This page intentionally left blank.

This page intentionally left blank.

Organisation: Connectus

Document Title: Industrial and Trade Activities Environmental Management Plan

Fulcrum Document Number: CRL-PAT-ENV-CON-PLN-000895

Document based on MMS No: n/a

Client: Auckland Transport Project: CRL Enabling Works: Contract Two

This document remains the property of Connectus. Its contents are confidential and shall not be reproduced, destroyed or given away without the express, written permission of Connects. The electronic version of this document in MMS Database on designated server(s) is the Master Copy and is a controlled document. Unless specifically noted thereon, other copies of this document are uncontrolled.

This page intentionally left blank

ACZ Active Construction Zone (D and E relate to the Project works) – identified during the consenting process to delineate construction methodology for different areas of the project.

AT Auckland Transport

CEMP Construction Environmental Management Plan

CLG Community Liaison Group

CRL City Rail Link

CSA Construction Support Area

EHS Environmentally Hazardous Substances

EMP Environmental Management Plan

ESCP Erosion and Sediment Control Plan

ITA Industrial and Trade Activity

ITA

EMP Industrial and Trade Activities Environmental Management Plan

MSDS Material Safety Data Sheet

SOP Standard Operating Procedure

This page intentionally left blank.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000895

Revision: 04, Date: 21 March 2016

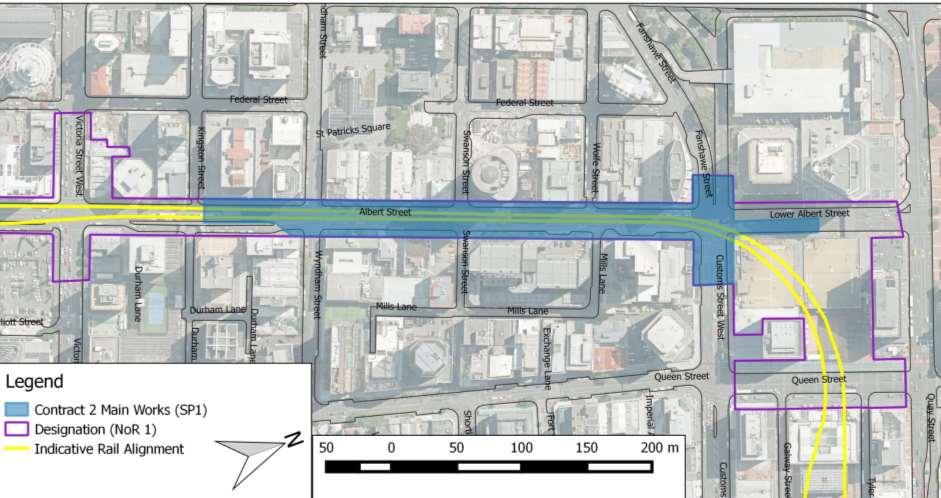

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line in the vicinity of Mt Eden station. The works relating to this Industrial and Trade Activities Environmental Management Plan (ITA EMP) constitute part of the enabling works for the CRL. The works (the Project) involve the construction of twin rail tunnels within the Albert Street road corridor from Customs Street West to Wyndham Street. The tunnels will be constructed using a staged cut and cover method and are expected to take 33 months to complete. Figure 1 outlines the extent of works for the Project.

This ITA EMP has been prepared by AECOM New Zealand Limited (AECOM) and forms part of the Construction Environmental Management Plan (CEMP) for the Project. The ITA EMP specifically relates to conditions 95 – 104 of discharge permit R/REG/2014/5436.

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

This ITA EMP has been prepared to manage the ITAs that will be undertaken in Construction Support Areas (CSAs) 4, 5 and 6 which are associated with the construction of the Britomart Station to Wyndham Street (Britomart to Wyndham) section of the City Rail Link (CRL) project. It provides a framework for the effective management of stormwater discharges from these CSAs - i e the Northern Compound (CSA 4 and CSA 5) and the Southern Compound (CSA 6), and documents the management and operational systems employed by Connectus to ensure that the environmental objectives of the site are met. The Project site will be operated and managed in accordance with this ITA EMP at all times.

The Project comprises Active Construction Zones (ACZ) D and E (refer Figure 2), which were identified during the CRL Britomart to Wyndham enabling works consenting process to delineate construction methodology for different work areas. This ITA EMP does not apply to the ACZs because potentially contaminated stormwater generated in the ACZs will be pumped out of the trenches for treatment prior to discharge to the public stormwater system or managed as part of the erosion and sediment control processes (refer to the Project Erosion and Sediment Control Plan (ESCP) –Appendix I of the Project CEMP)

Condition 98 of R/REG/2014/5436 requires that a copy of the ITA EMP (certified version) is kept on site and is accessible at all times.

This ITA EMP has been prepared in consultation with a Community Liaison Group (CLG) prior to submission to Auckland Council (as per resource consent condition 19). A record of consultation outcomes is included in Appendix D.

A number of related management plans are referenced throughout this ITA EMP to avoid duplication of information and thereby enable efficient document control. The other relevant plans are the Project CEMP, Project ESCP (Appendix I of the Project CEMP, including Appendix D - Chemical Treatment Management Plan (CTMP)) and the Project Emergency Spill Response Plan (ESRP) (Appendix T of the Project CEMP)

Figure 2 Location of ACZs D and E

This ITA EMP has been developed specifically to fulfil the requirements of Discharge Permit R/REG/2014/5436, for the discharge of water and wastewaters.

Table 1 identifies the relevant consent conditions and where these are addressed within the ITA EMP.

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Table 1 ITA consent conditions from R/REG/2014/5436 and the relevant sections of this document

Condition Number Condition

95 This consent shall expire 15 years after the consent commences unless it has been surrendered or been cancelled at an earlier date pursuant to the Resource Management Act 1991.

