The construction team is using an array

By Chuck MacDonald CEG CORRESPONDENT

With the nation’s 250th birthday just a year away, Philadelphia is busy preparing to commemorate that event. The city had a foundation-

al role in those history-making events and the celebrations promise to be memorable.

The city is working with the Pennsylvania Department of Transportation (PennDOT) and other entities to create an unusual park that could play a role in the festivities. Although it will not

By Lucy Perry CEG CORRESPONDENT

be completed by America’s Sesquicentennial Celebration, the 11.5-acre park should bring a lot of pleasure to locals and visitors hoping to maximize their visits to this historic city. The job is expected to be completed in early 2029.

see CAP page 28

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

DUE TO BRIDGE PROJECTS

PennDOT and Bridging Pennsylvania Constructors said the closure of Jenks Street in the town of Brookville will be extended through the summer of 2026 to allow for the partial demolition of the Interstate 80 bridges.

A state and federal project that installed high-tech monitors on a Huntington, W.Va., bridge could be rolled out to other West Virginia bridges to identify tural issues before they become safety hazards.

14 CGA LAUNCHES NEW PSA ABOUT DAMAGE PREVENTION FOR 8/11

Common Ground Alliance (CGA), the national association working to prevent damage to underground infrastructure, released a new radio PSA to highlight the importance of contacting 811 before beginning digging projects.

18 KEY BRIDGE DEMOLITION CONTINUES; OFFICIALS PREPARE TO BUILD NEW SPAN

Demolition of the remaining structures that were once part of the collapsed Francis Scott Key Bridge in Baltimore is in full swing as transportation officials prepare to lay the foundation for a new, taller replacement.

State Transportation Secretary Stephen Todd Rumbaugh presented the West Virginia University Institute of Technology with a $10,000 check for the university’s Beckley campus.

A project to rebuild a street bridge between the northern Virginia cities of Arlington and Alexandria will start in mid-August 2025, bringing approximately two years of construction impacts, Patch Media noted July 30.

24

New York City’s plans for a direct train link from Brooklyn to Queens, known as the Interborough Express (IBX), took a big step toward being realized July 30 when the MTA announced a board-approved design contract.

Granite announced that it has completed two acquisitions that strengthen its vertically-integrated home markets for a combined purchase price of $710 million, subject to customary closing adjustments.

Earlier this year, the Iowa Department of Transportation (Iowa DOT) purchased the state’s first self-contained pothole filling truck — a more efficient and safer option for fixing potholes on state roadways.

66

ENHANCING SECURITY

Recent reporting indicates that instances of equipment theft are on the rise — creating new challenges on job sites and driving up costs for operators, contractors and business owners.

70 WILMINGTON

Delaware’s Wilmington Airport is currently undergoing a $9.8 million expansion to attract a third Avelo Airlines plane and expand its commercial services. The airport began the work in September 2024.

76

Among its many projects, MacKay Construction, a heavy civil and utility contractor based in Wilmington, Mass., recently tackled a challenging electrical duct bank trenching project at Boston College.

PIRTEK USA’S CONTINUED GROWTH

The company announced the opening of nine new locations and the signing of 10 new units, further expanding its footprint to meet the rising demand for premium hydraulic and industrial hose services.

56 CONSTRUCTION EQUIPMENT GUIDE’S LIGHT TOWER CHARTS 56 DITCH WITCH JT21 DRILL SLASHES JOB TIMES WITH POWER, SPEED 58 SULLAIR CELEBRATES ITS 60TH ANNIVERSARY WITH PICNIC, DONATION

SIZE YOUR POWER: WHAT TO KNOW BEFORE CHOOSING GENERATORS

LEICA DS4000 REVEALS PREVIOUSLY UNDETECTABLE UTILITY ASSETS

to

N. Oxford (508) 987-8786

Billerica (978) 667-4345

Plymouth (508) 830-9997 (413) 543-5595

Swansea (508)379-9810

Hermon (207) 947-6786 Houlton (207) 532-6517

(207) 834-6701

(207) 773-3777

Still your Authorized Takeuchi Dealer for Nassau, Suffolk and the Five Boroughs of NewYork City. For all your Takeuchi Needs Parts/Service/Rentals Email us at Info@allislandequipment.com for your immediate parts / service needs 0% for 60 mo.

www.allislandequipment.com follow us on Instagram

The TB260 has exceptional power, performance, a wide working range, and impressive feature set. The cabin is spacious and well appointed, ensuring operator comfort and efficiency.

for 48 mo.

The TL10V2 features a vertical lift loader arrangement and is Final Tier 4 emissions compliant. The cab is completely redesigned and enlarged and features a low-effort overhead door design for improved entry and egress.

The Pennsylvania Department of Transportation (PennDOT) and Bridging Pennsylvania Constructors (BPC) said Aug. 12, 2025, that the closure of Jenks Street in the town of Brookville will be extended through the summer of 2026 to allow for the partial demolition of the Interstate 80 bridges that pass over the roadway.

The project is in support of the larger I-80 North Fork Bridge Project, a $328 million effort to upgrade the freeway and its structures in Jefferson County, northeast of Pittsburgh.

BPC’s subcontractor, Pittsburgh-based Fay, had closed Jenks Street/Pa. Highway 4003 in September of 2024 to allow for partial demolition of the I-80 bridges over the roadway.

The shutdown was originally anticipated to end on Dec. 31; however, due to project scheduling needs, the closure will now remain in effect through the summer of 2026, PennDOT noted. Once a specific date is scheduled to reopen the road, additional information will be released.

Work also is under way in Pine Creek to replace the Richardsville Road/Pa. 4005 bridges over the interstate highway, as well as the extension of the North Fork Park Culvert, which carries I-80 traffic across the tributary to North Fork Redbank Creek.

In PennDOT’s most recent update on the project, it noted that Richardsville Road, which was shuttered in January 2025, will remain so until March 2028. During that time, crews will fully remove and reconstruct the roadway’s bridge over the freeway.

The entire construction effort is part of the PennDOT Major Bridges P3 Program.

Bridging Pennsylvania Developers — I, or BPD-I, is led jointly by Shikun & Binui Ltd. and Macquarie Capital as the lead project developers and equity members.

The BPC joint venture consortium includes the design and construction expertise of S&B USA Construction in Pittsburgh, and FCC Construction. S&B USA serves as the construction arm of Shikun & Binui and also is the parent company of Fay.

Other major bridge subcontractors on the I-80 North Fork Bridge Project include H&K Group in Skippack, Pa.; Wagman Heavy Civil in York, Pa.; Kokosing Construction Co.; and the lead designer, Michael Baker International — both of which are located in Pittsburgh.

The $328 million I-80 North Fork Bridge Project first got under way in June of 2024 with a projected completion set for the summer of 2028, according to the state transportation agency.

The interstate bridges are dual structures (one eastbound and one

westbound) originally built in 1962 and most recently rehabilitated in 2013. They support freeway traffic over North Fork Redbank Creek and Water Plant Road within a deep gorge in the Jefferson County communities of Brookville

and Pine Creek.

