In the rapidly growing west end of Des Moines, a $94 million, three-phase construction project is expected to increase traffic flow and increase safety. The Iowa Department of Transportation (Iowa DOT) is adding another diverging diamond interchange to a rapidly growing list of updated interchanges in the state, expected to number seven in the upcoming years.

Work on the first phase of the project on Hickman Road at the interchanges of Interstates 80 and 35 began in October 2024. Crews of

Construction contractors have a lot to think about now that President Trump has signed the One Big Beautiful Bill Act (OBBBA) into law. The legislation contains provisions that will affect business planning and operations well into the future, say financial advisors. More than one urged contractors to quickly match strategies and operations with the legislation for a solid future.

“The OBBBA offers significant planning opportunities for

Cleveland Hopkins International Airport is embarking on a new chapter of transformation with the first phase of a multi-year development plan. The “CLEvolution” paves the way for the future of aviation in northeast Ohio.

Utility tractors are versatile, powerful machines that help operators tackle demanding tasks on a variety of job sites. A key advantage of utility tractors is their ability to work with a wide range of attachments and implements.

Terramac, a global crawler carrier manufacturer based in the United States and a division of the CK Power Family of Companies, announced Roland Machinery Co. as its new dealer in Wisconsin and the Upper Peninsula of Michigan.

Gov. Laura Kelly announced July 29 $25 million for 30 projects to improve intersections and roads across the state. The projects were selected for funding through the KDOT’s City Connecting Link Improvement Program (CCLIP).

24

As ConExpo -Con/AGG 2026 nears, the construction industry’s premier event celebrates its rich lineage — 117 years in the making and North America’s unmatched platform for construction innovation.

24

The Illinois Tollway board of directors on July 28 approved six construction and professional engineering contracts totaling nearly $44 million at its July board meeting.

On Aug. 3, Nebraska Department of Transportation crews demolished two sections of the Columbus Loup River Bridge in Nebraska. Originally built in 1933, the bridge is being removed to make way for construction of a new bridge.

A team of Volvo engineers and designers picked up a Red Dot Product Design award for the L120 electric wheel loader. The design supports improved visibility, safety and sustainability and is the first of its kind within Volvo’s electric portfolio.

34

Branch Manager announced its acquisition of TMW, also known as Thielen Machine and Welding. The move brings together two companies with highly complementary product lines.

38

Caterpillar Inc. and Luck Stone announced a significant milestone in their ongoing collaboration: one million tons autonomously hauled at Luck Stone’s Bull Run Quarry in Chantilly, Va.

58 VOLVO CE TO EXPAND MACHINE PRODUCTION IN NORTH AMERICA

Updates will be made to the existing space within the factory to install assembly lines, integrate more automation technologies into the manufacturing process and train employees, with the goal to be production-ready in the first half of 2026.

58 NEWSWEEK SELECTS BOBCAT AS ONE OF AMERICA’S GREATEST WORKPLACES

Bobcat was recognized in seven distinct award categories, reflecting its commitment to meaningful work, employee wellbeing and continuous career development for more than 5,000 employees in the United States.

70 OHIO LAUNCHES EFFORT TO EXPAND COMMERCIAL TRUCK PARKING SPACES

48 TEREX NAMES ROCK MACHINERY NEW CANICA, SIMPLICITY DEALER IN INDIANA 52 SOLVING QUARRY BLASTING CONUNDRUM WITH TOKU

DESIGNING CLEANER CONCRETE THAT ABSORBS CARBON DIOXIDE

Following an extensive review of ODOT property, Ohio has identified 33 sites in 19 counties where long-term truck parking lots will be created or expanded, more than doubling current truck parking capacity at ODOT-maintained sites. 44 SANDVIK LAUNCHES NEW GENERATION OF JAW CRUSHERS

Cape Girardeau, MO

STK# KM2022307, 4628 HRS, Bridgeton,

KM2024119,

HRS, Franksville, WI 2020 Komatsu PC170LC-11 $139,500 stk# KM2024104 1404 hours, Slinger, WI

2021 Case TV450B, S/N JAFTV450KLM487291, 541 Hrs, CAB/AIR/HEAT, 2 SPEED, HYDRAULIC COUPLER, 84" GP BUCKET, HIGH FLOW PERFROMACE PACKAGE, SERVICED AND READY TO GO, UNIT WILL HAVE A NEW DOOR

$69,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION FULL MACHINE WARRANTY UNTIL 11-22-24 $47,000

Mike Garrard • (630) 492-9115 Bolingbrook, IL Contact us at Used@McCannOnline.com

our complete Used & “Like New” inventory at McCannOnline.com

2018 Case 521G, S/N NHF240998, 813 Hrs, Cab/Air/Heat, JRB Coupler 3 Yard GP Bucket Third Valve Ride Control Limited Slip Diff

$107,500

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$82,500

$72,500

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS

$109,900

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $54,900

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No Bucket, Bucket available at additional charge, Rental Fleet Roll Out $193,500

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

THE BEST PARTS ALL IN ONE PLACE B N HE BE O T PAART EST P TS

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static $85,500

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................

AGGREGATE EQUIPMENT

Sakai R2H-4 static roller - ‘23, approx. 120 hrs., #C002897

$108,800

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

$P.O.R.

ASTEC GT205MF, (’18), 3,296 Hrs, 5 x 20 top deck, 5x18 bottom deck, 8 cu. yd. hopper, 5' wide double deck multi-frequency screen w/hydraulic vibrators, #C005896 $229,900

HAUL TRUCKS

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550 $CALL

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL

Sakai SW884ND - ‘19, approx. 2900 hrs., #C002777, Double drum Oscillatory

$148,400 Sakai SW300 - approx. 450 hrs, 39” drum, #C000211

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd ..............

$P.O.R.

$26,850.

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

$148,900

Superior DT74J - ’19, approx. 1300 hrs. AC, Side shift, gutter brush, #C001774 $35,400

KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher

$546,950

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor

$152,800

Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum

$311,400

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’,

HAZEMAG APPH1515QL, (’93), Primary Impactor Portable Plant, 400HP electric crusher drive, 15 cu. yd. hopper, #C005559

LOADERS AND EXCAVATORS:

$370,000

HAZEMAG APS1315, (’10), 7'x20' triple deck screen, #C005792

$362,500

SIMPLICITY 6203, (’96), Dual Portable Screening Plant, 6’ x 16’ Triple Deck Primary Screen, 6’ x 20’ Triple Deck Secondary Screen, #4873

LIEBHERR L550 XPOWER, (’17), 2,722 Hrs, innovative machine concept which combines performance, fuel efficiency, robustness and comfort. Power split driveline, #C003118 $125,747

$295,000

SUPERIOR BROOM SM80K, (‘17) 2,250 Hrs, Enclosed Rops, AC, #C006107 $26,500

SUPERIOR BROOM SM80K, (‘17) 2,090 Hrs, Enclosed Rops, AC, #C006106

$26,500

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

LIEBHERR R924 LITRONIC, (‘23), 10 Hrs, The R 924 (Tier IV) crawler excavator replaces the predecessor R 924 (Gen 6) model. Its completely updated design is characteristic of the new range of "generation 8" machines, #C005679 $CALL LIEBHERR R934 LITRONIC, (‘23), 485 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

$1,099,000

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141

LIEBHERR R936 COMPACT LITRONIC, (‘18), 1,042 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377$CALL

$885,850

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

$628,750

LIEBHERR R956 LITRONIC, (‘22), 1,800 Hrs, 35' boom and 21' stick, #C004867 $CALL SAKAI SV544TB, (‘23), 2 Hrs, #C005470 $CALL

May

Cleveland Hopkins International Airport (CLE) is embarking on a new chapter of transformation with the first phase of a multi-year development plan. The “CLEvolution” evolves to meet the needs of today’s travelers while paving the way for the future of aviation in northeast Ohio.

In 2021, CLE completed its master plan, a study that provided a long-term blueprint including a conceptual layout and guidance for future airport growth and development. It included airfield planning, terminal planning, landside planning, other facilities and environmental considerations.

Since completion, airport executives have worked with industry consultants and forged a new relationship with the Paslay Group consulting firm in fall 2023 to advance the plan into actionable steps.

