All text and illustrations in WCN are copyright protected. Copying contents by any means is forbidden without the publisher’s written consent. The publisher, agents, printers and contributors are not responsible for the accuracy of claims printed or implied in the editorial or advertisements published in this, previous or subsequent editions. The publication in this newsletter of brand names, trade names and trade marks and similar does not imply that these may be used elsewhere. WCN reserves the right to edit, reword and sub-edit all editorial submissions in accordance with editorial policy. Al l matters relating to this disclaimer are governed by English law.

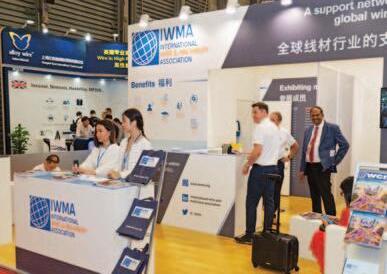

THE strong industry appeal of September’s wire China exhibition once again pushed the event to a new attendance record. The four-day Shanghai exhibition attracted 45,120 professionals from 91 countries – almost seven per cent more than in 2016.

A large number of overseas buyers, mainly from India, the Far East and Russia, joined Chinese nationals and major players from Europe and America to see the latest machinery and ideas in the wire and cable industries – many hoping to get involved in China’s massive “Belt and Road” and “Made in China 2025” programmes.

As usual the IWMA, as a Messe Düsseldorf partner, had its own vital role to play in the exhibition, namely helping things go more smoothly for exhibitor-members and visitors alike.

The IWMA’s much admired-travelling stand (right and far right) attracted hundreds of visitors during the exhibition.

The stand, manned by senior IWMA staff and association representatives, offered a place to do business in private with contacts old and new – which often went even better thanks to the presence of the association’s official translator.

The stand also offered refreshments, free wifi, promotional activity for member companies, fast copying and printing and other services, this time also including a professional videographer and photographer, who could turn round promotional pictures almost instantly, allowing client companies to put them online even while the show was still on.

A“We saw a big increase in inquiries and use of the stand over the 2016 show,” said IWMA executive manager Andy Lewis (pictured above). “People from our member companies increasingly seek it out as a place to get information, have a meeting or get a couple of things printed off before they see potential clients. And since we offer instant membership facilities – which means companies new to the organisation instantly get the benefits of their membership – we tend to turn quite a lot of companies into members at each of these events. No doubt Mumbai will show the same sort of pattern.”

n If you work in a subsidiary or international office of one of the main IWMA member companies, you can keep up with IWMA and industry developments by joining our mailing list and receiving a free copy of the IWMA newsletter, Wire and Cable News. Visit our website or contact info@iwma.org for details.

S one door closes, so the saying goes, another door opens. I wonder if there is a similar saying about suitcases? As one case closes (full of stuff for wire China), another case (full of stuff from wire India) opens. It might not have the same philosophical ring to it, but the sentiment is accurate enough...

It’s pretty hectic at the moment: after a ton of preparations for the visit to Shanghai followed by hectic days and nights at the show – including hosting our riverboat cruise – followed by a trip home, a busy few weeks in the factory to catch up, followed by... well, the same thing all over again, except this time the is destination is India.

The wire China show was a tremendous hit all round: numbers were up, inquiries on the stand rose appreciably, more and more members used our private rooms (and interpreter services) for business meetings and there was great approval from the local wire and cable business community for the special Chinese version of this magazine.

And so – I have no doubt – it will also be when we visit Mumbai at the end of November. China is hot, financially speaking, but India is hotter. There are big differences in scale, but the Indian market for wire and cable, as our wire India introduction on page six points out, is faster growing – which will no doubt be reflected in the energy and (literally) heat of the wire India show (as well as in the warmth of the welcome at our ever-popular Indian night out, free for members).

This activity and energy all points to an industry right at the centre of post-recession global spending on infrastructure. The public often doesn’t often look at cable and wire with shock or awe of any kind, but it’s fair to say that for every mile of road we build round the world there are probably two or three miles of cable; same for railways. Buildings, telecommunications, power and automobiles need thousands and thousands of miles of cable and wire or they don’t work. If you want to see how the post-recession planet is succeeding, take a look at our industry and you will see it’s not doing too badly at all...

Martin Van Der Zwan Chairman, International Wire & Machinery Association

LEONI is to become the largest industrial employer in Serbia, employing more than 10,000 people in the country once a new plant, in Kraljevo, becomes fully operational.

The global energy and data management company will open its fourth Serbian plant, to become the country’s largest industrial employer, and recently held its general management meeting in Serbia to underscore the country’s importance in the development strategy of its Wiring Systems Division (WSD). Once the new plant opens in early 2020, almost doubling Leoni’s workforce in the country, Serbia will be the only European country

AFTER a highly-successful stay at wire China, Rosendahl Nextrom has announced the acquisition of technology for seam-welding smooth and corrugated metal tape sheathing systems from Weber & Scher.

Rosendahl Nextrom CEOs Gerhard Jakopic (centre) and Segfried Altmann (centre right) said the deal strengthens the company’s position as a complete turnkey-system supplier.

Greg and Doug Scher of Weber & Scher also said they were “very pleased” with the deal.

www.rosendahlnextrom.com

in the WSD network with four production facilities. Since setting up in Serbia in 2009, Leoni has invested around EUR 90million in plant, machinery and staff training, and currently employs about 6,000 people.

"Leoni has proven to be a reliable investor and business partner and, with the new plant, will once again establish modern as well as innovative working conditions for many thousands of jobs,” board member and Leoni WSD head Martin Stüttem told the Serbian press before the landmark management meeting.

Leoni WSD human resources chief Bianca Scheller added: “Serbia has great potential from the human capital point of view, and

a work culture and ethic we appreciate.

“When we look at our existing 6,000 employees, we see a very loyal team that supports us through the challenges of important projects with our customers.”

Over the past 10 years, Leoni has paid more than EUR 52million in taxes and contributions to the Republic of Serbia.

“We are pleased to be developing our business in Serbia further. Growing here comes with great responsibility towards both customers and the people we employ,” said Clemens Sachs, managing director of Leoni Serbia.

www.leoni-serbia.com

LEADING speciality lubricant manufacturer Metalube hosted a conference in Kuala Lumpur for its Asia team, drawing delegates from across the region including Vietnam, UAE, India, Malaysia, Thailand, Indonesia and China.

Commercial director Douglas Hunt said: “We had a great few days getting our teams together, sharing product developments and conducting training. With a global company such as ours the opportu-

nity to get employees usually scattered across the region into one room was fantastic. The attendees had a chance to share experiences and form bonds – something we are very keen on within the Metalube family.”

Metalube exports 95 per cent of its production to more than 90 countries worldwide and has offices in Manchester, Dubai, Mumbai, São Paulo and Shanghai.

www.metalube.co.uk

HE introduction of EU-wide Construction Products Regulations for cabling has meant cables used in construction projects are required to contain flame retardants and offer low smoke-emission properties. This has led West Midlands UK company

H&R ChemPharm (UK) – one of the world’s leading developers of cable compounds for the energy and telecommunication sectors – to develop Insojell FR, a synthetic elastomer introduced at wire 2018 in Düsseldorf.

Insojell FR has specially-selected flame-proofing chemicals and materials that offer cable manufacturers several benefits.

One is a simple cost reduction: CPR requires manufacturers to specify expensive sheathing polymers, but Insojell FR removes this need, improving overall cable performance while reducing cost.

