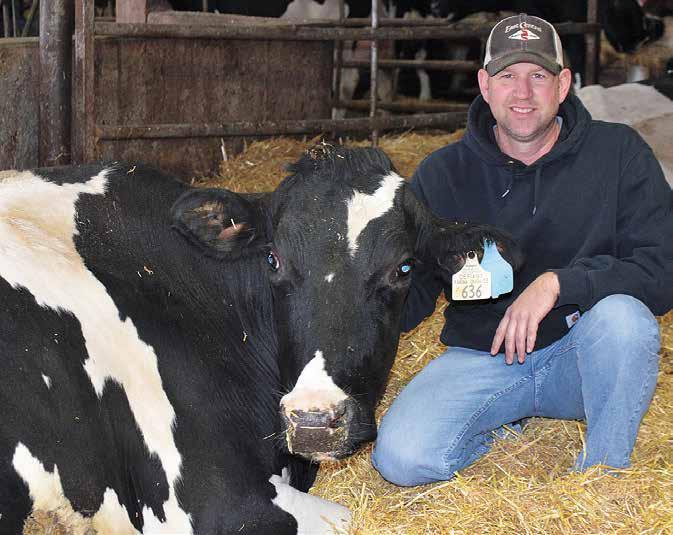

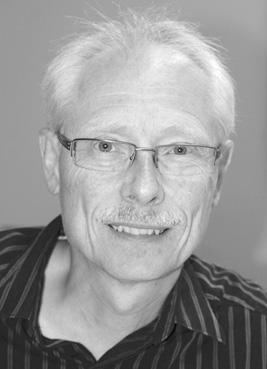

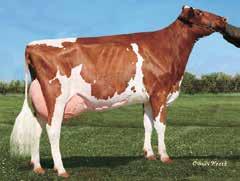

FENNIMORE, Wis. – Powerhaus Deant Reese has always been a special cow to the Holthaus family because of her friendly demeanor and long line of good genetics. After surviving a surgery to remove a volleyball-sized uterine tumor and then becoming pregnant again against all odds, she is even more special.

“She’s such a nice cow, and she’s got a great pedigree,” Jeremy Holthaus said. “Genetically, she was worth working with.”

Holthaus milks 310 cows with the help of his parents, Lonnie and Rochelle Holthaus, and their herdsperson, Bridget Achterberg, near Fennimore.

The uterine tumor was discovered in 2019 during a routine herd health check. At the time, there appeared to be a golf-ball-sized mass on the uterus. The family’s veterinarian, Steve Holler, was unable to tell exactly what it was through ultrasound, so they decided it must be a cyst. She went through a round of fertilization shots and everyone thought it would clear up.

Unfortunately, the mass continued to grow. Within a year, it had grown to the size of a volleyball.

“It weighed her uterus all the way down so we couldn’t breed her,” Holthaus said. “It wasn’t cancer. It was like a big abscess in there, but we couldn’t tell that by ultrasound.”

The family wanted to continue utilizing the genetics from Reese. Reese’s dam had died at a young age, but her grandmother had lived to be 13 years old with a milk production record of 257,000 pounds.

Achterberg said the whole cow family has made consistent daughters on the farm.

Achterberg said.

The Holthauses decided to explore their options. They rst contacted the University of Wisconsin-

LITTLE ROCK, MN 320-584-5147 PIERZ, MN 320-468-2168 LASTRUP, MN 320-468-2543 BUCKMAN, MN 320-468-6433

“They all milk really well and look good doing it,”Madison and asked about exploratory surgery. They were quoted more money than the family was willing

to spend with no guarantee of a good outcome. Holthaus said the next option was shipping her.

That is when their vet agreed to remove the tumor. The cow was taken to the vet’s ofce in Prairie du Chien Aug. 19, 2020, where Holler performed the surgery.

The incision was made on the left side of the cow. It was similar to a displaced abomasum surgery but with a longer incision. The tumor was removed in the course of two hours. Holthaus had his arm in the cow rectally to hold the uterus so the vet would not cut it.

The cow lost a lot of blood during surgery and was very weak at rst. She had a 30-minute trailer ride home and was put in the calving pen to recover. The family continued to focus on helping Reese regain her health so she could either calve again or have her embryos ushed.

Once Reese recovered, she was taken to an in vitro fertilization facility where it was discovered one of her uterine horns had been accidentally removed during the surgery. Additionally, the side of her uterus with the remaining horn had fused to her body wall, making her ovary inaccessible.

“They called her a non-breeder,” Holthaus said. “They couldn’t do anything with her.”

Besides her reproductive issues, Reese was perfectly healthy. The family brought her home and put her in a

pasture while they debated what to do.

“There was no other place for her so we put her in a pasture with some little bulls that were about 500 pounds,” Holthaus said. “We thought we’d get some weight off her and bring her back to try one last time.”

When she was brought home about seven months later, she appeared to be bagging up. Achterberg sleeved her and discovered there was a calf present. The vet determined she was less than a month away from calving.

A few weeks later, Reese gave birth to a healthy heifer calf.

After she calved, Holthaus had her scored right away.

“Her udder looked gorgeous,” Holthaus said. “She scored 93 points. So that’s going to be her max.”

Holthaus does not plan on breeding Reese again, even though the vet said another pregnancy would help her reproductive organs because they are somewhat adhered to her body wall and the gradual weight gain of a calf would help to pull it away. They are working with an IVF team to try to carry on her genetics. There have not been any fertilized results so far, but they are going to continue to try.

“When she was milking with the herd, anytime you were walking through the barn she would follow you around like a puppy dog,” Holthaus said. “Genetically, she is one of our best lines here. We’re going to try again.”

“It weighed her uterus all the way down so we couldn’t breed her. It wasn’t cancer. It was like a big abscess in there, but we couldn’t tell that by ultrasound.”

JEREMY HOLTHAUS, DAIRY FARMER

As reported last week, the U.S. Department of Agriculture left its 2022 milk production forecast unchanged in its World Agricultural Supply and Demand Estimates report but raised the 2023 estimate slightly, citing higher expected cow numbers and slightly more rapid growth in output per cow.

Cheese was projected to average $2.11 per pound in 2022, up a penny from last month’s WASDE, and compares to $1.6755 in 2021 and $1.9236 in 2020. The 2023 cheese average was projected at $1.9950, up 2.50 cents from a month ago, but that would be 11.50 cents below the projected 2022 average.

