GUARDIAN

Issue 3 www.cvsa.org

Issue 3 www.cvsa.org

n

n

n

n

GUARDIAN

“Guardian” is published quarterly by the Commercial Vehicle Safety Alliance with support from the Federal Motor Carrier Safety Administration. CVSA and FMCSA are dedicated to the government and industry working together to promote commercial motor vehicle safety on North American highways.

Copyright 2025, CVSA. All rights reserved. No part of this issue may be reproduced without written permission from the publisher.

For comments, suggestions or information, email communications@cvsa.org.

CVSA is looking for interesting, relevant content for its quarterly magazine. We would be happy to consider your news, ideas, insights and articles on issues facing the commercial motor vehicle safety community for upcoming editions of “Guardian” magazine.

The deadlines for upcoming editions are available at www.cvsa.org/guardianmagazine/deadlines-for-submissions.

Questions? Please contact CVSA Writer-Editor Emily Moorhead at emily.moorhead@cvsa.org.

By Capt. John Hahn, Motor Carrier Safety Section, Colorado State Patrol; CVSA President

By the time everyone reads this, we will be closing out the summer and preparing for fall and winter ahead. Baseball will be nearing its end, and we will be preparing for the return of hockey. It will be a change of seasons in many respects. For me, it will be nearing the time for me to complete my term as CVSA president. In my final article to the membership, I wanted to take just a moment to speak from a personal perspective on what CVSA is and what it means.

As I related in my first article, I did not “grow up” in my agency in commercial motor vehicle (CMV) enforcement. The path to my current role had several stops along the way, from working the road as a trooper, to being a field sergeant, to working at headquarters, the state capitol and in our hazmat unit. The one thing that sticks out to me as I look back at that journey is how unique this Alliance truly is. There is nowhere else where we, in the enforcement community, experience a similar reality.

When I first arrived in my role as the new commander of our hazmat unit, I knew some things about the CMV world from my time as a road trooper. At that point, all of our troopers went through North American Standard Inspection Part A during their last week in the academy. The sum total of my knowledge then was that I needed to get 32 inspections accomplished to remain certified and avoid getting into trouble. I had zero real knowledge of CVSA and what the organization does – and even less knowledge about its greater impact on safety.

Fast forward to my first CVSA event, an annual workshop in Los Angeles, California, where I did not understand at all what was going on or the conversations that were taking place. It became very clear to me that I was surrounded by people who were incredibly knowledgeable about what they were doing. I also knew that it was something I wanted to be a part of. My understanding of the organization and appreciation for what we do grew quickly as I began to understand how very different this organization is from any other.

Nowhere else do enforcement personnel, regulators and the regulated community all convene on a regular basis to tackle the challenges of the day. There is no such group in any other sector of the enforcement world.

While there may be groups and associations that focus on things like transportation, there really isn’t a place where everyone is not just involved in the discussion but is also a part of the decision-making process to find solutions.

Many people often see CVSA solely through the lens of the roadside inspection program and the out-of-service criteria. These two things are central to who we are as an organization, but they are not what makes us so unique. I would challenge our membership to look at our organization much more broadly than that.

Jurisdictions at the local, state, provincial and territorial levels are charged with enforcing laws and safety regulations pertaining to CMVs in North America. Imagine a world where all jurisdictions operated in their own way by applying the regulations differently and determining unilaterally what constitutes an imminent hazard. Imagine a circumstance where there was no level of reciprocity nor any concerted efforts to engage with industry and federal partners. Imagine a situation where challenges were to arise in various aspects of what we do, and there was nowhere to go for guidance and nowhere to engage with peers in any meaningful, collaborative way. For our associate members, imagine if there was no forum to work through issues with other industry leaders, and enforcement was patchwork at best.

CVSA is not just an organization that provides a roadside inspection program and outof-service criteria. It is a gathering place of ideas and input. It is a place where the enforcement and regulatory community sits next to the very people who are the subject of that enforcement, with a shared goal of

solving problems. Ours is an organization that is not just about serving as the hallmark for consistency across three nations.

Many in the law enforcement community know of Sir Robert Peel, likely having heard of him at some point in the course of their training. For those who do not know, Peel was a 19th-century statesman often recognized as the father of modern policing. One of his contributions was Peel’s Principles of Law Enforcement. Frequently quoted by many, one of his key principles was this: “The police at all times should maintain a relationship with the public that gives historic tradition that the police are the public and the public are the police.” We see this principle often playing out in community meetings and gatherings across North America, where enforcement personnel place themselves at the same table as the community they serve.

While the functions we perform inside our organization are critical to CMV safety, I would say that the function of our Alliance is to be the conduit outlined so well in Peel’s principles. CVSA serves as the very best example I can think of where enforcement and the community enforced upon and served are the same thing. If our organization can serve as a hallmark for anything, it would be that we are a gathering place for handling the most pressing challenges we face – a place where everyone is at the table and where we all are representative of the people we serve and who we serve with.

As I close out my term as president, I will simply say thank you. Thank you for the opportunity to represent your amazing efforts and for the opportunity to serve alongside each of you. n

"The police at all times should maintain a relationship with the public that gives historic tradition that the police are the public and the public are the police."

–Sir Robert Peel

By Collin B. Mooney, MPA, CAE, Executive Director, Commercial Vehicle Safety Alliance

The approximately 13,000 enforcement officials who make up CVSA’s core membership are responsible for the day-to-day execution of all elements of the commercial motor vehicle (CMV) roadside enforcement and inspection activities under the North American Standard Inspection Program. As the organization that represents the CMV enforcement community, CVSA has a vested interest in the continued success of the program. The consistency and uniformity in the application of the CMV roadside enforcement and inspection process, and the data generated from this activity, form the cornerstones and foundation of the program.

The Alliance actively works to reduce crashes, fatalities and injuries involving CMVs through a combination of activities, such as enforcement of the CMV safety regulations; monitoring CMV regulatory effectiveness; development and delivery of training materials for the CMV enforcement community and the motor carrier industry; identifying, recommending, and implementing enforcement and inspection data quality improvements; improving crash reporting and data collection; and various outreach initiatives to the motor carrier industry, the enforcement community and the general public.

Through a partnership with the Federal Motor Carrier Safety Administration (FMCSA), CVSA’s state, provincial, territorial and local members, and industry, the Alliance helps to ensure that both the CMV enforcement community and the motor carrier industry understand the CMV safety regulations, know how to interpret the roadside enforcement and inspection data, and be knowledgeable of the CMV crash investigation and reporting protocols. This activity leads to uniform enforcement and improved compliance, promotes safe practices and fosters a better working relationship with the motor carrier industry.

Regarding CMV enforcement and inspection data management and quality, consistent, timely and accurate data is critical to a member jurisdiction’s CMV enforcement and inspection activities. Enforcement personnel within member agencies use data from motor carriers’ past performance to prioritize motor carriers for roadside inspections, safety audits and

compliance reviews. Roadside inspection data identifies trends and areas where improvement is needed. For member jurisdictions in the U.S., the data is used to craft Motor Carrier Safety Assistance Program Commercial Vehicle Safety Plans, determining resources for enforcement and education initiatives targeting specific safety problems.

Throughout North America, data from roadside inspections is improving; however, more improvement is necessary. Inconsistencies in violation documentation and human error during the data collection process result in discrepancies in roadside inspection data. Data quality assurance is a crucial component of any program’s effectiveness, providing federal, state, provincial, territorial and local agencies the information they need to make strategic decisions regarding the investment of their limited resources. Accurate data is critical to the overall success of our collective CMV enforcement and inspection programs.

As CMV enforcement initiatives continue to grow and evolve, CVSA aims to help improve overall data quality within the CMV enforcement and inspection program. As a result, over the past few years, CVSA has organized, coordinated and implemented a three-day system-wide training event for all state personnel dedicated to data management and quality control practices and to provide subject matter expertise to FMCSA. The objective is to improve the uniform collection and analysis of CMV roadside enforcement, inspection and crash data generated by nearly 4 million annual roadside inspections. This annual training helps to ensure that crash records and inspection data reports are consistent, timely

and accurate. In addition, CVSA continues to provide input regarding what updates are needed in developing or maintaining relevant FMCSA data systems.