Insojell FR forms a protective layer, allowing the cable’s inner structure to remain intact with minimum service disruption in the event of fire. Smoke and toxic gases also make firefighting difficult as well as being potentially life threatening. Insojell FR is itself structurally protective, retaining its shape within the cable and avoiding the generation of flaming droplets that can cause injury or spread the fire.

Ultimately, the retardant is self-extinguishing, preventing the spread of flame through the cable.

Insojell FR is suited to harsh applications such as ship and military cables, threecore power cables and mining, gas and oil cables.

H&R’s cable compound manufacturing business offers customers an established international service with production sites in the Netherlands, Asia and South Africa.

www.hur.com

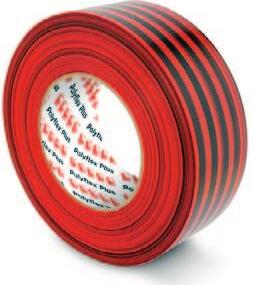

LEADING bonding products and adhesives company Scapa has added a new fire retardant polyethylene (PE) film tape to its high quality PE range.

Polyflex Plus FR100 incorporates the premium performance features of the standard range but with fire retardant qualities, and is the first of a new generation of PE film tapes to meet the requirements of the North American market, where fire safety is an increasing priority.

Marketed under the Scapa Polyflex Plus banner, FR100 tape is one of the first of its kind to meet standard 701 of the National Fire Protection Association, which covers fire tests and flame propagation in textiles

and films. It also conforms to ASTM E84 recognised tests for building material surface-burning characteristics.

FR100 tape features a distinctive red and black striped appearance, allowing users to easily identify it as an approved FR product. The tape will be available through approved Scapa partners in a number of standard widths and lengths, to satisfy a wide range of technical applications. Scapa tapes are produced entirely in-

house in Renfrew, Canada, allowing for complete process control, product quality and a wide range of coating and converting capabilities.

All Scapa PE tapes are manufactured under comprehensive QA processes and meet strict QC standards.

The Scapa Polyflex range of PE tapes is widely recognised as the leading polyethylene tape in agricultural, asbestos abatement, automotive, construction, marine, military, nuclear, stucco and general industrial markets.

WHEN the West fell into recession in 2007-2008, many countries without such well-developed and easily-undermined economies started to show unprecedented growth.

China has been an obvious success story, but so too has been India.

Indeed, as China’s economy has started to slow, India’s has continued to surge, with GDP growth in 2015 and this year that has outstripped China to make India the world’s fastest-growing economy. While it is true that India has major problems with inefficiency and

bureaucracy, both of which diminish the potential growth, the fact remains that this nation of very rich and ultra-poor is at last working hard to update its technologies and infrastructures and improve the lot of the poorest sectors of society.

Research suggests the economy will grow five-fold in the next two decades. India's infrastructure financing needs will mean a trillion dollars’ worth of opportunities for global investors in the next halfdecade alone.

All this means, of course, that India is a major buyer of materials

such as wire, cable and optical fibres and the means to produce and use them. An industry that has been growing at up to 15% a year in the past half-decade could jump to nearer 20% for the next. What is fuelling this growth? The main customers are the automotive, telecommunications and construction industries – which in recent years have enjoyed an annual growth of about 25%. When we think of automobiles we think of the US, Europe and even China as the major producers, but India is now the seventhlargest producer in the world, with an industry worth over $150bn.

Likewise real-estate in India is a massively-growing market, expected to hit $180bn by 2020.

The Indian government’s focus has been on public-private partnerships on major infrastructure projects such as bridges (like the cable-stay Bandra-Worli Sea Link on the cover, opened eight years ago to link south and west Mumbai and the city’s port), as well as $93bn worth of road projects, canals and around $100bn worth of railway works.

In the automotive sector, millions of jobs have been created since

wire India is set to have another great year as India continues its infrastructure push

LEADING Indian cable trade fair wire India returns – alongside its partner exhibitions Tube India and Metallurgy India – to the Mumbai Convention and Exhibition Centre at the end of November.

And as seems to be the case these days, the event is expected to surpass its 2016

predecessor for scale, visitor numbers and exhibitors.

Last time around 406 companies exhibited, visited by 12,300 people from all parts of the world – visitors keen to make one journey to experience the latest developments in all three technical fields. At the time of writing, this year’s fairs al-

ready have registrations from 400 companies and expect to comfortably exceed 2016’s visitor numbers.

None of this is very surprising, since wire India is a power-packed technology display in a field of vital importance to the Indian sub-continent. India is increasingly spending money earned from its

Continued from page 7

2006 as the Indian government doubled the industry's contribution to the country's GDP.

The Indian telecommunications market is the fastest growing in the world, pushed by an explosion of wireless and telephony demands from a mobile phone-buying population and a government project to hook a quarter of a million local councils to the internet.

The Smart Cities Mission, Make in India Campaign, the Saubhagya Scheme (which aims to connect more and more rural homes to the power grid) and the Housing for All 2022 project are some of the plans in place that will help in the expansion of power utilities, manufacturing and public infrastructure.

India's domestic cable market is growing strongly year on year –currently over �40,000 “crore” rupees (about $5.5billion) a year – but penetration from out-of-country major companies is unexpectedly small.

This is often because the industry is divided roughly and unofficially into “organised” and “unorganised” sectors: the former manufactures with tested, virgin stock and the products are certified for particular requirements and priced accordingly. The unorganised industry doesn’t conform to the same quality standards and its products, often produced within India, usually end up in domestic dwellings and other buildings, for which quality standards aren’t as high. The two sectors are gradually beginning to merge, though, driven partly by the need for safety and by the need for cleaner power supplies for telecoms and technology, and when they do high-quality cables will be in greater demand.

According to one report, the insulated wire and cable market generally could grow at around 10.3% over the next five years, thanks to the infrastructure measures and the growing demand across the sub-continent for reliable energy for the millions of phone networks now in use.

The Indian government has also announced plans in the last few weeks to build a huge number of wind and solar power stations to supply up to 40 per cent of the nation’s energy by 2030 as polluting coal is phased out. This move alone will offer a massive boost to cable and wire manufacturers.

Along with the overall demand comes a need for products that fuel the growing complexity of product manufacturing. The electric wire and cable market in India is expected to continue to grow steadily in the next half-decade and beyond – and exhibitors at wire India can be expected to be among those supplying the nation’s growth.

powerhouse growth of the past decade to fuel infrastructure and technology. In times of fundamental global, economic and political changes it is as important as ever to expand worldwide technical expertise to continue playing in the top league with international competitors.

A strong demand in the Indian automotive industry, construction sector and the energy segment will also ensure filled order books for the upstream suppliers for wire, cable and pipes.

The Indian subcontinent is experiencing a phase of heavy investment in canals, bridges and other major civil engineering projects. At wire India, companies will be showing the latest machinery and equipment, stateof-the-art technologies and services in wire

IWMA staff will be manning our familiar satellite stand in Mumbai to meet members and potential members. Visitors will be able to get refreshments, use the private rooms for meetings and negotiations and find out more about IWMA services to smooth future international exhibition visits.

As at wire China, a photographer will also be available at the stand to help members produce professional images to use in their own online and promotional work during the show and beyond. Members can look forward to another night of fun at our “Taste of Bollywood” event at the five-star ITC Maratha hotel on November 28, run in conjunction with Mikrotek Machines and Niehoff of India. In 2016 our “Taste of Mumbai” night was a big hit and this one promises to be more of the same, with highly-entertaining music and dancing reminiscent of the colour and energy of Bollywood movies, spiced up – literally – with great Indian food!

The free evening, for member-companies only, is bound to be very popular which is why tickets will be awarded first-come, first-served.