The 2022 butter price average was estimated at $2.8750 per pound, up 3 cents from a month ago, and compares to $1.7325 in 2021 and $1.5808 in 2020. The 2023 average was projected at $2.4650, up a penny from a month ago, but 41 cents below the expected 2022 average.

Nonfat dry milk will average $1.68 in 2022, unchanged from last month’s estimate and compares to $1.2693 in 2021 and $1.0417 in 2020. The 2023 average was estimated at $1.3750, down 3 cents from a month ago and would be 30.50 cents below the anticipated 2022 average.

The dry whey average for 2022 was unchanged at 60.50 cents per pound, and the 2023 average was lowered 2 cents to 46.50 cents per pound, 14 cents below the expected 2022 average.

The 2023 Class III milk price was projected to average $19.80 per hundredweight, up 15 cents from last month’s WASDE but would be $2.15 below what the 2022 average is expected to be.

The 2023 Class IV price was estimated to average $20.10, down 25 cents from last month’s estimate and would be $4.40 below the anticipated 2022 average.

This month’s corn outlook is for lower exports and greater ending stocks. Exports were lowered 75 million bushels as competition from other exporters and relatively high U.S. prices have resulted in slow sales through early December. Corn ending stocks were raised 75 million bushels. The season-average corn price was lowered a dime to $6.70 per bushel. Corn exports were raised for Ukraine but lowered for the U.S., Russia and the EU, according to the WASDE.

Soybean projections were unchanged from last

month. Based on a review of the Environmental Protection Agency’s recent proposed rule for renewable fuel obligation targets, soybean oil used for biofuel was reduced 200 million pounds to 11.6 billion. Soybean oil exports were also reduced. With those reductions, food use and ending stocks were raised. The season-average soybean price forecast was unchanged at $14 per bushel. Soybean oil was reduced a penny per pound to 68 cents, and the soybean meal price forecast was increased $10 to $410 per short ton.

Speaking of feedstuffs, StoneX Dec. 12 U.S. Dairy Outlook points out that alfalfa in the West is priced at record highs. California was seeing average hay at $370 per ton and Arizona at $340, with high quality prices much higher.

Alfalfa in Wisconsin, on the other hand, is around $169, which is close to the ve-year average, StoneX said. Western prices could decline from their record highs moving forward, but the water situation in parts of the West remains tenuous, which could keep input costs in the region expen-sive relative to other regions.

This week’s Livestock, Dairy and Poultry Outlook reported that October alfalfa hay averaged $281 per short ton, $4 higher than September and $62 above October 2021. The ve-state weighted-average price for premium alfalfa hay was $348 per short ton, $6 higher than September and $94 higher than October 2021.

The Outlook reected milk price and production projections in the Dec. 9 WASDE and reported that dairy cow slaughter has been active and has been in line with 2021 for the past couple of weeks.

The Outlook said the National Restaurant Association reported restaurant activity from January to October was below 2021 levels. Nevertheless, the restaurant performance index has been above 100 points, showing an expansion that may boost domestic use for dairy products for the rest of 2022 and 2023.

Things are looking a little better for consumers. The Consumer Price Index fell for a second month, from 7.7% to 7.1%. Core ination fell in November from 6.3% to 6%, which is the best reading on ination since December 2021, according to StoneX, but with one sticking point: Rents were up 7.1% yearover-year and accounted for almost half the total increase in core ination.

Meanwhile, the Federal Reserve raised its inter-

est rate a half-point this week, which was slightly less than previous raises; however, the rate is at the highest level in 15 years.

Dairy product consumption in October was a mixed bag, according to HighGround Dairy’s Lucas Fuess in the Dec. 19 Dairy Radio Now broadcast.

Cheese disappearance totaled 1.22 billion pounds, up 2.4% from October 2021 and the third month in a row to top that of a year ago, though Fuess said the gain weakened slightly from September’s growth. Year-to-date consumption was up 2.1%. U.S. cheese exports, at 81.4 million pounds, were up 4.5%.

Butter disappearance totaled 199.9 million pounds, down 8% from a year ago pulled lower by an 11.3% drop in domestic consumption; though, exports were up 61.9%, the strongest of any month since 2014. October was the third consecutive month total butter utilization was below a year ago, and HGD said it was the lowest October utilization since 2017.

Nonfat dry milk skim milk powder disappearance amounted to 208.5 million pounds, down 12.8%. Domestic usage was down 49.4% while exports were up 10.6%, rst year-over-year gain since November 2021, according to HGD.

Dry whey utilization totaled 76.3 million pounds, down 4.5% from a year ago; though, like nonfat dry milk, exports were strong, up 20% from a year ago, as Chinese demand for dry whey has returned, Fuess said.

The demand picture in next month’s report will be interesting, Fuess said, as U.S. milk production growth will not bow well for milk price increases in 2023.

The Dec. 13 Global Dairy Trade Pulse, auction No. 11, saw 2.1 million pounds of Fonterra whole milk powder sold, down 38 million pounds from the last Pulse and down 0.3%, or $10 per metric ton, from the Dec. 6 GDT event.

HGD said buyers are nding value at this current price point following the slight strength that materialized at last week’s main GDT auction.

Eyes will be on CME powder in the coming days after Fonterra increased its forecast total over quantity for skim milk powder for the next 12 months by 21.2 million pounds between January and April. The

upcoming event offering was increased by almost 816,000 pounds.

Cooperatives Working Together member cooperatives accepted two offers of export assistance this week from CWT that helped capture sales contracts for 1.2 million pounds of American-type cheese. The product is going to customers in Central America and Oceania from January through May 2023.

CWT-assisted exports to-date total 93.3 million pounds of American-type cheeses, 657,000 pounds of butter, 30.7 million pounds of whole milk powder and 8.8 million pounds of cream cheese. The products are going to 21 countries and are the equivalent of 1.168 billion pounds of milk on a milkfat basis.

More details were announced Dec. 12 on the USDA’s solicitation of the Special Supplemental Nutrition program for Women, Infants and Children. A total of 8.56 million pounds of natural cheddar was awarded to three different vendors, with delivery between March and September 2023, or about a 1.22-million-pound average per month. No processed cheese or uid milk was awarded.

HighGround Dairy said USDA awarded far more than the 2.1 million pounds of natural and processed cheese in the original solicitation, but with just 1.22 million pounds per month, it equates to about 30 truckloads per month. The bigger news was that the uid milk solicitation was canceled, meaning USDA will focus its efforts on their normal uid purchasing programs for the up-coming year.

This news should have little impact on the current trend of the market, said HGD, though it may create disruptions depending on USDA’s order patterns.

