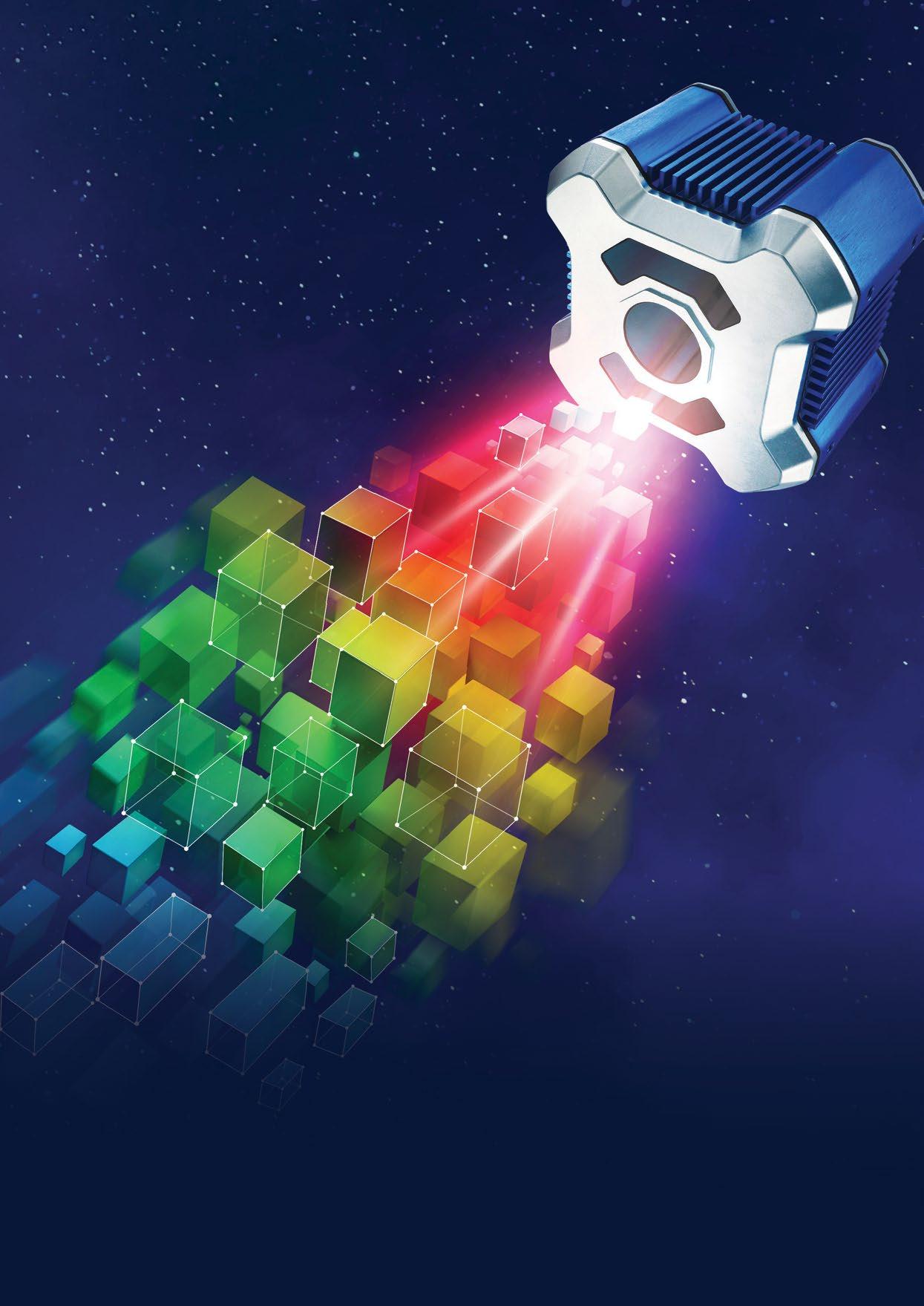

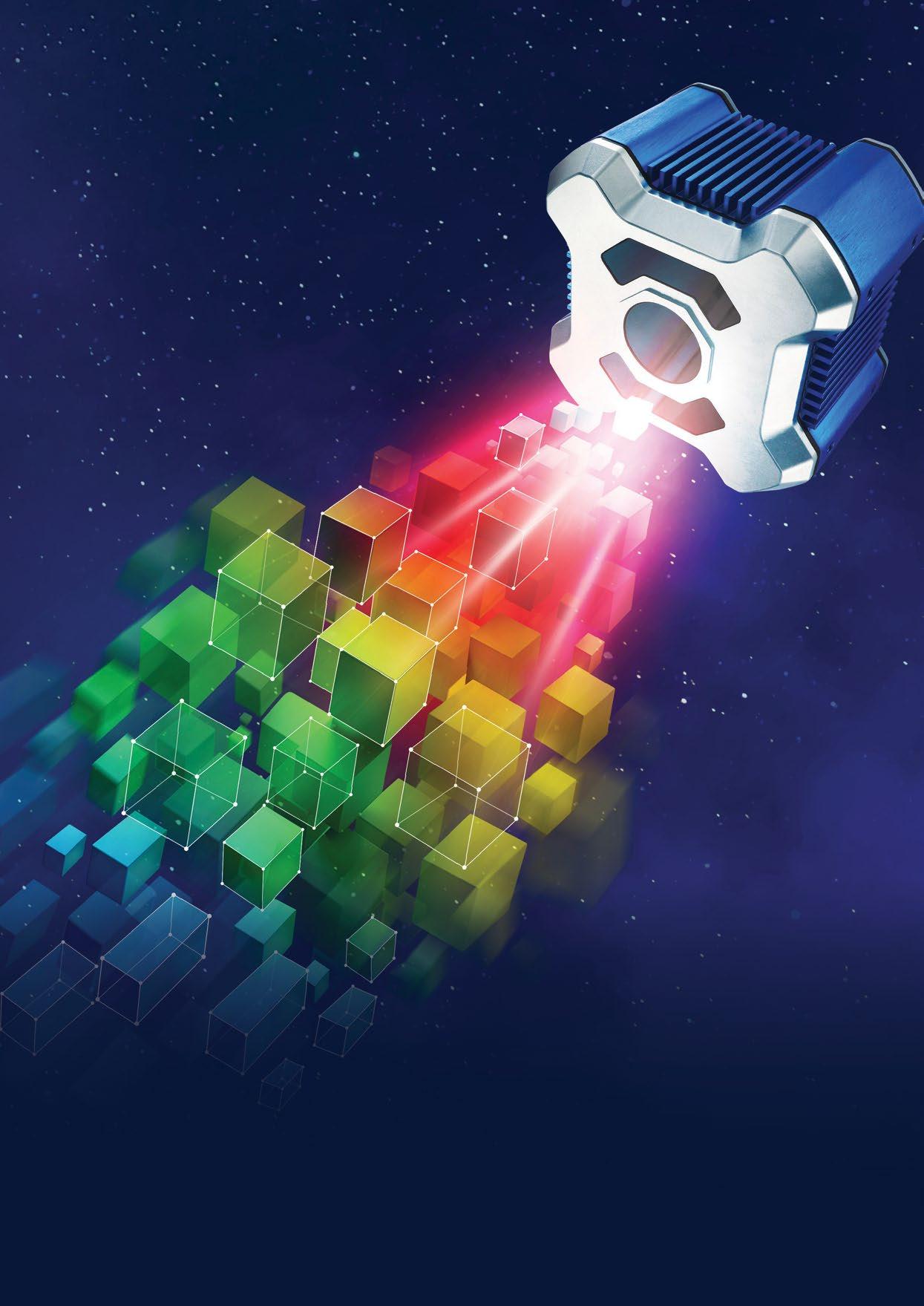

A compact and affordable Smart Camera 3D utilizing Time-of-Flight (ToF) technology for real-time depth measurement with embedded image processing. No external illumination or processing computer is required. The camera captures 3D images in real time, applies internal algorithms, and evaluates scenes in real-time according to customer-defined parameters, providing a clear pass/fail result for each inspected piece.

The camera provides preconfigured use cases for common industrial tasks, such as multi-zone distance measurement, object completeness checks, and object sizing. Customers can easily set up and configure these use cases using our no-code configuration app, with no programming required. Configurations can be saved and reloaded via without the need to reconnect to the app, ensuring seamless operation. The app is available on major app stores and is fully compatible with smartphones, tablets, and laptops, making setup and customization fast, simple, and convenient.

The first smart 3D camera with output, delivering both process parameters and the results of its embedded image processing. It uses standard cables, eliminating the need for expensive specialized connectivity, and supports multiple interfaces — Ethernet, SIO, , and API modes — for seamless and flexible integration into a wide range of systems.