Make sure you book in advance because we don’t want to leave anyone outside,

IWMA, UK

Stand: G101 www.iwma.org

www.iwma.org

and cable making, wire production and finishing, forming and spring making, as well as tools and accessories for process engineering, measuring and control technology. All types of wires (rolled, bare and speciality formulations) cable and sheet metal are covered, and for the first time, exhibitors of fastener technology get their own special mini-show, the Fastener Special Zone, to respond to the growing interest voiced by the industry.

The seventh wire India will see most of India’s major cable-industry players line up alongside exhibitors and companies from neighbouring countries, as well as the industry world centres in Germany, Italy, Austria, the USA and China.

27-29 Nov 2018

INDIA is an important market for InnoVites, and the company will be at wire India for the sixth time to reveal its latest software.

InnoVites is a software developer and independent software vendor, with offices in India and the Netherlands exclusively focused on the global wire and cable industry. InnoVites offers a wide-range of wire industry software, principally its CableSuite industry-specific IT platform.

CableSuite comprehensively supports all business functions for wire and cable manufacturers and distributors, from design and engineering through warehousing and logistics to finance, sales, production and planning.

One significant user is RR Kabel, which has its HQ in Mumbai: “We use CableBuilder and CableERP (both elements of the CableSuite platform) as our key IT solutions,” said the company’s group head of IT Pragnesh Parikh. “These integrated applications support our critical business processes and enable us to improve our business performance.“

CableSuite consists of CableBuilder, CableERP and CableMES. CableBuilder is design and quotation software for all cable types. CableMES is a manufacturing execution system for the wire and cable manufacturing industry – the engine that drives productivity and process improvement, while CableERP is world-class enterprise resource planning software offering industry best-practice for sales, warehousing, planning and production.

InnoVites CEO Albert Groothedde said: “We look forward to meeting many of our friends at wire India.”

Innovites BV, Netherlands Stand: P34 www.innovites.com

MASCHINENFABRIK Niehoff and its Indian subsidiary Niehoff of India will be on show at wire India.

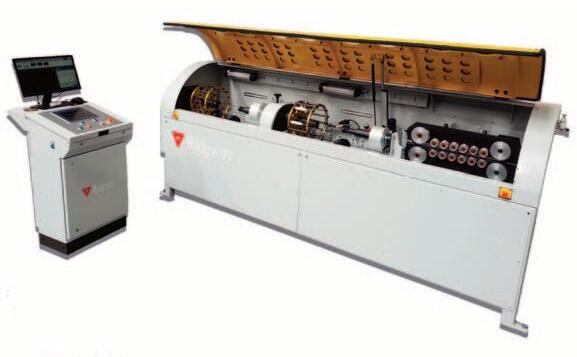

Machines include a 32-wire drawing machine (MMH 121, above) and a data cable stranding machine (DSI 631) with a back-twist pay-off (type ARD 630).

The MMH 121, built by NoI under Niehoff licence, draws 32 wires simultaneously in one level from 2.05mm inlet diameter to a minimum final diameter of 0.20-1.05mm (hard copper) at a maximum speed of 35m per second.

The machine is designed to produce electronic wires and building wires, and is constructed on modular principles that lend themselves to adaptation to customer requirements. Around 1,500 of the machines are in operation worldwide.

The DSI 631 double-twist stranding machine and upstream ARD 630 are designed to strand insulated conductors

into pairs and quads and to strand four conductor pairs into LAN cables. The machine can make LAN cables of all categories as well as pairs, with tape shielding, bus cables and other telecoms cables.

The DSI system includes additional equipment, allowing customer-specific lines created to order.

Niehoff’s partners, August Strecker, Zeller+Gmelin, H Folke Sandelin AB of Sweden, Johann Leimbach and Plasmait of Austria will also be on the Niehoff stand showing products and services that include wire-welding machinery, drawinglubricants, horizontal lead extrusion and cable stripping, repair and recovery equipment, cable industry equipment and heat and surface treatment machines.

Niehoff began operating in India in 1986 with Indian company ASACO, and in 1997 the two founded common joint-venture company Niehoff of India, which Niehoff bought outright in 2003.

The company manufactures mainly for the local market, but also sells to Sri Lanka, Bangladesh, Pakistan and Africa.

Maschinenfabrik Niehoff GmbH & Co KG, Germany Stand: H18 www.niehoff.de

EDER Engineering GmbH brings over 70 years of experience and exposure to the global market with high quality machines for die processing, reconditioning and the production of ultra-hard drawing die-tools. Indian companies strive increasingly to penetrate newer-developed markets and have concentrated on superior quality items, says Austria’s Eder Engineering. The company’s wide range of high-quality drawing dies is thus a good fit for the Indian market.

In Mumbai, Eder Engineering will highlight its entire range of equipment for the dieworking and wire industry, with a special

accent on PCD dies, from machines for working tungsten carbide and diamond dies to die workshop ancillary equipment, working materials and consumables. Most of these products will be presented in a multimedia show on a video wall, and will also be detailed in extensive catalogues, also available on the stand. Personnel at the show will include company president KG Eder and vice-president Suhas Salunkhe, as well as a range of other staff.

Eder Engineering GmbH, Austria Stand: G74 www.eder-eng.com

IN its 45th anniversary year, Sikora’s wire India stand will present a broad range of the company’s innovative measuring, control, inspection, sorting and analysis technologies for the wire and cable, optical fibre and plastics industries. The newly-launched X-Ray 8000 Advanced (right) will be a highlight on the stand. The system is tailored to the demands of MV, HV and EHV cable production and represents an advanced alternative to the established X-Ray 8000 NXT. The system has 16 sensors and measures the diameter, wall thickness and eccentricity of cables in CV lines up to a factor of 10x faster than the previous model.

Other highlights include the Laser Series 2000 and Series 6000 diameter measurement devices. The high-end devices are used in extrusion lines or rewinding applications for wire drawing and stand out with their high precision, continuous operation without calibration or maintenance time. With up to 5,000 measurements a second per axis, the 6000 offers the highest single-value precision for efficient line control, while an integrated lump detector picks up irregularities on the product surface.

Sikora’s Centerview 8000 measuring system (left) offers non-contact, eight-point eccentricity, four-axis diameter and eight-point ovality measurement to coax and LAN cables automotive and installation cables. The device offers a graphic visualisation of measured values and a scatter plot shows the distribution of shortterm variations in thickness, as well as the automatic positioning of the gauge head for the highest reli ability. Another feature is the mea surement of micro coax cables ranging in diameter from 0.1mm to 10mm.

A model drawing tower shows off Sikora’s various systems for the quality control of optical fibres. Sys tems measure the diameter and position of the naked and coated fibre, determine the tension, detect airlines, measure fibre temperature (hot position) of the drawing process, to determine the fibre temperature for control of the furnace, cold-position temperature to exactly dose the helium for cooling. Another gauge determines the concentricity of the coating and detects lumps on the coated fibre. Also at wire India will be a purity scanner, for the online inspection and sorting of plastic pellets used to make the insulation for medium, high and extra-high voltage cables. The combination of X-ray camera and optical system reliably detects surface and interior contamination of plastic pellets, and sorts the pellets automatically.