Mid-December cheese prices headed sharply lower and butter oscillated, as traders awaited the November Milk Production report Dec. 19.

The cheddar blocks plunged to $1.9775 per pound Friday, lowest since Nov. 1, down 11.75 cents on the week but still 9 cents above a year ago.

The barrels saw their Friday nish at $1.74, 21 cents lower on the week, lowest since Jan. 27, 11 cents above a year ago and 23.75 cents below the blocks. CME sales for the week included four carloads of block and seven of barrel.

StoneX said Buyers are just not banging down doors looking for fresh loads of cheese here in midDecember. And then, we have the appearance of a well-supplied barrel market.

Central cheese sales are seasonally steady, according to Dairy Market News, with moderate to busy production reported. Milk is plentiful with spot loads priced as much as $6 under Class, with some at Class. Barrel production is busier, as some cheesemakers report sales at slight premiums. Some cheddar and Italian-style cheesemakers report somewhat tight inventories for the rest of the year.

Retail and food service demand for cheese is steady in the West. Export demand is mixed. Lower prices for internationally produced cheese is contributing to softer demand, while strong demand remains from Asian purchasers. Contacts report that block loads are selling more quickly while barrel inventories are growing. Milk is available for strong regional cheese production; however, labor shortages and delayed deliveries of supplies continues to limit output of some.

Spot butter started the week falling 11.25 cents to $2.70 per pound, lowest since Nov. 3, but then reversed direction and ended Friday at $2.8550, up 4.25 cents on the week and 76.25 cents above a year ago, putting 23 sales on the board.

Butter producers report slowing demand, as retail customers have their holiday ordering met. Food service demand has also seasonally slowed, said DMN, particularly as butter prices remain above where some were expecting them to be this late in the year. Cream availability is mixed. Some plants are full and not entertaining spot offers while others say cream availability is steady with previous weeks. Churning remains very busy, and plant managers expect to churn as much butter as possible despite the holidays.

Demand for cream is steady to lighter in the West. Cream multiples have moved lower in the region amid softer demand and strong availability. Butter makers are running busy schedules, though some say tanker and labor shortages continue to keep them operating below capacity. Demand for butter is softening in retail markets, as customers have lled holiday needs. Food service demand is steady. Spot purchasers report butter loads are becoming more available, said DMN, though unsalted butter inventories remain tighter than salted. Some players anticipate that butter prices will slip lower into the new year, thus causing buyers to limit their orders.

Grade A nonfat dry milk fell to $1.34 per pound Wednesday, lowest since Sept. 16, 2021, but closed Friday at $1.35, down 1.50 cents on the week and 32.75 cents below a year ago, with 14 sales reported.

Dry whey closed the week at 45.50 cents per pound, 2 cents higher, but 27.50 cents below a year ago, with four loads exchanging hands at the CME.

Dairy Market News said online sources say August milk production in Ukraine was approximately 711,000 tons, compared to 845,000 in August 2021. The Russian invasion of Ukraine has disrupted normal dairy business activities and the recent missile attacks left numerous processing facilities without power.

The Ukrainian agricultural ministry, as of Dec. 1, reported that the 2022 Ukraine grain harvest is approximately 85% complete for a total of 41.9 million tons. Ukraine has been able to export 17.2 million tons of grain so far in the 2022-23 grain season, down 31.9% from a year ago.

Looking down under, DMN reports that New Zealand’s dairy industry resilience has been tested in recent months. The country has seen slow pasture

growth in most dairy regions this production season. New Zealand’s dairy exports have seen a rise due to the build-up of inventory caused by the coronavirus pandemic and China interruptions in earlier months. Meanwhile, with the weak New Zealand dollar and falloffs from key dairy exporting regions, the industry now expects the country’s export revenue to climb 6% to a record high $23.3 billion in the 2022-23 season. Australia continues to lag last year’s milk output. Rain soaked elds in the Eastern states have impacted the wheat quality, prompting downgraded yields and could lead to market ooding of devalued feed grade grain, DMN said.

ST. CLOUD, Minn. – Around 500 attendees are expected for the 2023 Minnesota Organic Conference, a two-day event running Jan. 5-6, 2023, at River’s Edge Convention Center in St. Cloud.

“This is our 20th year,” said Cassie Dahl, the event’s coordinator. “Time really ies.”

The conference is offered through the Minnesota Department of Agriculture. A wide variety of educational sessions, two keynote speeches, an 80-booth trade show and plenty of food are included in the cost for attendance. Online registration will close Jan. 2, 2023, but walk-in registrations at the event are accepted.

Many sessions address topics in dairy.

“We have sessions on interpreting the origin of livestock rules, putting organic dairy research to work, grazing for grassland, conservation grazing into the future, grazing season health issues and others that relate directly to dairy,” Dahl said. “There are always other sessions that can apply to dairy as well.”

The trade show will have plenty of representatives from dairy as well as all aspects of farming.

“There’s a wide variety,” Dahl said. “We have feed suppliers, certiers, consultants, equipment dealers -people from the marketing, fertilizer, solar and livestock minerals industries – and more.”

The size of the trade show is a big draw for the conference.

“Our trade show really helps fund the conference,” Dahl said. “We also have a lot of sponsors, some sponsoring the keynotes and others sponsoring breakout sessions. We have them listed on our website.”

This year’s keynote speakers are Sarah Vogel and Carmen Fernholz.

Vogel will give the keynote address on the rst day. She is an attorney and advocate specializing in

“I believe producers would nd lots of educational and working value from our conference.”

CASSIE DAHL, MINNESOTA ORGANIC CONFERENCE COORDINATOR

agriculture issues and has written several books including “The Farmer’s Lawyer: The North Dakota Nine and the Fight to Save the Family Farm.”

“My speech, which is titled ‘Strength from the Soil: How Organic Farmers Can Straighten the Whifetree of U.S. Agriculture,’ will draw on tactics and remedies that were developed in the 1930s and the 1980s that can inspire us today,” Vogel said. “It is an honor to be able to speak to a group of farmers who show by their deeds how to build a better future for people, soil, air, water and the future of our small towns and rural communities.”

Fernholz will give the keynote speech on the second day. He is well-known as a pioneer in the eld of organic farming.

“I am truly looking forward to getting together once again in person at the great Minnesota Organic Conference,” Fernholz said. “It is always a lively venue for organic farmers, merchandisers and those who value our work. As a keynoter, I am especially excited about the opportunity to share some of my personal thoughts regarding my organic farming experiences over the nearly 50 years as an organic farmer.”

