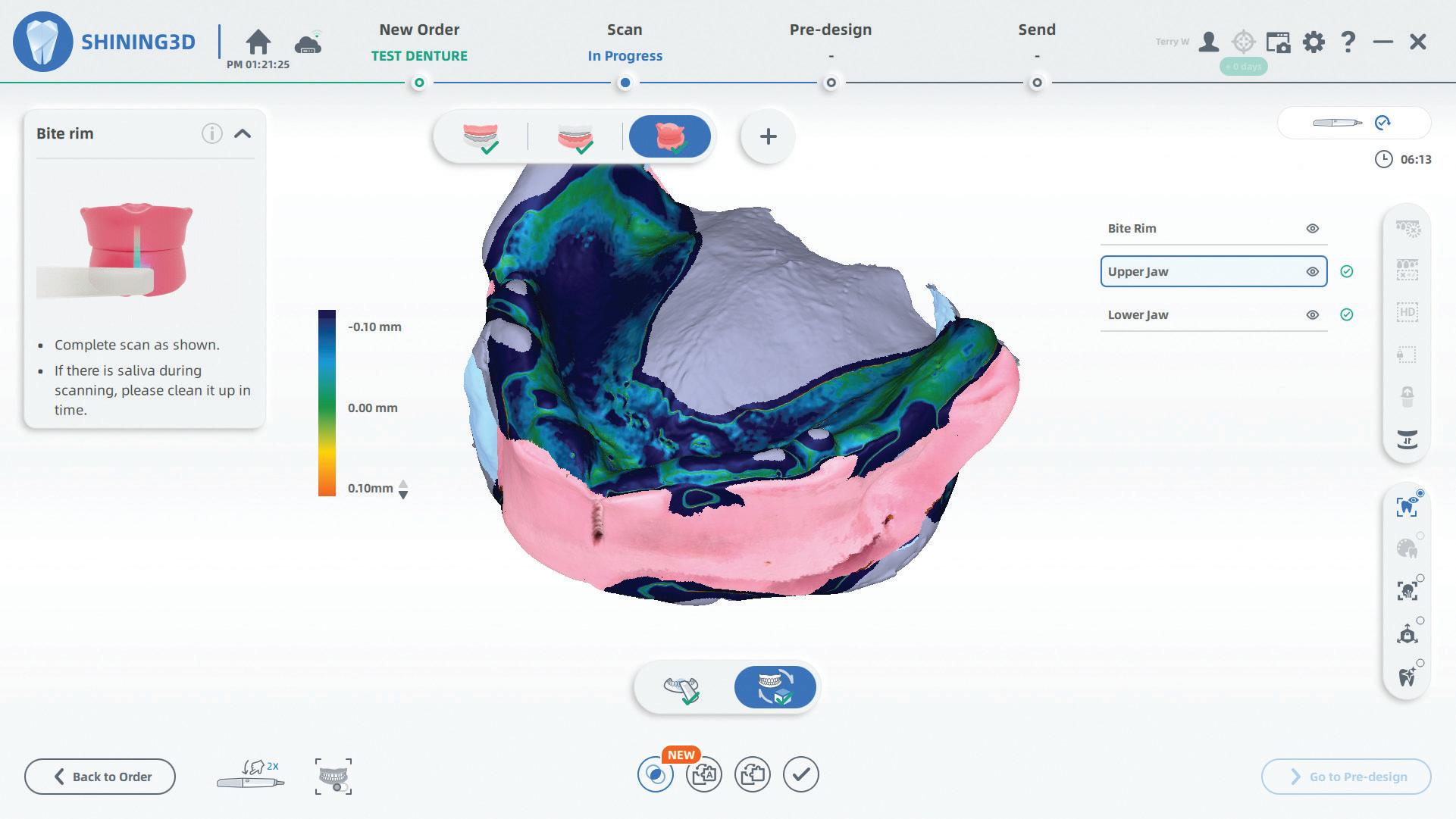

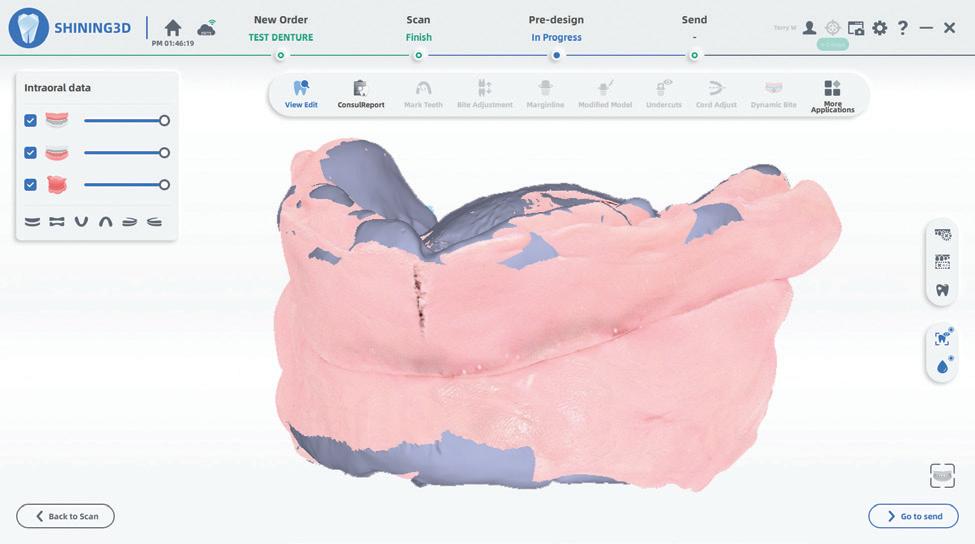

3. Setting up the case in Shining 3D scanning software. Note select removable denture and my bite record type in this case is “bite rim”.

The Elite scanner uses simple ergonomic one button operation and has a built in LED light on the button that changes colour to indicate the status of the scanner. It also uses an advanced motion sensing technology so the scanner can be used seamlessly to activate menus on-screen to proceed to the next step and to view the scan and move it for inspection without touching a monitor, a keyboard or mouse. Of course you can, if you wish, control the functions with a touchscreen or a mouse and keyboard if desired.