Sikora AG, Germany Stand: I73 www.sikora.net

WIRE & Plastic Machinery Corporation’s huge stock of wire and cable production machines will be open for viewing – remotely – on the company’s stand at wire India 2018. Around 30,000 items are housed in five warehouses across America, but executive vice president Rahul Sachdev will be at the company’s stand to provide access to the website inventory, which features

second-hand and reconditioned machines covering several types of products, from fibre optic and low-voltage cable, to data cable, automotive and specialised cables. Production categories include barrel packers, binders, bobbin winders, capstans, braiders, caterpillars, coilers, dancers, plastic and rubber extruders and extrusion lines, granulators, motors, ovens, payoffs, preheaters, printers, reels and rewinders, rotating equipment,

screws, stripers and strippers, take-ups, tapers, testers, tubular stranders, welders and wire-drawers.

Now in its fourth decade, Wire & Plastic Machinery Corporation has earned a strong reputation for product quality.

Wire & Plastic Machinery Corp, USA Stand: E115

www.wireandplastic.com

A Karpat Ltd Canada

ACIMAF Italy

ACOTEQ GmbH Germany

Acuity Products Ltd UK

AEI Compounds Ltd UK

AESA Cortaillod Switzerland

AFH-Antriebstechnik GmbH Germany

Ajex & Turner Wire Dies Co India

Aleados del Cobre SA Spain

Aliaj Fanar Omid Industrial Co Iran

Alloy Wire International UK

Ambrell Group Netherlands

Anglia Metal Ltd UK

Arcelor Mittal Luxembourg

Associated Engineers & Industrials Ltd India

AstroPlast, Kunststofftechnik GmbH & Co KG Germany

August Strecker GmbH & Co KG Germany

Australasian Wire Industry Association Australia

Aversion Technologies Europe SL Spain

Aymak Makine Mühendislik Hizmetleri San ve Tic Turkey

Badger Wire Australia

Balloffet SA France

Bar Products & Services Ltd UK

BASEC (British Approvals Service for Cables) UK

Bonakdar Ind & Com Group Iran

Bongard Machines GmbH & Co KG Germany

Bridon International Ltd UK

British Diamond Wire Die Co Ltd UK

BWE Ltd UK

Cable Tapes UK Ltd UK

Calmec Precision Ltd Canada

Cape Gate (PTY) Ltd UK

Carl Bechem GmbH Germany

Ceeco Bartell - Bartell Machinery Systems USA

Cemanco LC USA

Central Wire Industries UK Ltd UK

CeramTec GmbH Germany

Chaplin Bros (Birmingham) Ltd UK

Chemetall Ltd UK

Cimteq Ltd UK

Commission Brokers Inc USA

Condat Ltd France

Consultex SP Zo o Poland

Control and Power Engineering Ltd UK

Copperweld Bimetallics UK Ltd UK

CRU Events UK

CSM Metalurji Imalat Sanayi Ve Muhendislik Ltd STI Turkey

Danross Engineering UK

De Montfort University UK

Deutsches Kupferinstitut Berufsverband EV Germany

DLB Draht und Litzen GmbH Germany

Dongguan XinMei Precision Mold Co Ltd China

Drahtwerk Waidhaus GmbH Germany

DRT Impianti SRL Italy

DSE Test Solutions AS Denmark

Ducab UAE

Eder Engineering GmbH Austria

EFD Induction AS Norway

EJP Maschinen GmbH Germany

Er-Bakir Elektrolitik Bakir Mamulleri AS Turkey

Eurobend GmbH Greece

Eurotek SRL Italy

FH Machinery USA

FIB Belgium SA Belgium

Fisk Alloy Conductors BVBA Belgium

FMS Force Measuring Systems AG Switzerland

Fort Wayne Wire Die Inc USA

Foxton Dies Ltd UK

Frontier Composites & Castings Inc Canada

Fuchs Lubricants (UK) PLC UK

G & A Engineering Ltd UK

G Church - Consultant UK

Gauder Group Belgium

Geca-Tapes BV France

Gem Gravure Co Inc USA

GEO Reinigungstechnik GmbH Germany

Golden Technologies Wire & Cable Equipment Co Ltd China

Goodwin Machinery Ltd UK

Guidetti SRL Italy

Gurfil Sanayi VE Elektronik Cih Paz AS Turkey

H&R ChemPharm (UK) Ltd UK

H Folke Sandelin AB Sweden

Häfner & Krullmann GmbH Germany

Hans Schmidt & Co GmbH Germany

HB Cables & Components Ltd UK

Heda Industries Co Ltd China

Heinze & Streng GmbH Germany

Hipo Electrix Science & Technology Co Ltd China

Hoang Hung Long Co Ltd Vietnam

Holton Crest Ltd

Huestis Industrial

Huntstar Trading Ltd

ICE Wire Line Equipment Inc Canada

Inductotherm HW (Radyne) UK

InnoVites BV Netherlands

Institute of Spring Technology Ltd

Integer Research Ltd

Interlink Ltd

International Trade Shows Link Ltd

Intras Ltd

Itaya Europe Ltd

JG Tec Ltd

Jiangsu Handing Machinery Co Ltd China

Jina Special Steel Works Pvt Ltd India

John Binns & Son (Springs) Ltd UK

Kabel.Consult.Ing Germany

Kelani Cables PLC Sri Lanka

Kieselstein International GmbH Germany

Knight Precision Wire Ltd UK

Koner SpA Italy

LA.M.Plast SAS Italy

Lanfang Xinming Cable Machinery Ind Co Ltd China

Lanka Special Steels Ltd Sri Lanka

Lantor BV Netherlands

Leoni Temco Ltd UK

Lewis Wire Ltd

Locton Ltd

Lune CHF GmbH Germany