The existing bridges are separated by approximately 1,100 ft., with the Walter Dick Memorial Park located between and below the two structures.

Combined, the twin bridges are expected to carry approximately 30,900 vehicles daily — 44 percent of which is truck traffic.

PennDOT and its construction partners are aiming to provide safe, efficient and effective crossings of I-80 over the creek and Water Plant Road that appropriately accommodates interstate traffic with respect to connectivity, mobility, loading and geometry, according to an online description on the agency’s website.

The main spans of the existing bridges are steel two-girder systems with floor beams and stringers. In addition, the structures are fracture-critical since many of their components are nonredundant.

Both spans also have problematic fatigue details which have received multiple retrofits during their service lives, PennDOT noted. The department added that the eastbound bridge is in poor shape, while the westbound span is in fair condition. Inspections are required on a six-month and one-year basis, respectively.

As a result of their multiple issues, both bridges are nearing the end of their serviceable lifespans.

This particular section of I-80 has a posted speed limit of 70 mph but does not have the proper horizontal and vertical geometry to meet the 70 mph design criteria, according to PennDOT. Many vehicle crashes — nearly twice the statewide average — have occurred on this segment of I-80 due to a substandard curve on the western approach to the eastbound bridge.

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

New Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

A state and federal project that installed hightech monitors on a Huntington, W.Va., bridge could be rolled out to other West Virginia bridges to identify structural issues before they become safety hazards.

Gov. Patrick Morrisey and state Department of Transportation (WVDOT) Cabinet Secretary Stephen Todd Rumbaugh joined Shaz Umer, the director of strategic initiatives for the U.S. Department of Transportation (USDOT), for an event Aug. 7, 2025, to celebrate the initial phase of a project to install sophisticated Structural Health Monitoring (SHM) equipment on the Frank Gatski Memorial Bridge over the Ohio River.

The $812,000 project, started by WVDOT in 2024, is being funded through USDOT’s Strengthening Mobility and Revolutionizing Transportation (SMART) Grant Program. The funds will go toward the deployment of advanced structural health monitoring technology that uses sensors and data-driven tools to enable real-time tracking of bridge conditions.

system made possible by the federal SMART grant program.

demonstration projects that use technology to improve road and bridge efficiency and safety.

Common Ground Alliance (CGA), the national association working to prevent damage to underground infrastructure, released a new radio PSA to highlight the importance of contacting 811 before beginning digging projects.

The SHM system includes accelerometers, crack meters, tilt sensors and vessel collision detectors, according to a news release from Morrissey’s office. These tools provide continuous data that allows engineers to quickly address threats that could go undetected for months or even years.

According to officials, the system helps maintenance workers shift from reactive repairs to proactive monitoring. It is designed to enhance safety, improve efficiency, save tax dollars and establish the state as a leader in infrastructure innovation.

West Virginia is the first state in the country to use the Stage One SMART Grant specifically for this type of advanced bridge monitoring.

“Through the … SMART grant program, we’re bringing the future of infrastructure management right here to West Virginia,” Rumbaugh said. “What does that mean for our state? It means we can detect problems early before they become an emergency. It means we can prioritize our resources, making smart and more cost-effective repairs. And most importantly, it means safer roads, stronger connections and peace of mind for every West Virginian who travels across one of our bridges.”

In his remarks, Umer added, “This isn’t just about upkeep. It’s about pushing the boundaries of what’s possible in infrastructure care.

“The technology installed in this bridge includes vibration sensors, tiltmeters, crack meters, displacement sensors, a weather station and a vessel collision detection system. These advanced technological sensors provide critical data on the bridge’s structural performance, enabling West Virginia’s Department of Transportation to prioritize repairs and make decisions more effectively. The system’s real-time data collection is a game changer.”

The SMART Grant program was created by the 2021 Infrastructure Investment and Jobs Act with $100 million in annual appropriations through federal fiscal year 2026. The grant is designed to provide funding for transportation

The program’s funding is divided among two stages, the Parkersburg, W.Va., news source reported Aug. 8.

The Huntington bridge was one of 127 first stage projects approved so far. Stage One projects also are eligible to apply for Stage Two grants, which could award up to $15 million and 36 months of additional funding.

“This project is a prime example of innovation and safety meeting critical infrastructure,” said Umer. “Every day, we’re dedicated to finding innovative ways to help people and goods move around safely and save taxpayer dollars in maintaining the infrastructure to do so. Today, we celebrate a significant advancement in that mission.”

The project is a partnership between the West Virginia DOT, HMTV and Marshall University.

Morrisey thanked U.S. DOT Secretary Sean Duffy and President Donald Trump for their support for the project.

According to the American Road and Transportation Builders Association, among West Virginia’s total of 7,348 bridges, 3,489 need repairs and of those, 1,370 bridges, or 18.6 percent, were classified as being deficient.

In June, Morrisey announced a series of WVDOT reforms that included a directive ordering the agency to create a new project list to assess the need for repair and replacement of bridges and highways statewide. It also should prioritize the order in which those projects are to be completed.

In addition, the governor asked the state transportation department to work with federal counterparts and local counties to leverage additional resources for existing road and bridge maintenance and make better use of data to create a long-term plan to prioritize maintenance and make betterinformed financial decisions.

Morrisey pointed to the state’s use of a SHM system on the Gatski Bridge as a good example of what he wants to do across the state, according to the News and Sentinel.

“This is just an incredible opportunity, and it fits in very well with our long-term strategy in terms of how we’re trying to build up our infrastructure,” he said. “We’re rolling up our sleeves, and we’re getting to work and we’re laying out our plan. We need to be patching potholes and fixing the bridges, and that’s got to be a big priority. That’s why today’s announcement is so terrific.”

Nearly 200,000 times each year, buried power, water, internet, natural gas and other utility lines are damaged by digging, costing the United States $30 billion annually.

The 30-second spot entitled “Problem” features a homeowner and contractor discussing the construction of a new deck, the contractor’s failure to contact 811 beforehand and the sound of a struck utility line. CGA President and CEO Sarah K. Magruder Lyle reminds listeners what’s at stake — communities, property and lives — and encourages listeners to visit 811beforeyoudig.com to find their state 811 one-call center.

The PSA will be distributed to radio stations nationwide beginning today, and also will be available on streaming services including Spotify, Apple Music, YouTube Music, Pandora and others. The spot was specifically released today, Aug. 11, to mark National 8/11 Day — the national awareness campaign day that reminds Americans to contact 811 before digging.

“Nearly 200,000 times each year, the buried utilities upon which all Americans rely are damaged through digging by homeowners, contractors and others,” said Sarah K. Magruder Lyle, CGA president and CEO. “This year, we’re taking to the airwaves to remind everyone that contacting 811 before digging is free, easy and in many places, it’s the law. On 8/11 Day and every day, those three simple numbers can help prevent utility outages, community disruptions, injuries and worse. Whether major construction or a small DIY backyard project, it takes just moments to contact 811. Doing so may save lives — including your own.”

For more information, visit 811beforeyoudig.com.