It’s also amazingly fast. This next generation scanner has some high tech hardware under the bonnet not seen before and very advanced software that lends itself to some of the fastest scanning imaginable. But there is more to scanning than just raw speed. It comes with a selection of tip sizes. There is a paediatric tip for small children or hard to access mouths, the regular-sized tip suitable for most people, then something new–a special edentulous tip for fully edentulous scanning and that’s exactly what we are interested in here.

Of course the tips can be autoclaved up to 100 times each or as a semi-critical item, it can be disinfected in the appropriate way which may lead to longer life. The replacement tips are inexpensive so having extras is not going to break the bank.

Figure 4. Upper impression ready to scan . In this demonstration, I’m using an impression but you could use a direct intraoral scan or a scan with a stone model, or even a scan of the fitting surface of a denture.

Figure 6. The software automatically makes a virtual model from the scan, effectively “turning it inside out”.

Figure 7. Lower impression scan, again takes about 30 seconds and it’s automatically inverted as well.

For edentulous scanning, Shining 3D has opted for a very large tip which allows for a lot of data to be captured at one time, making it fast and because there is a large area being captured, this can be “stitched” accurately. However, in reality, any tip size can be used but it may take a little longer.

Taking edentulous scans is a polarising issue as some argue it can be done with great success and others will tell you that it can’t be done successfully at all. There is no doubt it is an evolving part of dentistry but I believe as always, patient selection is paramount and it’s all in the

equipment and most importantly the technique. There are many resources on the internet that help with the techniques of edentulous scanning and I do suggest you check these out , remembering that its all about practice and honing your skills until you find the right technique.

A great place to start is with the Lo Russo Retractors. Dr Lucio Lo Russo, the inventor, has devised specific devices for taking edentulous scans and scanning strategies to help you get started easily. Also, the Mod Institute has some good videos on YouTube well worth a look that show a team approach to scanning, especially the mandibular ridge as it can be most tricky.

If you don’t want to take edentulous scans or you just don’t have the correct patient or for whatever reason, fear not! You can always take a traditional impressions and scan it. Also you can take an intraoral scan and merge it with an impression scan and you may just get the best of both worlds. You can even scan stone models. Regardless of how you get your scans, it is fantastic how the digital workflow allows such flexibility with gaining an edentulous scan.

Back to the Elite scanner workflow. It all starts with setting up the case in the case manager page. Put in the name of the patient, their age and any other details you want. Select “full denture”, both arches if it’s a full-on-full denture and then select the type of MMR you will use be it registration rims or the patient’s previous dentures. If you do use the patient’s current dentures, it’s a good idea to give them a quick reline with PVS or some other impression material. This is not an impression as such, just a way to help the software locate the MMR accurately as in most cases, the fitting surface will not reflect the patient’s current anatomy so it needs to be updated.

The New ELITE Intra Oral

The New ELITE Intra Oral

The New ELITE Intra Oral

Scanner from Shining 3D uses patented Intra Oral

The New ELITE Intra Oral

Scanner from Shining 3D uses patented Intra Oral

Photogrammetry Technology to be the most accurate scanner available.

Scanner from Shining 3D uses patented Intra Oral

Scanner from Shining 3D uses patented Intra Oral

• Edentulous Scanning for Dentures !

• Partial Denture Scanning

• Impression Scanning

• Edentulous Scanning for Dentures !

• Partial Denture Scanning

• Duplicate Denture Scanning

• Impression Scanning

• Scan All On X Cases Accurately

• Duplicate Denture Scanning

• Suitable for all Intra Oral Scanning

• Scan All On X Cases Accurately

• Now Mac or Windows Compatible

• Suitable for all Intra Oral Scanning

• Now Mac or Windows Compatible

I know what some of you are you are thinking–that it is blasphemy to use the patient’s old dentures for an MMR, however you are really only using them as a guide to help re-establish their vertical and AP relationship. I’m sure most people will have the skillset to manipulate the current dentures to a satisfactory restored MMR using varied techniques and materials that are in common use. The other method is to use traditional-style registration rims. Now note I said “style” because these could be fabricated in wax or they may be 3D printed or could be silicone putty rims or the like as these types of techniques are mainstream.

In the software, you will choose either to scan the patient directly or to scan an impression of the patient and in fact, you could even scan a model–the choice is completely yours. If you scan an impression, the software will automatically invert the scan to create a 3D virtual model, a neat addition and it’s easy to do. Once you have scanned the upper, go ahead and do the same with the lower–intraoral scan, impression or model, the choice is yours. Next comes the fun part. Let’s imagine we have registration rims and we have taken the patients MMR. Dry them off and start to take a scan of the fitting surface of the upper, move to the buccal and facial and next, the fitting surface of the lower. You will find this quite easy to do and what you are actually doing is giving the software enough information to orient your scans from before into the patient’s MMR captured with the registration rims. It seems a little bit of magic and it is in a way, but you will end up with your edentulous scans (or impression scans) now oriented correctly to the new MMR. The software does all the work for you!

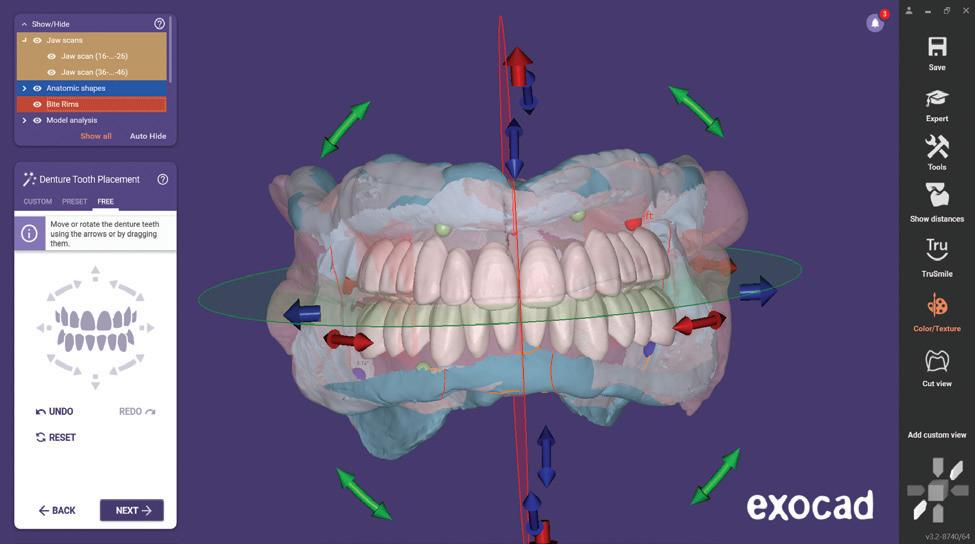

Once this has been completed, you will have a set of scans in an MMR ready to export to your favourite denture designing software. I like exocad for its flexibility, but the 3Shape Dental Designer program is quite good too and some may like inLab from Dentsply Sirona and don’t forget Blender4Dental have a great module for dentures too.