Madem SA Ind E Com de Madeiras Brazil

Maillefer Extrusion Oy Finland

Manentimacchine SRL Italy

Marldon Group Ltd UK

Mathiasen Machinery Inc USA

Medek & Schörner GmbH Austria

Meisenbach GmbH Germany

Metalube Ltd UK

Microdia SA Switzerland

Mikrotek Machines Ltd India

MSS Products Ltd UK

Nanjing Zhongchao New Materials Corporation China

Nano-Diamond America Inc USA

NDC Technologies (Beta LaserMike Products) USA

NeoFil Ltd UK

Nexans Deutschland GmbH Germany

Niehoff Maschinenfabrik GmbH & Co KG Germany

Ningbo Kaite Machinery Co Ltd China

Nota-Zaklad Mechaniki Precyzyjnej Poland

NV Bekaert SA Belgium

OMA SRL Italy

OMA (UK) Ltd UK

Ormiston Wire Ltd UK

P F Consulting UK

Pamica Group Ltd China

Pan Pioneer Co Ltd Taiwan

Peddington Lubricants and Coating Pvt Ltd India

Pentre Group Ltd UK

Performance Springs Ltd UK

Permanoid Ltd UK

Plasmait GmbH Austria

Pneuform Machines Ltd UK

Premier Cables (Pty) Ltd Pakistan

Pressure Welding Machines Ltd UK

Proton Products International Ltd Belgium

Prysmian Group UK

PS Costruzioni Meccaniche SRL Italy

Q8Oils Belgium

QED Wire Lines Inc Canada

Qingfeng Electrical Technology (Hong Kong) Co Ltd Hong Kong

Queins Machines GmbH Germany

Qunye Electrical Co Ltd China

Rautomead Ltd UK

Ravicab Cables Pvt Ltd India

Reb Mech Pvt Ltd Canada

Reber Systematic GmbH Germany

Redies SRL Italy

Reelex Packaging Solutions Inc USA

RichardsApex Inc USA

Ridgway Machines Ltd UK

RK Umformtechnik GmbH & Co KG Germany

Roblon AS Denmark

Rosendahl Nextrom GmbH Austria

SACO AEI Polymers UK Ltd UK

Sanxin Wire Die Inc USA

Sarkuysan Elektrolitik Bakir Sanayi ve Tic AS Turkey

Scapa UK Ltd UK

Scott Precision Wire Ltd UK

Shanghai Geili Precision Dies Co Ltd China

Shanghai HOSN Machinery Technology Co Ltd China

Shanghai JNL Industry Co Ltd China

Shanghai Kechen Wire & Cable Machinery Co Ltd China

Shanghai Singcheer Technology Co Ltd China

SHI Kabel GmbH & Co KG Austria

SI Interline Ltd Russia

Siebe Engineering GmbH & Co KG Germany

Sikora AG Germany

Simplex Rapid SRL Italy

Sinoleader Industries Group Co Ltd China

SKET Verseilmaschinenbau GmbH Germany

Smeets NV SA Belgium

Sneham International India

South African Wire Association South Africa

Spring Tooling Ltd UK

Stonepark Consultancy Ltd UK

Stride Supplies Ltd UK

Supermac Industries India Ltd India

T Fukase & Co Ltd Japan

TapeFormers Ltd UK

Techna International Ltd UK

Techno Commerce Ltd UK

Technokabel SA Poland

The Worshipful Co of Tin Plate Workers Alias Wire Workers UK

Thermogreen Solutions Czech Republic

Thompson & Hudson Wire Machinery UK

Tianjin Huayuan Times Metal Products Co Ltd USA

Traxit International GmbH Germany

Troester GmbH & Co KG Germany

U Gear Automatic Machinery Ltd Taiwan

Uhing GmbH & Co KG Germany

UL International (France) SA France

University of Southampton UK

Uniwire Ltd UK

Untel Kablo AS Turkey

Uygar Makina San.Ve Tic Ltd STI Turkey

Vietnam Electric Cable Corp (CADIVI) Vietnam

Vinston US Corp USA

Warbrick International Ltd UK

WCISA c/o Wire Lab Co USA

Weber & Scher Mfg Co Inc USA

Webster & Horsfall Ltd UK

White & Street International Ltd UK

Whitelegg Machines Ltd UK

Windak Group USA

Wintwire Ltd UK

Wire & Cable Technology International USA

Wire & Plastic Machinery Corp USA

Wire Association International Inc USA

Wire Lab Co USA

WOLCO Sp Zo o Poland

WTI Fasteners Ltd UK

XL Technologies UK Ltd UK

Yangzhou Havet Machinery Co Ltd China

YTC America Inc USA

Zeller+Gmelin GmbH & Co KG Germany

Zumbach Electronic AG Switzerland

27-29 Nov 2018

LUBRICANTS specialist

Metalube Ltd will introduce some of its latest innovations in lubrication technology at wire India, including its complete range of non-ferrous wire-drawing lubricants.

In addition to new formulations, Lubricool 250B and Alumol 615W, recently seen at wire China, Metalube will also showcase its full range of lubrication systems.

The Metalube range of wire-drawing lubricants addresses the growing demand for increased efficiency and reduced running costs. Though traditional lubrication techniques can in many instances meet the needs of the sector, Metalube has identified and addressed areas in which new ideas are required, including the two latest products.

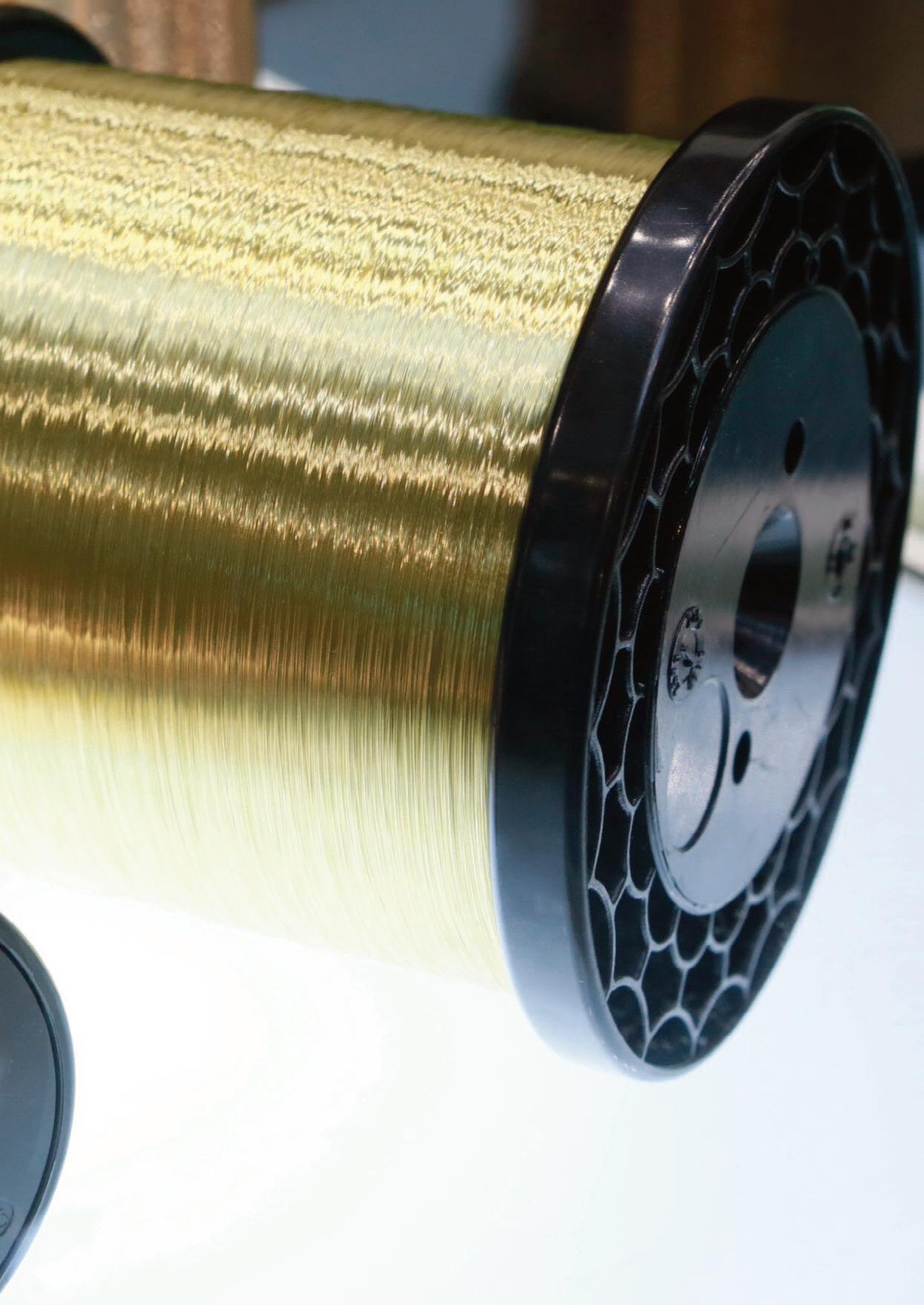

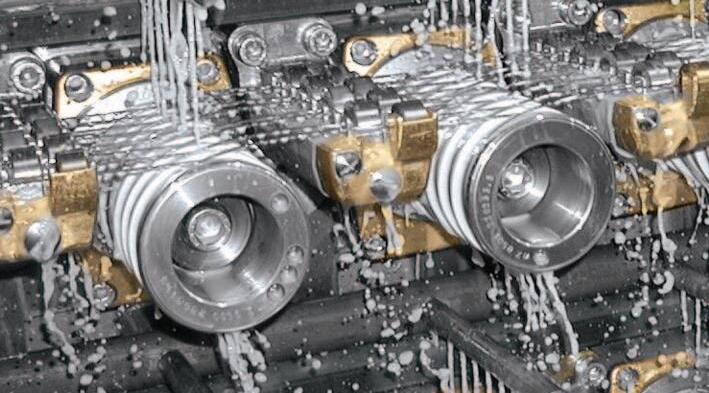

Lubricool 250B is a full synthetic wire-drawing lubricant for drawing copper and plated copper wires on high speed multiwire drawing machines. It is oil free for the cleanest working, and can draw wires down to 0.05mm while leaving drawing cones and dies free from debris.