96 At least 20 working days prior to the commencement of construction, a final Industrial and Trade Activities Environmental Management Plan (“EMP”) shall be submitted to the Council (Team Leader Central Monitoring) for certification. The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the EMP can be certified, in writing, within 10 working days following receipt of the EMP. The EMP shall be prepared by a senior qualified person and shall include, but not be limited to, the following:

a. identification of the specific activities conducted on the site; 4

b. the identification of potential contaminants associated with these activities; 5

c. methods used to prevent identified contaminants contacting stormwater runoff as far as practicable and methods to manage environmental risks from site activities;

d. an Emergency Spill Response Plan (which includes the provision that all spills over 20 litres, or any spill of Environmentally Hazardous Substances that has entered the stormwater system, a water-body or has contacted unsealed ground, shall be reported immediately to the Auckland Council’s 24 Hour Pollution Hotline (09-377-3107));

6

Appendix T of the Project CEMP (Emergency Spill Response Plan)

e. an up-to-date and accurate site drainage plan showing the location of all site catchpits and the final discharge point(s) of the site stormwater system; 4 and Appendix A

f. an appropriate auditing programme to ensure site performance with all components of the sites EMP;

g. methods for providing and recording staff training; and 8

h. a monitoring programme as outlined in Condition 101.

97 The Consent Holder shall ensure that the site is operated and managed in accordance with the certified EMP to ensure the risks from the site are managed appropriately.

98 The Consent Holder shall ensure that a copy of the certified EMP is kept on site and accessible at all times.

99 The Consent Holder shall ensure that the following structural controls are constructed for the following catchment areas and design requirements and they are completed prior to discharges commencing from the site.

Works Device catchment area Design requirements Works Device catchment Design Requirement

Settlement Tanks (2x 12,000l tanks), located in CSAs 2 and 4

Bunding of Environmentally Hazardous Substances

All ACZs Discharge levels as per monitoring Condition 101

As required 110% of largest container

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

100 In the event that any minor modifications to the structural controls system are required, the following information shall be provided to Council:

a. Plans and drawings outlining the details of the modifications; and 6.1

b. Supporting information that details how the proposal does not affect the capacity or performance of stormwater management system.

All information shall be submitted to, and the proposed modifications certified by the Council (Team Leader Central Monitoring), prior to implementation.

101 Within 30 days of the installation of the water treatment system, and prior to operation, a discharge monitoring programme, to assess the ongoing adequacy of all management practices, shall be developed and submitted to the Council (Team Leader Central Monitoring) for certification. The monitoring programme shall include, but not be limited to:

2.3, 6.3 and Section 3.5 of the Project CTMP

a. sampling location for final discharge from the site(s); 2.3, 6.3 and Section 3.5 of the Project CTMP

b. sampling locations on site (i.e. swale inlets, outlets etc); 2.3, 6.3 and Section 3.5 of the Project CTMP

c. methods and procedures for discharge sampling on a quarterly basis;

d. monitoring parameters for analysis, which shall include:

a) sampling location for final discharge from the site(s);

b) sampling locations on site (i.e. swale inlets, outlets etc);

c) methods and procedures for discharge sampling on a quarterly basis;

d) monitoring parameters for analysis, which shall include:

Daily

Turbidity (NTU)

pH

Weekly

Total Suspended Solids mg/L

Copper (total) mg/L

Zinc (total) mg/L

Lead (total) mg/L

Total Petroleum Hydrocarbons mg/L

e. identified trigger levels for each of the above parameters. These trigger levels shall be developed with reference to the ANZECC Guidelines for water quality where applicable; and

f. the methods and procedures for investigating and reporting stormwater discharge monitoring results to the Council (Team Leader Central Monitoring).

102 The discharge monitoring programme shall be implemented upon completion of works set out in Condition 99.

2.3, 6.3 and Section 3.5 of the Project CTMP

2.3, 6.3 and Section 3.5 of the Project CTMP

2.3, 6.3 and Section 3.5 of the Project CTMP

2.3, 6.3 and Section 3.5 of the Project CTMP

2.3, 6.3 and Section 3.5 of Project the CTMP

103 Within five working days of receipt of sample results showing contaminants exceeding the agreed trigger levels (Condition 101(e)): 2.3, 6.3 and Section 3.5 of the Project CTMP

a. an investigation shall be undertaken to determine why exceedances were detected and to identify any additional source controls or treatment required; and

b. the results of the investigation shall be reported to the Council (Team Leader Central Monitoring).

2.3, 6.3 and Section 3.5 of the CTMP

2.3, 6.3 and Section 3.5 of the CTMP

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000895

Revision: 04, Date: 21 March 2016

Condition Number Condition Relevant

104 Within eight weeks following the start of the monitoring required by Conditions 101 and 102, a monitoring report shall be submitted to the Council (Team Leader Central Monitoring). The monitoring report shall include, but not be limited to, the following:

2.3, 6.3 and Section 3.5 of the CTMP

a. a summary of the monitoring results to date; 2.3, 6.3 and Section 3.5 of the CTMP

b. an interpretation of those results and suggestions for improvement to the site operations;

2.3, 6.3 and Section 3.5 of the CTMP

c. a programme for ongoing monitoring including the reporting of results; and 2.3, 6.3 and Section 3.5 of the CTMP

d. a programme for the ongoing maintenance of the discharge water management and treatment system.

2.3, 6.3 and Section 3.5 of the CTMP

This ITA EMP has been prepared by Justine Bennett, Associate Director and Team Leader Natural Resources at AECOM. Justine has 18 years’ professional experience as an environmental scientist, focussed on water quality, stormwater and wastewater discharge management.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

This section presents a summary of the Project in relation to the matters required to be addressed by the ITA EMP. A detailed description of the construction works is provided in the Project CEMP.

Connectus will use a staged cut and cover methodology to construct two parallel rail tunnels within the Albert Street road corridor between Customs Street and Wyndham Street. The total length of the tunnel for the Project will be 340m. A number of utilities are required to be removed, relocated, or supported during construction.