No matter what design software you choose to use, you can export the files you need out of the Shining 3D software program and import these directly into your software of choice and you have a choice of file formats - STL, PLY and OBJ - so everything is covered.

The Shining 3D Elite intraoral scanner is a breakthrough in size, weight, speed and accuracy and now a dedicated edentulous scanning mode that will yield fantastic results and definitely be a game changer to the way you take records for dentures.

Terence Whitty is a well-known dental technology key opinion leader and lectures nationally and internationally on a variety of dental technology and material science subjects. He is the founder and owner of Fabdent, a busy dental laboratory in Sydney specialising in high tech manufacturing. Using the latest advances in intra- and extra-oral scanning, CAD/CAM, milling, grinding and 3D printing, most specialties are covered including ortho, fixed and removable prosthetics, computerised implant planning and guidance, TMD, sleep appliances and paediatrics.

By Charlie Anderson, Monocure 3D

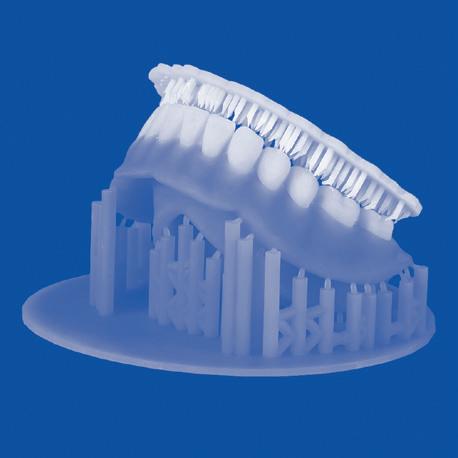

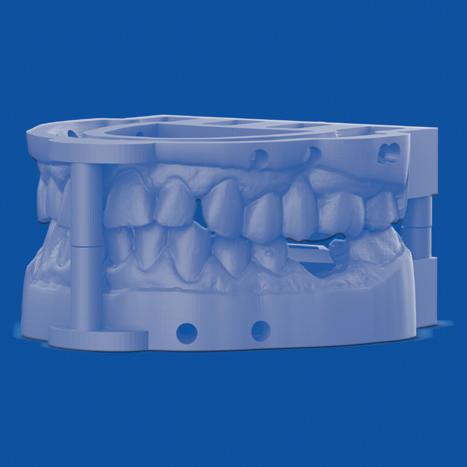

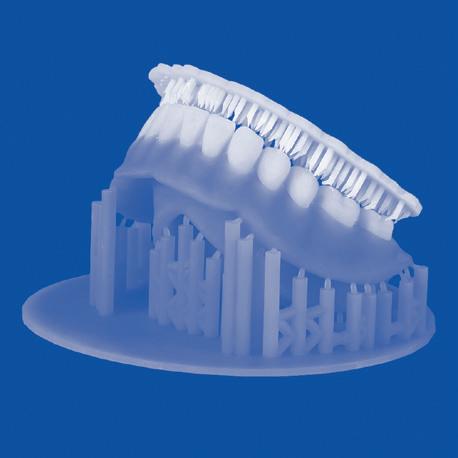

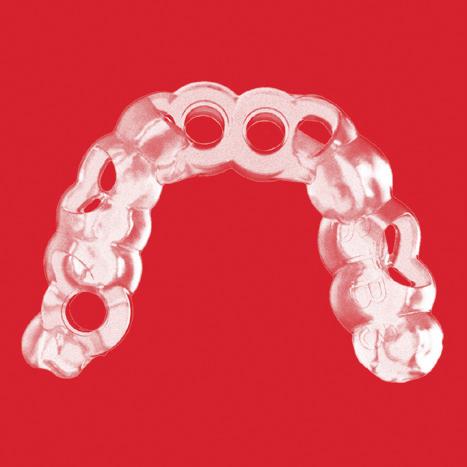

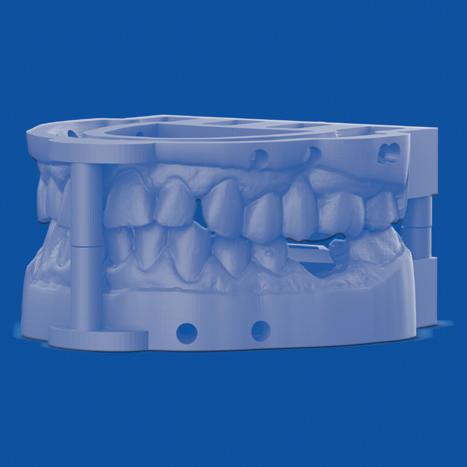

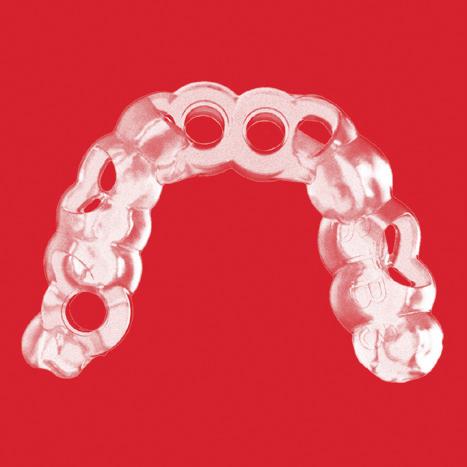

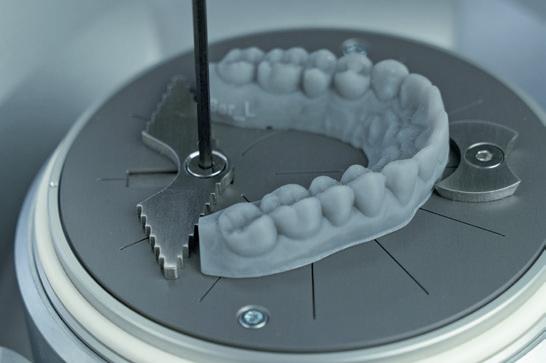

Resin 3D printing has quickly become a standard tool in dental laboratories and clinics, supporting the production of appliances such as surgical guides, splints and night-guards. While the technology offers exceptional accuracy and repeatability, technicians often face the challenge of how to correctly orient and support models that cannot be printed flat on the build plate. These are functional dental appliances, not study models or demonstration pieces. Their organic geometry, combination of thin and thick sections and critical fitting areas mean they demand a precise approach to achieve the best results.