Plug & Play Setup – Configure in minutes with a no-code app on any device

Smart Vision – Embedded intelligence delivers instant pass / fail results without a PC

Ready-to-Use Applications – Preloaded embedded use cases for measurement, completeness, and sizing

Affordable Connectivity – First Smart 3D Camera with output and standard cabling

Built for Industry – Reliable ±5 mm precision in industrial environments – Save and reload configurations

TARGET APPLICATIONS

Automated logistics and warehousing

Production lines and quality checks

Industrial assembly and completeness verification

The Contrinex Smart Camera 3D utilizes advanced Time-ofFlight (ToF) technology to deliver accurate 3D imaging. Unlike conventional cameras, it calculates the distance to every point in an object by measuring the time it takes for light to travel from the camera to the object and back — with each pixel capturing own depth information.

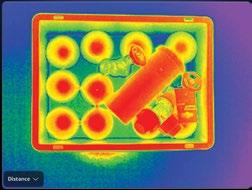

This technology generates a detailed 3D point cloud, where every point corresponds to an exact position in space — with measurement precision of up to 5 mm. The result is a fully reconstructed 3D representation of the object given in a colorized distance image or a black and white amplitude image.

Our powerful onboard algorithms process this data in a real time, enabling the system to evaluate objects against predefined criteria. This makes it ideal for applications such as object sizing, position control and completeness checks in crates or packaging systems.

• Real time 3D depth measurement camera

• Embedded intelligence

• Ready-to-use embedded use cases for measurement, completeness, and sizing

• No-code configuration of use cases with companion app

• First 3D camera with output

• SIO, or REST API over Ethernet operating mode

• No need for illumination or external PC

• Best suited for medium to large-sized objects

Distance

Amplitude

Recommended

• Medium to large-sized objects

• Flat, low-glare backgrounds

• Matte or low-reflective surfaces

• Indoor industrial environments such as warehouses, production lines, and logistics systems

• Moderate dust, vibration, and stable humidity

• Accuracy of up to ±5 mm

• Very small objects of less than 10 x 10 x 10 mm

• Cluttered, glossy, or uneven backgrounds reduce accuracy

• Highly reflective, shiny, or very dark surfaces

• Outdoor use or non-industrial environments (e.g., offices, open air)

• Excessive dust, vibration, moisture, fog

• Target variations smaller than 5 x 5 mm

• Cross-Platform — Compatible with iOS, Android, and Windows devices

• Wireless Connectivity — Seamless communication between the Smart Camera 3D and the App

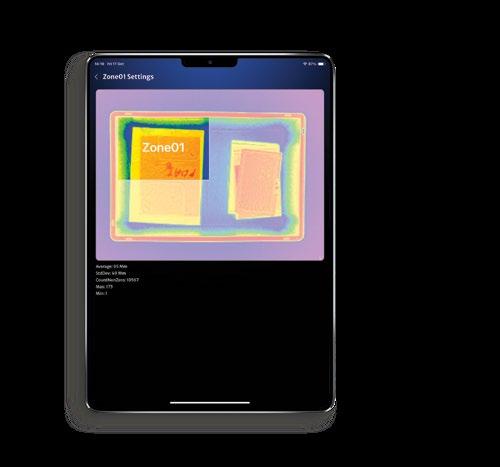

• Live Image Streaming — View real-time depth and amplitude images from the camera

• Use Case Library — Access pre-configured use cases for standard camera tasks

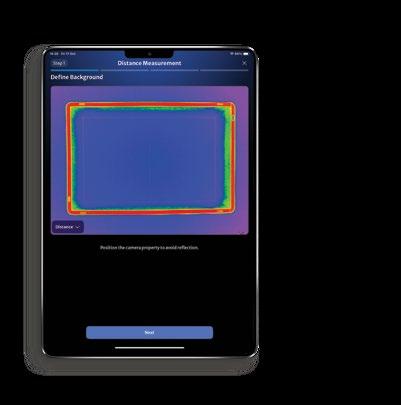

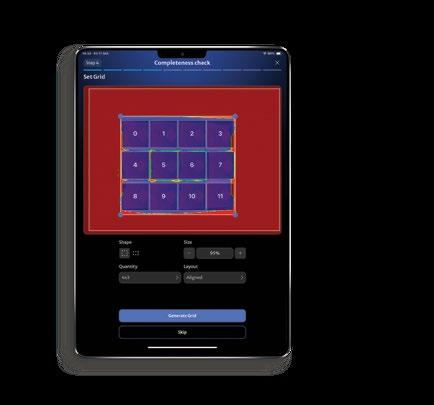

• Guided Setup — Step-by-step teaching process to configure and adapt use cases easily