Each day offers breakfast and lunch. A reception and social time will run from 4:30-7 p.m. on Thursday night. The conference will wrap up at 3 p.m. on Friday.

Dahl said the conference has a lot to offer for everyone interested in learning about organic practices, innovation or issues.

“I believe producers would nd lots of educational and working value from our conference,” Dahl said.

Sanborn, MN

Meadowlands

Farmers Co-op 6.6714.71

Almena, WI

Synergy Cooperative 5.9214.06

St. Cloud, MN

ADM 6.2714.56

Westby, WI

Premier Co-op 6.1214.03

Cadott, WI

Cadott Grain Service 6.1214.06

Pipestone, MN

Cargill 6.6714.76

Muscoda, WI Riverdale Ag Service 6.2214.01 Wheat 6.91

Gar eld

Pro-Ag Farmer’s Co-op 6.3714.66 Wheat 9.08

Monona, IA

Innovative Ag 6.2314.18

Watertown, SD Watertown Co-op Elevator 6.6414.68 3.89 S. Wheat 9.03 W. Wheat 8.27

Whitewater, WI

Landmark Services Co-op 6.4014.19 Wheat 6.58

Dennison, MN

Central Farm Service 6.3714.27

Belleville, WI Countryside Co-op 6.3714.19 Wheat 6.58

Glenwood, MN

CHS Prairie Lakes 6.4714.76 S. Wheat 8.88

Every Christmas I remember my worst nightmare, and favorite memory of the season. My wife and I fed cattle and crop farmed the first half of our life. One Christmas I was in a hurry to get chores done to get to the family and forgot to shut off the water hydrant in the sick pen and flooded the barn. It was so cold that it was freezing instantly. The last thing we needed was to have a skating rink in our cattle working tub and sorting allies so I had no choice but to call the family and let them know I wouldn’t make it as I had to clean out the barn. A short while later a caravan of cars full of family showed up with pickaxes, spades, and shovels. An hour later we all loaded up to head to my parents smelling like ruminant fecal material and the evidence of our fun dripping from us.

Milk markets will finish the year with cheese prices fading, butter remaining resiliently firm, and powder markets in a weaker trend. U.S. cheese prices remain competitive to international markets with sub $2.00 block cheddar and mid $1.70 barrel prices. This compares to EU and NZ cheese above $2.20/lb.

U.S. spot butter prices are trading $2.85 at the time of this writing. January butter futures are trading at a 30-cent discount to December at $2.51. Now that

holiday demand is covered, U.S. butter prices are trying to find a balance with cheaper international offerings.

Protein powder markets are sending mixed signals. Nonfat dry milk prices are pretty well in line with most markets trading in the $1.30-1.40 range. Sweet whey is trading in the low 40’s. Based on current trends and expectations of various dairy product prices, it looks like Class IV may weaken to Class III in 2023.

Global dairy demand typically grows at about 2% per year, but over the past five years has been running near 1%. If this demand is still in the weeds wanting to come to life, it seems that it will take cheap milk prices to make it happen. If cheaper milk prices don’t stimulate this pent-up demand, margins will need to come from cheaper feed. I wouldn’t hold my breath for this over the short term as feed and grain markets have a lot of fundamental and psychological bullishness undertone at the moment.

DairyVisor would like to wish all of you a Merry Christmas and Happy New Year. May 2023 bring you and your family many blessings.

*Futures and options trading involve significant risk of loss and may not be suitable for everyone. Therefore, carefully consider whether such trading is suitable for you in light of your financial condition. Past performance is not indicative of future results. DVi is an equal opportunity employer.

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

VARHAUG, Rogaland, Norway –

Regardless of where on the globe their dairy farm might be located, cow care and comfort drive dairy farmers.

That is the case for Elin Hobberstad of Hobberstad Gard.

“What I really love about the farm is working with the animals,” Hobberstad said. “Animal welfare is a very high priority for us.”

That core principle also serves as a source of frustration for Hobberstad.

When it comes to dealing with the general public whom are often times generations removed from the family farm, tension arises.

“One of the biggest challenges we face is ignorance,” Hobberstad said. “People have absolutely no idea what is going on in a barn and tend to humanize the animals. I try to tell people that my cows are better cared for than most of our sick and elderly. If needed, a vet will come here within the hour.”

Hobberstad, along with her husband Norodd Lode, is the sixth generation to operate the farm that has been in her family since 1892.

She purchased the farm from her

parents in 1997. There is a philosophy in Norway known as “odelsloven,” which gives the rstborn child the legal right to purchase the farm. Hobberstad said it worked out well for her own family, as none of her younger sisters had an interest in pursuing a career in dairy farming.

A chicken barn was constructed in 2007, and the farm diversied by adding poultry production. Norodd also operates a transport company along with handling the farm’s eldwork. Their oldest son, Rasmus Lode, works for the transport company and his girlfriend, Amalie Ravndal, helps Hobberstad on the family farm. Their youngest son, Martin Lode, works as an automatician.

“My great-great-grandfather purchased this farm when his farm at the time was expropriated to build a prison that is known as Aana Kretsfengsel,” Hobberstad said.

The farm is near the village of Varhaug, which is located about a mile from the North Sea. The area has a relatively mild climate compared to the rest of the country, with an average annual temperature around 45 degrees Fahrenheit. The area receives about 50 inches

of precipitation each year. It is at compared to other parts of Norway, which makes it well suited for agricultural pursuits.

“In this part of Norway, the climate is quite mild,” Hobberstad said. “We get below zero sometimes in the winter and sometimes even snow.”

Hobberstad Gard consists of 65 acres, and Hobberstad rents an additional 25 acres. They grow only timothy and rye grass. First crop is stored in silos, while second and third crops are baled using a McHale Fusion baler. Hobberstad utilizes 14 acres for pasture.

Hobberstad milks between 45 and 50 cows using a DeLaval robotic milking system which was installed in 2014 when a new barn was built. Earlier this year, an automatic calf feeder was installed, giving Hobberstad the option of using either fresh or powdered milk. Calves are also fed grain from an automated feeder integrated into the system.

“We decided to build a new barn and have never regretted this one second,” Hobberstad said. “When we were planning our new barn, there was never any question as if to install a robot milker; the only question was which one.”

When Hobberstad took over the farm in 1997, she was utilizing the old barn built by her parents in 1969, and the herd’s annual production was just over 249,920 pounds of milk per year. With the improvements Hobberstad has made to the farm, she has been able to increase her production to just under 908,800 pounds annually, with an average energy-corrected milk production of 22,720 pounds per cow.