Printing directly on the build plate is not a practical option, as these appliances rarely feature flat surfaces suitable for that method. Without a flat surface, there is

not enough area on the model to achieve proper adhesion to the build plate. This makes the use of supports essential, along with careful positioning of the model to ensure consistent and successful results.

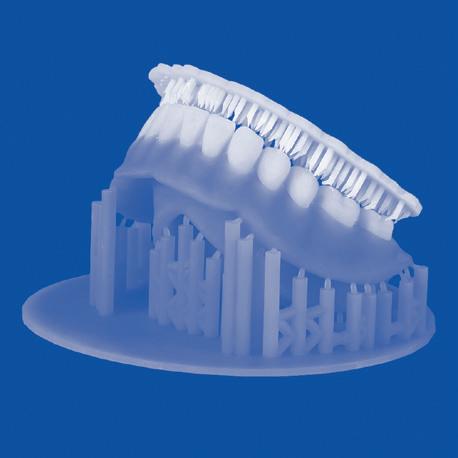

The reason angled printing is required is that when supports are used, they can sometimes create issues with dimensional accuracy due to the peeling forces inherent in top-down printing systems. Certain resins, particularly high-performance urethanes such as those used in Monocure3D’s new SPLINT™ resin, have a stronger tendency to adhere to the FEP release film. This can lead to printing complications, including supports being ripped away mid-build, distortion or loss of accuracy. The most effective solution is to angle the print.

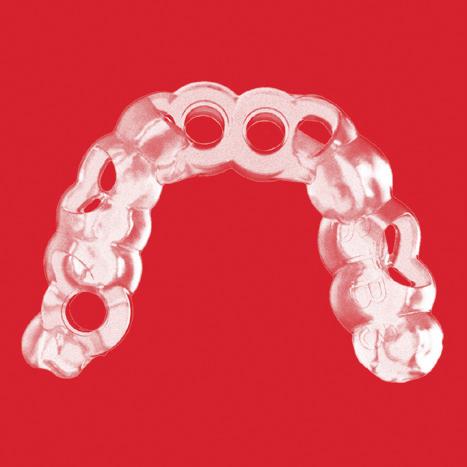

By tilting the model between thirty and seventy degrees from the build plate, resin drains more effectively and the forces on each layer are reduced. This gradual build process promotes greater dimensional stability, smoother separation and more predictable results. For appliances such as splints or surgical guides, where even a fraction of a millimetre can alter the clinical outcome, angled printing is not only advantageous but essential. Orientation, however, is only the first part of the process. Equally critical is the design and strength of the supports. Dental appliances are often heavier and more complex than other resin prints, particularly when produced in biocompatible materials such as Monocure3D’s TRY-IN™, GUIDE™ or TRAY™ resins.

To hold these models securely throughout the build, medium to heavy supports with a dense distribution are recommended.

Supports must be strong enough to prevent movement, with contact points large enough to stay locked in place, yet not so large that they damage the surface during removal.

For broader areas, dense bracing is also recommended to stop flexing, while thicker pillar supports provide stability for heavy occlusal or structural zones.

Protecting critical surfaces is another key consideration. The fitting surface of a splint or the guide sleeve of a surgical template must not be compromised. Support placement in these areas should be avoided wherever possible. If it is absolutely necessary, the smallest contact points should be used and careful finishing is required to ensure geometry is preserved. Striking the right balance between stability and protection lies at the heart of successful dental printing.

Before committing to a full production build, laboratories should review the model carefully in the slicer software. The layer preview can reveal unsupported islands or weak areas that need additional attention. Anti-aliasing and light smoothing settings can reduce visible stair-stepping on angled surfaces, while checking that all supports are anchored firmly to the build plate helps prevent mid-print failures. For especially intricate appliances, it may be worthwhile to run a smaller section test print first, rather than risk the cost of a failed full build.

At Monocure3D, we understand that technicians need more than just quality resin. They need confidence in their entire

workflow. This is why our dental resins are designed for consistency, reliability and ease of use across the latest printers and slicing platforms. With biocompatible formulations such as TRY-IN™, GUIDE™ and TRAY™, laboratories can achieve repeatable results with the reassurance that every batch is manufactured and quality tested here in Australia.

Support is equally important. Our technical team works closely with laboratories and our reseller network to provide practical guidance on setup, orientation and support strategies. For those new to supported dental printing, we share tested slicer profiles and presets to reduce trial and error. This level of service is backed by our national network of distributors, with Monocure3D dental products available through resellers in every Australian state. Local supply ensures fast delivery without the uncertainty of overseas shipping, giving laboratories the confidence to plan production schedules around dependable access to materials.

With careful orientation and well-placed supports, even the most complex dental appliances can be printed cleanly and accurately. This reduces waste, minimises rework and ensures consistent results for clinicians and patients. Combined with Monocure3D’s Australian-made dental resins, expert support and national reseller coverage, laboratories can integrate resin 3D printing into their workflows knowing they have both the products and the partnership required to succeed.

1. Check adhesion first: Without a flat base, adhesion depends on supports. Position the model carefully to maximise stability.

2. Angle matters: Keep models between 30° and 70° to reduce peeling forces and improve resin flow. This is especially important with strong urethane-based resins such as Monocure3D’s SPLINT™.

3. Build strong supports: Use medium to heavy density, with thicker pillars under heavier zones. Check that contact points are secure but not oversized.

4. Protect the fitting surface: Never place supports on critical fitting areas unless unavoidable. If you must, use the smallest tips possible and take extra care during post-processing.

5. Preview before printing: Review every layer in your slicer. Look for unsupported islands and weak points. It is often worth running a partial test print before committing to a full appliance.

