Australian design with a tradition of innovation and quality for over 45 years.

From humble beginnings in Sydney in 1976, Abbott & Ashby engineered a bench grinder that would become the trusted choice in the industry, and a symbol of Australian quality and innovation. Almost 50 years on, that same legacy of creating tough, reliable products remains at the heart of everything we do.

Today, Abbott & Ashby's Australian design team continues to deliver market-leading industrial tools that stand up to the toughest jobs - whether you're a serious DIYer or a professional operator. Our ever-expanding product range is available and backed by a network of over 2,000 stockists throughout Australia and New Zealand.

Building on decades of experience, every new Abbott & Ashby product is designed to improve performance where it matters most, without compromising on durability, safety, or quality. This focus on innovative technology has led to the development of the new Professional range - our most powerful bench grinder yet - and the expansion of the Abbott & Ashby range into new and improved linishing tools, bench vices and workshop accessories.

Every feature has been carefully considered for the Australia and New Zealand market, to ensure Abbott & Ashby products meet the needs of each and every job.

• Compounds 11 LINISHING

• Grinder & Linisher Combos

• Linishing Attachments

• Standalone Linishers

• Drill Press Vices 18 BUFFING

• Buffing Machines

• Polishing Mops

• Heavy Duty Bench Vices

• Universal Bench Vice

• Offset Bench Vice

• Abrasive Belts

• Abrasive Discs

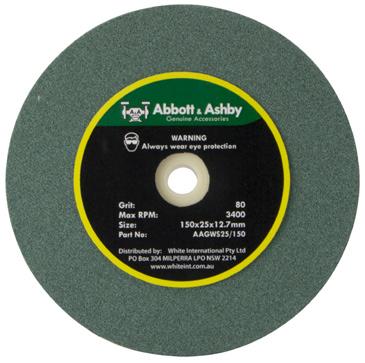

• Grinding Wheels

• Spindles

• Tools

• Pedestals

• Quick Clamp

• Mitre Table

• Vice Jaws

Our bench grinders are engineered for reliability, safety and performance across the entire range, from the Utility model to our top-tier Professional series. That's why Abbott & Ashby has been the trusted name in Australian workshops for nearly 50 years. Whether you're sharpening tools, shaping metal workpieces or carrying out precision finishing work, there's an Abbott & Ashby grinder to suit every application.

There is no doubt that Abbott & Ashby bench grinders are in a league of their own, with innovative features that offer maximum functionality. All models are built around a powerful induction motor with capacitor start-stop for smoother, more reliable operation. Wide wheel guards allow for free-running wire wheels, large eye shields offer better user protection, fully adjustable tool rests and solid construction materials ensure the longevity of the product.

A comprehensive range of accessories is available to suit different applications and give you the ability to customise your machine to suit the specific needs of each and every job.

Use the coarse wheel for rapid removal of material. Then shape, descale and prepare the job for finishing. Use the fine wheel to remove small surface imperfections and obtain a smooth finish.

Sharpen knives, axes, drills, chisels and most cutting implements. Use the coarse wheel if necessary to prepare, then the fine wheel to achieve a high quality smooth finish.

T he N ext S tep Forward in D urability, Performance and I nnovation

ATBG1100/8

With a robust 1.5HP (1100W) motor at its core, the 8" Professional bench grinder delivers unrivalled power and efficiency while incorporating innovative features for safety and durability. Comes standard with 36 and 60 grit 25mm wide Aluminium Oxide grinding wheels.

True 1.5HP Motor: Engineered for professional metalworkers, our bench grinders deliver up to 41% more torque for effortless material removal and unmatched performance.

Runs Cooler: Featuring an advanced cooling system for extended durability, keeping temperatures up to 9% cooler than competitors to reduce wear and tear.

Enhanced Durability: Crafted from high-tensile cast aluminum, our bench grinders offer superior strength without the weight.

NVR & E-Stop Switch: Safety is paramount - No Volt Release and Emergency Stop switch cuts out power entirely during outages and prevents accidental restarts.

More Power for Big Jobs, Less Wear for Everyday Use:

Designed for workshop and industrial applications, our Professional range ensures optimal performance and longevity, making it the ideal choice for metalworking professionals in Australia and New Zealand.

Part No: ATBG1100/8

Item Code: 811513

Input/Output: 1300W/1100W - 1.5HP

Volts: 240V ~ 50Hz (1Ph)

Amps: 5.3 (10A plug)

RPM: 2850

Wheel Size: 200mm / 8"

Weight: 21kg

ATBG600/8 & ATBG280/6

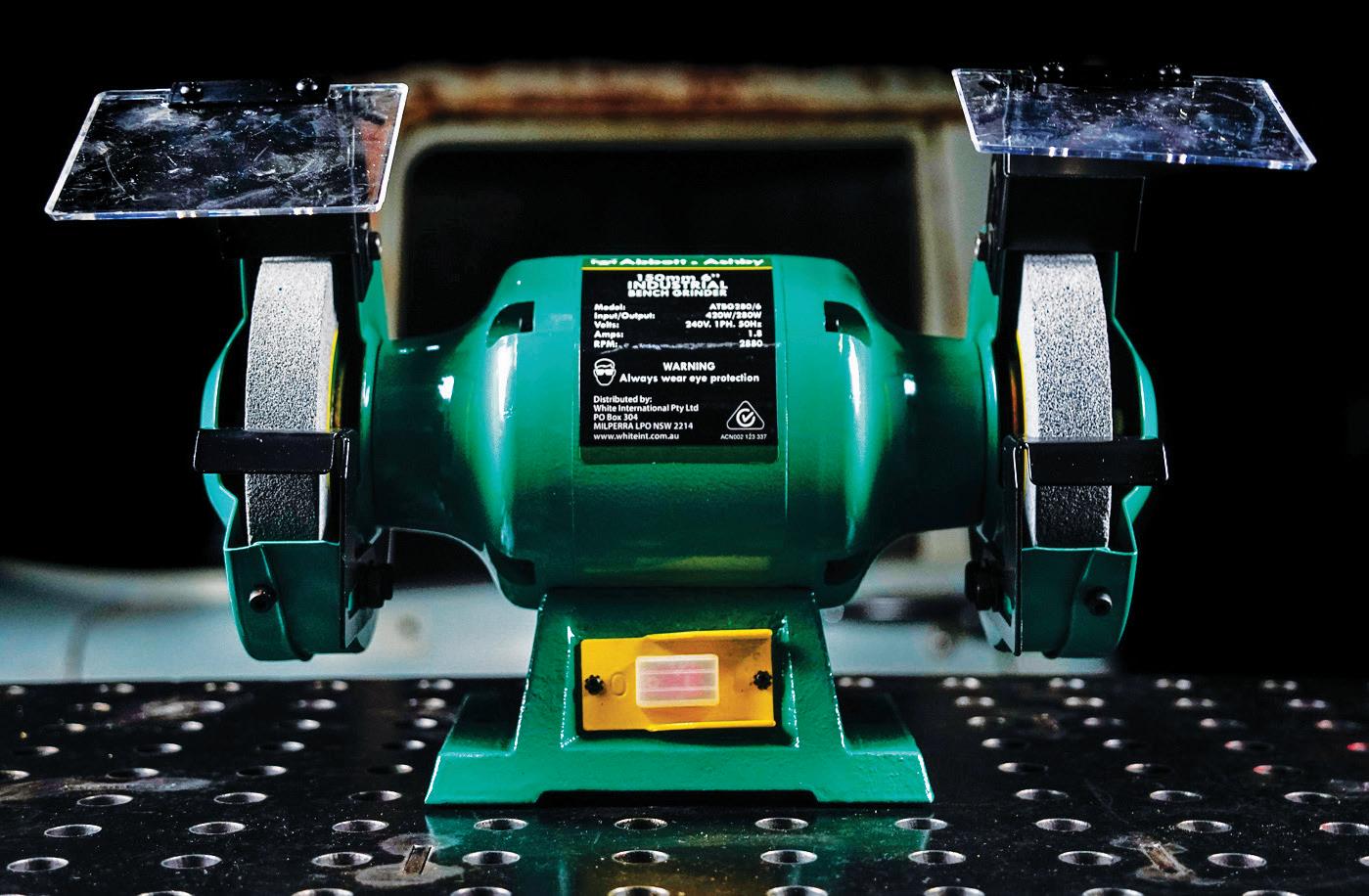

The Industrial Range boasts a powerful induction motor and is available in two models: 8" (200mm) and 6" (150mm). Featuring a capacitor start-stop motor for maximum reliability, inside a cast iron body and base for years of strong performance.