Cleveland Hopkins International Airport rendering

The “CLEvolution” evolves to meet the needs of today’s travelers while paving the way for the future of aviation in northeast Ohio.

Early last year, the airport’s signatory airline partners approved $175 million to begin the implementation of the Terminal Modernization Development Program (TMDP). Early work has already occurred, such as the demolition of the former Sheraton Hotel.

“We’ve heard our guests loud and clear and, in collaboration with our airline partners, the decision was made to begin moving this program forward,” said Bryant L. Francis, director of Port Control. “The feedback of our airline representatives has been central to our planning process, and their ideas surrounding our future are greatly valued.”

ed to be completed in 2032. Further airline funding approvals will be required.

In total, the landside projects of the TMDP represent an investment of approximately $1.6 billion.

Supporting the Paslay Group, consultants serving the program include Corgan, an international design and architecture firm; Connico; DVA Architecture LLC; Robert P. Madison International Inc.; McGuiness Unlimited Inc.; and Regency Construction Services Inc.

Decisions will be made later regarding the extent of improvements to the airside of the terminal campus, after execution has begun on the landside phase. Phase one includes the most critical components of the project due to the strain on the airport’s landside infrastructure and facilities.

Since CLE’s terminal facilities must remain operational during its multi-year transformation, these improvements will evolve in phases.

On May 1, 2025, signatory airline partners unanimously approved an additional $301 million of funding to support increased public parking capacity, a critical component of the first phase. This phase will contribute to addressing the taxed front of the house: parking, roadways, ticketing level and security checkpoints.

First, the new Gold Lot will be created

“Cleveland Hopkins International Airport is more than just a transportation hub; It’s the front door to our region, shaping the first and last impressions of everyone who visits our city,” said Cleveland Mayor Justin M. Bibb. “As mayor, I am fully committed to advocating for the transformation of this vital asset. I stand proudly behind the airport team’s efforts to deliver a modern, welcoming experience that reflects the innovation, pride and momentum of our city. Cleveland deserves, and will have, a world-class airport.”

adjacent to Concourse D. The $22.5 million project, approved as part of the initial $175 million in airline funding in 2024, will add 1,600 parking spaces and is expected to debut in 2026.

Once the Gold Lot is operational, work will begin on a new, larger parking garage at the site of the current Orange Lot. This garage will increase the airport’s garage parking capacity from 4,000 to 6,000 spaces and will include a new Ground Transportation Center and RTA station.

Without the recent funding approval from the airline partners, this project would not be possible. This $301 million project will welcome vehicles by early 2029.

After the new garage is in place, the current Smart Parking Garage will be demolished. The site of the old garage will evolve into the new, modernized front door of CLE. This estimated $1.1 billion project is expect-

“This multi-year project promises to unlock a wave of opportunity for our local economy and our community,” said Cleveland City Council President Blaine A. Griffin. “I, along with the entire City Council, stand firmly behind the airport’s vision and hard work. We’re excited and optimistic about the future these improvements will bring to Cleveland.”

CLE’s vision is one of continuous evolution. From the Airport’s rich history to its groundbreaking future. The nation’s first municipal airport will not only revolutionize the travel experience for residents and visitors alike, but it will position northeast Ohio for growth throughout the next century and beyond. It will be a bold departure from the existing guest experience, aiming to exceed expectations and “transform the way we fly.” For more information, visit itsaclevolution.com.

715-752-8112

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$45,000

Kubota KX057-5, A/C, Hyd Thumb, Angle Blade, Aux Hyd, #296470 ........................$76,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $65,000

JD 310SL, A/C, 4X4, Ext Dipper, Ride Control, #262892 .... $99,000

JD 130G, A/C, Hyd Thumb, Aux, 9’11” Stick, 24” Shoes, #261469 ....................................$119,000

Komatsu PC138LC-11, A/C, Long Arm, CPLR, Rubber Pads, #298908 ......................$165,000

JD 550K, A/C, XLT 18” Pads, 6 Way 105” Blade, 4th Function Aux, #262480 $105,000

JD 950K, A/C, LGP, 36” Pads, 184” Blade, Ripper, #301142 ...... $375,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

New Holland E57C, A/C, Hyd Thumb, Cplr, Aux Hyd, Blade, #293430 ........................$64,000

JD 650K, A/C, LGP, 28” Pads, 6 Way 128” Blade, Rev Fan, IGC, #262371 $114,000

JD 444K, A/C, JRB Coupler, Ride Control, #262773 ..$76,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

Volvo EC240BLR, A/C, 60’ Long Reach, 60” Ditch Bucket, #292240 ........................$84,000

JD 700K, A/C, LGP, 36” Pads, 6 Way 132” Blade, Rev Fan, #291338 $155,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $127,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$198,000

JD 325G, A/C, Joysticks, 2 Speed, Aux Hyd, #293433 ......................................$52,000

JD 700L, A/C, LGP, 30” Pads, 6 Way 127” Blade, Drawbar, #298880 $158,000

JD 624L, A/C, 3rd Spool, Ride Control, Roll Out BKT, Rev Fan, #292312 $85,000

Utility tractors are versatile, powerful machines that help operators tackle demanding tasks on a variety of job sites.

A key advantage of utility tractors is their ability to work with a wide range of attachments and implements. Bale forks, tillers, box blades, angle blades, flex wing rotary cutters and tine rakes are just a few examples of attachments and implements that can be paired with utility tractors to meet specific needs. This versatility allows operators to transition seamlessly between tasks, improving efficiency and productivity year-round.

Bobcat recently introduced three new utility tractors — the UT6066, UT6566 and UT6573. These models are built for heavyduty applications and are designed to help users of all experience levels accomplish more on their properties.

The Bobcat utility tractors come standard with a 12x12 power shuttle transmission. The attachment and implement versatility of these machines makes them ideal for various applications, whether you’re cutting hay, clearing snow, feeding livestock, seeding food plots or handling materials. Some of the most popular implements that make utility tractors so dynamic include these:

Brush Grapple: Brush grapples are lightweight but tough, using more of the tractor’s lift capacity to lift and handle material. This attachment can coax out buried roots, branches and other material with its belowgrade capability.

Pallet Fork: Operators can move bulky, bagged or palletized material quickly and easily with a pallet fork attachment. Ideal for landscaping work, construction sites, farm chores, fertilizer handling and municipal projects, pallet forks are built for loading and unloading, lifting and carrying, moving and placing material.

Snow Blade: Snow blades remove light or moderate snow from sidewalks, driveways and parking lots. Its high-carbon steel cutting edge comes standard, and the trip moldboard reduces potential impact damage from obstructions. Fingertip controls make it easy to configure they hydraulically operated blade.

Bale Fork: The 3-point bale fork mounts to a standard or heavy-duty pallet fork attachment frame to handle a variety of bale shapes, including round, square or uneven.

Flex Wing Rotary Cutter: A flex wing rotary cutter is used for roadside and highway mowing, clearing overgrown fields, pasture and ranch maintenance and more. Its wide-cutting capability spans from 12 to 15 ft., depending on the model, and can clear brush and trees up to 3 in. in diameter.

84-in. Tiller: Tear through clumps and hardened materials with the new 84-in. tiller

attachment. It’s built for soil preparation and quickly turns a backyard plot into a soil bed. 84-in. and 96-in. Box Blades: These rearmount box blades offer versatility for leveling, backfilling, grading and moving various aggregates. Their cutting edges are strong enough to retain gravel, topsoil or other material and they feature adjustable and replaceable ripper shanks to break up hard ground or compacted soil for easier move-

ment.

96-in. Angle Blade: An angle blade is excellent for leveling, backfilling, grading and removing snow. This implement does not require power take off (PTO), can rotate 360 degrees and angles to move material from either side of the machine.

96-in. Tine Rake: Streamline lawn preparation and gravel surface maintenance with the new 96-in. tine rake. Quickly collect

debris, smooth lawns and remove unwanted materials like rocks, roots, hay, weeds and leaves. Easily adjust the 3-point rake angle to control debris movement.