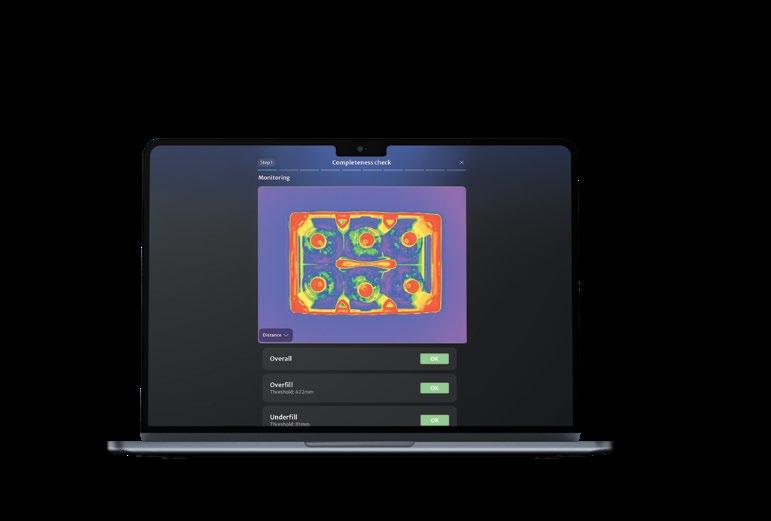

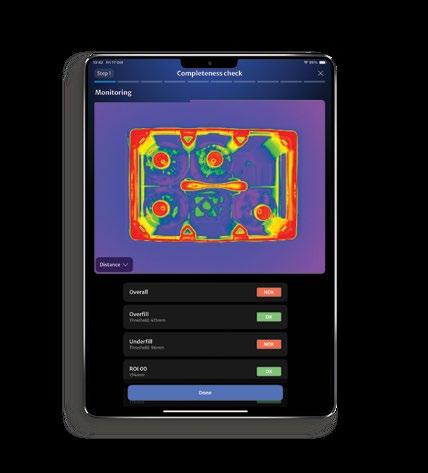

• Live Performance Monitoring — Track and visualize results of configurations in real time

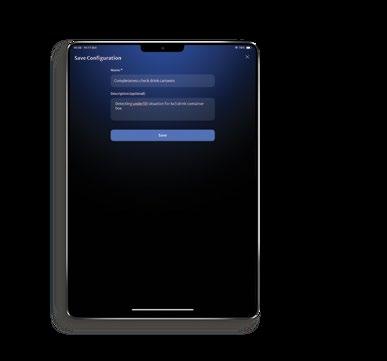

• User Configuration Library — Save, manage, and reload saved configurations

Designed for simplicity, the Contrinex Smart Camera 3D lets anyone master and fine-tune vision applications autonomously, without relying on a specialist.

The Smart Vision App provides a library of preconfigured use cases predefined sequences of image-processing algorithms tailored

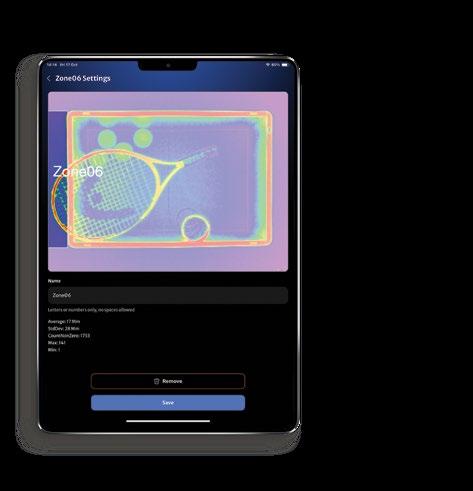

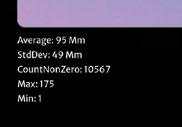

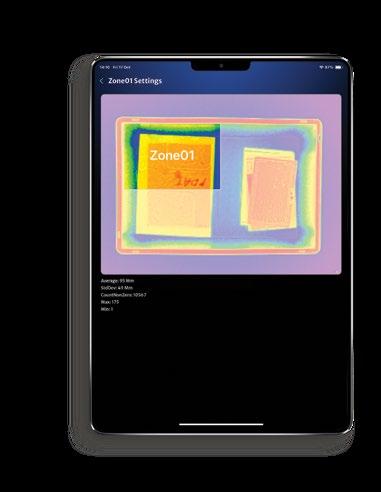

The camera provides accurate distance measurement in millimetres for multiple user-defined zones. Using the intuitive wizard of our Smart Vision App, users draw their zones on the screen and set the parameters for the measurement. The camera will measure the distance for each zone, enabling reliable positioning, clearance checks, and level control.