MANASSAS, VA

6918 Wellington Rd. Manassas, VA 20109 703/257-2381

JESSUP, MD

10421 Guilford Road, Jessup, MD 20794 410/792-9134 from Washington D.C. 301/725-7394

DELMAR, DE

38420 Sussex Highway Delmar, DE 19940 302/846-3033 HARRISBURG, PA 6680 Allentown Blvd., Harrisburg, PA 17112 717/652-5430

OF PRUSSIA, PA 450 E. Church Road, King of Prussia, PA 19406 610/279-5200 (1)

Demolition of the remaining structures that were once part of the collapsed Francis Scott Key Bridge in Baltimore is in full swing as transportation officials prepare to lay the foundation for a new, taller replacement.

Gov. Wes Moore led a delegation of federal, state and local officials on a tour of the bridge site July 30, 2025, as workers stripped slabs of decking from the steel skeleton.

Afterwards, Moore told reporters that the speed of the demolition work has been impressive and compared its progress to that of the building of Detroit’s Gordie Howe International Bridge, which he said, “took years just to get the permitting done.”

Initial estimates place the cost of the bridge reconstruction at about $2 billion, although its price tag has not yet been finalized.

“This is a team that has now gotten the permitting done in a matter of months,” he said. “That’s been able to really keep us on track to deliver something that’s going to be powerful, and a true project that the people of the state can be proud of.”

In March 2024, the Dali, a 948-ft. container ship, collided with a support structure on the 47-year-old bridge over the Patapsco River as it was leaving Baltimore’s harbor, causing the span’s center section to collapse. Six people on a road crew working on the bridge died as a result of the accident.

Demolition crews are now methodically peeling away the decking from what remains of the bridge. Each slab weighs between five and seven tons. Onlookers at the site on July 30 could feel the remaining structure shake as heavy equipment moved large chunks of the decking, according to Maryland Matters.

State officials said that bringing the bridge down piece by piece rather than using controlled demolition is environmentally sound and eliminates the need to remove debris from the river channel. The process to clear the road surface from the steel structure is expected to take nine months.

The demolition, including removing the steel structure itself, will continue throughout 2025, the online news site noted. Initial work is set to begin on the new bridge in late 2025, possibly as early as September.

Maryland state transportation executives have noted that the new span will be 230 ft. above the water line — about 45 ft. higher than the original bridge. The new alignment will run parallel to the old structure but will be approximately 260 ft. to the east.

Brian Wolfe, the director of project management at the Maryland Transportation Authority (MDTA), told Maryland Matters that re-siting the new bridge was necessary to avoid debris and a riverbed he described as “almost like soup.”

“It’s upwards of 60 to 70 feet of very loose material [on top of] a hard layer that we can actually put our foundations into,” he said. “There was also some debris on the far side, by the north end, that we thought we could miss as we were starting the original design. But as we progressed, we realized that it was going to be in conflict, which was going to potentially [cause] a delay in the project.”

By shifting or moving the bridge alignment to the current location, he said, the designers were able to avoid that potential conflict.

The new span will be more than 400 ft. longer than the original bridge, with a length of 1,665 ft. between the two piers over the Patapsco River shipping channel.

The initial phase of the new Key Bridge construction includes a series of test piles, or 2-in.-thick steel rolled into cylinders 8 ft. in diameter.

According to Wolfe, they will be driven into the riverbed and tested with millions of lbs. of force “in order to verify the foundation design our engineers are currently working on. Once we verify that it can carry the loads that we anticipate, that confirms the design and lets us finalize the details, lets us move ahead with procuring more materials, progressing the design and getting into construction.”

Plans for the four-lane highway bridge project also include inside and outside shoulders in each direction, something the original Key Bridge did not have, according to Maryland Matters.

Initial estimates place the cost of the bridge reconstruction at about $2 billion, although its price tag has not yet been finalized.

“We’re discovering a lot of things as we go along,” Bruce Gartner, MDTA executive director, told reporters at the demolition site. “Later this year, we hope to be out with more information, but we really want to get farther along before we do that update [so we] know exactly where we stand with cost and schedule.”

He noted that among the factors being examined are how inflation, supply chain issues and tariffs could affect the final project costs.

Hours after the bridge collapsed last year, then-President Joe Biden promised full federal funding for a replacement span.

Today, however, concerns persist that the federal government might renege on the earlier agreement.

President Donald Trump continues to follow through on campaign promises to reduce federal spending. Included in that effort are cuts in aid to state and local governments. He also has shown a willingness to disregard funding earmarked by federal lawmakers and to take those battles to court.

Despite that, Maryland U.S. Sen. Chris Van Hollen has expressed confidence in the federal reimbursement.

“The federal funds are secure,” he said. “We put the funds earmarked essentially in what’s called the Emergency Relief Fund, and we increased [it] to $8 billion, so those funds are set in stone.”

Transportation Secretary Todd Rumbaugh presented the check to Civil Engineering Professor Steven Leftwich, an instructor of Tech for the past 38 years.

State Transportation Secretary Stephen Todd Rumbaugh presented the West Virginia University Institute of Technology with a $10,000 check for the university’s Beckley campus.

In October 2024, the West Virginia Department of Transportation (WVDOT) won the 2024 America’s Transportation Awards People’s Choice Award for the Wellsburg Bridge project. Sponsored by the American Association of State Highway and Transportation Officials (AASHTO), AAA and the U.S. Chamber of Commerce, the America’s Transportation Awards recognizes the positive impacts of state department of transportation projects have on communities across the nation.

West Virginia was one of 12 finalists in the national competition of the America’s Transportation Award. The People’s Choice Award was determined by public vote, and carried a $10,000 prize to be donated to a charity of the winning state’s choice.

Then-Transportation Secretary Jimmy Wriston, an alumnus of Tech’s engineering school, decided that the $10,000 should go to Tech’s Beckley campus to be used for a scholarship fund at his alma mater.

Current Transportation Secretary Rumbaugh, also a Tech engineering alumnus, recently presented the check to Civil Engineering Professor Steven Leftwich, an instructor of Tech for the past 38 years.

“A lot of students can’t afford to go to college,” Leftwich said. “I wasn’t able to get all my degrees without scholarships.

“This is really going to help our students,” he said. “We need more scholarships like this.”

Rumbaugh said he was proud to be able to present the check to help train a new crop of engineers.

“They’re our future,” he said.

The Wellsburg Bridge, which connects the communities of Wellsburg, W.Va., and Brilliant, Ohio, opened in September 2023 to a fanfare of marching bands, confetti and fireworks, completing a project that residents of the two communities had been pursuing for a century. An estimated 2,500 people turned out for the bridge grand opening.

A project to rebuild a street bridge between the northern Virginia cities of Arlington and Alexandria will start in midAugust 2025, bringing approximately two years of construction impacts, Patch Media noted July 30.

Arlington County is leading the effort to reconstruct the Arlington Ridge Road/Mount Vernon Avenue Bridge over Four Mile Run, which is actually a more than 9-mi.-long creek that empties into the nearby Potomac River just south of Reagan National Airport.