Generally, the Project works undertaken within the relevant ACZs (D and E) will consist of:

1. Utilities relocation and exposure

2. Piling and capping beam construction within Albert Street;

3. Piling and road deck construction within the Customs Street intersection;

4. Trench Excavation, including using shotcrete and rock dowelling;

5. Construction and waterproofing of the rail tunnels; and

6. Backfill of the trench, including construction of the new road pavement.

Full details of the construction methodology can be found in the Project CEMP.

The Project makes use of three of the CSAs identified during the consenting process. The locations of these are shown in Appendix A. In addition, a construction support deck will be constructed adjacent to the trench in Albert Street.

Details of each CSA are provided below.

CSA 6 – at the southern end will provide for:

A small site office

A laydown area for materials and equipment

A small toilet and lunchroom facility

A generator

A load-in area for backfill material.

Concrete pumping equipment and concrete load-in.

Skip bins / rubbish and recycling bins

Provision for 150m³ of stockpiled material during the tunnel backfilling.

An earthworks storage area used for storing spoil during excavation and storing backfill material during backfilling

Project #: 2665

Client: Auckland Transport

CSA 4 – at the northern end will provide for:

General and hazardous goods storage

Piling and deck equipment laydown

Skip bins / rubbish and recycling bins

Spill kits

Jet grouting equipment storage

A more substantial lunchroom and toilet facility

Site offices

A generator

Vehicle and Equipment Parking

Materials delivery and handling

Settling tanks

CSA 5 – On Customs Street:

Revision: 04, Date: 21 March 2016

CSA 5 will be a relatively fluid construction support area as the intention is to keep traffic lanes open through staged construction of a traffic deck. During deck piling and deck construction CSA 5 will be used for:

Piling equipment laydown

Jet grouting equipment

A Generator

Concrete delivery and pumping.

Portable toilet facilities

Skip bins / rubbish and recycling bins

Parking for the spoil removal truck

A bunded stockpiling area

Once the bridge deck is complete, most of the area identified as CSA 5 during consenting will be open to traffic as works are carried out beneath the bridge.

This ITA EMP relates only to activities in the CSAs 4, 5 and CSA 6 Appendix A provides plans showing an indicative layout for each CSA.

Drawing CRLC2-SKE 0355 provides an over view of the Customs Street/Albert Street Intersection where CSAs 4/5 are located.

Drawing CRLC2-SKE 0356 provides an over view of CSA 6 located on Albert Street.

Locations of site offices, stockpile areas, spill kits and Environmentally Hazardous Substances (EHS) storage are indicated along with specific construction equipment locations.

Groundwater and rainwater which collects in the trench during construction works will be treated as detailed in the ESCP and CTMP. During the first phase of trench excavation, dirty water will be pumped to settlement devices. As trench excavation proceeds, a specifically designed water treatment plant (WTP) will be located within the trench. The WTP will treat water from the ACZs and a small amount of water from the fill handling area in CSA 6. The details of the water treatment system are included in the ESCP.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000895

Revision: 04, Date: 21 March 2016

It is noted that with the exception of CSA 6, the runoff from the ITA areas will not be treated by the WTP.

Within 30 days of the installation of the water treatment system, and prior to operation, a discharge monitoring programme, to assess the ongoing adequacy of all management practices, shall be developed in accordance with Resource Consent conditions 101-104 (refer Section 2.3 of this ITA EMP and Section 3.5 of the CTMP).

As required by Resource Consent condition 103, action is required if discharge sample results exceed trigger levels. The ESM will be immediately notified and communicate with Council to fulfil the following consent requirements:

Within five working days of receipt of sample results showing contaminants exceeding the agreed trigger levels (Condition 101(e)):

a) an investigation shall be undertaken to determine why exceedances were detected and to identify any additional source controls or treatment required; and

b) the results of the investigation shall be reported to the Council (Team Leader Central Monitoring).

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

The site activities occurring within CSAs 4, 5 and 6 are summarised in Table 2:

Table 2 Summary of Site Activities

Activity

Site offices and construction personnel amenities including portaloo or similar

Loading and unloading of construction materials including sand and aggregate.

Temporary storage area for backfill materials

Storage of construction materials such as steel reinforcing cages, pre-cast concrete elements, geotextiles, formwork (timber and steel), bagged cement

Storage of Environmentally Hazardous Substances

Fuel storage for pumps, generators etc

Use and storage of diesel pumps and compressors

Use and storage of concrete pumps

Use and storage of mobile generators

Localised refuelling of non road registered construction vehicles

Storage of jet grout pump and mixing plant (use will be limited to within the excavation)

Liquid waste storage and collection ( e g contaminated water, used chemicals, liquids and slurry from spill clean up, “slops and slurry” skips from active work zones

Solid waste storage and collection

Washdown of equipment (Excluding vehicles)

Vehicle movements between active work zones and construction support areas.

Stormwater/groundwater containment and/or treatment facility

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

The existing drainage system consists of the Auckland Council stormwater network currently in place within the Project site. This drainage system collects runoff from the road pavements and directs it to the stormwater pipelines which then discharge directly into the Waitemata Harbour through the existing discharge structure located at the Promenade The release of contaminants to the stormwater network will be managed using the controls described in the Project ESCP and this ITA EMP.

Appendix A provides site plans showing the existing stormwater drainage system within and adjacent to the Project site, including the ITA areas of CSAs 4, 5 and 6. The drawings also outline methods to manage sediment release during construction. Further details on sediment control methods can be found in the ESCP.

Drawing CRLC2-SKE 0351 provides an over view of the Project site

Drawing CRLC2-SKE 0355 provides an over view of the Customs Street Intersection where CSAs 4/5 Northern Compound) are located.

Drawing CRLC2-SKE 0356 provides an over view of CSA 6 (Southern Compound) located on Albert Street.