CVSA offers recommendations and participates in FMCSA’s inspection modernization effort by facilitating state input and providing technical feedback, as appropriate. Additionally, CVSA has been active in developing operational policies and guidance, correctly mapping and classifying roadside data consistently across all jurisdictions throughout North America. Recommendations for hardcoding violations and implementing smart logic for the inspection software will further enhance CMV enforcement and inspection data quality. Accurate roadside data recordation, through reduced human error, will enhance decision-making for FMCSA and the states. Subsequent DataQ challenges for incorrect violations or incorrect designation of an out-of-service condition will be reduced through hardcoding efforts.

In closing, CVSA is committed to improving driver, vehicle and motor carrier safety through a variety of activities, including national enforcement and education campaigns, support of innovative safety technologies that improve safety, critical mandatory in-service/refresher inspector training, data quality improvements, production of roadside enforcement training multimedia and crash reporting. These initiatives also include targeting unsafe driving in high-risk crash corridors and rural roads, improving the safe transportation of goods and persons in foreign commerce, improving CMV safety and compliance with safety regulations, and public awareness and education. n

By Sgt. Dickie Murchison, Traffic Services Unit, Connecticut State Police

On May 15, the Connecticut State Police Traffic Services Unit, managed by Sgt. Dickie Murchison; the Connecticut Department of Motor Vehicles (DMV) Commercial Vehicle Safety Division (CVSD), managed by Sgt. William Vieweg; and federal and other state law enforcement agencies conducted a multiagency commercial enforcement operation at the Union weight/safety facility located on I-84 westbound in Union, Connecticut.

The operation, called COBRA (Collaborative Operations by Response Agencies), utilized multiple law enforcement resources with specific disciplines to identify carriers, commercial motor vehicle (CMV) drivers and CMVs performing unsafe and/or illegal activities while engaged in commerce and operating on a public roadway.

The mission of the Connecticut State Police Traffic Services Unit and the Connecticut DMV CVSD was to identify CMVs and/or their drivers violating Federal Motor Carrier Safety Regulations (FMCSRs) and Connecticut General Statutes relating to motor vehicles. Connecticut State Police and Connecticut DMV then investigated if additional state or federal laws were being broken and used the proper resources available to conduct a complete investigation with law enforcement partners. This included, but was not limited to, FMCSRs, narcotics trafficking, human trafficking, undeclared hazmat, cargo theft and stolen trailers, weapons trafficking and violations of local laws pertaining to oversize and weight.

Before the operation, all personnel met at the Union weight/safety facility, where they were given an operational plan, put together by the Connecticut State Police Traffic Services Unit and the Connecticut DMV CVSD. Though fluid, this plan provided specific assignments to law enforcement personnel for maximum effectiveness and efficiency. The assignments given to Motor Carrier Safety Assistance Program (MCSAP) personnel covered not only the weight/safety facility but also eastbound I-84 CMV traffic and secondary roads within the area, stopping trucks that exited the highway to avoid the weight/safety facility.

The Connecticut State Police Traffic Services Unit and the Connecticut DMV CVSD worked alongside other state and federal agencies. The additional agencies involved in this operation included the Transportation Safety Administration, the U.S. Department of Transportation Office of Inspector General, the Connecticut Department of Transportation, the Connecticut Department of Energy and Environmental Protection, and additional

With multiple agencies involved in this operation, a unified command structure was put into place. This structure allowed agencies to assign incident commanders and give them functional responsibility to represent each agency. It also provided a common set of objectives and strategies, with a collective approach to reaching the incident objective. During the COBRA operation, MCSAP personnel conducted 40 inspections, including 11 Level I, 23 Level II and six Level III Inspections. Three drivers and 20 vehicles were placed out of service. Additionally, two CMVs were towed from the scene.

After the operation, a debriefing occurred at the Union weight/safety facility. Each agency recorded its respective statistics related to the operation, which will be used to compare to past operations and set the pace for future operations.

In conclusion, the COBRA operations have been a success since their inception in 2017. Future COBRA operations are scheduled throughout the year at various weight/ safety facilities in Connecticut, working collaboratively with multiple law enforcement agencies to make the roadways safe. n

Region I

Connecticut, Delaware, District of Columbia, Maine, Maryland, Massachusetts, New Hampshire, New Jersey, New York, Pennsylvania, Puerto Rico, Rhode Island, U.S. Virgin Islands and Vermont

Region II

Alabama, American Samoa, Arkansas, Florida, Georgia, Kentucky, Louisiana, Mississippi, North Carolina, Oklahoma, South Carolina, Tennessee, Texas, Virginia and West Virginia

Region III

Colorado, Illinois, Indiana, Iowa, Kansas, Michigan, Minnesota, Missouri, Nebraska, North Dakota, Northern Mariana Islands, Ohio, South Dakota and Wisconsin

Region IV

Alaska, Arizona, California, Guam, Hawaii, Idaho, Mexico, Montana, Nevada, New Mexico, Oregon, Utah, Washington and Wyoming

Region V

Alberta, British Columbia, Manitoba, New Brunswick, Newfoundland and Labrador, Northwest Territories, Nova Scotia, Nunavut, Ontario, Prince Edward Island, Quebec, Saskatchewan and Yukon

By Sgt. Justin Willis, Commercial Motor Vehicle Enforcement Section, Public Service Commission of West Virginia

In the world of commercial motor vehicle (CMV) enforcement, we often think of inspections and routine day-to-day activities. However, on May 14, during the CVSA’s International Roadcheck, I, along with Cpl. Jack Woods of the West Virginia State Police – CMV Enforcement Section and his K-9 partner, found ourselves in a situation much deeper than just a routine CMV inspection. I was working the second shift post at the Bluestone Travel Plaza located on the West Virginia Turnpike on I-77. During my shift, which began at 3 p.m., I was training an officer who was conducting Level III Inspections. As the evening progressed, I didn’t realize I was about to uncover something much deeper than a violation.

I was standing at the cones that blocked off the parking lot area where CMVs would drive by so officers could determine which vehicles to inspect. Around 5 p.m., just two hours into my shift, I observed a white tractor-trailer entering the area and decided to pull it for a random inspection. As the tractor-trailer approached, the driver appeared to ignore me and pass by without stopping. I ran across the parking lot to chase down the truck and make the driver pull into the inspection area. The driver positioned his truck at an angled position instead of pulling into the marked parking area. He rolled down his window and left the truck running.

I advised the driver that I would be conducting a Level II Inspection and asked him to open the door so I could gather his documents.

At this point, I began noticing several things that indicated that this was something more than a random inspection. As I started the driver interview, the driver began sweating profusely. I observed the air conditioning was on high, and the cab was extremely cold, so the driver should not have been sweating. After gathering information about the load, the driver got out of the truck, under the guise of throwing away trash, but he was looking around the area, specifically into a wooded area with a field nearby. I asked the driver to get back in his truck, and while I waited for him to return, I went back in my cruiser to run the driver’s information through the Commercial Driver’s License Information System.

The query came back as not eligible on his commercial status, as well as not eligible on his regular driver’s license. I called 911 to check with the dispatcher on the status of the driver and perform a warrant search. Meanwhile, I continued to observe the driver’s behavior as I made my phone calls. The driver exited the truck several more times, changing his shoes and looking across to the wooded area. Cpl. Woods and his K-9 stuck close by to assist if needed.

I received a response from the dispatcher, inquiring, "Sir, are you secure?" – and in this moment, I knew I had run across something more serious than just a suspended operator. The driver had a full extradition warrant from Kentucky. I requested the dispatcher send off for a hit confirmation and extradition confirmation, and I asked Cpl. Woods to run his K-9 to check the vehicle, as the warrant didn’t have charge information initially available. The dispatcher notified me that they did have confirmation, and they would do a full extradition. It turns out the driver was wanted by the FBI Kentucky Division for multi-state wire fraud and conspiracy to commit wire fraud. Cpl. Woods and I took the driver into custody and turned him over to the FBI without incident.

I reaffirmed several lessons that day. Trust your gut. Prioritize officer safety. Both lessons remain paramount to CMV enforcement. Be safe, everyone.

If this motor carrier had better understood its responsibilities and liabilities, this driver and vehicle would never have been allowed to leave the yard. I can honestly say I made a difference that day on our roadways. n

The West Virginia Public Service Commission (WVPSC) recently took home two awards from the Governors Highway Safety Program’s (GHSP) “Highway 2 Safety” traffic safety conference May 14-16 in Bridgeport, West Virginia.