Both localities cite the poor condition of the bridge, located within the lower 2 mi. of the stream, and which already has its west sidewalk closed due to structural deficiencies.

Preparations for the bridge’s upgrade are slated to begin during the first week of August on the Alexandria side of Four Mile Run.

The two cities, across the Potomac from Washington, D.C, are splitting the costs of the $23.8 million project. Its construction is expected to be completed in the summer of 2027.

Patch Media reported that the work will involve upgrading both the crumbling road and the underlying bridge deck.

Due to the condition of the current structure, Arlington County and the city of Alexandria are working as partners to fasttrack the design and construction of the replacement bridge.

Responding to citizen concerns for connectivity between the two towns and the impact to residents living in proximity, the Arlington Ridge Road/Mount Vernon Avenue Bridge will continue to operate during construction, but with reduced lane capacity.

Work will happen on one side of the street bridge at a time, meaning that the other side

will remain open to traffic in both directions. A sidewalk also will be available for people walking or biking throughout the duration of the bridge’s reconstruction, Alexandria municipal officials noted.

The initial phase of the rebuilding effort is likely to last for a year, with a single lane of traffic in each direction staying open while the southbound lanes are being improved. However, weekend parking along Mount Vernon Avenue will not be available at any time during the reconstruction.

The Alexandria city government said on its website that it will maintain proper erosion and sediment controls along Four Mile Run, which will include tree fencing.

The goals for the street/bridge improvements include:

• returning the structure to a safe operational condition for all users;

• improving access for people walking, biking and driving; and

• advancing the community vision of the Four Mile Run Master Plan, which looks to reinvigorate the stream, its trails and the floodplain to a more enjoyable state for residents and visitors alike.

Earlier, in 2022 and 2023, Alexandria and Arlington collaborated on a project to repair the West Glebe Road Bridge, another deteriorating bridge over the creek that links the two vibrant communities.

A local artist, Vicki Scuri, also is incorporating art elements into the design of the Arlington Ridge Road/Mount Vernon Avenue Bridge that takes inspiration from the natural beauty of Four Mile Run.

Once complete, that bridge and the West Glebe Road Bridge, located just a mile upstream, will be seen as a pair. The Arlington Ridge Road/Mount Vernon

Bridge

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER....................................................$32,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT....$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

EXCAVATORS:

SKID STEER LOADERS:

$105,000

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD CPLR, 78” BKT, BACKUP CAMERA....SOLD

$149,995

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS..................................SOLD

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER SOLD

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS $45,000

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES........................$42,000

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..............

$169,995

MISCELLANEOUS:

$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

SCREENERS:

2021 VIBROSCREEN SCM40

$79,995

2021 VIBROSCREEN SCM27 $62,995 NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................$195,000 NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........ $179,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED

$295,000

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD

THUMB, RUBBER TRACKS, 4 TON........................................SOLD

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS SOLD

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION..........................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER..................................................................................$39,995

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995 HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED..................................................................................$3000

KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR

$3,199

REVERSE LUG GRADING BUCKET, FITS KUBOTA

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

New York City’s plans for a direct train link from Brooklyn to Queens, known as the Interborough Express (IBX), took a big step toward being realized July 30 when the Metropolitan Transportation Authority (MTA) announced a board-approved design contract.

The board voted at its monthly meeting to approve the full design of the proposed rail line, which will connect Queens commuters to the Brooklyn waterfront in Bay Ridge, all while bypassing Manhattan. Members okayed a nearly $166 million design contract with a joint venture made up of Jacobs Engineering and HDR.

In total, the construction is expected to cost $5.5 billion, amNY reported.

The design contract will include a “comprehensive scope of work,” where engineers will conduct surveys, geotechnical and environmental investigations and structure inspections, among other tasks, to advance the design.

MTA officials said that engineers also will assist in third-party negotiations and public outreach.

“The joint venture was selected because of its strong leadership team, thoughtful management approach, its comprehensive

understanding of corridor constraints and its extensive experience performing the work of comparable magnitude and complexity,” said Charles Gantz, IBX project executive.

The Interborough Express is seen by the MTA, along with many other state and local officials, as being a transformative rapid transit project that will connect currently underserved areas of Brooklyn and Queens.

When operational, the IBX “will substantially cut down on travel times between the two boroughs, reduce congestion and expand economic opportunities for the people who live and work in the surrounding neighborhoods,” according to the transportation agency.

Plans for the IBX include turning existing infrastructure — notably a freight rail line that carries one to two trains a day — into a light-rail line that will serve approximately 200,000 passengers.

The project would be built along the existing Long Island Rail Road (LIRR)-owned Bay Ridge Branch and the CSX-owned Fremont Secondary, a freight line that extends from Bay Ridge in Brooklyn, to

Jackson Heights in Queens.

Using the existing rail infrastructure means the IBX could be built more quickly and efficiently, according to MTA. It also would preserve the Bay Ridge Branch’s use as a freight line, providing an opportunity to connect to the Port Authority of New York and New Jersey’s Cross-Harbor Freight project.

After it is completed, the IBX rail line will start at Roosevelt Avenue in Queens and feature 19 stops along the corridor before reaching the Brooklyn Army Terminal in Bay Ridge.

Its route will bypass Manhattan, but carry commuter trains through several neighborhoods, including Jackson Heights, Maspeth, Ridgewood, Midwood, East Flatbush, East New York and Brownsville — just to name a few — before the final stop at the army terminal.

Close to 900,000 people living along the route would have access to the new transit option, along with another 260,000 who work in Brooklyn and Queens.

The entire 14-mi. route would likely take about 40 minutes and connect to 17 subway lines, including the LIRR, adding more travel alternatives for New Yorkers who live in

transportation deserts with minimal train availability.

Daily weekday ridership projections by the MTA are estimated at 115,000.

Janno Lieber, who serves as the MTA’s chair and president, told amNY that the IBX will offer a “complete change of mobility and access for so many people.”

“This is a huge deal. The IBX is going to change people’s lives and folks are understandably psyched about it,” she said.

New York Gov. Kathy Hochul has championed the IBX project for the state-run MTA since she took office in 2021.

“She has been pushing it forward every step of the way and making sure we had the resources to advance it,” said Lieber.

In early 2022, Hochul directed the MTA to begin the environmental review process for the new rail line.

A year later, after extensive planning, analysis and public engagement, light rail was chosen because it promised to provide the optimal service for riders at the best value.

The IBX project will be funded through investments made for expansion within the MTA’s approved $68.4 billion 2025-2029 capital plan.

Granite announced that it has completed two acquisitions that strengthen its vertically-integrated home markets for a combined purchase price of $710 million, subject to customary closing adjustments.

Together, the acquisitions are expected to contribute approximately $425 million in revenue annually with an expected adjusted EBITDA margin of approximately 18 percent. This implies a blended multiple of approximately 9.2x expected adjusted EBITDA.