Comes standard with:

• 36 and 60 grit 25mm wide Aluminium Oxide grinding wheels for fast removal of material

• Wide wheel guards for the use of wire wheels without fouling for greater user protection

• ‘Sealed for life’ ball bearings for prolonged life

• Vibration absorption pads on the base for smoother running and a better finish

• Adjustable tool rests for ease of use in different applications

Part No: ATBG600/8 ATBG280/6

Item Code: 804532 804531

Input/Output: 900W/600W

Amps: 3.8 (10A plug) 1.8 (10A plug)

RPM: 2880 2880

Wheel Size: 200mm / 8" 150mm / 6"

Weight: 23kg 10kg

The Industrial 8” (200mm) bench grinder is pre fitted with 8”(200mm) crimped wire and grinding wheel. Comes standard with:

• Powerful 3/4 HP+ induction motor

• 36 grit 25mm wide aluminium oxide grinding wheel for fast removal of material

• Crimped wire wheel for cleaning and deburring material

• ‘Sealed for life’ ball bearings for prolonged life

• Vibration absorption pads on the base for smoother running and a better finish

• 50mm wide wheel guards for the use of wire wheels without fouling for greater user protection

• Fully adjustable tool rests for ease of use in different applications

The Utility bench grinders are the perfect choice for the DIY enthusiast. Comes standard with:

Part No: ATBG600/8WBM

Item Code: 804533

Input/Output: 900W/600W

Volts: 240V ~ 50Hz (1Ph)

Amps: 3.8 (10A plug)

RPM: 2880

Wheel Size: 200mm / 8"

Weight: 22kg

• 25mm wide grinding wheels with 36 and 60 grit for fast removal of material

• Powerful induction motor

• ‘Sealed for life’ ball bearings for prolonged life

• Vibration absorption pads on base for smoother running and a better finish

• Cast Iron body and base make the grinder strong and hard wearing for years of performance

• Capacitor start-stop motor for maximum performance

• Fully adjustable tool rests for ease of use in different applications

Part No: ATBGU/8

Item Code: 804535

Output: 375W

Volts: 240V ~ 50Hz (1Ph)

Amps: 2.6 (10A plug)

RPM: 2880

Wheel Size: 200mm / 8"

Weight: 18kg

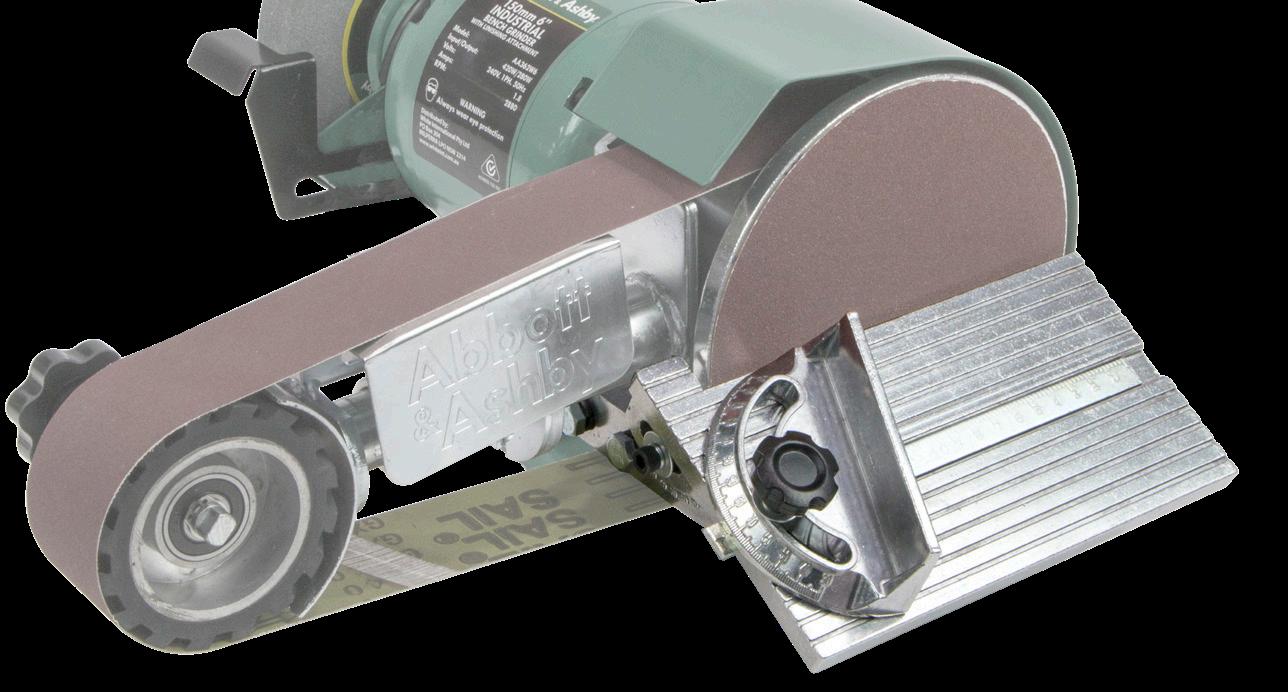

Grinder & Linisher Combos Linishing Attachments Standalone Linishers

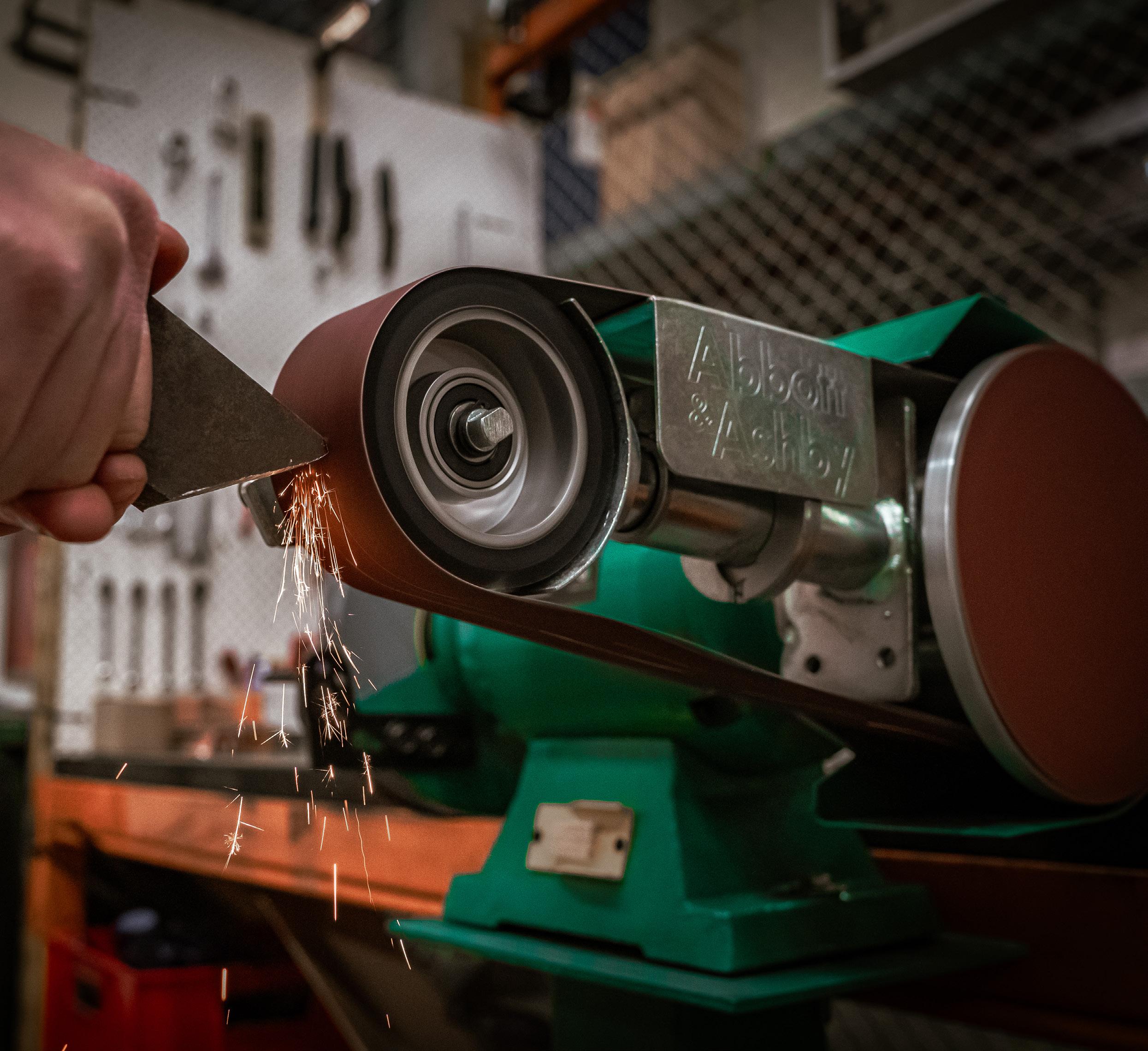

With a robust 1.5HP (1100W) motor at its core, the 8" Professional range delivers unrivalled power and efficiency while incorporating innovative features for safety and durability. Factory fitted with a 25mm wide 60 grit grinding wheel and the award-winning AA362 linisher, ideal for finishing jobs such as tool sharpening, edge sanding, smoothing welds and polishing.

True 1.5HP Motor: Delivers up to 41% more torque for effortless material removal and superior performance.

Runs Cooler: Improved sealed cooling system keeps operating temperatures up to 9% cooler than competitors, reducing wear and tear.

Enhanced Durability: Crafted from high-tensile cast aluminum, offering superior strength without the weight.

NVR & E-Stop Switch: Ensures safety by cutting power entirely during outages and preventing accidental restarts.

More Power for Big Jobs, Less Wear for Everyday Use: Ideal for professional and industrial applications.