to standard industrial tasks. Each use case is set up through an intuitive no-code wizard, allowing easy object teaching and individual

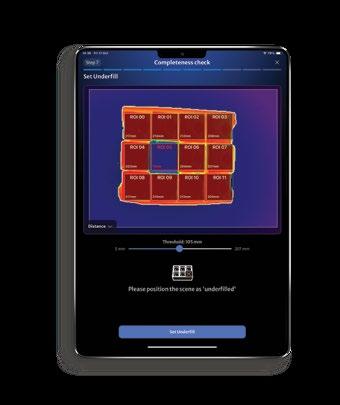

The camera verifies underfills or overfills of packaging. The Smart Vision App wizard lets users draw inspection zones and set different filling criterions. The camera ensures that each zone is filled correctly for reliable quality control.

parameter adjustment to achieve optimal performance in real-world conditions.

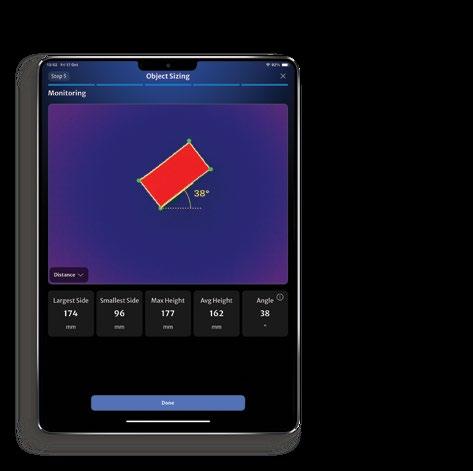

The camera provides full measurement of objects in millimetres, including length, width, height, and orientation — for dependable size control and sorting of objects. Measurement options can be configured in the Smart Vision App.

In logistics warehouses, it is essential to ensure that boxes are properly filled, with items correctly positioned, no protrusions, and the proper fill level. This allows boxes to be safely stacked on warehouse shelves without risk of damage or instability.

The Smart Vision App includes a ready-to-use algorithm for obtaining distance measurements across multiple user-defined zones, making setup fast and effortless. Its intuitive no-code wizard allows users to draw inspection zones directly on the screen and configure measurement parameters with ease. In the first image, the tennis racket is seen protruding from the cardboard box, indicating a potential stacking issue. In the second image, all items are correctly positioned inside the box, confirming it can be safely stacked in the warehouse.

• Ensures safe stacking by verifying item positioning, clearance, and fill levels

• Prevents product damage by detecting protrusions or overfilled boxes

• Improves warehouse efficiency with real-time inspection and level control

• Quick, no-code configuration via Smart Vision App no coding experts required

The Smart Camera enables reliable positioning, clearance checks, and level control in real time, supporting efficient stacking, safe storage, and smooth warehouse operations.

• Reduces labor costs by eliminating manual checks

• Supports consistent, reliable operations in high-volume logistics workflows

• Seamless plug-and-play integration with onboard image processing

When filling crates with bottles, it is essential that each compartment contains exactly one correctly positioned bottle. Missing bottles or overfilled crates, can disrupt automated handling, reduce packing efficiency and lead to costly shipping returns.

The Smart Camera 3D from Contrinex, using Time-of-Flight technology, ensures reliable quality control by performing two critical checks. First, it detects overfill situations where a bottle is placed on top of the first layer, protruding from the crate. Second, it identifies underfill conditions where one or more bottles are missing. With onboard image processing, the Smart Camera requires no coding for configuration and can be quickly set up using a dedicated iOS, Android, or Windows companion app delivering an easy-to-use, plug-and-play solution for packaging inspection. Complete Overfill Underfill (Bottles missing)

The Smart Vision App comes with a ready-to-use algorithm for performing completeness checks, making setup fast and effortless. Its intuitive nocode wizard allows users to teach objects, draw inspection zones, and define different filling criteria in just a few steps. During configuration, real-time images of the crate clearly indicate whether there is an overfill or underfill situation. For example, the first image shows an overfill with a bottle placed on top, the second highlights three missing bottles, and the third confirms a correctly filled crate ready for dispatch.