Project #: 2665

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Table 3 sets out the activities on site with the potential to generate contaminants which may enter the stormwater network. It also provides an assessment of the level of that risk and outlines structural and procedural controls to manage that risk. Appendix B provides examples of some of the procedures that will be used on site during the construction period.

Risk has been assessed in accordance with the Contractor’s Risk Assessment Guideline to establish an initial risk prior to controls (R1) and a residual risk after controls have been put in place (R2). Both assessments consider both likelihood of occurrence and level of consequence.

Table 3 Potential Contaminants and Controls

Site offices and amenities

Construction vehicle parking (limited number)

Construction equipment storage (pumps, compressors, mobile generators)

Storage, loading and unloading of construction materials, backfill and spoil

Storage, loading and unloading of construction materials

Loading and unloading of construction materials

Storage of fuel for generators, pumps and other equipment (includes non road registered construction vehicles )

Spillage from Portaloos

Oil and hydraulic fluid leakage

M

L

Oil, fuel and hydraulic fluid leakage M

Procedure for emptying of Portaloos to be developed and in the event of a spill the processes outlined in the Project Emergency Spill Response Plan will be implemented.

Regular inspection and servicing of vehicles. Repair to minimise leakage

Regular inspection and servicing of equipment. Repair to minimise leakage

Sediment laden runoff from soil and aggregate and used formwork.

Alkaline runoff from bagged cement leakage and grout.

Alkaline runoff from spillage of wet cement from trucks when delivered to site.

Spillage of fuel during delivery or refuelling activity.

M

Storage such that stockpile areas can be covered or stored in a bunded area so that sediment laden water can be treated prior to discharge.

Storage such that cements and grouts are either inside a shipping container or covered outside with a waterproof material.

Standard Operating Procedure (SOP) to be developed for process.

Check for spillage and clean up as required by the Project Emergency Spill Response Plan.

Site fuel tanks on bunded concrete pad with containment for spills so that spillage can be captured and disposed of appropriately.

Application of on site procedures for refuelling to minimise the risk of spillage.

Check frequently for leaks and spills and address as required by the Emergency Spill Response Plan

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

Loading and Unloading of EHS

Handling and temporary storage of excavated or demolition materials such as soil and used asphalt

Vehicle movements between active construction zone and CSAs

Equipment wash down (excludes construction vehicles which will be washed down in ACZ)

Storage of Jet grout pump and mixing plant (only on CSA 2 and 4).

Accidental spills of EHS

Stormwater and groundwater treatment tanks in CSA4

Stormwater runoff contaminated by spillage or temporary storage of spoil and other excavated materials.

Tracking of contaminants to the CSA catchment area

Washwaters drain to the stormwater system

Hydrocarbon leakage

Spillage of jet grout waste water prior to collection by waste disposal contractor

Overflow from stormwater and groundwater treatment tanks to the stormwater system

Liquid Waste storage and collection.

Solid Waste storage and collection.

M Store hazardous materials in designated and bunded EHS storage locations as soon as they are received. Use spill kits to clean up any spillage during transfer and use as required by the Project Emergency Spill Response Plan

M Load excavated spoil material and asphalt directly onto truck for removal from site.

If stored on site then either cover to prevent rain water contact or locate in contained area to enable runoff to be treated prior to discharge.

Rainwater ingress into waste containers and leaching of contaminants into stormwater

Rainwater ingress into waste containers and leaching of contaminants into stormwater

M

M

Regular cleaning of connecting access ways.

Install catchpit protection to minimise sediment discharge into the public stormwater system.

Washdown areas to be located on designated hardstand or plastic lined areas and drained such that washwaters are contained and treated prior to discharge or removed from site by liquid waste contractor.

Regular inspection and servicing of equipment. Repair to minimise leakage

Ensure jet grout waste skip is stored in designated area and emptied on regular basis.

SOP to be developed to check waste levels and for arrangement of disposal.

M

Treatment tank size and pump rates to be set to allow required residence time and additional containment of any peak flows or over flows to be provided.

M Regular inspection of skip to prevent overfilling.

All waste storage areas/skips to be covered to prevent rainwater entry.

M

All waste storage areas/skips to be covered to prevent rainwater entry. L

Project #: 2665

The following structural controls will be put in place to ensure that spills and contaminated water do not enter the stormwater system and receiving environment:

o Bunding of Environmentally Hazardous Substances (EHS) – bunding will be provided where required and designed to contain a volume of 110% of the largest container. This ensures that if the largest container ruptures the spillage can be contained until it can be disposed of safely.

o Settlement Tanks- Settlement tanks will be used to treat water from both the CSAs and the active construction zones. The tanks and any associated treatment device(s) will be designed to ensure that discharge levels comply with the identified trigger levels which are associated with the monitoring parameters established under Resource consent condition 101.

Resource consent condition 99 specifies using two 12,000L settlement tanks to achieve the discharge levels outcomes specified as per resource consent condition 101. However Resource consent condition 100 enables modifications to the specifications of condition 99, subject to providing the following information to Council for their certification:

- Plans and drawings outlining the details of the modifications; and

- Supporting information that details how the proposal does not affect the capacity or performance of stormwater management system.

Section 2.1.8 of the Project ESCP outlines the proposed water treatment methodology which is to be applied to the ACZ and CSAs Connectus have investigated modifying the structural control specifications outlined in condition 99 to achieve better and more efficient water quality outcomes. Connectus and AT have been in dialogue with Council Officers, who have provided agreement in principle to such modifications to the structural controls specifications.

If Connectus decide to proceed with the current modifications to the structural controls (or any other such specification which achieves the outcomes specified by condition 101), such changes will be certified by AC in accordance with condition 100.

An ESRP has been prepared for the Project. It includes the provision that all spills over 20 litres, or any spill of Environmentally Hazardous Substances that has entered the stormwater system, a waterbody or has contacted unsealed ground, shall be reported immediately to the AC 24 Hour Pollution Hotline (09-377-3107).