WVPSC came in eighth place for speed enforcement and fifth place for seatbelt enforcement. It is notable that while the other contenders deal with both passenger vehicles and commercial motor vehicles (CMV), WVPSC only interacts with CMVs, meaning they enforced enough speed and seat belt violations in CMVs alone to receive these awards. Their efforts equated to 539 speed citations on highway safety enforcement and 320 seat belt citations on highway safety enforcement.

WVPSC conducted this enforcement under a grant funded by GHSP. The work shifts are voluntary overtime grant shifts, and each month has a different focus topic, such as seatbelt usage, distracted driving, speed patrol and work zone safety. WVPSC has about 20 officers who participate in this program. CVSA Director of Enforcement Programs Jake Elovirta also attended the conference and participated in a roundtable discussion on commercial motor vehicle enforcement, education, training and resources, along with three WVPSC employees: Robin Lassak, who served as moderator, Sgt. Justin Wills and Capt. A. W. Ryan. n

By Lt. Shawn Gobble, Motor Carrier Safety Unit, Virginia State Police

The Port of Virginia is the fifth-largest container port in the U.S., spanning 1,864 acres. It features 19,885 linear feet of berth space, 50-foot-deep channels, and 48 kilometers (30 miles) of on-dock rail. The port handles over 2.3 million twenty-foot equivalent units (TEUs) of cargo annually and is one of the busiest seaports in the U.S., adding over $153 billion to the U.S. economy each year.

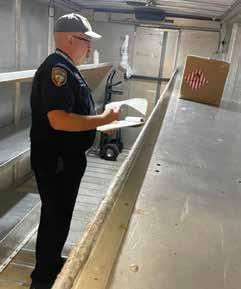

Every May, the Virginia State Police Motor Carrier Safety Unit conducts the annual Spring Port Check at the Port of Virginia. This project utilizes Motor Carrier Safety Unit troopers from across the Commonwealth for the fiveday concentrated check project. The project has been highly successful for the past several years due to its immeasurable contribution to highway safety. It has become a biannual project focusing on the safety of both drivers and equipment used to move massive amounts of cargo from the port to locations across the U.S.

Troopers were assigned to 12-hour shifts each day and completed more than 700 inspections. The project resulted in 554 Level I, 65 Level II and 113 Level III Inspections, as well as 375 CVSA decals issued. Over 789 total violations were cited during the five-day project. Of the violations cited, 136 were outof-service (OOS) violations for the power unit and driver, and 653 were non-OOS violations.

Total chassis violations cited during the project were 170, with 30 OOS violations.

The annual Fall Port Check will be conducted with the goal of making highways safe, not only in the Commonwealth of Virginia but across the U.S. n

By Monica Greiss, North Carolina State Highway Patrol

1st Sgt. Brandon Vick of the North Carolina State Highway Patrol’s (NCSHP) Commercial Vehicle Enforcement (CVE) Section recently completed the 101st session of the North Carolina State University Administrative Officers Management Program (AOMP).

AOMP, established in 1989 through the School of Public and International Affairs at North Carolina State University, is a premier educational initiative designed to prepare public safety professionals for administrative and leadership roles. Held three times annually – spring, summer and fall – the program is a 12-week, in-residence experience at the NCSHP Training Academy in Raleigh, North Carolina.

Each session is composed of 25 public safety professionals nominated by their agencies. Participants earn 15 academic credits (nine undergraduate, six graduate) and receive a certificate of completion. AOMP emphasizes a theory-to-practice framework, integrating current academic research with real-world public safety management challenges. The result is a powerful environment for innovation, collaboration and professional growth.

Commercial motor vehicles (CMV) play a vital role in the economy, transporting goods across vast distances daily. However, their size and operational characteristics present unique challenges to motorists. Traffic crashes involving CMVs often result in severe consequences due to the vehicles' size, weight and limited maneuverability. Recognizing this issue, 1st Sgt. Vick leveraged his opportunity at AOMP to conduct focused research on improving public safety through enhanced driver education – specifically, the need to better equip drivers with the knowledge and skills to safely interact with CMVs on public roadways.

1st Sgt. Vick’s initiative reflects the mission of AOMP: to cultivate forward-thinking leaders who identify challenges and implement actionable solutions. His work exemplifies how law enforcement professionals can drive policy reform and public safety improvements beyond traditional enforcement roles.

As the transportation landscape continues to evolve – with increasing freight movement, driver shortages and autonomous vehicle technology – such leadership and research are essential to ensuring the safety and adaptability of our roadway systems. n

By Tpr. Brandon S. Johnson, North Carolina State Highway Patrol

In the early morning hours of Jan. 21, the quiet of Forsyth County’s stretch of I-74 was broken by a life-or-death emergency that would underscore the true meaning of public service. At approximately 7 a.m., NCSHP Tpr. Mills responded to a call involving a vehicle stopped in the middle of the interstate at US-421. The driver was unresponsive, suffering from a severe medical condition that left him incapacitated behind the wheel.

Joined by License and Theft Agent C. Angel, Tpr. Mills acted without hesitation. Together, they quickly removed the unconscious driver from the vehicle and began administering CPR. Recognizing the urgency, Tpr. Mills retrieved his AED and deployed it in a courageous attempt to revive the individual. The duo continued life-saving efforts until emergency medical services arrived on the scene and took over care.

His actions reflected the core values upheld by NCSHP CVE. n

By Monica Greiss, North Carolina State Highway Patrol

NCSHP CVE Section members presented at the Volvo Group North America Safety Recall Summit. The members in attendance were Capt. T. G. Wilson, 1st Sgt. B. D. Vick, Sgt. M. G. Conley and Tpr. W. S. Skinner. Sgt. Conley conducted a traffic safety information presentation on the 37-step North American Standard Level I Inspection while Tpr. Skinner demonstrated the inspection. This is NCSHP CVE Section’s second year presenting at the summit. n

By Sgt. Joe Berrong, North Carolina State Highway Patrol

It was just after 10 p.m. when I received the call. One of my troopers on I-26 had encountered something he had never seen in his career. A CMV had pulled over after spotting the trooper’s marked patrol car. The driver wasn’t lost, broken down or in violation. He was seeking help.

The driver, clearly shaken, explained that he was brought into the U.S. from Eastern Europe by a motor carrier that promised him work and opportunity. But what he found instead was something far more sinister. The carrier had reportedly taken control of his documents and forced him to drive nearly nonstop – far beyond the federally mandated hours-of-service regulations. He was given little or no time off, and any mention of rest was met with pressure and threats. His “debt” for being smuggled into the country was held over his head like a chain. He was told he had no choice but to keep driving, day in and day out, until it was paid off.

The trooper, recognizing this as something far outside the normal scope of a roadside interaction, called me immediately. While we are trained to spot hours-of-service violations, equipment issues and falsified logs, few officers expect to uncover a potential human trafficking case on the shoulder of a highway.

Human trafficking for labor is a hidden crime, often cloaked in the appearance of employment. It takes vigilance – and often the courage of the victim – to bring it to light. Fortunately, this driver had the courage to pull over and ask for help.

In North Carolina, the State Bureau of Investigation (SBI) is the lead agency for human trafficking investigations. Upon confirming the seriousness of the allegations, we contacted local SBI agents and initiated the appropriate response. The driver was connected with resources and services to ensure his immediate safety and to begin the process of rebuilding a life free from coercion and exploitation.

The SBI conducted an evaluation to determine the driver’s classification as a trafficked individual, which allowed tailored support to be provided, ranging from housing and legal aid to victim advocacy and immigration guidance.

This case is a powerful reminder: human trafficking isn’t confined to urban centers or back alleys. It can ride silently down our highways, hidden in plain sight behind the wheel of a commercial truck. It can be disguised as a job, a promise or an opportunity. As law enforcement officers, we must remain alert not just to violations of law but to signs of exploitation and abuse that may lie beneath the surface.