Factory Fitted AA362 Linisher with:

• 915 x 50mm (36 x 2”) 240 grit belt

• 178mm (7”) diameter 100 grit disc

• 89mm (3 1/2”) contact wheel

Part No: AA362W8-1100

Item Code: 811514

Input/Output: 1300W/1100W - 1.5HP

Volts: 240V ~ 50Hz (1Ph)

Amps: 5.3 (10A plug)

RPM: 2850

Wheel Size: 200mm / 8”

Weight: 23kg scan here to watch

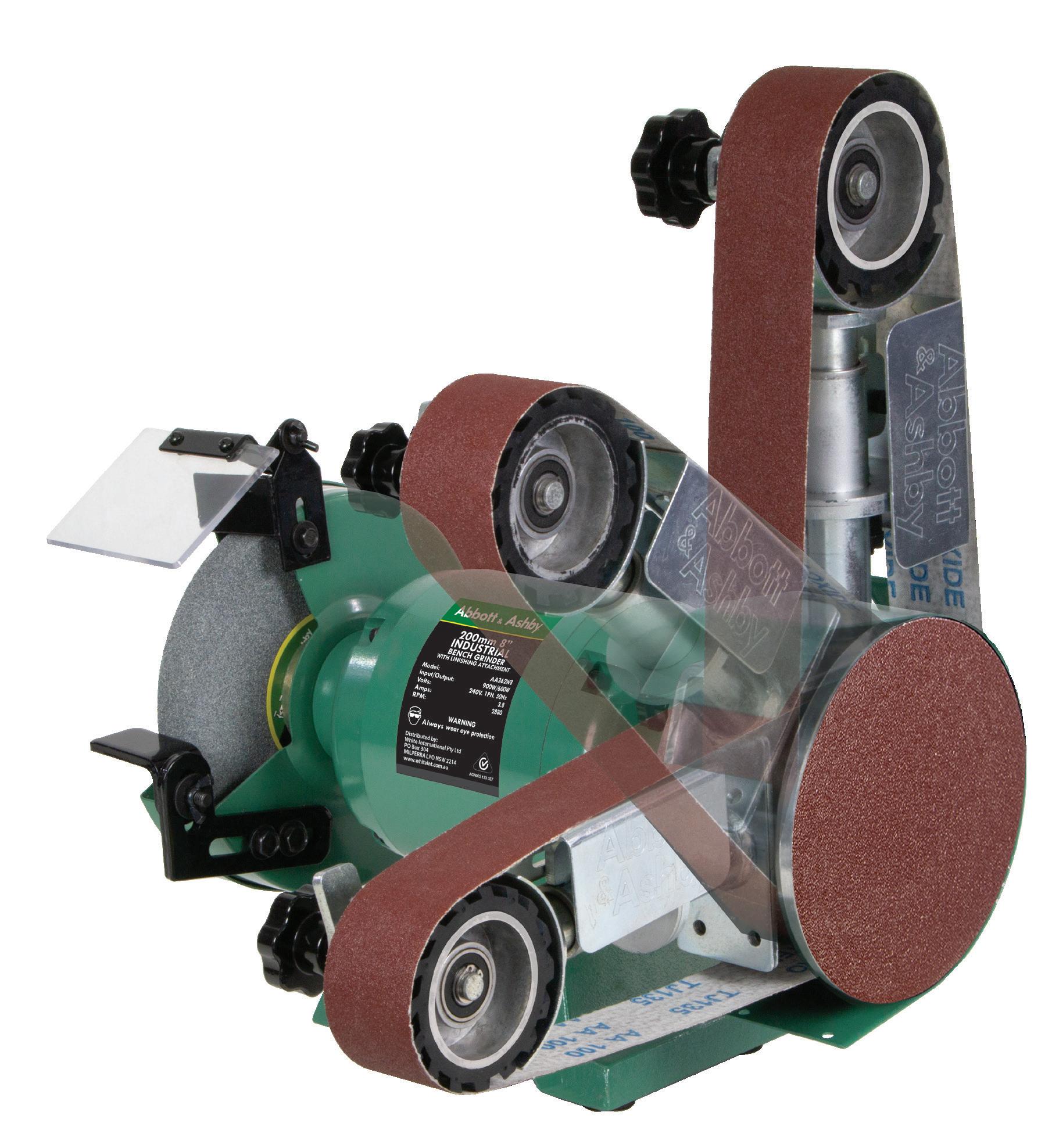

AA362W8 & AA362W6

The 8” (200mm) and 6” (150mm) high powered Industrial bench grinders are complete with the AA362 linishing attachment. Comes standard with:

• 915 x 50mm (36 x 2”) 240 grit belt

• 178mm (7”) diameter 100 grit disc

• 89mm (3 1/2”) contact wheel

• 25mm wide 60 grit grinding wheel

Part No: AA362W8 AA362W6

Item Code: 808440 808439

Input/Output: 900W/600W 420W/280W

Volts: 240V ~ 50Hz (1Ph) 240V ~ 50Hz (1Ph)

Amps: 3.8 (10A plug) 1.8 (10A plug)

RPM: 2880 2880

Wheel Size: 200mm / 8" 150mm / 6"

Weight: 24kg 15kg

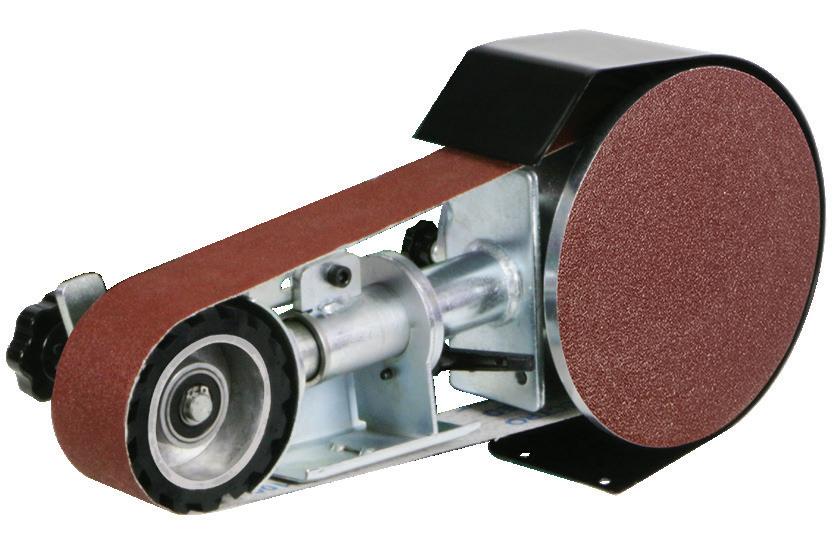

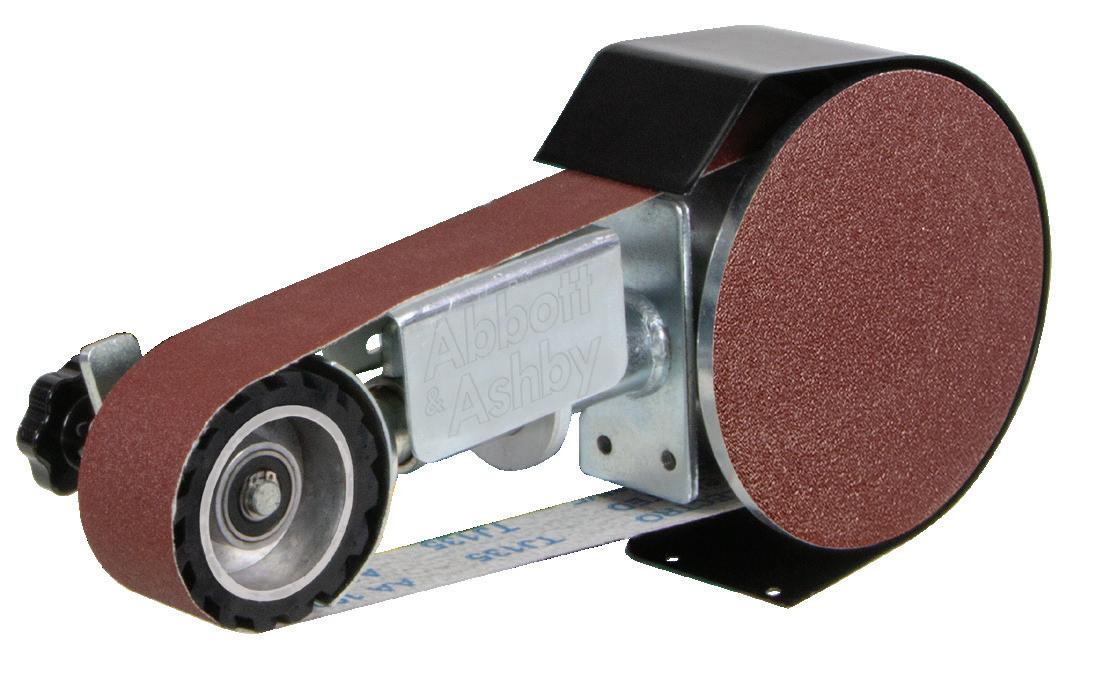

The innovative Linisher is available as an attachment for a Bench Grinder or as a complete unit.

The linisher can be purchased pre installed to our 6” or 8” bench grinders and come fully assembled out of the box.