Milk production in Norway is regulated through a quota system that helps ensure the country’s production of both cow milk and goat milk adapt to meet the needs of the market. Increasing her farm’s production requires Hobberstad to obtain quota increases; she now owns 568,000 pounds of quota and rents the additional needed quota from another farmer.

Building the new barn turned out to be about more than making a better living environment for the cows.

“When we built the new barn, the entire family took an increased interest in what was happening in the barn,” Hobberstad said. “Before that, my husband took no interest in what was inside the barn. He took care of most of the eld chores and ran his company. Now, he sits in his ofce and logs into the computer to check that everything is OK. He knows how much each cow eats, her expected yield and her cell count.”

The herd consists primarily of Nor-

wegian Reds. A few animals are crossed with Holstein.

“Norwegian Reds are good on fertility and calving ease,” Hobberstad said.

The Norwegian Red breed is best known for emphasizing a balance between functional type traits, health traits and production.

The low end of the herd and the heifers are bred to Angus. Hobberstad raises her own replacement heifers.

Cows are bred to calve throughout the year. Cows wear activity monitors to aid in heat detection, and cameras are mounted in the barn to help detect heifers in heat.

The youngest heifers are grazed close to home and fed grain twice daily while on grass. Older heifers are grazed on pastures located further from the farm and remain on pasture from May through September.

“Regulations in Norway say that all livestock over the age of 6 months should be able to graze for a minimum of eight weeks in the summer,” Hobberstad said.

The milking herd grazes from the beginning of May until early October as well as being supplemented with feed in the barn. Grain is fed in the robot with an automated system. Silage is fed every three hours.

“We have an automated feeding

system,” Hobberstad said. “It will fetch feed from either a stationary (mixer) or from the silos. Every other day, I put bales in the (mixer); only bales – no other grains or minerals.”

Many of the concerns that plague U.S. dairy farmers are also concerns for their Norwegian counterparts. Inputs, commodity prices and regulations all create issues for Hobberstad.

“2022 has been a rough year for farmers,” Hobberstad said. “As unrest and war has hit the world, the prices for fertilizer and imported grain have raised substantially. The price of electricity and gas have increased. While farmers have been able to get some compensation from the state, we have been forced to change some of our systems.”

Zumbro

Zumbrota, MN • 651-380-2856

Dairyland Equipment of Menahga Menahga, MN • 218-564-4958

Current Defense & Supply Beresford, SD • 605-212-6005

Livestock Systems Charles City, IA • 641-220-0732

Tri-County Dairy Supply Watertown, WI • 608-757-2697

Total Dairy Service, LLC Kewaunee, WI • 920-680-4441

B&R Dairy Equipment Winthrop, MN • 507-647-7000

NEW AUBURN, Wis. – Growing up, McKinsey Gotham always wanted to have goats. And, for the last ve years, she has been living that dream as she develops a rst-generation goat dairy near New Auburn.

“My parents milked dairy cows when I was younger,” Gotham said. “After high school, I started milking cows for others and did for several years. In 2015, my husband decided we should go ahead and try our hand at running our own dairy, so we started building our herd.”

Gotham, along with her husband Ezra and son Oscar, milks about 120 goats and markets the milk through Quality Dairy Goat Cooperative.

“Quality Dairy Goat Cooperative has been a great organization to work with,” Gotham said. “They really care about their farmers and take a genuine interest in our success.”

During the summer months, Gotham milks as many as 140 does. The herd averages about 6.5 pounds of milk per day per goat.

Gotham handles the herdsman duties with the goats while Ezra handles the eldwork and mainte-

nance work as well as working full time off the farm. Gotham’s father comes on a daily basis and helps with the goats and chores. Growing their herd to its current level has allowed Gotham to be a full-time dairy

Gotham establishes rst-generation goat dairyDANIELLE NAUMAN/DAIRY STAR McKinsey Gotham and her son Oscar check on their dairy goats Nov. 28 on their farm near New Auburn, Wisconsin. Gotham milks 120 does, which average 6.5 pounds of milk per day per goat.

“I want goats that can last a long time in the herd too; ones that can hold up, kid every year, year after year.”

MCKINSEY GOTHAM, DAIRY GOAT FARMER

Starting from scratch, the Gothams built their dairy from the ground up. They did the work themselves and built what they could afford.

“The best advice I could give someone wanting to establish a goat dairy is to do everything you can to avoid taking on debt,” Gotham said. “Start small so that you don’t get quickly overwhelmed. Milking dairy goats is a different industry, and it takes some time to learn.”

The goats are milked in a single-12 parlor using six units. When the Gothams built the parlor, they designed it with room to turn it into a double-12 to help speed up milking. It takes Gotham around two hours to milk the herd.

Gotham kids her does year-round to help maintain production and keep a viable supply of milk to market.

“It is not overwhelming to have a few kids to care for each month rather than having all of them in a couple of months’ time frame,” Gotham said. “A few will have longer lactations, but the majority will kid each year.”

Goats typically breed seasonally, so Gotham uses CIDRs to bring the goats in heat throughout the year.

Gotham said one of the best purchases she has made was an ultrasound machine, which allows her to detect pregnancies.

Gotham said she is satised with the current size of the herd and does not have plans to expand. To maintain the

herd, Gotham sells replacement doelings, and many of her bucklings are sold to a grower. Each year, Gotham keeps between 20 and 30 does as replacements.

The Gothams’ herd of Alpine and LaMancha is a closed herd other than the purchase of breeding bucks. Gotham makes breeding decisions with a focus on milk production.

“I want goats that can last a long time in the herd too; ones that can hold up, kid every year, year after year,” Gotham said.

The Gothams own 40 acres of land and rent an additional 180 acres where they grow corn, soybean, rye and oat. They market the excess crops, and mix their own feed to save money. The goats are fed a whole-grain mixture of corn, soybean, oat and protein pellet.

“It is nice to be able to get whole grains for them instead of feeding ground feed,” Gotham said.

The Gothams also make alfalfa baleage and grass hay to feed their goats.

At the end of each day, Gotham said she is thankful for the life she is leading as a dairy goat farmer and the ability to raise Oscar on the farm around the goats.

“Goats are just such happy animals to be around,” Gotham said. “They are so energetic, and you never know what they’ll get into next.”