6. Leverage local expertise: For tested slicer profiles, support strategies, and the right resin for your application, Monocure3D’s technical team and reseller network are here to help.

By Lukas Wichnalek, Norbert Wichnalek, Arbnor Saraci and Patricia Strimb, Highfield.Design, Augsburg, Germany with Dr Bayer, Augsburg, Germany

Manually adjusting denture teeth to a model casting framework is tedious work that does not allow for true precision. There is a fair amount of guesswork involved as it is ground out until it fits and often more of the basal tooth is sacrificed than would have been necessary. With the digital workflow, innovative materials for removable partial dentures, which now enable custom-fit prosthetic components based

on the lock-and-key principle, have been introduced. These only need to be bonded together using modern adhesive systems. This means that high-precision production technology is replacing the guesswork of manual grinding. In this article, Norbert Wichnalek, Lukas Wichnalek, Patricia Strimb and Arbnor Saraci (all Zahntechnik Wichnalek – HIGHFIELD.DESIGN, Augsburg, Germany) show how the polychromatic VITA VIONIC DENT DISC multiColor is now being used to create precision-fit premium teeth in a digital workflow and discuss the advantages this offers.

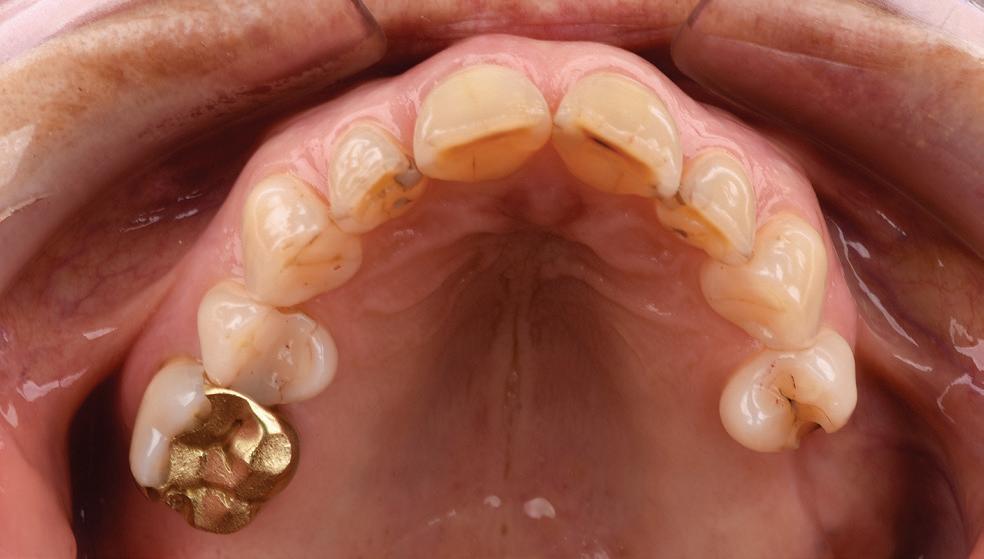

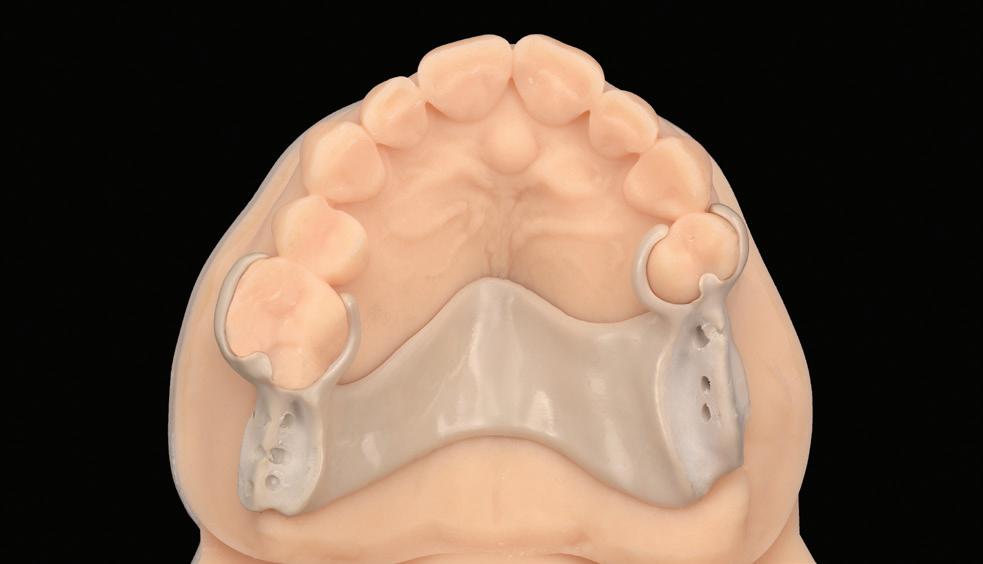

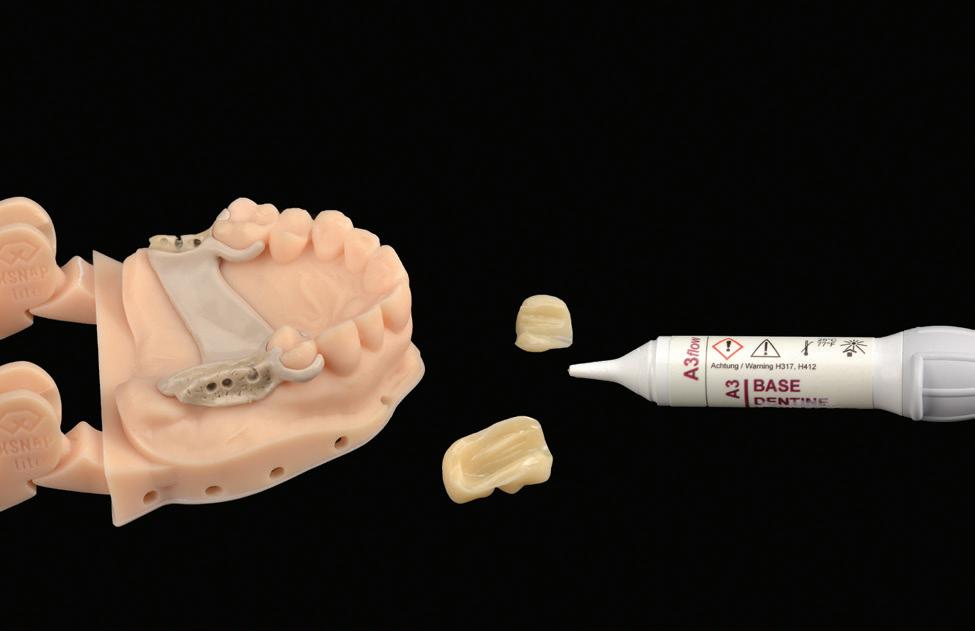

Apatient in his early 60s presented at a dental practice for a routine visit. Teeth 17, 26 and 27 were missing in his upper jaw. Due to the free-end situation, mastication was limited. The patient also wanted the situation to be stabilised so that he could later be fitted with fixed implants. The dentures needed to be as inconspicuous as possible, be as comfortable as possible and not too expensive. The decision was made to use a clasp denture with a PEEK framework in order to avoid exposing any metal clasps and to offer the desired level of comfort, thanks to its low weight. The tooth material on the denture saddles was to be milled out of the VITA VIONIC