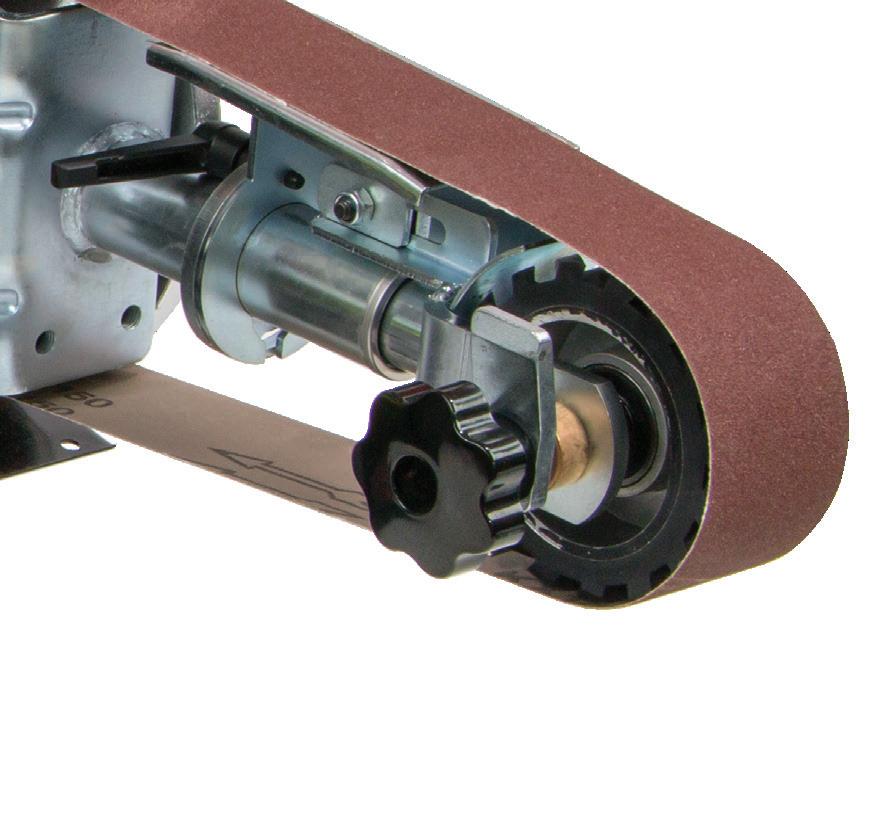

Easy belt tracking adjustment knob and lock at the front of the unit.

Fast belt changes with patent pending self-locking arm and no moving external parts to engage the lock.

When purchased separately as an attachment it can be mounted to the left or right hand side of most existing bench grinders with a max shaft size of 16mm.

Mitre Table Attachment available (See page 34)

The patent pending pivoting arm allows for fast and complete control of the working angle without disassembly in 6° increments.

Allows for easy cleaning and hassle free polishing belt changes. We recommend that the guard is kept in place during use.

Top platen can be used for flat surface grinding and can tilt out of the way for flexibility in free strapping mode.

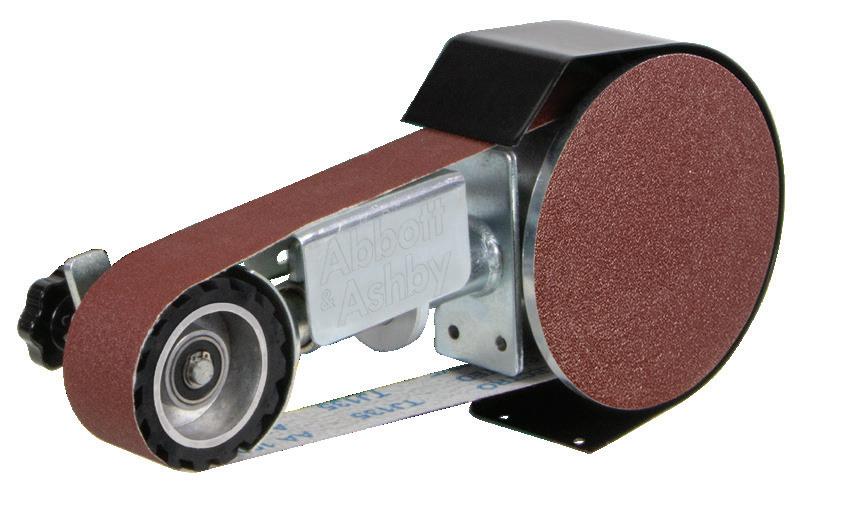

Featuring an extra long 48 x 2"" belt for larger work pieces, the AA482 linishing attachment can be easily installed to the left or right hand side of most 6” (150mm) or 8” (200mm) bench grinders with a max shaft size of 16mm. Ideal for those finishing jobs such as tool sharpening, edge sanding, smoothing welds, polishing etc. Use on many materials such as wood, plastics, metals and ceramics with a quick change of belts.

Features:

• Extra long 48” (1,220mm) x 2" (50mm) 240 grit belt for larger work pieces

• Patent pending design allows for fast changes to the working angle without disassembly in 6° increments

• Top platen can be used for flat surface grinding and can be moved out of the way for convenient free strapping

• Easy belt tracking adjustment knob and lock

• Fast belt changes with patent pending self-locking push in push out arm

Part No: AA482

Item Code: 812145

Belts Size: 1,220 x 50mm / 48 x 2" (240 Grit)

Disc Diameter: 178mm / 7" (100 Grit)

Contact Wheel: 89mm / 3 1/2"

Weight: 6.5kg

The linishing attachment is easily installed to the left or right hand side of most 6”(150mm) and 8”(200mm) bench grinders with a max shaft size of 16mm. Ideal for those finishing jobs such as tool sharpening, edge sanding, smoothing welds, polishing etc. Use on many materials such as wood, plastics, metals and ceramics with a quick change of belts.

Features:

• 36" (915mm) x 2" (50mm) 240 grit belt

• Patent pending design allows for fast changes to the working angle without disassembly in 6° increments

• Top platen can be used for flat surface grinding and can be moved out of the way for convenient free strapping

• Easy belt tracking adjustment knob and lock

• Fast belt changes with patent pending self-locking push in push out arm

Part No: AA362

Item Code: 808438

Belt Size: 915 x 50mm / 36 x 2" (240 Grit)

Disc Diameter: 178mm / 7" (100 Grit)

Contact Wheel: 89mm / 3 1/2"

Weight: 5.4kg

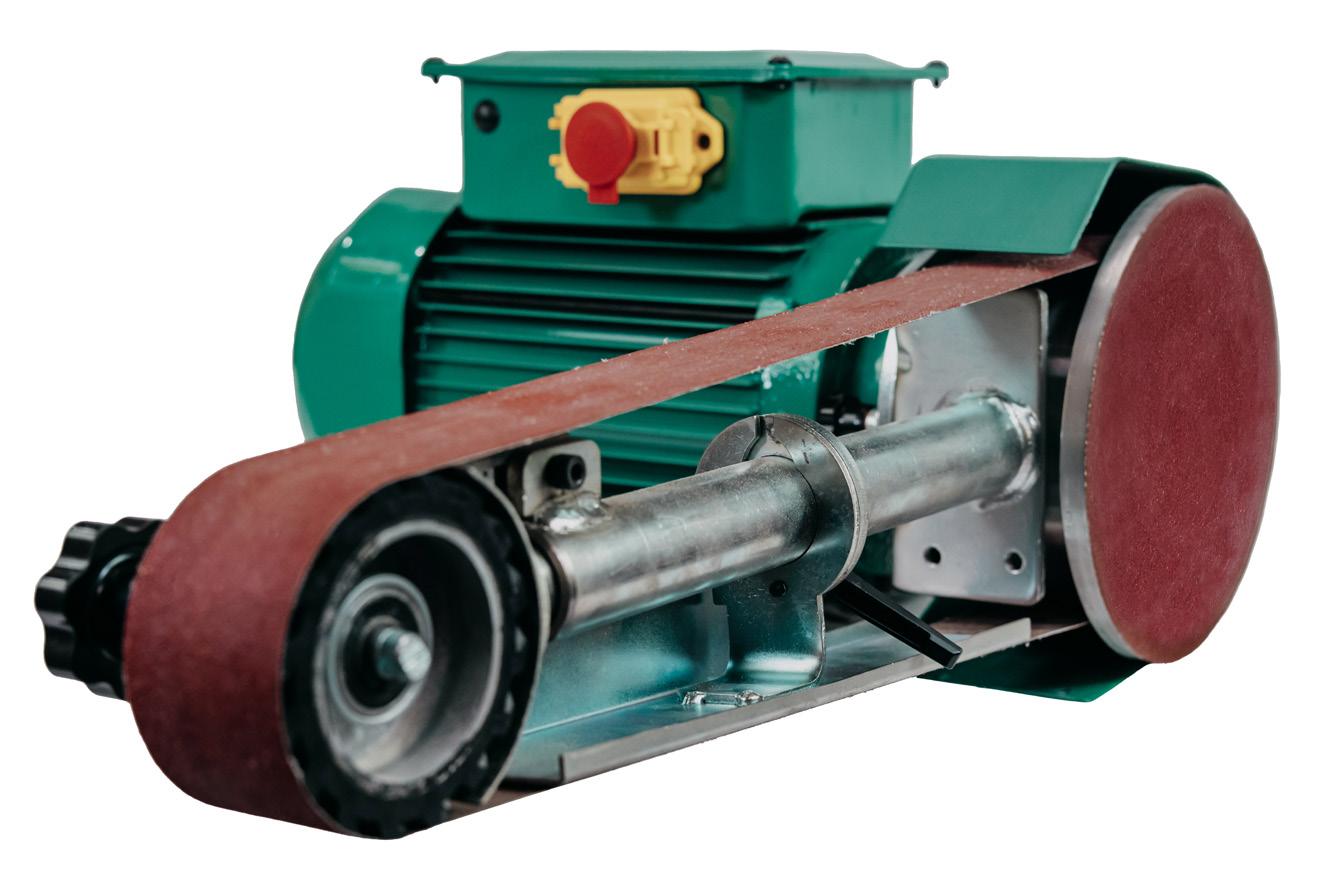

The Abbott & Ashby 2HP Bench-Mounted Belt Grinder is built for tough jobs, featuring a powerful 2HP motor and anti-vibration feet for stable operation. The NVR E-Stop switch provides added safety by preventing automatic restarts after power outages. Comes standard with:

• Powerful 2HP motor to handle the toughest tasks

• Rubber antivibration feet to avoid vibrating when mounted to a bench or pedestal.