Modern utility tractors can come equipped with features that enhance their performance in challenging conditions, making them especially useful in winter or spring. Bright LED headlights illuminate the job for evening work and other low-light conditions, and additional LED work lights on the front and rear provide extra illumination and visibility for the work at hand. Fourwheel drive provides superior traction on wet or soft terrain, ensuring stability and control after heavy snow or rainfall. Climate controlled cabs provide comfort no matter the weather conditions. Some utility tractor models also may feature wide glass panels, visibility to the 3-point hitch, power and tilt steering and ergonomic controls thoughtfully laid out to enhance operator performance and minimize fatigue.

Utility tractors’ efficiency, durability and comfort make them a valuable asset on your farm, acreage or job site. When paired with high-quality attachments, these machines deliver exceptional performance and help operators complete their jobs quickly and effectively — no matter the season.

(This article is courtesy of Bobcat.)

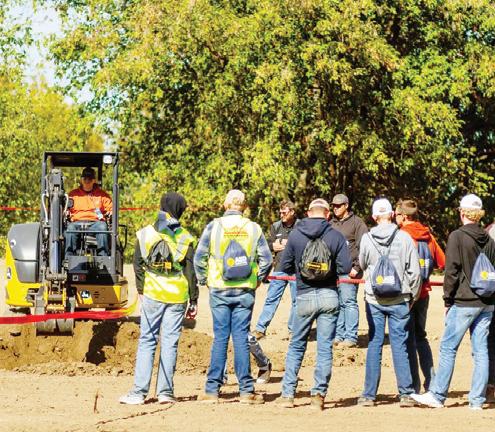

The AED Foundation (AEDF) announced that Warrick Pathways and Career Center in Booneville, Ind., has become the 115th Recognized High School Program under its national workforce development initiative.

This significant achievement marks a new milestone in the foundation’s ongoing Vision campaign, launched in 2020 to address the skilled technician shortage facing the equipment industry.

“The future of our industry — and our country — depends on today’s youth,” said Bob Brucken, CEO of Diamond Equipment Inc. and AED member. “With AI rapidly evolving, we need bright, driven students to help build our industrial and commercial landscape — and that path doesn’t always require a college degree. Warrick Pathways and centers like it are shaping the future, and Diamond Equipment is proud to support their mission. Skilled trades offer rewarding careers, and we rely on that talent to drive our success. We encourage more schools to partner with the AED Foundation to grow the industry.”

The AED Foundation connects schools, educators and the equipment industry to strengthen the pipeline of future talent. Its success depends on the active support and participation of AED members. The Warrick Pathways and Career Center benefited from many contributors — but especially from the strong involvement of AED member Diamond Equipment, Inc.

In the fall of 2024, Diamond Equipment hosted students from Warrick Pathways and Career Center’s Civil Construction program at its facility, where they had the opportunity to operate a Case CX170E hydraulic excavator

equipped with a Hemisphere 3D GPS machine guidance system. Very few of the students had ever been on a machine of that size — much less operated one. They were introduced to the technology used today to help operators dig efficiently and safely.

“The AED Foundation’s ability to connect industry with schools is one of the most powerful tools we have to solve the technician shortage,” said Brian P. McGuire, president of

Terramac, a global crawler carrier manufacturer based in the United States and a division of the CK Power Family of Companies, announced Roland Machinery Co. as its new dealer in Wisconsin and the Upper Peninsula of Michigan.

“We are proud and excited to represent the Terramac product within Wisconsin and the Upper Peninsula of Michigan,” said Del Keffer, vice president and general manager of Roland Machinery Co. Wisconsin Division. “This hard working, heavy-duty product is used throughout North America by many engineering, pipeline and land clearing companies who rely on both the simplicity of operation as well as the power and capacity in remote areas with compromised terrain. American made and engineered, this product has a following of loyal users we are proud to be

able to serve.”

Terramac, founded in 2011, is a leading manufacturer of rubber tracked crawler carriers and supplier of wheeled dumpers.

the AED Foundation. “Our 115th recognized high school isn’t just another number — it represents a real, local partnership that prepares students for in-demand careers and strengthens the workforce pipeline for our industry.”

Since Vision’s inception, the AED Foundation has:

• delivered more than 5,600 technicians through accredited programs;

• certified nearly 5,000 more through industry-aligned testing;

• raised more than $8 million;

• expanded from 5 to 115 recognized high school programs — a more than 20-fold increase in less than five years; and

• added 52 new accredited post-secondary programs to the network Beyond education.

Vision is building a comprehensive support network that includes:

• nearly $10 million in public funding secured to expand Registered Apprenticeships;

• more than $500,000 returned to industry partners through grants;

• more than $200,000 invested in programs introducing youth to equipment industry careers; and

• innovative research such as the joint National Immigration Forum report exploring foreign-born talent solutions.

Since Vision, the AED Foundation has hosted over 75 workforce development events, with 60 more planned for 2025.

For more information, visit aedfoundation.org.

Terramac, a global crawler carrier manufacturer based in the United States and a division of the CK Power Family of Companies, announced Roland Machinery Co. as its new dealer in Wisconsin and the Upper Peninsula of Michigan.

The company brought manufacturing and upfits in-house, allowing for greater customization and flexibility. Terramac focuses on customer-centric solutions to adapt to construction equipment industry needs.

“The addition of Roland Machinery to our family of dealers is a big win for our customers,” said Matt Slater, Terramac president. “Their proven track record of providing exceptional service and support aligns perfectly with our brand values. We are excited for our customers to experience the outstanding service and in-depth product knowledge that Roland Machinery is known for.”

For more information, visit terramac.com and rolandmachinery.com. CEG

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Gov. Laura Kelly announced July 29 $25 million for 30 projects to improve intersections and roads across the state. The projects were selected for funding through the Kansas Department of Transportation’s (KDOT) City Connecting Link Improvement Program (CCLIP).

“Enhancing the safety and accessibility of our local highways is made possible by grants through this essential program,” Kelly said. “In turn, these roadway improvements help bring in resources and improve connectivity in various regions of the state.”

CCLIP provides funds for cities to make improvements on city connecting links that are on state highways. Selected projects are funded for the state fiscal years 2027 and 2028 selection cycle.

Under CCLIP, cities with populations more than 2,500 have local minimum contribution requirements, and cities with populations more than 100,000 are required to have a 25 percent match. Local contributions significantly expanded the scope and total impact of the selected projects, bringing their

combined value to more than $39 million.

“The essence of the City Connecting Links program lies in the shared commitment between KDOT and our communities,” said Secretary of Transportation Calvin Reed. “It’s through this vital partnership that we can address both state and local transportation needs, fostering economic growth and connectivity across Kansas.”

Projects in this program may fall into one of three categories: Surface Preservation (SP), Pavement Restoration (PR) or Geometric Improvement (GI).

SP projects extend the life of the driving surface, such as overlays or joint repair, and are funded up to $400,000 per project. PR projects typically involve extensive pavement rehabilitation or full-depth pavement. GI projects focus on roadway geometrics that address safety, capacity or operational needs, such as adding turn lanes or improving intersections. The PR and GI categories are funded up to $1.5 million per project. For more information, visit ksdot.gov/home.

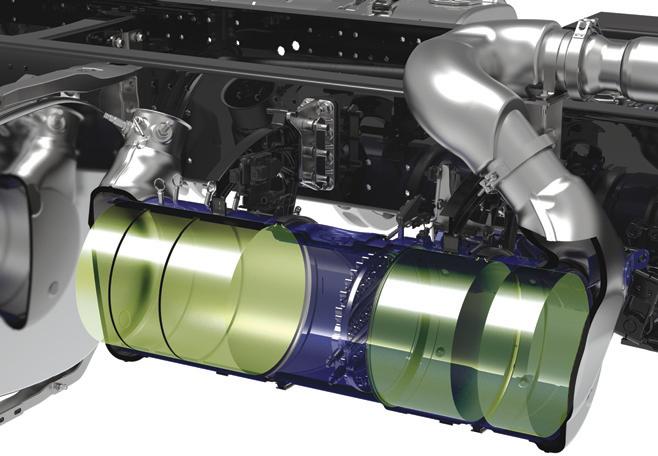

John Deere is enhancing its portfolio of articulated dump trucks with the introduction of next-generation models, now featured across the 260 P-Tier, 310 P-Tier, 410 P-Tier and 460 P-Tier.