Editor’s note: This is part two of a two-part series to focus on the Dairy Innovation Hub’s annual Dairy Summit, which was held in person and online Nov. 16 at the University of WisconsinRiver Falls in River Falls. Topic areas of research included human health and nutrition, animal health and welfare, stewarding land and water resources, and farm business and communities.

RIVER FALLS, Wis. – Research on enriching human health and nutrition through processing techniques is being done through the Dairy Innovation Hub at the University of Wisconsin-River Falls, UW-Madison and UWPlatteville.

Grace Lewis, with the department of animal and food science at UWRiver Falls, and Scott Rankin, with the department of food science at UWMadison, are nding ways to enrich dairy products to make vitamins, drugs and colorants, among others, more favorably digested and to utilize lactose as a natural sweetener in dairy products while aiding in the disposal of acid whey.

Part of Lewis’ research is encapsulating things like vitamin D to aid in digestion. For example, vitamin D is sensitive to light; therefore, when it is encapsulated from external stimuli like light and heat, it also makes its way through the gastrointestinal tract more favorable so it is not digested in unfavorable places.

Lewis is using high-pressure homogenization to disassemble the casein micelle protein in milk, add a variety of compounds in and encapsulating them, making them pass through the gastrointestinal tract more favorably.

Lewis forces a 100 mL sample of milk through a .13 mm nozzle on the high- pressure homogenizer. The sample is forced through then enters a heat exchanger to cool it down. Back pressure is then applied, and the homogenized sample is collected.

“Because of the small nozzle, you can achieve pressures of up to 300 megapascals,” Lewis said. “That is about three times the deepest part of the ocean.”

What actually happens when the

sample is forced through the homogenization is that the casein micelle, or the spherical protein structure, is broken into its counter parts. In addition to high-pressure homogenization, ethanol is used to aid in the process and to heat the sample up.

The ethanol is then evaporated off and pressure is released to reaggregate the proteins. This allows Lewis to add a variety of compounds in.

“Think about vitamin D, medicines, drugs, colorants, etc.,” Lewis said. “We can reassemble this protein when we evaporate the ethanol off to encapsulate these various things.”

So far in her research, Lewis has found that 60% ethanol is effective at dissociating these casein micelles, and high-pressure homogenization helped with this process. With the initial step completed, the next step is to aggregate them.

Lewis was joined by Rankin, who discussed research on his pilot-scale process to convert an acid whey waste stream to high-value food products.

Rankin’s research program focuses on the characterization and manipulation of small molecules to convert acid whey to glucose lactose syrup and milk minerals.

Rankin said the idea is to take the lactose-rich streams from dairy processing and convert them into a sweetener. While lactose is not a particularly sweet sugar, it becomes one when it is converted to glucose and galactose.

The research began with looking at acid whey, a byproduct of Greek yogurt production, and has expanded to other subjects that involve lactose. Greek yo-

gurt was discovered about 15-20 years ago and now claims over half the market in the U.S. for yogurt. Rankin said it generates waste streams that are challenging to manage.

“We work with some processors that would make more product not if they had a market, not if they could nd the milk, but if we could get rid of the waste,” Rankin said. “It has a big footprint for the processors.”

The challenge for Rankin has become to generate technology around using a catalyst to convert acid whey. It works similar to a catalytic converter on a car where it is transforming toxic molecules from the combustion engine into relatively less toxic molecules as they leave the catalytic converter. The same concept is being applied to acid whey.

“One of our parameters when we make lactose-free ice cream is we incubate ice cream mix for four to six hours at 70 degrees Fahrenheit,” Rankin said. “That’s to get the enzyme to do its thing. With catalysts, we make that conversion in a matter of minutes.”

The hope is to make continuous ow catalytic converters in tandem with dairy processing to get rid of lactose, which is then converted to glucose and galactose, its monomers.

Rankin is working with the Food and Drug Administration to get approval for the converted proteins.

“We can do studies and generate papers,” Rankin said. “But the Dairy Innovation Hub has helped us bridge the gap between this neat idea and something that may end up in our processing industry soon.”