DENT DISC multiColor in shade A3 with a precise fit. As with the proven VITA premium teeth, the polychromatic disc is based on the same VITA MRP composite formulation, ensuring high abrasion resistance and a long service life. The shade gradient integrated into the composite crown provides a basic natural appearance, which is why the material is also ideal for use in the anterior region.

After the intraoral scan of the dental arches and the habitual final bite position, the prosthetic components were designed to fit together precisely in the exocad software (exocad, Germany). The framework structure was designed using Juvora Dental PEEK natural (Juvora, UK). The precision-fit tooth material from the VITA VIONIC DENT DISC multiColor then followed on the saddles, with the saddle base being incorporated into the design. Teeth 26 and 27 were also given an interlocking design and the adhesive gap was kept even and as small as possible to ensure the greatest possible stability. If the adhesive gap is too small, the bond will be weaker; if the adhesive gap is too large and unhomogeneous, this can result in chipping. It was possible to functionally design the occlusion to match the natural opposing dentition. Both prosthetic components were then fabricated one after the other in the imes-icore 350i PRO milling unit (imesicore, Germany) with CAD/CAM support.

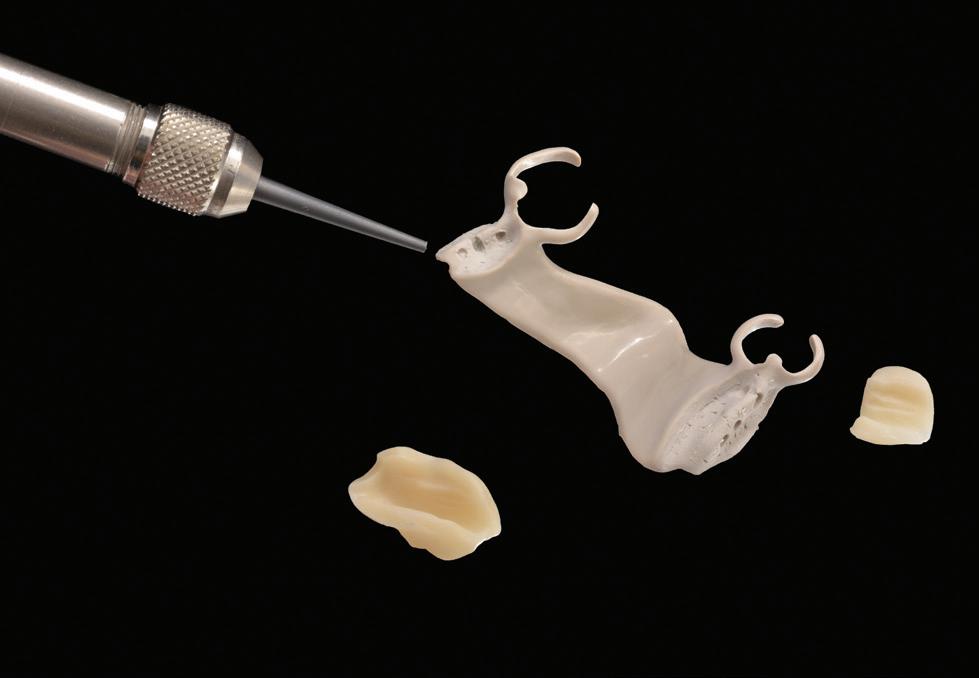

Figure 8. The individualised dental material made from the polychromatic composite disc VITA VIONIC DENT DISC multiColor.

Figure 10. The chemical bond of the prosthetic components was established using the universal VITA VM LC PRIMER.

The tooth material was finished and the micromorphology determined using standard grinding tools. This was followed by a simple pre-polishing using the VITA ENAMIC Polishing Set technical and a short high-gloss polishing using VITA Polish Hybrid (both VITA Zahnfabrik, Germany), as well as a brush with goat hair bristles and a leather buff. The basal adhesive surfaces of the prepared tooth material and the complete saddles made of PEEK