The 410 P-Tier and 460 PTier models are powered by the new JD14 engine and come equipped with the Advanced Vision System.

Designed with serviceability and repairability in mind, the JD14 engine, featuring hydraulic lash adjusters and integrated oil and coolant paths for enhanced reliability, helps achieve a 20 percent reduction in repair time by eliminating the need for valve lash maintenance and streamlining service processes. With a new HPCR (High Pressure Common Rail) fuel system, the JD14 engine has improved fuel economy and efficiency over the previous engine. Integrated harnesses increase the overall design’s durability, while better battery access streamlines maintenance, according to John Deere

John Deere photo

and come equipped with the Advanced Vision System.

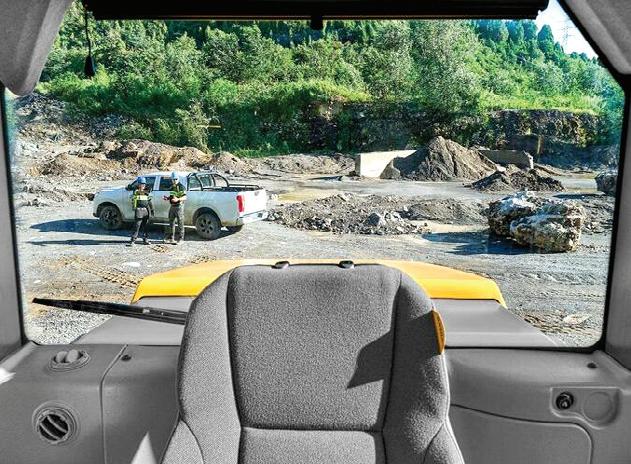

Building upon the John Deere advanced object detection and vision solutions, the new ADTs are equipped with the impressive Advanced Vision System (AVS). This system expands an operator’s field of view, and enhances operator jobsite awareness when in reverse. Digital cameras positioned on the front grill and right and left mirror bow help improve visibility to the machine’s sides, while the in-cab display monitors, positioned in the operator’s line of sight, offer a

seamless, real-time perspective. The user-friendly interface, paired with three 8 in. displays, helps operators identify objects and view surroundings. The system comes standard with a digital rear camera, with these features, operators gain improved spatial awareness with wider views, auto panning views with articulation, and enhanced clarity of the job site

“With the introduction of our next-generation articulated dump trucks, John Deere is once again raising the bar for both performance and situational awareness on the job site,” said Matt Costello, product marketing manager, John Deere. “The JD14 engine and the innovative Advanced Vision System were developed with one goal in mind — enhancing operator productivity and confidence. These advancements not only improve the durability and efficiency of our machines but also set a new standard in visibility, supporting our customers to work smarter, faster and safer.”

Trimble announced a new integration between its B2W Track and Trimble Siteworks software systems to automate and enhance progress quantity tracking for earthwork and civil contractors.

This field-to-office connection allows contractors to compare actual material production quantities achieved to planned quantities more easily and accurately. Continuous assessment of field progress can be critical for civil contractors, enabling them to make timely operational adjustments to protect profitability and to bill for accurate payments as work increments are completed, according to Trimble.

“Civil contractors must continuously evaluate how well projects are progressing against budgets, timelines and productivity goals,” said John Sheedy, director of product management of Trimble. “Relying on phone calls, forms, e-mails and other disconnected communications tools to report on production quantities limits timeliness and accuracy of that reporting. This new software integration brings automation to the process to increase efficiency, eliminate errors and provide an auditable progress trail for billable milestones.”

ing, machine guidance and site management capabilities. For production quantity tracking, devices enabled with Siteworks software technology precisely measure distances, angles and elevations on job sites and process the resulting 3D data sets to assess production quantities in terms of linear distances, areas and volumes.

B2W Track is a comprehensive Trimble performance tracking application for civil construction. Through customized electronic daily logs and fieldcentric reporting, the software streamlines collection and analysis of data on productivity, labor, materials and equipment use.

The new Trimble progress-to-plan reporting workflow allows project managers to create requests for quantity measurements — such as the amount of material added, moved or removed at a site — within the B2W Track performance tracking application. Those requests are relayed automatically to personnel in the field who use Siteworks software to fulfill the request at survey-grade accuracy and send the data back to B2W Track via Wi-Fi or cellular connections.

B2W Track users can then review and validate the data and reconcile it with information from other sources such as field logs. Production quantity data also can be transferred from B2W Track to the Trimble Viewpoint Vista, Viewpoint Spectrum accounting systems, or to third-party construction accounting systems.

Integrating Construction Solutions for Connected Job Site

Trimble Siteworks software provides construction survey-

“This new integration advances the Trimble Construction One vision of connected workflows and data,” said Steve DiBenedetto, product manager of Trimble. “The intuitive process removes friction, delays and risk for errors and makes essential progressto-plan data available with the push of a few buttons. By building on and linking existing B2W Track and Siteworks software capabilities, we’ve made it easy for new and existing users to automate this important reporting process at no additional cost.”

The integration between Trimble Siteworks software and B2W Track is available now in North America at no additional cost to contractors that have licenses for both software systems.

For more information, visit heavyindustry.trimble.com/en/products/ siteworks-positioning-systems.

37 Hours $230,000

PIRTEK USA continued its growth in the second quarter of 2025, marking another milestone in its franchise development journey.

The company announced the opening of nine new locations and the signing of 10 new units, further expanding its footprint to meet the rising demand for premium hydraulic and industrial hose services across the United States.

This quarter, PIRTEK’s nine new locations saw the company expand its presence in Colorado, Georgia, Louisiana, Maryland, North Carolina, Texas and South Carolina, as well as its first-ever location in Delaware. The franchise agreements for 10 units bring eight new owners to its growing franchisee network. This expansion includes three new units in Ohio, underscoring the brand’s commitment to strategic growth in high-potential regions.

“Our Q2 performance reflects the strength of our brand and the unwavering demand for fast, reliable hydraulic and industrial hose solu-

tions,” said Kim Gubera, CEO of PIRTEK USA. “We are proud to welcome new franchisees and expand into new markets, including our first location in Delaware. Our commitment to exceptional service and franchisee support remains at the heart of our continued success.”

In addition to its franchise growth, the company continues to champion military veterans. One of the new franchisees signed this quarter is a Navy veteran, Allen Wix, who will own and operate PIRTEK North Charleston in Charleston, S.C. This reinforces PIRTEK’s dedication to supporting veterans in entrepreneurship.

“As a Navy veteran, I’ve always been drawn to structured systems and mission-focused work, and PIRTEK immediately stood out as a natural fit,” said Wix. “With my background in B2B marketing and leadership, I recognized the essential value this service brings to the industries that keep our country running. I’m proud to bring PIRTEK to Charleston and join a fran-

chise system that truly supports its owners and the communities they serve.”

PIRTEK prides itself on quickly and efficiently filling customers’ hose service needs, having the widest variety of superior products and parts to keep essential projects running. Their quick turnaround time also is credited to the one hour ETA on-site emergency hose service offered 24/7/365. This service enables customers to be up and running again quickly, minimizing equipment downtime due to a hose failure.

PIRTEK onboards potential franchisees who prioritize customer service, and welcomes driven individuals from all industries, regardless of technical experience. The initial investment ranges from $235,137 to $666,638. Franchisees can expect extensive in-person and online training, ongoing support and exclusive territories.

For more information, visit pirtekusafranchise.com.

The Illinois Tollway board of directors on July 28 approved six construction and professional engineering contracts totaling nearly $44 million at its July board meeting, including a contract secured through the use of bid credits for participation in Tollway workforce programs.

“The contracts approved today are supporting construction and engineering jobs throughout the Tollway system this construction season,” said Cassaundra Rouse, Illinois Tollway executive director. “In addition, one firm was able to secure its low bid by using bid credits earned by hiring workers through the Tollway’s ConstructionWorks program.”