Within 30 days of the installation of the water treatment system, and prior to operation, a discharge monitoring programme, to assess the ongoing adequacy of all management practices, shall be developed and submitted to AC (Team Leader Central Monitoring) for certification.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000895

Revision: 04, Date: 21 March 2016

The type and design of the water treatment system has yet to be confirmed. Once confirmed the Discharge Monitoring Programme will be developed. The programme will be developed to comply with the requirements of resource consent conditions 101 -104.

The monitoring programme will be set out in Section 3.5 of the CTMP (Appendix D of the Project ESCP)

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

The purpose of the ITA related site inspections is to ensure the integrity of activities on site and to ensure that those activities do not result in the off-site discharge of contaminants that might have adverse effects on the receiving environment.

The general type and frequency of inspection is provided in Section 5.2 of the Project CEMP A list of relevant checks is provided below and an example weekly inspection check list is provided in Appendix C:

Check site for litter

Check that portable toilets are is good condition and have capacity

Check that EHS and fuel storage area bunds and containment systems are intact

Check that all required catch pit protection is properly in place

Check catchpit for presence of debris and solids.

Check that water treatment system is operating correctly to manage contaminated water

Check all loading and unloading areas are clear of spillage and debris

Check that all materials on site are stacked and stored safely to prevent spillage

Check site for evidence of spills that require clean up

Check for tracking of sediments and contaminants off site

Check that all EHS are stored in designated EHS storage areas

Check that all EHS storage containers and storage areas have appropriate HAZCHEM warning and information signage.

Check copies of relevant procedures and MSDS sheets are stored on site

Check construction vehicles for signs of leakage

Check that drip trays are in place where required and empty if required

Check that all spill kits are fully resourced, clearly labelled and located for easy access and use

Check remaining capacity of solid and liquid waste containers

Check waste skips and containers for signs of leakage and ensure they are covered to prevent rain water ingress

External environmental audits will be carried out on the Project on at least an annual basis by Connectus Parent Company Staff. The purpose of carrying out an environmental audit is to have the implementation of and compliance with environmental management procedures and control measures checked independently. This can then be reported accordingly to enable any discrepancies to be identified and actioned.

The environmental audit will include the requirements of this ITA EMP and further detail is provided in Section 5.3 of the Project CEMP.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Staff and visitors will require training to increase awareness of the environmental risks associated with the activities on site and to ensure that the appropriate control measures are properly implemented.

Training related to ITA activities will include the following:

Identification of key environmental risks and consequences

Identification of ITA “at risk” activities and control measures

Roles and responsibilities

Identification and familiarity with relevant procedures and SOPs

Site housekeeping

EHS management

Waste management

Spill management and emergency response

Site Inspections

Incident reporting

The HSNO Act 1996 requires that certain hazardous substances are under the control of an Approved Handler. Any staff required to handle such substances will be required to hold or obtain an Approved Handler Certificate.

Section 4.2 of the Project CEMP along with the Project Training Plan (CONCRL-EC2-ENV-PLN000062) sets out the way training will be delivered and identifies how records will be kept to demonstrate that training has occurred.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

This ITA EMP will be reviewed at least annually throughout the course of the Project or as a result of any material changes associated with a new or changed activity, equipment or location of activities. The review process is detailed in Section 5.7 of the Project CEMP and will consider the environmental controls and procedures to make sure they are still applicable to the activities being carried out Any change to the ITA EMP will be submitted to AC for certification and no activity reliant upon a change to the ITA EMP can be undertaken until the change has been certified.

The reasons for making any changes to the ITA EMP will be documented and a copy of the original ITA EMP document and subsequent versions will be kept for the project records, and marked as obsolete.

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Notes:

1. This EPI provides a format for documenting the Environmental Controls to be implemented on the Project or Facility. This includes the levels of environmental sensitivity on and around the project or facility, as well as summarising client requirements (for projects) and protecting key stakeholder interests.

2. Items shown in BLUE require insertion of data, deletion or acceptance where applicable.

3. Items shown in RED are for instruction only and must be updated to be site specifc.

4. DELETE this face sheet when the attachment below has been finalised.

5. Suggestions for improvement of this template should be directed via MMS feedback.

Environmental Representative: [Insert Contact Details ]

OBJECTIVES:

[Insert Project specific Storage, Maintenance and Refuelling objectives]

Minimise impacts from refuelling practices

Prevent contamination of groundwater and surface water

Prevent the release of toxic, flammable and combustible vapors

Ensure that all spills are cleaned up and reported to the Environment Team immediately

Improper procedure can lead to ground and water contamination and have negative environmental impacts

Spills and failure to follow maintenance procedures can delay the project

[Insert Project specific management measures]

Road registered plant should be refuelled offsite where possible

Vehicle refuelling of light vehicles and transfer tanks shall occur on the designated hardstand area at the refuelling facility

Where field based machinery is refuelled, a drip tray will be used at the transfer point

Fuel Spill Kits must be on hand during refuelling of land vehicles, plant and machinery

Refuelling operations must be attended at ALL times. Do not rely on the automatic shutoffs

A funnel or spout is to be used when refuelling from a jerry can to minimise spills

Refueling activities need to take place away from drainage lines and water courses

FOR FURTHER INFORMATION TALK TO YOUR SUPERVISOR OR THE SITE

ENVIRONMENTAL

REPRESENTATIVE

Before refuelling check that refuelling areas are capable of containing all possible spills (i.e. concrete lining, aprons or other suitable lining is in place) Images 1 & 2: Responsible Refuelling Practices

ALL SPILLS ARE TO BE CLEANED UP AND REPORTED TO THE ENVIRONMENTAL TEAM IMMEDIATELY

See the Hazardous Substances EPI [Insert document number] for further information

[Insert Project specific management measures]

All chemicals, fuels and dangerous goods (including waste products) will be bunded at all times, in areas with the capacity to hold 110% of the volume of all liquids stored in them

Small plant and equipment (such as pumps and generators) are to be stored in a bund or on spill kit pads

When the bunded area is to hold multiple containers, the bund needs to be capable of holding at least 25% of the total volume of all containers

When there is the potential for exposure to harmful levels of flammable or toxic materials detectors will need to be installed

All containers must be clearly labelled in English, legible and contain all important information relating to their contents

All hazardous substances are to be stored above the site 100 yr average recurrence interval (ARI) flood levels

ALL spills land and water need to be communicated to your Supervisor and/or HSE Manager/Environmental Representative.