“We are excited to welcome Warren Paving and Papich Construction,” said Kyle Larkin, Granite president and chief executive officer. “Their management teams have strong track records of success, and we look forward to combining our businesses. These acquisitions mark another significant step forward as we continue to grow our industry–leading, vertically-integrated business. With our strong cash generation and robust acquisition pipeline, I expect to continue to grow our home markets through bolt-on transactions and expansion into new markets.”

“We are excited to welcome Warren Paving and Papich Construction.”

Kyle Larkin Granite

Warren Paving is a aggregates producer with vertically-integrated operations in the Mississippi River and Gulf Coast regions, operating a network of strategically located assets, including one quarry, one sand and gravel operation, 11 aggregate yards, three asphalt plants and a fleet of 168 owned and leased barges. This acquisition adds more than 400 million tons of aggregate reserves and resources and is a transformative opportunity to own and operate one of the largest and most attractive quarry and distribution networks in the Southeast, according to Granite.

Warren Paving’s assets are highly complementary to Granite’s

southeastern platform’s plant networks across Mississippi and is expected to generate annual revenue and adjusted EBITDA of approximately $275 million and $52 million, respectively, representing an expected adjusted EBITDA margin of approximately 19 percent, according to Granite.

Papich Construction specializes in infrastructure projects, including road, rail and highway construction and supplies both internal projects and third-party customers with a full suite of asphalt and aggregates products, including sand, gravel and crushed rock. The acquisition includes a gravel mine,

two quarries and two asphalt plants.

Strengthens vertical integration with enhanced scale: The acquisitions strengthen Granite’s vertical integration in both the California and Southeast markets. The barge network in the Southeast presents significant opportunities to supply additional locations as we continue to expand and work to increase volumes.

Increases exposure to aggregates: These acquisitions increase Granite’s aggregates reserves and resources by approximately 30 percent and annual aggregate production by approximately 5 million tons, or 27 percent.

Enhances financial profile: The acquisitions are expected to be immediately adjusted EBITDA margin accretive, with an estimated annual uplift of approximately 60 basis points driven by the increased aggregates exposure.

Capitalizes on strong financial position: The strength of our bal-

ance sheet and underlying operations, supplemented by the amended and restated credit facility position us to continue to invest in organic growth and strategic acquisitions.

The acquisitions were financed through a new 5-year $600 million term loan, $100 million of cash on hand and $10 million drawn on an upsized revolver of $600 million. Granite’s pro forma net leverage ratio1 for an annual period, inclusive of the acquisitions, is well below its target of 2.5x.

“These acquisitions are in line with our capital allocation strategy and reinforce our focus on driving sustainable, long-term value creation for our shareholders,” said Staci Woolsey, Granite executive vice president and chief financial officer. “Our cash generation and upsized credit facility allow us to continue to execute on high quality M&A transactions while maintaining a prudent leverage ratio.” For more information, visit graniteconstruction.com.

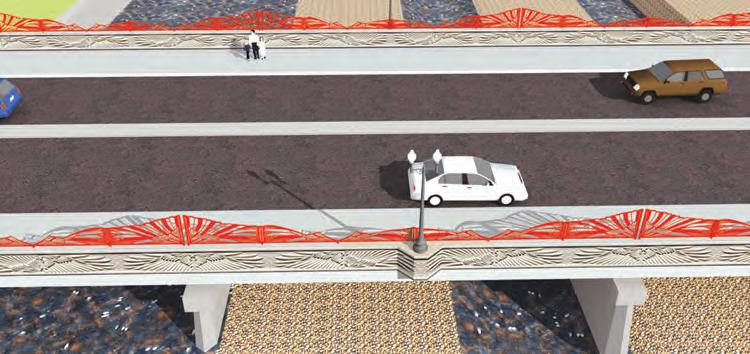

The aptly named Central Access Philadelphia (CAP) seeks to place a “cap” on top of busy roadways, including Interstate 95, at the eastern edge of the city. The CAP will be a concrete lid on top of the highways that will enable people to walk or bicycle from downtown’s historic areas to Penn’s Landing at the Philadelphia waterfront. There, people will be able to take in the waterfront views, enjoy restaurants, amusements and hotels. Meanwhile, the traffic will continue to flow unencumbered beneath the park.

Along the way, people will be able to pause at the greenspace on the cap to relax under some 100 trees, catch a concert or even go skating in the winter. Making this dream come true will require some big muscles and big plans. Buckley & Co. will be bringing it all together as the general contractor for the cap job. Chad Lavallee PE, project manager of Buckley, will be coordinating an army of subcontractors with an equally impressive army of equipment for the job. The price tag for the work is $340 million.

The lid of the cap will be comprised of an 8-in. slab of concrete, complete with troughs to hold the trees. Of course, a lid like this will require enormous support from steel beams and a sturdy steel web to connect the beams to the concrete lid.

Workers are setting the steel pilings and footers that will support the cap. The Buckley team is working with High Steel Fabricator from Lancaster, Pa., to produce the steel and Connell & Co to install the steel girders to support the CAP. Workers will be using 240 girders, most of them 130 ft. long. By mid-July, the team had the first set of 80 girders placed over I-95 southbound. Workers hope to have another set of 80 girders hoisted into position over northbound I-95 in the summer of 2026.

Lavallee describes the cranes used for this work as “huge.” Buckley has used a 250-ton Kobelco crane for the work, assisted by a 200-ton Kobelco. “We had to use stretch trailers to bring in the beams,” said Lavallee. “We are using 100-ton Manitowoc cranes to place the cross braces between the girders to stabilize everything.”

American Pile is playing a key role by driving caissons 6 ft. in diameter to provide the footings for the support. The cap plan calls for 26 of these caissons to be installed. The team will be using a Liebherr 45-ton for this work, including coring through concrete. American Pile also has been using a Junttan pile rig on site driving 24-in. pipe piles into the ground. “Our team will be drilling into the bedrock to make sure we have a solid foundation for the bridges to support the

cap. We have run into some obstructions while drilling for the caissons, but we will work through that.”

Lavallee and the construction team will be starting two retaining walls this summer. The team will be using 80,000 cu.-yds. of Ultra-Lightweight Foamed Glass Aggregates (UL-FGA). This material is made from 99 percent recycled container glass and is 85 percent lighter than traditional materials. It is produced by a local contractor, AeroAggregates.

Working in tight spaces with active roadways is challenging. Workers and equipment have been equal to the task.

“JPC Group has been doing a great job of rerouting sewers,” said Lavallee. “That part of the work is about 75 percent finished. We needed that room to build some of the Front Street abutments.”

While construction for the cap is happening, parallel work has proceeded in a nearby parking lot.

“People entering the park from the south side will use a pedestrian bridge to get to the cap. When the south side pedestrian bridge is finished, it will be rolled into place. The cable-stayed bridge will weigh about 1,000 tons but building it away from the highway is much safer,” said Lavallee. Cyclists and pedestrians must now carefully negotiate busy

The south side pedestrian bridge is being built in a separate area. The cable-stayed bridge will weigh about 1,000 tons and will be rolled into place when finished.

CAP from page 28

traffic to get to the recently completed Delaware River Trail along the waterfront. The team will be cooperating on another heavy lift — relocating massive memorial statues that had to be moved away for the construction project. The bronze Irish monument weighs six tons, while the granite Scottish memorial weighs about 30 tons.