Illinois Tollway offers contractors and subcontractors the opportunity to earn bid credits by participating in select construction assistance programs, including ConstructionWorks, the Earned Credit Program and Partnering for Growth. These programs provide incentives to hire a more diverse construction workforce or to provide mentoring opportunities for small and diverse businesses.

Bid credits may be used toward future Tollway construction bids to lower their bid amount and increase the chances of winning the contract as the low bidder.

The July construction contract awards include:

• a $21.7 million contract awarded to K-Five Construction Corp., Westmont, Ill., for toll plaza improvements on the Reagan Memorial Tollway (I-88) between Winfield Road and Highland Avenue;

• a $1.1 million contract awarded to Cardinal State, Barrington Hills, Ill., for landscape planting improvements

on the Tri-State Tollway (I-294) between I-55 and Plainfield Road; and

• a $987,695 contract awarded to Cardinal State, Barrington Hills, Ill., for landscape planting improvements on the Tri-State Tollway (I-294) between 95th Street and I55.

The July professional engineering services contract awards include:

• an $8.7 million contract awarded to Crawford, Murphy & Tilly Inc., Springfield, Ill., for design services for roadway and bridge rehabilitation on the Jane Addams Memorial Tollway (I-90) between Rockton Road and the Kishwaukee River;

• a $6.2 million contract awarded to Singh & Associates Inc., Chicago, Ill., for design services for toll plaza improvements on the Tri-State Tollway (I-94/I-294); and

• a $4.9 million contract awarded to The Roderick Group dba Ardmore Roderick, Chicago, Ill., for design services for toll plaza improvements on the Reagan Memorial Tollway (I-88) and Veterans Memorial Tollway (I-355).

The July contracts include 20 certified disadvantaged, minority- and women-owned business enterprise (D/M/WBE) firms, as well as four certified veteran-owned firms. Commitments for D/M/WBE participation range from 21.05 percent to 77 percent per contract and commitments for veteran participation range from 2.01 percent to 5.01 percent per contract.

For more information, visit illinoistollway.com.

As ConExpo-Con/AGG 2026 nears, the construction industry’s premier event celebrates its rich lineage — 117 years in the making and North America’s unmatched platform for construction innovation.

From humble beginnings in 1909, when the original Road Show in Columbus, Ohio hosted 40 equipment manufacturers in a 40,000-sq.-ft. space, to today’s 2.9 million-sq.-ft., 2,000 exhibitor event, ConExpo-Con/AGG’s evolution embodies the exponential growth of the construction industry.

• 1909 — The inaugural Road Show, Columbus, Ohio, spotlighted machinery soon dubbed “hazardous equipment” over 40,000 sq. ft.

• 1928 — Detroit hosted the Combined Biennial Show, later known as the Concrete & Aggregates Show.

• 1963 — The Columbus Road Show rebranded to the

martinequipment.com

Goodfield, IL 309-965-2502

Peru, IL 815-224-4711

Rock Island, IL 309-787-6108 Springfield, IL 217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA 319-365-0515

Dubuque, IA 563-588-1950 Columbia, MO 573-657-2154

Palmyra, MO 573-769-2274

murphytractor.com

Park City, KS 316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS

620-473-7020 Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177

Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085 Brunswick, OH 330-220-4999 Cambridge, OH 740-439-2747 Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232 Columbus, OH 614-876-1141

Jackson, OH 740-688-4100 Lima, OH 419-221-3666 Painesville, OH 440-639-0700

Construction Equipment Exposition & Road Show.

• 1969 — “ConExpo” emerges as the new moniker for the event.

• 1996 — ConExpo and Con/Agg formally unite under the ConExpo-Con/AGG banner in Las Vegas, transitioning to a triennial frequency.

• 2005 — AEM assumes sole responsibility for managing the show; in 2018, it secures operation rights through 2040.

1996 vs. 2023: Exhibitors rose from 800 to 2,056; exhibit space ballooned from 1 million to 2.83 million sq. ft.; attendees jumped from 84,000 to 139,110.

In 2023, ConExpo attracted ~139,000 visitors — including 24,000

international attendees from 133 countries — with exhibitors representing 36 nations.

ConExpo-Con/AGG 2026

Set for March 3–7, 2026, at the Las Vegas Convention Center and Las Vegas Festival Grounds, the next edition continues the tradition of excellence with:

• 2,000 exhibitor brands;

• 2.9 million sq. ft. of indoor and outdoor displays;

• 150 educational sessions spanning technology, sustainability and industry best practices;

• new ground breakers stage; and

• new workshops: small business, EmpowerHER, shop talks and walks, “A century of progress is reflected in ConExpo-Con/AGG’s scale, scope and spirit,” said Dana Wuesthoff, ConExpo-Con/AGG show director. “This event continues to elevate the equipment manufacturing industry — amplifying innovation, insight and influence.”

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000 Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

Bridgeport, MI 989-777-0090

Grand Rapids, MI 616-538-2400

Lenox, MI 586-727-7502

New Hudson, MI 248-437-8121 Williamsburg, MI 231-267-5060

www.brookstractor.com

Madison (Sun Prairie), WI 608-837-5141 Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700 Sparta,WI 608-351-2101

www.lec1.com

Beaver, WV 304-255-1525

Cowen, WV 304-226-3299

Cross Lanes, WV 304-204-1818

Pleasant Valley, WV 304-534-5454

Norton, WV

304-636-6421

Marietta, OH 740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY 606-432-0321

www.westsidetractorsales.com

Lisle, IL

630-355-7150

Rockdale, IL 815-730-9011

Rockford, IL 815-961-3160

South Holland, IL 708-331-6362

Wauconda, IL 847-526-7700 Bloomington, IN 812-333-9677

Fort Wayne, IN 260-482-8576 Indianapolis, IN 317-544-3411 Lafayette, IN 765-447-6933

South Bend, IN 574-232-1461

Terre Haute, IN 812-645-7160

In this line of work, it’s all about pushing forward. Meet the machine with the strength and smarts to help you move in the right direction. The 650 P-Tier is built with the brawn you’ve come to expect from John Deere dozers. And with flexible grade-management solutions, you can combine impressive power with elite precision.

JohnDeere.com/Dozers

mccoycf.com

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI 715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

Marquette, MI 906-789-7689

Fenton, MO 636-349-0200

Foristell, MO 636-463-2500

Mitchell, IL 618-931-1034

Mt. Vernon, IL 618-244-6800

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131 Cuba, MO 573-885-0500 Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207 Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400

Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY

606-862-8447

On Aug. 3, Nebraska Department of Transportation (NDOT) crews demolished two sections of the Columbus Loup River Bridge in Nebraska. Originally built in 1933, the bridge is being removed to make way for construction of a new bridge.

The demolition is part of the Columbus South Bridges Project, which began in April 2025 and is scheduled to complete in November 2027.

Improvements on this project will replace the southbound Columbus Loup River Bridge; repair the deck of the northbound bridge; and replace the southbound part of the Pawnee Park Drive underpass.

The new southbound bridge will include a shared use path along the west side of the bridge, connecting to the Pawnee Park Trail on the north side of the river and a future trail to be built along U.S. 30/ U.S. 81 south of the river. Roadway lighting will be replaced; portions of the existing roadway pavement and driveways will be replaced; and utilities close to the existing road will be relocated.

Aug.

NDOT is working with the city of Columbus to design and install a re-creation of one of the trusses from the historic bridge within Pawnee Park as mitigation under Section 106. The mitigation is not part of this planned construction but would be installed later.

The mitigation installation would be constructed with new materials, not parts of the old bridge. It would include an interpretive display incorporating photos, maps and information on the history of the Columbus Loup River Bridge, according to the NDOT project sheet.