350

Rounds 16.89 8.17 75.01

980 Large Squares 16.99 22.61 150.95 4 27.01 $175.00

18.76 $125.00

19.99 $95.00 363 Large Rounds 15.84 11.44 82.29

370 Large Rounds 15.74 18.74 153.19 1 26.86 $150.00

403 Large Rounds 16.76 17.86 112.44 1 20.89 $130.00

407 Large Rounds 11.6 8.19 69.17 1 23.46 $80.00

410 Large Rounds 13.19 10.91 90.3 1 20.7 $80.00

411 Large Rounds 15.67 10.48 83.32 1 20.55 $75.00

414 Large Rounds 13.19 10.91 90.3 1 20.88 $85.00

415 Large Rounds 15.67 10.48 83.32 1 20.35 $95.00

416 Large Rounds 15.37 8.48 93.89 1 19.55 $80.00

419 Large Rounds 13.19 10.91 90.3 1 20.41 $95.00

420 Large Rounds 15.37 8.48 93.89 1 20.75 $95.00

421 Large Rounds 17.09 19.19 124.43 1 15.78 $120.00

422 Large Rounds 13.94 10.92 79.56 1 19.73 $85.00

429 Large Rounds 16.34 19.04 133.05 1 16.06 $115.00

989 Large Rounds 17.58 19.27 118.44 2 23.33 $140.00

991 Large Rounds 15.55 19.85 126.06 2 23.35 $150.00

999 Large Rounds 15.69 18.92 114.91 2 23.3 $145.00

364 Large Rounds 12.88 18.05 111.99 2 20.71 $150.00

365 Large Rounds 16.12 19.72 126.43 2 23.22 $135.00

396 Large Rounds 17.96 21.31 123.23 2 24.11 $125.00

398 Large Rounds 13.99 9.21 87.1 2 26.3 $115.00

427

Large Rounds 14.1 18.8 144.69 2 22.8 $180.00

428 Large Rounds 14.43 11.87 80.55 2 21.88 $90.00

993

Large Rounds 15.3 19.11 138.69 3 18.29 $140.00

1000 Large Rounds 15.02 20.93 153.3 3 24.75 $220.00

352 Large Rounds 15.02 20.93 153.3 3 3.33 $170.00

404 Large Rounds 16.37 18.01 134.3 3 18.24 $135.00

426 Large Rounds 13.09 17.75 117.28 3 25.13 $120.00

992 Large Rounds 15.4 18.9 128.59 1&2 16.39 $150.00

362

Large Rounds 16.76 17.86 112.44 1&2 20.44 $140.00

406 Large Rounds 16.66 16.44 113.11 1&2 17.9 $125.00

405 Large Rounds 15.07 21.31 146.55 2&3 19.52 $175.00

998 Large Rounds 11.6 8.19 69.17 23.67 $80.00

430 Large Rounds STRAW 34 $30.00

981 Large Squares 14.45 18.41 126.21 1 26.44 $160.00

986 Large Squares 13.05 16.46 104.96 1 26.59 $170.00

996 Large Squares 17.64 21.23 141.03 1 23.99 $155.00

997

Large Squares 16.51 21.28 139.95 1 23.58 $145.00

366 Large Squares 14.68 14.57 75.95 1 27.34 $70.00

367 Large Squares 14.68 14.57 75.95 1 26.81 $75.00

402 Large Squares 15.88 16.48 117.23 1 21.68 $160.00

423 Large Squares 16.19 18.54 95.58 1 25.11 $130.00

984 Large Squares 13.58 19.27 142.54 2 27.33 $170.00

990 Large Squares 16.62 18.61 107.37 2 24.37 $165.00

360 Large Squares 12.01 17.21 139.98 2 27.27 $170.00

361 Large Squares 13.39 17.93 136.54 2 22.48 $185.00

368 Large Squares 15.15 19.03 112.66 2 22.05 $160.00

374 Large Squares 12.35 26.88 188.46 2 27.49 $275.00

375 Large Squares 87.65 26.88 188.46 2 28.16 $290.00

399 Large Squares 15.15 19.03 112.66 2 24.58 $150.00

400 Large Squares 15 18.69 113.19 2 24.52 $155.00

356 Large Squares 12.99 19.76 167.37 3 14.62 $190.00 358 Large Squares 12.64 19.56 114.81 3 25.25 $160.00

357 Large Squares 18.58 22.86 163.83 4 25.71 $185.00

413 Large Squares 17.1 23.28 164.11 4 27.29 $170.00

425 Large Squares 17.56 21.62 140.79 4 25.57 $130.00 979

Large Squares STRAW 23.35 $100.00 983 Large Squares STRAW 25.58 $100.00

383 Large Squares STRAW 24.17 $90.00

982

354

Medium Squares 11.07 17.61 117.52 1 22.67 $160.00

Medium Squares 10.96 16.91 122.18 1 25.88 $175.00

Medium Squares 11.32 18.13 129.42 1 26.19 $175.00 376 Medium Squares 14.1 9.97 78.89 1 16.12 $95.00 382

355

Medium Squares 12.57 20.33 164.27 1 26.58 $265.00 988 Medium Squares 15.31 19.08 109.83 2 23.23 $165.00 351 Medium Squares 16.4 22.2 149.19 2 25.81 $175.00 371 Medium Squares 13.66 19.13 121.99 2 24.35 $175.00 384

Medium Squares 15.37 23.13 142.31 2 24.91 $190.00 397 Medium Squares 16.19 18.54 95.58 2 24.65 $140.00 401

Medium Squares 15.44 19.8 110.5 2 21.83 $160.00 359 Medium Squares 15.78 22.62 161.74 3 22.66 $220.00 377 Medium Squares 15.9 21.04 145.79 3 10.92 $210.00 408 Medium Squares 13.97 19.31 152.41 3 8.92 $200.00 409 Medium Squares 14.85 24.16 171.62 3 4.39 $220.00 381 Medium Squares 13.99 19.26 162.09 4 25.43 $245.00 985 Medium Squares STRAW 57 $37.50 987 Medium Squares STRAW 78 $30.00 372 Medium Squares STRAW 78 $35.00 373 Medium Squares STRAW 25 $50.00 412 Medium Squares STRAW 70 $43.00 418 Medium Squares STRAW 72 $40.00 995 Small Rounds 14.49 9.62 95.94 1 19.26 $125.00 379 Small Rounds 14.58 7.05 86.4 1 19.11 $80.00

MADISON, Wis. – Whether a person is 25 or 55, it is never too early or too late to start planning for retirement. Some people dream of traveling the world when their working days are done. While for others, relaxing on the couch and reading a good book might be all the excitement they need. No matter what a person’s goals are, planning for retirement can be overwhelming.

“You don’t need to start with a large chunk of money,” Sarah Wiersma said. “Rather, putting it away slowly and consistently is going to be your best bet.”

Wiersma, a nancial advisor at Ameriprise Financial Services LLC, offered retirement planning advice Dec. 1 during a Professional Dairy Producers Dairy Signal webinar.

“There are a lot of options when planning for retirement,” Wiersma said. “It’s all a matter of what’s right for you, and that may include a combination of things.”

deduction for the year for your income taxes,” Wiersma said.

A person under age 50 can put up to $6,000 per year in either type of IRA. A person over age 50 is allowed to put in up to $7,000 per year. Those numbers will increase in 2023 to $6,500 for under age 50 and $7,500 for over age 50.

“If you have a business and want your retirement plan to benet not only you but your employees as well, then you may need to look at something bigger, like the SIMPLE IRA,” Wiersma said.

This plan allows larger contributions than a Roth or traditional IRA –$14,000 for people under age 50 and $17,000 for those over 50. In 2023, those numbers will jump to $15,500 if under 50 and $19,000 if over 50.

“There is a matching element with the SIMPLE IRA similar to a 401k,” Wiersma said. “You could match 3% for any employees participating. Or if you don’t want to worry about match-

SARAH

SARAH

Wiersma recommends a Roth IRA or a traditional IRA as a good starting point. In a Roth IRA, contributions are made after having paid taxes on the money. The funds then grow tax deferred. Once a person reaches 59 years, 6 months and has had the money in the IRA for at least ve years, those funds come out completely tax free.

“For a lot of people, that is a huge benet, especially if you’re starting younger,” Wiersma said.

In a traditional IRA, pre-tax contributions can be made to provide an immediate tax break. The funds grow tax deferred, and when they are pulled out at retirement, the money is considered taxable income.

“The traditional IRA is an option if you don’t meet the requirements for a Roth IRA or if you really need that tax

FINANCIAL SERVICES LLC

FINANCIAL SERVICES LLC

ing, you could give all employees who qualify a 2% contribution, for example.”

A SEP IRA is an option that works well for a self-employed individual who is the only person in his or her business. This type of IRA allows a person to put in up to 20% of their income. This option offers exibility in that contributions can be made in bigger lump sums versus per paycheck.