Alumol 615W is a water-miscible aluminium wire-drawing lubricant for rod, intermediate and multiwire machines, and addresses the weaknesses of traditional neat-oil technology. Alumol 615W delivers significant improvements in machine cleanliness, ease of filtration and cleanliness of the drawn wire and is particularly suitable for automotive and enamelled wire.

Metalube global product manager Albert Molloy said: “We believe wire India provides a great platform for Metalube to

showcase the resources available in the region and the latest innovations in lubrication technology.”

Present at the show will be general manager of Metalube India, Amit Gupte: “We will also be highlighting some of our Metaform range, which offers a comprehensive range of lubricants for almost every cold and warm-forming process. We are also introducing Copaslip, made by our sister company Molyslip, which is formulated to protect fasteners from seizure induced by extremes of temperature, pressure and corrosion.”

The company, based in Manchester, Dubai, Mumbai, São Paulo and Shanghai, now exports to over 90 countries worldwide.

Metalube Ltd, UK Stand: G112 www.metalube.co.uk

CABLE packaging machinery company Windak will team up with partner company Axjo Plastic AB at wire India, showing off the duo’s latest QuickPac series of coilers and MultiPac 360° concept. The Quickpac series of single and dualhead coilers (pictured) offers rapid coils of variable length, the coil held firmly in place with an automatically-applied final band of stretch-wrap. Different models offer coil production from nine to 12 finished coils a minute, and coil lengths from 10m-100m. The system can be extended with boxing and palletising equipment.

The Multipac concept reinvents the spool as a two-part element that allows empty spools to be stacked for transport with up to three times greater density for a given volume.

Windak Group, Sweden Stand: F104 www.windakgroup.com

ZUMBACH goes to wire India having just released its new Profilemaster SPS80 rebar measuring device, which can measure rebar in the rolling mill regardless of rolling speed.

Since many rolling mills produce rebar in more than one strand, a single SPS80 can handle up to three strands simultaneously. The full contour of a rebar is captured and the cross section extracted in such a way that core diameter, rib height, width and height can all be measured.

Zumbach Electronic AG, Switzerland Stand: I154 www.zumbach.com

GERMAN machine manufacturer Kieselstein of Chemnitz will join its local agent Kemtech International Pvt Ltd on a stand at wire India.

Kieselstein will present its latest machine engineering and technological approaches The company’s comprehensive portfolio of wire-drawing machinery (right) for a wide range of wire materials and diameters, and in particular its wire-shaving technology (below), have established Kieselstein strongly in the Indian market. Kieselstein has products for shaving steel, aluminium or titanium wire, hot-drawing

difficult transformable materials, drawing round and profiled wire, wet drawing or thermal treatment and coating, all adaptable to individual customer demand. The company also offers comprehensive services to support plant operators in production as well as in maintenance and servicing. Specially developed digital solutions are also available, such as production optimisation or implementation, commissioning

HANNOVER, Germany-based Troester, which celebrated its 125th year in 2017, returns to wire India with a wide selection of its leading cable industry extrusion systems, from CV Lines for XLPE and rubber cables, silicone

and trial support and retrofitting machinery to existing plants.

Kieselstein International GmbH, Germany Stand: E57

www.kieselstein.com

insulation lines and sheathing and insulation lines, as well as its complete range of downstream equipment such as winders, caterpillars, capstans and accumulators.

This year’s exhibition will see Troester offer its latest information and developments in CCV and VCV Lines for medium to extra-high voltage cables (up to 1000kV); rubber CV and CCVlines up to 35kV, insula-tion and sheathing systems, CV tubes and components such as variable-endseal machine Trendseal, silicone insulation lines with Triox ovens and production equipment for submarine cables.

Troester Group member X-Compound, which specialises in complete systems for the compounding of plastics, will be showing kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, semiconductive materials and EPR or EPDM.

Troester Group employs over 600 people across five sites from Germany to the USA, China and Russia, and turnover reaches around 120m Euro a year. The company ranks some of the biggest names in the tire and rubber industry as its clients and has customers in 40 countries.

Over the years, Troester has developed from a machine maker into a full systems provider, producing comprehensive electronics, control and automation units as well as machines and production lines.

The company prides itself on research and development – on which it spends around two per cent of revenue.

Troester GmbH & Co KG, Germany Stand: I81 www.troester.de

ETHERNET cables are a vital element in railway rolling stock, offering effective and efficient data connection for everything from control and security to passenger entertainment.

Operators face a multiplication of data traffic from several sources (wifi systems, interactive technology and so on), which is reaching the limit of traditional Cat 5 cabling.

Nexans’ recently-announced Flamex® cable range (for categories 6A-7A) has been designed to address the increasing demand for bandwidth.

Data transmission in new platforms is mainly designed with Ethernet CAT 7 cables, while the cable looms for local networks inside coaches are usually CAT 5 quads, which are faster to install. Nexans customers can currently specify both, though Cat 5 cables remain limited to 1Gbps rather than the Cat 7 version’s 10fold capacity.

Flamex meets the electrical requirement of IEC 611566 and conforms to the highest fire hazard level 3 (HL3) standards required by EN 455451 and 2 (fire retardant, halogen free, low smoke).

www.nexans.com

ALLOY Wire International (AWI) grabbed some of the headlines at this year’s Farnborough Air Show.

Exhibiting for the fourth time, the company received several inquiries for its high performance alloys, whose applications range from very fine wire mesh and aircraft locking wires and pins to springs and electrical resistance wire for aircraft potentiometers. The company had the same high level of interest in its products at wire China, from which staff returned after more than 140 meetings with visitors from across the Far East.

Farnborough show and AWI had a great location, with Prime Minister Theresa May, Bank of England governor Mark Carney and astronaut Tim Peake (below, in blue) all visiting and making speeches in our hall,” explained Stephen Olley, AWI’s sales executive.

““Demand was so high for our technical literature that we had all but run out by the end of the first day and had to go back to Shanghai for emergency supplies,” said sales director Angus Hogarth.

The company prides itself on bing able to supply customers anywhere in the world within three weeks of the order being specified and placed.

“Over 80,000 trade visitors visited the

“It created a lot of interest and a lot of people walked past, which was great since we used the show to launch our first-ever corporate film, showcasing what makes us different. The event was great for catching up with existing clients and for meeting potential customers.”

The company managed to make one girl’s visit to “Futures Day” go brighter when she asked if the company was still giving away promotional rulers.

She had been given one two years before and had given it to her mother, who had found it invaluable for measuring rolled pastry. Sadly the numbers had rubbed off with use... so the stand team was happy to hand over the 2018 model!

www.alloywire.com

LEICESTER, UK-based leading manufacturer of taping and winding machines, Ridgway Machines, has produced a new taping line for applying Kapton and glassfibre to round or flat cables and conductors.