Heavy Equipment Rental Locations www.macallister.com

Indianapolis HQ 317-545-2151 Fort Wayne 260-483-6469

Lafayette 765-449-8191

Terre Haute 812-478-3155

South Bend 574-288-6622 Washington 812-254-1712

MINNESOTA ZIEGLER CAT www.ZieglerCAT.com

Minneapolis 800-352-2812

Brainerd 877-829-9850 Buhl 800-446-9795

Columbus 866-982-5656 Crookston 800-422-5782 Duluth 800-421-3831 Fergus Falls 800-346-7649

Jackson 866-847-6401 Marshall 800-325-4929 North Mankato 877-845-3938 Rochester 800-247-1068 Shakopee 800-352-2812 St. Cloud 800-522-9469

OHIO CAT

www.OhioCAT.com

Richwood

859-372-4665

859-282-4343 (Rental)

ZIEGLER CAT

www.ZieglerCAT.com

Altoona

800-342-7002

Atlantic

877-547-3819

Sioux City

712-252-4401

Fort Dodge

800-342-1848

Mason City

800-342-1849

Postville

800-526-0889

OHIO CAT

www.OhioCAT.com

Broadview Heights

440-526-6200

440-658-2000 (Rental)

Cadiz

740-942-4626

740-942-6100 (Rental)

Canton

330-244-2444

330-966-4674 (Rental)

Cincinnati

513-771-0515

513-612-5600 (Rental)

Columbus

614-878-2287

614-851-3737 (Rental)

Lima

567-242-6860 (Rental) Perrysburg

419-874-7975

419-872-7368 (Rental)

Troy

937-335-7660

937-440-2900 (Rental) Upper Sandusky 419-731-2170

419-731-2060 (Rental) Washington Court House

740-636-2429

740-636-2430 (Rental) Youngstown

330-530-9010

330-799-1800 (Rental) Zanesville

740-453-0563

740-455-8400 (Rental)

The L120 electric wheel loader won over an international judging panel to scoop a Red Dot Product Design award at the annual ceremony in Essen, Germany.

The Red Dot is one of the world’s largest and most respected design competitions and recognizes achievements in product and

industrial design. The machine’s modern look was the result of a year of bold thinking by technology and design teams from Jinan in China and Eskilstuna and Gothenburg in Sweden. This award achievement is therefore a testament to the power of global collaboration.

Peter Reuterberg, senior chief advanced designer of Volvo CE, said: “I’m happy we won this award but I’m especially happy that we won it for this machine. The change from diesel to electric gave us the opportunity to think

differently and strive for big impact. Our hope is that this new silhouette will be instantly recognizable as electric.”

The streamlined frame of the electric loader is made possible due to the removal of a combustion engine. The result is a transformation from a boxy’ rear end com-

mon to diesel machines into a sleeker shape for the new era of electric.

If designers replaced the combustion engine with larger-in-size batteries, this would have not only created a ‘bulkier’ shape but would have also reduced visibility from the cab. As wheel loaders are designed to be driven both forward and backward in equal measure, all-round visibility is crucial to their safe and efficient operation.

Instead, engineers and designers worked together on a more thoughtful solution and agreed to integrate the batteries into the counterweight of the machine. The heavy weight of a battery is often seen as a problem in electric machine design, but in this case, the battery is being used to replace a concrete counterweight required for wheel loaders.

The result is a machine that not only looks great, but provides enhanced visibility, safety and sustainability compared to traditional diesel variants.

Annie Gao, product platform engineer of the Jinan Technology Center, Volvo CE China, said: “When we debuted the machine it marked a significant breakthrough, truly capturing the spirit of an electric vehicle. It is our relentless pursuit of innovation, close attention to detail and commitment to quality that made this possible.”

FAE is updating its SSM line of forestry tillers for 170-300 hp tractors.

The HP models now have a side gearbox cooling system, while all versions benefit from interchangeable wear-resistant Hardox inner plates inside the crushing chamber.

The main applications of the SSM line are plantation and nursery maintenance, vineyard and orchard upkeep, agriculture tilling and soil reclamation and soil mixing. This equipment is able to shred roots and stumps up to 20 in. in diameter, down to a maximum working depth of 16 in., according to FAE.

Its most notable technical features include the wear-resistant Hardox plates, the central gearbox alignment system specially developed by FAE, the transmission with side gearbox and the adjustable Hardox counter blade. To complete the offer, an adjustable hood grille, a dozer blade and a rear hydraulic support roller also are available.

The SSM comes standard with A/3 teeth, or with A/3/HD and F/3 teeth upon request. It is available in three widths: SSM-200, SSM225 and SSM-250. The same sizes are also available for the HP version: SSM/HP-200, SSM/HP225 and SSM/HP-250.

For more information, visit faegroup.com/en_US/products/land-clearing/pto-driven-heads/tillers-for-tractors/ssmssm-hp.

The Blue Diamond Attachments parts and accessories division announced an expanded line of replacement work tool wear parts solutions for the landscape and grounds maintenance industries, providing both end users and dealers access to a wide range of parts and accessories geared specifically to those industries.

The Blue Diamond parts and accessories division has ramped up its commitment to landscape and grounds maintenance customers by offering a one-stop-shop for all replacement needs that are in stock ready to ship. Parts specifically available for these industries include (among others):

• pallet fork tines;

• boron steel cutting edges;

• serrated reversible cutting edges;

• bucket teeth (230 side pin);

• auger bits, adapters and extensions;

• auger bit teeth and drilling points; • conversion interfaces;

• 18x19 excavator mounting brackets; and

• broom wafers.

The full lineup can be found at the www.BDAparts.com website.

“People in the landscaping and grounds maintenance industries rely heavily on skid steer and CTL attachments to get their work done, and if something breaks, they need to know they have replacement parts at the ready,” said Darren Barnes, product support manager of Blue Diamond Attachments. “That is where we come in. We have just about anything they would need in our warehouse and most can be shipped the same day they are ordered — getting that customer back up and running, so they can get on to the next job.”

Blue Diamond parts and accessories come with the Blue Diamond Satisfaction Guarantee and a standard 1-year warranty (some exceptions may apply).

For more information, visit BDAparts.com.

Branch Manager Attachments announced its acquisition of TMW Attachments, also known as Thielen Machine and Welding. The move brings together two companies with highly complementary product lines and a shared commitment to customer service and quality.

Branch Manager Attachments has built its reputation as a leader in mini-grapples and other attachments for smaller, stand-on and mini-skid machines for the tree care sector.

For nearly four decades, TMW Attachments, operating as Thielen Machine and Welding, has been producing attachments for full-sized skid steers, tractors and telehandlers used in construction, landscaping and agriculture. The company also has served as a trusted white-label manufacturer for numerous well-known brands. The two product lines don’t overlap, which means this acquisition will give customers a wider selection of high-quality tools.

A key part of the deal is TMW Attachments’ in-house fabrication, which will provide benefits for both companies and customers. TMW Attachments will continue to operate under its own brand, ensuring a smooth transition and continued focus on its

established product lines.

“This acquisition is a natural fit for us. Our goal has always been to make tree work simpler and more efficient for our customers,” said David Nordgaard, president of Branch Manager Attachments. “By bringing TMW Attachments into the family, we can now offer that same commitment to quality and service to a whole new group of people. We’re excited to give our customers a wider range of the high-quality attachments they’ve come to expect from us, whether they’re working with a mini-skid or a fullsized machine.”

For customers, this means a single source for a wider range of high-quality attachments, all backed by the same dedication to quality and service, according to the compa-

ny. Branch Manager Attachments is known for its “Customers First!” philosophy, and TMW Attachments has a long history as a family-owned business focused on a similar commitment to its clients.

“For 40 years, we’ve built our business on customer service, hard work, quality craftsmanship and attachments that get the job done right,” said Dan Thielen, former owner of TMW Attachments. “We’re proud of the reputation we’ve earned in this industry. Partnering with Branch Manager Attachments feels like the right next step for us. They share our values of putting the customer first. This new arrangement ensures our attachments will continue to be built with the same quality and care, now with an even wider reach.”