Thanks to the vigilance of one trooper – and the bravery of one driver – we were able to break that silence on I-26. n

Continued on next page

By Tpr. B. P. Daniels, North Carolina State Highway Patrol

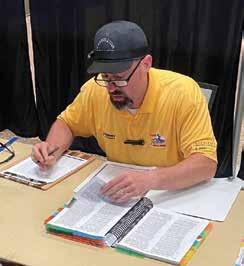

On May 5, I traveled to Louisville, Kentucky, to speak on cargo theft prevention at the 2025 Transported Asset Protection Association (TAPA Americas) T1 National Cargo Theft Summit. More than 350 supply chain professionals attended, including manufacturers, shippers, carriers, brokers, insurers, security service providers and law enforcement officers. In my presentation, I shared practical ways to prevent cargo theft. Additionally, law enforcement professionals from across the U.S. and the Peel Region of Ontario, Canada, attended and shared presentations on their various areas of specialized expertise.

I began my presentation, “Partnerships for Safer Communities – Combating Cargo Theft,” by emphasizing the vital importance of collaboration and well-established working relationships between the law enforcement and supply chain communities. The goal of this program is to educate, encourage and empower all participants to enhance their vital role in the proactive detection of criminal behavior prior to the point of compromise and to deter a criminal act from being carried out. In other words, I call it “protecting your brand.”

There are three expectations of the program: Through education and raising awareness, we will become better equipped to take a proactive approach to mitigating risk before a cargo theft occurs.

We will effectively establish and maintain a network of dedicated professionals who continuously collaborate to greatly reduce criminal activity within the supply chain. We will increase our effectiveness in the workplace through trust, collaboration, communication and vigilance.

The point of compromise can be prevented through the following:

Site security

Carrier verification and selection

Vehicle and driver violations

Vehicle and driver security measures

(physical security devices and vigilance)

In-transit monitoring and escorted highvalue load shipments

I also spoke on the effectiveness of utilizing a “rapid assessment” technique taught in the Federal Motor Carrier Safety Administration’s (FMCSA) Drug Interdiction Assistance Program CMV Interdiction course. A rapid assessment can also be conducted when interviewing carrier representatives and the drivers who come on-site to take delivery of products for shipment. A rapid assessment is highly effective in quickly distinguishing the professionals in the industry from the bad actors of the criminal element seeking to defraud and deprive companies of their products, which is the commonality of all cargo theft.

Cargo theft has increased dramatically on an international scale, and the negative effects on businesses and consumers are very costly. Cargo thefts are carried out in various ways, including straight theft, pilferage and strategic theft, such as double-brokered loads, hostage loads and fictitious pickups.

According to its annual analysis, CargoNet reported unprecedented levels in 2024, with 3,625 incidents representing a stark 27% increase from 2023. The estimated average value per theft rose to $202,364, up from $187,895 in 2023. Each quarter of 2024 surpassed previous comparable quarters in 2023, though the margin of increase narrowed as the year progressed. The most dramatic spike occurred in Q1 2024, with 317 more incidents than the same period in 2023, while Q4 2024 showed a more modest increase of 94 incidents, representing an 11.81% yearover-year growth.

I currently serve on TAPA Americas’ Law Enforcement Committee, which is actively

seeking new membership at no cost to active law enforcement officers. In May of 2025, TAPA Americas launched a Law Enforcement Grant Program to support law enforcement agencies through education and training, thereby enhancing their ability to prevent and reduce cargo theft.

TAPA Americas’ mission is to minimize cargo losses from the supply chain. The organization achieves this through developing and applying global security standards, recognized industry best practices, technology, education, benchmarking, regulatory and law enforcement collaboration, and the proactive identification of crime trends and supply chain security threats. Key to TAPA Americas’ mission is the critical work done by law enforcement agencies and active law enforcement personnel. The TAPA Americas’ law enforcement grants will help fund professional training and education for these groups that would otherwise be costprohibitive.

Two of the greatest benefits of being a member of TAPA Americas and attending a National Cargo Theft Summit are networking and continued learning. Several people approached me after my presentation to express their gratitude and were eager to discuss what they had learned with their colleagues in their respective workplaces.

I have been a CVSA-certified inspector with NCSHP since November 2007 and proudly serve with the CVE Section, the Criminal Interdiction Unit and the K-9 Unit. I will retire from NCSHP on Aug. 1. I encourage everyone to keep an open mind to learning and remain vigilant in their daily duties. n

By Sgt. M. G. Conley, North Carolina State Highway Patrol

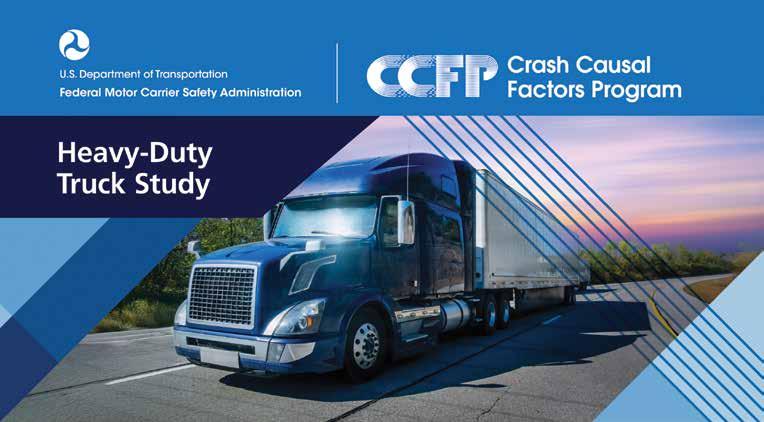

NCSHP CVE Section members have recently completed an intensive series of advanced training sessions designed to enhance the quality of post-crash collision investigations. This initiative reflects NCSHP’s ongoing commitment to improving accident analysis capabilities, aligning with FMCSA’s Crash Causal Factors Program Study.

The training included a rigorous five-day Advanced Post-Crash Inspector Course, supplemented by three specialized classes led by the Forensic Training Group. These additional sessions addressed critical components of traffic crash investigation, focusing on heavy vehicle crash reconstruction techniques, event recorder analysis using advanced tools like the Forensic Link Adapter and Smart Sensor Simulator 2 (SSS2) and targeted training on heavy vehicle event data recorder (HVEDR) analysis.

The Advanced Post-Crash Inspector Course is an innovative program designed to equip NCSHP members with essential forensic skills crucial for conducting thorough

examinations of CMVs involved in accidents. This comprehensive training underscores the importance of identifying causal factors that lead to roadway incidents, which is vital for supporting reconstruction efforts and related legal proceedings.

The curriculum is structured to blend theoretical instruction with hands-on fieldwork, allowing members to acquire practical experience in executing post-crash inspections. The training is grounded in current evidence and best practices, enabling members to enhance their capabilities in conducting meticulous inspections, recognizing violations, identifying contributing factors and effectively documenting their findings. In an era when road safety and effective accident analysis are paramount, the course signifies a significant step forward in strengthening the forensic investigation skills of NCSHP.

Another key element of the training was the Heavy Truck Reconstruction Techniques Course, which offered an intensive five-day educational experience tailored for members specializing

in vehicle traffic crash reconstruction. This program equipped members with essential skills to evaluate the performance and dynamics of heavy vehicles involved in traffic crashes.

Throughout this training, members learned to assess heavy vehicle stopping capabilities and gained insights into the complexities of reconstructing axle weights. These factors are pivotal for understanding vehicle stability during incidents. The program also included hands-on practice, allowing members to calculate dynamic vehicle rollover thresholds, a critical skill for accurately analyzing accident scenarios involving heavy trucks.

Today, when data drives decision-making and safety enhancements in the heavy vehicle industry, the HVEDR analysis training has become a pivotal program for our members. This comprehensive four-day training course delved deep into the intricacies of HVEDR digital data analysis.

Continued on next page

Continued from page 9

The training commenced with an interactive session, laying the groundwork for the critical components of HVEDR technology. Members engaged in extensive validation exercises, exploring various research articles and previous studies that addressed the collision mitigation processes employed by leading original equipment manufacturers, including Wabco, Bendix and Detroit Assurance.

One of the standout features of this course was its hands-on approach. Members were given the opportunity to analyze actual cases of digital data from the field. This real-

world application not only helped members relate theory to practice but also enriched their understanding of how real-time data influences safety protocols and incident analyses.

The curriculum further included a specialized lecture focusing on expert evidence, outlining common pitfalls and traps to avoid when interpreting digital data. This segment was particularly beneficial for those making informed decisions based on HVEDR insights, emphasizing the importance of accuracy and caution in data interpretation.