9. Conditioning of the adhesive surfaces by sandblasting with 50 μm aluminum oxide.

11. The light-curing composite VITA VM LC flow BASE DENTINE A3 was used to fix the tooth in the denture.

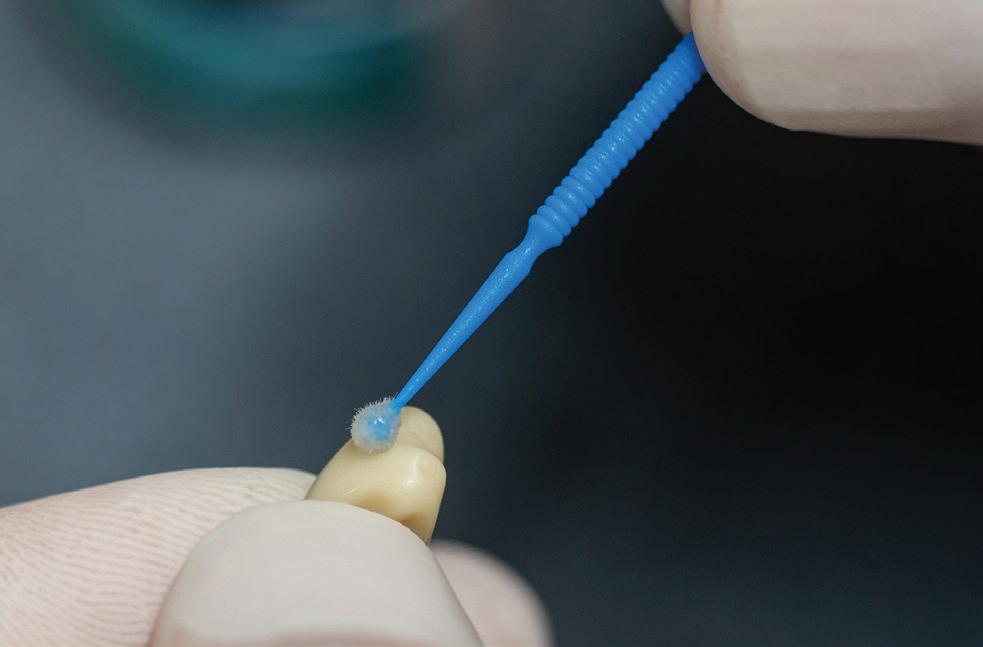

were first cleaned and conditioned in a vacuum plasma chamber – normal practice in our laboratory – using oxygen and argon as the ignition gas. Afterwards, conditioning was done with 50 μm aluminum oxide and the universal VITA VM LC Primer. This was followed by controlled adhesive cementation of the denture components using the flowable and light-curing composite VITA VM LC flow BASE DENTINE A3 (all VITA Zahnfabrik).

14. The resulting excess material clearly shows the homogeneous adhesive gap.

16. Curing of the VITA VM LC flow BASE DENTINE A3 composite using the polymerisation lamp.

15. Removal of excess using the microbrush.

Figure 17. The gingival customisation of the saddle area was achieved with composite stain and a fluid veneering composite.

The basal, vestibular and oral parts of the saddle were then completed with cold-curing resin. After sandblasting, again with 50 μm aluminum oxide and conditioning the base with the VITA VM LC Primer, deeper blood vessels in the area of the mobile gingiva and in the interdental areas were established with the light-curing composite stain VITA AKZENT LC EFFECT STAINS dark-red (VITA Zahnfabrik, Germany). After suitable

fixation with the polymerisation light, VITA VM LC flow GINGIVA 4 (G4/brown-red) was used to create a thinly tapering mucosa, which also created a fine, definitive gingival margin around the teeth in the vestibular area, which was no longer subtractive as it progressed. After 90 seconds of intermediate curing, cervical and interdental contouring was performed with GINGIVA 1 (G1/dusky pink).

The palatal tooth and base areas from the VITA VIONIC DENT DISC multiColor were not individualised gingivally. To prevent an oxygen inhibition layer, final curing was carried out in 180 seconds using the Otoflash G171 polymerization device (NK Optik, Germany) in a wavelength range of 280-580 nm under an inert gas device with nitrogen. The entire saddle area was then washed off, sandblasted with 50 μm aluminum oxide and the tooth material in the fissures and interdentally characterised with the composite stains VITA AKZENT LC EFFECT STAINS russet and khaki. Finally, a uniform gloss level was established with a wafer-thin application of VITA AKZENT LC GLAZE. After another 90-second curing period – as described above – the high-gloss polish was applied with a cotton buff using light pressure.

he VITA VIONIC DENT DISC multiColor now makes it possible to create removable prosthetics with premium teeth from the disc individually and as required. Only the dental material that is needed is produced with CAD/CAM support. The “guesswork” involved in the tedious and time-consuming process of grinding out prefabricated teeth is a thing of the past. The ability to fabricate interlocking and integrate parts of the base into the tooth material provides maximum durability. The optimised design of the adhesive gap also ensures stability and a reliable bond. The polychromatic VITA VIONIC DENT DISC multiColor offers an inherently natural appearance, meaning that finishing and polishing are usually all it takes to achieve the desired aesthetic effect. The basic shade accuracy of the composite shade to the VITA shade standards, in combination with the equally accurate and coordinated material components from VITA Zahnfabrik, provides true added value for fabricating removable partial dentures reliably and efficiently.

Composite milling blank for the fabrication of removable partial and full dentures.

• High abrasion stability for long-lasting denture teeth

• Simple processing and good polishability

• Natural multicolor esthetics

By Peter Herring, Adv Dip Dent Tech, ACCDP

The Occ3-PMF is a new accessory for the Occluform-3 device, designed to make thermoforming with printed models quicker and more intuitive. It allows for precise, direct imprinting of the opposing dentition and establishment of occlusion during the forming cycle when working with reduced-height printed models, whether solid or hollow.

Step 1. Take the Occluform-3 model pot out of the Erkoform-3 form pot. Remove any dirt or debris from the form pot.

Step 3. Clamp the upper jaw model and fix the clamping jaws. The model must rest flush on the model disc.

Step 5. Place the model on the counterbite holder and fix with the Occluform-3 hex wrench.

Step 7. thermoform and...

By applying the average-value articulator geometry of the Occluform-3, the Occ3-PMF enables functional contacts to be reproduced while the appliance is still moldable. This reduces chairside adjustments, variability and the need for post-processing.

This article outlines the device concept, applications and workflow.

Step 2. Insert and engage the Occ3-PMF model pot insert. Position so the wide clamping jaw points to the marking on the unit form pot.

Step 4. Insert the Occ3-PMF counterbite holder in the Occluform-3 model plate.

Step 6. Now articulate the models according to the Occluform-3 instructions (with construction bite, if available) and continue...

Step 8. adjust the opposing bite. Finish the occlusal splint.

Peter Herring is a dental technician, prosthetist and a regular contributor to eLABORATE. He is the Australasian and Indonesian distributor for Erkodent products and spends his time between offices in Perth and Bali. He also operates a busy Australian lab dedicated to thermoformed appliances. He can be contacted at pjh@erkodent.com.au or for general enquires, call Freecall 1800-242-634.

Occ3-PMF also enables the production of Playsafe triple sports mouthguards with printed models (thermoplastic filament models are not suitable due to the heat load).

Occluform-3 PMF Components:

Model pot insert with model disc and clamping jaws.

Opposing model holder and fixing key for the clamping mechanism.