Murphy Tractor & Equipment Co.

murphytractor.com

Park City, KS (316) 942-1457

Great Bend, KS (620) 792-2748

Humboldt, KS (620) 473-7020

Olathe, KS (913) 298-7373

Topeka, KS (785) 233-0556

Ulysses, KS (620) 356-1071

Dodge City, KS (620) 227-3139

Gering, NE (308) 436-2177

Omaha, NE (402) 894-1899

Lincoln, NE (402) 467-1300

Grand Island, NE (308) 381-0741

North Platte, NE (308) 534-7020

Kansas City, MO (816) 483-5000

Springfield, MO (417) 863-1000

Des Moines, IA (515) 263-0055

Fort Dodge, IA (515) 576-3184

Sioux City, IA (712) 252-2753

Waterloo, IA (319) 235-7085

Brunswick, OH (330) 220-4999

Cambridge, OH (740) 439-2747

Canton, OH (330) 477-9304

Cincinnati, OH (513) 772-3232

Columbus, OH (614) 876-1141

Jackson, OH (740) 688-4100

Lima, OH (419) 221-3666

Painesville, OH (440) 639-0700

Poland (Youngstown), OH (330) 629-6299

Rossford, OH (567) 352-7001

Vandalia (Dayton), OH (937) 898-4198

Waratah Forestry Equipment recently introduced the new H427 harvester head at ForExpo 2025 in Mimizan, France.

Built for extreme forestry conditions, the H427 delivers performance, durability and precision for harvesting large timber on steep and rugged terrain. Designed for today’s forestry jobs, Waratah’s H427 is a powerhouse built to handle big wood with confidence and control.

“The H427 is purpose-built to meet the demands of high-production harvesting in larger timber conditions,” said Brent Fisher, product marketing manager of Waratah. “Its design enhances operational efficiency, ensures long-term durability and simplifies maintenance, supporting reliable performance in the forest.”

Featuring a top saw, strong frame and optional HD tilt frame, the H427 delivers performance and productivity. Its high feed

bility needed for the most demanding applications, according to Waratah. Its efficient, powerful control valve and optimized four-roller feed arm geometry ensure consistent productivity on wheeled and tracked carriers.

The four-knife delimbing system delivers results, while simplified service access and a streamlined design help reduce downtime in the field. The H427 offers long-lasting reliability in highimpact forestry applications.

As with all Waratah products, the H427 comes with easily accessible support for dealers and customers, as well as genuine Waratah parts with an industryleading warranty. The Waratah H427 will be available to customers in the United States, Canada, Europe, Australia, New Zealand, Africa, Brazil and Latin America starting in early 2026.

from 3,704 lb., the H427 offers agility with the durability and sta-

For more information, visit Waratah.com

Caterpillar Inc. and Luck Stone announced a significant milestone in their ongoing collaboration: one million tons autonomously hauled at Luck Stone’s Bull Run Quarry in Chantilly, Va.

The achievement marks a first for Caterpillar in the aggregates industry and underscores the success of Caterpillar’s autonomous haulage system (AHS) in a quarry environment. The milestone demonstrates the safety and productivity of autonomy beyond traditional large mining applications.

“This milestone is a powerful demonstration of what’s possible when we collaborate with our customers to deliver solutions for their critical needs,” said Denise Johnson, group president, resource industries, Caterpillar. “Reaching one million tons hauled autonomously at Bull Run shows that autonomy isn’t just for mining — it’s scalable, reliable and ready to transform the aggregates industry. We’re proud to collaborate with Luck Stone to lead that transformation.”

“This autonomous journey with Caterpillar has been one of the most powerful and transformative projects in our 100-year history,” said Charlie Luck, president and CEO, Luck Cos. “What once felt like a dream at our Bull Run site is now a reality — thanks to the trust, collaboration and shared commitment between our teams.

“Reaching the one million tons hauled milestone has engaged every part of our operation, from training and mine planning to operating efficiency and teamwork, proving that this technology can work, and work well, in a quarry environment. Most importantly, it’s creating opportunities for our associates to grow, lead and be part of something groundbreaking.

“At Luck Stone, our mission is to ignite human potential, and this project is an example of what’s possible when people, purpose and progress come together. We’re grateful to Caterpillar and confident that operators across the country will have a similar experience.”

The collaboration between Caterpillar and Luck Stone began with a shared vision to transform quarry operations through technology. Bull Run Quarry became the first site in the aggregates industry to deploy Caterpillar’s autonomous Cat 777 trucks, supported by a full autonomy technology stack and site integration services.

Since the initial deployment, the collaboration has focused on validating autonomy along with the people and processes in conditions that are typical in quarry operations but distinct from mining.

Reaching the one million tons hauled autonomously milestone confirms that autonomous haulage can deliver consistent, repeatable performance. Also it signals how autonomous solutions will address skilled labor shortages, improve site safety, increase operational efficiency and upskill quarry employees to run autonomy.

This milestone aligns with Caterpillar’s enterprise strategy in several key areas:

• Customer Back Solutions: Luck Stone’s operational insights helped shape the deployment and refinement of the AHS.

• Productivity: Autonomous trucks have demonstrated improved cycle consistency and reduced idle time.

• Safety: Removing operators from the cab reduces exposure to potential hazards and enhances site control.

• Sustainability: Autonomy enables more efficient fuel use and supports emissions reduction goals.

Caterpillar and Luck Stone continue to explore opportunities to expand autonomy across additional sites and applications. The success at Bull Run sets a precedent for the broader aggregates industry and reinforces the companies’ commitment to innovation and operational excellence.

For more information, visit cat.com.

McCann Industries Inc.

543 S Rohlwing Rd. Addison, IL 60101 630-627-0000

1360 N Rand Rd. Wauconda, IL 60084 847-526-9444

23921 S Northern Illinois Dr. Channahon, IL 60410 815-467-4480

www.McCannOnline.com

W250 N6851 Hwy 164 Sussex, WI 53087 262-246-5700 Fax: 262-246-5719

DeForest, WI 608-222-9191

Eau Claire, WI 715-832-3443

De Pere, WI 920-338-5800

Marathon, WI 715-443-6000

Negaunee, MI 906-475-4181

www.miller-bradford.com

Roland Machinery Co. www.rolandmachinery.com

Bridgeton, MO

(314) 291-1330

Cape Girardeau, MO (573) 334-5252

Columbia, MO (573) 814-0083

Palmyra, MO (573) 769-2056

Portage, IN (219) 764-8080

Bolingbrook, IL (630) 739-7474

Carterville, IL (618) 985-3399

East Peoria, IL (309) 694-3764

Marengo, IL (815) 923-4966

Springfield, IL (217) 789-7711

DePere, WI (920) 532-0165

DeForest, WI (608) 842-4151

Eau Claire, WI (715) 874-5400

Franksville, WI (262) 835-2710

Schofield, WI (715) 355-9898

Slinger, WI (262) 644-7500

Escanaba, MI (906) 786-6920

Joplin, MO (417) 726-5373 Maryland Heights, MO (314) 427-4911 Springfield, MO (417) 865-0505 Colby, KS (785) 462-8211 Liberal, KS (620) 624-7274 Salina, KS (785) 825-8291 Wichita, KS (316) 789-7370

1801 Watterson Trail Louisville, KY 40299 (502) 491-4000

Bowling Green, KY (270) 780-3004

Corbin, KY (606) 528-3700

Lexington, KY (859) 259-3456

Paducah, KY (270) 444-8390

Stanville, KY (606) 478-9201

Evansville, IN (812) 425-4491

Fort Wayne, IN (260) 489-4551

Indianapolis, IN (317) 872-8410 Brandeis Machinery & Supply Company www.brandeismachinery.com

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

The new upgraded Sandvik jaw crusher range is another step forward in ensuring performance for its customers’ crushing operations.

Merging new jaw crusher capabilities and design with the existing standards of the entire Sandvik range was a natural next step, according to Sandvik. Sandvik jaw crushers are now better equipped to deliver the performance customers expect from a global leader in mining and quarry solutions.

“Our new upgraded jaw crushers are now more aligned with the full Sandvik range,” said Martin Johansson, global product manager, jaw crushers. “They give our customers even more ability to secure safety, improve productivity and availability, reduce costs and accelerate sustainability with a partner they can count on.”

“Our new upgraded jaw crushers are now more aligned with the full Sandvik range.”

The latest Sandvik jaw crushers come complete with the features customers need for plug-and-play primary and tough material crushing. New and improved Sandvik jaw crushers now include even more of the safety, performance, availability and sustainability benefits customers expect from Sandvik solutions:

• new hydraulic wedge setting adjustment;

• synchronized retraction arrangement;

• improved power pack;

• upgraded guarding;

• new ACS-j monitoring and control system; and

• clear role-based user documentation.