In summary, the HVEDR analysis training was more than just an educational experience; it was a vital step toward building a more knowledgeable workforce adept at leveraging digital technologies to enhance safety and performance in heavy vehicle operations.

As the industry continues to evolve, such training programs are essential for equipping professionals with the necessary tools and knowledge to navigate the complex landscape of vehicle data and analytics.

The Advanced Direct to Module Training for the SSS2 was a focused two-day program aimed at enhancing the skills of professionals working with HVEDRs. Members gained in-depth knowledge of the SSS2, exploring its features, functionality and practical applications in real-world scenarios.

Key elements of the training included comprehensive instruction on fault code management, where members learned to effectively identify, troubleshoot and eliminate fault codes. The curriculum also emphasized the development of loadable files

tailored specifically for the SSS2, alongside best practices for maximizing the simulator's efficiency and effectiveness.

By the conclusion of the training, members emerged with enhanced technical capabilities and confidence in troubleshooting and utilizing the SSS2 in their respective fields, ultimately contributing to the advancement of their careers in heavy vehicle technology. This training represented a valuable opportunity for members eager to deepen their understanding and practical skills in modern vehicle event data recording technology.

Overall, the completion of this advanced training is a testament to the dedication and professionalism of NCSHP in prioritizing road safety and enhancing its investigative expertise in commercial vehicle crashes. Through such initiatives, NCSHP is better positioned to ensure the safety of roadways across North Carolina and improve overall traffic enforcement strategies. n

By Chief Troy Thompson, Office of Commercial Vehicle Enforcement, Florida Highway Patrol

On March 25, Florida Highway Patrol (FHP) members partnered with the Florida Department of Transportation (FDOT) to conduct the Battle of the Belts outreach at Fort White High School. On March 28, FHP and FDOT members conducted a similar outreach at Columbia High School. During the outreach, FHP members discussed best practices for operating around commercial motor vehicles (CMV), how to operate a vehicle safely, road rage and the use of safety belts while operating a vehicle. n

The FHP Commercial Vehicle Enforcement (CVE) unit teamed up with the International Fuel Tax Association (IFTA) and the Florida Trucking Association in Orlando, Florida, on June 4 for a presentation at the IFTA Educational Forum. Lt. Artez Lester and Lt. James Hightower gave an overview of FHP’s dyed fuel enforcement and radiological detection assets to more than 320 attendees from across the country who are involved with the IFTA program. n

Since July 2024, 3-year-old Jr. Tpr. Lincoln, grandson of Sgt. Denise Meredith, has starred in multiple traffic safety messages on FHP social media platforms. Tpr. Lincoln’s first video centered around him learning about weigh station facility operations, discussing safety with CMV drivers and assisting FHP troopers with a Level I Inspection.

In July 2024, Tpr. Lincoln was featured on “Trooper Tuesday” with his black and tan CVE SUV and his K-9. In August of 2024, Tpr. Lincoln interviewed a school bus driver in Lake County. This video provided helpful tips to kids and drivers on the importance of school bus stop safety. In November 2024, Tpr. Lincoln teamed up with troopers Dowler and Estelus in a match with Belleview High School football players. The video described the stopping distance of a loaded truck. During the 2024 holiday season, Tpr. Lincoln traveled around central Florida, participating in Christmas parades with Tpr. Dowler. Tpr. Lincoln loves being a Florida Junior State Trooper. For May’s Share the Road Campaign this year, Tpr. Lincoln collaborated on a video with Tpr. Dowler to demonstrate the no-zone areas around CMVs. You can see Tpr. Lincoln’s public safety videos on Instagram and X by following FHP_CVE. n

Continued on next page

Continued from page 13

On April 3, FHP conducted a CMV enforcement detail to remove unsafe vehicles and drivers from our roadways. The detail emphasized identifying criminal elements who have been pirating legitimate motor carriers’ names and USDOT numbers.

During the detail, members conducted 496 inspections, which resulted in 161 vehicles and 50 drivers being placed out of service. Two vehicles were identified as potentially pirating legitimate motor carriers’ names and USDOT numbers.

One of those traffic stops resulted in criminal charges. The second traffic stop resulted in a field interview for further investigation. n

On May 13, Maj. Thomas Pikul led a presentation on FHP’s human trafficking prevention efforts at the American Association of Motor Vehicle Administrators (AAMVA) Conference in Tampa, Florida. Maj. Pikul discussed FHP’s enforcement efforts with local law enforcement agencies, participation in CVSA’s Human Trafficking Awareness Initiative and combined efforts with partner states during our SafeDRIVE (Distracted-RecklessImpaired-Visibility-Enforcement) waves. Maj. Pikul further discussed the initiatives of FHP and its parters to conduct industry and public outreach and he shared resource materials available on CVSA's website. There were approximately 100 attendees at Maj. Pikul’s presentation.

Additionally, Lt. Artez Lester led a presentation on FHP’s efforts regarding Level VI Inspections and preventative radiological nuclear detection (PRND) at the AAMVA Conference. During the presentation, Lt. Lester

discussed the goals and strategies of FHP's hazmat/PRND program and the equipment used to complete mission assignments. There were approximately 30 attendees at Lt. Lester’s presentation. n

By Master Sgt. Victor McCarty, Public Affairs, Mississippi Commercial Transportation Enforcement Division, Mississippi Department of Public Safety

commercial

(CMV) has long been a factor in crashes on Mississippi roadways. In a forward-thinking move, the Mississippi Department of Public Safety’s (MDPS) Commercial Transportation Enforcement Division (CTED) has taken decisive steps to confront this issue head-on. Thanks to newly enacted legislation and advanced training initiatives, CTED is now enforcing speed and following distance laws for large trucks. This development is already making highways safer across the state.

Passed during the 2024 Regular Session and signed into law, House Bill 1015 marked a turning point for CTED’s enforcement authority. The bill authorized CTED inspectors to operate speed detection equipment and issue speeding citations to CMVs, expanding their role in promoting roadway safety. It also allowed CTED personnel to assist other law enforcement officers and administer breath tests, further aligning CTED with the mission of the Mississippi Department of Public Safety.

In the second quarter of 2025, CTED launched a comprehensive light detection and ranging (LIDAR) training initiative for its officers.

LIDAR offers precise speed detection that is ideal for large vehicle enforcement. With this new capability, inspectors can accurately measure CMV speeds and take action against dangerous driving behavior.

According to Federal Motor Carrier Safety Administration (FMCSA) data, speeding is a leading contributor to large truck crashes. The Large Truck Crash Causation Study revealed that driving too fast for conditions was a contributing factor in 23% of crashes involving large trucks. By empowering CTED officers to cite speeding violations, Mississippi is proactively working to reduce these numbers.

The speed detection equipment CTED has deployed includes advanced features beyond measuring speed. These units can also detect when vehicles follow one another too closely – a critical safety issue for heavy trucks. Following too closely is the second most common driver-related factor in fatal large truck crashes. FMCSA notes that truck drivers who tailgate limit their ability to stop in time and create dangerous chain-reaction collisions. CTED’s enforcement of following distance violations addresses this behavior before it leads to crashes.

The effort is not merely punitive; CTED’s strategy is rooted in public safety. FMCSA’s researchbased driving tips emphasize the importance of maintaining proper following distance, especially for heavy vehicles that require longer stopping distances. By enforcing these laws, CTED is aligning its operations with best practices that are proven to reduce crash risk.

CTED officers now serve not only as inspectors but as proactive highway safety professionals – trained, equipped and legislatively empowered to protect Mississippi motorists from the dangers posed by speeding and tailgating CMVs.

CTED’s expansion into speed and following distance enforcement is part of a broader culture shift in Mississippi’s approach to CMV safety. With strong legislative support, cuttingedge training and advanced enforcement tools, CTED contributes to Mississippi's public safety mission.

From highways crisscrossing the Delta to the interstates that carry goods through the Magnolia State, Mississippi’s roads are becoming safer, one citation – and one life saved – at a time. n

Continued on next page

Continued from page 15

Earlier this year, the Mississippi Highway Patrol (MHP) and CTED joined forces to complete an intensive Advanced Post-Crash Inspection Course certified by CVSA. This specialized training brought troopers and CTED officers together in a shared classroom, highlighting Mississippi’s commitment to interagency collaboration and continuous improvement in commercial vehicle safety.