A 401k plan is the option that allows for the largest contribution –$20,500 if under age 50 and $27,000 if over age 50. Next year, those amounts will increase to $22,500 for under age 50 and $30,000 for over 50. Wiersma

“Make sure your investments are ready for whatever stage of life you’re in. How your money is allocated should be appropriate for when you’re going to need it, so that no matter what market we go through, you can sleep at night.”

WIERSMA, AMERIPRISE

said she does not see many farmers use this option as there is a great deal of additional testing, reporting, requirements and costs that go along with it.

“Usually, you can get by with a SIMPLE IRA instead,” she said.

Contributions can be made to Roth, traditional and SEP IRAs up until the tax ling deadline of April 15. Therefore, 2022 contributions can be made well into next year. SIMPLE IRAs must be set up between Jan. 1 and Oct. 1.

To avoid paying higher taxes in the future, a person may consider transferring money in traditional funds over to a Roth IRA. The account holder pays taxes on that money now, but then any future gains happen in the Roth IRA, and those gains come out tax free.

“When doing a Roth conversion, you’re moving money out of an account you’re going to have to pay taxes on eventually,” Wiersma said. “Don’t let the market recovery of those funds happen there. Rather, have it occur in an account where you don’t pay taxes.”

When it comes to investing money for retirement, options should be customized according to what is best for the individual.

“You can do this on your own or you can work with an advisor,” Wiersma said. “If you’re not comfortable with the market and don’t want to take risk, you can open up retirement accounts at your local bank. You could do a savings account or IRA CDs. Historically, stocks and bonds, specically stocks, have gotten better returns.”

For people who are young, starting small is what Wiersma recommends. A Roth IRA is what she nds to be the best solution in which an individual makes monthly contributions or puts in a lump sum. Wiersma said it is important to line up potential investment returns with a person’s goals. A person must also decide what level of risk they want to take.

“What do you want your future to look like?” Wiersma said. “That’s a big unknown for many people, and it will adapt and change over time. Talk to somebody who is going to be able to give you unbiased advice about the steps you need to take based on your goals and where you are now in life.”

A person must also consider how much of their own money they want to put in versus how much they want the market to return. Those not starting early will need to increase the amount they are putting in and setting aside.

“Obviously the more risk you take, the more potential return and the less you might have to put in to meet your goals,” Wiersma said. “There may be a year or two where you don’t put money in, and that’s OK. I have many clients who say, ‘This year was a very good year for me, what extra can I do?’ Then

the next two or three years, maybe they can’t make any contributions or will lower it drastically. Every little bit you can do makes such a difference in the long run.”

Wiersma said to make sure an accountant is part of retirement discussions. The accountant knows a business’s books and can ensure the legality of actions being taken.

“As a farmer, are you paying yourself a salary?” Wiersma said. “Do you have a draw? You can only make contributions from income, which is your salary. It’s not from your draws. So that’s a big area where things might have to be restructured with your accountant to make sure it’s going to t within the rules.”

A difcult market this year has caused concern for some of Wiersma’s clients.

“It’s very easy to make the decision to get out when times are tough, but it is 10 times harder to make that decision to get back in,” Wiersma said. “You have to stick with it because you can’t time the market; it’s time in the market.”

When the market is down, Wiersma said to think of it as an opportunity.

“If saving for retirement is something you haven’t thought about, now is a great time to do it,” Wiersma said. “It’s a volatile market and economy we’re living in, but when the market’s down and you’re not close to retirement, view it as the market is on sale. I don’t know when the market is going to come back, but I know it will.”

People in their 50s can also take advantage of buying in at a lower rate as many in this age group still have time before they need to pull the money for retirement.

“When everybody is getting fearful is usually the time to be adding, but it’s denitely not the time to be making changes,” Wiersma said. “Part of my job is making sure you’re not doing the wrong things at the wrong time.”

Conversations vary depending on how close a person is to retirement. An individual in their 60s or 70s will take a different approach than someone in their 40s.

“Make sure your investments are ready for whatever stage of life you’re in,” Wiersma said. “How your money is allocated should be appropriate for when you’re going to need it, so that no matter what market we go through, you can sleep at night.”

Despite a farmer’s busy days, it is important to think about what life after farming will look like. To ensure a nancially comfortable future, do not delay in saving money for retirement.

“The most important part is to just get started,” Wiersma said. “And, it’s never too late to start.”

From

Deep dish pizza

2 6.5-ounce pizza crust mix packages

15 ounces canned tomato sauce

12-16 ounces pork sausage

1 pound marble cheese, sliced long ways

Optional:

1/2 onion, diced

1/2 green pepper, diced 15 ounces canned mushrooms 15 ounces canned black olives, sliced Garlic powder Italian seasoning

Cook sausage. When sausage is half cooked, add in diced onion and green pepper. Prepare pizza crust mix according to packages. Take 9-by-12 cake pan and coat with cooking spray. Spread pizza dough in pan, bringing dough up on inner side of pan edges. Spread can of tomato sauce evenly on dough. Sprinkle desired amount of garlic powder and Italian seasoning on top of tomato sauce. Spread pork sausage evenly. Add black olives on pork sausage. Layer cheese across top. Bake according to pizza crust mix package. To make sure pizza is done, check crust by using a fork to pull back toppings to see that the dough is fully baked. All ingredients can be tweaked to your liking.

2 pounds macaroni, uncooked

1 pound marble cheese, cubed 1 pound ham (cooked), cubed

15 ounces peas, canned 2 cups mayonnaise

Cook macaroni and drain water. Add cheese, ham, peas and mayo into macaroni. Then mix together. Salt may be added if desired. All ingredients can be tweaked to your liking.

4 boneless skinless chicken breasts

1 can of Campbell’s cheddar cheese soup

1 cup milk

1 1/2 cups Ritz crackers (one sleeve)

4 tablespoons of melted butter 8 ounces frozen broccoli 4 ounces shredded cheddar cheese 1/2 teaspoon seasoned salt

Preheat oven to 350 degrees. Make can of cheddar cheese soup mix according to package directions (one can of soup mix to one can of milk). Place chicken breasts in a baking dish. Season with seasoned salt. Pour 3/4 of the prepared soup over the chicken breasts. Add broccoli to chicken that has been covered with the cheddar soup. Melt butter and combine with crackers, sprinkle buttered crackers over the broccoli. Add remaining soup mix and bake for approximately 45 minutes or until the chicken is done. Check chicken by cutting the thickest part and look to see that the chicken is uniform in color. When chicken has been removed from oven, sprinkle with shredded cheddar cheese.