The model pot inset reduces the amount of air to be evacuated for faster and better molding.

Australia & New Zealand’s trusted source for Erkodent thermoforming equipment, materials, and training

• 24-hour online ordering – Fast, simple, and secure.

• Full technical support – Expert service and training when you need it.

• Resources at your fingertips – Download instructions, videos, stay up to date with new product releases.

Australia: www.erkodent.com.au

New Zealand: www.erkodent.co.nz

Email: info@erkodent.com.au

Information contained in this section is provided by the manufacturers or distributors. eLABORATE does not assume responsibility for the accuracy of the data.

Introducing the ASIGA Ultra Crown Kit — your solution for fast, efficient, and precise crown production on the ASIGA Ultra. Designed with a compact build platform and tray, this kit minimises material usage while maximising pro-

ductivity. Achieve 3D printed crowns in under 12 minutes, streamlining your workflow without compromising accuracy or quality. Perfect for crowns, inlays, onlays, veneers, and more, the Ultra Crown Kit empowers dental professionals to deliver exceptional restorations quickly and consistently. Experience a new level of speed and efficiency — print faster, handle less material, and elevate your digital dental production with ASIGA’s advanced innovation.

Available: ASIGA Dealers Tel: (02) 9417-6660 info@asiga.com www.asiga.com/australia

The Aoralscan Elite is the world’s first device to integrate both intraoral scanning and photogrammetry into a single unit. The device functions as a standard intraoral scanner (IOS) for capturing images of dentate cases, allowing for detailed scans of teeth and oral structures. Additionally, it serves as a photogrammetry system, which is used to accurately record the position of dental implants in edentulous cases. This dual

functionality makes it versatile for both traditional dental work and advanced implant procedures. This groundbreaking innovation allows for comprehensive dental imaging and precise implant positioning, setting a new standard in dental technology.

Available: Fabdent Tel: 1300-878-336 www.fabdent.com.au

Rodin All-purpose Glaze enhances characterisation for a wide range of applications, such as crowns, bridges, inlays, onlays, veneers, dentures, and all-on-x provisionals. It enhances translucency for 3D printed oral appliances and surgical guides and seals and repairs micro-fractures resulting from support removal and finishing processes. Userfriendly application enables increased productivity and it features best-in-class wear resistance for long-lasting results. Rodin All-purpose Glaze exhibits low water sorption and resistance to discolouration, ensuring durability. Available in 15g and 60g configurations to suit various professional needs.

Available: CM Medical Tel: 1300-466-588 info@cm-medical.com.au www.cm-medical.com.au

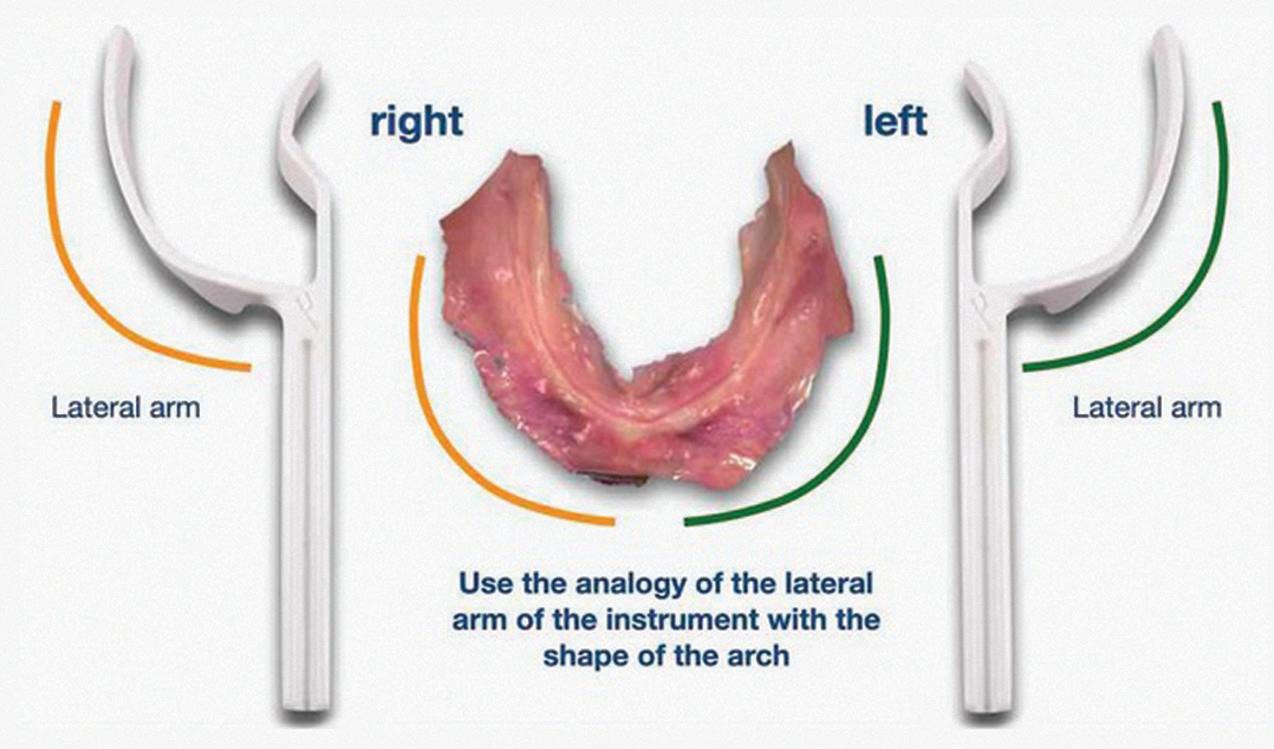

Lo Russo Retractors are the essential tool for precise intraoral scanning of edentulous arches. Specifically designed to optimise visibility and access, these retractors gently and effectively displace soft tissues, ensuring a clear, unobstructed scanning field. Their ergonomic, patientfriendly design enhances comfort while improving accuracy and efficiency during digital impression procedures.

Ideal for full-arch or edentulous workflows, Lo Russo Retractors help clinicians capture data more reliably. Durable, autoclavable and easy to handle, they’re a must-have accessory for any clinician aiming to achieve consistent, highquality digital impressions.

Available: Fabdent Tel: 1300-878-336 www.fabdent.com.au