The training, designed exclusively for law enforcement personnel, equips officers to conduct full forensic examinations of CMVs involved in crashes. This includes identifying mechanical defects, assessing contributing factors, and assisting crash reconstructionists and prosecutors with accurate, comprehensive evidence. Officers also learned how to

determine whether violations were preexisting or crash-induced – vital distinctions in both criminal and civil investigations.

What sets this training apart is its real-world impact. By improving the investigative capabilities of both troopers and inspectors, the program helps ensure that every serious crash involving a CMV is not only thoroughly examined but also contributes to long-term safety improvements on Mississippi highways.

“This training directly benefits the people of Mississippi,” said CTED Director Matt Lott. “It strengthens our ability to determine why a crash occurred and how to prevent similar incidents. It also reinforces the trust the public places in our commitment to highway safety.”

Driver impairment, including drug and alcohol use, was also a focus, aligning with FMCSA’s regulations on post-crash testing. The course prepared officers to document and respond to possible impairment, ensuring that impaired drivers are held accountable and that necessary follow-up procedures are initiated.

By completing this rigorous training, MHP and CTED have raised the standard for post-crash investigations in the region. More than just technical training, the course exemplifies a shared mission: protecting the lives of CMV drivers and the motoring public through diligent, informed enforcement. n

Criminal interdiction officers with CTED made a major drug seizure on May 29, during a routine CMV inspection on Interstate 22 in Lee County, Mississippi.

The stop involved an 18-wheeler car hauler registered in Oklahoma City, Oklahoma. The truck was en route to Florida, transporting a load of passenger vehicles. During the inspection, CTED officers noticed irregularities that prompted a deeper roadside investigation.

Upon further inspection of the vehicles on the trailer, officers discovered approximately 185 pounds of illegal marijuana concealed in the bed of a black pickup truck. A records check revealed that the black pickup truck had been reported stolen, raising additional red

flags in the investigation. The driver of the car hauler was immediately taken into custody and transported to the Lee County Detention Center.

This successful seizure is a testament to the vigilance and expertise of CTED officers, who are trained not only in CMV enforcement but also in advanced criminal interdiction tactics. Their work protects Mississippi roadways and helps prevent illegal drugs from reaching communities across the southeastern U.S.

The Mississippi Department of Public Safety continues to prioritize highway safety and criminal interdiction, working hand-in-hand with local, state and federal partners to ensure the safe and lawful movement of commercial traffic throughout the state. n

Approximately 185 pounds of illegal marijuana were concealed in the pickup truck, which had been reported stolen.

Continued on next page

Continued from page 17

The Mississippi Truckers Association hosted the annual Mississippi Truck Driving Championship May 2-3 in Gulfport, Mississippi. The event, organized by the Mississippi Trucking Association, brought together top-tier professional drivers and safety officials for a showcase of skill, precision and collaboration. Drivers competed in various categories, including pre-trip inspections, written tests and driving skills courses.

The MDPS CTED played a pivotal role in the event to ensure that safety remained the cornerstone of the competition. This partnership underscores the critical importance of cooperation between the transportation industry and regulatory bodies in promoting highway safety.

In addition to the driving competitions, the event hosted the 2025 MDPS Inspectors' Competition, where inspectors demonstrated their vehicle safety and compliance expertise. These competitions recognize the dedication of MDPS inspectors and emphasize their shared commitment to maintaining high safety standards on Mississippi's highways. CTED appreciates the efforts of training instructors Master Sgt. Kristen Beamon and Senior Staff Sgt. Level Walley Jr. for their outstanding work in organizing the Inspectors' Competition.

The collaboration between MDPS and industry professionals at the competitions exemplifies how joint efforts can lead to safer roads for all. By fostering strong relationships between drivers and inspectors, Mississippi continues to set a standard for highway safety and professional excellence. n

INSPECTORS' COMPETITION RESULTS:

1st Place: Sgt. Jaclyn Pendleton

2nd Place: Ofc. Tanner Moody

3rd Place: Sgt. Marquis Fisher

HAZMAT OLYMPICS RESULTS:

1st Place: Crimson Thunder

Team Leaders: John Williams and James Guthrie

2nd Place: Blue Fury

Team Leader: Keith Joseph (2022 Inspector Champion)

3rd Place: Emerald Green

Team Leader: Bradley Hogue (2024 State Competitor and National Attendee)

Presented by the Cooperative Hazardous Materials Enforcement Development (COHMED) Program, the COHMED Conference is a focused, one-of-a-kind event for individuals and organizations involved in the regulation, enforcement and safety of transporting hazardous materials and dangerous goods. Join us Feb. 2-6, 2026, in San Antonio, Texas, for the COHMED Conference.

To learn more, visit www.cvsa.org/events/ cohmed-conference. n

By Orlando Ortega, Commercial Vehicle Enforcement, Texas Department of Public Safety

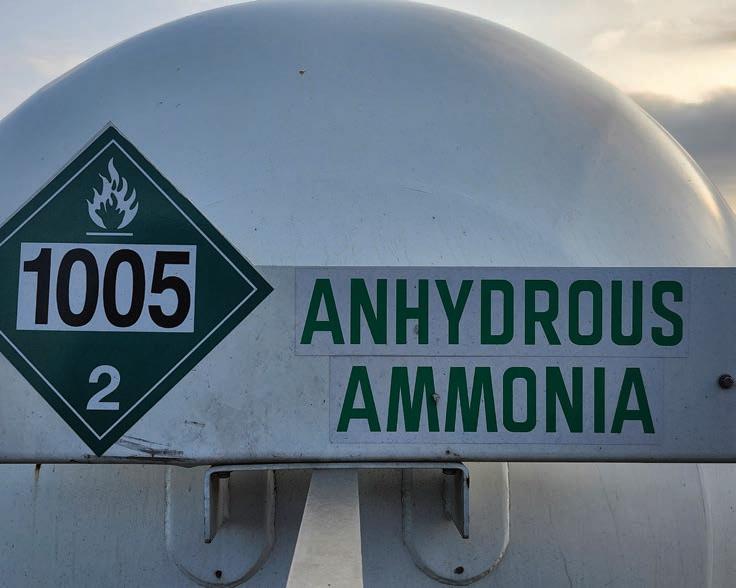

UN3252 Difluoromethane is a 2.1 flammable gas and was placarded incorrectly on each side and each end. The driver stated he thought all the hazmat products he was transporting were 2.2 non-flammable gas.

This container is displaying a label out of specification, per § 172.442. This package contained an ammonia solution.

The placard was water-damaged from a rainstorm during transport. The placard and incorporated marking are out of specification due to damage; see § 172.516(c)(6) and § 172.332(c).

Anhydrous ammonia is a 2.2 non-flammable gas and requires a non-flammable placard. The placard has a flame at the top, which is incorrect. The non-flammable placard should have a cylinder at the top.

By Lt. Mike Maytum, Carrier Enforcement Division, Nebraska State Patrol

Imagine, if you will, the need to stop a fleeing vehicle. One option we have at the Nebraska State Patrol (NSP) is the Stop Stick, which has proven to be a valuable tool. Now, imagine that vehicle isn't just a passenger vehicle but a large commercial motor vehicle (CMV) – and it won't stop. What next?

The NSP Carrier Enforcement Division was challenged with that question a couple of years ago after a CMV pursuit traversed more than half of the state, refusing to stop. Stop Sticks were largely ineffective, and tactical vehicle intervention was impractical. We were challenged to find a better way. One of the tools we discovered was the Barracuda, a tactical tool similar to a Stop Stick but with features that make it effective on a large CMV.

The challenge of using traditional tire deflation tools is that the quills are narrow and not

terribly long. On passenger car and light truck tires, the quills can penetrate the tire and deflate it. As tire sizes increase, so does the available air that needs to escape the tire before it is flat. Additionally, the tires have many more plies, making quill penetration difficult. The design of the new tool involves much larger, more rigid quills that can penetrate the heavy truck tire. The unit is also self-uprighting, meaning the quills should always point upward, which assures correct deployment.