• Mounting pattern suits pedestal stand

• Fitted with a No-Voltage Release E-Stop Switch which kills power to the machine during a power outage and won’t turn back on when power is restored.

• Patent pending design allows for fast changes to the working angle without disassembly in 6° increments.

• Top platen can be used for flat surface grinding and can be moved out of the way for convenient free strapping

• Easy belt tracking adjustment knob and lock

• Fast belt changes with patent pending self-locking push in push out arm

Part No: ATL1500/482

Item Code: 812146

Input/Output: 1700W/1500W - 2HP

Voltage: 240V ~ 50Hz (1Ph)

Amps: 5.2 (10A plug)

RPM: 2850

Belt Size: 1,220 x 50mm / 48 x 2" (240 Grit)

Disc Diameter: 178mm / 7" (100 Grit)

Contact Wheel: 89mm / 3 1/2"

Weight: 24kg

ATBM280/6

The general purpose buffing machine uses the industrial 6”(150mm) bench grinder with powerful induction motor. Premium features achieve a high shine and brightness from just about any metal. Perfect for polishing most metals.

• 150mm precision made tapered jewellers spindles included as standard

• ‘Sealed for life’ ball bearings for prolonged life

• Vibration absorption pads on base for smoother running and a better finish

• Cast iron body and base make the grinder strong and hard wearing for years of performance

• Capacitor start-stop motor for maximum performance

Part No: ATBM280/6

Item Code: 804536

Input/Output: 420W/280W

Volts: 240V ~ 50Hz (1Ph)

Amps: 1.8 (10A plug)

RPM: 2880

Wheel Size: 150mm / 6"

Weight: 7kg

Abbott & Ashby buffing mops are used in conjunction with compounds to obtain a more refined, brighter finish to your work. Buffing mops are available in both loose leaf calico and stitched sisal to ensure that you achieve the desired finish on your metal or alloy work piece. All mops have tapered centre bores and may be mounted on the left or right of your grinder using a tapered buffing spindle.

Stitched mops are used to obtain a heavy polish on metals and alloys.

Part No: AAMOPST150/1 AAMOPST200/1

Item Code: 500163 500165

Diameter: 150mm/6” 200mm/8”

Width: 25mm/1” 25mm/1”

Bore: Tapered Tapered

Loose leaf mops are used for polishing all metals and alloys.

Part No: AAMOP150/1 AAMOP200/1

Item Code: 500122 500123

Diameter: 150mm/6” 200mm/8”

Width: 25mm/1” 25mm/1”

Bore: Tapered Tapered

• Avoid using different compounds on one mop. Keep a separate mop for each compound and label it clearly.

• Select the correct mop for the job - a stitched mop for cutting back or general purpose work, or a loose leaf calico mop for high gloss polishing.

• Dress the mop with compound across the rotating face for a few seconds, taking care not to overload the mop. It is far better to apply a little compound more frequently than to overdress the mop.

• After applying the compound, bring the work piece to the wheel and with light pressure move back and forth across the job.

• After the job is finished, remove any compound residue with mineral turpentine or methylated spirits.

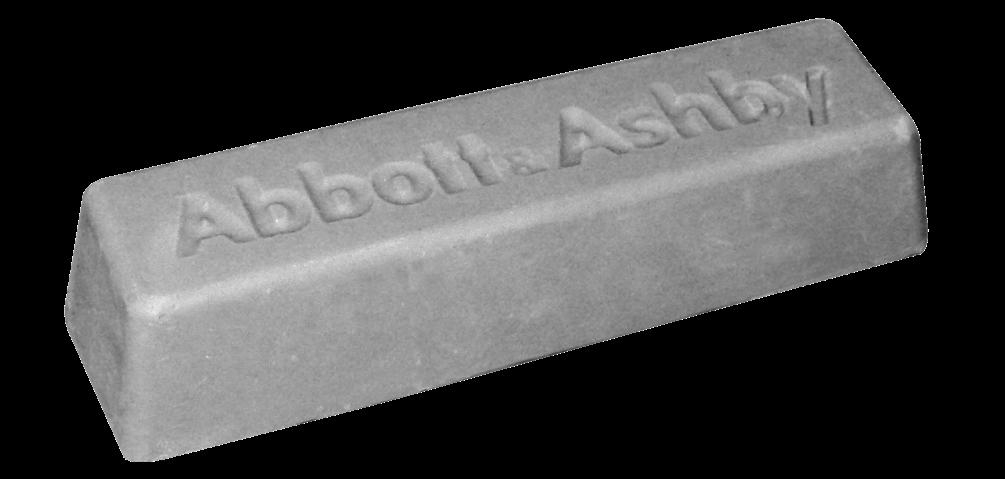

Abbott & Ashby compounds are used with mops to achieve the desired finish to your work piece. All metals have unique characteristics. This makes it imperative to choose the correct compound and polishing mop to do the job properly and achieve the best possible result.

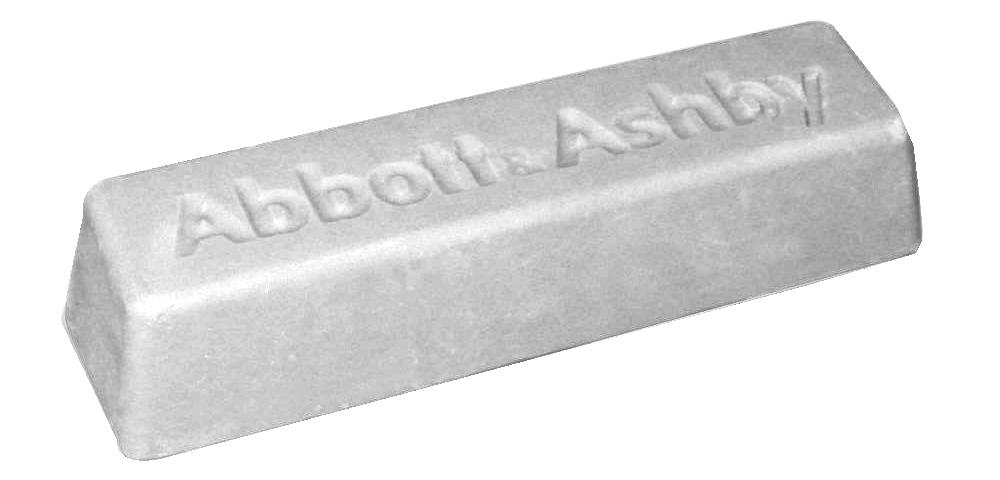

Grey Compound AACOMGREYBL

• Quick removal of deep marks, rust and pitting

• Used to cut back light scratch marks on copper, brass and stainless steel, prior to polishing