The new line comes with a leading-edge camera system to monitor the tape as it is applied. Also built into the line is a radiant oven, which retracts when the line stops to prevent burning. An induction heater aids adhesion and a conductor cooling unit completes the process. The whole line, from pay-off to take-up drum stand, is controlled through an advanced HMI control system. Ridgway offers a wide range of cable and conductor taping machines, from precision high-speed machines for high frequency small wire sizes for aviation and aerospace to standard mica and paper covering machines.

www.ridgwayeng.com

PRYSMIAN Group has completed a three-year task to install a cable array system for the Wikinger offshore wind farm, West of the Adlergrund cluster in the German Baltic Sea.

The cable systems giant won the contract in February 2015 from Iberdrola, the world-leading renewables developer.

“The project marks a further significant milestone for the group –being one of the first large offshore wind farms for which we have been responsible for the full inter-array turnkey supply and installation contract,” said project manager David Rayner.

Prysmian was responsible for the design, manufacture, installation, burial, termination and testing of 81km of 33kV submarine cables of various cross-sections to connect the 70 five megawatt wind turbines with the offshore substation within the 350MW farm. The cables were produced by the group’s Drammen, Norway plant.

CIMTEQ’S stand at the largest wire and cable trade fair in the Far East, wire China, showcased its flagship products

CableBuilder and CableMES, the latter a manufacturing execution system specifically for the wire and cable industry.

APAC business development manager

Yufei Du and Matt Rowlands, a manufac-

In recent years, Prysmian has moved ahead with major investment, introducing new and upgraded assets, several ultra-modern cable-laying vessels and a full range of cable protection equipment, broadening the range of its products and services.

The group also offers a fresh approach to cable repair and management.

Prysmian is particularly active across the entire northern region, where it offers turnkey products and services to the growing number of offshore wind generation projects. Prysmian has already completed work on projects such as Hornsea 2, Borssele III & IV, Horns Rev 3, Merkur, BorWin2, BorWin3, Helwin1, Helwin2, SylWin1 and DolWin3.

Prysmian Group sales exceed EUR11 billion and the group employs about 30,000 people in 112 plants in over 50 countries

turing systems engineer, welcomed visitors to the newlybranded stand.

“The exhibition has been a great success. We had the chance to meet many industry professionals and had experts doing several demonstrations a day of both CableMES and CableBuilder. These resulted in a 107% rise in leads compared to the 2016 event.”

www.prysmiangroup.com

In the past 12 months Cimteq has won a major contract to implement CableMES in the USA for an international manufacturer of custom wire and cable. The company also won a significant contract

from a leading cable manufacturer to implement CableBuilder at its design and manufacturing hub in China.

CableBuilder is the world leader in wire and cable industry software.

www.cimteq.com

WHEN his school had the careers adviser round, Mark Ormiston probably didn’t bother going to see him. For it must always have seemed clear what Mark would be doing when he entered the world of work: going into the business five previous generations of his family had run, stretching back to 1793.

Mark, now in his sixties, runs Ormiston Wire, which started in the City of London and has had various locations over the past 225 years. The company is now based in a trading unit in Isleworth, Middlesex, where Mark oversees six permanent and six parttime staff as they take on jobs of all kinds.

“If it involves wire of some kind, we can do it,” says Mark confidently, and he has been proved right too many times for that to be an idle boast.

Ormiston isn’t the oldest wire-making company around: Mark knows of companies in Birmingham and the South West that are older. But it seems pretty certain his is the oldest wire-producing firm still operated by the same family.

You don’t have to be a Fortune 500 company or employ thousands to have a great reputation, as UK-based wire manufacturer Ormiston Wire knows. We speak to MD and sixthgeneration member of the founding family, Mark Ormiston (below), about the family business

Ormiston Wire won a Queen’s Award for Sustainability in 2002.

The firm continues to make everything from the wires used to hold up those “Sale! Everything must go!” signs in your local supermarket to stainless steel braids, and from wire rope to wire surgical bone saws.

That Ormiston has managed this, in the light of many recessions, wars and other business-killing events in the last two and a quarter centuries, is a tribute to the firm’s resilience and adaptability.

“When times get bad many companies cut staff and stop research and development,” said Mark.

“Instead, we started saving money within the business: we installed solar panels and a wind turbine and recycled packaging and did a lot of other things to make the company more efficient.”

Over the past 50 years the company has also gained a reputation far beyond its size for diving in wholeheartedly when film, TV and the world of the arts comes to call. Ormiston produced the wires that held up the puppets in Gerry Anderson’s famous TV series Thunderbirds (above left), Captain Scarlet and Stingray, among others, and helped Harry Potter’s broomsticks – not to mention Christopher Reeve as Superman – to fly. They made over 800,000 metres of delicate wire used in 2002 by artist Thomas Heatherwick to create Bleigiessen (far right), a huge sculpture that hangs 150,000 glass baubles on 27,000 wires down the eight-storey atrium of the Wellcome Trust HQ in central London, mimicking the shapes made by molten lead dropped in water.

“We also hung on to some of our old machinery, so now when anyone needs products made by machines no longer available, we can still make them. We have a reputation for providing what our customers need,” said Mark.

That applies no matter what the quantity. The Mercedes-McLaren SLR grand touring car (left) used a novel, Ormiston-made synthetic wire harness to keep the engine and passenger compartment apart in an accident

in the early Noughties – production running to just over 300 cars a year. At the other end of the scale, back in the Sixties Ormiston Wire had 10 machines running 10 hours a day for years, turning out the tiny steel braids used to connect Scalextric cars to their powered track.

The other end of the adaptability scale is experience and expertise: you can’t wipe the dust off a mothballed machine and make some specialised product when the people who knew how best to use it are long-since retired.

“Fortunately we have a history of staff staying with us a very long time, and of course being very experienced in all aspects of wire and braid-making because of it,” said Mark. More family than workforce (two members

of Mark’s actual family work alongside him), employees have an attrition rate, mainly through retirement, of about one person every two years.

“We had one guy, Arthur, who joined us after he retired at 65 and came to work like every other employee every day – in later years part-time, because he loved it – until he was in his mid-nineties,” said Mark, who currently presides over a group ranging from their twenties to beyond retirement age.

Over such a long period, part of the company’s adaptability has been its ability to grow or shrink as the era demands.

When Mark’s father was in charge it was a different era of mainstream British manufacturing, and he was the image of the successful businessman, riding around in his Rolls Royce and presiding over a company with dozens of employees producing millions of feet of wire stocks a year.

Over the last few years the workforce has fallen dramatically – though the business remains remarkably profitable with its £1.5 million a year turnover – and has incorporated a second company at Redditch, actually now, says Mark Ormiston “one woman in a unit the size of a double garage”, making the company’s “turbulators” – spring wires (left) that introduce turbulence in heating pipes to improve heat output.

“We have been around a long time and that has partly happened because we have encouraged people to come to us with unusual projects, which have allowed us to become better known,” Mark explained.

“Gerry Anderson’s company came to us because they had heard of our expertise, not because we were relatively close by. Every time a project like that, or Mercedes, or Heatherwick, comes to us, the publicity it generates (which the company’s publicityminded MD and lively website are only too happy to exploit) means other people with unusual projects come to us too.

“As a nation we have pretty much given up on our manufacturing industry, so the great days my father and grandfather knew have gone to other countries and are never coming back. What remains are a lot of companies like ours, which survive on specialism and expertise and a size that allows us to experiment. It’s because of a willingness to have a go that Ormiston Wire is still around, and long may it continue.”

If your IWMA-member company has an interesting case history, makes an unusual product or undertakes major research or production, we would love to talk to you about featuring a profile like this one. Contact us at info@iwma.org

IWMA Educational Trust chairman Peter Large reveals how the trust can help members to train the next generation of industry professionals.