As part of the vetting process, it was determined that the agency should evaluate live testing of the equipment. The challenge became finding willing partners who would let us poke irreparable holes in their tires. Fortunately, the Carrier Enforcement Division maintains good working relationships with many of our Nebraska trucking industry

partners. Once the offer was made, several willing companies volunteered equipment and drivers to conduct the testing.

With several industry partners watching, we rolled three different trucks across the tool in a controlled environment. The results of that testing demonstrated its effectiveness in quickly flattening CMV tires, taking less than 30 seconds in each test case. The truck drivers all said the same thing: It would be nearly impossible to continue driving the vehicle once the steer tires were flat, which is the ultimate goal when deployed.

We owe our thanks to Crete Carrier, Transport Specialists Limited, Fremont Contract Carriers, Pomp’s Tire and the Nebraska Trucking Association for their assistance in making this testing possible. n

Motor carriers with oversized loads in Oregon have a new way to get the permits they need to ensure their loads are legal and safe. The Oregon Department of Transportation (ODOT) has streamlined the permit process by launching Oregon Routing Information Online (ORION).

ORION is a web-based, self-service permitting system provided by the ODOT Commerce and Compliance Division. It allows motor carriers to request over-dimension permits 24 hours a day, seven days a week, 365 days a year.

"ORION’s implementation is a priority in ODOT’s Strategic Action Plan, which calls for an efficient, innovative and technologically advanced transportation system,” said ODOT Commerce and Compliance Interim Division Administrator Carla Phelps. “The new permitting system has been years in the making and is an exciting development for the trucking industry in Oregon. We’re pleased to join 44 other states that have implemented similar modernized systems.”

ORION is a result of ODOT’s dedication to enhancing convenience and efficiency.

Benefits include:

Automated routing for trip planning and single-trip permits

Improved safety by reducing the risk of errors

Auto-issued permits for qualified loads Decreased wait times for obtaining overdimension permits

Timely notification of route closures or restrictions

The Oregon Trucking Association is also contracted to issue over-dimension annual permits for its customers.

All other Commerce and Compliance business transactions remain available through existing processes, including Oregon Trucking Online. ODOT contracted with ProMiles, a leading provider of over-dimension permit systems, to develop ORION. n

By Susan Chang, Motor Carrier Safety Manager, Hawaii Department of Transportation

The Hawaii Department of Transportation (DOT) Motor Vehicle Safety Office continues to be active in the Federal Motor Carrier Safety Administration’s mission of saving lives and ensuring safety on our roadways for everyone. Enforcing full compliance is one of our main goals as we strive for zero crashes and fatalities.

Hawaii participated in International Roadcheck from May 13-15, conducting inspections on the islands of Oahu, Maui and Kauai.

Vehicle inspections conducted: 96

Safety violations found: 135

Vehicles placed out of service: 15

Drivers placed out of service: 12

Citations issued: 18

In addition to the vehicle inspections, officers educated drivers on the 2025 International Roadcheck focus: tires and false records of duty status. Officers also emphasized the importance of safe driving behaviors on the roadways. n

On March 10, Engineer Jesús Antonio Esteva Medina, secretary of infrastructure, communications and transportation, participated in the conference series "Dialogue with Engineers," organized by the Mexican Association of Civil Engineers (CICM). During this event, some of the most critical challenges and opportunities for the future of Mexico's infrastructure were discussed.

One of the highlights of his speech was the announcement of a new national aviation policy, designed to make the sector cleaner, safer and more efficient. This new policy will include measures such as the use of renewable energy, compliance with international standards and the strengthening of airport infrastructure and services – all with the goal of positioning Mexico at the forefront of global air transportation.

In addition, Esteva Medina acknowledged the fundamental role that the CICM has played in contingency situations and in developing technical solutions to address the country’s infrastructure challenges. CICM’s ongoing support has been key to building more resilient and modern infrastructure.

This effort is part of the Mexican government's commitment to promote more sustainable and competitive transportation, aligned with global trends and the policies advocated by organizations such as the Organisation for Economic Co-operation and Development and the International Transportation Workers’ Federation.

The event also served as an opportunity for Esteva Medina to detail the National Road Infrastructure Program 2025-2030, which will involve an investment of 173 billion pesos for more than 4,000 kilometers of roads.

Work is underway on 43,371 kilometers of toll-free roads and 10,614 kilometers of the Federal Toll Road Network. Together, these make up 54,000 kilometers of the Federal Road Network, for which the Ministry of Infrastructure, Communications and Transportation (SICT) is responsible for building and maintaining. Of these, 19,240 kilometers make up the 15 main corridors where most of the country's cargo and people travel.

Throughout the event, the importance of reinforcing technical ties with the CICM was emphasized. The aim was to improve infrastructure practices, adopt international standards to boost the sector's competitiveness and strengthen collaboration mechanisms to more efficiently address future challenges. n

On March 25, the National Gazette published an agreement to simplify regulations and services for regulatory improvement, aiming to modernize processes and the operation of services. These improvements may be expedited through general agreements on matters of federal motor transportation and preventive medicine.

The agreement includes the unification of two procedures: registration of motor transportation companies and registration modification. These were not substantively altered but rather had nonessential official documentation removed.

Regarding changes in protection and preventive medicine, three procedures were unified:

The Comprehensive Psychophysical Exam for Federal Public Transportation Personnel

The Comprehensive Psychophysical Exam for Revaluation of the Toxicological Test

The Comprehensive Psychophysical Exam for Revaluation of the Medical Exam in Operation

These updates allow medical personnel to request additional medical information as needed. n

From May 13-15, SICT, through the General Directorate of Federal Motor Carriers (DGAF), participated in CVSA’s International Roadcheck.

This year's operation focused on tires and false records of duty status. SICT deployed specialized personnel to fixed size and weight verification centers to carry out physical and mechanical inspections of vehicles providing public and private federal freight motor carrier services.

Inspections included detailed checks of critical systems such as lighting, steering, brakes, fuel, exhaust, suspension, chassis, wheels, rims, windshields and – as a priority this year – tire condition. Tread depth, proper inflation pressure and possible damage such as air leaks, tread separation, cuts, bulges or sidewall deterioration were all evaluated.

This coordinated effort is part of SICT’s ongoing actions to ensure road safety and compliance with the Official Mexican Standard NOM-068-SCT-2-2014, which establishes the physical and mechanical conditions that federal motor carrier vehicles must meet to operate safely. n

of an infraction ticket.

In May, SICT, through the Undersecretary of Communications and Transportation, published the new violation ticket format in the Official Gazette of the Federation. This document will be used by authorities during inspection and verification duties related to federal motor transportation, auxiliary services and private transportation.

The implementation of this new format represents a significant change within the current regulatory framework. It aligns with the Law of Roads, Bridges and Federal Motor Transportation as well as various regulations related to weight, dimensions, safety and the transportation of hazardous materials. It came into effect on June 27, officially repealing the previous format issued on Dec. 10, 2021.

The new format will be issued by authorized SICT personnel at key control points, including fixed verification centers, passenger and cargo terminals, airports, ports, and highways under federal jurisdiction. Its use will be mandatory during verification operations inspecting vehicle mechanical conditions, safety standards compliance, transportation of hazardous materials, and adherence to legal weight and size limits.

DGAF and SICT state centers throughout Mexico are authorized to carry out inspections, issue new violation tickets and apply sanctions in accordance with applicable legislation. These actions are conducted under the powers granted by Articles 23 and 41 of the SICT Internal Regulations.

SICT remains committed to informing and training all stakeholders in the transportation sector in a timely manner, promoting regulatory compliance as the foundation of a safer, more efficient and competitive logistics system in Mexico. n

The CVSA Workshop, held from April 27 to May 1 at the Hilton New Orleans Riverside in Louisiana, is a key event that brings together government authorities, law enforcement and transportation industry representatives from across North America. During this year’s workshop, the Mexican delegation, through SICT, highlighted significant progress in mobility, road safety and inclusion.

Director of International Motor Carrier Services

Claudia Franco represented Mexico and expressed SICT’s gratitude to the CVSA for the opportunity to participate. She extended greetings on behalf of SICT Undersecretary Tania Carro Toledo and SICT-DGAF Director General Luis Ruiz Hernández. She also gave special thanks to CVSA President Capt. John Hahn and CVSA Executive Director Collin Mooney for their kind invitation and hospitality.