• Eliminates costly shipping returns by detecting missing or misplaced bottles

• Ensures packaging quality with real-time overfill and underfill detection

• Prevents downtime and product damage by avoiding crate handling issues

Complete Overfill Underfill (Bottles missing)

• Quick, no-code configuration via iOS / Android / Windows app no specialist staff required

• Reduces labor costs by eliminating the need for manual inspection

• Seamless plug-and-play integration with onboard image processing

Accurate package measurement is essential when handling items of different sizes. Knowing each object’s length, width, height, and angle relative to the horizon allows Knowing each object’s length, width, height and angle relative to the horizon allows object sorting for correct conveying.

Small Cardboard box

The Smart Vision App includes a ready-to-use algorithm for object sizing, making setup fast and easy. Its intuitive no-code wizard lets users configure measurement options in just a few steps. During configuration, real-time images display objects with full dimensional measurements in millimeters. Here, the first image shows a small cardboard box with its corresponding measurements, while the second image shows a larger box. The angle values clearly indicate that the boxes are positioned differently on the conveyor, providing precise orientation data for accurate handling.

• Provides accurate package measurements for correct handling

• Improves sorting efficiency with real-time dimensional data

• Quick, no-code configuration via Smart Vision App no coding experts required

The Smart Camera 3D using Time of Flight technology delivers fast and precise dimensional data, ensuring efficient, error-free sorting and handling.

Large Cardboard box

• Versatile for different package sizes and shapes in dynamic production lines

• Seamless plug-and-play integration with onboard image processing

CAM-3TIQC-C99S-SN-A

CAM-3TIQC-C99S-SF-A

Part Reference

CAM-3TIQC-C99S-SN-A

Wireless Connection Yes

Connector 1

CAM-3TIQC-C99S-SF-A

Male M12 – 5 PIN: Power supply PNP / NPN 1.1.4

Connector 2 N/A

Operating Voltage 18… 30 VDC

Female M12 4 Pin D-coded Fast-Ethernet

Dimensions 92 x 92 x 68 mm

Mounting 8 x M4 x 5/6 holes (4 x on each opposite side)

Housing Materials Aluminum, PMMA, PC, PA IP Rating IP65, IP67

Operating Temperature 0 ..+ 50°C

All listed values are indicative and may be subject to change

With eight M4 mounting threads (four on each opposite side), the camera can be mounted easily with mounting plates or directly to any custom mounting fixture.

• Companies around the world trust us to solve their sensor problems

• Like our sensors, our engineering teams thrive on your toughest challenges

• You can rely on leading-edge Swiss technology, certified to international standards

• Our connected Smart Sensors are IIoT-capable and ready for your transition to Industry 4.0

• Our products withstand extremes of environment, weather and contamination

EUROPE

Austria

Belgium

Croatia

Czech Republic

Denmark

Estonia

Finland France Germany*

Great Britain

Greece

Hungary

Ireland

*Contrinex subsidiary

Italy

Luxembourg

Netherlands

Norway

Poland

Portugal*

Romania

Slovakia

Slovenia

Spain

Sweden

Switzerland* Türkiye

General Terms and Conditions of Sales apply, please see www.contrinex.com/download

Terms of delivery and right to change design reserved.

HEADQUARTERS

CONTRINEX SA Industrial Electronics

Route du Pâqui 3 – PO Box

CH 1720 Corminboeuf – Switzerland

Tel: +41 26 460 46 46 – Fax: +41 26 460 46 40

ASIA

China*

India*

Indonesia

Japan*

Korea

Philippines

Singapore

Sri Lanka*

Taiwan

Thailand

• Global sales network covering 60+ countries

• International customer services

• Solution-oriented application support

• 3 production sites for worldwide availability

• 3 logistics hubs for rapid delivery

THE AMERICAS

Argentina

Brazil*

Canada

Chile

Mexico*

Peru

United States*

MIDDLE EAST

Israel

United Arab Emirates

AFRICA

Tunisia

Morocco

South Africa

AUSTRALIA

Australia

Internet: www.contrinex.com – E-mail: info@contrinex.com

www.contrinex.com

We made these pages with care, but we decline liability for any errors or omissions. © CONTRINEX SA 2025