• Use only with a stitched mop

Part No: AACOMGREYBL

Item Code: 500049

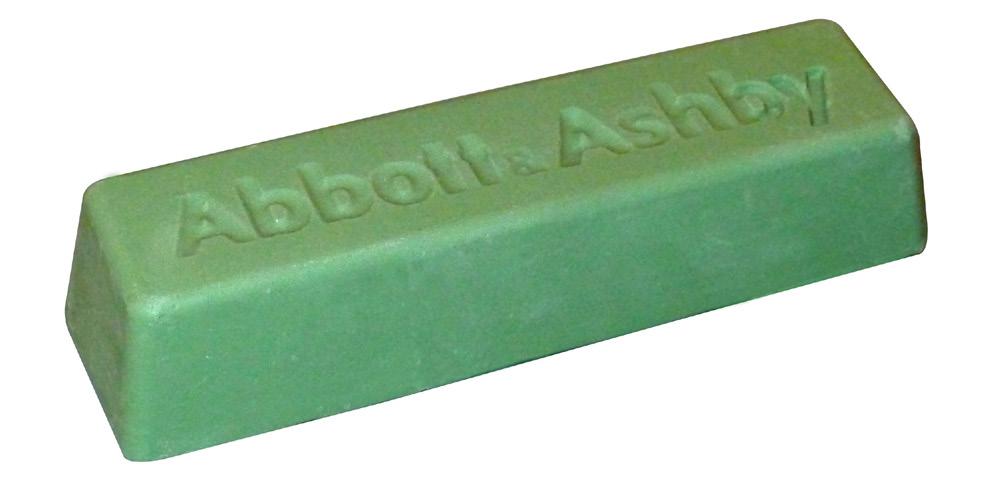

Green Compound AACOMGREENBL

• Use for high gloss finish on copper, brass and stainless steel

• Use with a loose leaf calico mop

Part No: AACOMGREENBL

Item Code: 500047

• General purpose compound for copper, brass, aluminium and most other metals

• Can be used with a stitched rag or loose leaf calico mop

Part No: AACOMREDBL

Item Code: 500051

AACOMWHITEBL

• For high quality finish on aluminium and aluminium alloys

• Use with a loose leaf calico mop

Part No: AACOMWHITEBL

Item Code: 500053

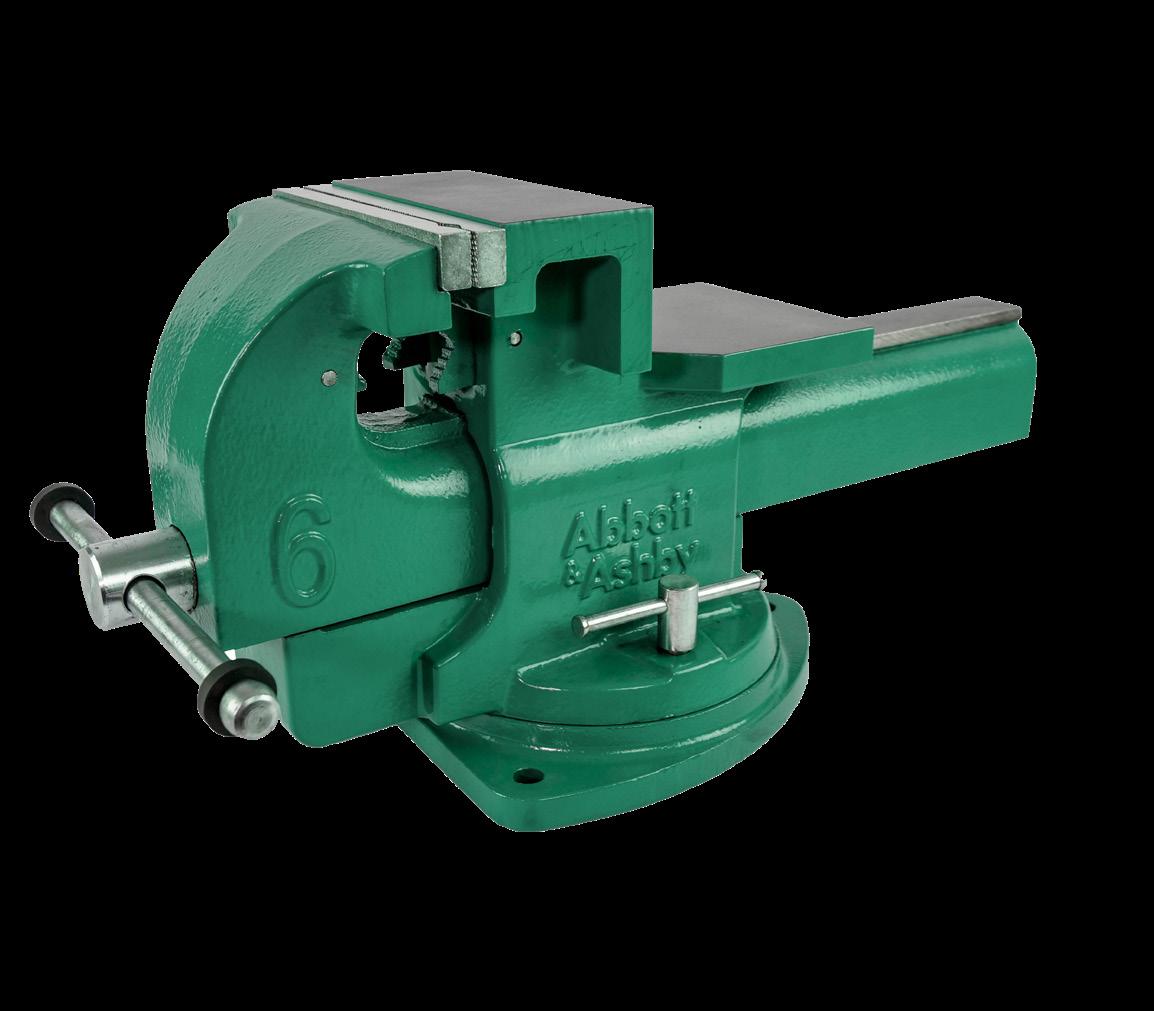

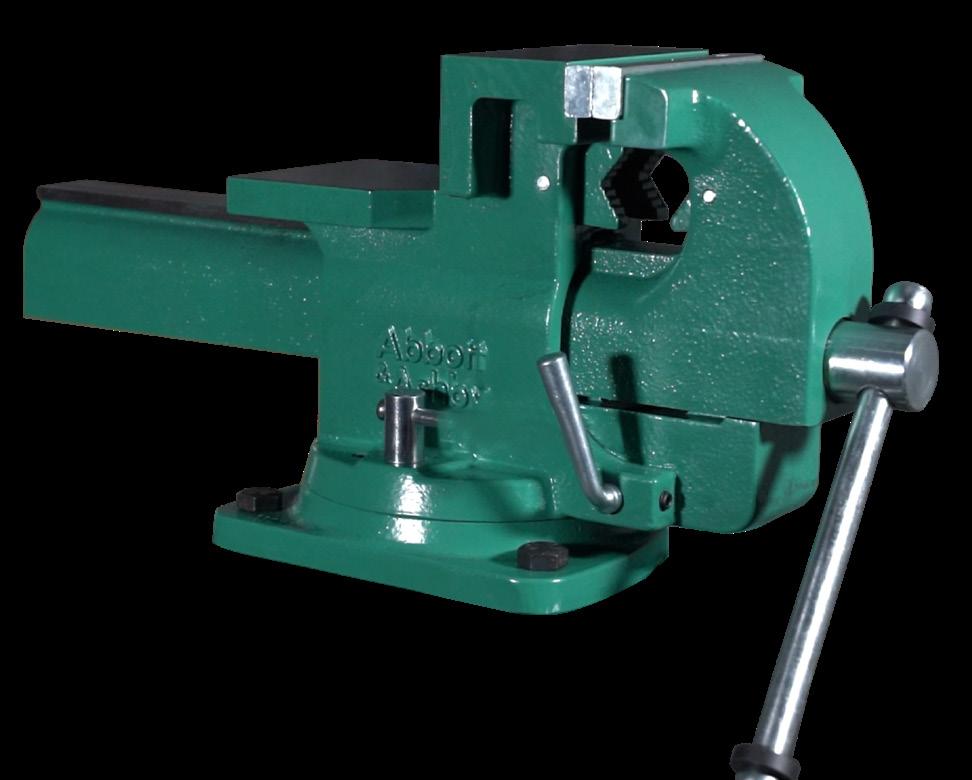

Abbott & Ashby bench vices are made from a high quality cast iron base and have been designed with the true professional in mind.

Our heavy duty bench vices have 3 integrated anvils which provide you with ample space for wood or metal working applications and are protected by a registered design. Our vices come standard with 360 degree swivel bases with dual lockdown handles to ensure that you always have a firm platform.

Features & Benefits:

• Heavy duty cast iron body

• 360o swivel base

• Quick release function

• 3 x Integrated large steel anvil

• Hardened steel jaws with vertical notch

• Integrated pipe jaws

Part No: ATBVHD125

Item Code: 810221

Jaw Width: 125mm

Jaw Opening Size: 178mm

Length: 461mm

Depth: 194mm

Height: 232mm

Weight: 21kg

Features & Benefits:

• Heavy duty cast iron body

• 360o swivel base

• Quick release function

• 3 x Integrated large steel anvil

• Hardened steel jaws with vertical notch

• Integrated pipe jaws

Part No: ATBVHD150

Item Code: 810222

Jaw Width: 150mm

Jaw Opening Size: 203mm

Length: 508mm

Depth: 207mm

Height: 244mm

Weight: 23kg

Features & Benefits:

• Heavy duty cast iron body

• 360o swivel base

• Quick release function

• 3 x Integrated large steel anvil

• Hardened steel jaws with vertical notch

• Integrated pipe jaws

Part No: ATBVHD200

Item Code: 810223

Jaw Width: 200mm

Jaw Opening Size: 254mm

Length: 591mm

Depth: 240mm

Height: 263mm

Weight: 35kg

Abbott & Ashby bench vices are made from a high quality cast iron base and have been designed with the true professional in mind. Our large integrated anvil provides you with ample space for wood or metal working applications. Abbott & Ashby vices come standard with 360o swivel bases with dual lock-down handles to ensure that you always have a firm work platform.

Features & Benefits:

• Heavy duty cast iron body

• 360o swivel base

• 360o rotating jaws

• Integrated large steel anvil

• Hardened steel jaws

• Integrated pipe jaws

Part No: ATBVU125

Item Code: 810220

Jaw Width: 125mm

Jaw Opening Size: 125mm

Length: 420mm

Depth: 150mm

Height: 230mm

Weight: 19kg

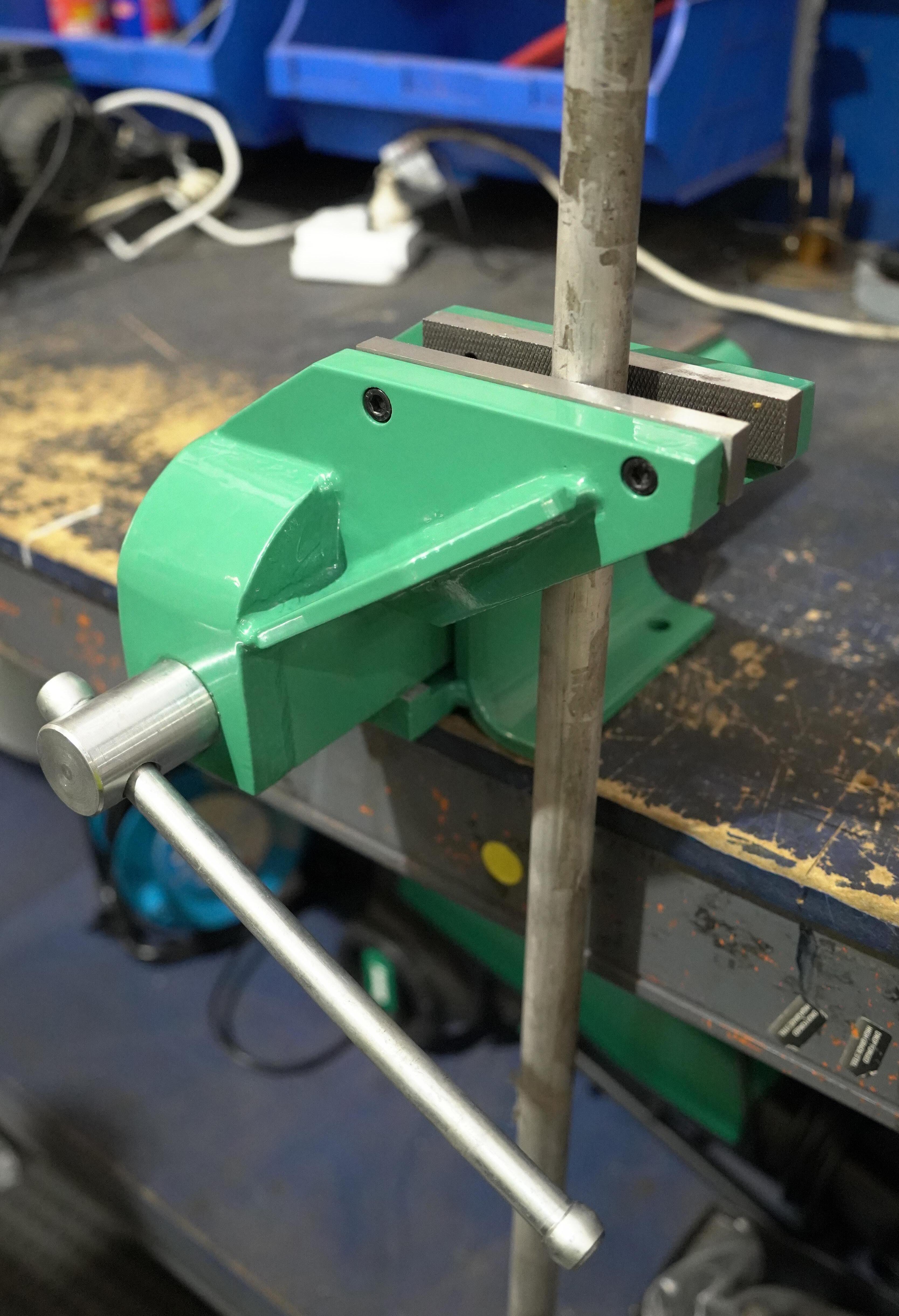

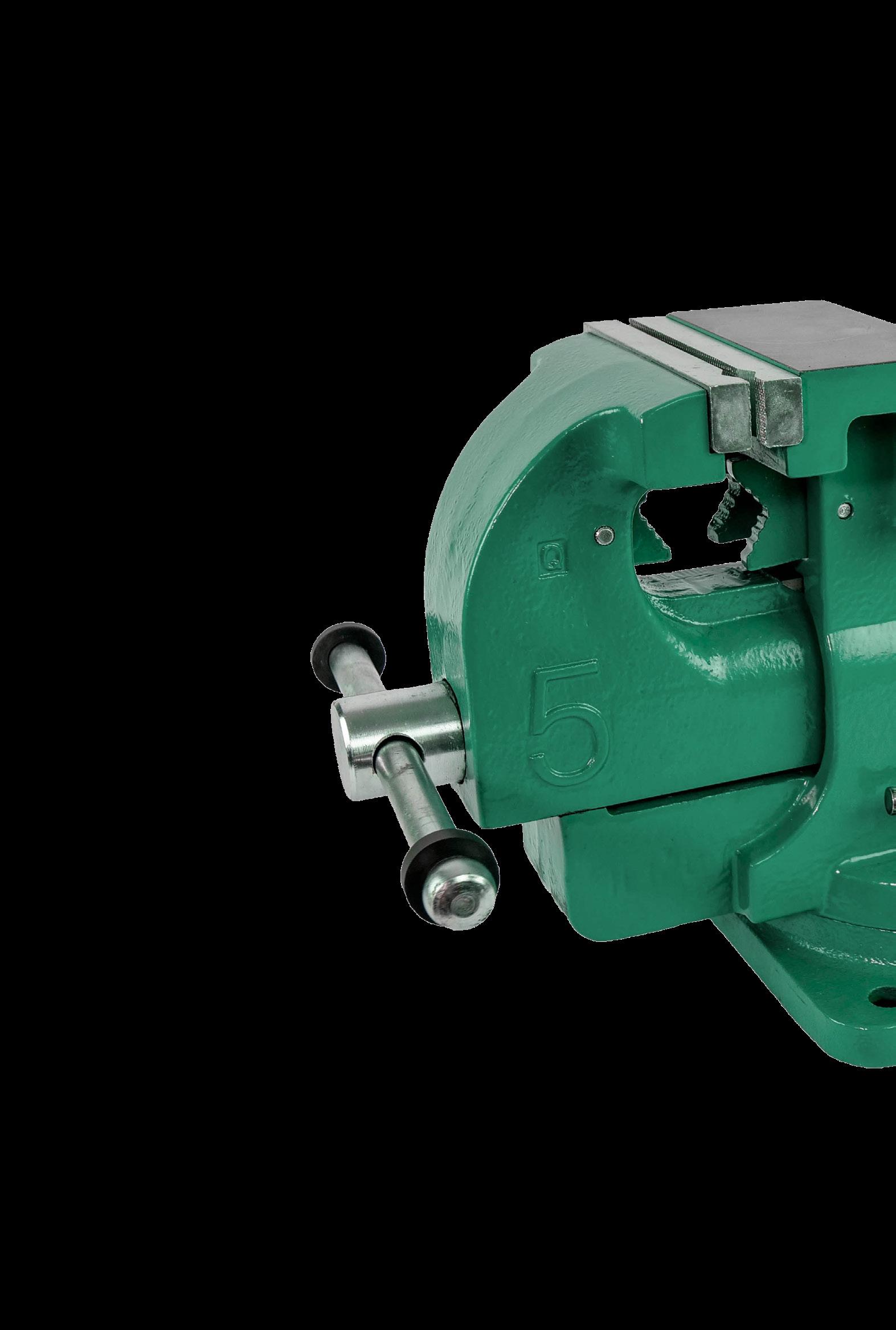

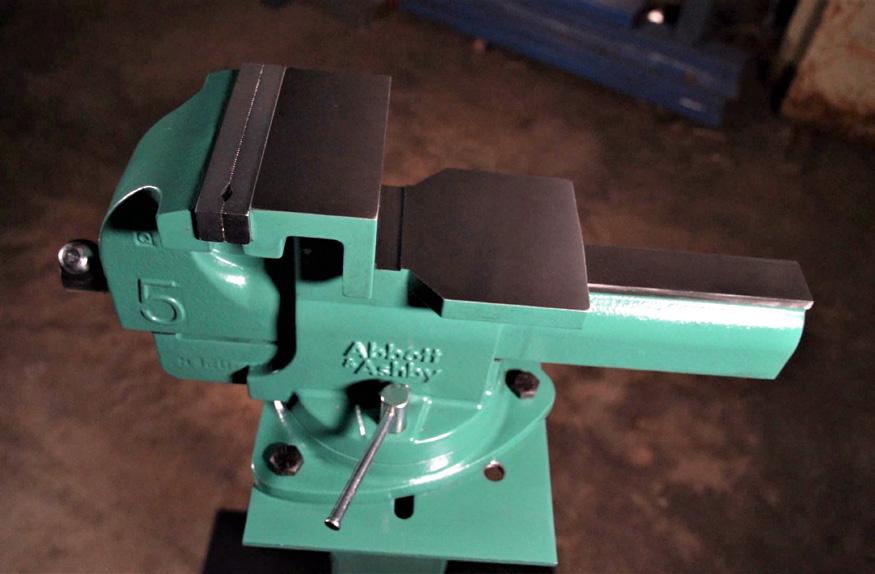

Introducing the NEW 6” Offset Vice from Abbott and Ashby, a pinnacle of Australian engineering, designed to deliver superior performance and versatility.

Key Features :

Innovative Offset Design: Allows for clamping long vertical workpieces with full jaw width access, free from obstructions by the vice body.

Exceptional Quality: Provides a firm grip with no flex, making it ideal for the most demanding tasks.

Heavy Steel Construction: ensuring durability in the harshest industrial environments.

Replaceable Hardened and Serrated Steel Jaws: Guarantees extended lifespan, consistent performance and easy to replace when needed.

Secure Mounting: Equipped with a fixed base and four bolt-down points for safe and stable installation.

Part No: ATBVQS150

Item Code: 811618

Jaw Width: 150mm

Jaw Opening Size: 190mm Length: 470mm

280mm

190mm

23kg

Introducing Abbott & Ashby’s NEW range of precision-engineered Drill Press Vices, proudly designed right here in Australia. Perfect for machine shops, fabrication workshops and tool rooms, these vices are built to impress.

Key Features:

Key Features :

Premium Cast-Iron Construction: Ensures robust durability and long-term reliability.

Precisely Machined & Case-Hardened Steel Jaws: For superior strength and performance.

Replaceable Steel Serrated Jaws: Built to last, and easy to replace when needed.

Corrosion-Resistant Screw and Handle: Designed for enduring performance in demanding environments.

Heavy-Duty Swivel Crank Clamping Threads: Made from high-quality, corrosion-resistant steel for secure and stable clamping.

Versatile Slotted Base: Fits most drill press base tables, ensuring easy and stable mounting.