THE IWMA is always looking to the future. Through its educational trust fund and travel award scheme, the association actively promotes the learning of new skills and the gaining of greater experience for tomorrow’s talent, whether the skills are in engineering, management or some related field. Our new CabWire Fundamentals workshops (see opposite) are aimed precisely at that objective.

The association has always taken a keen interest in helping young people in the industry. The IWMA Educational Trust scholarship prpgramme exists to provide funding to train individuals supported by member companies, and applications can be made through the IWMA website at any time.

In the past such help has always been financially limited. From this year the IWMA Educational Trust has access to

greater funding and can now review each application on its merit, before awarding whatever amount it feels will help the applicant to achieve their aims

So whether a member company is planning to recruit an apprentice, supporting an apprentice keen to learn in night classes or a block course, or one trying to achieve higher specialist qualifications, funds could be available from the IWMA Educational Trust to help with the cost.

Our latest recipient is 21-year-old James Bunn from Pontefract, nominated by his employer Bridon Bekaert.

James has just begun a three-year, parttime foundation degree in materials engineering at Sheffield Hallam University, with the IWMA Educational Trust paying the degree fees.

The course will allow James to build on his existing BTEC Level 3 qualification in manufacturing engineering metallurgy.

The IWMA is firmly committed to the future of the wire and cable industry and actively encourages the acquisition of new skills and experience.

Through the Educational Trust, the IWMA helps promote education, new technology and growth.

Another IWMAET facility is the travel award scheme, through which we give young newcomers to the industry the chance to attend major events such as the wire Düsseldorf exhibition and CabWire technical conference and Fundamentals workshops by contributing towards their travel costs. Successful applicants get to learn about the latest innovations and meet influential people.

The IWMA is also forging links with universities such as Southampton and De Montfort in Leicester to explore ways of working together – on research papers or training p lacements, for example We are here to help our members by assisting in the training of the next generation of professionals. Wherever possible we will give support.

Details:www.iwma.org/education

Highly-successful changes to the IWMA’s international CabWire Industry Forum in 2017 will continue with a new, separate IWMA Educational Trust-sponsored event at Southampton University, UK, on April 2-3, 2019.

The event is organised by the IWMA and IWCEA in partnership with Southampton-based Prysmian UK and the university. CabWire Training Fundamentals are workshop sessions covering the basics of nonferrous metals good practice, aimed at newcomers to the industry and those keen to have a refresher on current developments and trends.

cables and the influence of Industry 4.0.

“The decision to run a CabWire Fundamentals event came out of the success of 2017, when all the sessions were very well attended,” said IWMA education director, Peter Large.

“The Fundamentals programme falls nicely within the IWMA’s education programme, so the Educational Trust will be sponsoring the day and providing free places for students, graduates, apprentices and entry-level staff.”

The two-day event, on the university’s Highfield campus, will hear from IWMA training lead Amanda Shehab and Dr James Pilgrim (above), head of the university’s physics lab, before a series of 45-minute sessions running through the day, with lunch and refreshment breaks.

The programme will feature expert-led talks on wire drawing, stranding, extrusion, cable design, cable armouring, optical

As well as the training sessions, attendees will get the chance to tour the university’s fascinating high-energy laboratory.

That evening, delegates can enjoy a private tour and meal at the National Motor Museum at nearby Beaulieu, while the next morning brings a tour of the Prysmian UK factory.

The event will also feature a number of “table-top” exhibitions.

The event costs £120 for members, £150 for non-members.

Get full details on the CabWire website, where accommodation is also available separately.

wire India 27-29 November

Bombay Convention & Exhibition Centre

Mumbai, India

Tel: +49 211 4560 579

Email:muellersm@messe-duesseldorf.de

Website: www.wire-india.com

Interwire 13-16 May

Georgia World Congress Center, Atlanta, Georgia, USA

Tel: +1 203 453 2777

Email: sales@wirenet.org Website: www.wirenet.org

wire Russia 18-20 June

EXPOCENTRE Exhibition Centre

Moscow, Russia

Tel: +49 211 4560 7725

Email: AhernsG@messe-duesseldorf.de Website: www.wire-russia.com

wire Southeast Asia 19-21 September

BITEC, Bangkok, Thailand

Tel: +65 6332 9642

Email: beattrice@mda.com.sg

Website: www.wire-southeastasia.com

wire South America

3-5 October

São Paulo Expo, Brazil

Tel: +49 211 4560 478

Email: BagciC@messe-duesseldorf.de Website: www.wire-south-america.com

wire Düsseldorf

30 March -3 April

Messe Düsseldorf GmbH

Düsseldorf, Germany

Tel: + 49 211 4560 478

Email: BagciC@messe-duesseldorf.de Website: www.wire.de

wire China

23-26 September

SNIEC Shanghai, China

Tel: + 49 211 4560 579

Email: MuellersM@messe-duesseldorf.de Website: www.wirechina.net

Founded in 1970, the IWMA is the world's largest and most influential corporate association for the wire and cable industry.

The association promotes new technology, education and industry growth through events, conferences and publicity opportunities. These offer an international forum for technological advance and best practice for IWMA members.

Membership offers companies an international platform for the exchange of technology, regular, focused meeting places for the industry, as well as superb reference sources from a library of past technical conference papers.

The IWMA attends the biggest international exhibitions with a prominent stand that provides support for members exhibiting or just visiting each event.

The stand was recently redesigned to provide more and better facilities for members, and offers a range of business services, from private meeting space and printing to internet access and refreshments.

meet customers and talk business, or just catch up with colleagues over a beer, the stand’s facilities are freely available. As well as exhibition business facilities, the IWMA also organises networking events for members attending exhibitions, which are always very well attended.

Our friendly stand team is available at exhibitions to help members sort out any problems. The association offers a great network when members are overseas, and can also help with hotels, transport and other vital elements of international trade.

As a wire industry partner of exhibition organiser Messe Düsseldorf GmbH, the IWMA can advise members on the shipping of display items, transportation or general accommodation or other essential matters.

Whether members want to use a private room in which to

IWMA members also enjoy many other benefits, such as funding for training, access to business advice and the use of modern meeting rooms and hot-desk facilities at the association’s offices near Birmingham airport in the UK.

Pamica, established in 1991, specialises in the research, development, manufacture and marketing of mica insulation materials.

Pamica’s size and capitalisation make it the biggest company involved in China’s mica insulation materials industry. Pamica is an ISO9001:2008 and ISO14001:2004 certified company.

www.pamica.com

Hung Long Co Ltd

company

is a general manufacturer of steel welding products, electrode rod and mig & tig wires and rods, The company also handles steel scrap, especially used rail and I-beam.

WIRE and Cable News brings you the best print round-up of what’s going on among wire and cable industry members – but you can now also enjoy watching the pick of IWMA events and show footage on the IWMA YouTube channel.

We are making our YouTube channel a go-to place for members, dedicated to IWMA news and member developments, shot by our own camera operator.

Take a look now: go to (www.youtube.com and search for IWMA channel).

Over the coming months we will be adding lots of videos from the shows we visit, the members we talk to and the events we hold –all free for members to enjoy.

Companies get many other benefits from joining the IWMA, one of which is a dedicated, members-only area of the website.

This has access to a catalogue of past technical papers useful in research – thousands of pages going back to the 1970s – and lots of events and other news and information of specific interest to members.

Check it out at www.iwma.org

IWMA: industry partner to the major wire and cable exhibitions

For more information or to book tickets for any of these events, please visit the IWMA website, www.iwma.org/events, or email info@iwma.org

www.iwma.org

2-3 APRIL, 2019

Southampton, UK