Franco emphasized that since Mexico’s last participation in the CVSA Workshop, the commitment to improving federal motor transportation and road safety has been maintained. She highlighted actions taken in

compliance with the General Law on Regulatory Improvement, which mandates that all public policies focus on streamlining processes and services, under principles of legality, normative hierarchy and institutional efficiency.

In federal transportation, key changes were made to registration processes, merging the registration and modification procedures for individuals and legal entities into a single process. Additionally, the procedures for comprehensive psychophysical exams were unified. These apply to drivers of federal public transportation and ground support personnel and include specific medical evaluations such as post-accident assessments and toxicological tests.

One of the most significant topics addressed was the institutional response to complaints from the Federal Motor Carrier Safety Administration regarding irregularities in the issuance of federal licenses.

SICT, DGAF, Protection and Preventive Medicine in Transportation, and Information

and Communications Technologies conducted an exhaustive analysis of the reported cases. Using bilateral cooperation mechanisms, 68 license verification requests were addressed, irregularities were corrected and interagency collaboration was strengthened. Eight cases remain under document and technological review.

Finally, the Mexican delegation presented a regulatory update on road safety. As of Feb. 7, a visual identification system – or “balizado” (marking) – was implemented for federal transportation units. This measure includes the use of visible, reflective and durable characters (via decals or paint) to identify vehicles by type and configuration, reinforcing monitoring and control on federal highways.

Through its participation, Mexico reaffirms its commitment to regional cooperation, institutional transparency and continuous improvement in federal motor transportation services, fostering safer, more efficient and inclusive mobility for all of North America. n

By Jimmy Valenti, Cedar Hill (Texas) Police Department

Hello, my name is Jimmy Valenti (AKA JIMMMMMY), and I am a local inspector from Cedar Hill (Texas) Police Department. As I sit here in my squad car waiting for a truck to inspect, I am overwhelmed with the thoughts of the past week. Last week, I had the honor of attending my 15th CVSA event, the 2025 CVSA Workshop in New Orleans, Louisiana, and again, I was not disappointed. As the week ended, I talked with Emily Moorhead, the amazing editor of the awesome, informative and revitalized CVSA magazine, “Guardian.” While speaking with her, she planted a seed in my head of writing an article for the new local’s section of the “Guardian.” So here I go.

I, along with several hundred other people, spent the week learning, fellowshipping, contributing to committees and meeting new contacts from fellow law enforcement, industry and government, all to advance and maintain commercial motor vehicle (CMV) safety. Every day was filled with hard work from breakfast (on the house) to the end of the workday. It always amazes me how we can come together from all over the U.S., Canada and Mexico and function as one big family. We truly watch major work be planned and executed in one week, despite not seeing each other for four to six months. This work is done with precision, comparable to a major corporation comprising folks who work together daily.

As I think about all the accomplishments of the week, I consistently come back to the answer on how this can be done time and time again, year after year, conference after conference and workshop after workshop. The answer is the CVSA leadership and staff.

Executive Director Collin Mooney and Deputy Executive Director Adrienne Gildea have steered this ship in the right direction for many years. I often say to others that they seem to use Chick-fil-A's approach in hiring and assembling their staff and teams. For those who don’t know, Chick-fil-A is a chicken restaurant chain, and they seem to hire employees and assemble teams who smile all the time, say “my pleasure” constantly and genuinely make you feel good going there. They appear to love their jobs and enjoy working together. As I watch the CVSA staff work together, I often see them all smile, work hard together and use an all-hands-on-deck approach to the week. We have seen moves and changes – people coming and going in the Alliance – and somehow it still works.

The new people work, the old people work, the process works, and it all falls back to the two at the top. I mean, they take the best from enforcement, industry and the professional world and make them part of the team. I’ve also got to shout-out Director of Enforcement Programs Jake Elovirta, Director of Hazardous Materials Programs Bill Reese, Roadside Inspection Specialist John Sova, Multimedia Specialist Terry Moore, Traffic Enforcement Specialist Kevin Andrews and Roadside Inspection Specialist Jeremy Disbrow, and all I have to say is … WOW.

During the week, you will see Adrienne put out fires, guide, lead, advise and do whatever needs to be done. Collin also leads, advises and counsels, walking around with a regulations book in his hand while talking to someone. He goes from committee to committee, all the while knowing the key discussions taking place – not to mention, he’s incredibly approachable the whole time.

At 7 a.m., Multimedia Specialist Mark Mills will greet us at breakfast one minute and work a microphone the next. Director of Conference and Event Services Kristin Yednock will hand us our pretzels, change committee signs and let hotel staff know something isn’t quite right.

You’ll see Director of Compliance Programs

Katie Morton running a microphone in a committee and keeping a conversation going. Director of Inspection Programs Kerri Wirachowsky is getting hit from every angle by people just wanting to ask her a question or pick that brain of hers – and she takes it all in stride. I have not even mentioned the work of Manager of Meetings and Events Cassy Dafin, Certification Coordinator Paola Berridi, Training Coordinator Amy Molina, Learning Management System Specialist Annie DeGennaro, and Manager of State and Local Contracts David Findlay and all the work they do from early morning to late at night. I am sure I forgot some, and I am sorry if I did, but they all do this with smiles on their faces, all for us, the members.

The CVSA Board of Directors, Executive Committee, Finance Committee, region and local member leadership, committee and program chairs and vice chairs, local and associate member presidents and vice presidents – all the leadership from the top down – work together toward one noble mission: to prevent CMV crashes, injuries and fatalities throughout North America.

For those local, state, federal and industry personnel, along with all the others that read this magazine, if you have not attended an event, please check it out for yourself to see what I am talking about. See what goes into that Out-of-Service Criteria Handbook that you use daily in your profession. If you attend, you will also have the privilege of having a part in the future of the Alliance, along with meeting new peers and lifelong friends. Come see where the rubber meets the road, where it all starts and ends – with the Commercial Vehicle Safety Alliance. n

By Christopher Vinson, Midlothian (Texas) Police Department; CVSA Local Member President

On behalf of the CVSA Class II Local Members, we would like to congratulate two of our best on reaching retirement and recognize their service to law enforcement and CVSA.

Ofc. Thomas Mrozinski served 32 years, retiring from the Frisco (Texas) Police Department, and Ofc. Lincoln Sweeney served 21 years, retiring from the Cedar Hill (Texas) Police Department. Both men have been consistently committed to highway safety through commercial motor vehicle enforcement and represented the local member inspector community well through their leadership as former CVSA Class II Local Member presidents.

You both have paved the way for locals to become more involved and serve in greater capacities, cementing a more impactful future for local inspectors who come after you. Thank you, gentlemen, for your service and friendship. n

By Thomas Durham, Traffic Enforcement Unit, Buckeye (Arizona) Police Department

Officers from the Buckeye (Arizona) Police Department (PD) and Goodyear (Arizona) PD traveled to Flagstaff, Arizona, to participate in International Roadcheck. Ofc. Demaro with Buckeye PD recently finished his supervised inspections and is now starting his independent inspections. Ofc. Webster with Goodyear PD recently passed the hazmat course and was working on her supervised inspections during the detail. n

By Christopher Vinson, Midlothian (Texas) Police Department; CVSA Local Member President

Earlier this month, while attending the DallasFort Worth Council of Safety Professionals Meeting, I was honored by the presence and story of two legends who just happened to be in attendance. These two are some of the most intelligent and most humble men you could ever meet, and they represent everything we should aspire to achieve in our careers. This is a story that time must remember, as this is what the relationship between enforcement and drivers should look like. These two light up whenever they are together, as if they are family, and time stands still between encounters.

Charles “Chuck” Longfellow, whom we all know as “The Legend,” started his career with the Texas Department of Public Safety (TXDPS) in 1972, transitioning into license and weight –now commercial vehicle enforcement (CVE) – in 1977, when he was assigned to Amarillo, Texas. Gary Black started his driving career hauling grain for Hughes Elevator in Panhandle, Texas, in 1976. Gary says that Chuck was the first license and weight trooper to stop him when it was normal to run at 100,000 pounds because the fine was only $28.50. Chuck says that Gary was one of the drivers in the area he came to know as a professional.

Gary always talks about the 237 horsepower Mack five-speed he drove then, but he was happy as could be because he was driving a truck. He has since driven an impressive 5 million miles, even serving as one of Walmart’s