Part No: ATBVQ193A

Item Code: 811619

Jaw Width: 75mm

Jaw Opening Size: 80mm

Length: 140mm

Depth: 150mm

Height: 45mm

Weight: 1.7kg

Part No:

ATBVQ195A

Item Code: 811620

Jaw Width: 100mm

Jaw Opening Size: 128mm

Length: 247mm

Depth: 185mm

Height: 60mm

Weight: 3.0kg

Part No:

ATBVQ196A

Item Code: 811621

Jaw Width: 150mm

Jaw Opening Size: 150mm

Length: 280mm

Depth: 223mm

Height: 68mm

Weight: 4.0kg

Abrasive Belts

Abrasive Discs

Grinding Wheels

Spindles

Tools

Pedestals

Quick Clamp

Mitre Table

Vice Jaws

Abbott & Ashby’s range of abrasive belts covers a wide range of applications. Whether the job calls for aluminium oxide or surface conditioning belts, you are sure to find the right size and grit within the range. Not only does the density of sandpaper grit make a difference in the success of your sanding project, but the type of abrasive material does too. Some types of grit grain are better suited to smooth and sand different types of materials (metal versus wood, for example).

suits AA362

suits AA362

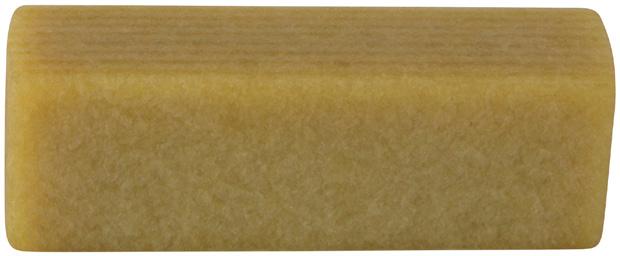

The belt restoring stick is the quick and easy way to rejuvenate sanding belts and discs. While running the machine, slightly press the edge of the cleaning stick against the belt or disc. Embedded material is removed quickly and easily with little effort. Fast and easy to use.

• Clean while sander is running

• Saves money and time

• Improves finish quality

• Prevents burns and marking

General purpose & versatile abrasives for use with sanding applications.

Abrasive discs suit AA362 and AA482 Abbott & Ashby Linishing Attachment and other same sized linishers.

Has self adhesive back for easy installation onto linishing attachment.

Used in conjunction with self adhesive backing pad on linishing attachment. Ideal for quick removal and replacement.

Hook loop self adhesive backing pad. Used for mounting abrasive disc with loop back onto sanding machine.

Silicon Carbide: The most durable of all synthetic abrasives. Good for sanding a wide range of materials, including plastic, metal, hardwoods and softwoods.

Surface Conditioning: For use on steel, stainless steel and a variety of other metals, to clean, blend, deburr and finish.

Sturdy and reliable, this multi-bore bench grinding wheel is ideal for sharpening a variety of cutting tools, giving you a fine grain surface finish.

• Vitrified bonded silicone carbide wheel

• Ideal for quick removal of material

• For general purpose grinding of carbon steel, stainless steel, alloys, cast iron, non ferrous metals, non metallic materials such as glass, ceramics and rubber

• Multi-bore fits most 6” and 8” bench grinders

The wire wheels are made of crimped brass coated carbon steel wire. The crimped wire wheel offers high flexibility for applications on irregular surfaces. Excellent for light brushing, surface preparation, general purpose cleaning and deburring. They also support consistent, uniform brushing since the tool’s cutting action is at the filament tips.

• Carbon Wire: 0.014

• Bore Diameter: 32mm with multi-bore adapters - fits most 6” & 8” bench grinding machines

• Best results are achieved by applying light pressure, which will ensure the fastest brushing action and longest brush life

• Excessive pressure will cause over bending of the filaments which can result in filament breakage, rapid dulling and reduced brush life

• Periodically reverse the wire brush to take advantage of the opposite cutting edge of the filament

Abbott & Ashby Spindles are used to allow the fitting of mops and buffs to most bench grinders.

AATBE/200MPK

Suitable for both 6” (150mm) or 8” (200mm) bench grinders to allow our range of buffing mops to be used for the desired finish.

Part No: AATBE/150MPK AATBE/200MPK

Item Code: 805953 805952

Includes: Left and Right Left and Right

Shank 12mm 16mm

Suits Size: 150mm 200mm

Allows mounting of small mops to our popular 6” (150mm) grinders. Ideal for jewellery polishing or any detailed or intricate work. Smooth bore to prevent potential for catching.

Part No: AATBE/150JMPK

Item Code: 805954

Includes: Left and Right

Shank: 12mm

Suits Size: 150mm

• Remove outer wheel guard, grinding wheel and inner guard from the side of the machine that you want to fit the tapered spindle.

• Screw on the tapered spindle noting that the internal thread of the spindle is counter bored to allow the spindle to cover the entire grinder shaft length.

• Carefully screw the buff onto the tapered spindle with the thickest flange facing inwards. Screw on as far as the buff will reasonably fit.

• Turn on bench grinder and the buff will tighten further against the tapered spindle. To ensure your safety, do not stand in front of the machine when you first turn it on and allow it to run for a minute before bringing your work to the machine.

Adjustable 2 pin spanner to suit the locking nut on most angle grinders. Adjustable from 18mm to 38mm. Made from hardened steel.

Part No: AAAPS

Item Code: 808857

The heavy duty pedestal is designed to suit most benchtop tools and allows for comfortable extended usage with no interference. Manufactured from heavy duty steel sections, the pedestal is designed to support both 6” (150mm) & 8” (200mm) bench grinders without taking up valuable bench space.

• Easy to assemble with included tools

• Coolant cup mounting bracket

Part No: ATPED-HDK

Item Code: 500870

Height: 860mm

Weight: 14.0kg

The emergency stop can be mounted onto most existing pedestals.

• Push stop button allows for quick knee operation to stop the machine

• Can be used to convert any 10Amp machine to have an emergency stop

• Complies with AS/NZS IEC 60947 standard

Part No: ATPED-ESTOP

Item Code: 805518

Our favourite heavy duty pedestal and the innovative E-Stop have joined forces to give you a practical solution to your grinding and linishing needs, without compromising on safety.

• Assembly required to mount the E-Stop button to the pedestal

• E-Stop complies with AS/NZS IEC 60947 standard

Part No: ATPED-HDK+ESTOP

Item Code: 805630

Height: 860mm

Weight: 16.0kg

Maximise efficiency and ease in your workshop with our versatile and durable Quick-Clamps. Designed for rapid and secure clamping, these clamps are perfect for securing equipment on benches or presses. Ideal for quick adjustments of drill press vices on drill press tables, they streamline your workflow and enhance productivity.

Features :

• Built for rapid and secure clamping

• A robust design that delivers exceptional grip strength and stability

• Keeps your workpieces firmly in place

• Ergonomic handle ensures an easy and comfortable operation

• Quick-release mechanism allows for effortless adjustment and repositioning

(Pack of 2)

Part No: AAQC-50

Item Code: 811798

Length 100mm

The mitre table provides an accurate way to grind ends square and adjust lengths and angles. It is an after market accessory that allows even more versatility when using the linisher. A simple 2 bolt attachment fixes it to the linisher. It has the ability to tilt both up and down and comes with a protractor to allow great control over the working angles when using the abrasive disc on the side of the linishing attachment.

• Fits the AA362 and AA482 Abbott & Ashby linisher attachment

• Table can be tilted up 10° & down 45°

Part No: AAMT

Item Code: 808861

Size: 110 x 204mm

Abbott and Ashby’s Vice Jaws enhance your clamping capabilities for both intricate projects and heavy-duty tasks. They provide a secure, accurate grip, suitable for fine craftsmanship and industrial-grade work. Compatible with Abbott and Ashby vices and other brands , they ensure seamless attachment and optimal performance. Item Code

812309 AAVJT42 4” Vice Jaw Standard Soft Moulded Magnetic (PACK OF 2)

812310 AAVJT62 6” Vice Jaw Standard Soft Moulded Magnetic (PACK OF 2)

811790 AAVJR41 4” Vice Jaw Standard

Nylon Moulded Magnetic (PACK OF 2)

811791 AAVJR61 6” Vice Jaw Standard Nylon Moulded Magnetic (PACK OF 2)

811794 AAVJA41 4” Vice Jaw Standard Aluminium Magnetic (PACK OF 2)

811795 AAVJA61 6” Vice Jaw Standard Aluminium Magnetic (PACK OF 2)

812289 AAVJS42 4” Vice Jaw Multigrip Soft Moulded Magnetic (PACK OF 2)

812290 AAVJS62 6” Vice Jaw Multigrip Soft Moulded Magnetic (PACK OF 2)

811792 AAVJR42 4” Vice Jaw Multigrip Nylon Moulded Magnetic (PACK OF 2)

811793 AAVJR62 6” Vice Jaw Multigrip

Nylon Moulded Magnetic (PACK OF 2)

811796 AAVJA42 4” Vice Jaw Multigrip Aluminium Magnetic (PACK OF 2)

811797 AAVJA62 6” Vice Jaw Multigrip Aluminium Magnetic (PACK OF 2)

• Easy to use, simply place over existing jaws

• Protects the work piece from scoring or marking

• Magnets hold jaws in place

• Fits any vice

• Easy to use, simply place over existing jaws

• Protects the work piece from scoring or marking

• Multigrip face for holding variety of round or square objects

• Magnets hold jaws in place

• Fits any vice