When the support structures for the cap are complete, Buckley will be partnering with Daniel Keating Company and Delaware River and Bay Authority (DRBA) for the final build-out of the lid for the cap. The new park will be called the Park at Penn’s Landing and will link Philadelphia’s historic downtown and the scenic Delaware River.

(All photos courtesy of Buckley) CEG

A Montano Co., Inc.

www.amontanoco.com

571 Route 212 • Saugerties, NY 12477

845.247.0206

All Island Equipment www.allislandequipment.com 39 Jersey St. • West Babylon, NY 11704 631.643.2605

Butler Equipment

www.butlerequip.com

631 New Park Avenue West Hartford, CT 06110

860.233.5439

George & Swede Sales & Service www.georgeandswede.com

7155 Big Tree Rd. Pavilion (Buffalo/Rochester), NY 14525 585.584.3425

Lorusso Heavy Equipment, LLC

&

Loved for the features. Trusted for the performance.

MAKE YOUR MOVE

...to greater versatility, performance, comfort, and visibility

...to more standard features

Standard features include:

Do more without feeling like it in Hyundai’s easy to own, easy to operate, skid steer and compact track loader.

...to easier service

• LED front and rear work lights

• Auto leveling bucket

• Ride control

...to excellence in earthmoving equipment

• Review camera

• Two speed travel

• AM/FM bluetooth radio

...to HiMATE telematics, for greater operational intelligence

• Free Hi MATE telematics access for 5 years

At bauma 2025, Joseph Vögele AG presented the SUPER 1300-5e, the company’s first fully electric compact paver.

Its little brothers, the battery-powered MINI 500e and the MINI 502e pavers with an electrically heated screed, have now also joined the family of machines with zero operating emissions.

Whether it be official environmental standards, noise abatement regulations or sustainability goals, the demands for environmental compatibility and carbon neutrality on infrastructure projects are a constant growing challenge for construction companies. In view of this, electrified construction equipment plays an increasingly important role in the achievement of zero operating emissions in road construction.

Vögele has therefore expanded its range in the E-Power segment and is presenting not only the MINI 500e and MINI 502e mini class pavers at bauma 2025, but also is celebrating the first public appearance of the company’s new, fully electric, compact class paver, the SUPER 1300-5e.

All three models feature a battery-electric drive concept and an electrically heated extending screed. As low-noise machines with zero operating emissions, they are ideal for paving in urban settings, enclosed spaces, or in particularly sensitive areas, according to Vögele.

the SUPER 1300-5e is the first fully electric compact class paver from Vögele, and simultaneously the first electric paver of the Dash 5 generation.

In combination with the AB 340 extending screed, it has pave widths between 5.9 ft. and 13.7 ft., making it the ideal choice for small and medium scale road construction projects. The liquid-cooled lithium ion battery from Kreisel Electric has a storage capacity of 126 kWh and works with 400 V in the high-voltage range. Depending on the paving method, it provides sufficient power reserves for a full working day.

With its powerful battery, the SUPER 1300-5e achieves comparable drive power and paving performance to its conventionally powered counterparts in the compact class. As a Dash 5 paver, it offers an even higher level of operating comfort, automated functions and shorter set-up times than its Dash 3 predecessor, according to Vögele. The new technologies include the ErgoPlus 5 operating concept, new assistance and automatic control systems, additional comfort features and a new lighting system.

Vögele also is showing the MINI 500e and MINI 502e battery-electric mini class pavers. Both models are available

now, with a choice of two different battery options: The standard option has a storage capacity of 15 kWh and delivers sufficient power for a full working day. For longer operating times, Vögele offers an alternative, 22 kWh battery option that is good for up to two days of paving without recharging.

Both battery options work with 48 V in the low voltage range. In combination with the electrically heated AB 135 extending screed, the mini pavers offer pave widths from 10 in. to 5.9 ft., which enables construction companies to complete even the smallest paving jobs with a machine.

Both the electric mini class pavers and the SUPER 13005e can be charged quickly and easily: The mini pavers can be connected to a household socket or a wallbox. Depending on the battery version, the charging process takes around 5 to 7 hours.

The easiest way to charge the SUPER 1300-5e is by using a wallbox or a charging station. With a charging capacity of 22 kW, charging takes about five hours, while the use of a rapid charging station can shorten this to only one hour.

As the compact pavers use the same battery and drive technologies as all other compact e-machines from the Wirtgen Group, construction companies also enjoy the added value of synergy effects resulting from common charging procedures, maintenance and service and spare and wear parts.

For more information, visit wirtgen-group.com.

39 Jersey Street

West Babylon, NY 11704

631/643-2605

www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542 845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374 860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146 804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY 3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Opening This FallLancaster, PA 20 Stauffer Lane Ephrata, PA 800/325-6455 www.stephensonequipment.com

814-371-3600 McKean, PA 800-872-2390 Wilkes-Barre, PA 570-410-2123 Zelienople, PA 724-452-7800

Mike Skinner, director of pavement engineering of the Colorado Asphalt Pavement Association (CAPA), is taking the helm of the Asphalt Pavement Alliance (APA), effective May 27, 2025.

2019 Weiler P385B track paver, 8-16 ft electric heated vibratory screed, All new screed plates, 9 ton hopper, Cat dsl eng, steel tracks - $84,000

2018 Rosco Max 2B distributor, 1950 gallons, Max2B computer, 12 ft spray bar, propane burners, overnight heater, spray wand & hose, Freightliner w/Cummins dsl eng, auto trans, 800 miles$174,000

“It’s an honor to lead an organization built on such a strong foundation of technical excellence and collaborative industry leadership,” Skinner said. “My focus will be on bringing strategic vision and unified momentum while continuing to support the quality programs and initiatives that have made APA a trusted voice in our field. By building on that legacy, we can elevate APA’s impact and grow the value we deliver to stakeholders nationwide.”

2023 Volvo PT125C pneumatic roller, s/n 327364, 9 wheel rubber tire, Volvo D3.3H diesel engine, water system, canopy OROPS, tires 90%, 96 hrs - $65,000

2006 Etnyre Centennial distributor, 2000 gal, computerized w/New computer processor, 14 ft spray bar, propane burners, Ford F750XL w/Cat C7 dsl eng, 5 spd manual trans, 2 spd axle, 100,242 miles$69,000

New Marathon TPS500PT tack distributor, Briggs gas eng, 18GPM pump, 500 gal, spray wand w/50 ft hose, hose reel, hand wand recirculation plumbing, 6 ft spray bar, operator’s platform, propane burners, overnight heater, flushing system, dual material baffles - $34,550

New Marathon TPS250PT tack distributor, Briggs gas eng, 10GPM pump, 250 gal, spray wand w/50 ft hose, hose reel, propane burners, flushing system - $17,500

Founded more than 20 years ago, the APA is a partnership between the National Asphalt Pavement Association (NAPA), Asphalt Institute (AI) and SAPAs. The partners represent the asphalt pavement and binder industries in the United States, working together in the areas of asphalt pavement promotion and pavement type selection to ensure asphalt is the pavement of choice, foster market growth and safeguard the industry’s longevity.