Upgraded Sandvik jaw crushers are engineered to the same specifications for seamless compatibility with the full range of Sandvik solutions and now come with a 3-year standard warranty.

www.aisequip.com

3600 N Grand River Ave Lansing, MI 48906

517-321-8000

Grand Rapids

600 44th Street SW Grand Rapids, MI 49548

616-538-2400

Northeast Detroit 65809 Gratiot Avenue Lenox, MI 48050 586-727-7502

Saginaw 4600 AIS Drive Bridgeport, MI 48722 989-777-0090

Traverse City 8300 M-72 East Williamsburg, MI 49690 231-267-5060

West Detroit 56555 Pontiac Trail New Hudson, MI 48165 248-437-8121 800-457-8121

www.butlermachinery.com

3630 Miriam Ave Bismarck, ND 58502

701-223-0890

7910 US-2

Devils Lake, ND 58301 701-665-3800

2803 I-94 Business Loop E Dickinson, ND 58601

701-456-1400

3402 36th St SW Fargo, ND 58104 701-280-3100

1201 S 46th St Grand Forks, ND 58201 701-775-4238

1910 27th Ave SE Jamestown, ND 58401

701-251-1400

4950 U.S. Highway 12 Aberdeen, SD 57401 605-225-6240

3601 Deadwood Ave N Rapid City, SD 57702 605-342-4850

20571 Truck Stop Ave Pierre, SD 57501 605-224-5400

3201 N Louise Ave Sioux Falls, SD 57107 605-336-3010

603 10th St NW Watertown, SD 57201 605-954-7100

1715 US Hwy 14 W Huron, SD 57350 605-353-1200

1505 Hwy 2, Bypass E Minot, ND 58701 701-852-3508

www.centralsands.com

4219 E 50th St • Des Moines, IA 50317 800-247-2400 • 515-964-8600

www.rbscott.com

1011 Short St Eau Claire, WI 54701 715-832-9792

17403 County Road 75 NW Clearwater, MN 55320 320-558-8100

www.roadbuildersmachinery.com

1001 S 7th St Kansas City, KS 913-371-3822

4115 S 90th St Omaha, NE 402-331-9200

5601 Fletcher Ave Lincoln, NE 402-325-0447

4949 Juergen Rd Grand Island, NE 308-384-2620

1303 S Chestnut St Norfolk, NE 402-316-4640

www.rolandmachinery.com

Escanaba, MI

906-786-6920

DePere, WI

920-532-0165

DeForest, WI

608-842-4151

Eau Claire, WI

715-874-5400

Franksville, WI

262-835-2710

Schofield, WI

715-355-9898

Slinger, WI

262-644-7500

www.rmsequipment.com

Savage, MN

800-888-9515

Des Moines, IA

800-555-1445

Cedar Rapids, IA

800-616-6615

Sioux City, IA

800-633-9104

East Moline, IL

800-633-9114

Duluth, MN

800-888-9535

Virginia, MN 800-752-4304

www.vlpco.com

4100 Gardner Avenue

Kansas City, MO

64120

866-928-4055

816-241-9290

Garden City, KS

800-511-1435

Joplin, MO

417-781-8222

Topeka, KS

785-267-4345 Wichita, KS

316-838-3346

www.brandeismachinery.com

Bowling Green, KY

270-780-3004

Corbin, KY

606-528-3700

Lexington, KY

859-259-3456

Louisville, KY

502-491-4000

Paducah, KY

270-444-8390

Stanville, KY 606-478-9201

Evansville, IN 812-425-4491

Ft. Wayne, IN 260-489-4551 Indianapolis, IN 317-872-8410

Terex MPS (Minerals Processing Systems) announced the expanded partnership with Rock Machinery Inc., now an authorized distributor for all three legacy brands: Cedarapids, Simplicity and Canica in the state of Indiana.

Rock Machinery has been a respected distributor of high-quality crushing, screening and specialty equipment for the aggregate, mining and recycling industries across the Midwest.

Founded in 2004 by Larry Hetzel, Rock Machinery built its reputation on delivering exceptional equipment and parts support to producers throughout the region. Currently a full-line Cedarapids distributor in Indiana, Rock Machinery will now represent Simplicity Vibratory Equipment and Canica Vertical Shaft Impactors (VSI) as well, offering customers a complete crushing and screening product solution in the state of Indiana.

“We’ve proudly served the Indiana market since 2015,” said Bryant Fazer, president of Rock Machinery. “The addition of Simplicity and Canica to our Cedarapids offering gives us the ability to provide a full range of crushing and screening solutions to our customers. We’re excited to represent these historic brands known for quality, performance and durability.”

Cedarapids, Simplicity and Canica have long been recognized for engineering excellence and dependable performance, according to the company. Cedarapids offers a complete range of portable, modular and static crushing and screening systems. Simplicity is known for its vibratory screens and feeders, while Canica delivers vertical shaft impactor technology for a wide range of applications.

“We’re excited to represent these historic brands known for quality, performance and durability.”

“We are thrilled to expand our partnership with Rock Machinery,” said Russ Burns, director of sales of Terex MPS. “Their in-depth industry knowledge, commitment to customer service and strong presence in the region make them an ideal representative for our full product portfolio in Indiana. This expansion ensures that our customers continue to receive the highest level of support and expertise.”

Since being unified under the Terex MPS umbrella in 2009, Cedarapids, Simplicity and Canica have carried for-

ward a rich tradition of innovation and customer commitment. Serving customers across aggregates, mining, recycling, demolition and industrial minerals sectors, these brands provide solutions designed to deliver performance and longevity, according to the company.

For more information, visit terex.com/mps/en/canica, terex.com/cedarapids/en, terex.com/simplicity/en and rockmachinery.com.

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem , BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

Many quarry companies still use drill-and-blast for large rock extraction.

Legal zoning regulations, or the proximity of houses or other buildings, may mean explosive blasting is not possible in some quarries. Using explo sives also requires various stages and long downtimes — such as preparation of the rounds, distancing of personnel and cessation of activities. As a result, many operations are seeking alterna tive solutions that can reduce costs while increasing safety, production and lessening the impact on the environ ment, according to Toku America.

While drill-and-blast continues to prove problematic in a quarry setting, a large-sized excavator equipped with a heavy, powerful breaker can provide an alternative. Heavy-duty hydraulic breakers represent an economic solu tion as they also provide high produc tivity and continuous production — without the risk of excessive vibrations, noise or potentially harmful flying debris.

In response to meeting this blasting dilemma head-on, Toku America Inc. has recently advanced its Striker TNB large quarry breakers line with a range of options that allows quarry operations to choose the right breaker specifically designed to their material size, hardness and other jobsite condition variables.

energy recycled and used for the next blow.

Consisting of five TNB models (TNB-151, 90, 30K, 40K, 400), the large hydraulic quarry breakers are engineered for Cat, John Deere and Komatsu excavators. Featuring “accumulator free” technology, they also boast a simple and efficient design with only two moving parts — requiring no maintenance, according to Toku.

Ultimately, this configuration delivers impact energy, long life and low operating costs — while providing performance to overcome blasting safety, downtime and zoning limitations.

Paired to a carrier or pedestal boom system, with proper sizing based on material hardness and size, Toku’s large TNB quarry breakers all feature the following:

• short, fully enclosed tie rods;

• long-stroke piston: the most efficient design for energy transfer and recoil reduction;

• control valve: “flow through” design reduces hydraulic surge and efficiently controls the breaker operat-

murphytractor.com

5255 N Deere Rd Park City, KS 67219 316-942-1457

325 S Highway 281 Great Bend, KS 67530 620-792-2748

1141 Kanza Drive, Humboldt, KS 66748 620-473-7020

15854 S US 169 Hwy Olathe, KS 66062 913-298-7373

1621 NW Gage Blvd Topeka, KS 66618 785-233-0556

1410 W Oklahoma Ave Ulysses, KS 67880 620-356-1071

10893 112 Rd Dodge City, KS 67801 620-227-3139

220810 Hwy 92 Gering, NE 69341 308-436-2177

• Box housing isolators help eliminate recoil shock to the carrier;

• Box housing with sound suppression for more quiet operation; and

• Box housing key slot anti-vibration design in front head.