If a spill occurs, work needs to stop immediately in the area. Follow the steps outlined in the Responding to Spills EPI [Insert document number] and talk to your Supervisor or the HSE Manager/Environmental Representative for more information.

MAINTENANCE:

ENSURE THAT REGULAR SERVICING AND MAINTENANCE IS UNDERTAKEN TO ENSURE OPTIMUM EFFICIENCY AND THE BEST POSSIBLE OPERATION OF PLANT AND MACHINERY.

Servicing and maintenance of machinery can only occur in a facility which is approved by the HSE Manager/Environmental Representative

Where possible, construction light vehicles and equipment will be sent off site for major maintenance

Service trucks, refuelling trailers and other vehicles used for the transportation of hydrocarbons and chemicals will be fitted with spill kits and drip trays

Image 3: Ensure that all regular maintenance is undertaken for all plant and equipment to reduce the possibility of leakage from faulty or inoperable equipment and slowing down works

Notes:

1. This EPI provides a format for documenting the Environmental Controls to be implemented on the Project or Facility. This includes the levels of environmental sensitivity on and around the project or facility, as well as summarising client requirements (for projects) and protecting key stakeholder interests.

2. Items shown in BLUE require insertion of data, deletion or acceptance where applicable.

3. Items shown in RED are for instruction only and must be updated to be site specific.

4. DELETE this face sheet when the attachment below has been finalised.

5. Suggestions for improvement of this template should be directed via MMS feedback.

[Insert Project specific Hazardous Substances objectives]

Compliance with [Insert relevant applicable guideline/legislation] the requirements for the use, storage and handling of hazardous substances

encourage the use of chemicals with lower health and environmental risks

Minimise the total number of chemicals required at the site

Environmental Representative: [Insert Contact Details ] [Insert Substances Applicable to the Scope of Works]

IS IT

Prevent the contamination of soils

Prevent the contamination of groundwater and surface water

Limit the number of injuries/fatalities to terrestrial fauna

Limit the release of toxic, flammable and combustible vapors

SAFETY DATA SHEETS (SDS): MUST BE HELD FOR ALL HAZARDOUS SUBSTANCES ON SITE

SDS’s provide information on the properties of the hazardous chemicals and how they affect health and safety in the workplace

SDS folders need to be kept up to date in an easily accessible location

FIBROUS MATERIALS AND SYNTHETIC MINERAL FIBRES:

Prior to the commencement of work, the area is to be inspected for any suspect materials such as asbestos, litter or a large quantity of organic material

If any material or suspected material is found, work is to stop immediately and the Supervisor in charge is to be contacted immediately

If material is found, all works will need to comply with the relevant codes of practice (See your Supervisor for more information)

RADIOACTIVE SUBSTANCES AND DEVICES:

The Construction Manager must approve the use of radioactive substances/devices before they are brought on site

Only licensed personnel may use radioactive devices If you become aware of an activity that causes or threatens to cause serious or material environmental harm, notify your supervisor.

Used (empty) hydrocarbon and chemical containers shall be treated as full and bunded appropriately

Arrangements for their transportation and use are the responsibility of the intended user

FOR FURTHER INFORMATION

TALK TO YOUR SUPERVISOR OR THE SITE ENVIRONMENTAL REPRESENTATIVE

Hydrocarbon contaminated material shall be disposed of at a licensed facility

Controlled waste is to be transported and disposed of only by licensed operators

Waste Tracking receipts and records need to be kept for all transportation

Don’t store hazardous substances over or adjacent to any water body

All fuels and chemicals must be stored in bunded areas capable of containing 110% of the volume of the largest container and be capable of preventing pollution in the case of a failure

When the bunded area is to hold multiple containers, the bund needs to be capable of holding at least 25% of the total volume of all containers

Store hazardous substances in closed containers

All hazardous substances must be clearly labelled

A chemical inventory of all hazardous substances must be kept

All dangerous goods must be segregated from incompatible materials

When there is the potential for exposure to harmful levels of flammable or toxic materials detectors will need to be installed

All containers must be clearly labelled in English, legible and contain all important information

Corrosive substances need to be stored in bunded areas at all times

Avoid unnecessary purchase, storage and handling of hazardous substances

Do not decant any substance into another container; try to purchase the correct amount for direct use

Substances not in their original containers are to be labelled clearly, including all critical information

Refuelling and chemical related activities are not to be undertaken in areas near water unless you have consent from your supervisor

For information about spill response procedure see the:

Spill Response EPI [Insert document reference]

Your Supervisor

HSE Manager/Environmental Representative

Notes:

1. This EPI provides a format for documenting the Environmental Controls to be implemented on the Project or Facility. This includes the levels of environmental sensitivity on and around the project or facility, as well as summarising client requirements (for projects) and protecting key stakeholder interests.