NAPA staff manage APA’s strategy, programs and operations. As APA executive director, Skinner will report to NAPA President and CEO Audrey Copeland and oversee a team consisting of Buzz Powell, APA technical director, along with a to-behired APA deployment manager. Skinner will continue to reside in Colorado and Powell in Alabama while both travel extensively across the country to promote the benefits of asphalt pavements, partake in industry and agency events and collaborate with NAPA’s regional advisory councils.

Skinner has more than 30 years of experience in the industry. In his 10 years at CAPA, he grew local agency member engagement, local agency roadway funding and the region’s asphalt trade show. Prior to joining CAPA in 2015, he worked in the consulting engineering industry providing asphalt pavement and materials engineering for heavy highway civil infrastructure design, construction and asset management in the Western United States.

Skinner is a member of the Consortium for Asphalt Pavement Research & Innovation (CAPRI) and the Transportation Research Board’s AKP30 committee. He has long been involved with the APA, including advancing its

parking lot and private market programs.

As the new APA executive director, Skinner will bring together the collective minds and expertise of those in the pavement industry with a focus on advancing asphalt pavements for quality, sustainability and long life. This includes identifying and capitalizing on market opportunities for asphalt pavements including bringing research, development and technology to market (i.e., deployment) faster, along with being a trusted resource to pavement stakeholders and decision makers.

“Mike has been an active supporter of the APA for many years, serving as a speaker for educational programs, sharing technical expertise to educate and inspire members and stakeholders and serving on several APA Task Groups,” said Copeland. “His commitment to the industry, his experiences working with agencies in Colorado and with SAPA colleagues nationwide and his engineering expertise will drive the APA’s vision and maintain asphalt pavement’s market-leading performance.”

The APA has enjoyed successes resulting in asphalt pavements’ continued dominance in the pavement marketplace at more than 94 percent of the market share nationwide. Successful programs include the Perpetual Pavement Awards, education resources such as webinars and publications used by pavement stakeholders, market outreach such as trade show participation and ongoing collaboration among the partners to serve as a trusted resource and respond effectively to competitive threats.

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605 allislandequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W

Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787

ambroseequipment.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741

www.monroetractor.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810 203/775-1203 80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Opening This FallLancaster, PA 20 Stauffer Lane Ephrata, PA 800/325-6455

BOMAG Americas, a Fayat Company, announced additions to its light equipment team, strengthening the level of support to the rental sales channel.

Jim Davis was recently appointed to the new position of director of national accounts, light equipment, to address the unique needs of the larger rental customers with multiple locations throughout North America.

The recent appointments of three regional sales managers help to further reduce sales territory size and increase the level of support BOMAG provides to all its light equipment rental and preferred customers. These include:

• Cody Nichols as the regional sales manager northeast;

• Alex Schmantowsky as the regional sales manager midwest; and

• Jacob Salinas as the regional sales manager pacific southwest.

“BOMAG continues to add experience and talent to the sales team to match our superior equipment quality and performance with a premium level of sales and support for our light equipment channel,” said Tom Watson, director of sales, light equipment. “In turn, this enables the rental companies to help their customers get the most from the entire rugged and dependable BOMAG light equipment line.”

Jim Davis brings more than 40 years of industry and sales experience to the BOMAG team. As director of national accounts, Davis is charged with formalizing and implementing the program designed to support large national rental chains such as United Rentals, Sunbelt, Sunstate and HERC.

This includes managing contracts, pricing, warranty and rebate programs and service and equipment training to help rental outlets select the right equipment for the market’s needs and keep it well maintained.

Davis’s work history includes more than two decades of national rental account management, sales direction and management of key roles in the light equipment and fuel storage markets.

“Once you get in the industry, it gets in your blood,” said Davis. “BOMAG has a well-earned reputation for equipment quality that consistently delivers a high return on investment to reduce total cost of ownership. We are putting

in place a formalized structure to better support our national program.”

As the regional sales manager, northeast for BOMAG, Cody Nichols supports rental partners across Maine, Vermont, New Hampshire, Massachusetts, Rhode Island, Connecticut, New York, New Jersey, Pennsylvania and Delaware. Nichols brings more than a decade of experience in equipment sales and business development, with a focus on the construction industry and other sectors where uptime, quality and dependable service are critical.

“BOMAG has the reputation for manufacturing reliable equipment that’s engineered for durability, simplified maintenance and operator comfort,” said Nichols. “I’ll ensure our partners get the right machines for the job, backed by the responsiveness and expertise they need to keep their customers productive and projects moving.”

Alex Schmantowsky is the new Midwest regional sales manager, supporting rental customers in North and South Dakota, Minnesota, Wisconsin, Iowa, Nebraska, Kansas, Missouri and Illinois. He brings a diverse range of experience to BOMAG from working in product and technical sales management for Western Global — where he assisted contractors in optimizing their energy consumption and safety operations — to working for the NFL and owning a classic car restoration company.

Working with independent rental companies and assisting with national rental accounts, Schmantowsky plans to support customers by helping them to optimize their operations and prof-

itability with the use of BOMAG light rental equipment.

“I plan to use a mastery of the BOMAG product portfolio to fully support our customers from all angles and cover a lot of ground in the territory,” Schmantowsky said. “BOMAG’s equipment and technology innovations are amazing, from safe operation offered by the remote trench compactor to the simplicity of our single direction plate compactors to the wellbalanced tamper series.”

A second-generation industry professional, Jacob Salinas is charged with supporting rental companies operating in California, Nevada and Arizona as the pacific southwest regional sales manager. With his father working for compaction and paving equipment manufacturers, Salinas grew up around the industry and most recently sold equipment for an industrial manufacturer representative in the Rocky Mountain region. As regional sales manager, Salinas sees much opportunity to build the BOMAG brand and offer consistent representation to rental outlets in the territory.

“BOMAG offers a wide range of light compaction equipment — from tampers and plate compactors to trench compactors and ride-on rollers — so we can flexibly serve the independent rental outlet’s needs,” said Salinas “And BOMAG’s low-emission electric construction e-Performance machines offer an opportunity for rental companies to serve customers working in regions that are requiring the removal of gas and diesel equipment.”

For more information, visit bomag.com/us-en.

www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285 304/636-6421

136 Clifftop Drive Beaver, WV 25813-1525 304/255-1525

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT www.grofftractor.com 800-33-GROFF 800-33-(47633)

6779 Carlisle Pike Mechanicsburg, PA 17050 210 Rolling Ridge Drive Bellefonte, PA 16823

963 South Center Ave New Stanton, PA 15672

179 Perry HWY Hamony, PA 16037

2550 East Cumberland St. Lebanon, PA 17042

640 Lowther Rd. Lewisberry, PA 17339

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537 508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730 207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

www.traceyroad.com

6803 Manlius Center Road East Syracuse, NY 13057 315-437-1471 • 800-872-2390

Albany, NY 518-438-1100 866-740-8853

Kirkwood, NY 607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390

Adams Center, NY 315-788-0200 888-335-0200

Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390

Freehold, NJ 732-780-4600

Earlier this year, the Iowa Department of Transportation (Iowa DOT) purchased the state’s first self-contained pothole filling truck — a more efficient and safer option for fixing potholes on state roadways.