2. Items shown in BLUE require insertion of data, deletion or acceptance where applicable.

3. Items shown in RED are for instruction only and must be updated to be site specific.

4. DELETE this face sheet when the attachment below has.

5. Suggestions for improvement of this template should be directed via MMS feedback.

Environmental Representative: [Insert Contact Details ]

OBJECTIVES:

[Insert Project specific Solid and Liquid Waste objectives]

Minimise waste generated activities through avoidance, reducing, reusing, reprocessing and recycling waste products

Ensure waste is being managed in compliance with relevant legislation and the project requirements

Prevent harm to native fauna and flora from litter onsite

Waste is a health and safety issue as well as an environmental concern. Potential impacts include:

Use of natural resources at an unsustainable rate

Surface and ground water contamination

Soil contamination

Attraction of pests, vermin and weeds

Odour

Looks untidy

Hazardous work environment

Increased demand for landfill space from waste materials

Regulated wastes need to be managed differently in accordance with relevant regulations. Waste Certificates need to be completed.

For further information relating to waste disposal, handling and spill management please refer to:

The Spill Response EPI [Insert document number]

The onsite HSE Manager/Environmental

Representative

Your Supervisor

The image below is a classification of waste management options based on their environmental impact.

ALL SPILLS ARE TO BE CLEANED UP AND REPORTED TO THE ENVIRONMENTAL TEAM IMMEDIATELY.

FOR FURTHER

INFORMATION TALK TO YOUR SUPERVISOR OR THE SITE ENVIRONMENTAL REPRESENTATIVE

The following is a list of regulated wastes which may be found on site:

Tyres

Oily wastes

Batteries

Portable toilet waste

Asbestos

Used spill kits

Contaminated material

WASTE STORAGE:

[Insert Project specific management measures]

Avoid overfilling bins, call for collection before the bin is full

Use the right bin for the application

Use bins with lids for wastes that could be transported by the wind and when disposing of food scraps

Segregate wastes when possible

Place regulated wastes in separate bins

Keep liquid wastes in secure containers with lids. Correctly bunded and labeled

Waste bins/skips are to remain covered when not in use

WASTE ON SITE:

Keep the area you work in tidy and free of rubbish

No litter will be left onsite. All work areas shall be tidied each day

Bins shall not be overfilled to prevent the lid from closing

Small items of litter that may blow out of skip bins in windy conditions shall be placed in bins with lids

WASTE SEGREGATION:

Ensure all waste types are segregated and placed in the correct bin as follows:

Recyclables: This includes plastic bottles, containers, paper, cardboard, aluminium and steel cans, glass bottles and jars

Scrap Metal: including scrap steel and copper

Regulated Waste: This includes hazardous materials, oily rags, grease cartridges, empty chemical and hazardous containers, used spill kit materials and contaminated materials

General Waste: This includes food scraps, and non-recyclables for example plastic wrap, packaging materials

Waste Batteries: This includes all exhausted batteries and those not fit for use

Regulated wastes are not to be mixed with un-regulated wastes (Refer pg1).

Water courses, drains and any water bodies are not to be polluted by waste

WASTE DISPOSAL:

[Insert Project specific management measures]

All regulated waste removed from the site. Solid and liquid wastes must be removed by a person who holds a current license to transport that waste

Concrete waste and washout (including waste grout water) to be washed out ONLY designated disposal bay

Concrete washout bay must be plastic lined

The discharge of concrete waste water to the surrounding environment is prohibited

Place all used cigarette butts in the provided cigarette butt containers ‘Butt Stops’

Do NOT burn any waste material without the necessary approval

Notes:

1. This EPI provides a format for documenting the environmental controls to be implemented on the Project or Facility. This includes the levels of environmental sensitivity on and around the project or facility, as well as summarising client requirements (for projects) and protecting key stakeholder interests.

2. Items shown in BLUE require insertion of data, deletion or acceptance where applicable.

3. Items shown in RED are for instruction only and should be deleted.

4. DELETE this face sheet when the attachment below has been finalised.

5. Suggestions for improvement of this template should be directed via MMS feedback.

[Insert Project specific Surface and Groundwater objectives]

Minimise impacts on surface water bodies, groundwater and drainage

Maximise capture and reuse of stormwater and runoff

Minimise deterioration in groundwater quality, levels or volumes as a result of Project activities

Environmental Representative: [Insert Contact Details ]

Do not store materials, plant or equipment within the high water mark of any waterway or area prone to flooding

High pH runoff from concrete wastes and slurries can change the pH of the receiving waters. Resulting in fish kills and other aquatic animals

Make sure you contain your wastes and do not let them enter drains, creeks or other waterways

[Insert Project specific management measures]

Deploy silt curtains to contain sediment

Protect stormwater drains, gullies and channels

[Insert Project specific management measures]

Where possible plumb toilets directly into the sewer

Licensed contractors are to empty Portaloos

Need to be cleaned up and contained in reference to the Spill Response EPI [025-L021-100]. Modify processes to avoid future impact.

REPORT ALL DIRTY WATER DISCHARGES TO THE ENVIRONMENTAL TEAM

FOR FURTHER

INFORMATION TALK TO YOUR SUPERVISOR OR THE SITE ENVIRONMENTAL REPRESENTATIVE

Implement site restoration plans as soon as possible

Visually monitor adjacent waterways and let the Environment Team know if the visual quality of the water has changed

Refuel away from waterways and drains

Bund all fuels and chemicals

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Project:

Inspection by:

Area Identification/Zone/Chainage/ Entire Site:

Project No.:

Date of Inspection:

[Delete line items/ sections that are not applicable to the Project]

Shaded rows are relevant for protection of stormwater in Construction Support Areas. ITEM

Were all vehicles and construction equipment cleaned by the contractor prior to arrival at the construction site?

Are vehicles being kept clean of excess mud etc?

Is a Log book or Vehicle Wash down Register available for vehicle washes?

Are all vehicles keeping to authorised access tracks?

Are vehicles adopting a safe speed limit within the ROW?

Are all vehicles clear of any vegetation build up?

Are vehicles parked and/or being kept away from remnant vegetation

Is all construction equipment/vehicles well maintained so that there are no signs of leaks, excessive exhaust fumes or noise etc?

Are drip trays available to catch drips and leaks when vehicles are parked.

Are fire extinguishers available in vehicles?

Have all environmentally significant areas been marked on site (e.g. flagging, bunting, fencing)?

Are weed infested areas clearly labelled? Have weed management measures been put in place?

Are Tree Protection Zones (TPZ) in place around all significant trees? Are any vehicles, plant, or materials within exclusion zones?

Is there clear delineation of the extent of cleared vegetation?

Is effective fauna exclusion fencing in place, and well maintained?

Is there sufficient fauna escape ramps provided in long term excavations?

Are all construction personnel maintaining appropriate hygiene practices to minimise the transfer of weeds/diseases via clothing or equipment?

SEDIMENT AND EROSION CONTROL

Are all sediment controls adequately maintained? Do they need further maintenance?

Are any sediment control structures filled to more than 70% of capacity?

Is there sufficient silt fencing for the area of cleared land?

Is there sediment or mud visible on any of the access or haul roads?

Is contaminated material (soil and water) being treated and stockpiled as per the requirements of the CEMP/ relevant management plan?

Are vehicle wash facilities available to limit the movement of contaminated material?

Has all earth moving equipment and all materials brought onto site been certified clean prior to entry?

Are stockpiles located in suitable locations away from waterways, drains and high velocity wind areas?

Are stockpiles covered to prevent rain water runoff or located in a contained areas such that runoff can be excluded from stormwater drainage system

Have stockpiles been profiled and covered to protect from wind impacts or stabilised ?

Are stockpiles free of weeds and other rubbish?

Are ASS/PASS management measures in place?

Are ASS/PASS stockpiles located in appropriate locations? (i.e. away from drainage lines)

Are temporary storage areas (<5 days) underlain with a bed of aglime?

COMPLIES (Y,N,N/A)

Is the concrete washout basin being used correctly?

Are there appropriate dewatering protection controls in place?

Is water being discharged in a controlled manner?

Are the banks of waterways adequately stabilised?

Are drainage controls downstream of the work area working effectively?

Are sediment and litter protection measures installed at entrances to stormwater drains? (e.g. silt fences, litter traps)

Is contaminated water adequately contained and treatment occurring?

Are spill kits and floating or containment booms available (where required)?

Is non-potable water being used for construction activities?

Are catchpits being checked regularly and sediment build up/debris being removed and disposed of appropriately ?

ATMOSPHERIC EMISSIONS

Does exterior fencing have shade cloth attached?

Have work areas, access roads and stockpiles been sufficiently watered to prevent the generation of dust?

Are trucks and plant using only designated haul and access roads? Are speed limits being adhered to?

Is there visible exhaust gas continuous for more than 10 seconds emitted from any of the vehicles or plant?

NOISE EMISSIONS AND VIBRATION

If required, are vibration mitigation measures in place?

Is there screening or enclosures around fixed plant with noise sensitive receptors nearby?

Are generators and other fixed machines situated to minimise noise disturbance to local residents and the general public?

CHEMICAL MANAGEMENT AND HAZARDOUS MATERIALS STORAGE

Are spill kits readily accessible? Is there sufficient material to clean up a range of spill sizes?

Do trucks or vehicles carrying hazardous substances have the appropriate licenses to transport those goods? Are they carrying the required shipping and emergency response documentation and have stocked spill kits?

Are HAZCHEM signs displayed as necessary?

Is the control, usage, transportation and storage of hazardous substances in accordance with manufacturer’s instructions and license requirements?

Are hazardous substances stored neatly in a secure container?

Are chemicals stored away from watercourses and drains?

Are all containers carrying chemicals clearly and correctly labelled?

Are the storage areas for fuel and other hazardous substances bunded correctly?

Is mechanical plant free from oil leaks and in good mechanical condition?

Are drip trays, funnels and decanting vessels readily available to minimise the risk of spillage when refuelling or decanting hazardous materials?

Are there temporary bunds placed around fixed plant? Are drip trays placed under fixed plant to prevent leakage?

Are surplus oils, grease and other hazardous materials collected and stored separately in bunded areas prior to removal off site?

Do any fuel tanks, caps, hoses etc. have signs of damage or visible leaks? Is there any evidence of physical damage or deterioration? (e.g. rust, cracks, dents)

Is there sufficient access around fuel tanks? Is the fuel tank isolated from ignition sources (>15m)?

Is bunding of hazardous goods (including fuels) of an adequate capacity, free of rubbish and properly maintained?

Are toilets being emptied regularly enough? Are any overfull?

Are empty chemical vessels being stored in manner that avoids contamination of stormwater until Chemical Waste Contractor collects it?

Is chemical waste material, hydrocarbons and spill clean up material being stored in a covered area prior to collection by Chemical waste contractor ?

Are site compounds and storage areas kept tidy?

Are bin(s) of sufficient size? Are any overflowing?

Are covered bins provided for the collection of domestic waste?

Is there evidence of tracking of sediments from site into the Construction Support Areas and onto public roads?

Is there evidence of correct waste stream separation? (e.g. correct recycling)

Is concrete and grout waste and washout being carried out ONLY is designated plastic lined area ?

Where applicable, has all appropriate documentation been obtained for any waste identified for disposal (e.g. EPA Waste Transport documentation)?

COMMUNITY MANAGEMENT

Is access maintained to all properties and adequate traffic management implemented?

Do community walkways adjacent/ through the site provide for controlled and safe travel?

Are areas of cultural heritage importance clearly marked?

Have all aspects identified and documented on the inspection checklist No ………………….…. been rectified?

Yes No

If No give details:

Reviewed by Project Manager -

Description of Action

To be completed by:

Description of Action

To be completed by:

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000895

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Connectus Industrial and Trade Activities Environmental Management Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000895

Revision: 04, Date: 21 March 2016

No comments were received from the Community Liaison Group regarding Industrial Trade and Activity Environmental Management Plan