Operated by a single individual, the Cimline Durapatcher — currently deployed in Iowa DOT’s District 4, based in

Council Bluffs and in District 1, based in Ames — this selfcontained vehicle mixes and applies emulsion in a fraction of the time with a fraction of the labor.

More importantly, it is safer than the current pothole-filling method, which requires a dump truck and a trailermounted hopper to be followed by two or three staff to spread the material with shovels and compaction tools by hand — all while exposed to traffic.

After a tragic I-80 work zone crash that killed Matt Dickerson, an Iowa DOT District 4 staff member, near Council Bluffs in 2024, the agency’s field staff and leadership have sought out safer ways to accomplish routine work like pothole patching.

“The ability to remove staff from the operation takes more employees off the road … to do different tasks for the day. It also increases safety by putting one operator in a protected truck cab that protects them,” said Cory Kirkpatrick, maintenance supervisor for Iowa DOT’s DeSoto/Perry garage, in a blog post.

“With no staff on the roadway and faster filling, this truck also reduces the disruption to the public, so we’re able to provide a higher level of service to our customers.”

The agency said the Cimline Durapatcher pothole patching machine preps and installs a patch in minutes without the need for compaction. The truck chassis houses a hopper to hold the supply of rock chips and a 300-gal. heated oil tank that together produce enough product to apply approximately 10 tons of patch material.

Inside the cab, the operator uses a joystick to control mixing and pump the oil — known as emulsion — and rock material forward to a hydraulic arm and nozzle in the front of the unit. When the Durapatcher approaches a pothole, the operator can activate a compressor to clear debris and water.

The next step is to spray the emulsion to fully coat the inside of the pothole, followed by the application of a rock and emulsion mixture.

“We’re looking for a salt and pepper look with the black emulsion oil and the light-colored rock,” said Matt Conaway of the DeSoto Maintenance garage. “Then we’re adding another layer of clean rock over the top to protect the public’s vehicles from the oil.”

As Iowa DOT’s maintenance shops continue to learn more about operating the new system, the agency said reviews of the new pothole filling machine are positive as staff find the new technology to be more streamlined than the conventional dump truck and trailer method.

Iowa DOT added that staff report that the system is “instinctive” to new operators and allows them to get closer to the pothole to see where levelling is needed to provide a better seal and more comfortable ride for the public.

Murrysville, PA

724-327-1300

Erie, PA

814-898-3388

Somerset, PA 814-445-7915

Clearfield, PA 814-765-1611

Mansfield, PA 570-662-7171 Kane, PA 814-778-5250

Mt. Pleasant, PA 724-696-4080

Watsontown, PA 570-538-2551

Ephrata, PA 717-859-4905 State College, PA 814-237-8338 Harrisburg, PA 717-564-2121

Pittston, PA 800-922-8630

Bridgeport, WV 304-842-2222

Shinnston, WV 304-592-5855 Bellefonte, PA 814-353-2800 Blawnox, PA 412-828-7810

Camp Hill, PA 717-730-7435 Cranberry Twp, PA 724-776-7660

Ebensburg, PA 814-471-1710

Indiana, PA 724-463-8743

Barnesville, PA 570-773-1720 Howard, PA 814-355-3500

Hunker, PA 724-861-6080

Eighty Four, PA 724-325-9297

foleyinc.com

Piscataway, NJ 732-885-5555

Hammonton, NJ 609-561-0308

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800 Bloomingburg, NY 845-733-6400

Holtsville, NY 631-758-7500

Newington, CT 860-666-8401

Bensalem, PA 215-639-4300 Whitehall, PA 610-261-4887 Bear, DE 302-328-4131 hopenn.com

RI 401-946-6350

Richmond, VT 802-434-7800

Londonderry, NH 603-665-4500

Brewer, ME 207-991-3100

Scarborough, ME 207-885-8000

Batavia, NY 585-815-6200

Binghamton, NY

607-772-6500

Clifton Park, NY 518-877-68000

Tonawanda, NY 716-799-1320 N. Syracuse, NY 315-703-7000

Volvo wheel loaders can help you speed up cycle times to improve your bottom line. You’ll get more power, fuel efficiency and uptime while staying comfortably productive — that means you can confidently take on all your toughest jobs to earn more.

www.tylerequipment.com

860.356.0840

HDD contractors can now more efficiently complete fiber and other underground utility jobs with the new JT21 directional drill from Ditch Witch.

An upgraded replacement for the JT20, the JT21 delivers up to 40 percent more downhole horsepower than its predecessor and 35 percent faster carriage speed than any drill in its class, empowering crews to work more effectively, increasing ROI.

The JT21 features 21,000 lbs. of pullback, 20,000 lbs. of thrust and 2,250 ft.-lbs. of torque, allowing crews to complete installations at a faster pace in a variety of soil conditions. Also, a new design and lower center of gravity increases stability, according to the manufacturer.

“Any operator who puts the JT21 drill to work will quickly see why it’s the most powerful drill in its class,”

said Britton Yunker, HDD product manager of Ditch Witch. “But it’s not sheer power alone that sets the JT21 drill apart from other drills in its class. It also incorporates several productivity-boosting enhancements, making it an ideal choice for contractors whether they’re looking to replace an aging drill or make crews more effective.”

Among the JT21 features that help boost productivity and ease operations are:

• Improved hydraulic efficiencies and a direct-drive rotation motor delivering more downhole horsepower.

• Virtually Assisted Make-up (VAM) technology provides software-driven make-up and breakout of pipe to simplify operators’ jobs and help prevent pipe-thread damage to extend pipe longevity.

• A proven pipe-loading system provides the horizon-

tal-style pipe loading customers asked for and helps optimize efficiency and uptime on job sites.

• An enhanced operator station provides a common display with other HDD platforms and multi-mode joysticks that allow operators choose their preferred control style, minimizing training needs across multiple platforms.

• Advanced telematics give operators access to a wide range of drill health and operating parameters, helping them make quick, informed decisions while improving overall jobsite management and reducing maintenance.

• A larger displacement pump, generating 35 gpm and running at a lower rpm, increases the life of the pump and wearables.

Newington: 860-665-7470

New Haven: 203-848-6735

MASSACHUSETTS

Avon: 508-584-8484

Whately: 413-665-7009

Woburn: 781-935-1919

NEW

Holmes: 845-878-4004

RHODE ISLAND

Smithfield: 401-942-9191

fosterfwineland.com

PENNSYLVANIA

Ebensburg: 814-472-4441

Martinsburg: 814-793-3734

St. Mary’s: 814-781-1365

VIRGINIA

Bealeton: 540-439-0668

Chesapeake: 757-485-2100

Chester: 804-748-6411

Fishersville: 540-887-8291

Salem: 540-380-2090